Solving the Difficulties and Challenges Facing Construction Based on Concurrent Engineering in Yemen

Abstract

1. Introduction

2. Current Issues in the Construction Industry in Yemen

3. Necessity and Feasibility of the Implementation of CE in Construction

3.1. CE

3.2. CE in the Construction Industry

- The aim is to produce products that provide service and satisfaction to the customer;

- Both co-handle raw materials and assemble many different pre-manufactured components in the final products;

- Both industries are faced with similar problems the most important of which is the high cost of correcting design errors due to delayed variables, the misuse of resources and insufficient information management;

- Both take advantage of frequent processes in designing and manufacturing their products.

3.3. The Potential Benefits of Adopting the Principles of CE in the Construction Industry in Yemen

4. Application of CE in Construction Industry

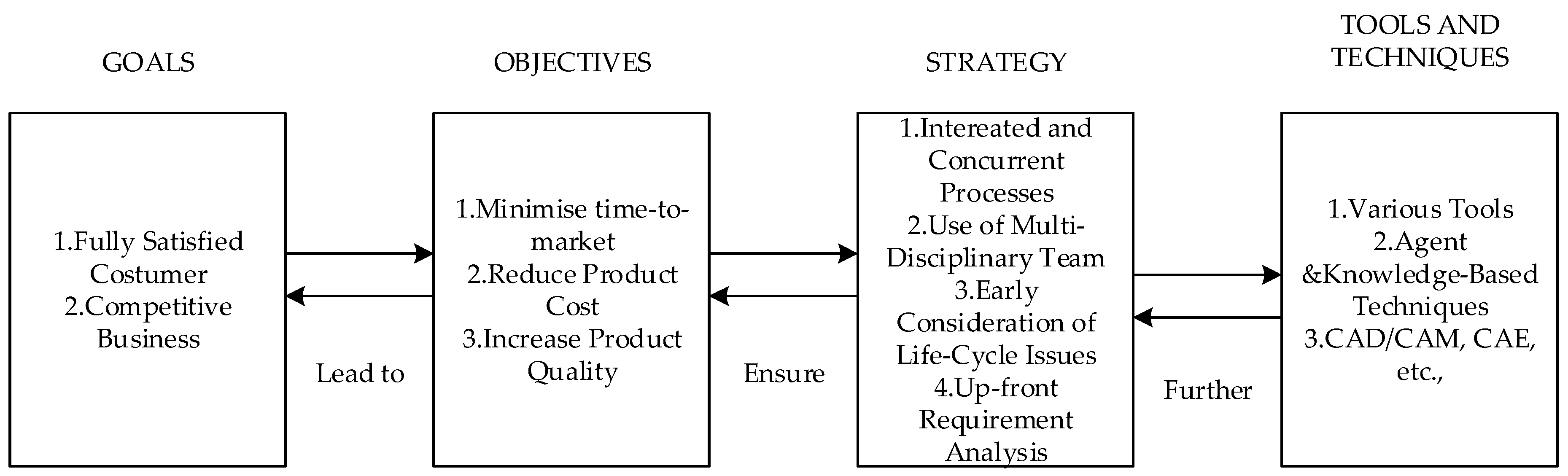

