Research of Modified Atomizers and Their Application for Moistening of Air-Cleaning Device Charges

Abstract

:1. Introduction

2. The Research Methodology

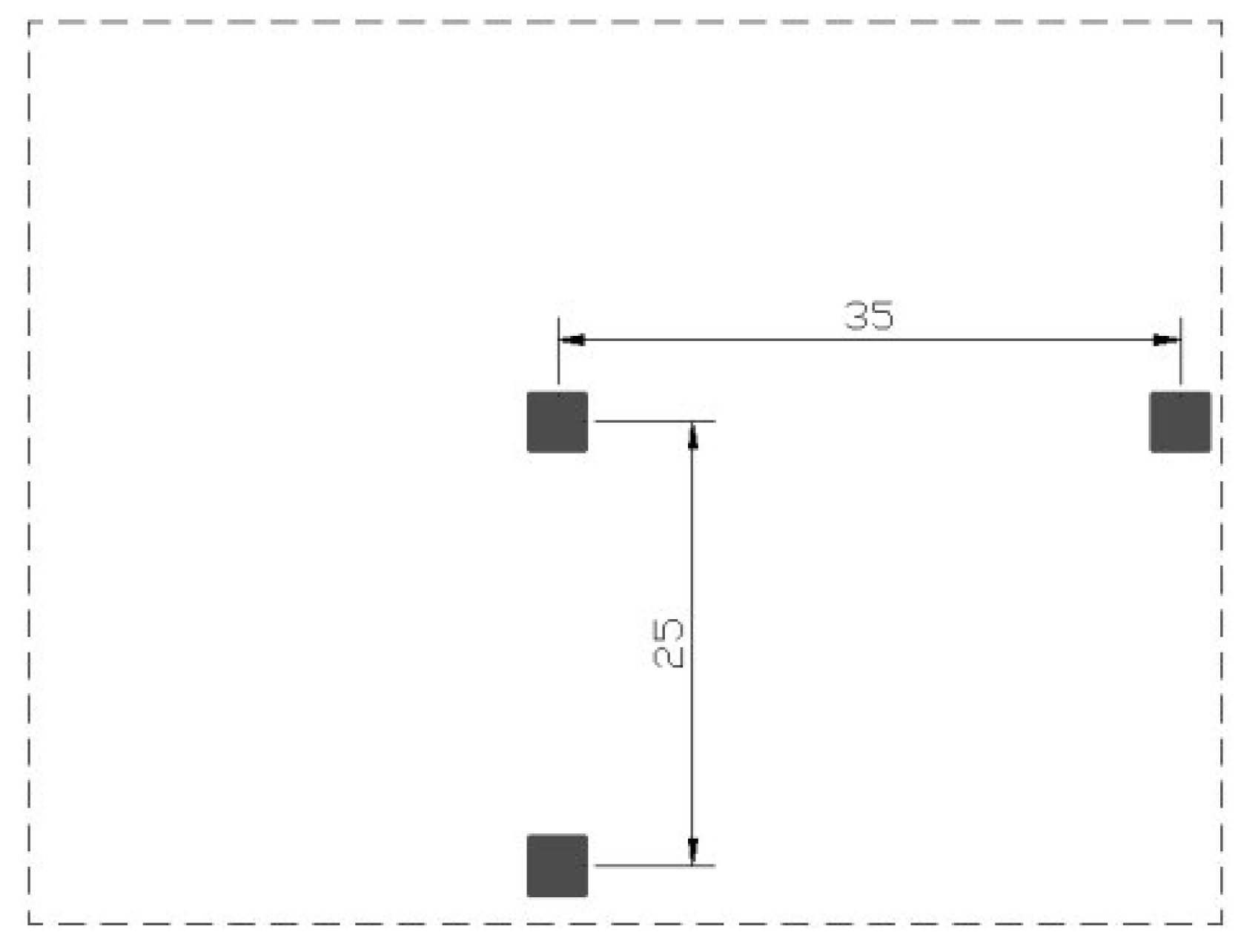

2.1. The Course of the Experiment

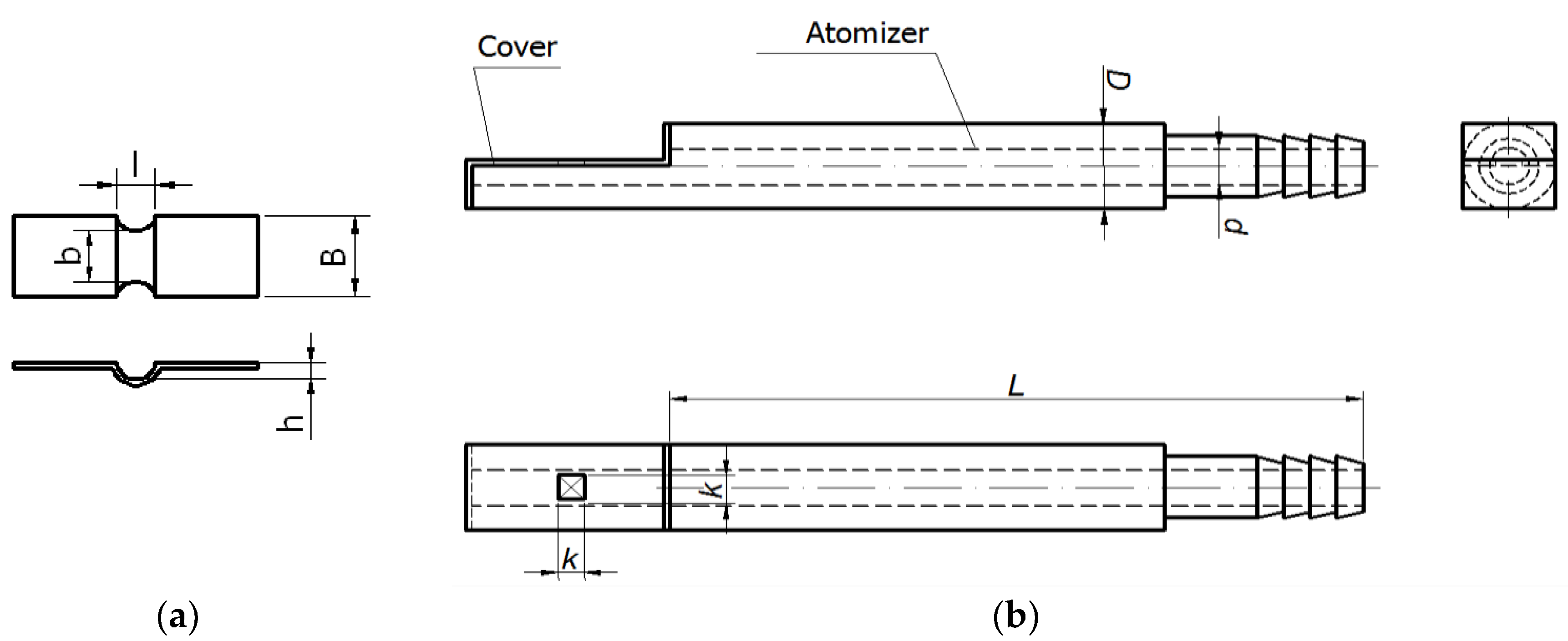

