The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations

Abstract

:1. Introduction

2. Methods

2.1. Taxonomy

2.2. Case Study Selection and Evaluation

3. Results

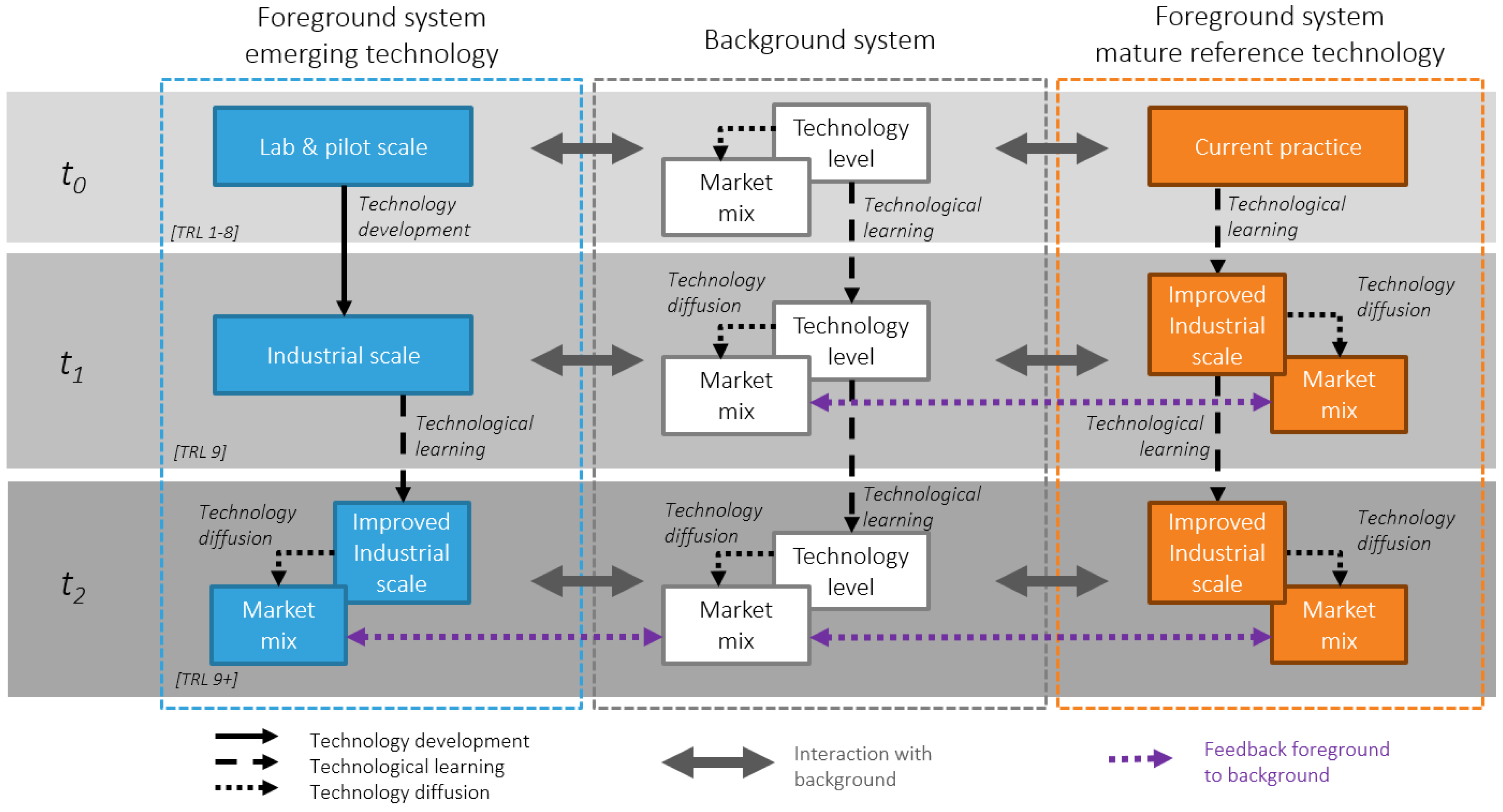

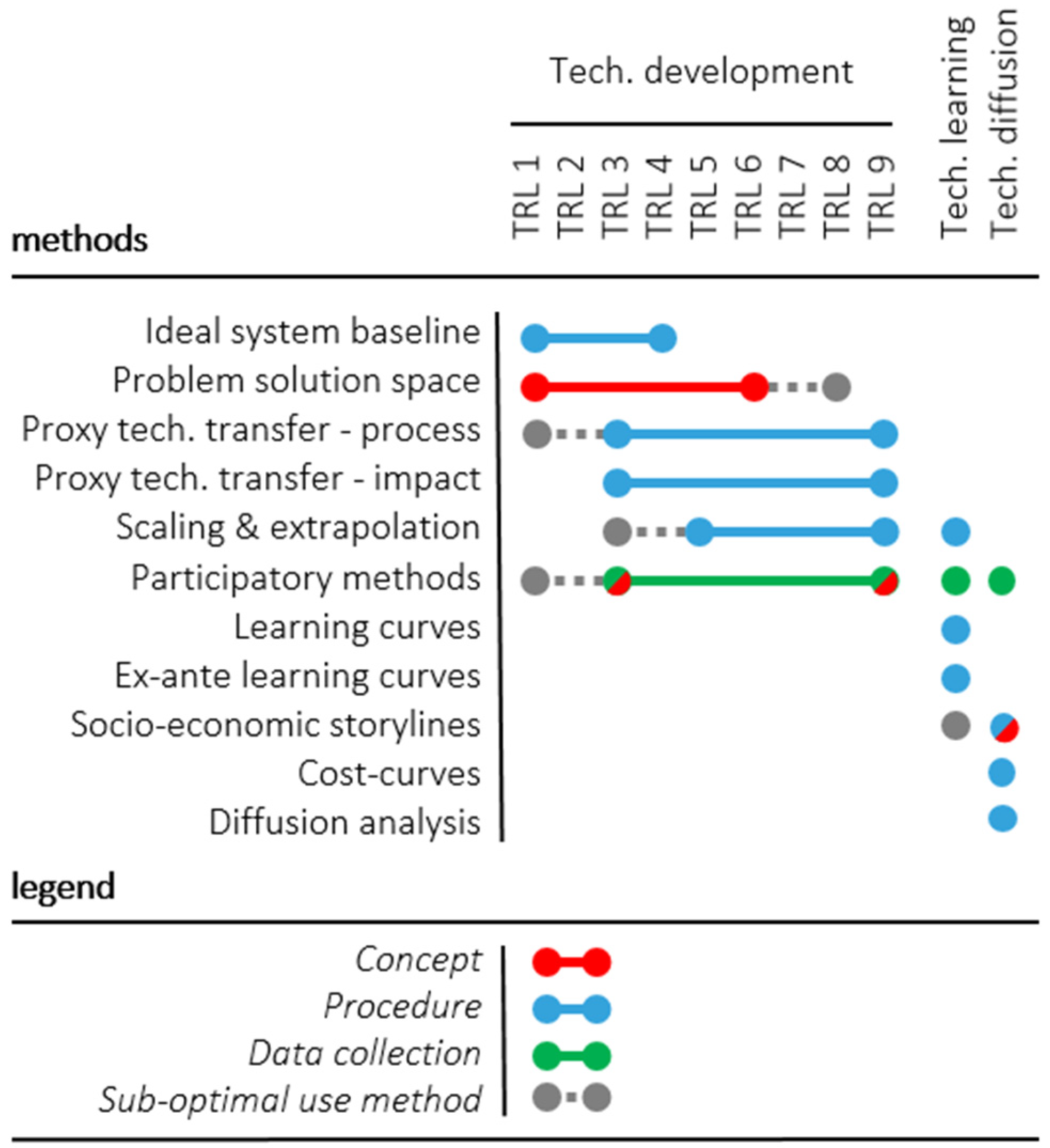

3.1. Framework for Ex-Ante LCA

3.2. General Observations

3.2.1. Uncertainty

3.2.2. Functional Equivalence

3.2.3. Scenario Building

3.2.4. System Models

3.3. Technology Development

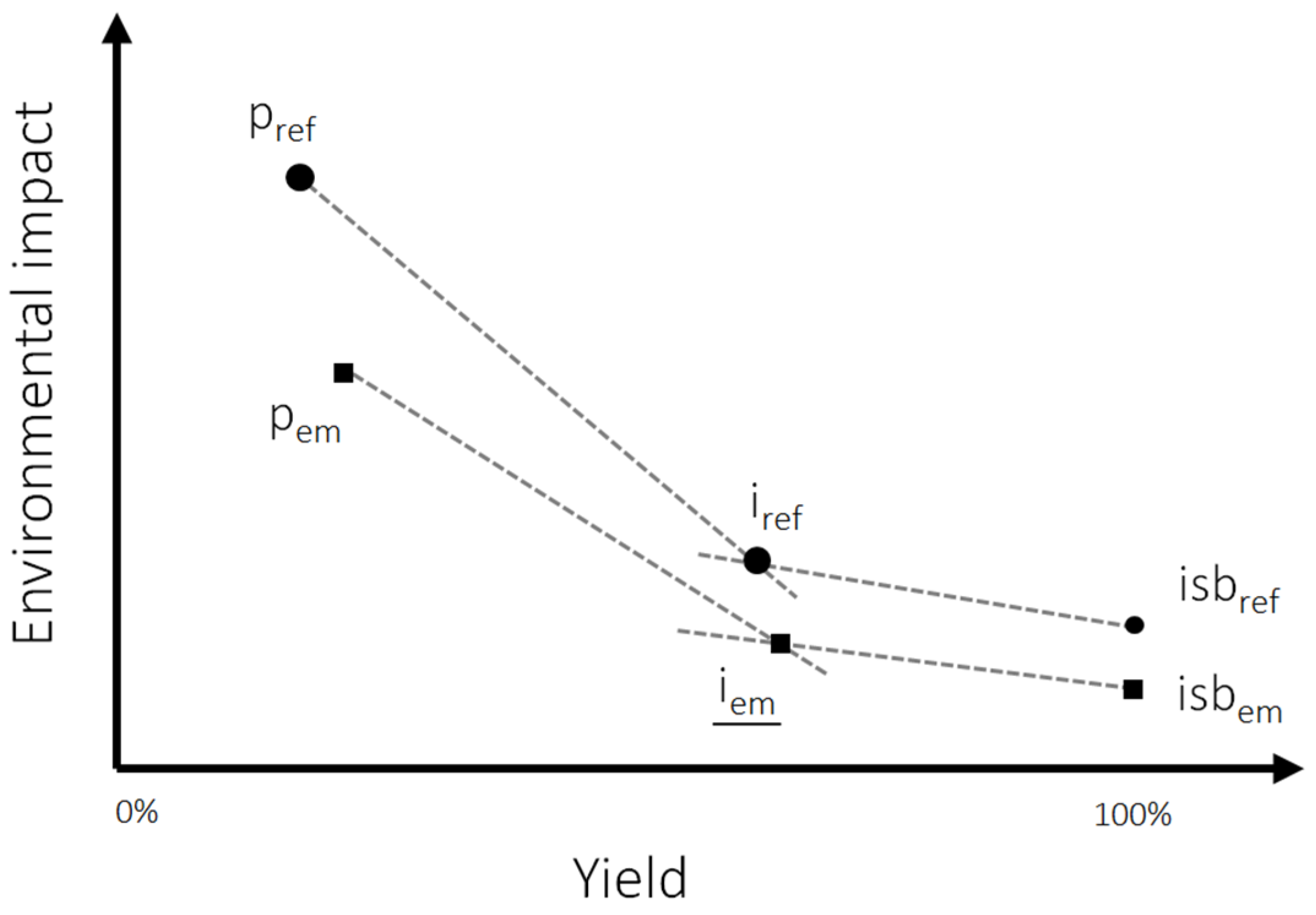

3.3.1. Ideal System Baseline (ISB)

3.3.2. Problem Solution Space (PSP)

3.3.3. Proxy Technology Transfer—Process (PTTp)

3.3.4. Proxy Technology Transfer—Impact (PTTi)

3.3.5. Scaling and Extrapolation (S&E)

3.3.6. Participatory Methods (PM)

3.4. Technological Learning

3.4.1. Learning Curves (LC)

3.4.2. Ex-Ante Learning Curves (Ex-Ante LC)

3.4.3. Socio-Economic Storylines (SES)

3.5. Technology Diffusion

3.5.1. Diffusion Analysis (DA)

3.5.2. Cost-Curves (CC)

4. Discussion and Conclusion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| LCA | life cycle assessment |

| LCIA | life cycle impact assessment |

| LCI | life cycle inventory |

| ALCA | attributional LCA |

| h-CLCA | heuristic consequential LCA |

| eq-CLCA | equilibrium model-based consequential LCA |

| CED | cumulative energy demand |

| GWP | global warming potential |

| FSA | formative scenario analysis |

| TRL | technology readiness level |

| MRL | manufacturing readiness level |

| ISB | ideal system baseline |

| PSP | problem solution space |

| PTTp | proxy technology transfer – process |

| PTTi | proxy technology transfer – impact |

| S&E | scaling and extrapolation |

| PM | participatory methods |

| LC | learning curves |

| SES | socio-economic storylines |

| DA | diffusion analysis |

| CC | cost-curves |

References

