1. Introduction

In modern production and the Industry 4.0 era, many industries like aerospace, automobile, medicine, maritime, arts, and other fields open new paths for metal additive manufacturing (MAM) [

1]. Metal additive manufacturing technologies are listed in the ISO/ASTM 52900 and include the following categories: binder jetting (BJ), sheet lamination (SL), direct energy deposition (DED), and power bed fusion (PBF). Today, the prevalent metal additive manufacturing technologies usually employed are: powder bed additive manufacturing (PBAM), which makes use of metal powder layers melted either through selective laser melting (SLM) or electron beam melting (EBM) and direct laser deposition (DLD), which adds metal directly on the target surface using a laser to melt either powder (laser powder deposition) or a metal wire (laser wire deposition) in a similar manner to traditional welding [

2,

3,

4,

5].

Every new process and the majority of maintenance activities require new procedures that can optimise and raise the production quality and performance of specific manufacturing industries. Sustainability is a challenging topic to address along the whole multiple-life cycle of specific products [

1,

2]. In terms of widespread 3D metal additive manufacturing process innovation with regard to search methods and technologies for material and energy consumption minimisation, multiresearch work is needed to attain MAM sustainability performance. In addressing the challenges related to its key enabling technologies, namely, “materials”, “MAM process technologies”, and “metrology”, it is very important to achieve this performance functionality in a predictive and reproductive way [

3,

4,

5,

6]. Only about 10% of companies interviewed by Schniederjans (2017) and a few companies presented by Wholers (2017, 2019) use MAM technologies for end-use production and for spare parts in large quantities [

6,

7,

8]. However, the trends in additive manufacturing (AM) development continue to keep a growing percentage of 40% in revenue annually since 2013 [

8]. Research studies of components production or repairs using MAM in general present a positive opportunity for implementation, even if companies are not aware of the advantages of using digital spare parts in their supply chain operations as a tool for sustainability performance [

6,

8,

9]. As many manufacturers do not have knowledge of effectively optimal design for parts from AM processes and how to integrate these technologies in the traditional manufacturing models, there is also a lack of international product standards and process certification for widespread MAM adoption for large amounts of commercial parts [

1,

4,

7,

9].

Several standardisation organisations, such as the ASTM F42 Committee, ISO TC/261 Committee, and a few manufacturers, are making efforts to elaborate a set of standards for AM, taking the sustainability aspects into consideration. Elaborating standards for these emerging industries and technologies such as MAM can be long and laborious, and as such, new educational and professional skills are important for the development of the AM market.

To understand the environmental impact of MAM applications, much research is concerned with:

basic principles of the sustainability approach in additive manufacturing;

relevant issues related to materials;

methods for uses/reuses, recycling tools;

repair aspects that affect manufacturing sustainability performance.

Firstly, a brief introduction draws attention on the new route and challenges MAM technology is facing. The background and framework on the principles and the basis of MAM sustainability performance are analysed in the next two sections. To provide a better understanding of the influence of MAM recycling and use tools on manufacturing performance, the relationship between industry acceptance and demonstration of sustainability performance is highlighted in the fourth section, where the research on material reuse, recycling tools, and repairs techniques is presented. In the fifth section, some perspectives conclude why the research topics presented in this work offer a great perspective for using MAM technologies as methods for raising sustainability performance, and finally, some significant conclusions are offered.

2. Background and Framework

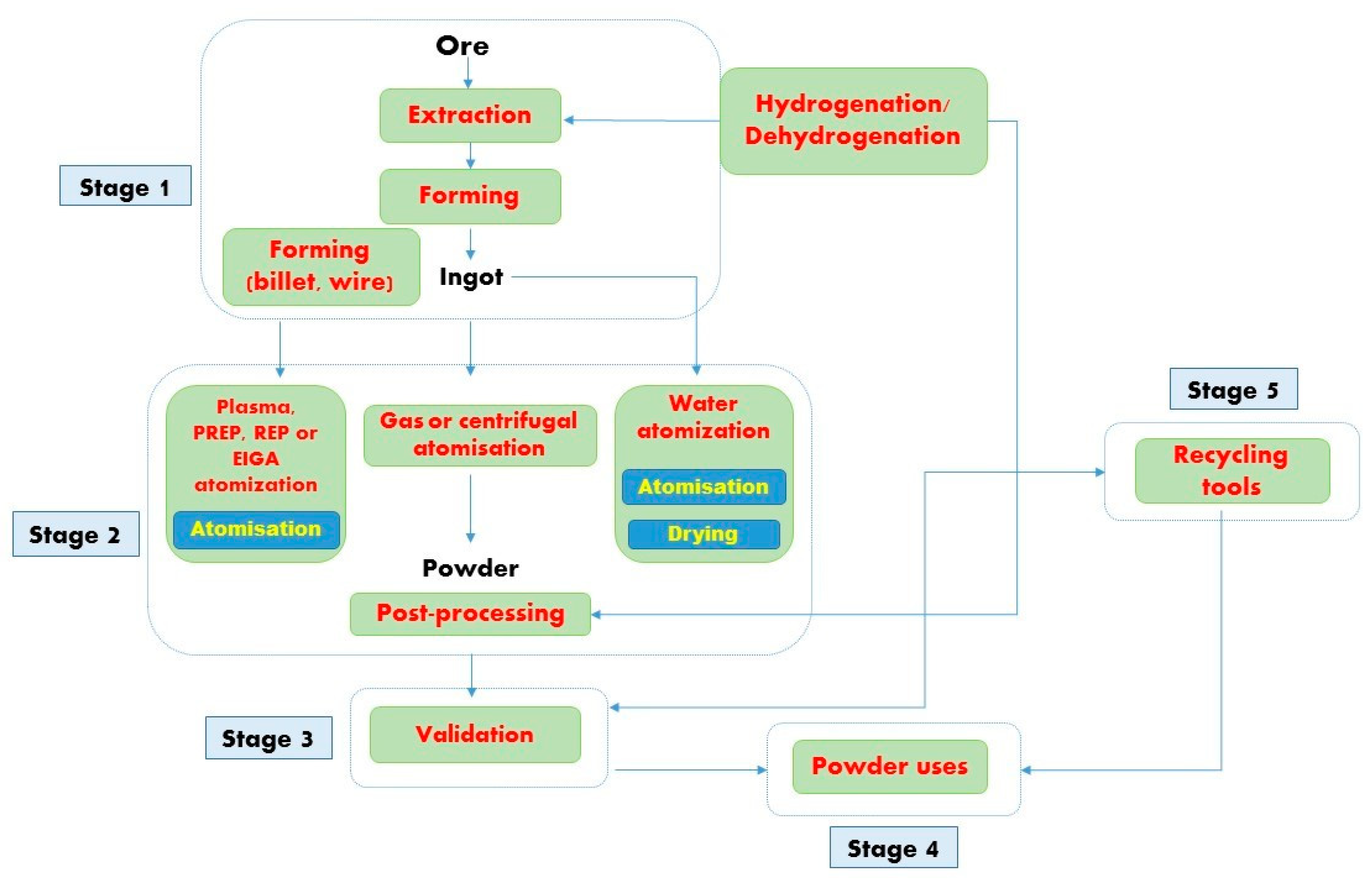

Related to sustainability, it is important first to understand metal powder (MP)’s production life cycle, highlighted in

Figure 1, which includes [

3]:

ore extraction to form a pure or alloyed metal product (ingot, billet, and wire) (Stage 1);

some specific additional processing steps for appropriate powder production and analysis of powder specificity during production (Stage 2);

validation for customised 3D metal AM equipment producers (Stage 3).

Additionally, to raise the sustainability performance of MAM technologies, it must be suitable to introduce methods and tools to extend the life cycle of powder production and uses. Therefore, it is proposed to assess the available, developing, or new options for powder uses (Stage 4) and to add recycling tools (Stage 5) with methods to optimise powder recovery, reuse, and recycling technologies for different materials and MAM processes (

Figure 1).

The AM metal powder production processes are: water atomisation, gas atomisation, plasma atomisation, the plasma rotating electrode process, and centrifugal atomisation or hydride–dehydride process. Atomisation in inert hot gas (argon and nitrogen) is the most suitable metal powder production process due to the quality of geometrical properties, finer particle size distribution, fitting non-reactive or reactive (Ti, Al compositions) materials, and performing characteristics required by powder feedstock customs [

5,

8,

10]. To avoid contamination, one notable option is to introduce in the gas atomisation system an electrode induction melting gas atomisation (EIGA) process, consisting in a variation of gas atomisation, where the metal is fed into the atomiser in the form of a rod that is melted by an induction coil just before entering the atomisation chamber, as shown in

Figure 2 [

3,

11]. In addition, the vacuum inert gas atomisation (VIGA) system offers high-quality metal powder products with low oxygen content, high sphericity, and excellent flowability, material parameters very important for quality MAM production [

11].

