1. Introduction

The philosophy of Lean management has its origins in the Toyota Production System [

1]. This philosophy presents new strategies of maximizing value while minimizing waste [

2]. Lean philosophy, culture, and technology are the three key aspects for a global understanding of Lean [

3]. Koskela [

4] adapted this approach to the construction industry, introducing what is known as Lean Construction [

5,

6]. Koskela [

4] proposed eleven important principles for flow process design and improvement: (1) reduce the share of non-value-adding activities; (2) increase output value through systematic consideration of customer requirements; (3) reduce variability; (4) reduce the cycle time; (5) simplify by minimizing the number of steps, parts, and linkages; (6) increase output flexibility; (7) focus control on the complete process; (8) increase process transparency; (9) build continuous improvement into the process; (10) balance flow improvement with conversion improvement; and (11) benchmark.

Some of these Lean Construction Principles (LCPs) are directly related to sustainability; for example, the flow view entails eliminating material waste that directly affects sustainability [

7]. Researchers state that the synergy between Lean and sustainability is proven, since both approaches aim to reduce waste and prioritize cleaner production [

8]. In addition, Martínez-León and Calvo-Amodio [

9] noted that Lean tends to facilitate the adoption of environmental practices primarily by involving people and enhancing their problem-solving skill sets. This also represents an advantage for companies that adopt continuous improvement, as they tend to be more likely to implement environmental practices [

10].

For all of the above reasons, the industry believes that graduates in the Architecture, Engineering, and Construction (AEC) field must be well-formed in Lean concepts and methods [

11,

12]. The application of Lean principles in the construction field can improve the efficiency of construction planning [

13]. In view of the interests of academics and industry, universities are offering courses on Lean at both undergraduate and graduate levels [

14]. Lean provides key skills for professionals in construction management [

15]. However, traditional teaching methods do not effectively reach and convince the audience [

16]. Some authors [

17,

18] have also indicated that traditional lectures present difficulties for learners in applying the information in an authentic context, particularly when being immersed in complex scenarios. Pellicer and Ponz-Tienda [

19] and Nofera et al. [

20] demonstrated the added value of using multiple teaching methods for students. Specifically, Kuriger et al. [

21] stated that simulation games are effective tools for teaching Lean concepts, as participants can see and experience what they have learned in regular sessions through lectures and other teaching techniques.

Game-based learning (GBL) is a widely recognized teaching method in higher education due to its pedagogical benefits [

22,

23,

24]. Using games as a teaching tool makes the learning process more enjoyable, which in turn makes the learners more receptive to the information the game’s creator or the instructor intends to convey [

25]. A game-based learning approach might be effective in facilitating students’ skills development (e.g., collaboration, creativity, communication, or critical thinking, among others) [

26]. GBL is a method with defined learning outcomes [

27]. Usually, it is assumed that the game is a digital one. However, GBL can be any kind of game. A corollary to this definition is that the design process of GBL involves balancing the need to cover the subject with the desire to prioritize the game play [

28]. Badurdeen et al. [

29] presented a literature review of simulations used to teach Lean manufacturing for academic instruction and also for industry participants. Regarding Lean Construction, most of the games focus on project planning, such as Last Planner System Games [

2,

19,

30,

31]. GBL presents multiple advantages, but it is also important to consider its limitations. Deif [