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. ILCD Handbook: General Guide to Life Cycle Assessment–Detailed Guidance, 1st ed.; Publications Office of the European Union: Luxembourg, 2010; ISBN 9789279190926. [Google Scholar]

- Hellweg, S.; Canals, L.M.I. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- Frischknecht, R.; Büsser, S.; Krewitt, W. Environmental assessment of future technologies: How to trim LCA to fit this goal? Int. J. Life Cycle Assess. 2009, 14, 584–588. [Google Scholar] [CrossRef]

- Cucurachi, S.; Van Der Giesen, C.; Guinée, J. Ex-ante LCA of Emerging Technologies. Procedia CIRP 2018, 69, 463–468. [Google Scholar] [CrossRef]

- Jeswiet, J.; Hauschild, M. EcoDesign and future environmental impacts. Mater. Des. 2005, 26, 629–634. [Google Scholar] [CrossRef]

- Collingridge, D. The Social Control of Technology; Frances Pinter: London, UK, 1980; ISBN 0903804727. [Google Scholar]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental assessment of emerging technologies: Recommendations for prospective LCA. J. Ind. Ecol. 2017, 22, 1286–1294. [Google Scholar] [CrossRef]

- Rubin, E.S.; Azevedo, I.M.L.; Jaramillo, P.; Yeh, S. A review of learning rates for electricity supply technologies. Energy Policy 2015, 86, 198–218. [Google Scholar] [CrossRef]

- Bass, F.M. Comments on “A New Product Growth for Model Consumer Durables The Bass Model”. Manag. Sci. 2004, 50, 1833–1840. [Google Scholar] [CrossRef]

- Green, R.; Agarwal, R.; Logue, D. Innovation. In International Encyclopedia of the Social & Behavioral Sciences; Wright, J.D., Ed.; Elsevier: Amsterdam, The Netherlands, 2015; pp. 145–151. [Google Scholar]

- Menten, F.; Tchung-Ming, S.; Lorne, D.; Bouvart, F. Lessons from the use of a long-term energy model for consequential life cycle assessment: The BTL case. Renew. Sustain. Energy Rev. 2015, 43, 942–960. [Google Scholar] [CrossRef] [Green Version]