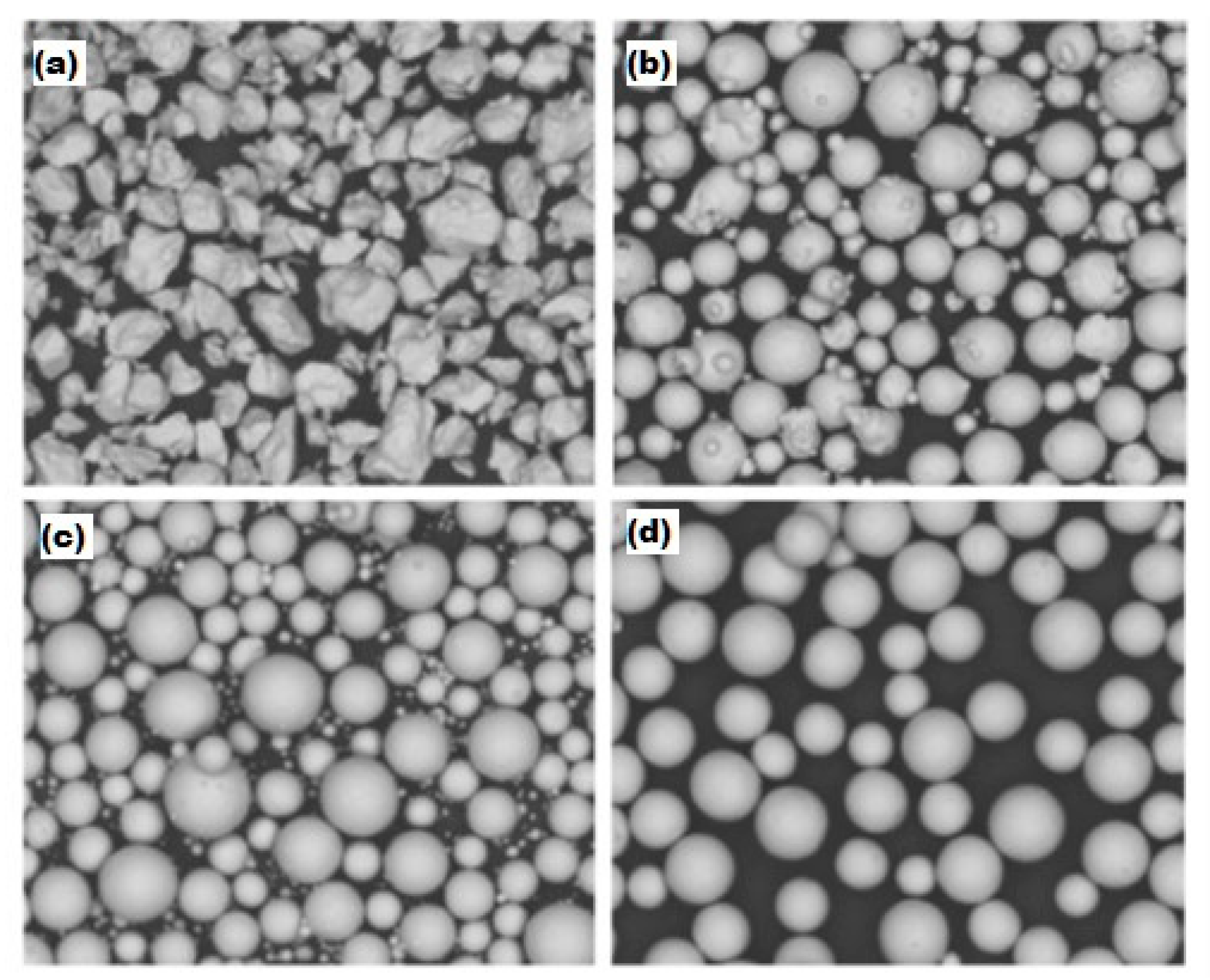

Moreover, plasma atomisation or plasma rotating electrode processes are superior to other powder production methods, offering a more homogenised size and spherical shape of particles, as presented in

Figure 3. The particular choice of inert gas influences the development of the microstructure of the particles and consequently also affects the microstructure of the parts manufactured via MAM [

3,

4,

5,

11].

If the metal source is from a recycled MP source, little information or lack of specific research on MP quality and recovering options lead producers and manufacturers to avoid the adoption of a greener supply chain. Although, with this, MAM may experience a new future step in the multi-lifecycles approach for metal powder production and product lifespan.

The product quality and the efficiency of industrial processes are dependent not only on the performance of materials (MP) or machine tools, but also on the accuracy and repeatability mode of measurement/control instruments that the process integrates. On this path, many MAM developers have established new research areas, especially in the aerospace, medicine, maritime, and information and communications technology (ICT) industries [

2,

10,

12].

Controlling and understanding the quality of the powder, both in its as-supplied or reused condition, is essential in order to achieve the desired mechanical properties of the laser melted/sintered components and to keep the same performance of the final designed product [

3,

4,

10,

11,

12,

13]. Being a relatively new technology when compared to prevalent metal-working technologies, MAM faces few unique challenges. One very important factor throughout the entire process is the quality of the used powder as it dictates the material properties of the final product. The production process of the powder itself, being rather complex, makes powder recovery a very important step for ensuring process sustainability along the entire life cycle of the product. Since any impurities in the used powder will show up as defects in the final part, the recovered powder needs to be of the highest quality possible, targeting and extended product life [

5,

10,

11,

12,

13].

Furthermore, MAM technical challenges still include material characterisation, material development, process control, process understanding and modelling, machine qualification, machine modularity and precision, design tools and software for optimisation of AM efficiency, aspects very important for a balanced sustainability. The MAM data related to these challenges have proposed few new options for sustainability performance. Moreover, those require further testing, and new validated methods need to demonstrate competent acceptance for recycling and optimal use tools (powder use/reuse, repairing parts, recycled powder, hybrid or consolidated parts) [

12,

13,

14,

15,

16].

In general, MAM was used for prototyping, but now it has become an industrial process facilitating the production of smart objects and sustainable repairs/re-manufacturing of damaged parts or associated with conventional processes in hybrid technologies. Many AM technologies provide faster and customised products in addition to reducing component weight by up to 30% and gaining efficiency by the use of the new design/re-design solutions (e.g.,: hydraulic components by 250%) [

1,

16,

17].

Another important aspect on MAM sustainability is the control of defect generation with robust techniques and evaluation methodologies to ensure quality and safety for high-value components. Recent progress on the SLM and EBM has been highlighted in some research works, especially for porous components used in biomedical applications, the influence of porosity levels on the mechanical properties (elasticity, static compression, Young modulus), and fatigue properties for materials such as Ti-6Al-4V or 17-4 PH stainless steel [

18,

19].

AM technologies offer many benefits within their rooted processes, such as: freedom and customised design, high shape complexity, improved and stronger structures with fewer materials, a wide range of materials used for adaptable design in a short period of time, and reduced weight [

10,

20,

21]. However, there are many problems that should be solved for MAM acceptance and technical consolidation: standards, materials, definite technologies, process and quality control, business integration, sustainability indicators. Most of all, only best practices, after much research and testing procedures, can determine adequate and specific solutions for the specificity of every industry choosing AM.

Consistently, MAM industries have adopted smart materials, such as shape memory alloys (SMA, Ni-based alloys), to provides flexible features like the reconfiguration of component structure and attaining the desired material property in limited time [

22]. These materials are extremely useful for micro & nano-technologies used in medicine, space, synthetic biology, precise mechanics, computing, ICT, and other fields [

19,

20]. Furthermore, MAM has also been successfully adopted within hybrid manufacturing, offering a way to practice subtractive methods accompanied by additive ones in order to fabricate better products with increased surface quality, fatigue strength, and extended quality over the life of product [

12,

13,

14,

15,

16,

17].