2.2. Types of Special Atomizers

3. Results and Discussion

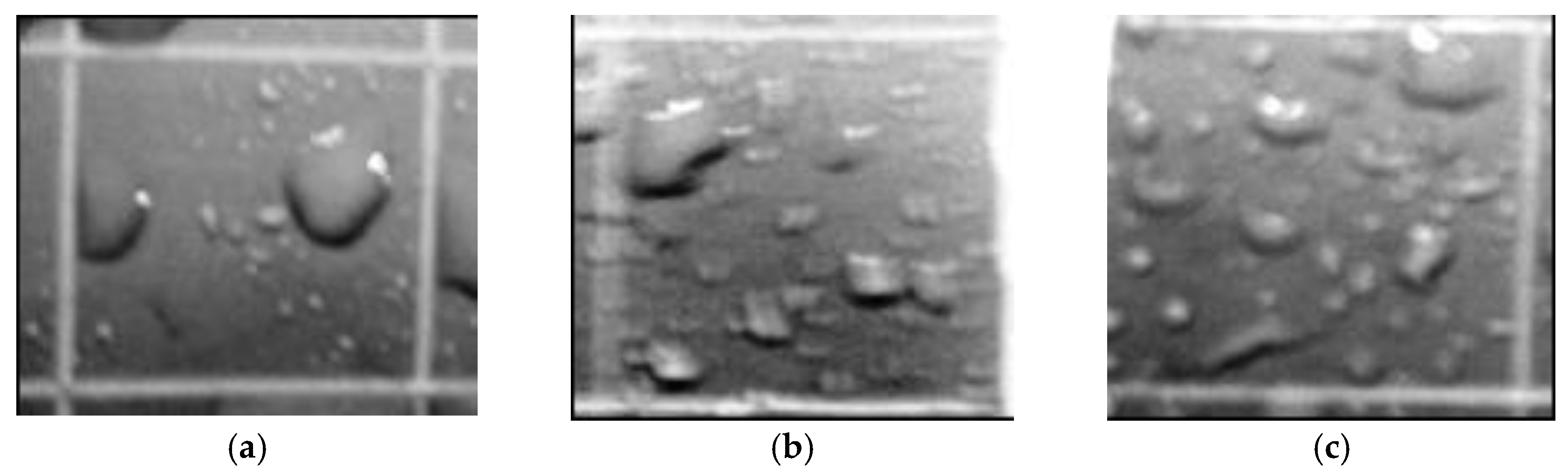

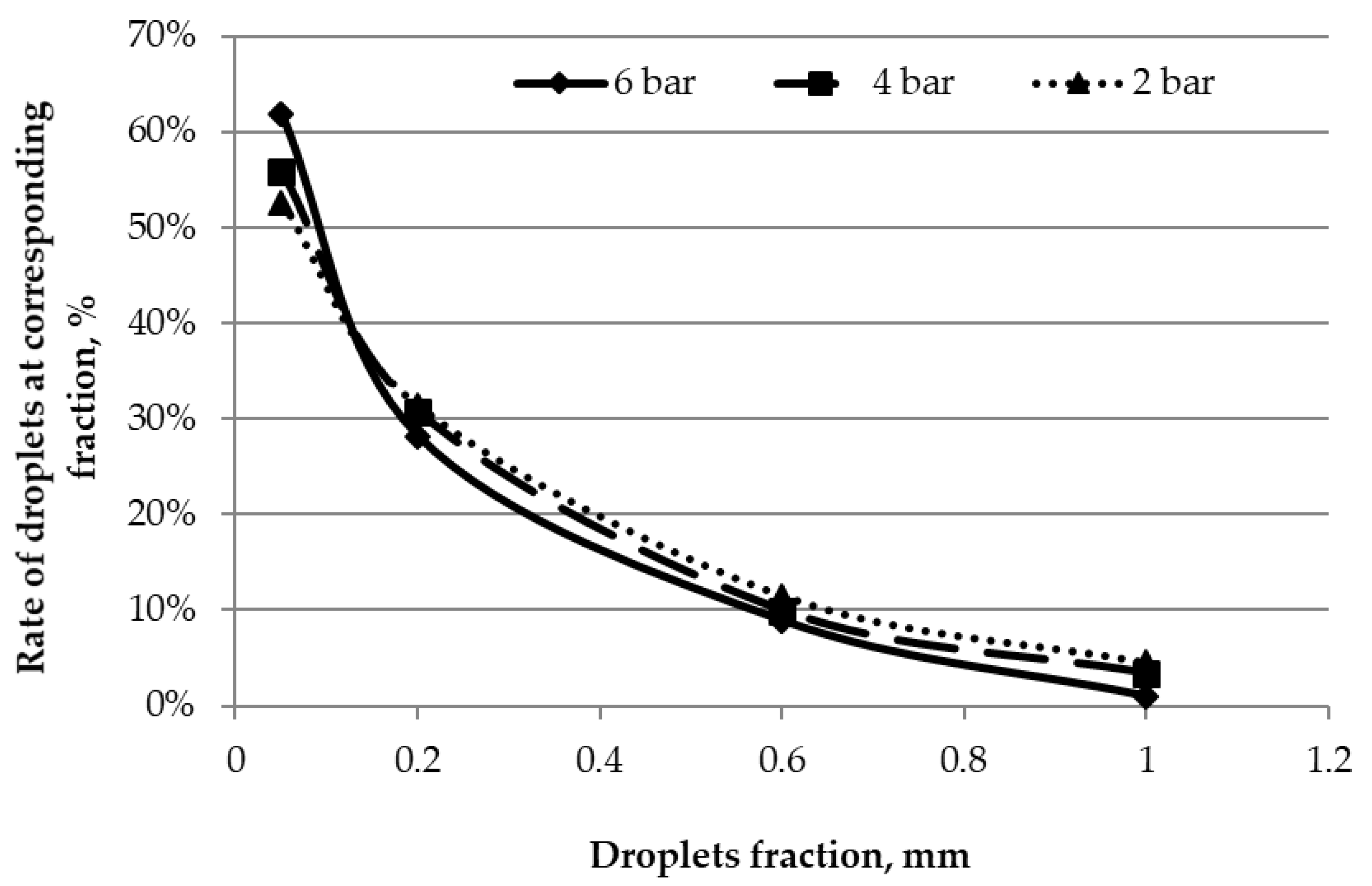

3.1. Special Atomizer: Modification No. 1

3.2. Special Atomizer: Modification No 2

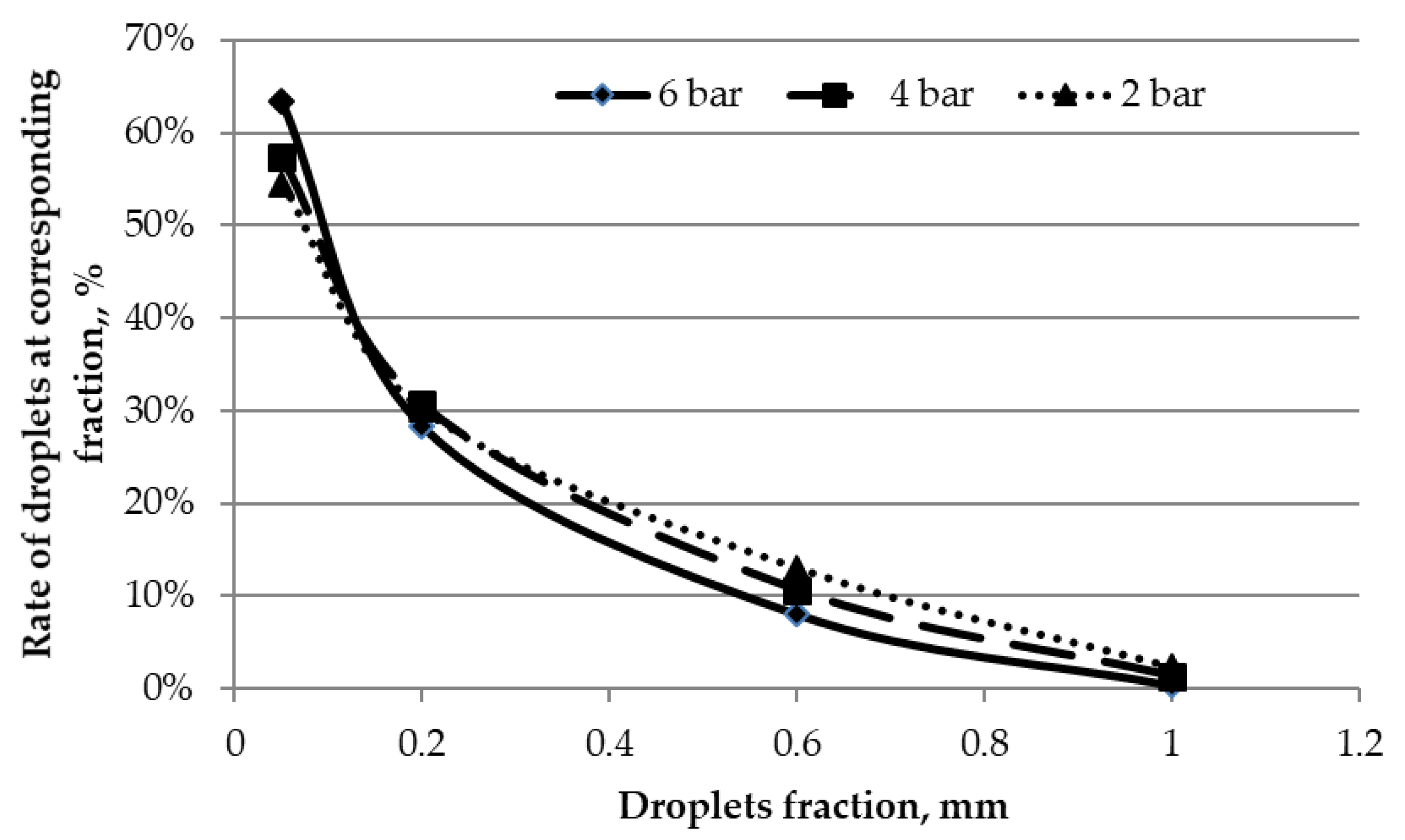