- Mendoza Beltran, A.; Cox, B.; Mutel, C.; van Vuuren, D.P.; Font Vivanco, D.; Deetman, S.; Edelenbosch, O.Y.; Guinée, J.; Tukker, A. When the Background Matters: Using Scenarios from Integrated Assessment Models in Prospective Life Cycle Assessment. J. Ind. Ecol. 2018, 1–16. [Google Scholar] [CrossRef]

- Vandepaer, L.; Treyer, K.; Mutel, C.; Bauer, C.; Amor, B. The integration of long-term marginal electricity supply mixes in the ecoinvent consequential database version 3.4 and examination of modeling choices. Int. J. Life Cycle Assess. 2018. [Google Scholar] [CrossRef]

- International Organisation for Standardization. ISO 14040—Environmental Management—Life Cycle Assessment—Principles and Framework; International Organisation for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- International Organisation for Standardization. ISO 14044—Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organisation for Standardization: Geneva, Switserland, 2006. [Google Scholar]

- Kendall, A. Time-adjusted global warming potentials for LCA and carbon footprints. Int. J. Life Cycle Assess. 2012, 17, 1042–1049. [Google Scholar] [CrossRef]

- Tan, L.; Mandley, S.J.; Peijnenburg, W.; Waaijers-van der Loop, S.L.; Giesen, D.; Legradi, J.B.; Shen, L. Combining ex-ante LCA and EHS screening to assist green design: A case study of cellulose nanocrystal foam. J. Clean. Prod. 2018, 178, 494–506. [Google Scholar] [CrossRef]

- Breton, C.; Blanchet, P.; Amor, B.; Beauregard, R.; Chang, W.-S. Assessing the Climate Change Impacts of Biogenic Carbon in Buildings: A Critical Review of Two Main Dynamic Approaches. Sustainability 2018, 10, 2020. [Google Scholar] [CrossRef]

- De Rosa, M.; Pizzol, M.; Schmidt, J. How methodological choices affect LCA climate impact results: The case of structural timber. Int. J. Life Cycle Assess. 2018, 23, 147–158. [Google Scholar] [CrossRef]

- Guinée, J.B.; Cucurachi, S.; Henriksson, P.J.G.; Heijungs, R. Digesting the alphabet soup of LCA. Int. J. Life Cycle Assess. 2018, 23, 1507–1511. [Google Scholar] [CrossRef] [Green Version]