In the context of Industry 4.0, digitalisation of MAM has created opportunities to overcome design-related barriers of the novel production technologies and the new computational tools for simulation, visualisation, and instant analysis. These are the intelligent tools available to be included in an optimal industrial management system and sustainable value chain [

23,

24,

25,

26]. The digital tools, correlated with the principles of extended life cycle products based on the 6R concept (reduce, re-use, recover, re-design, recycle, re-manufacture) shape the path for the sustainability performance of the modern smart production.

MAM and hybrid production are the next key technologies for multi-lifecycle products, which will be adopted in future sustainable and intelligent manufacturing aiming towards a circular economy.

3. Basis of MAM Sustainability Performance

In present conditions, many authors have considered that traditional manufacturing has a more substantial environmental impact than MAM [

10,

12,

13,

14,

15]. Important topics to be analysed are as follows: design for AM (DfAM), design for environment (DfE), repair and redesign, recycled material and waste, energy consumption and emissions, health and safety, topics highlighted for an entire lifecycle assessment (LCA) based on lifecycle inventories (LCIs), databases that are partially started to develop information in this topic area [

20,

24,

25,

26,

27]. These are important when sustainability performance is seen as a key factor for AM absorption in a wide range of industries. A normal product lifecycle analysis from the “cradle to grave” perspective includes processes of raw material production, material processing, product manufacture, product distribution, use and service, and end-of-life activities [

21].

Since metals are the most common preferred material in some specific industries, MAM has received considerable attention in the Industry 4.0 expansion. AM processes using digital tools are increasing substantially the optimisation of industrial processes by contributing to sustainability performance [

23]. Referring to sustainability, MAM could greatly reduce the waste in manufacturing, lowering energy consumption in the production of raw materials and in the processing steps, technological allowances, chips from subtractive processes, etc. However, the most critical part of MAM’s widespread development is limited by many technical challenges that impede AM from being adopted, particularly in terms of metrology and standardisation, conditions very important for MAM use, recycling, repair, and re-manufacturing processes [

15,

16,

17,

21,

25].

The design for AM (DfAM) step is a crucial step for the lifecycle of the product. Hence, making the part optimised and integrating more specific features than possible with conventional processes allows for a low environmental impact of the product during its entire lifecycle. Design for environment (DfE) includes all environmental evaluations, especially considering materials and component (preferably modular) selection for a low environmental impact [

21,

23,

25].

Complex design process changes require the integration of lifecycle engineering (LCE) activities into an existing design process (DfAM, DfE). MAM is the most suitable technology to generate complex part geometries in metal production and is facilitated using an iterative and interactive approach that integrates process simulation, alongside less formal and operational process mapping activities for sustainable manufacturing [

26,

27].

Among many potential sustainability benefits of MAM technology, three stand out:

Resource and energy efficiency, which can be achieved in both the production and the use phases during all manufacturing processes by applying a product service system (PSS) approach that can include recovering, redesigning, re-use, repair or remanufacturing, as well reducing wastage or long recycling supply chains [

27,

28];

Extended product life by LCE, which is achieved through technical advantages such as repair, remanufacture, and refurbishment (techniques that require more profound research) as well as more sustainable socioeconomic patterns such as stronger customer affinities and closer relationships between manufacturers and consumers [

26,

27,

28];

Reconfigured value chains with shorter and simpler supply chains, established production, innovative distribution models, and new collaborations [

1,

15,

29].

Some of the highly recommended assets of MAM for sustainable production can be summarised as follows [

4,

5,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30]:

Direct transfer of 3D design to AM equipment, offering increased flexibility and material savings when compared with traditional metal-working technologies, depending on material characteristics;

Generation of highly customised parts with no additional tooling or optimised cost;

Functional design allowing the manufacturing of complex internal features, eco-designs, or sustainable process designs;

Flexible and lightweight component manufacturing with lattice internal structures;

Ability of direct manufacturing of components in their final (net) or near-final (near-net) shape with minimal additional processing;

Potential approach to zero-waste manufacturing by maximising material utilisation (re-design, repair, remanufacturing, recycling);

A great reduction in overall product development and manufacturing time, leading to quicker transfer to market;

Smaller operational carbon footprints of manufacturing for a large variety of parts along the supply chain;

On-demand manufacturing, moving away from classic project-based manufacturing;

A reconfiguration of the maintenance and service concept by transferring it to third parties using AM technologies and AM specialists along the whole supply chain;

Excellent scalability.

However, many of these advantages are theoretically present worldwide, despite the fact that MAM technologies are still making the first steps in terms of optimisation of materials, process design, post-processing, and quality of final or repaired product.

MAM is a new emerging technology ideal for low-to-zero waste production, and it is intuitively considered to be a “clean” or “green” process [

21,

26,

30]. This issue guides professionals to a concrete understanding of sustainability demand in MAM processes, and it requires including demonstrative and suitable methods of lifecycle assessment (LCA). The LCA is an environmental impact analysis of a product related to assembly operation, service life (e.g., usage or maintenance, repair, recycling scheme), and end-of-life (EoL) (e.g., disposal, reuse, remanufacture, and recycle), such that all of these evaluation stages are indispensable to establishing sustainability performance.

