Optimal Management of a Hybrid Renewable Energy System Coupled with a Membrane Bioreactor Using Enviro-Economic and Power Pinch Analyses for Sustainable Climate Change Adaption

Abstract

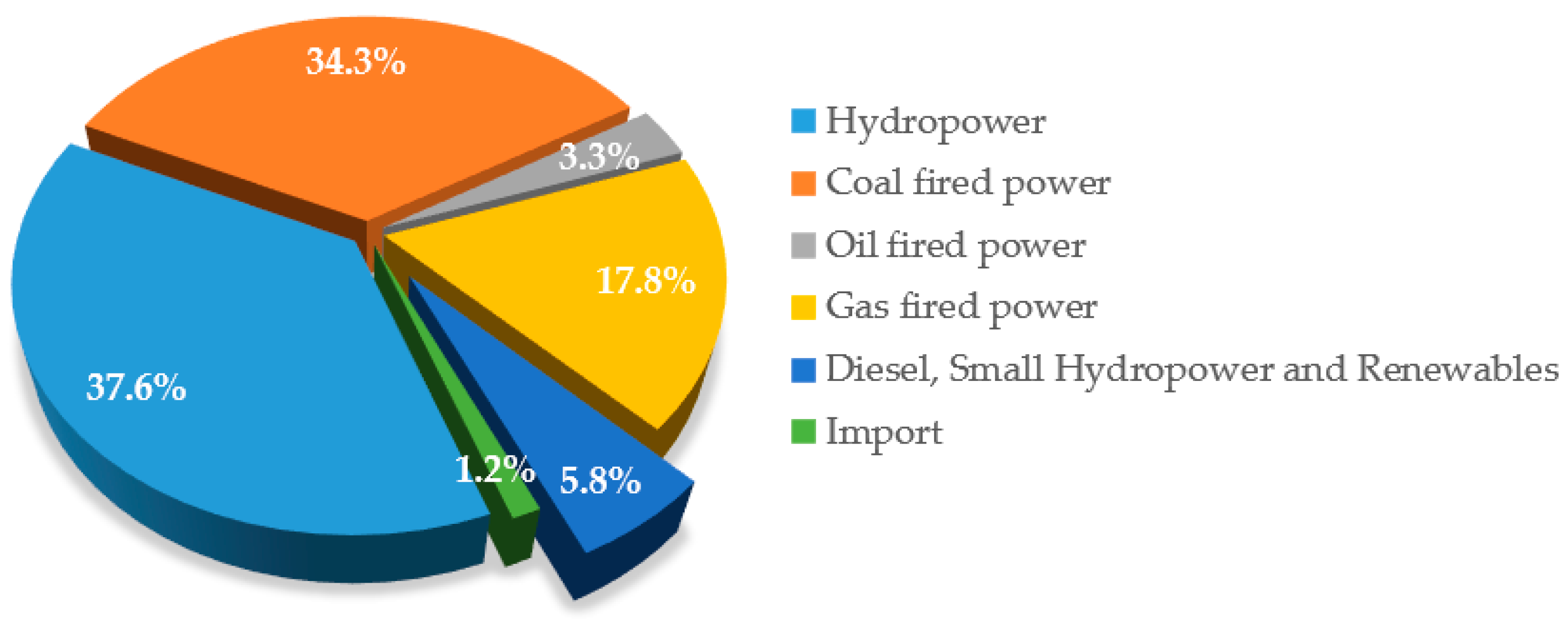

:1. Introduction

2. Materials and Methods

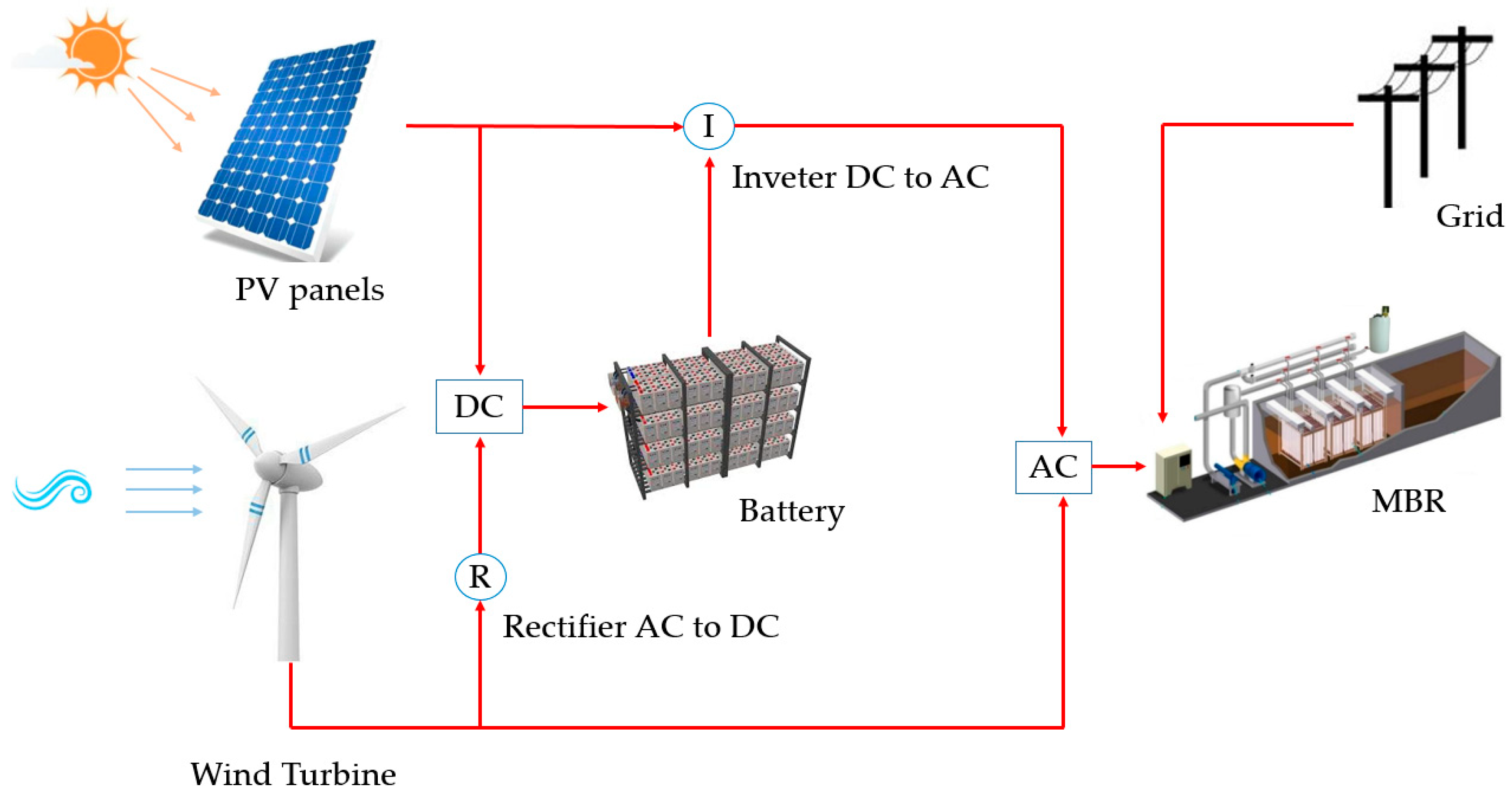

2.1. System Configuration and Energy Management Strategy

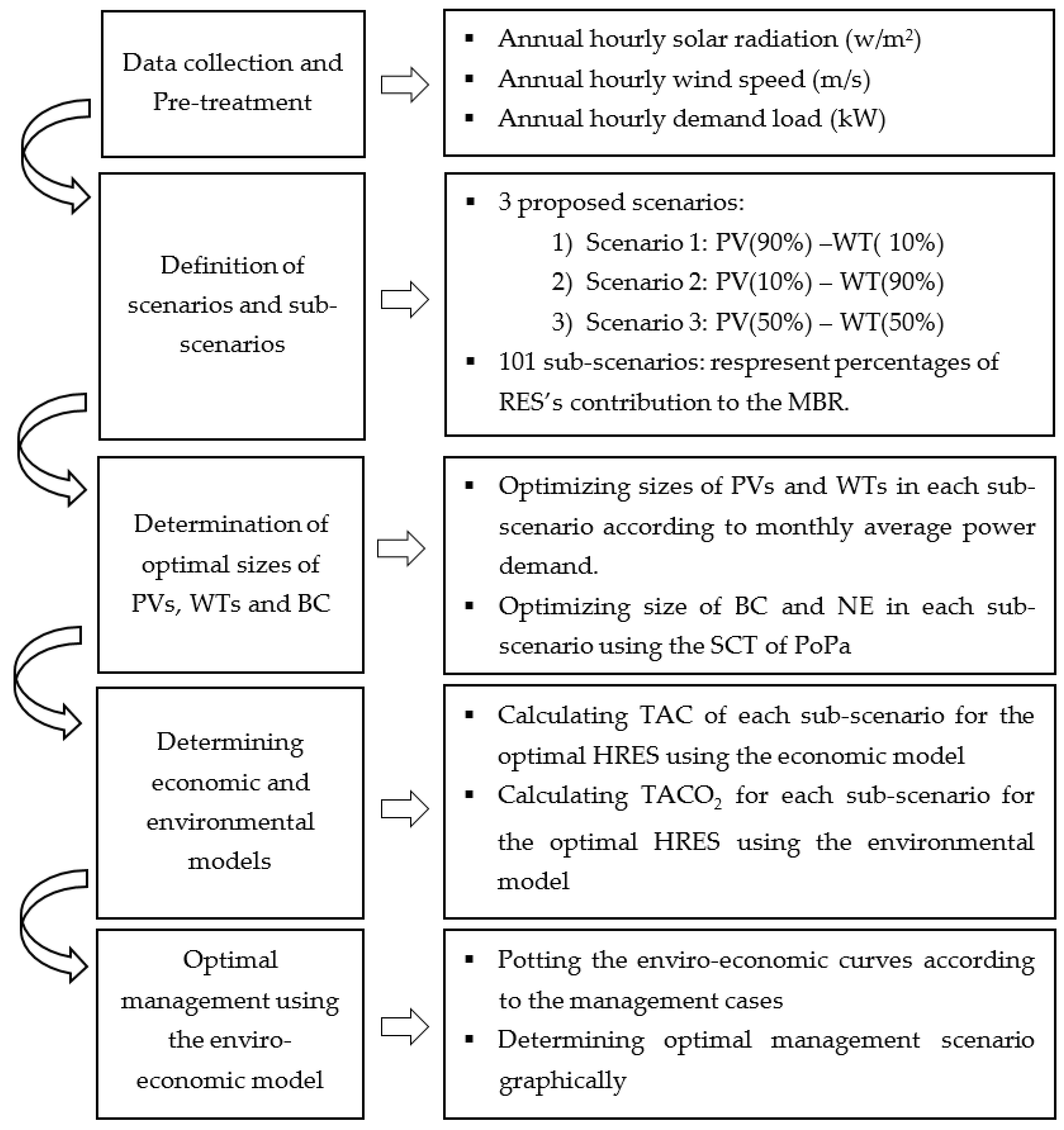

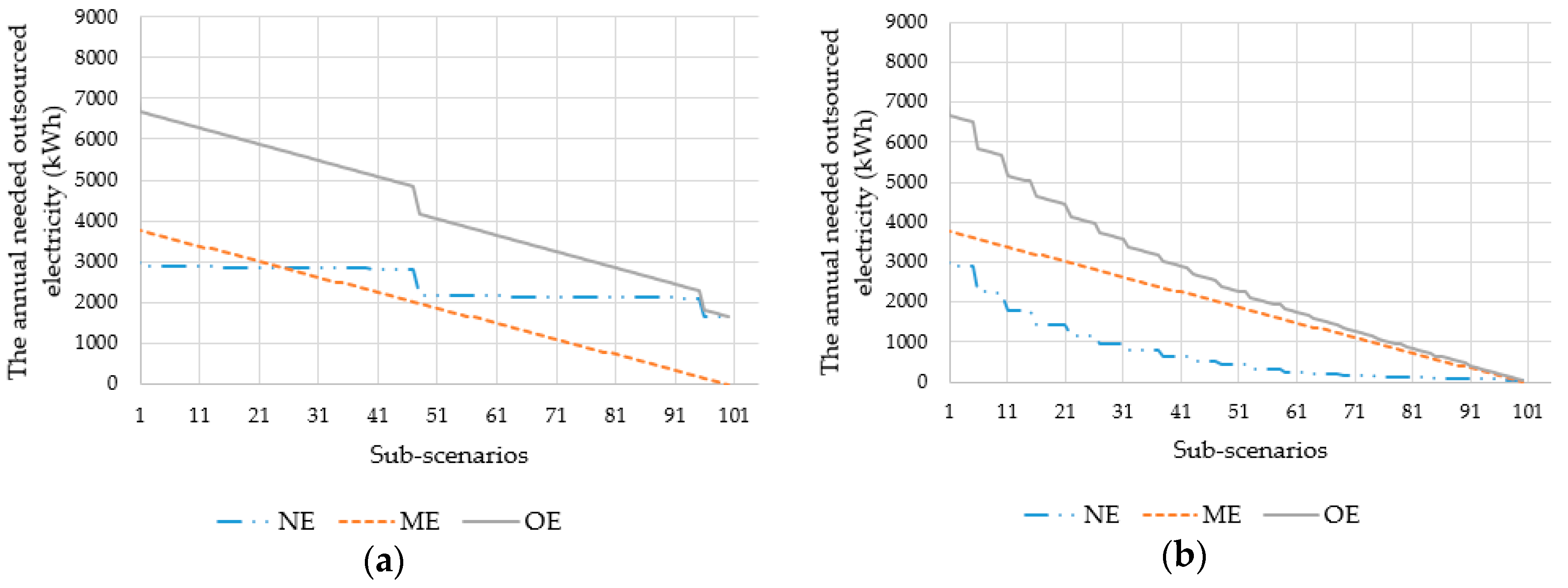

- The optimal numbers of PVs and WTs were determined according to sub-scenarios. This study considered three scenarios and 101 sub-scenarios. The sub-scenarios accounted for the percentage of RES contribution in satisfying the electricity in the MBR so that k% RES contribution was used in the (k + 1)th sub-scenario. The MBR operated without any contribution from the HRES in the first sub-scenario. To consider the individual contributions of each power source in one HRES configuration, three scenarios were assumed:

- Scenario 1: The solar (DC) source accounts for 90% of the total amount provided by the RES, while the wind energy (AC) source makes up the remaining 10%. This scenario is suitable for locations where the potential of solar energy source is dominant compared to that of wind energy source.