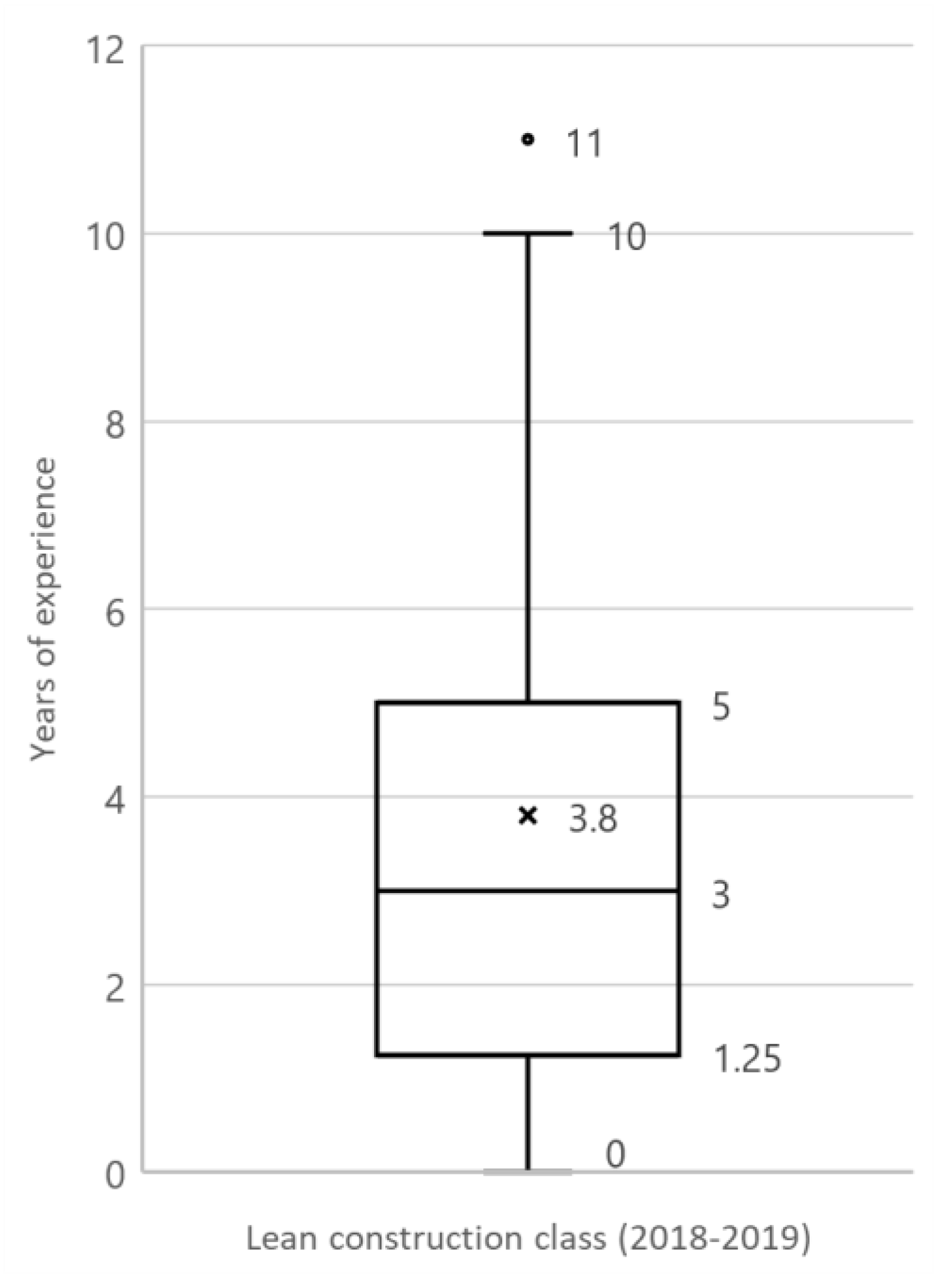

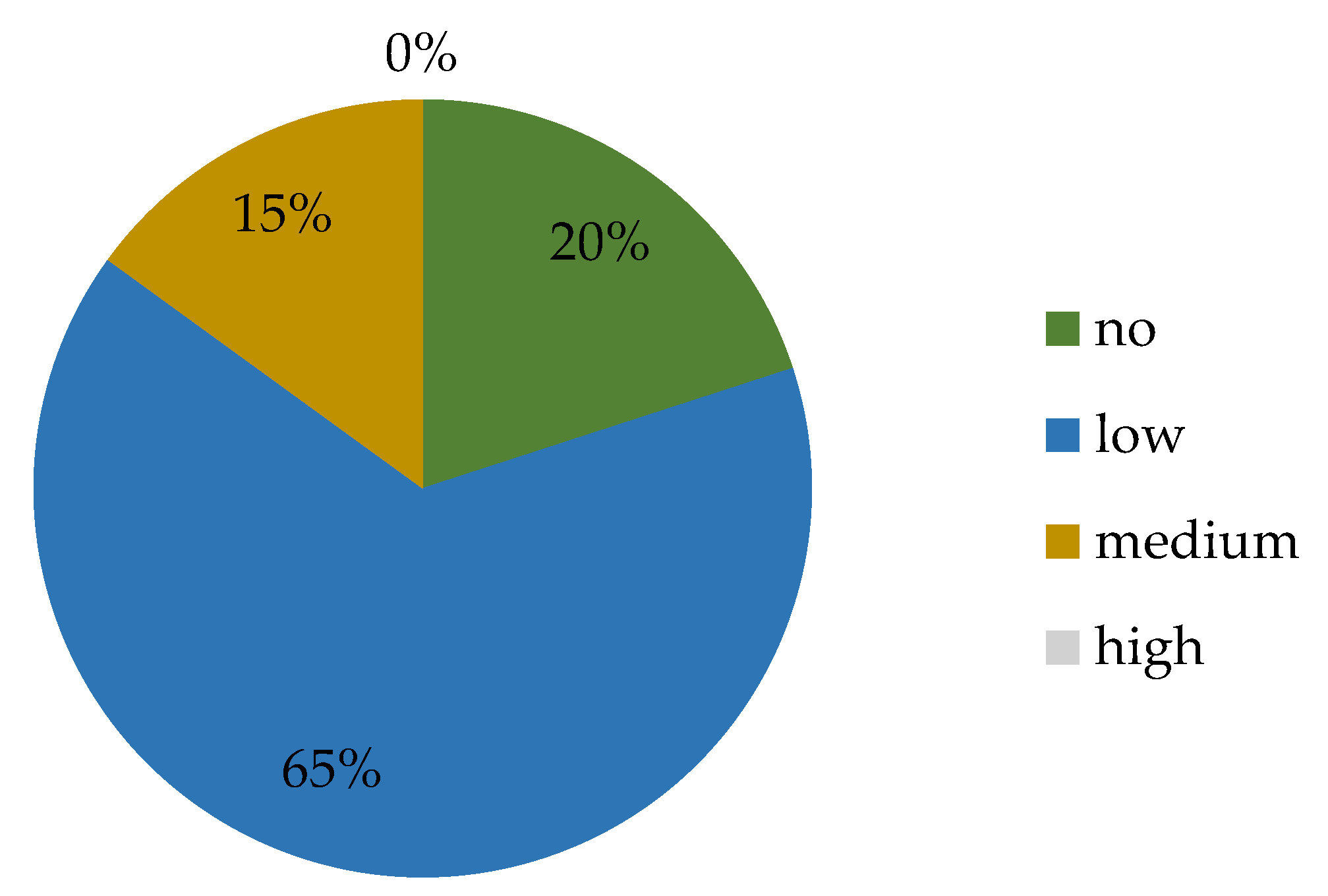

32] pointed out that GBL has the capability to motivate students and provides instructors with a tool for teaching Lean Construction in a practical manner, but it is important to take into account that Lean games must be adapted to the limited industrial experience of students [

32]. González et al. [

2] highlighted that one limitation of GBL is that games can sometimes be too complex to play and too complicated for implementation in university classes. Besides, as Hirota and Formoso [

33] noted, it is not easy for students to understand and comprehensively incorporate the LCPs. To this end, Brioso [

34] presented some activities including two simulation games to address the understanding of the LCPs. However, this author did not assess the effects of the activities on the learning of these principles, in contrast to González et al. [

2], who evaluated the results but only focused on some of LCPs.