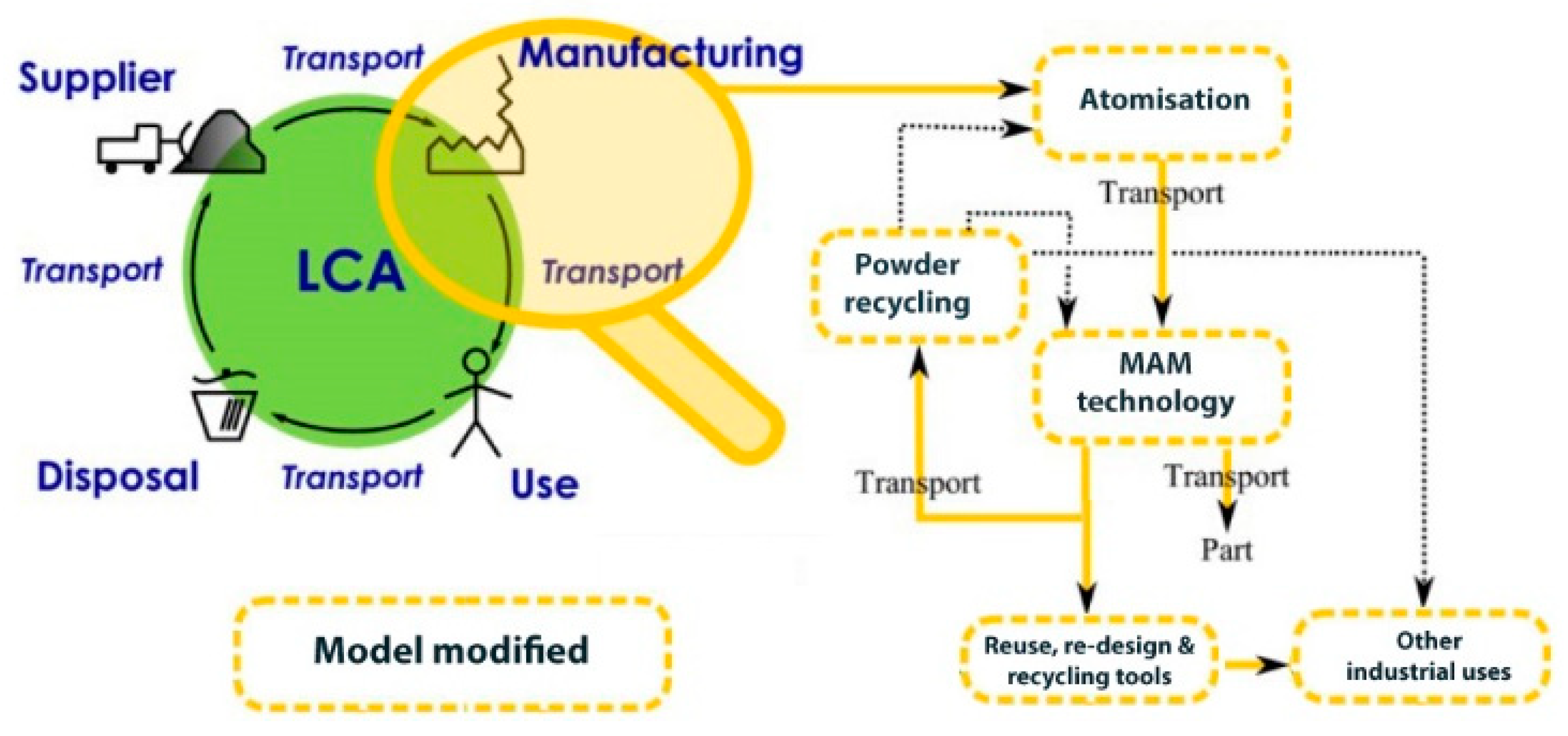

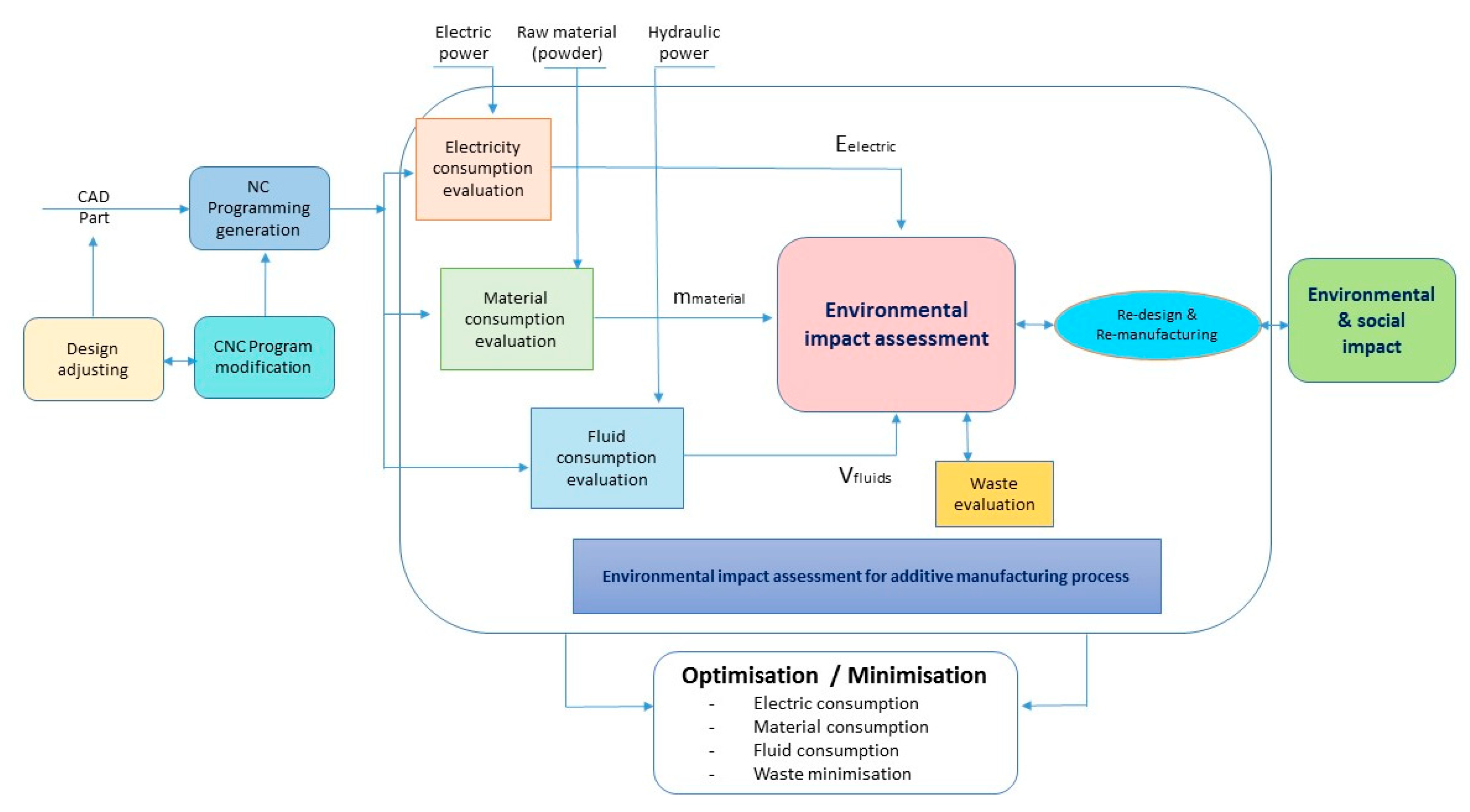

Following LCA methods, like the model proposed by Bourhis et al. [

26] for the manufacturing stage, an upgraded overview including reuse and re-design or recycling tools that can reduce the environmental impact of MAM technologies, a modified LCA scheme, is presented in

Figure 4.

Some examples of reuse, re-design, and recycling tools include powder reuse or recycling processes in the normal MAM production or in other industrial processes; additive repairs; design/re-design of complex parts, part consolidation, and remanufacturing of old parts by using different MAM technologies.

Commonly, recycled powder is reused in the MAM process or sent back to a reconditioning process, but it can be reused in a different industry as well. This is important to consider when the powder manufacturers do not take back the used powder for reconditioning. In the MAM process, after the printing is completed, a special vacuum cleaner is used to collect all MP from the printing chamber. This powder is typically wet or dry, depending on the vacuum cleaner used, and this MP recovery process may be valid for MP recycling and reuse.

Moreover, sometimes the powder does not meet the quality requirements. When this happens, additional processes for reconditioning the MP have to be carried out prior to use. Since energy and other materials might be used to recondition the powder, the sustainability performance needs to be evaluated.

In this regard, another sustainable aspect of MAM application is presented by Yang et al., who investigated the environmental impact of product consolidation using binder jetting (BJ) MAM, procedure that helps to simplify the product structure, promote modularity, and eliminate fasteners, joints, and connectors, reducing assembly difficulties and cost. Simplifying product structure and functionality by applying optimal design changes (DfAM), the use of MAM technologies (BJ) during production, service, and end-of-life (EoL) activities has two important implications [

21,

22,

31]:

The use of binder jetting moulds shows significant promise by optimising parts from a material perspective. It is stated that an average of about 20% less material is used for casting the parts, which means savings when it comes to energy use as well, but it also means an increase in health risk since the binder is fairly toxic.

The reuse of the mould material with factors ranging from 65% to 99% depends on the assumption of partial or complete recyclability of feedstock materials and the applied MAM technologies [

31]. Thus, it is crucial to analyse these technologies for sustainability improvement.

Many authors present the currently available studies analysing the environmental dimensions of AM, encompassing lifecycle stages from the design phase, followed by material production, to part manufacturing and the use phase up to the waste treatment of the AM production waste, along with the multi-lifecycles and the supply chain [

21,

26,

32,

33,

34,

35,

36,

37]. However, the LCI data are limited [

37] or even missing from the lifecycle stages of different MAM products and technologies used (depending on the materials and processes available on the market).

In order to assess the environmental impact of MAM processes or AM-related applications (e.g., optimised, consolidated, or repaired product), a series of tools should to be developed or adjusted for correct methodology application. Researchers and manufactures will have to solve the following issues: energy efficiency, resource use minimisation, weight reduction, flexible design/re-design, waste reduction, exposure to hazardous elements/process, optimal supply chain management along the whole lifecycle of AM products.

4. MAM Recycling and Use Tools for Sustainability Performance

This section presents a few experimental results identified in the literature and some limited and preliminary results obtained by our team. Obviously, more testing and experiments are needed for method validation. The final results could provide a starting point and direction for future research oriented towards optimal MAM use in production. To determine the sustainability indicators and methods, environmental aspects need to be evaluated and included in the development of innovative MAM technologies.

4.1. Materials, Recycling Tools, and Methods for Optimising MAM

Powder recycling and reconditioning in MAM technologies have been studied by a few researchers, testing different materials (Ti, Al, Ni, and stainless-steel-based alloys) and involving strict parameters for each MP and specific testing and validation processes [

31,

38,

39].

In general, the reused metal powder after reconditioning (sieving process suggested by MAM producers) must have similar characteristics to the raw MP. The recovered powder resulting from specific MAM technologies (Shinning 3D, EOS, Trumpf, etc.), using a water vacuum cleaner, may have different properties. Hence, subsequent build components from recycled powder have unknown properties and thus have not been the subject of intensive scientific study. In a few scientific journals published in the field of metal powder recycling processes in AM, it has been observed that recycling powders in powder bed MAM processes result in a slight increase in powder particle size distribution (PSD) [

2,

3,

29,

30,

31]. The thermal effects that result from the process, such as chamber temperature and the energy used in selective laser melting/sintering (SLM/SLS) may cause physical as well as light chemical changes to the recycled powder [

38,

39,

40]. Furthermore, MP contamination or reactivity (from vacuum water recovery), either through impurities, foreign bodies, or interstitial elements, may introduce changes in the powder as a result of handling during pre-processing or post-processing stages [

38,

39,

40,

41,

42,

43].