4.1. The Goal for CE in the Construction Industry

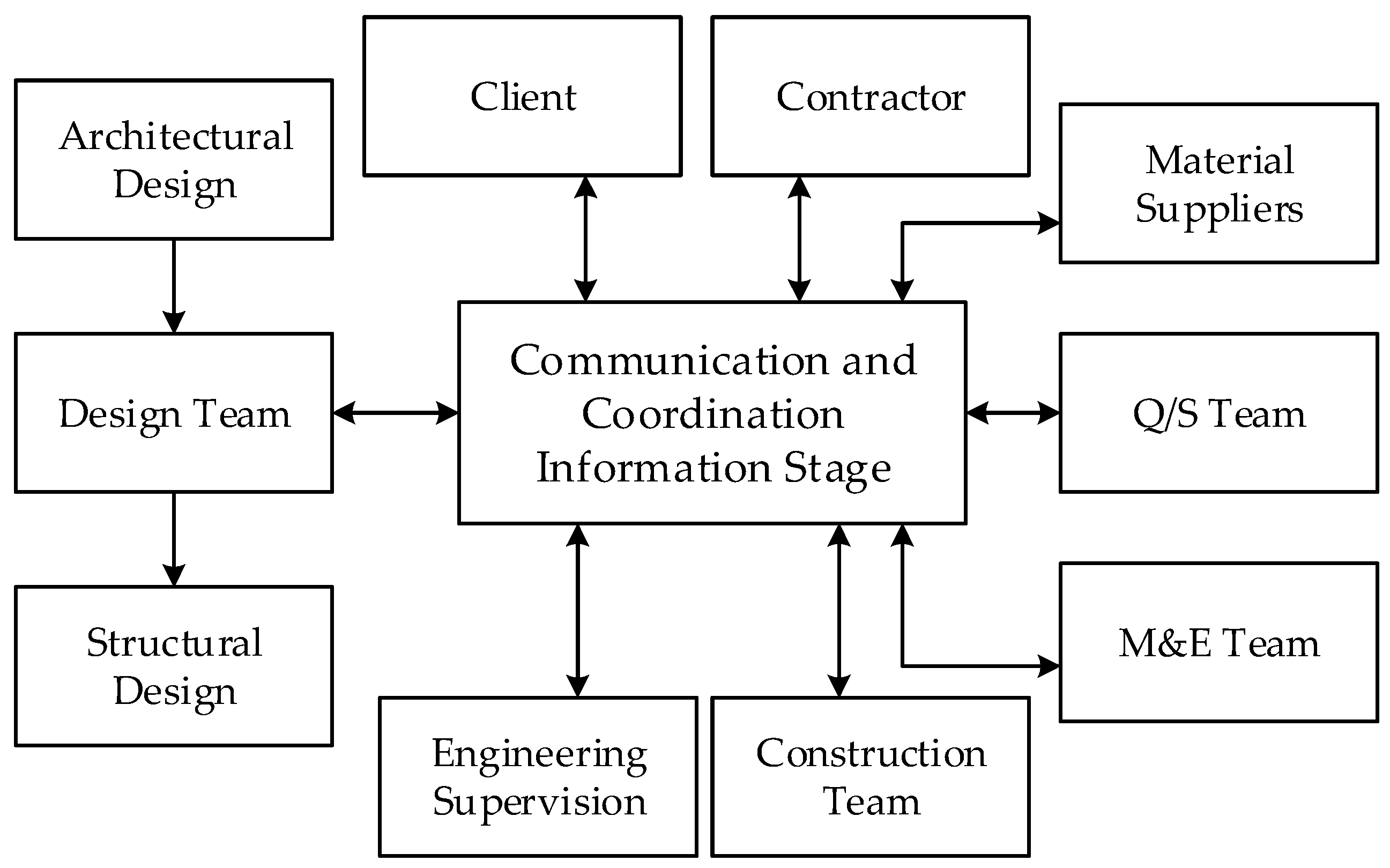

4.2. Construction Organizational Structure Model Based on CE

- It significantly improves the information transparency of the project and enhances the efficiency and validity of information exchange among the project participants.

- It is helpful for the project participants to know the construction situation of the project in time and improve the integrity and parallelism of the real estate project development.

- It is more conducive to the timely update of project information, thus avoiding project delay caused by information delay and shortening the time of information transmission and processing.

- The concurrent organization team exchanges information with each other based on the project communication and coordination information platform, thus forming a very nice working atmosphere, and successfully applying the concept of CE in the construction process of the project.