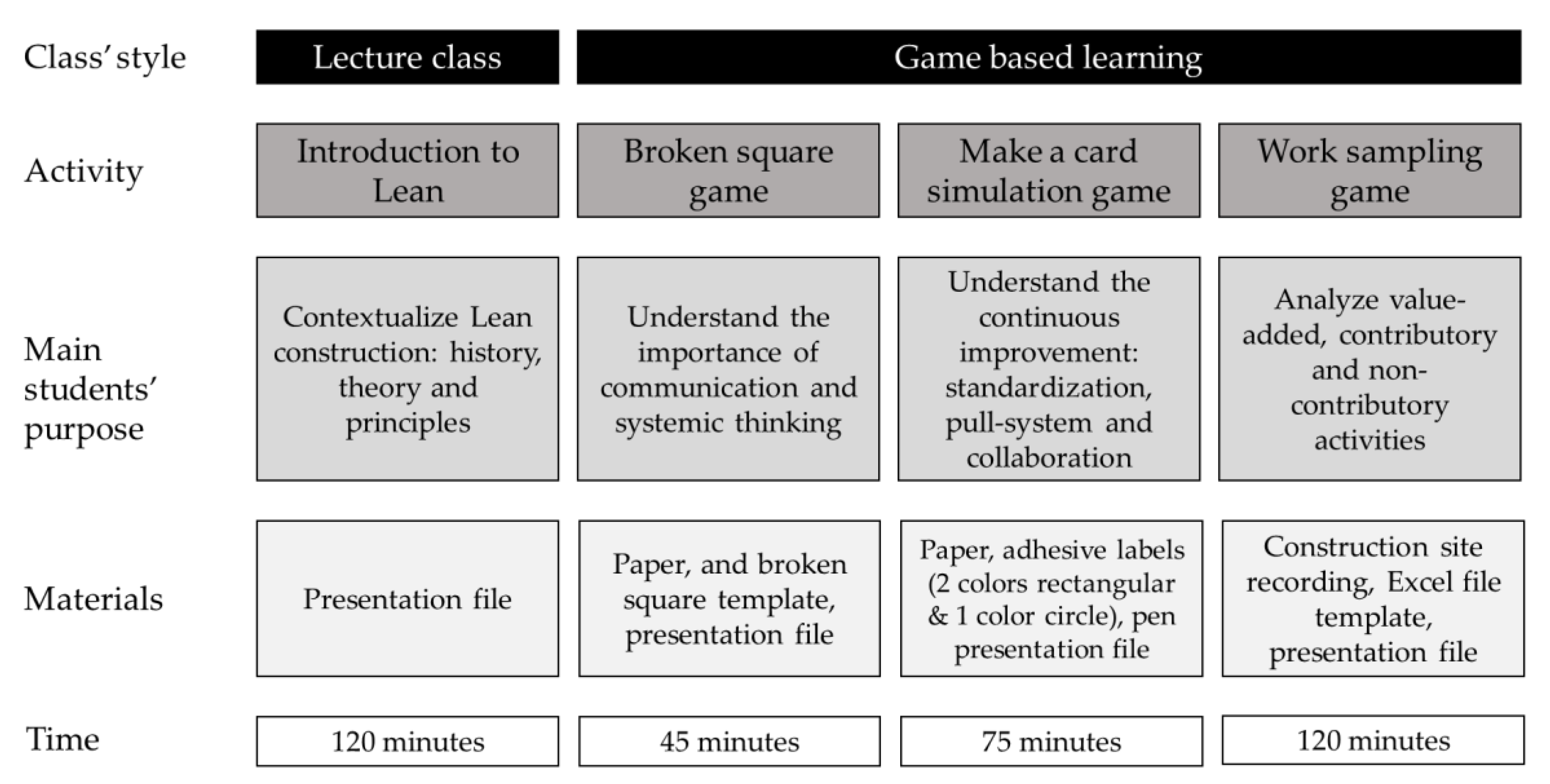

In this context, this paper proposes a combination of a traditional lecture and three simple games to learn Lean Construction Principles, analyzing the impact of each activity on the understanding of each LCP. These activities are implemented in a Master in Planning and Management in Civil Engineering program. Following the recommendations of González et al. [

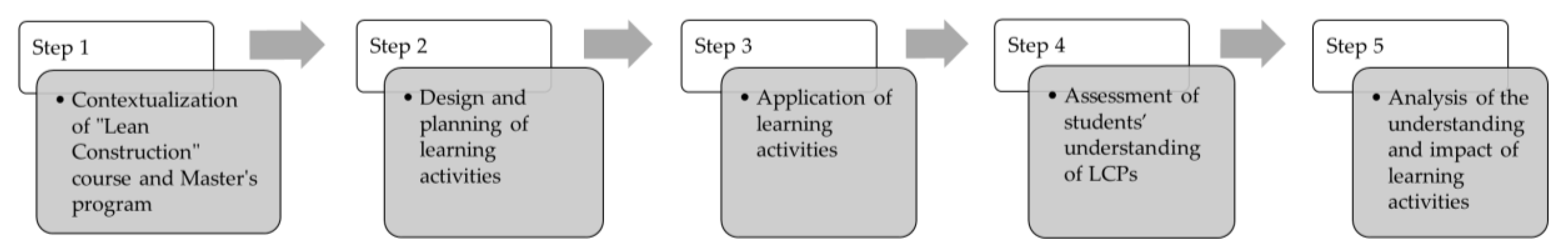

2], the learning experience of each student is evaluated through questionnaires at several stages: before starting each game and after the last game. Students also responded to a questionnaire that evaluated their understanding of each LCP after the lecture class.