The effect of recycling powder on mechanical properties for certain MPs (S17-4 PH, stainless steel) showed no significant changes in particle size (PS), particle size distribution (PSD), and particle shape, but apparent density and powder bed density increased, while flowability in time improved. Recycling the MP in a nitrogen atmosphere caused a slight increase in the martensitic–ferritic phase in predominately austenitic stainless steel powder (S17-4 PH) and showed a ratio of approximately 1:1 between austenitic and martensitic–ferritic phases. After post-treatment of final parts for stress relief, tensile tests showed a low influence on the final parts after 11 recycling cycles [

39].

Currently, not all materials can be recycled many times due to reactivity with environment conditions—humidity, temperature, oxygen (some Ti- and Al-based materials). The following section provides a preliminarily tested method of obtaining MP from MAM equipment with a proposed recycling method.

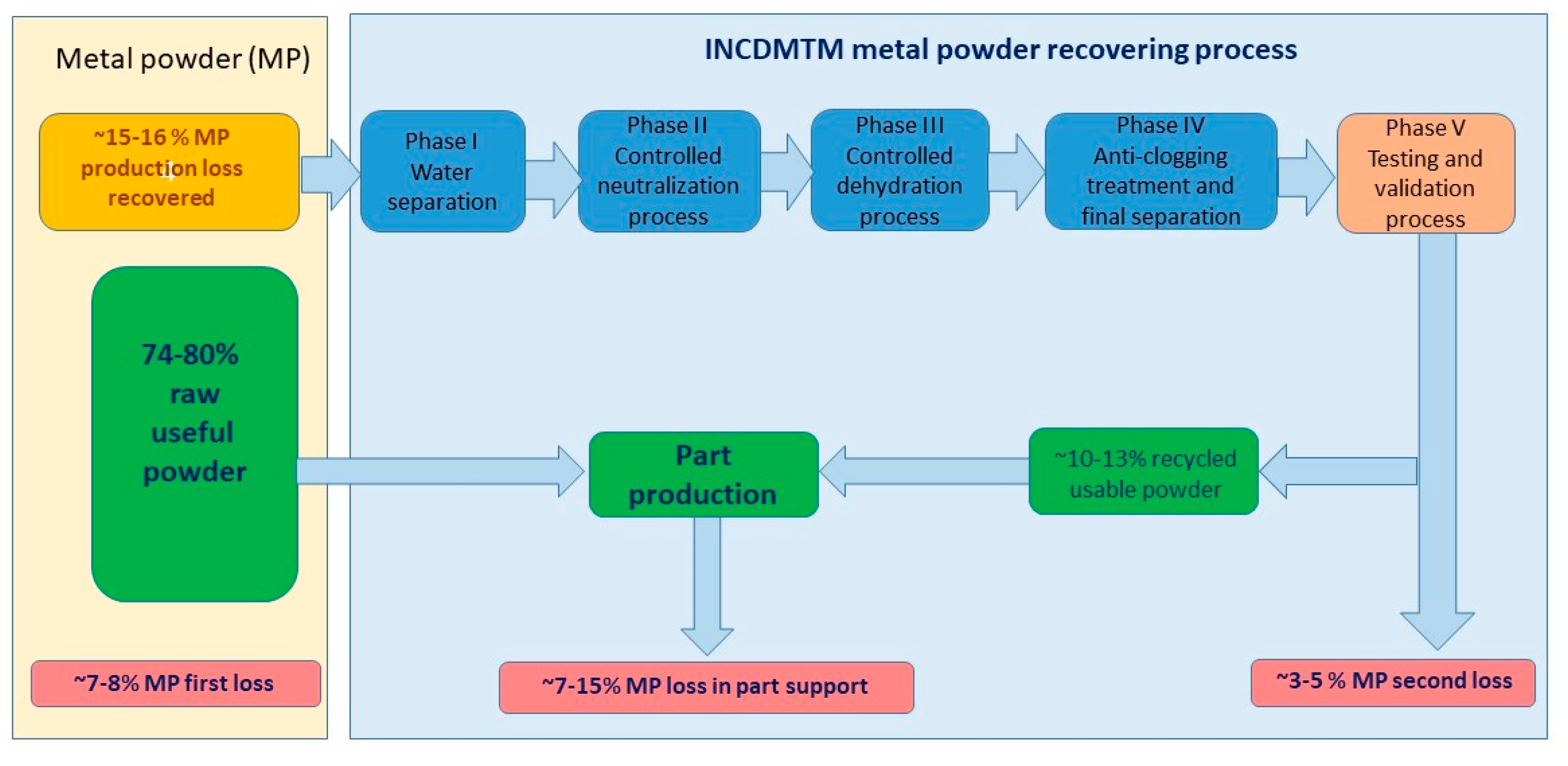

Generally, 3D MAM equipment manufacturers provide special recovery tools for MP recycling, but only for powder directly collected from the building chamber. Most of these consist in manual or automatic operations used to separate the large particles from the normal-sized ones by using calibrated mechanical sieve devices. The selected powder is reinserted into the next AM procedures, ensuring a high recovery percentage, approximatively 74–80%. These preliminary percentages have been achieved in an ongoing study conducted by using the MAM equipment SHINING 3D EP-M250 (manufactured by Shining 3D Tech Co. Ltd., Hangzhou, Beijing, China), in the Additive Manufacturing Laboratory of the National Institute of Research and Development in Mechatronics and Measurement Technique Bucharest (INCDMTM Bucharest) [

43], where a major future project based on these preliminary result, is expected to begin soon.

In the MAM building process, a range of recovery results of about 74–80% is observed using a classic recycling process by sieving powder after the printing process is finished, as suggested by the producer, which is similar to reports in the literature [

43,

44]. Our preliminary studies (not published yet) [

43] show an amount of 7–8% of irregular particles lost or to be returned to the MP producer or recycler in order to be retriggered into normal particle sizes (validated MP). The attractive amount of CoCr powder for recycling is approximatively 15–16% of MP, proposed lost by the producer as a result of technological processes that consist in vacuuming and constraining this residual MP under water. Actually, this percentage consists in normal small parts of metal powder, which can be saved as a result of a recovering recycling process developed in INCDMTM Bucharest shown in the scheme presented in

Figure 5.

In a first recycling phase, the metallic powder is separated from water using a centrifugal system in a well-controlled climatic environment. The second phase consists in a neutralisation process in order to eliminate conglomerated (e.g., oxides) or other specific impurities. The third and fourth phases represent a specific dehydration process in a controlled climatic environment, followed by an anti-clogging treatment and final separation using calibrated mechanical sieve devices (

Figure 6). As a result, there are 3–5% unrecovered MP, and most importantly, an amount of 10–13% of CoCr powder that is recovered and can be reinserted into the normal 3D printing process for new parts or repairs. This means that with MAM optimisation by the proposed recovery process, the consumption of MP can attain around 87–90% usable powder (including for part support).

In a lifecycle engineering approach, typically and as we suggested above, a new MAM technology requires important changes from the product design stage, along the production, uses, and reuses stages, as well as in the EoL processes. Because the majority of lifecycle costs of a product (some authors estimate that 70–80% of cost implications) are determined during product design and process phases [

25,

34], the main changes for AM production involve the incorporation of additional product requirements. Particularly, the cost related to service and maintenance (similar to a product service system—a customer facility offered by many manufacturers) will be positively inserted into the existing product and MAM process design for customer satisfaction and sustainability [

12,

21,

27,

34,

35,

36,

37].

4.2. New Products from Old Ccomponents

MAM can build up a new structure or repair damaged parts, making it a sustainable technology optimal for reversing the end-of-life (EoL) of a product by extension usage or second life in a circular economy [

32,

44,

45,

46,

47].

Additive manufacturing is rapidly gaining ground in the industrial sector with the help of direct metal laser sintering (DMLS) or direct laser deposition (DLD) technologies, which demonstrate new promising and innovative manufacturing techniques to be used as alternative methods for repairing parts or tools that would otherwise take considerable effort to repair or need to be replaced altogether [

45,

46,

47].

