1. Introduction

Companies seek to add value to their products through the processes of the supply chain (SC), which is defined as the conformation by all those partners involved directly or indirectly in the satisfaction of a customer’s request, including procurement, production and distribution, where innovation has been presented as an essential link. In this context, Cerchione and Esposito [

1] and Boiko et al. [

2] indicate that SC is considered a system of multiple objectives (economic, productive, strategic, environmental, social, among others), which passes through a wide range of flows (financial, material, information, technology, among others). To help achieve that goal, information and communication technologies (ICT) have been implemented in the SC reconfiguring the global landscape and facilitating the decision-making process [

3,

4].

In the SC, the

Information Exchange with suppliers facilitates the flow of materials and economic resources [

5], where networks of companies, services, and production processes are formed that execute operations where the application of ICT is required, which is defined as a set of elements and techniques that allow users to manipulate information, convert it, store it, manage it, transmit it, and find it through the use of computers, software, and computer networks [

6], which allow users to process and disseminate it simultaneously and in real time with partners.

The ICT application to SC has allowed companies to reduce transaction costs, including those related to transportation, communication, processes, and inventory and that is why companies from different sectors and sizes are currently using ICT to transform their ways of doing business, integrating processes, and improving productivity and relations among partners. Therefore, the competition will no longer be among production processes but in the SC [

7,

8], given that global commerce is interconnected and ICT is required to adequately address the competitive dynamism [

9].

This information flow using ICT allows decision-making in almost real time. In this context, Jorgenson and Vu [

10] point out that ICT has become a means of business development and a source of competitive advantage, however, it requires high economic investments that frequently put the company at risk of bankruptcy and involve multiple activities during its implementation; in addition, Cragg and McNamara [

8] mention that the company requires ICT implementation as a strategy that allows decisions to be made quickly in the dynamic environment, especially in its SC.

ICT implementation is a complex process and Pérez-López et al. [

11] discuss three stages: planning, execution, and control, and in each of them a series of activities are carried out. During the planning stage, a technological tracking for ICT is carried out based on the economic company’s capabilities, possible alternatives and benefits, which must be carried out by specialized personnel, generating an investment plan. In the execution stage the plans and programs developed in the first stage are carried out, the purchases are made and the ICTs are installed throughout the SC, and this is where most of the problems occur due to incompatibility in communication protocols with previously installed systems, lack of clear instructions, and translation issues; in the control stage, the aim is to monitor the efficiency indices expected from these ICT.

Despite the problems that may exist in the implementation process, ICT offers benefits because it allows collecting, storing, accessing, sharing, and analyzing effective information and this gives SC visibility and allows the data analysis and decisions made to maximize profitability [

12]. Levi et al. [

13] and Chung [

14] mention that companies investing in ICT are waiting: a) for information availability and visibility; b) to have the data available from a single access point; c) to facilitate decision making in a holistic manner, and d) to allow collaboration between partners.

Additionally, Levary [

15], Jorgenson and Vu [

10] affirm that ICT provides advantages to the SC such as cycle time reduction, low inventories, minimization of the whip effect, and improvements in channels distribution. However, ICTs must have a high level of integration, which is the degree to which the information systems are related and shared [

16], including the already established systems. ICT integration in SC helps to redesign internal processes, improve efficiency, practicality, precision, and allow a rapid response management. It also helps to visualize work instructions, quality, and productivity graphs, and flow diagrams, among other things [

17]. In addition, ICT allows the increasing of the volume of complexity of the information that needs to be communicated among partners, such as the level of inventory, delivery status, planning and production scheduling, which translates into a better SC control, which also facilitates coordination between clients and suppliers [

18]. However, investments in ICT can fail if the information that is really needed is not shared due to lack of coordination and integration that facilitates strategic decision making.

Finally, Monostori [

19] and Allaoui et al. [

20] declare that the ICT adopted in the SC decrease the complexity and streamline the information flows, improve the coordination in production process and partners because of the increase in profitability and efficiency, and this in turn facilitates operation planning and control. Based on the above, it can be concluded that by integrating ICT into a productive process and SC into a company, tangible

Operational Benefits are guaranteed that facilitate greater workforce capacity [

17].

All the above benefits are attractive for managers, especially in SC, where the adoption of ICT plays an important role. However, companies that have not invested in ICT have reduced ongoing production due to the lack of timely and reliable information, which leads to uncertain decision making [

21]. Due to the above, models have been studied to measure the integration of ICT in the SC [

22] where it is mentioned that access to ICT is hindered due to lack of training in its use, ignorance of the usefulness of the exchange of information, and managerial commitment.