3.3. Special Atomizer: Modification No 3

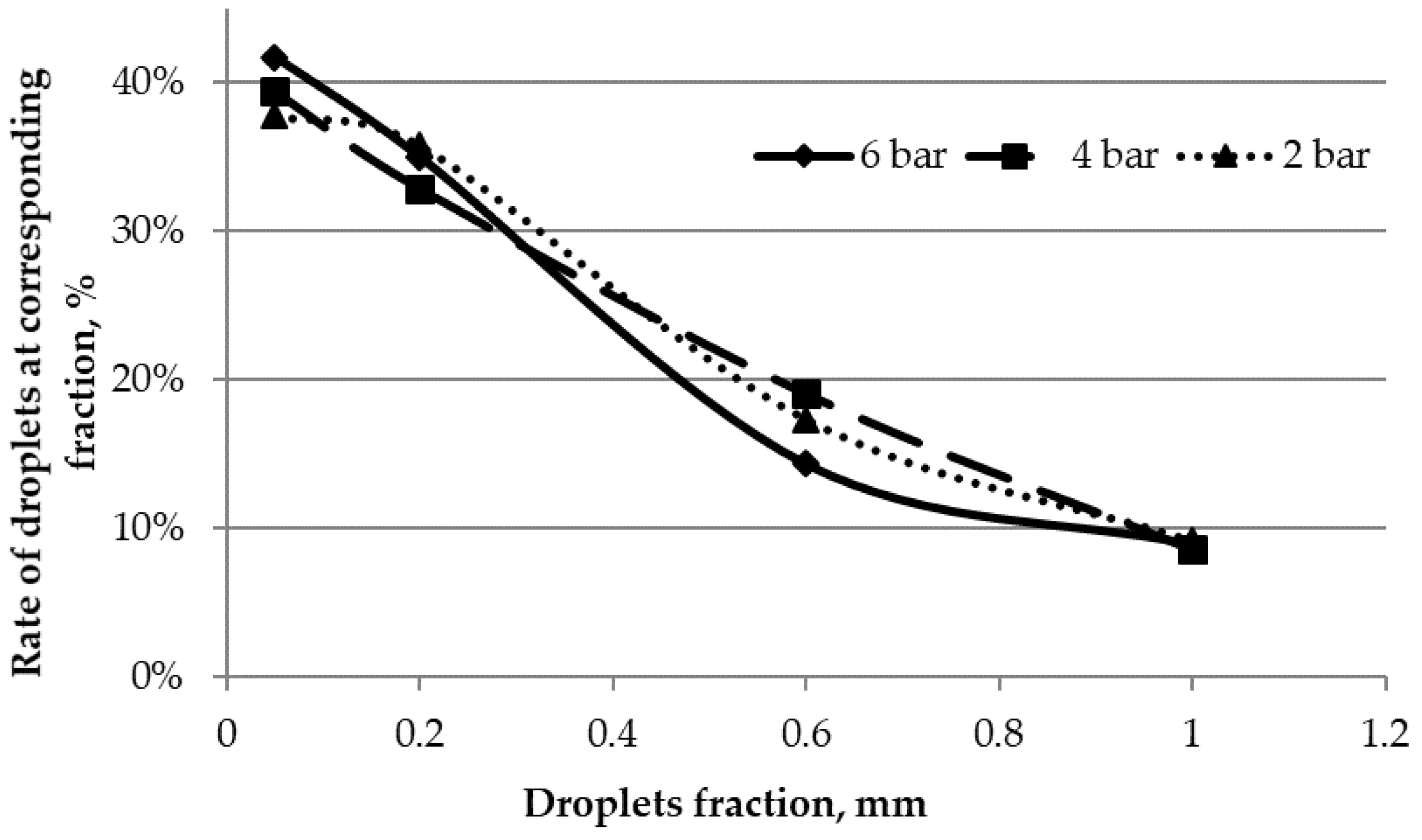

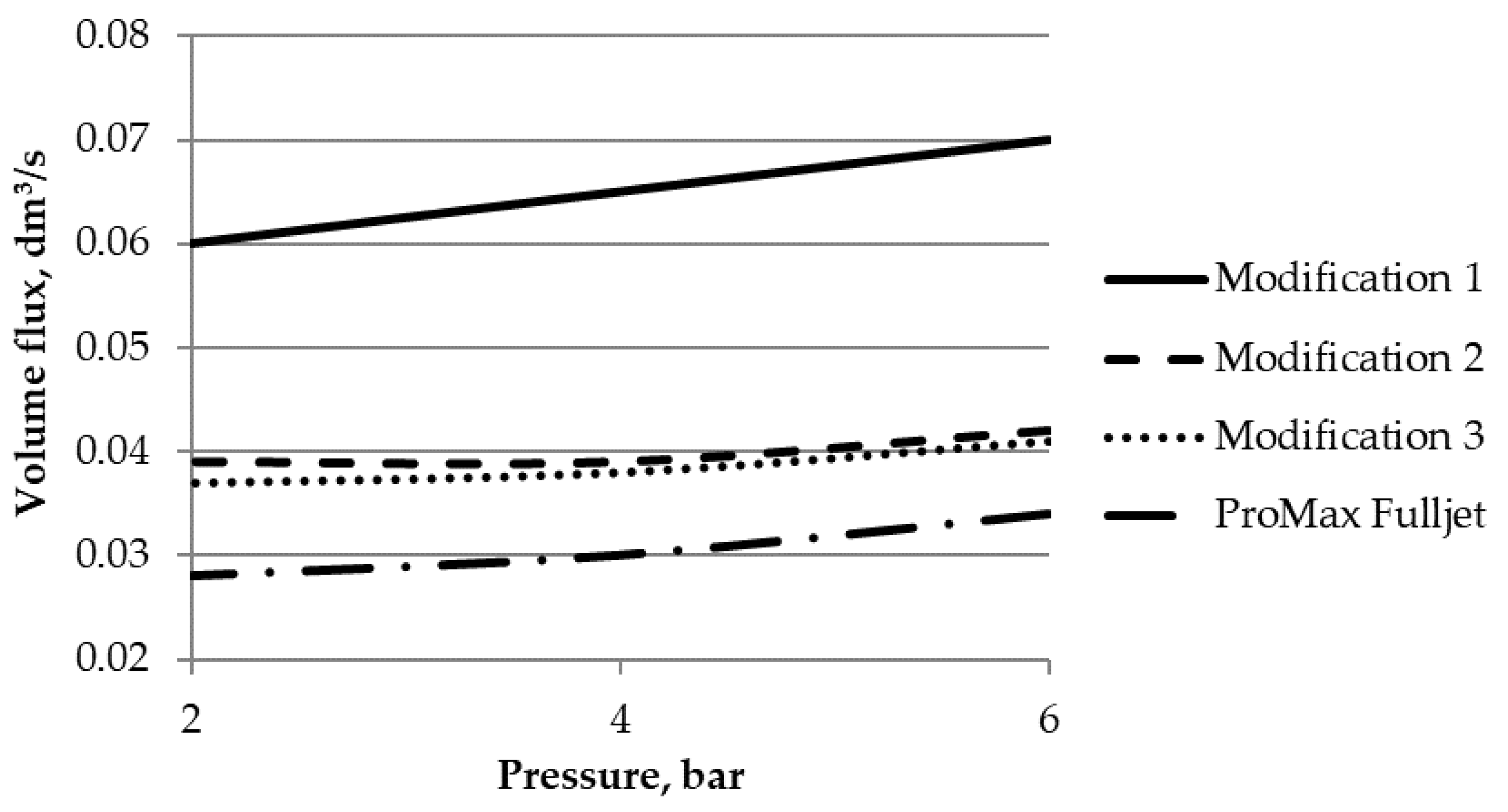

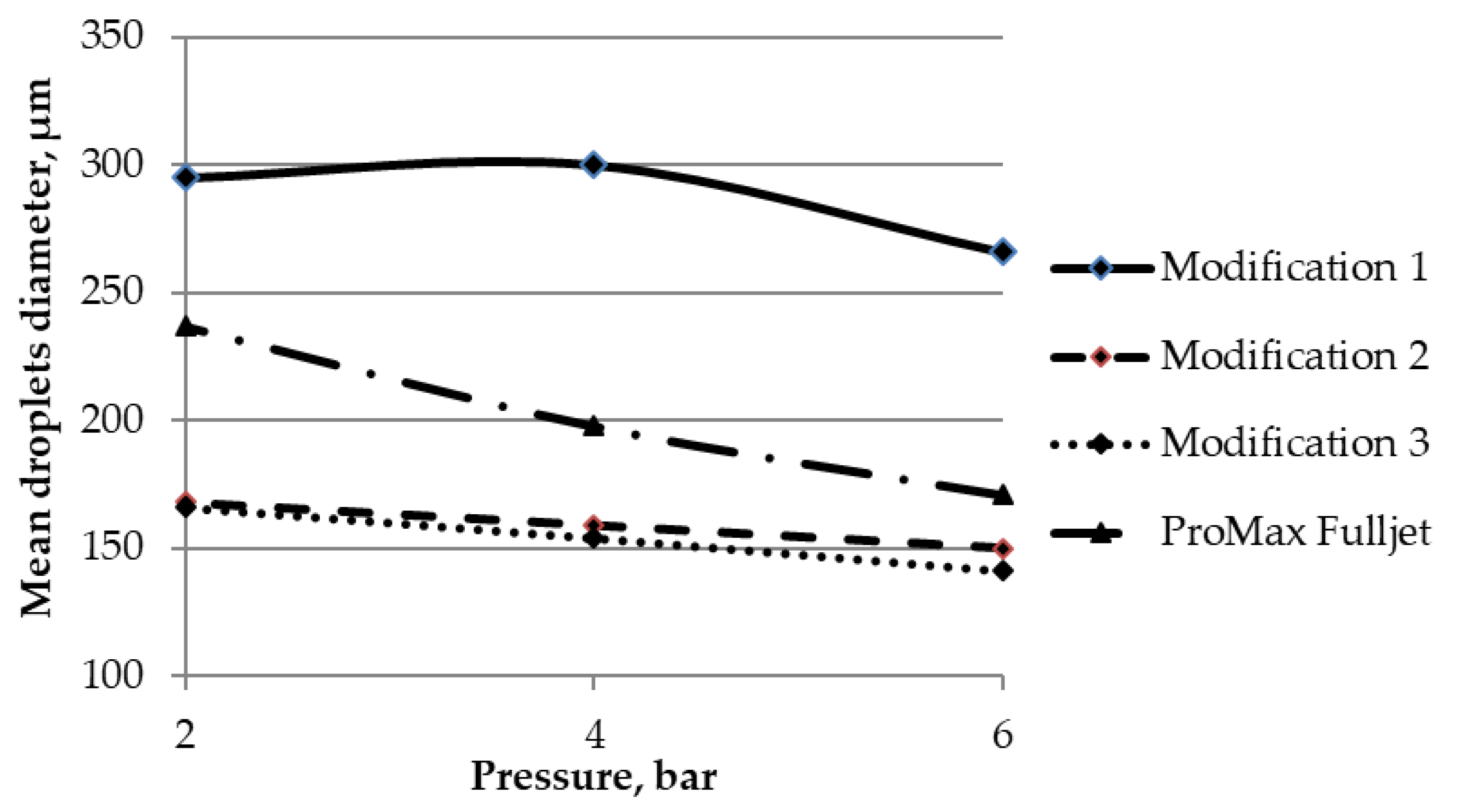

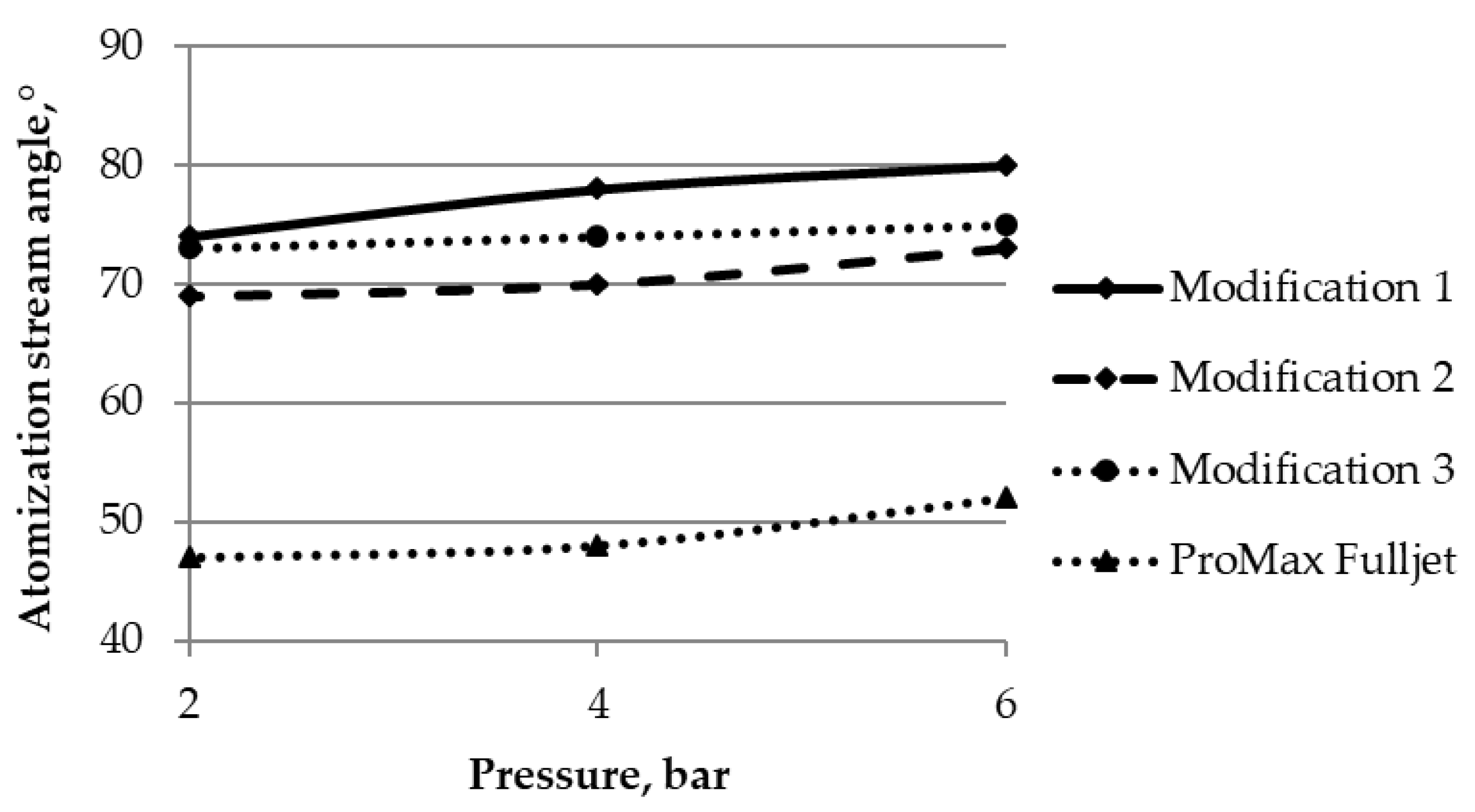

3.4. Comparison of the Results Using Different Modifications

4. Conclusions