- Scenario 2: The wind (AC) source accounts for 90% of the total amount provided by RES, whereas the solar (DC) source makes up the remaining 10%. This scenario should be considered in regions where the wind energy source has higher priority compared to solar energy sources.

- Scenario 3: The wind (AC) and solar (DC) sources contribute equally. In other words, each supplies 50% of the total amount provided by the RES. Here, the potential of both wind and solar energies is highly recommended.

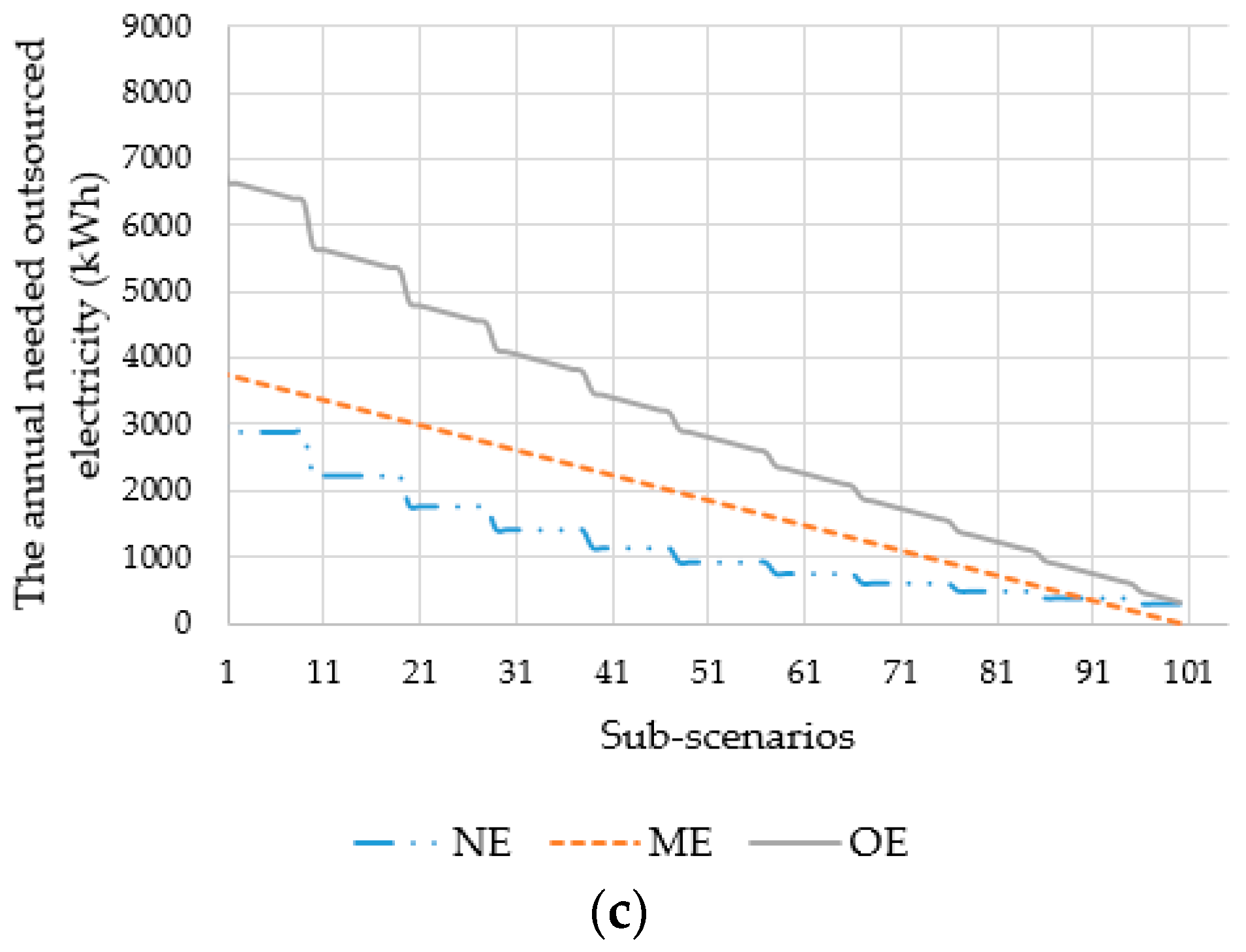

The representative of these three scenarios has the individual contribution in each RES source. This could give us an idea to select an appropriate source based on a specific location. - An appropriate battery capacity (BC) and the outsourced needed electricity (NE) for one operational year were determined for each sub-scenario using the storage cascade table (SCT) of PoPA [29].