- Zamagni, A.; Guinée, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and shadows in consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918. [Google Scholar] [CrossRef]

- Curran, M.; Mann, M.; Norris, G. The international workshop on electricity data for life cycle inventories. J. Clean. Prod. 2005, 13, 853–862. [Google Scholar] [CrossRef]

- Chen, I.C.; Fukushima, Y.; Kikuchi, Y.; Hirao, M. A graphical representation for consequential life cycle assessment of future technologies. Part 1: Methodological framework. Int. J. Life Cycle Assess. 2012, 17, 119–125. [Google Scholar] [CrossRef]

- Muñoz, I.; Portillo, F.; Rosiek, S.; Batlles, F.J.; Martínez-Del-Río, J.; Acasuso, I.; Piergrossi, V.; De Sanctis, M.; Chimienti, S.; Di Iaconi, C. Prospective environmental and economic assessment of solar-assisted thermal energy recovery from wastewater through a sequencing batch biofilter granular reactor. J. Clean. Prod. 2019, 212, 1300–1309. [Google Scholar] [CrossRef]

- Heijungs, R.; Huppes, G.; Guinée, J. A Scientific Framework for LCA; Institute of Environmental Sciences, Leiden University: Leiden, The Netherlands, 2009; p. 37. [Google Scholar]

- Wender, B.A.; Foley, R.W.; Hottle, T.A.; Sadowski, J.; Prado-Lopez, V.; Eisenberg, D.A.; Laurin, L.; Seager, T.P. Anticipatory life-cycle assessment for responsible research and innovation. J. Responsible Innov. 2014, 1, 200–207. [Google Scholar] [CrossRef]

- Walser, T.; Demou, E.; Lang, D.J.; Hellweg, S. Prospective environmental life cycle assessment of nanosilver T-shirts. Environ. Sci. Technol. 2011, 45, 4570–4578. [Google Scholar] [CrossRef] [PubMed]

- Miller, S.A.; Keoleian, G.A. Framework for analyzing transformative technologies in life cycle assessment. Environ. Sci. Technol. 2015, 49, 3067–3075. [Google Scholar] [CrossRef] [PubMed]

- Spielmann, M.; Scholz, R.W.; Tietje, O.; Haan, P. de Scenario Modelling in Prospective LCA of Transport Systems. Int. J. Life Cycle Assess. 2005, 10, 325–335. [Google Scholar] [CrossRef]

- Jamasb, T. Technical Change Theory and Learning Curves: Patterns of Progress in Electricity Generation Technologies. Energy J. 2007, 28, 51–71. [Google Scholar] [CrossRef]

- Stahl, B.C. What Does the Future Hold? A Critical View of Emerging Information and Communication Technologies and Their Social Consequences. In Researching the Future in Information Systems; Springer: Berlin/Heidelberg, Germany, 2011; pp. 59–76. [Google Scholar] [Green Version]

- Rotolo, D.; Hicks, D.; Martin, B.R. What is an emerging technology? Res. Policy 2015, 44, 1827–1843. [Google Scholar] [CrossRef] [Green Version]

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Fernandez, J.A. Contextual Role of TRLs and MRLs in Technology Management; Sandia National Laboratories: Albuquerque, NM, USA, 2010. [Google Scholar]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.J.; Koehler, A.; Hellweg, S. Wind power electricity: The bigger the turbine, the greener the electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Koehler, A.; Althaus, H.J.; Hellweg, S. Scaling Relationships in Life Cycle Assessment: The Case of Heat Production from Biomass and Heat Pumps. J. Ind. Ecol. 2014, 18, 393–406. [Google Scholar] [CrossRef]

- Nordelöf, A.; Alatalo, M.; Söderman, M.L. A scalable life cycle inventory of an automotive power electronic inverter unit—Part I: Design and composition. Int. J. Life Cycle Assess. 2019, 24, 78–92. [Google Scholar] [CrossRef]

- Nordelöf, A. A scalable life cycle inventory of an automotive power electronic inverter unit—Part II: Manufacturing processes. Int. J. Life Cycle Assess. 2019, 24, 694–711. [Google Scholar] [CrossRef]

- Arvidsson, R.; Molander, S. Prospective Life Cycle Assessment of Epitaxial Graphene Production at Different Manufacturing Scales and Maturity. J. Ind. Ecol. 2017, 21, 1153–1164. [Google Scholar] [CrossRef]

- Aryapratama, R.; Janssen, M. Prospective life cycle assessment of bio-based adipic acid production from forest residues. J. Clean. Prod. 2017, 164, 434–443. [Google Scholar] [CrossRef] [Green Version]

- Bauer, C.; Hofer, J.; Althaus, H.J.; Del Duce, A.; Simons, A. The environmental performance of current and future passenger vehicles: Life Cycle Assessment based on a novel scenario analysis framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Bergesen, J.D.; Suh, S. A framework for technological learning in the supply chain: A case study on CdTe photovoltaics. Appl. Energy 2016, 169, 721–728. [Google Scholar] [CrossRef] [Green Version]

- Blok, K.; Huijbregts, M.; Patel, M.K.; Hertwich, E.; Hauschild, M.; Sellke, P.; Antunes, P.; Hellweg, S.; Mays, C.; Ciroth, A.; et al. Handbook on a Novel Methodology for the Sustainability Impact Assessment of New Technologies; Utrecht University Repository: Utrecht, The Netherlands, 2013. [Google Scholar]

- Buyle, M.; Pizzol, M.; Audenaert, A. Identifying marginal suppliers of construction materials: Consistent modeling and sensitivity analysis on a Belgian case. Int. J. Life Cycle Assess. 2018, 23, 1624–1640. [Google Scholar] [CrossRef]

- Chen, I.C.; Fukushima, Y.; Kikuchi, Y.; Hirao, M. A graphical representation for consequential life cycle assessment of future technologies—Part 2: Two case studies on choice of technologies and evaluation of technology improvements. Int. J. Life Cycle Assess. 2012, 17, 270–276. [Google Scholar] [CrossRef]