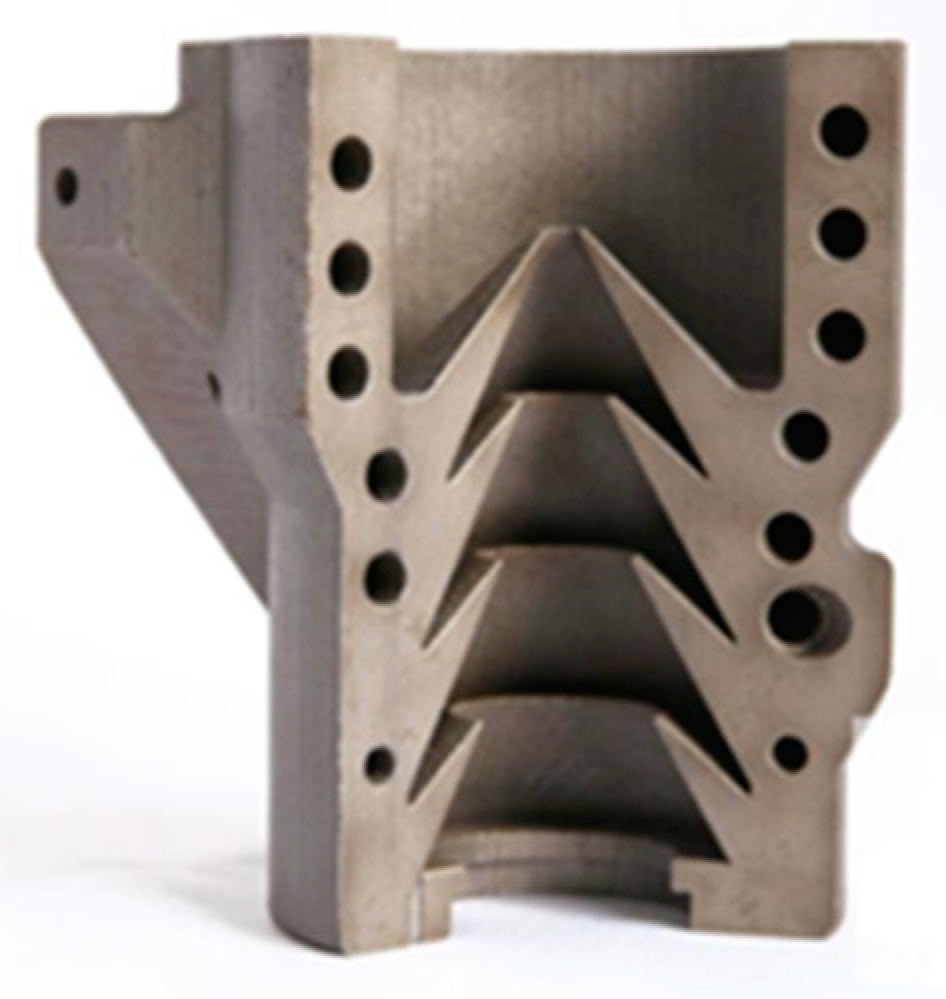

Traditionally, repairing worn-out tools or damaged parts is done by welding a new chunk of material that has to be brought to size using various machining processes, an example being presented in

Figure 7 [

48]. Depending on the part or tool geometry, these processes can take a long time, come at a great cost, or could be virtually impossible.

A set of advanced methodologies for the remanufacturing of complex geometry and expensive parts via reverse engineering, free-form surface modelling, laser additive repairs, and machining involves the integration of 3D non-contact scanning methods. It ensures the re-design of damaged parts, adaptive free-form surface reconstruction to create the digital model of a laser additive manufacturing process containing slicing, metrology, path planning, and a subsequent multi-axis machining operation, as shown in the

Figure 7 [

2,

45,

46,

47,

48,

49,

50,

51].

A handful of companies have started offering repair services making use of selective laser melting (SLM) and laser cladding (LC) technology [

17,

45,

50]. The parts to be repaired need processing until a straight plane surface is obtained on which the missing features are to be added using AM [

47,

48]. The advantages of this technology include the fact that the entire process is performed in an enclosed and controlled chamber, allowing for precise control over parameters like internal temperature, pressure, air flow, and most of all, air mixture, with the possibility of lowering oxygen levels dramatically so as to avoid oxidising. The fine control over the laser power and burn times allows for the precise and uniform melting of the metal layer, ensuring a homogenous volume with very low defect occurrence and completely merged with the undelaying layers [

50,

51,

52,

53].

The precision of the system also allows for the building of nearly finished parts with multiple complex channels for fluid flow, in many cases only needing small surface finish procedures, due to the relatively high roughness of the final surface, which is ideal for any cooling systems. An example is illustrated in

Figure 8 [

45,

47].

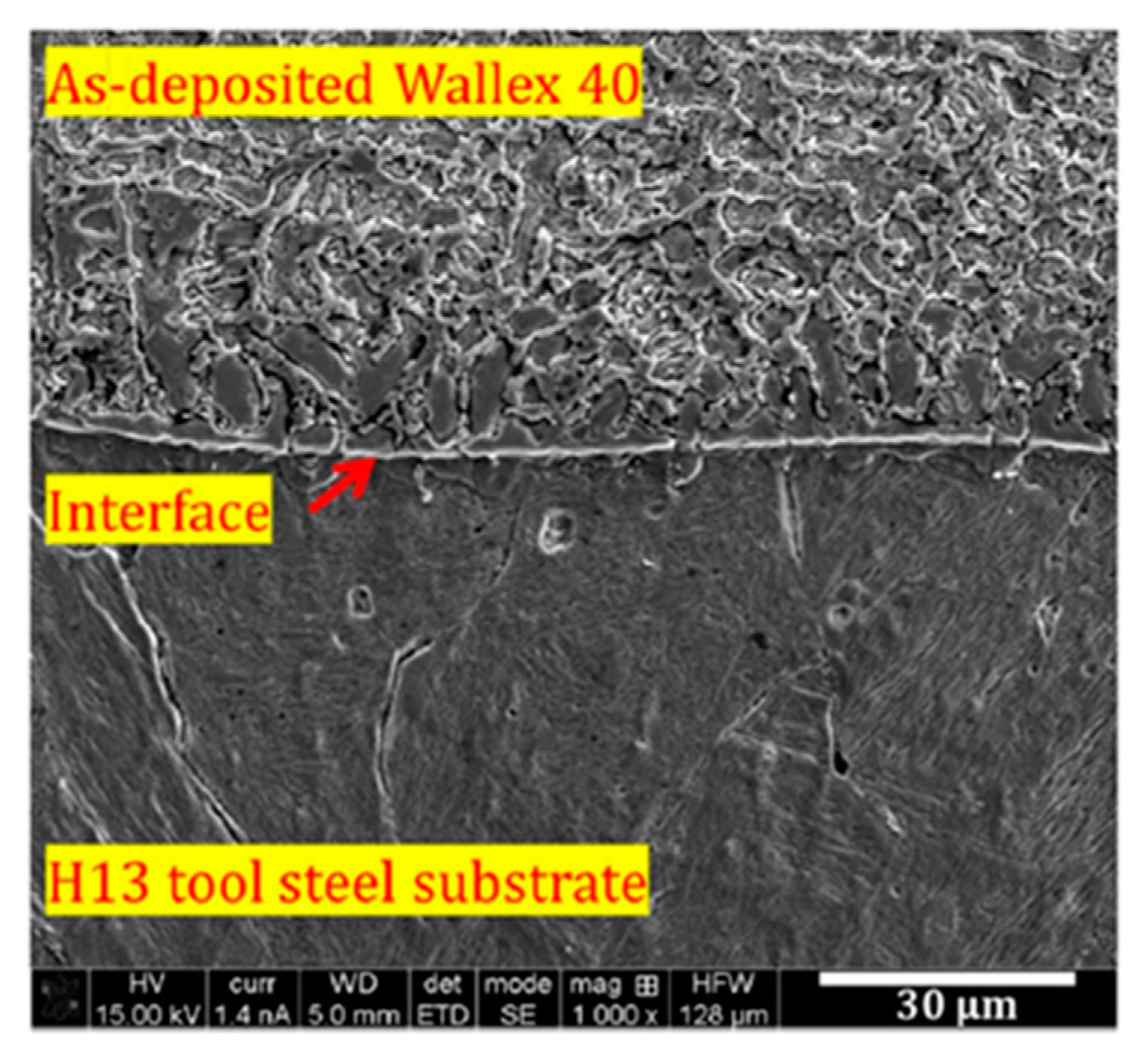

A study conducted on laser metal deposition (a DMD process) as a repair technology for stainless steel and titanium alloys and SLM for aluminium repairs showed that although there are occurrences of material defects like pores and microcracks at the interface layer between the repaired part and the added part, these do not seem to be of enough significance to render the area a weak point of the structure [

17,

52]. The metal melts on both the repaired part and the added part, forming a homogenous mixture and ensuring a strong bond, as seen in

Figure 9 [

47].