- The maximal influence on the spraying characteristics of the atomizers of the frontal streams is created namely by the depth of the channel of the inner shield. What strength the frontal streams will confront and what the size of sprayed droplets will be depends on the depth of this channel.

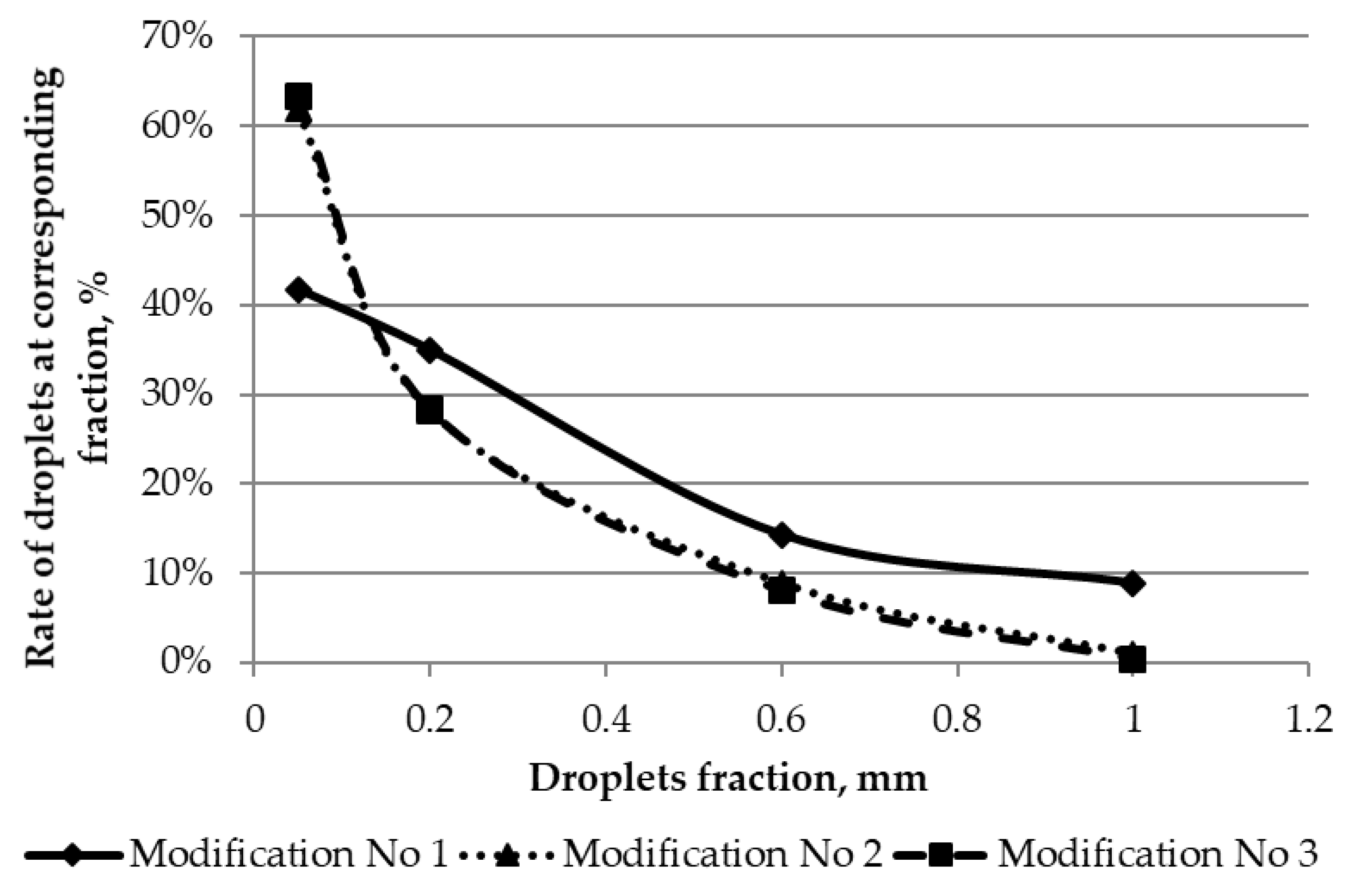

- The size of only 4 vol% of the droplets, which were sprayed with the special atomizer of modification 3, was 1.0 mm and more. The sizes of the sprayed droplets mainly varied from 0.05 mm to 1.0 mm. These sizes result in the intervals of actual sizes of the droplets that were determined by Schick in 2008, namely 500–5500 µm, and their minimum (0.05 mm) does not reach the beginning of the interval. For this reason, it can be stated that spraying with the special atomizer has been proven to be effective.