- Cox, B.; Mutel, C.L.; Bauer, C.; Mendoza Beltran, A.; Van Vuuren, D.P. Uncertain environmental footprint of current and future battery electric vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Aguilar, M.; Tarrés, Q.; Pèlach, M.À.; Mutjé, P.; Fullana-i-Palmer, P. Are cellulose nanofibers a solution for a more circular economy of paper products? Environ. Sci. Technol. 2015, 49, 12206–12213. [Google Scholar] [CrossRef]

- Dick, M.; Dewulf, W.; Birkhofer, H.; Duflou, J. Estimating the environmental impacts of similar products. In Proceedings of the DS 32: Proceedings of DESIGN 2004, the 8th International Design Conference, Dubrovnik, Croatia, 18–21 May 2004; pp. 1–6. [Google Scholar]

- Garcia-Gusano, D.; Garrain, D.; Dufour, J. Prospective life cycle assessment of the Spanish electricity production. Renew. Sustain. Energy Rev. 2017, 75, 21–34. [Google Scholar] [CrossRef]

- Gibon, T.; Wood, R.; Arvesen, A.; Bergesen, J.D.; Suh, S.; Hertwich, E.G. A Methodology for Integrated, Multiregional Life Cycle Assessment Scenarios under Large-Scale Technological Change. Environ. Sci. Technol. 2015, 49, 11218–11226. [Google Scholar] [CrossRef] [Green Version]

- Healy, M.L.; Dahlben, L.J.; Isaacs, J.A. Environmental assessment of single-walled carbon nanotube processes. J. Ind. Ecol. 2008, 12, 376–393. [Google Scholar] [CrossRef]

- Hospido, A.; Davis, J.; Berlin, J.; Sonesson, U. A review of methodological issues affecting LCA of novel food products. Int. J. Life Cycle Assess. 2010, 15, 44–52. [Google Scholar] [CrossRef]

- Hung, C.R.; Ellingsen, L.A.W.; Majeau-Bettez, G. LiSET: A Framework for Early-Stage Life Cycle Screening of Emerging Technologies. J. Ind. Ecol. 2018, 1–12. [Google Scholar] [CrossRef]

- Janssen, M.; Tillman, A.M.; Cannella, D.; Jørgensen, H. Influence of high gravity process conditions on the environmental impact of ethanol production from wheat straw. Bioresour. Technol. 2014, 173, 148–158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Katelhön, A.; Von Der Assen, N.; Suh, S.; Jung, J.; Bardow, A. Industry-Cost-Curve Approach for Modeling the Environmental Impact of Introducing New Technologies in Life Cycle Assessment. Environ. Sci. Technol. 2015, 49, 7543–7551. [Google Scholar] [CrossRef] [PubMed]

- Kushnir, D.; Sandén, B.A. Energy requirements of carbon nanoparticle production. J. Ind. Ecol. 2008, 12, 360–375. [Google Scholar] [CrossRef]

- Liptow, C.; Tillman, A.M.; Janssen, M. Life cycle assessment of biomass-based ethylene production in Sweden—Is gasification or fermentation the environmentally preferable route? Int. J. Life Cycle Assess. 2015, 20, 632–644. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Worrell, E.; Patel, M.K. Innovative membrane filtration system for micropollutant removal from drinking water—Prospective environmental LCA and its integration in business decisions. J. Clean. Prod. 2014, 72, 153–166. [Google Scholar] [CrossRef]

- Manda, B.M.K.; Worrell, E.; Patel, M.K. Prospective life cycle assessment of an antibacterial T-shirt and supporting business decisions to create value. Resour. Conserv. Recycl. 2015, 103, 47–57. [Google Scholar] [CrossRef]

- O’Brien, D.; Shalloo, L.; Crosson, P.; Donnellan, T.; Farrelly, N.; Finnan, J.; Hanrahan, K.; Lalor, S.; Lanigan, G.; Thorne, F.; et al. An evaluation of the effect of greenhouse gas accounting methods on a marginal abatement cost curve for Irish agricultural greenhouse gas emissions. Environ. Sci. Policy 2014, 39, 107–118. [Google Scholar] [CrossRef]

- Patel, A.D.; Meesters, K.; Den Uil, H.; De Jong, E.; Blok, K.; Patel, M.K. Sustainability assessment of novel chemical processes at early stage: Application to biobased processes. Energy Environ. Sci. 2012, 5, 8430–8444. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew. Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Piccinno, F.; Hischier, R.; Seeger, S.; Som, C. From laboratory to industrial scale: A scale-up framework for chemical processes in life cycle assessment studies. J. Clean. Prod. 2016, 135, 1085–1097. [Google Scholar] [CrossRef]

- Pini, M.; Cedillo González, E.; Neri, P.; Siligardi, C.; Ferrari, A. Assessment of Environmental Performance of TiO2 Nanoparticles Coated Self-Cleaning Float Glass. Coatings 2017, 7, 8. [Google Scholar] [CrossRef]

- Ravikumar, D.; Seager, T.P.; Cucurachi, S.; Prado, V.; Mutel, C. Novel Method of Sensitivity Analysis Improves the Prioritization of Research in Anticipatory Life Cycle Assessment of Emerging Technologies. Environ. Sci. Technol. 2018, 52, 6534–6543. [Google Scholar] [CrossRef]

- Ravikumar, D.; Sinha, P.; Seager, T.P.; Fraser, M.P. An anticipatory approach to quantify energetics of recycling CdTe photovoltaic systems. Prog. Photovolt. Res. Appl. 2016, 24, 735–746. [Google Scholar] [CrossRef]

- Roes, A.L.; Patel, M.K. Ex-ante environmental assessments of novel technologies-improved caprolactam catalysis and hydrogen storage. J. Clean. Prod. 2011, 19, 1659–1667. [Google Scholar] [CrossRef]