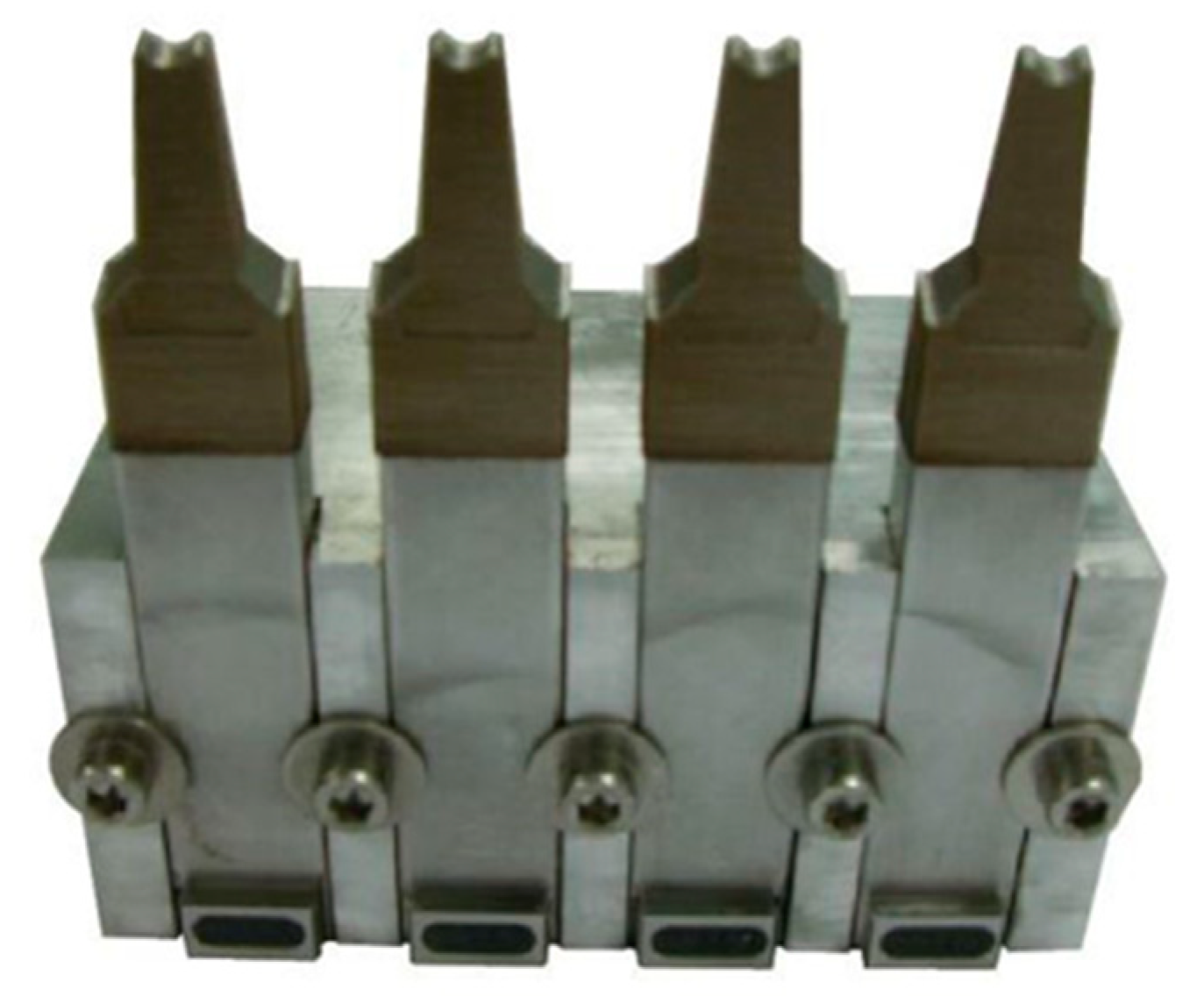

Additive manufacturing can also be used to add special geometry to pre-made incomplete parts [

54,

55,

56]. Remanufacturing is the key for damaged and retired impellers, engine blades, or other geometric repairs by using laser direct deposition or laser cladding based on reverse engineering and re-design [

55]. For example, special temperature-regulating ducts can be created for moulds only printing the areas that contain these ducts, while the main bulk of the mould can be made using traditional methods saving up valuable time and resources and thus ensuring the manufacture of geometries that could not be obtained otherwise (see

Figure 10) [

57].

While additive manufacturing has plenty of benefits and offers new geometry possibilities, being a new technology very promising especially for LCE and EoL activities, it still has quite a few drawbacks too. For example, the high cost of the materials used for AM process, the high level of precision required and relatively slow development of combining AM with subtractive processes, the low amount of information on material behaviour, as well as standardisation provide ample opportunities for research, optimisation, and sustainability [

55,

56,

57,

58,

59].

5. Methods for MAM Sustainability Performance and Applicability

The methodology to prepare a sustainable value stream of MAM process mapping includes various metrics to evaluate not only the economic performance, but also the environmental and societal sustainability performance of a manufacturing line. This consists in lifecycle assessment models using sustainability indicators to establish correct metrics from the first stages of MAM development for each specific industry. Metrics were selected to assess process water consumption, raw material usage, energy consumption, potential hazards concerning the work environment, and the physical work done by the employees [

1,

5,

10,

13,

14,

15,

16,

17,

21,

26,

27,

28,

29,

30,

31,

32].

Sustainability indicators and composite indices are increasingly adopted as useful tools for policy making, industrial acceptance, and public communication on MAM on a very large scale for conveying right information and results on performance-integrating factors as the environment, economy, society, or technological improvements or impediments. Some authors are proposing sustainability assessments by visualising phenomena and highlighting trends in patterns of consumption, though sustainability indicators simplify, quantify, analyse, and communicate otherwise complex and complicated information [

1,

2,

3,

4,

5,

6,

7,

8,

10,

13,

60,

61,

62,

63,

64].

To better understanding lifecycle sustainability in MAM processes, it is necessary to include demonstrative methods of lifecycle assessment (LCA), especially based on database inventories (like Ecoinvent, SimaPro, IDEA, GaBi), which consist in:

environmental impact analyses of a product, related to production and assembly operations;

service life (e.g., usage or maintenance, repair, recycling scheme); and

product end-of-life (EoL) (e.g., disposal, reuse, re-manufacture, and recycle).

From the very early time of MAM development, in-situ process monitoring and in-situ metrology dedicated to AM technologies are subject to machine capabilities. The market implementing MAM technologies underestimated the role of those aspects in regard to process sustainability. Being a high-quality issue required by the client industry, many research activities started to develop special processes and drivers, especially for tackling the AM challenges regarding quality control using different tools such as failure mode and effect analysis (FMEA) or similar tools [

50]. These tools should be integrated into the MAM environmental evaluations, and they are solutions that optimise industrial processes and sustainability performance.

One simple and efficient sustainability evaluation is proposed by Yang et al. for consolidated parts fabricated with MAM. It uses three factors: environmental impact—E

i, energy consumption—E

c, health impact—H, denoted as [E

i,E

c,H], for the following stages: design, manufacturing, assembly, service, and EoL [

21]. A MAM change resulting from part consolidation can be written as δ (material, geometry), and more information can be directly derived from δ, like mass saving and geometric complexity, which decides what material processing method is better to use. The change in sustainability using MAM for consolidated parts can be represented as follows [

21].

The sustainability evaluation function, S, is:

where Manuf is the process function defined by subactivities and includes material, energy, and fluid usage. The lifecycle environmental impact, energy consumption, and health impact are described with the next equations and the Ecoinvent database.