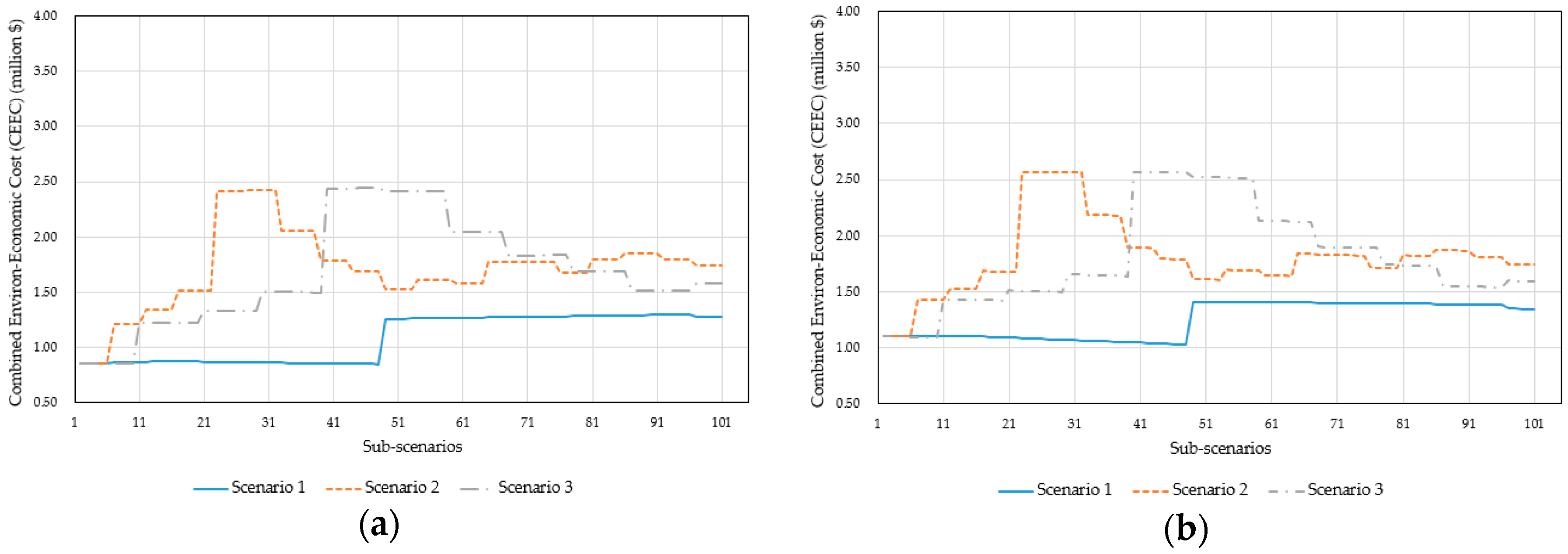

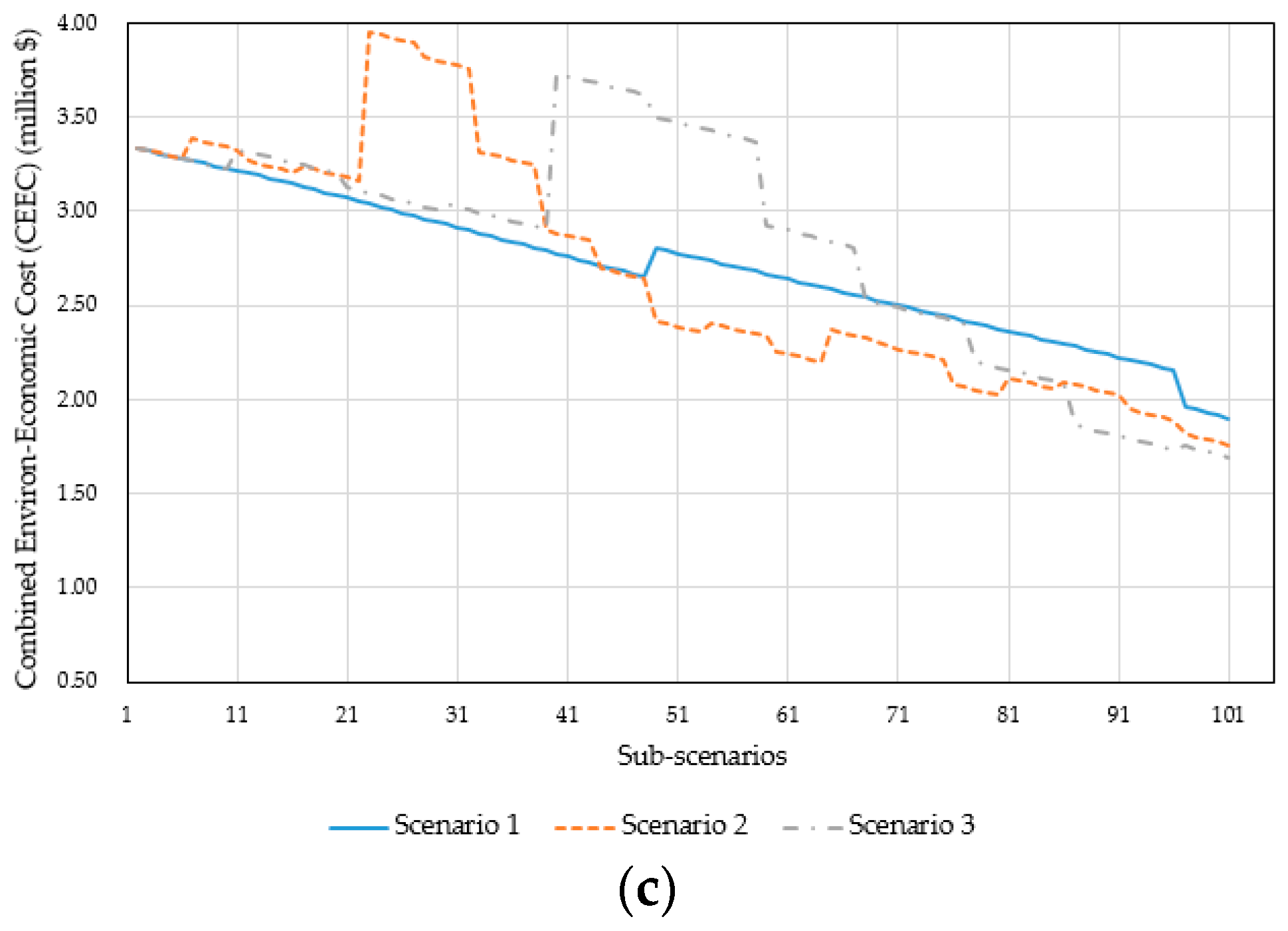

- Curves of the combined economic and environmental penalty costs (CEEPC) were plotted using economic and environmental models for all sub-scenarios in three management cases, and the optimal sub-scenario was determined graphically.