- Shibasaki, M.; Fischer, M.; Barthel, L. Effects on Life Cycle Assessment—Scale Up of Processes. In Proceedings of the 14th CIRP Conference on Life Cycle Engineering, Waseda University, Tokyo, Japan, 11–13 June 2007; pp. 377–381. [Google Scholar]

- Shibasaki, M.; Warburg, N.; Eyerer, P. Upscaling effect and Life Cycle Assessment. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006; pp. 61–64. [Google Scholar]

- Simon, B.; Bachtin, K.; Kiliç, A.; Amor, B.; Weil, M. Proposal of a framework for scale-up life cycle inventory: A case of nanofibers for lithium iron phosphate cathode applications. Integr. Environ. Assess. Manag. 2016, 12, 465–477. [Google Scholar] [CrossRef]

- Tecchio, P.; Freni, P.; De Benedetti, B.; Fenouillot, F. Ex-ante Life Cycle Assessment approach developed for a case study on bio-based polybutylene succinate. J. Clean. Prod. 2016, 112, 316–325. [Google Scholar] [CrossRef]

- Van der Voet, E.; Van Oers, L.; Verboon, M.; Kuipers, K. Environmental implications of future demand scenarios for metals: Methodology and application to the case of seven major metals. J. Ind. Ecol. 2019, 23, 141–155. [Google Scholar] [CrossRef]

- Vandepaer, L.; Bauer, C.; Treyer, K.; Mutel, C.L. Marginal electricity supply mixes and their integration in version 3.4 of the ecoinvent database. In Proceedings of the 23rd LCA Case Study Symposium, Barcelona, Spain, 27–28 November 2017; pp. 1–18. [Google Scholar]

- Villares, M.; Işildar, A.; Mendoza Beltran, A.; Guinee, J. Applying an ex-ante life cycle perspective to metal recovery from e-waste using bioleaching. J. Clean. Prod. 2016, 129, 315–328. [Google Scholar] [CrossRef]

- Villares, M.; Işıldar, A.; van der Giesen, C.; Guinée, J. Does ex ante application enhance the usefulness of LCA? A case study on an emerging technology for metal recovery from e-waste. Int. J. Life Cycle Assess. 2017, 22, 1618–1633. [Google Scholar] [CrossRef] [Green Version]

- Wender, B.A.; Foley, R.W.; Prado-Lopez, V.; Ravikumar, D.; Eisenberg, D.A.; Hottle, T.A.; Sadowski, J.; Flanagan, W.P.; Fisher, A.; Laurin, L.; et al. Illustrating anticipatory life cycle assessment for emerging photovoltaic technologies. Environ. Sci. Technol. 2014, 48, 10531–10538. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Graziano, D.J.; Riddle, M.; Cresko, J.; Masanet, E. Prospective energy analysis of emerging technology options for the united states ethylene industry. Ind. Eng. Chem. Res. 2016, 55, 3493–3505. [Google Scholar] [CrossRef]

- Zimmermann, B.M.; Dura, H.; Baumann, M.J.; Weil, M.R. Prospective time-resolved LCA of fully electric supercap vehicles in Germany. Integr. Environ. Assess. Manag. 2015, 11, 425–434. [Google Scholar] [CrossRef] [PubMed]

- Reap, J.; Roman, F.; Duncan, S.; Bras, B. A survey of unresolved problems in life cycle assessment. Part 1: Goal and scope and inventory analysis. Int. J. Life Cycle Assess. 2008, 13, 290–300. [Google Scholar] [CrossRef]

- Glenn, J.C. Introduction to the Futures Research Methodology Series; United Nations University: Washington, DC, USA, 1994. [Google Scholar]

- Pesonen, H.L.; Ekvall, T.; Fleischer, G.; Huppes, G.; Jahn, C.; Klos, Z.S.; Rebitzer, G.; Sonnemann, G.W.; Tintinelli, A.; Weidema, B.P.; et al. Framework for scenario development in LCA. Int. J. Life Cycle Assess. 2000, 5, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P. UMIP 2003 Method. Environmental News No. 74 2004. In Geographical, Technological and Temporal Delimitation in LCA; Danish Environmental Protection Agency: Kopenhagen, Denmark, 2004. [Google Scholar]

- Earles, J.M.; Halog, A. Consequential life cycle assessment: A review. Int. J. Life Cycle Assess. 2011, 16, 445–453. [Google Scholar] [CrossRef]

- Weidema, B.P.; Ekvall, T.; Heijungs, R. Guidelines for Application of Deepened and Broadened LCA—Deliverable D18 of Work Package 5 of the CALCAS Project; CALCAS—Co-ordination Action for Innovation in Life-Cycle Analysis for Sustainability: Colorado Spring, CO, USA, 2009; p. 49. [Google Scholar]

- Buyle, M. Towards a Structured Consequential Modelling Approach for the Construction Sector: The Belgian Case: A Fairy Tale on Methodological Choices in LCA. Ph.D. Thesis, University of Antwerp, Antwerpen, Belgium, 2018. [Google Scholar]

- Yang, Y.; Heijungs, R. On the use of different models for consequential life cycle assessment. Int. J. Life Cycle Assess. 2018, 23, 751–758. [Google Scholar] [CrossRef]

- Brandao, M.; Martin, M.; Cowie, A.; Hamelin, L.; Zamagni, A. Consequential Life Cycle Assessment: What, How, and Why? Encycl. Sustain. Technol. 2017, 277–284. [Google Scholar] [CrossRef]

- Dorst, K.; Cross, N. Creativity in the design process: Co-evolution of problem–solution. Des. Stud. 2001, 22, 425–437. [Google Scholar] [CrossRef]

- Haupt, G. Learning from experts: Fostering extended thinking in the early phases of the design process. Int. J. Technol. Des. Educ. 2015, 25, 483–520. [Google Scholar] [CrossRef]

- Hetherington, A.C.; Borrion, A.L.; Griffiths, O.G.; McManus, M.C. Use of LCA as a development tool within early research: Challenges and issues across different sectors. Int. J. Life Cycle Assess. 2014, 19, 130–143. [Google Scholar] [CrossRef]

- Weidema, B.P. Environmental Project No. 863. In Market Information in Life Cycle Assessment; Miljøstyrelsen: Copenhagen, Denmark, 2003. [Google Scholar]

- Wright, T.P. Factors Affecting the Cost of Airplanes. J. Aeronaut. Sci. 1936, 3, 122–128. [Google Scholar] [CrossRef]

- UNFCCC. The Cancun agreements. United Nations Framework Convention on Climate Change: Cancun Climate Change Conference. Available online: https://unfccc.int/event/cancun-climate-change-conference-november-2010-meetings-page (accessed on 9 May 2019).