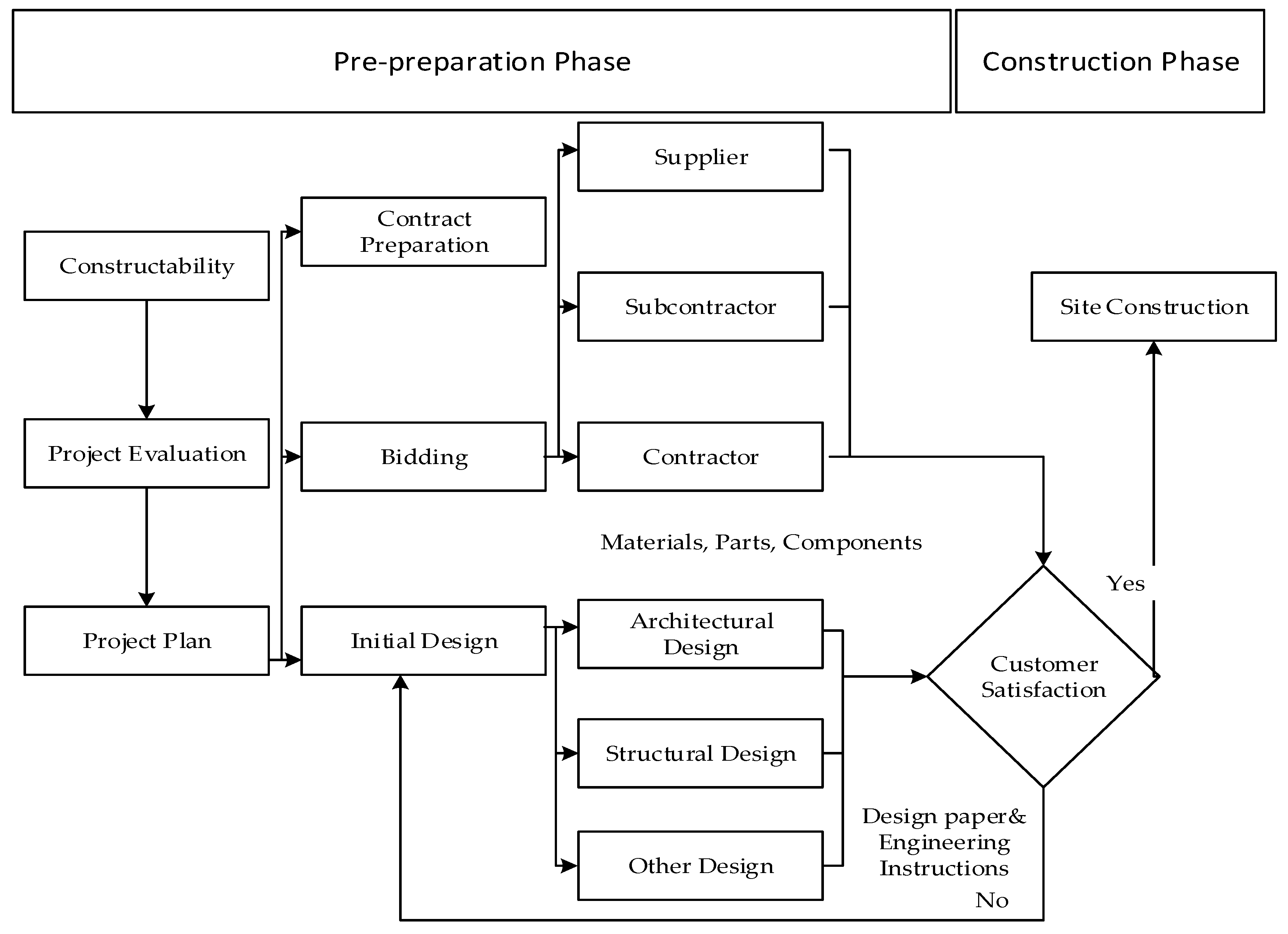

4.3. Construction Workflow Management System Based on CE

- Comprehensively considering the sharing of information resources among different departments and units of the project, thus greatly improving the efficiency of project construction and effectively reducing construction cost.

- The concept of CE uses information flow to control material flow to ensure the smooth progress of the project and increases the management efficiency of the enterprise.

- The concept of CE conforms to the needs of increasing amounts of project management information and accurately describes real-time information, dynamics and the interconnection of different departments and units of the project.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khalfan, M.; Raja, N. Improving Construction Process through Integration and Concurrent Engineering. Constr. Econ. Build. 2012, 5, 58–66. [Google Scholar] [CrossRef]

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Developments in the implementation of concurrent engineering in construction. Int. J. Comput. Integr. Des. Constr. 2000, 10, 10. [Google Scholar]

- Ahmad, S.B.S.; Svalestuen, F.; Andersen, B.; Torp, O. A Review of Performance Measurement for Successful Concurrent Construction. Procedia - Soc. Behav. Sci. 2016, 226, 447–454. [Google Scholar] [CrossRef]

- Khalfan, A. Benchmarking and readiness assessment for concurrent engineering in construction. This item is held in Loughborough University’ s Institutional Repository. Available online: https://dspace.lboro.ac.uk/ (accessed on 1 September 2001).

- Sultan Basel, M.; Kajewski Stephen, L. The Yemen construction industry: Readying the industry for the successful implementation of sustainability. In Proceedings of the International Conference on Smart and Sustainable Built Environment, Brisbane, Australia, 19–21 November 2003. [Google Scholar]

- Al-Momani, A.H. Construction cost prediction for public school buildings in Jordan. Constr. Manag. Econ. 1996, 14, 311–317. [Google Scholar] [CrossRef]

- Sultan, B. Housing construction costs in Yemen: Affordability & purchasing power. Yemen Times 2008, 6, 6–7. [Google Scholar]

- Ahmad, S.A.; Issa, U.H.; Farag, M.A.; Abdelhafez, L.M. Evaluation of risk factors affecting time and cost of construction projects in Yemen. Int. J. Manag. 2013, 4, 168–178. [Google Scholar]

- Issa, U.H.; Hassona, F.A.; EL-Sawah, H.M. Risk identification and assessment for the Egyptian water projects, economic and management of water in Arab world and Africa, In Proceedings of the 1st International Conference, Assuit University, Assiut, Egypt, 18–19 November 2009. [Google Scholar]

- Cordesman, A.H. The War in Yemen: Hard Choices in a Hard War. Available online: https://www.csis.org/analysis/war-yemen-hard-choices-hard-war (accessed on 9 May 2017).