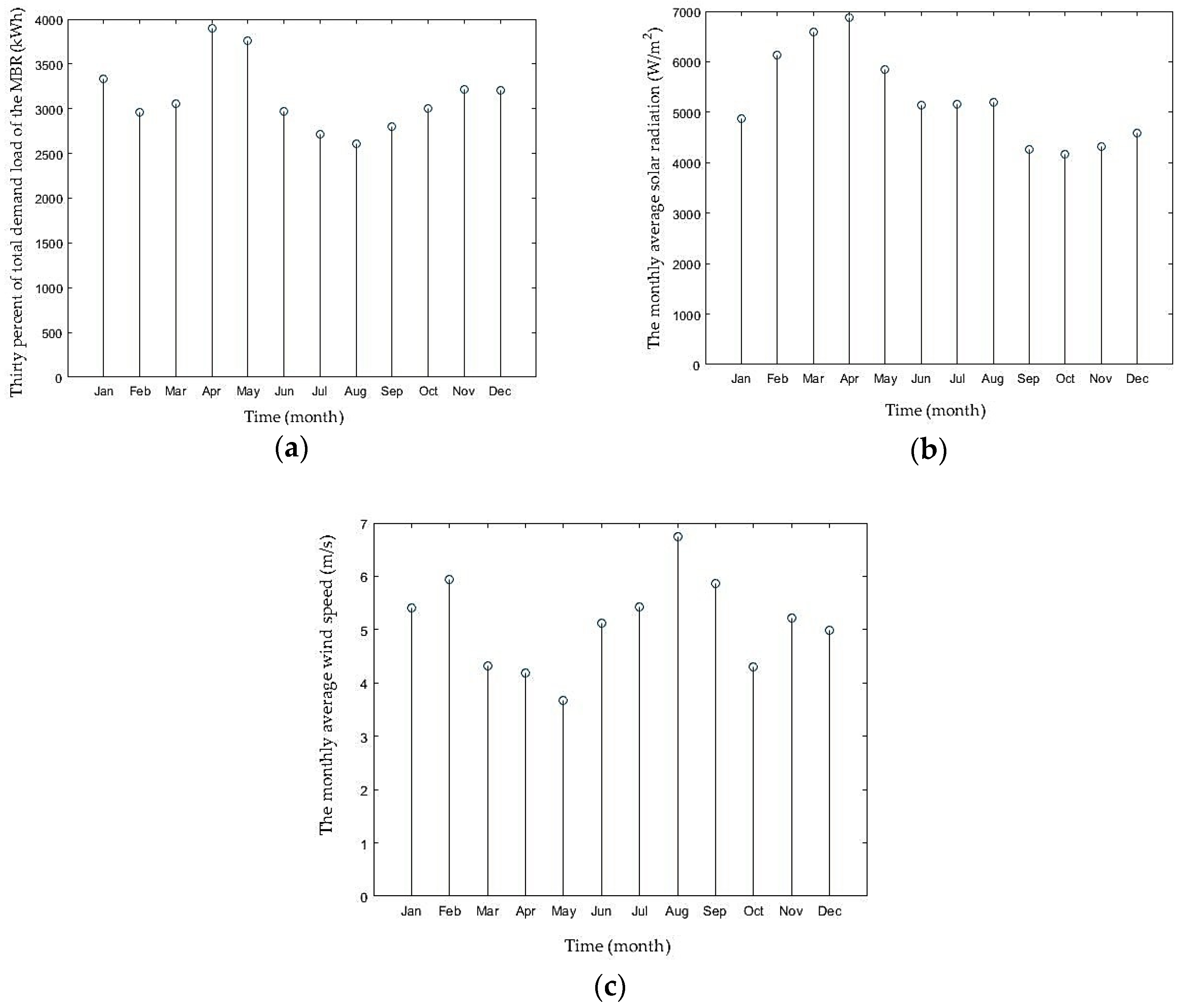

2.2. Data Collection

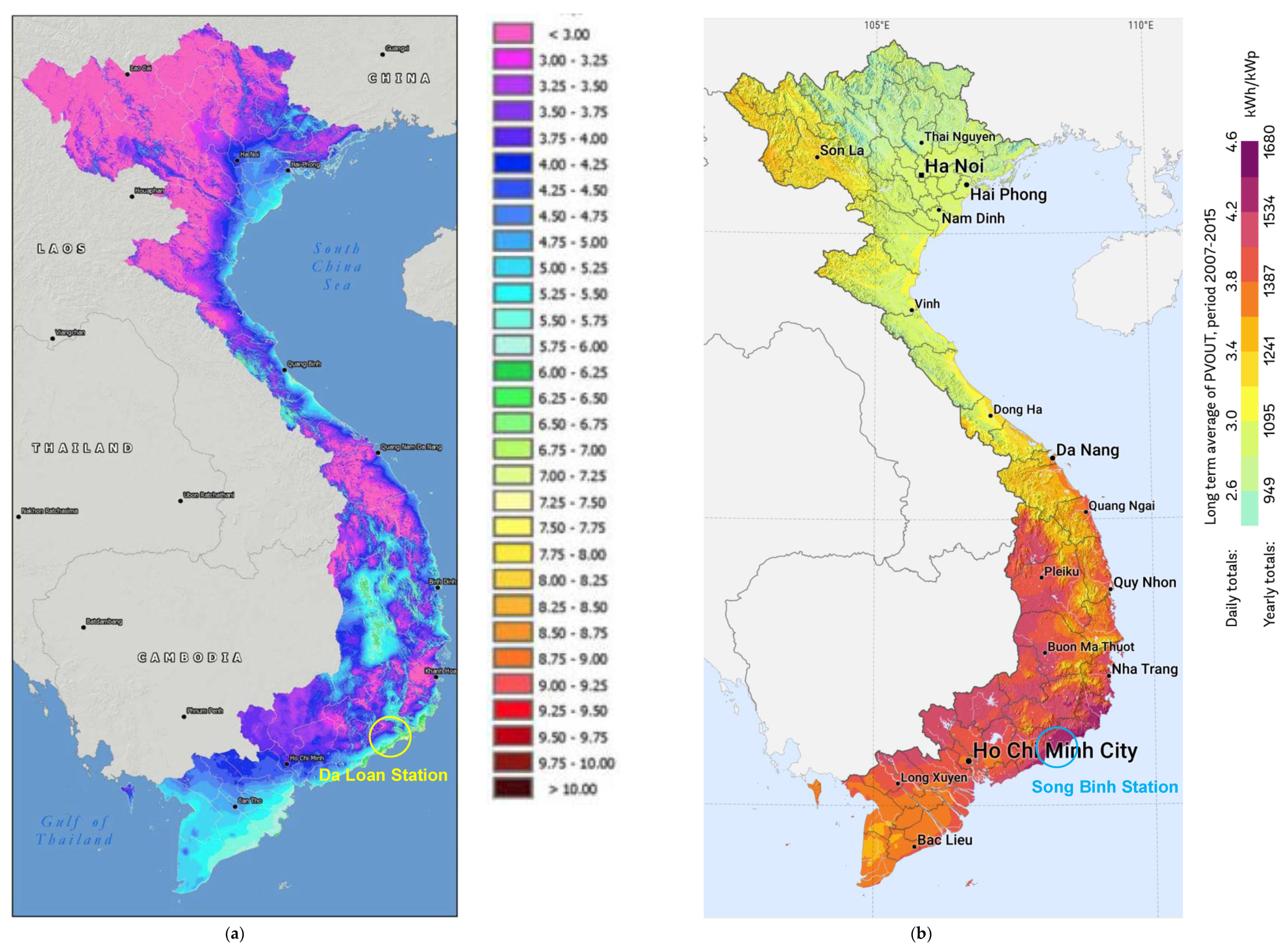

2.2.1. Solar Radiation and Wind Speed Data

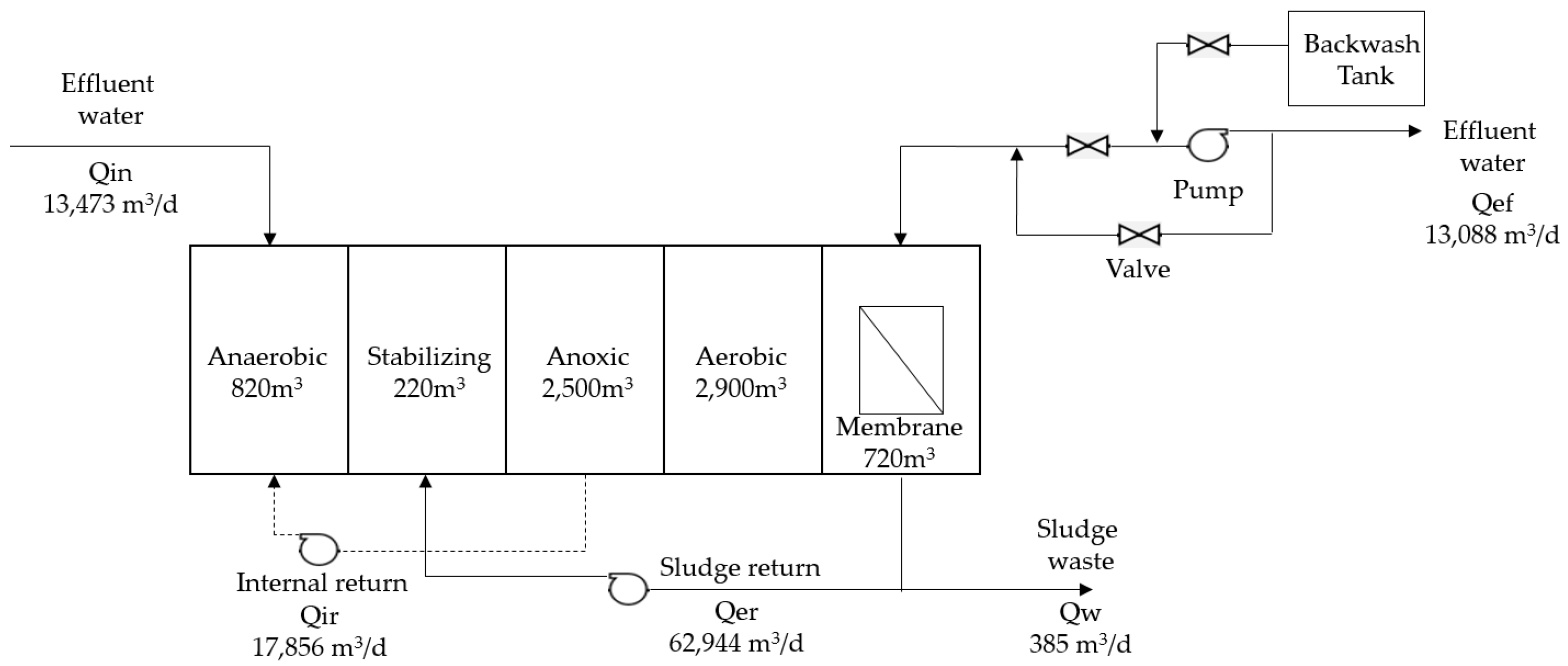

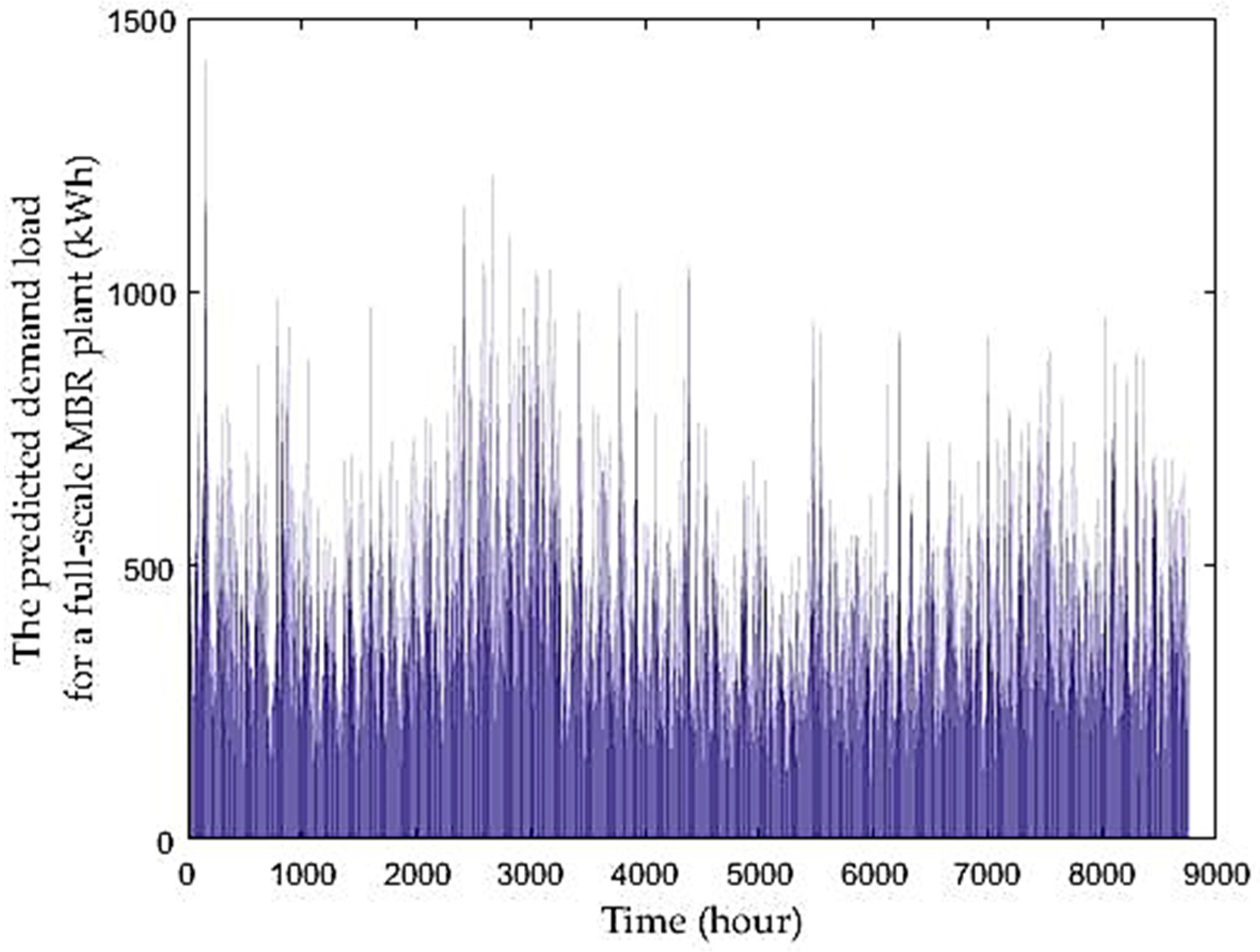

2.2.2. Demand Load of MBR

2.3. Optimal Configuration

- The intensity of diffuse sky radiation is uniform over the sky dome, and dust and dirt accumulation is neglected on photovoltaic panels.

- The effects of the wind velocity on the PV cell performance have not been considered.

- The power losses in the system were considered as reduction factors in the models.

- The uncertainties in the power market has been neglected.

- Operation hours are given in Column 1 that are listed from “1 h” to “24 h” in a daily pattern. Time intervals are the durations between two adjacent operation hours given in Column 2.

- Hourly DC and AC electricity are measured in kWh, and given in Columns 3 and 4, respectively, calculated using Equations (5) and (6) [37,38].where is the direct current produced by PV panels, is the area of the PV panel with a unit area of 1.63 m2/kWh, is the efficiency of the module (0.11), is the packing factor assumed to be 0.9, is the power conditioning efficiency assumed to be 0.86, is the solar radiation (W/m2), is the number of PV panels in a solar module, is the produced power by the WTs ( kWh), is the wind turbine’s power coefficient assumed to be 0.5, is the ambient air density considered as 1.225 kg/m3, is the wind speed in m/s, is the number of WTs in a wind farm, and is the swept area by the turbine blades that have rotor radius , which is obtained via Equation (7) [38].

- The hourly AC electricity demand of the MBR system () is given in Column 5 in kWh.

- If the AC electricity is not adequate to meet the demand load at any time intervals, the DC electricity is delivered. The required power is obtained using Equation (8) that is given in Column 6 [29].