The paper is organized as follows.

Section 2 introduces the Lean Construction Principles.

Section 3 presents the research process, describing its contextualization, the design of the learning activities, the questionnaires and the statistics used to analyze the results.

Section 4 shows the results of each learning activity, as well as the discussion regarding the impact of each activity on the understanding of Lean Construction Principles. Finally,

Section 5 presents the conclusions, providing the main contributions, limitations and future research.

2. Lean Construction Principles (LCPs)

Lean Construction serves two main goals during the construction process [

35]: (1) to minimize physical and process waste and (2) to improve the generation of value for the client. The key aspects of a global understanding of Lean in the construction context are [

3] culture (competent, flexible, empowered, and committed); technology (last planner system, just in time, value stream mapping, virtual modeling, and others); and philosophy (Lean principles, added value vs. non-added value, and type of wastes). Lean Construction Principles apply both to the total flow process and to its subprocesses; also, the principles implicitly define flow process problems such as complexity, transparency, and segmented control [

4]. These principles were summarized in the Introduction and are described in greater detail in

Table 1. A comprehensive understanding of these principles is essential to apply Lean correctly in the industry.

The activities that do not add value (also called waste) must be identified, analyzed, and eliminated from work processes. The seven forms of waste under the Lean system were originally conceived in Japan with the inefficiencies of manufacturing in mind, but they also apply to the construction industry. These wastes are as follows: (1) transportation, (2) unnecessary inventory, (3) unnecessary motion, (4) waiting, (5) overproduction, (6) over-processing, and (7) defects [

36]. Recently, an eighth waste has been defined for construction [

37]: “making-do,” a situation where a task is begun without all of its standard inputs, or the execution of a task is continued even though the availability of at least one standard input has ceased.