- Carapico, S. Civil Society in Yemen: The Political Economy of Activism in Modern Arabia; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Lichtenthäler, G. Political Ecology and the Role of Water: Environment, Society and Economy in Northern Yemen; Routledge: Abingdon, UK, 2017. [Google Scholar]

- El Mallakh, R. The Economic Development of the Yemen Arab Republic (RLE Economy of Middle East); Routledge: Abingdon, UK, 2014. [Google Scholar]

- Al-Sabahi, M.H.; Al-Hamidi, A.A.; Ramly, A.; Rejab, K.M. Exploring criteria and critical factors for governmental projects implementation in Yemen: A case study. J. Surv. Constr. Prop. 2014, 5, 1–17. [Google Scholar] [CrossRef]

- Nawi, M.N.M.; Baluch, N.; Bahauddin, A.Y. Impact of fragmentation issue in construction industry: An overview. Available online: http://docplayer.net/19192761-Impact-of-fragmentation-issue-in-construction-industry-an-overview.html (accessed on 14 September 2014).

- Nawi, M.N.M.; Lee, A.; Azman, M.N.A.; Kamar, K.A.M. Fragmentation issue in Malaysian industrialised building system (IBS) projects. J. Eng. Sci. Technol. 2014, 9, 97–106. [Google Scholar]

- Gann, D.M. Construction as a manufacturing process? Similarities and differences between industrialized housing and car production in Japan. Constr. Manag. Econ. 1996, 14, 437–450. [Google Scholar] [CrossRef]

- Egan, J. Rethinking construction accelerating change-a consultation paper by the strategic forum for construction. Nat. Acad. Scie. Eng. Med. 2002, 5, 34. [Google Scholar]

- Latham. Constructing the team. Constr. Team 1994, 7, 956–963. [Google Scholar]

- Nelson, M.M.L. The Applicability of I2i as A Supply Chain Management Tool in Facilities Management. Ph.D. Thesis, University of Salford, Manchester, UK, 2004. [Google Scholar]

- Evbuomwan, N.F.; Anumba, C.J. An integrated framework for concurrent life-cycle design and construction. Adv. Eng. Softw. 1998, 29, 587–597. [Google Scholar] [CrossRef]

- Ghazali, Y.E.; Lefebvre, É.; Lefebvr, L.A. RFID-Enabled Materials Management in the Industrial Construction Supply Chain. Proc. 5th WSEAS Int. Conf. Commun. Inf. Technol. 2014, 7, 167. [Google Scholar]

- Anumba, C.J.; Baugh, C.; Khalfan, M.M. Organisational structures to support concurrent engineering in construction. Ind. Manag. Data Syst. 2002, 102, 260–270. [Google Scholar] [CrossRef]

- Odeh, A.M.; Battaineh, H.T. Causes of construction delay: Traditional contracts. Int. J. Proj. Manag. 2002, 20, 67–73. [Google Scholar] [CrossRef]

- Nawaz, T.; Shareef, N.A.; Ikram, A.A. Cost performance in construction industry of Pakistan. Ind. Eng. Lett. 2013, 3, 19–33. [Google Scholar]

- Gray, C.; Hughes, W. Building Design Management; Routledge: Abingdon, UK, 2007. [Google Scholar]

- Mohamad, M.I. The application of concurrent engineering philosophy to the construction industry. Ph.D. Thesis, Loughbrgh University, Loughbrgh, UK.