- The battery is discharged when the total AC and DC electricity is not enough to meet the demand load, the required amount of battery power is obtained using Equation (9). The calculated quantities are given in Column 7 [29].where is the conversion efficiency (0.95).

- The battery is charged when the generated DC and AC electricity is greater than the MBR demand load. The amounts of surplus AC and DC power are, respectively, summarized in Columns 8 and 9. The charged () and discharged () power quantities are, respectively, calculated according to Columns 8 and 9, and Column 7. The and are obtained using Equations (10) and (11) and listed in Columns 10 and 11, respectively [29].where is charge/discharge efficiency (0.95).

- The maximum electricity storage capacity for the battery () and the outsourced electricity requirement at various time intervals were obtained by cascading the quantities of storage capacity and outsourced electricity columns, respectively. Infeasible storage capacity () and infeasible outsourced electricity () that represented the first day of operation are obtained using Equations (12) and (13) and given in Columns 12 and 13, respectively [29]. Feasible storage capacity (FSC) and feasible outsourced electricity (FOE) that represented a normal day of operation are obtained using Equations (14) and (15) and given in Columns 14 and 15, respectively [29]. Here, only the second day of operation was described as a normal day of operation for simplicity.where represents normal days (), represents hours (), is the self-discharged energy in the battery (0.004%/h), and is the charge/discharge efficiency (0.95) [39]. The available excess electricity for the next day () is obtained via Equation (16) [29], and used to determine minimum outsourced electricity supply () as formulated in Equation (17) [29].where , and represent excess electricity cascaded at 24 h in the first and normal days of operation, respectively.