- The spraying characteristics of the hydraulic atomizers depend on the pressure, i.e., the higher the pressure was, the finer droplets that were atomized (sprayed). It is exactly for this reason that the spraying characteristics of atomizers of different structure and different modifications are compared under the conditions of the utmost pressure, as well as under the conditions of the best characteristics of spraying.

- The tested special atomizers might be applied for watering of the charges of biofilters or for absorbing gases/dust in physical scrubbers. Coarser droplets (200–300 µm) produced by atomizers of modifications 1 or 2 may be beneficial for the purpose of flue gas scrubbing due to the slower evaporation of such droplets. Finer droplets (about 50 µm) that are produced in higher portions by the atomizer of modification 3 are better for moistening the substrate in the biofilter. In both the cases of application, the savings of water can be achieved due to smaller water losses. In the case of application in a biofilter, the less water usage is associated with the lower resistance generated by the less saturated substrate. In both the cases, the efficiency of treatment is achieved. Lower use and greater savings of water contribute to resource savings, which is an important indicator of sustainable development.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pushnov, A.; Berengarten, M. Ecological aspects of industrial cooling towers exploitation and it’s influence to environment. J. Environ. Eng. Landsc. Manag. 2011, 19, 158–166. [Google Scholar] [CrossRef]

- Bravo, D.; Ferrero, P.; Penya-roja, J.M.; Álvarez-Hornos, F.J.; Gabaldón, C. Control of VOCs from printing press air emissions by anaerobic bioscrubber: Performance and microbial community of an on-site pilot unit. J. Environ. Manag. 2017, 197, 287–295. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dobslaw, D.; Schulz, A.; Helbich, S.; Dobslaw, C.; Engesser, K.-H. VOC removal and odor abatement by a low-cost plasma enhanced biotrickling filter process. J. Environ. Chem. Eng. 2017, 5, 5501–5511. [Google Scholar] [CrossRef]

- Ménard, C.; Ramirez, A.A.; Nikiema, J.; Heitz, M. Effect of trace gases, toluene and chlorobenzene, on methane biofiltration: An experimental study. Chem. Eng. J. 2012, 204–206, 8–15. [Google Scholar]

- Dobslaw, D.; Schöller, J.; Krivak, D.; Helbich, S.; Engesser, K.-H. Performance of different biological waste air purification processes in treatment of a waste gas mix containing tert-butyl alcohol and acetone: A comparative study. Chem. Eng. J. 2019, 355, 572–585. [Google Scholar] [CrossRef]

- Koutinas, M.; Peeva, L.G.; Livingston, A.G. An attempt to compare the performance of bioscrubbers and biotrickling filters for degradation of ethyl acetate in gas stream. J. Chem. Technol. Biotechnol. 2005, 80, 1252–1260. [Google Scholar] [CrossRef]

- Dobslaw, D.; Woiski, C.; Winkler, F.; Engesser, K.-H.; Dobslaw, C. Prevention of clogging in a polyurethane foam packed biotrickling filter treating emissions of 2-butoxyethanol. J. Clean. Prod. 2018, 200, 609–621. [Google Scholar] [CrossRef]

- Schifftner, C.K. Air Pollution Control Equipment Selection Guide; CRC Press: Boca Raton, FL, USA, 2002; p. 248. [Google Scholar]

- Munson, B.R.; Young, F.D.; Okiishi, H.T.V. Fundamentals of Fluid Mechanics, 5th ed.; Wiley: New York, NY, USA, 2006; p. 766. [Google Scholar]

- Faeth, G.M.; Hsiang, L.P.; Wu, P.K. Structure and break-up properties of spray. Int. J. Multiph. Flow 1995, 21, 99–127. [Google Scholar] [CrossRef]

- Kärrholm, F.P. Numerical Modelling of Diesel Spray Injection Turbulence Interaction and Combustion. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 28 November 2008; p. 86. [Google Scholar]

- Schick, J.R. Spray Technology Reference Guide: Understanding Drop Size; Bulletin 459C; Spraying Systems Co.: Wheaton, IL, USA, 2008; p. 35. [Google Scholar]

- Liu, H. Science and Engineering of Droplets: Fundamentals and Applications; William Andrew Publishing: New York, NY, USA, 2000; p. 539. [Google Scholar]

- Datta, A.; Som, S.K. Numerical prediction of air core diameter, coefficient of discharge and spray conce angle of a swirl pressure nozzle. Int. J. Heat Fluid Flow 2000, 21, 412–419. [Google Scholar] [CrossRef]

- Patel, R.P.; Patel, M.P.; Suthar, A.M. Spray drying technology: An overview. Indian J. Sci. Technol. 2009, 2, 44–47. [Google Scholar]

- Bayvel, L.; Orzechowski, Z. Liquid Atomisation; Taylor & Francis Publ.: Washington, DC, USA, 1993; p. 462. [Google Scholar]

- Michelson, D. Electrostatic Atomisation; Adam Hilgier: New York, NY, USA, 2000; p. 164. [Google Scholar]

- Lohmann, M. Herstellung von Partikeln durch elektrostatische Zerstäubung von Flüssigmetallen in gasförmiger Umgebung. Ph.D. Thesis, Universität Duisburg, Duisburg, Germany, January 2001. [Google Scholar]

- Armster, S.Q.; Delplanque, J.P.; Rein, M.; Lavernia, E.J. Thermo-fluid mechanisms controlling droplet based materials processes. Int. Mater. Rev. 2002, 47, 265–301. [Google Scholar] [CrossRef]

- Spellman, F.R.; Whiting, N.E. Environmental Engineer’s Mathematics Handbook; CRC Press: Boca Raton, FL, USA, 2004; p. 664. [Google Scholar]

- Wang, L.K.; Pereira, N.C.; Hung, Y.T. Biological treatment processes. In Handbook of Environmental Engineering; Humana Press: New York, NY, USA, 2009; p. 818. [Google Scholar]

- Mondal, D.; Datta, A.; Sarkar, A. Prediction of drop size distribution in a spray from a pressure swirl atomiser using maximum entropy formalism. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 831–838. [Google Scholar] [CrossRef]