Currently there are many studies that indicate what should be measured to determine the ICT integration level in CS [

23], such as the level of

Information Exchange between the different partners of the SC, the ease with which the operations in the productive system and the outside of it are managed, the control they have over the operations in real time and the ease of handling of the variables, distribution of the goods produced, and the visibility of the products and services in the SC [

24]. However, these studies are descriptive and only analyze parts of the ICT implementation process without integrating the effect they have on the

Operational Benefits that are required in the production lines and the SC. Therefore, a manager knows that ICT will bring

Operational Benefits, but does not know how much and does not know if it is worth making the investment.

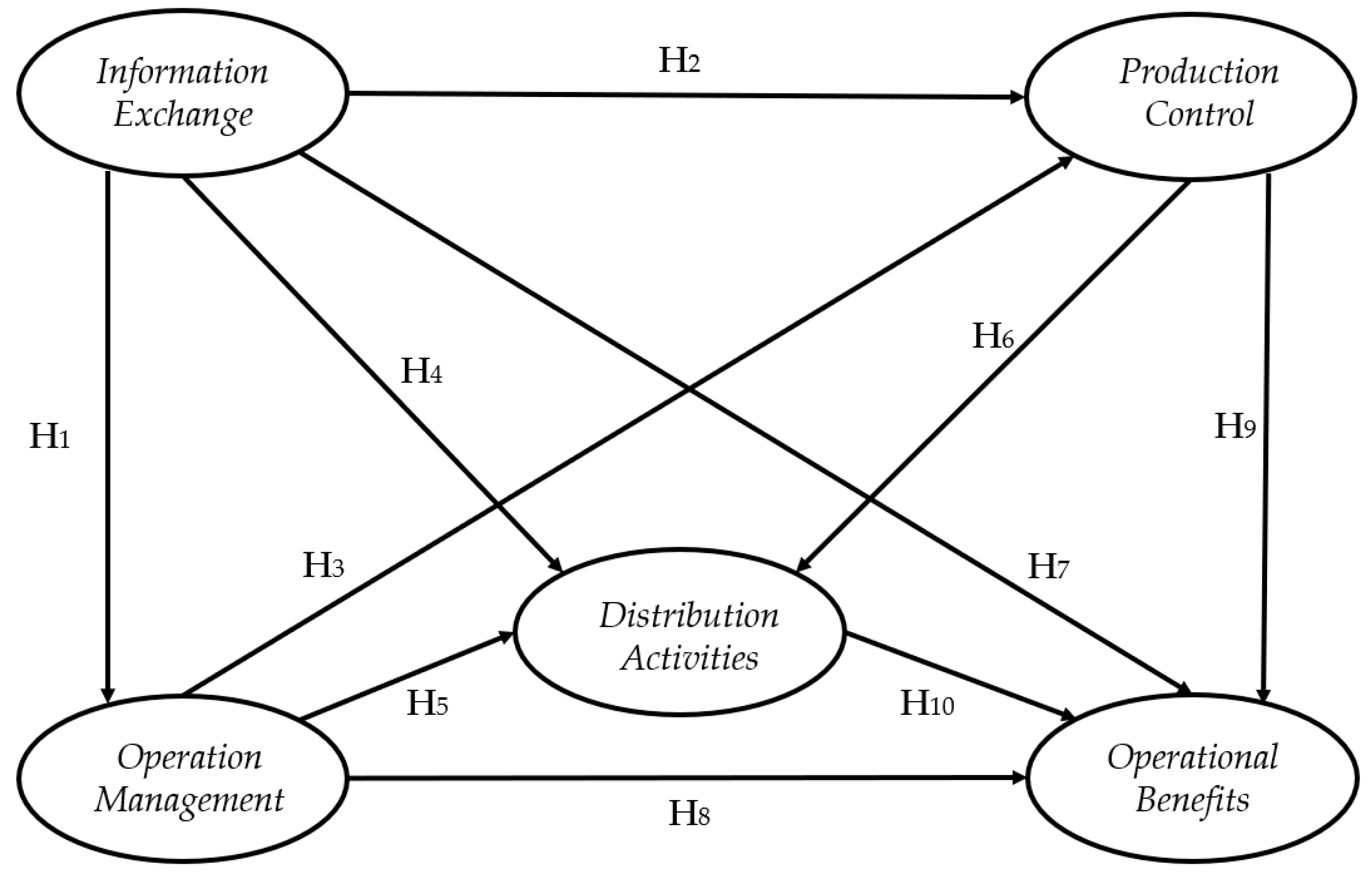

To contribute to this research area, the objective of this article is to quantify the ICT integration level in the SC, for which four latent variables are measured that allow knowing that level: Information Exchange, Operations Management, Production Control, and Distribution Activities, which are related to the Operational Benefits obtained through a Structural Equation Model (SEM) and ten hypotheses that lets dependence values among them be obtained. The results in the SEM will allow managers to identify the ICT integration level they have implemented and how it impact the benefits obtained, in addition to identifying those activities that are essential and differentiating them from the trivial ones, focusing on those that are important for the company.

The rest of the manuscript is structured as follows: After this introduction section,

Section 2 reports a literature review based on the five latent variables integrated in the SEM,

Section 3 reports the methodology and materials used,

Section 4 reports the results,

Section 5 reports a discussion of findings and

Section 6 reports the conclusions and practical implications.

5. Discussion

ICT integration in SC must be focused on obtaining

Operational Benefits.