5. Conclusions

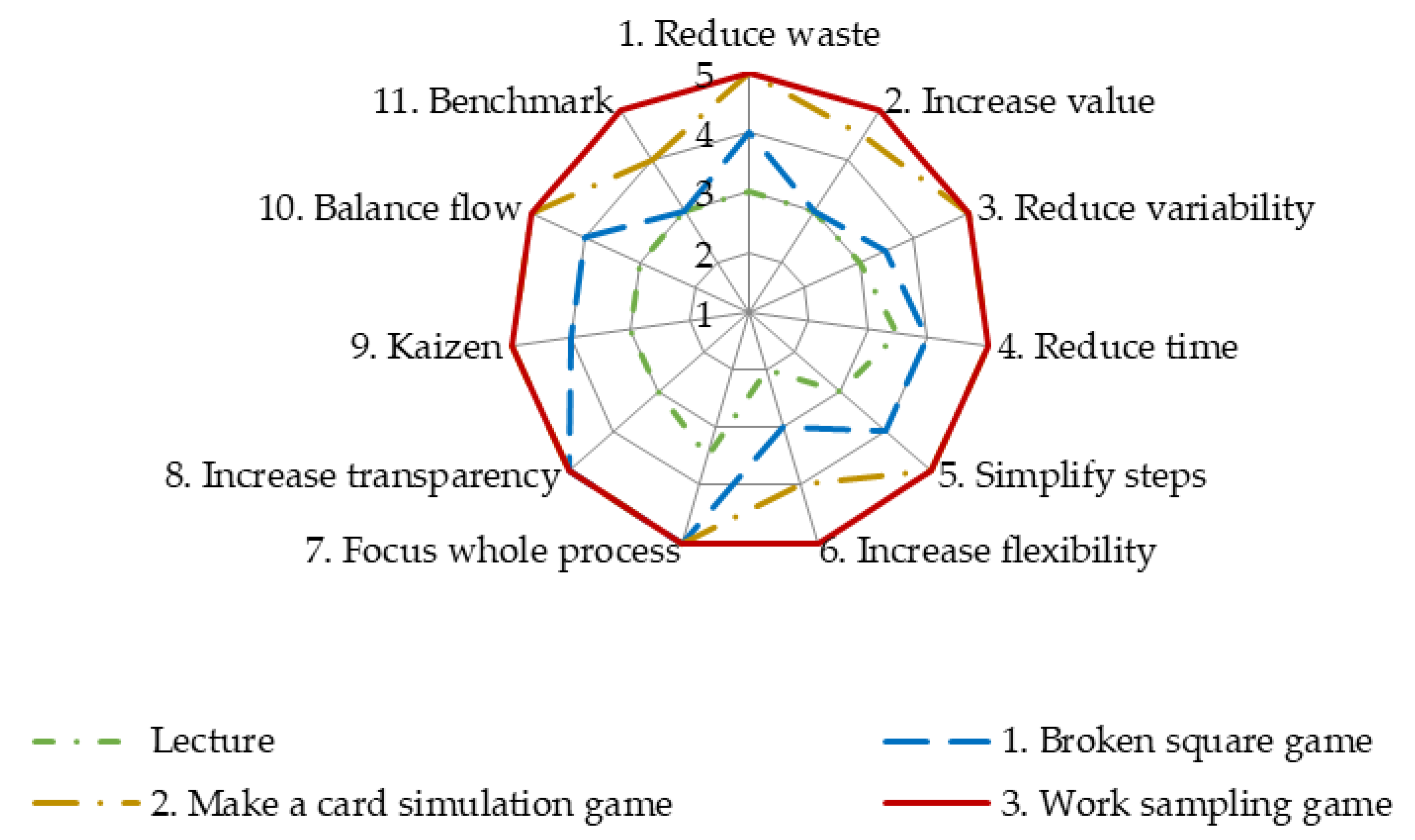

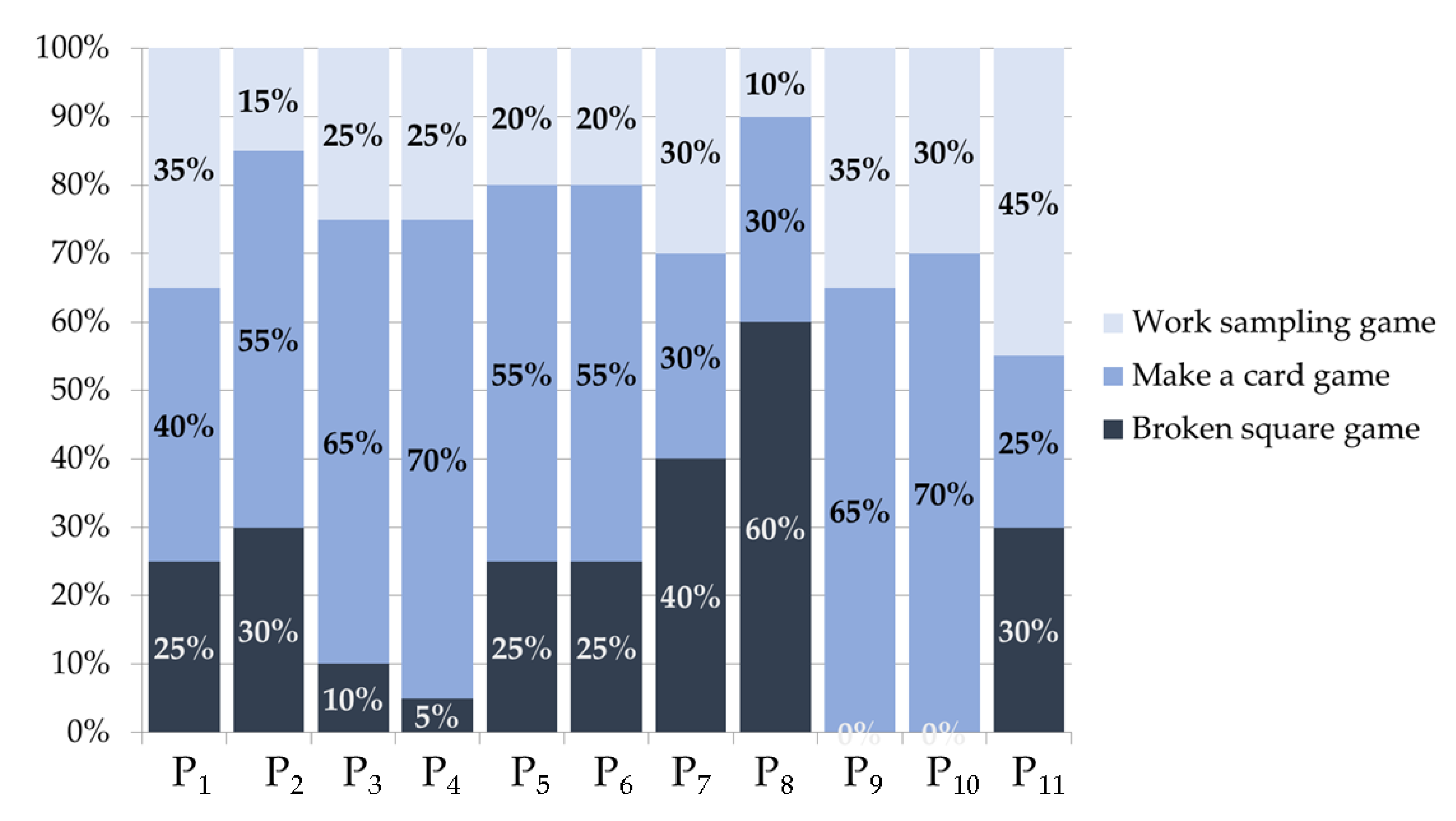

This study evaluated a combination of traditional lecture and three games (“broken square,” “make a card,” and “work sampling”) as a pedagogical approach to teach the Lean Construction Principles (LCPs) and their application in the construction industry. This paper aims to show the impact of each activity on the understanding of LCPs.

The lecture class was effective at teaching the theoretical approach associated with each Lean principle. However, the results highlighted that most students did not attain a clear perspective about the applicability of the Lean principles in the construction industry through the lecture class, resulting in the need to combine this technique with games to meet that goal. The results of the Mann–Whitney U-test indicated that this understanding did not depend on the professional expertise of the students. Practically, the three games showed a significant effect on the understanding of the eleven LCPs. However, the “broken square” game was especially effective at teaching about increasing transparency in the process (P8), reducing the cycle time (P4), and focusing control on the complete process (P7) by enhancing communication and systemic thinking in work processes; the “make a card” simulation game was particularly important for understanding the applicability of increasing output value through systematic consideration of customer requirements (P2) and for deepening students’ understanding of the rest of the principles; finally, the “work sampling” game reinforces the level of knowledge and understanding of the applicability of the eleven LCPs, being especially important for understanding the principles of increasing output flexibility (P6) and benchmarking (P11). Therefore, based on the results of the study, it can be stated that: (1) to guarantee successful learning outcomes for