- Doll, D.A.; Sojka, P.A.; Hallet, G.S. Microsphaeropsis amaranthi. Weed Technol. 2005, 19, 918–923. [Google Scholar] [CrossRef]

- Okita, Y.; Nakamura, K.; Nishimoto, K.; Yanasaka, N. Performance of Abrasive suspension jet nozzles with a singular annular conduit. In Proceedings of the 6th Pacific Rim International Conference on Water Jetting Technology, Sidney, Australia, 9–11 October 2000; pp. 111–114. [Google Scholar]

- Barber, J. How to Pre-empt a Significant Profit Drain: Atomiser Wear; Spraying Systems Co.: Wheaton, IL, USA, 2009; p. 6. [Google Scholar]

- Kutz, M. Handbook of Environmental Degradation of Materials; William Andrew Publishing: Boca Raton, FL, USA, 2005; p. 571. [Google Scholar]

- Wang, L.K.; Hung, Y.T.; Shammas, N.K. Advanced Physicochemical Treatment Processes. In Handbook of Environmental Engineering; Humana Press: New York, NY, USA, 2006; p. 45. [Google Scholar]

- Harrop, O.D. Air Quality Assessment and Management: A Practical Guide; Spon Press: London, UK, 2001; p. 281. [Google Scholar]

- Kemzuraite, A.; Raila, A.; Bimbiraite, K.; Kornysova, V.; Maniska, A. Moisture dynamics modelling in Hyssopi Herba drying process by active ventilation. J. Environ. Eng. Landsc. Manag. 2009, 17, 36. [Google Scholar]

- Cieciura-Włoch, W.; Borowski, S. Biohydrogen production from wastes of plant and animal origin via dark fermentation. J. Environ. Eng. Landsc. Manag. 2019, 27, 101–113. [Google Scholar]

- Aikaite-Stanaitiene, J.; Grigiskis, S.; Levisauskas, D.; Cipinyte, V.; Baskys, E.; Kackyte, V. Development of fatty waste composting technology using bacterial preparation with lipolytic activity. J. Environ. Eng. Landsc. Manag. 2010, 18, 296–305. [Google Scholar] [CrossRef]

- Pawłowska, M.; Zdeb, M.; Montusiewicz, A.; Lebiocka, M. Decomposition of hydrogen sulfide in organic materials. Environ. Prot. Eng. 2009, 35, 157–165. [Google Scholar]

- Abd-Elsalam, K.A.; Bahkali, A.H.; Moslem, M.A.; Al-Hazzani, A.A.; Amin, O.E.; Al-Khedhairy, A. Freeze- and thaw-based procedures for extracting DNA from activated sludge. Pol. J. Environ. Stud. 2011, 20, 643–648. [Google Scholar]

- Przybulewska, K.; Wieczorek, A. Biodegradation of methyl isobutyl ketone (MIBK) by Fusarium solani. Arch. Environ. Prot. 2009, 35, 3. [Google Scholar]

- Kierzkowska-Pawlak, H.; Chacuk, A. Kinetics of carbon dioxide absorption into aqueous MDEA solutions. Ecol. Chem. Eng. S 2010, 17, 463–475. [Google Scholar]

- Rajan, R.; Pandit, A.B. Correlations to predict droplet size in ultrasonic atomisation. Ultrasonics 2001, 39, 235–255. [Google Scholar] [CrossRef]

- Kim, K.D.; Jin, D.H.; Choi, Y.C. Numerical simulation on the generation of ultrasound and formation of water fog in the ultrasonic gas atomiser. Ultrasonics 2018. [Google Scholar] [CrossRef]

- Marchiewicz, A.; Sobczyk, A.T.; Krupa, A.; Jaworek, A. Induction charging of water spray produced by pressure atomiser. Int. J. Heat Mass Transf. 2019, 135, 631–648. [Google Scholar] [CrossRef]

| No. | Parameters, mm | |||||||

|---|---|---|---|---|---|---|---|---|

| l | B | b | h | d | D | L | k | |

| 1 | 4.0 | 7.0 | 7.0 | 2.7 | 6.0 | 16.0 | 135.0 | 4.0 |

| 2 | 3.4 | 6.8 | 4.5 | 1.6 | 6.0 | 14.0 | 135.0 | 4.0 |

| 3 | 3.2 | 6.7 | 4.3 | 1.4 | 6.0 | 12.0 | 135.0 | 4.0 |

| Atomizer Type | Pressure, bar | Mean Droplet Diameter, µm | ASAE (American Society of Agricultural Engineers) Standard | |||

|---|---|---|---|---|---|---|

| Symbol | Category | Code | Apx. MD | |||

| Modification 1 | 6 | 266 | C | Coarse | Blue | 250–375 |

| 4 | 300 | |||||

| 2 | 295 | |||||

| Modification 2 | 6 | 150 | M | Medium | Yellow | 175–250 |

| 4 | 159 | |||||

| 2 | 168 | |||||

| Modification 3 | 6 | 141 | F | Fine | Orange | 100–175 |

| 4 | 154 | |||||

| 2 | 166 | |||||

| ProMax Fulljet | 6 | 171 | M | Medium | Yellow | 175–250 |

| 4 | 198 | |||||

| 2 | 237 | |||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baltrėnas, P.; Baltrėnaitė-Gedienė, E. Research of Modified Atomizers and Their Application for Moistening of Air-Cleaning Device Charges. Sustainability 2019, 11, 5522. https://doi.org/10.3390/su11195522

Baltrėnas P, Baltrėnaitė-Gedienė E. Research of Modified Atomizers and Their Application for Moistening of Air-Cleaning Device Charges. Sustainability. 2019; 11(19):5522. https://doi.org/10.3390/su11195522

Chicago/Turabian StyleBaltrėnas, Pranas, and Edita Baltrėnaitė-Gedienė. 2019. "Research of Modified Atomizers and Their Application for Moistening of Air-Cleaning Device Charges" Sustainability 11, no. 19: 5522. https://doi.org/10.3390/su11195522

APA StyleBaltrėnas, P., & Baltrėnaitė-Gedienė, E. (2019). Research of Modified Atomizers and Their Application for Moistening of Air-Cleaning Device Charges. Sustainability, 11(19), 5522. https://doi.org/10.3390/su11195522