- It is necessary to calculate and in each single day to determine and in one operational year. The are the maximum quantities of given in Column 12 from 0 to 24 h for the first day of operation. The and are the maximum quantity of and the sum of all in an operational year, respectively. The and are given in Equations (18)–(21) [26,29].where and represent the present day and the previous day, respectively. is the needed electricity from the grid in a single day (kWh), is the maximum battery capacity in a single day (kWh), is the sum of needed electricity from the grid for one operational year, and is the maximum battery capacity for one operational year (kWh).

2.4. Optimal Management

2.4.1. Economic Model

2.4.2. Environmental Model

- The required coal was obtained to generate one-kilowatt-hour electricity. The amount of coal burned in the production of electricity (kg/kWh) depends on the heat rate () of the generator and the heat content () of the coal as given in Equation (27) [44].where is the heat rate of the generator, and is the heat content of coal. and were assumed to be 10,493 BTU/kWh and 4362.2 BTU/kg, respectively [44].

- Assuming that 2578 kg of CO2 are emitted while burning one short ton (2000 pound or 907.2 kg) of anthracite coal, the CO2 emitted to generate a kilowatt-hour of electricity is calculated using Equation (28) [44].

- The total annual amount of CO2 emitted (kg) to generate the outsourced electricity is calculated via Equation (29) [44].where is the amount of outsourced electricity, which is the sum of the needed electricity () and make-up electricity ().

2.4.3. Graphical Optimization

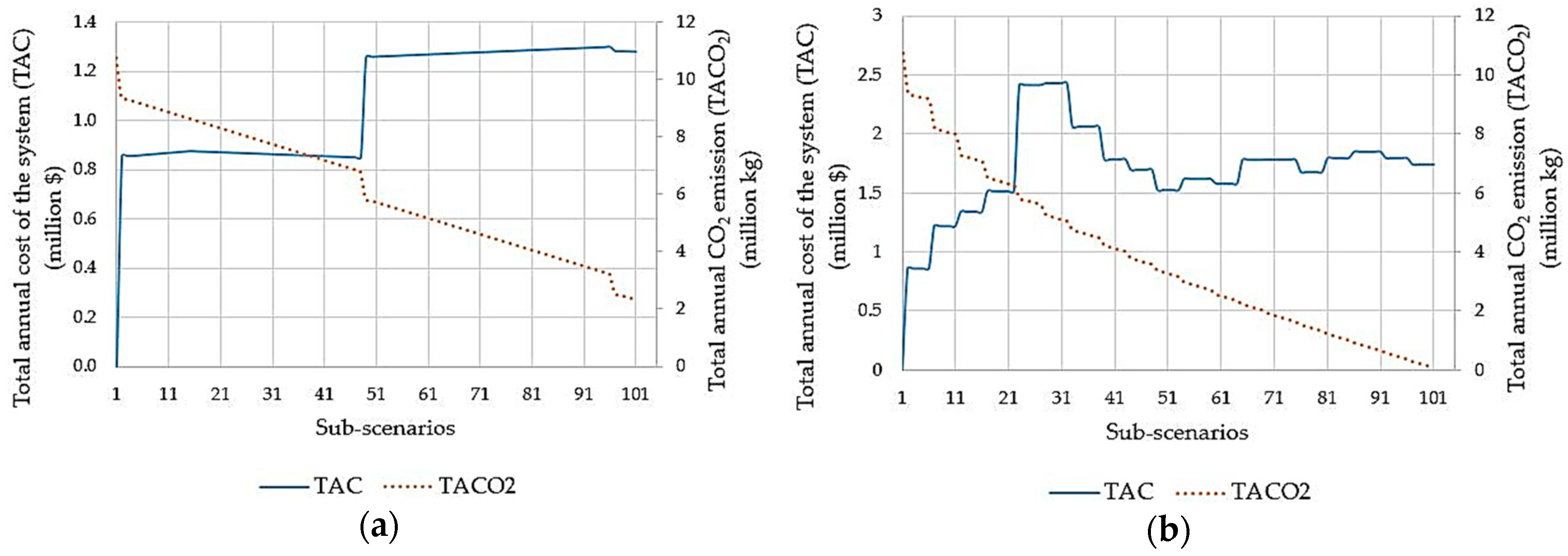

- Case 1: CO2 emissions are not fined so that , and only economic costs are considered for optimization. A slightly polluted environment would be considered as the best condition to apply for case 1.

- Case 2: Economic penalty costs of CO2 emissions conform to the international agreements, and . This case should be applied to a moderately polluted environment.