- Alashwal, A.M.; Rahman, H.A.; Beksin, A.M. Knowledge sharing in a fragmented construction industry: On the hindsight. Sci. Res. Essays 2011, 6, 1530–1536. [Google Scholar]

- Walker, P. Procurement, contracts and conditions of engagement within a concurrent engineering context. In Concurrent Engineering in Construction Projects; Routledge: Abingdon, UK, 2006. [Google Scholar]

- Dulaimi, M.F.; YLing, F.Y.; Ofori, G.; Silva, N.D. Enhancing integration and innovation in construction. Build. Res. Inf. 2002, 30, 237–247. [Google Scholar] [CrossRef]

- Anumba, C.J.; Kamara, J.M. Concurrent engineering in construction. In Construction Innovation and Process Improvement; Wiley: Hoboken, NJ, USA, 2012; p. 277. [Google Scholar]

- Love, P.E.; Gunasekaran, A.; Li, H. Concurrent engineering: A strategy for procuring construction projects. Int. J. Proj. Man. 1998, 16, 375–383. [Google Scholar] [CrossRef]

- Anumba, C.J.; Duke, A.K. Telepresence Environment for Concurrent Lifecycle Design and Construction; Taylor & Francis: Abingdon, UK, 2007; p. 218. [Google Scholar]

- Wolden, S. The Application of Concurrent Engineering in Infrastructure Projects. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2017. [Google Scholar]

- Brookes, N.J.; Backhouse, C.J. Understanding concurrent engineering implementation: A case-study approach. Int. J. Prod. Res. 1998, 36, 3035–3054. [Google Scholar] [CrossRef]

- Thamhain, H.J. Concurrent engineering for integrated product development. In The Wiley Guide to Managing Projects; Wiley: Hoboken, NJ, USA, 2004; pp. 450–470. [Google Scholar]

- Coşkun, H.; Erdiş, E.; Genç, O. Improving the performance of construction projects by employing concurrent engineering. Çukurova Univ. Mühendislik Mimarlık Fakültesi Dergisi 2016, 31, 7–58. [Google Scholar]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. In Automation in Construction; Elsevier: Amsterdam, The Netherlands, 2012; pp. 262–268. [Google Scholar]

- Crowley, A. Construction as a manufacturing process: Lessons from the automotive industry. In Computers & Structures; Elsevier: Amsterdam, The Netherlands, 1998; pp. 389–400. [Google Scholar]

- Love, P.E.; Gunasekaran, A. Concurrent engineering in the construction industry. Concurr. Eng. 1997, 5, 155–162. [Google Scholar] [CrossRef]

- Anumba, C.J.; Evbuomwan, N.F. Concurrent engineering in design-build projects. Constr. Manag. Econ. 1997, 15, 271–281. [Google Scholar] [CrossRef]

- Anumba, C.; Kamara, J.M.; Cutting-Decelle, A.F. Concurrent Engineering in Construction Projects; Routledge: Abingdon, UK, 2006. [Google Scholar]

- Zidane, Y.J.; Stordal, K.B.; Johansen, A.; Van Raalte, S. Barriers and challenges in employing of concurrent engineering within the Norwegian construction projects. In Procedia Economics and Finance; Elsevier: Amsterdam, The Netherlands, 2015; pp. 494–501. [Google Scholar]

| Need to Change in the Construction Industry | Goals and Principles of CE |

|---|---|

| The need for change in construction is due to the non-competitive nature of this industry, the inability to satisfy the customer in full regard to costs, quality and time. | The primary goals and principles of concurrent engineering include customer satisfaction, providing a competitive environment, reducing product development time, cost, and quality improvement. |

| Integration and coordination are considered in the construction process as one of the most important strategies to solve the problem of fragmentation in the construction industry. | The adoption of the concept of concurrent engineering in the construction industry facilitates the integration of members of the product development team and the manufacturing process, thus improving the product development process. |

| The strategies that are emerging to promote the construction process are inadequate, as they only address one side of the problem. | CE provides a framework not only for integrating construction processes but also for the various tools and technologies used in the process. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahmas, S.; Li, Z.; Liu, S. Solving the Difficulties and Challenges Facing Construction Based on Concurrent Engineering in Yemen. Sustainability 2019, 11, 3146. https://doi.org/10.3390/su11113146

Dahmas S, Li Z, Liu S. Solving the Difficulties and Challenges Facing Construction Based on Concurrent Engineering in Yemen. Sustainability. 2019; 11(11):3146. https://doi.org/10.3390/su11113146

Chicago/Turabian StyleDahmas, Sabrinaji, Zhongfu Li, and Sha Liu. 2019. "Solving the Difficulties and Challenges Facing Construction Based on Concurrent Engineering in Yemen" Sustainability 11, no. 11: 3146. https://doi.org/10.3390/su11113146

APA StyleDahmas, S., Li, Z., & Liu, S. (2019). Solving the Difficulties and Challenges Facing Construction Based on Concurrent Engineering in Yemen. Sustainability, 11(11), 3146. https://doi.org/10.3390/su11113146