the LCPs, it is recommended to combine the lecture class with multiple games; and, (2) it is key in selecting the games depending on the specific LCP that want to be taught, since not all games are proper to achieve a comprehensive understanding of all the LCPs. These conclusions are crucial for training in Lean Construction.

Even though the analyses conducted for this study have helped to understand the role that each activity (traditional lecture and three simple games) plays in teaching students the theoretical approach and the applicability of each Lean principle in the construction industry, this work is not exempt from limitations, since the sample focused on only one class of students who were of different nationalities and had varying levels of previous knowledge about the LCPs. However, the analysis demonstrated that these factors did not have influence over the results. Consequently, it is recommended to analyze the influence of these factors when assessing the level of knowledge after performing Lean games. Additionally, further research is needed to contribute to a better understanding of what games should be combined with the lecture class to teach about each specific LCP. Future research could focus on combining other games, analyzing the differences when implementing the games in different educational institutions or countries, studying the influence of the national or regional culture on the understanding of the LCPs, and assessing the differences when implementing the games in educational institutions vs. in companies. Above all, activities to teach the LCPs through game-based learning need to be widely studied to optimize the teaching process and maximize the learning results in educational institutions and companies. Besides, these activities can be applied to other disciplines. In this case, it is recommended to adapt the “work sampling” game to a real case related to the particular discipline