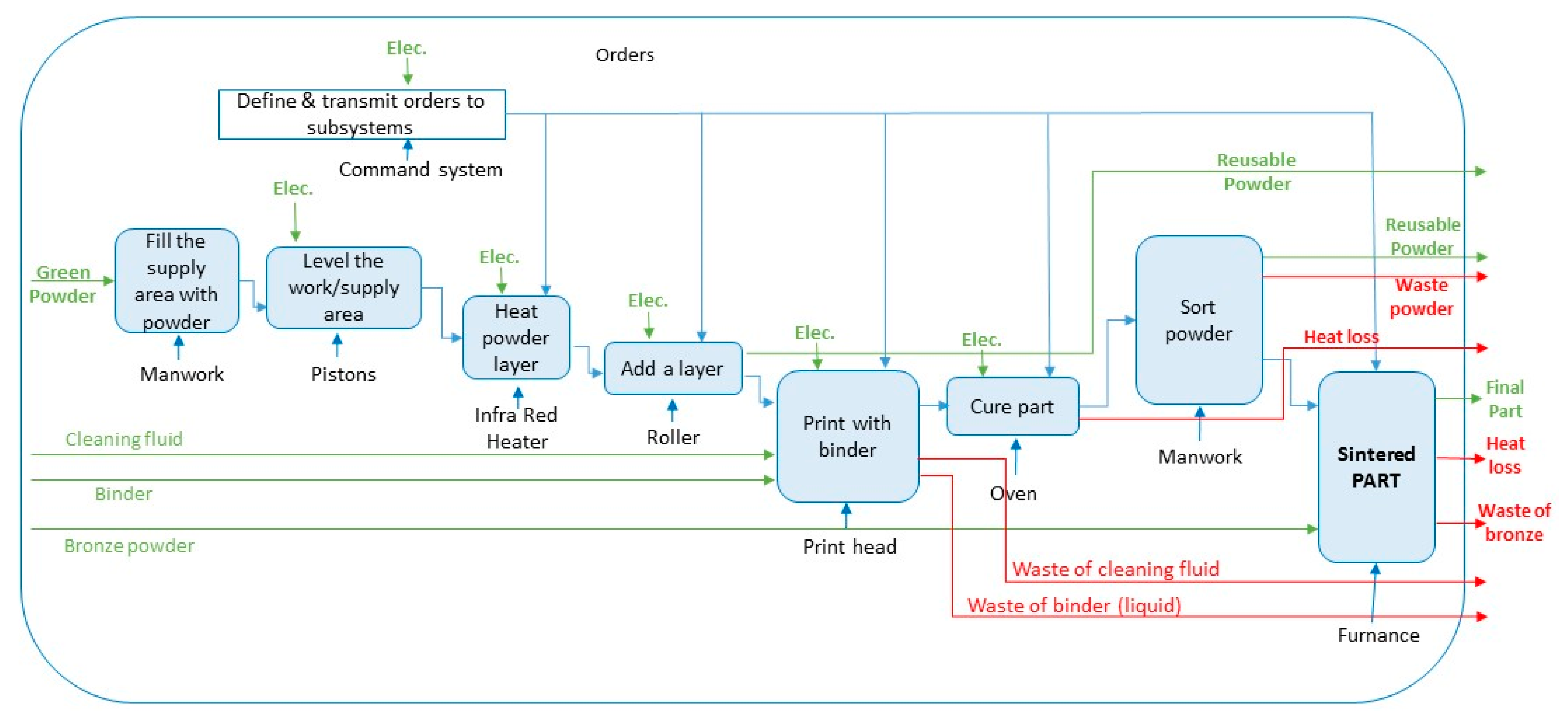

For the BJ-MAM process example described by Tang et al. & Yang et al., the Manuf function is constructed based on the flow-step processes model, as shown in

Figure 11 [

21,

65].

The total energy consumption of the manufacturing process, E

total, is:

where E

total is a function of volume and material:

where V is the volume of the model and it is a function of its geometry.

The material consumption, M

powder, is:

where

is the density of corresponding materials and φ is the buy-to-fly ratio. For MAM processes, φ is around 1.5, but for conventional manufacturing processes, it varies from 2 to 20 [

21,

24]. Similar equations are for the cleaner and binder consumption in the case of BJ processes.

Then, the Manuf change process function is:

Sustainability indices [Ei,Ec,H]m can be calculated with inputs of Manuf(δ). Similarly, each sustainability index of conventional manufacturing processes (e.g., milling) can follow the same procedure to break the machining process into substeps and energy, material, and fluid consumption can be modelled in a similar way. The change in sustainability indices, denoted Δ[E, E, H]m, marks the subtraction between the indices of the AM model and the conventional manufacturing model. For each manufacturing step, it is relevant to analyse the sustainability indices for any change that characterises the AM process as the optimal solution for part consolidation by using redesign.

Ma et al. [

31] propose a feedstock factor utilisation to be included in an LCA for environmental impact (E.I.) calculation from the perspective of material consumption in every manufacturing step from atomisation to powder recycling, highlighted in the following equation:

where, f.c.

material is the material characterization factor, d

p is powder feed rate, f is the feedstock utilisation factor, t

man is the manufacturing time, and k is the weighting factor.

These factors allow researchers to weight the impact of unused powder compared to the used powder from the built product.

In environmental evaluations, sustainability lifecycle assessment (SLCA) is a qualitative method to identify challenges and strengths in the complete lifecycle of a product, evaluating both the environmental and the social dimensions [

37,

38], and is also recognised as strategic lifecycle management [

39]. The SLCA has a lifecycle thinking perspective, evaluating all cycle stages.

Moreover, MAM is a new emerging technology ideal for low- or zero-waste production, making it intuitively considered as a “clean” or “green” process, and LCA is indispensable, in any case, for adopting the best innovative processes and systems for optimal products and businesses, integrating an evaluation methodology presented in

Figure 12 [

26,

63].

In the LCA methodology models developed for different MAM products, authors are using a set of part-processes of the technology, which allow taking into account different manufacturing strategies and their influences on the global environmental impact.

Every methodology using LCA models is based on both analytic models (validated by computer simulation) and experimental models (validated by experiments), which can be applied easily for each MAM process and technology.

It should be noted that sustainability performance is a key factor for AM absorption in a wide range of industries; topics to address are the following: design (eco-design), repair and re-design, production and recycling materials, waste, energy consumption and emissions, health and safety. All of these issues can be highlighted during lifecycle assessment (LCA) based on lifecycle inventories (LCIs) [

61,

62,

63,

66].

All new data obtained from the specific environmental assessments (LCAs) provided by researchers and industry should be integrated in the LCI databases according to the new processes for recycling, re-design, and repair tools to raise the sustainability performance for MAM technology. These data will be available to MAM actors to integrate into the development of more sustainable additive technologies.

6. Conclusions

The main sustainable benefits of MAM technology are resource and energy efficiency and extended product life through lifecycle engineering and reconfigured value chains. The sustainability performance of MAM technology depends on the involved metal powder quality and lifecycle, so powder recovery and recycling optimisation is a major research topic and industrial need. Nonetheless, more research is needed to efficiently standardise the continuously evolving MAM technologies. Some technical conditions, such as process control and metrics, should be developed in order to improve the precision of MAM, validation and demonstration of the structural integrity of components, energy and material efficiency, and efficient MP production and post-processing. Besides all of these, specific environmental aspects need to be taken into consideration: non-toxic and reusable materials, material and multi-material recycling and reuse strategies, integration of existing waste streams, alternative materials, improved support structures with less waste, design optimisation and simulation tools for minimising material and maximising process efficiency, closed-loop remanufacturing solutions, supply chain model and reverse logistics, demonstration and data collection for sustainability performance.

Research and industry must integrate sustainable options for lifecycle engineering and assessment (LCE & LCA) activities into an optimal MAM design process alongside with the less formal process-mapping activities, zero lead times, mass customisation, and automation processes. The sustainability performance of MAM technology depends on the involved metal powder quality and the lifecycle, so powder recovery and recycling optimisation is a major research topic and an industrial need. Related to MAM sustainability, this study highlights some relevant conclusions regarding the recycling and use/reuse tools and environmental performance.

Material production, design processes, component production, reuse, recycling and reconditioning of metal powder, and repairs and remanufacturing are investigated in the context of sustainability. Some methods of MP recycling have been underlined, as well as the important challenges that could arise before the technical validation for materials such as stainless steel and CoCr. In the case of the INCDMTM project, an assumption of 10–13% powder loss during the MAM process is saved. MAM and hybrid production are key technologies for multi-lifecycle products in a circular economy. To accelerate the maturation of MAM technology so as to make it suitable for implementation into mass production, more studies and research are essential. All specified challenges represent opportunities for new research regarding MAM technology development, process optimisation, integration, standardisation, and societal acceptability.