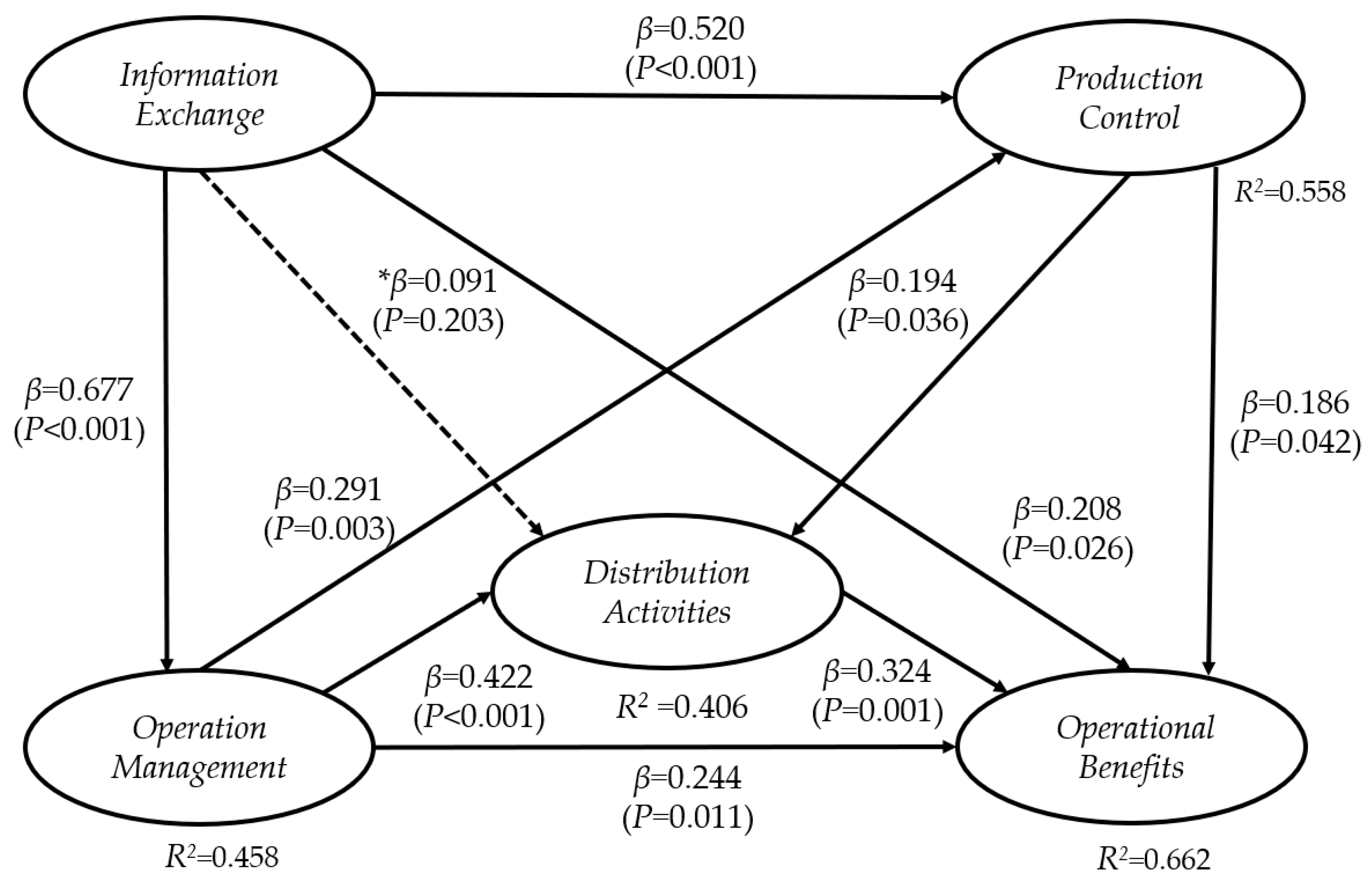

Table 6 shows the variance decomposition for every dependent latent variable in order to identify those independent variables that are more important for industrial sustainability. For example, it is observed that the most important variable for the achievement of the activities associated with

Operations Management is the

Information Exchange which is the only variable with 0.458. For

Production control the most important variable is again the

Information Exchange with 0.372, because is greater than

Operations Management with 0.186, so managers must therefore pay special attention to the activities associated with

Information Exchange-based in ICT. In other words, a company requires

Operations Management and

Information Exchange for guarantee the

Production Control and sustainability.

However, in order to achieve an adequate Distribution Activities, it is necessary first of all to have an adequate Operations Management (0.257) since it has a greater explanatory power in comparison with the Production Control (0.102) and the Information Exchange (0.047), where the direct effect was statistically non-significant, indicating that managers interested in achieving an adequate distribution of their products with ICT support should give preference to the operations that are related to Production Control.

Finally, to obtain Operational Benefits, companies must focus on achieving, first, adequate Production Control (0.245) and Distribution Activities (0.233) which have the greatest explanatory power, and then focus on Operations Management (0.166), and Information Exchange (0.140). The above indicates that the ICT applied to production processes and products distribution guarantee Operational Benefits associated with flexibility, cost competitiveness, and shorter order cycles.

From the analysis of direct, indirect, and total effects, it is observed that:

The biggest total effect is between the Information Exchange variable and Production Control variable with β = 0.717, which indicates that ICT makes it easier to respond quickly to changes in the market and introduce new products or their variants, minimizing delays in production orders (H2), coupled with the fact that they also favor the Operations Management for the manufacturer, since they facilitate the production planning efficiently, the control in maintenance systems, and the decision-making in the production lines (H1).