- Louwen, A.; Van Sark, W.G.J.H.M.; Faaij, A.P.C.; Schropp, R.E.I. Re-assessment of net energy production and greenhouse gas emissions avoidance after 40 years of photovoltaics development. Nat. Commun. 2016, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- De Wit, M.; Junginger, M.; Faaij, A. Learning in dedicated wood production systems: Past trends, future outlook and implications for bioenergy. Renew. Sustain. Energy Rev. 2013, 19, 417–432. [Google Scholar] [CrossRef]

- Fortes, P.; Alvarenga, A.; Seixas, J.; Rodrigues, S. Long-term energy scenarios: Bridging the gap between socio-economic storylines and energy modeling. Technol. Forecast. Soc. Chang. 2015, 91, 161–178. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2016; IEA: Paris, France, 2016. [Google Scholar]

- Sharp, B.E.; Miller, S.A. Potential for Integrating Diffusion of Innovation Principles into Life Cycle Assessment of Emerging Technologies. Environ. Sci. Technol. 2016, 50, 2771–2781. [Google Scholar] [CrossRef]

- Tholana, T.; Musingwini, C.; Njowa, G. An algorithm to construct industry cost curves used in analysing cash cost performance of operations for selected minerals in South Africa. J. South. Afr. Inst. Min. Metall. 2013, 113, 473–484. [Google Scholar]

- Ferioli, F.; Schoots, K.; van der Zwaan, B.C.C. Use and limitations of learning curves for energy technology policy: A component-learning hypothesis. Energy Policy 2009, 37, 2525–2535. [Google Scholar] [CrossRef]

- Huenteler, J.; Schmidt, T.S.; Ossenbrink, J.; Hoffmann, V.H. Technology life-cycles in the energy sector—Technological characteristics and the role of deployment for innovation. Technol. Forecast. Soc. Chang. 2016, 104, 102–121. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Delivering the Circular Economy: A Toolkit for Policymakers; Ellen MacArthur Foundation: London, UK, 2015. [Google Scholar]

| Author(s) | Topic | TRL 1 | Changes FG (ΔFG) | Changes BG (ΔBG) | Feed-back FG-BG | System Model | Technology Development | Technological Learning | Technology Diffusion | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ISB | PSS | PTTp | PTTi | S&E | PM | S&E | PM | LC | ea LC | SES | PM | SES | ICC | DA | |||||||

| Arvidsson and Molander [39] | Graphene production | 3–4 | + | -/+ | - | ALCA | - | - | + | - | - | + | - | - | - | - | - | - | - | - | - |

| Aryapratama and Janssen [40] | Adipic acid production | 3–4 | -/+ | - | - | ALCA | - | - | - | - | - | -/+ | - | - | - | - | - | - | - | - | - |

| Bauer et al. [41] | Passenger vehicles | 9+ | + | + | - | ALCA | - | - | - | - | - | - | + | + | -/+ | - | + | + | + | - | - |

| Beltran et al. [12] | Electric vehicles | 9+ | - | + | - | ALCA | - | - | - | - | - | - | + | + | + | - | + | + | + | - | - |

| Bergesen and Suh [42] | CdTe PV panels | 9+ | -/+ | + | - | ALCA | - | - | - | - | - | - | + | + | + | - | - | - | - | - | - |

| Blok et al. [43] | Nanotechnology, smartphones, energy production, paint | - | + | + | - | n.s. | - | -/+ | - | - | + | + | - | - | - | - | - | + | + | -/+ | ! |

| Buyle et al. [44] | Construction products | 9+ | -/+ | -/+ | - | h-CLCA | - | - | - | - | - | - | - | - | - | - | - | + | + | -/+ | - |

| Caduff et al. [36] | Heat pumps and biomass furnaces | 9+ | + | - | - | ALCA | - | - | - | -/+ | - | - | + | + | - | - | - | - | - | - | - |

| Caduff et al. [35] | Wind turbines | 9+ | + | - | - | ALCA | - | - | - | - | + | + | + | - | - | - | - | - | - | - | - |

| Chen et al. [23,45] | Hydrogen production | 4–5 | - | + | - | h-CLCA | - | - | - | - | - | - | - | - | - | - | - | + | - | - | - |

| Cox et al. [46] | Electric vehicles | 9+ | + | + | - | ALCA | - | - | - | - | + | + | + | + | - | - | + | - | - | - | - |

| Delgado-Aguilar et al. [47] | Nanocellulose-enforced paper | 3–4 | + | -/+ | - | ALCA | - | - | - | - | + | - | - | - | - | - | - | - | - | - | - |

| Dick et al. [48] | Structural elements and engines | 9+ | -/+ | - | - | ALCA | - | - | + | - | - | - | - | - | - | - | - | - | - | - | - |

| Garcia-Gusano et al. [49] | Electricity production | 9+ | + | - | - | eq-CLCA | - | - | - | - | - | - | + | - | - | - | - | - | + | - | + |

| Gavankar et al. [33] | Carbon nanotubes | 7–8 | + | - | - | ALCA | - | - | - | -/+ | - | + | - | - | - | - | - | - | - | - | - |

| Gibon et al. [50] | Concentrating solar power | 9+ | + | + | + | ALCA | - | - | - | - | + | + | - | + | - | + | + | + | + | - | - |