This Information Exchange also generates operating benefits in the production lines given that greater flexibility is achieved in responding to customers, offering alternative products, lower costs, and faster ordering cycles that increase consumer satisfaction (H1). However, this Information Exchange does not have a significant direct effect on Distribution Activities, but a large indirect effect through mediating variables, which indicates that this information should be useful in the production processes and operations being carried out (H4).

Proper Operations Management supported by ICT will promote Distribution Activities associated with the supply of raw materials and finished products as well as greater coordination between the manufacturer with suppliers and customers (H5), but also facilitates obtaining Operational Benefits given that greater flexibility is achieved in the production process, delays and downtime in operators and machines are reduced, which translates into short cycle times and satisfaction for customers (H8).

The use of ICT in Production Control is also reflected in the Distribution Activities given that it facilitates the management of raw materials that leave the production process towards the consumer, and this allows having better planning requirements and therefore, a more stable relationship with suppliers (H6). This Production Control is complex, but its Operational Benefits are reflected in a greater variety of products to the customer or flexible production, affordable costs, and short delivery times (H9).

Finally, the last step in the life of a product is to take it to the consumer, and the application of ICT in Distribution Activities, such as satellite tracking and radiofrequency systems, will allow Operational Benefits with a SC visible to the client, building trust in that relationship (H10).

To give managers a critical path with activities that guarantee industrial sustainability, and according to the biggest β values, the following sequence must be followed:

Information Exchange → Operation Management → Distribution Activities → Operational Benefits

However, last sequence does not integrate the Production Control related to production lines, where sustainability and operational benefits are gained, so the following sequence must be followed:

Information Exchange → Operation Management → Production Control → Distribution Activities → Operational Benefits

Here it is important to mention that the SEM and hypotheses are tested using information from Mexican maquiladora industry, an industrial sector that have specific characteristics, with a lot of raw material importation and finished product exportation, a globalized business and SC, different labour law, culture, among others. Findings here reported have been applied to similar sectors but must be adapted considering the regional context, and that can be somewhat of a limitation.