| Healy et al. [51] | Carbon nanotubes | 3–4 | + | - | - | ALCA | - | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| Hospido et al. [52] | Food products | - | + | - | - | ALCA | - | - | - | - | - | ! | - | - | ! | - | - | - | - | - | - |

| Hung et al. [53] | Screening framework | - | -/+ | - | - | - | - | - | - | - | ! | -/+ | ! | - | - | - | - | - | - | - | ! |

| Janssen et al. [54] | Ethanol production from wheat straw | 3–4 | + | - | - | ALCA | - | - | - | - | + | - | - | - | - | - | - | - | - | - | - |

| Katelhön et al. [55] | Chlor-alkali electrolysis | 3–4 | - | + | - | h-CLCA | - | - | - | - | - | - | - | - | - | - | - | - | - | + | - |

| Kushnir and Sandén [56] | Fullerene and carbon nanotubes | 3–4 | + | - | - | ALCA | + | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| Liptow et al. [57] | Ethylene production from wood | 7–8 | + | - | - | ALCA | - | - | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Manda et al. [58] | Membrane filtration system | 3–4 | + | -/+ | - | ALCA | - | - | - | -/+ | - | + | - | - | - | - | - | - | - | - | - |

| Manda et al. [59] | Antibacterial T-shirt | 5 | + | - | - | ALCA | - | - | - | -/+ | - | + | - | - | - | - | - | - | - | - | - |

| Menten et al. [11] | Energy system | 9+ | + | + | - | eq-CLCA | - | - | - | - | - | - | - | - | + | - | - | - | + | + | - |

| Muñoz et al. [24] | Wastewater treatment | 5 | + | - | - | h-CLCA | - | - | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Nordelöf [38] | Power electronic inverter | 9+ | + | - | - | LCI only | - | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| Nordelöf et al. [37] | Power electronic inverter | 9+ | + | - | - | LCI only | - | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| O’Brien et al. [60] | agriculture | 9+ | + | - | - | ALCA | - | - | - | - | - | - | + | + | - | - | - | - | - | + | - |

| Patel et al. [61] | But-1,3-diene | 3–4 | + | - | - | ALCA | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Pehnt [62] | Renewable energy technologies | 9+ | + | + | - | ALCA | - | - | - | - | + | -/+ | + | -/+ | - | - | - | - | - | + | - |

| Piccinno et al. [63] | Liquid phase batch reactions | 3–4 | + | - | - | n.s. | + | - | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Pini et al. [64] | Self-cleaning coated float glass | 4–5 | + | - | - | ALCA | - | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| Ravikumar et al. [65] | PV panels | 9+ | -/+ | - | - | ALCA | - | - | - | - | - | -/+ | - | - | - | - | - | - | - | - | - |

| Ravikumar et al. [66] | Recycling CdTe PV | 9+ | -/+ | - | - | ALCA | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Roes and Patel [67] | Caprolactam production | 2 | + | - | - | ALCA | + | - | - | - | + | + | - | - | - | - | - | - | - | - | - |

| Shibasaki et al. [68] | Scale up of a generic plant | 6–7 | + | - | - | ALCA | - | - | - | - | + | - | - | - | - | - | - | - | - | - | - |

| Shibasaki et al. [69] | Scale up of a generic plant | 7–8 | + | -/+ | - | ALCA | - | - | - | - | + | - | - | - | - | - | - | - | - | - | - |

| Simon et al. [70] | LFP-CnF batteries | 3–4 | + | - | - | ALCA | - | - | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Spielmann et al. [29] | Transport systems | 9+ | + | + | - | ALCA | - | - | - | - | - | - | + | + | - | - | - | + | + | - | - |

| Tan et al. [17] | Cellulose nanocrystal foam | 3 and 4 | + | - | - | ALCA | - | -/+ | - | - | - | + | - | - | - | - | - | - | - | - | - |

| Tecchio et al. [71] | Bio-based plastics | 3 | + | - | - | ALCA | + | - | - | + | - | - | - | - | - | - | - | - | - | - | - |

| Van der Voet et al. [72] | Metals | 9+ | + | + | - | ALCA | - | - | - | - | - | - | + | + | - | - | + | - | + | - | - |

| Vandepaer et al. [73] | Electricity production | 9+ | - | + | - | h-CLCA | - | - | - | - | - | - | - | - | - | - | - | + | + | -/+ | - |

| Villares et al. [74] | Metal recovery from e-waste | 2–3 | + | -/+ | - | ALCA | - | - | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Villares et al. [75] | Metal recovery from e-waste | 2–3 | + | -/+ | - | ALCA | - | ! | + | - | + | + | - | - | - | - | - | - | - | - | - |

| Walser et al. [27] | Nanosilver T-shirts | 3–4 and6–7 | + | - | - | ALCA | - | - | - | - | - | + | - | - | - | - | - | + | + | - | - |

| Wender et al. [26,76] | PV panels | 9+ | + | - | - | ALCA | + | -/+ | - | - | - | + | - | - | ! | - | - | + | - | - | - |

| Yao et al. [77] | Ethylene production | 4–6 | - | + | - | ALCA | - | - | - | - | - | - | - | - | - | - | - | + | + | - | - |

| Zimmermann et al. [78] | Electric vehicles | 9+ | - | + | - | ALCA | - | - | - | - | - | - | - | + | - | - | - | - | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; Van Passel, S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability 2019, 11, 5456. https://doi.org/10.3390/su11195456

Buyle M, Audenaert A, Billen P, Boonen K, Van Passel S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability. 2019; 11(19):5456. https://doi.org/10.3390/su11195456

Chicago/Turabian StyleBuyle, Matthias, Amaryllis Audenaert, Pieter Billen, Katrien Boonen, and Steven Van Passel. 2019. "The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations" Sustainability 11, no. 19: 5456. https://doi.org/10.3390/su11195456

APA StyleBuyle, M., Audenaert, A., Billen, P., Boonen, K., & Van Passel, S. (2019). The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability, 11(19), 5456. https://doi.org/10.3390/su11195456