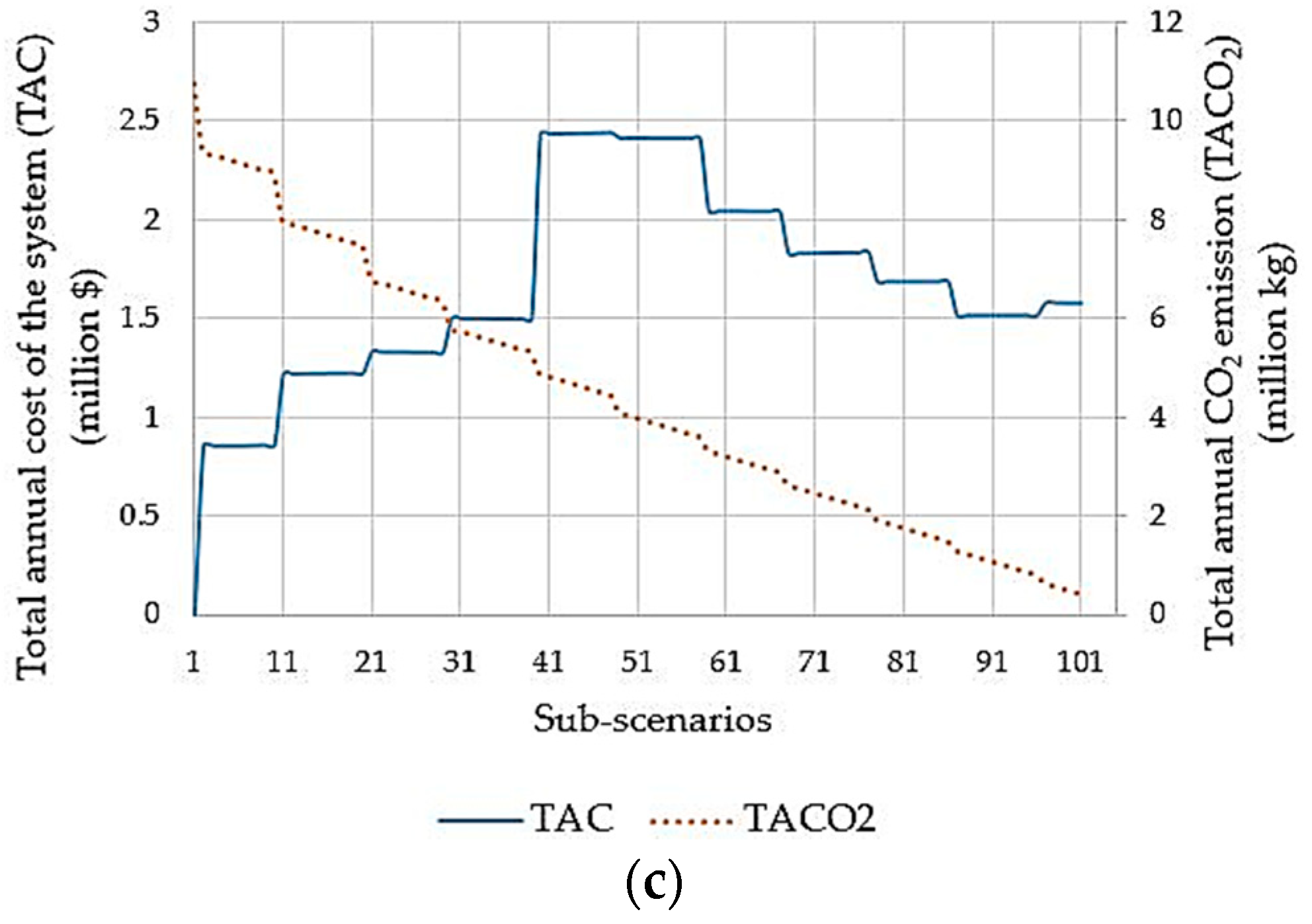

- Case 3: Air quality is sufficiently unhealthy to require that no additional pollution be emitted, and . This case is suitable for countries and regions, especially developing countries, having hazardous high levels in environmental pollution.

3. Results and Discussion

3.1. Component Sizing in an Optimal Configuration

3.2. Graphical Optimal Management

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Soares, N.; Martins, A.; Carvalho, A.; Caldeira, C.; Du, C.; Castanheira, É.; Rodrigues, E.; Oliveira, G.; Pereira, G.; Bastos, J. The challenging paradigm of interrelated energy systems towards a more sustainable future. Renew. Sustain. Energy Rev. 2018, 95, 171–193. [Google Scholar] [CrossRef]

- Luong, N.D. A critical review on potential and current status of wind energy in Vietnam. Renew. Sustain. Energy Rev. 2015, 43, 440–448. [Google Scholar] [CrossRef]

- Ifaei, P.; Karbassi, A.; Lee, S.; Yoo, C. A renewable energies-assisted sustainable development plan for Iran using techno-econo-socio-environmental multivariate analysis and big data. Energy Convers. Manag. 2017, 153, 257–277. [Google Scholar] [CrossRef]

- Le, V.V.; Nguyen, D.C.; Dong, V.H. The Renewable Energy in Vietnam: Potential, Development Orientation. Int. J. Sci. Technol. Res. 2017, 6, 204–207. [Google Scholar]

- EVN. Vietnam Electricity Annual Report; EVN: Hanoi, Vietnam, 2017; p. 12. Available online: https://en.evn.com.vn/userfile/User/huongbtt/files/2018/2/AnnualReport2017.pdf (accessed on 18 November 2018).

- Luong, N.D. A critical review on energy efficiency and conservation policies and programs in Vietnam. Renew. Sustain. Energy Rev. 2015, 52, 623–634. [Google Scholar] [CrossRef]

- Nguyen, K.Q. Wind energy in Vietnam: Resource assessment, development status and future implications. Energy Policy 2007, 35, 1405–1413. [Google Scholar] [CrossRef]

- Awan, A.B.; Zubair, M.; Abokhalil, A.G. Solar energy resource analysis and evaluation of photovoltaic system performance in various regions of Saudi Arabia. Sustainability 2018, 10, 1129. [Google Scholar] [CrossRef]

- Jianzhong, X.; Assenova, A.; Erokhin, V. Renewable Energy and Sustainable Development in a Resource-Abundant Country: Challenges of Wind Power Generation in Kazakhstan. Sustainability 2018, 10, 3315. [Google Scholar] [CrossRef]

- Ifaei, P.; Karbassi, A.; Jacome, G.; Yoo, C. A systematic approach of bottom-up assessment methodology for an optimal design of hybrid solar/wind energy resources–Case study at middle east region. Energy Convers. Manag. 2017, 145, 138–157. [Google Scholar] [CrossRef]

- Nguyen, D. A brief overview on assessments of wind energy resource potential in Vietnam. J. Fundam. Renew. Energy Appl. 2014, 4, 2. [Google Scholar]

- TrueWind Solutions, LLC. Wind Energy Resource Atlas of Southeast Asia; World Bank: Washington, DC, USA, 2001; Available online: http://documents.worldbank.org/curated/en/252541468770659342/Wind-energy-resource-atlas-of-Southeast-Asia (accessed on 18 November 2018).

- AWS Truepower, LLC. Wind Resource Atlas of Vietnam; AWS Truepower: Hanoi, Vietnam, 2011; Available online: https://www.esmap.org/sites/default/files/esmap-files/MOIT_Vietnam_Wind_Atlas_Report_18Mar2011.pdf (accessed on 18 November 2018).

- GIZ/MoIT. Wind Measurement for Developing Wind Power Plan and Wind Power Project; GIZ: Hanoi, Vietnam, 2013; Available online: www.giz.de/vietnam (accessed on 18 November 2018).

- Sakamoto, Y.; Shoji, K.; Bui, M.T.; Phạm, T.H.; Vu, T.A.; Ly, B.T.; Kajii, Y. Air quality study in Hanoi, Vietnam in 2015–2016 based on a one-year observation of NOx, O3, CO and a one-week observation of VOCs. Atmos. Pollut. Res. 2018, 9, 544–551. [Google Scholar] [CrossRef]

- ICEM. Analysis of Pollution from Manufacturing Sectors in Vietnam; International Center for Environmental Management: Indooroopilly, Australia, 2007; Available online: http://icem.com.au/portfolio_category/report/ (accessed on 18 November 2018).

- Environmental Performance Index. Available online: https://epi.envirocenter.yale.edu/epi-country-report/VNM (accessed on 18 November 2018).

- Nakagami, K. Environmental Management and Sustainable Development in Vietnam. Policy Sci. 1999, 7, 1. [Google Scholar]

- WB. Vietnam–Environmental Program and Policy Priorities for a Socialist Economy in Transition; 13200-VN; WB: Washington, DC, USA, 1995; Available online: http://documents.worldbank.org/curated/en/953301468761685706/The-supporting-annexes (accessed on 18 November 2018).

- Sartor, M.; Kaschek, M.; Mavrov, V. Feasibility study for evaluating the client application of membrane bioreactor (MBR) technology for decentralised municipal wastewater treatment in Vietnam. Desalination 2008, 224, 172–177. [Google Scholar] [CrossRef]

- Pabby, A.K.; Rizvi, S.S.; Sastre, A.M. Handbook of Membrane Separations: Chemical, Pharmaceutical, Food, and Biotechnological Applications; CRC: Boca Raton, FL, USA, 2008. [Google Scholar]

- Joss, A.; Böhler, M.; Wedi, D.; Siegrist, H. Proposing a method for online permeability monitoring in membrane bioreactors. Water Sci. Technol. 2009, 60, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-S.; Lee, C.-H.; Chang, I.-S. Effect of pump shear on the performance of a crossflow membrane bioreactor. Water Res. 2001, 35, 2137–2144. [Google Scholar] [CrossRef]

- Thunuguntla, R.; Mahboubi, A.; Ferreira, J.; Taherzadeh, M. Integration of membrane bioreactors with edible filamentous fungi for valorization of expired milk. Sustainability 2018, 10, 1940. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Rashidi, J.; Ifaei, P.; Yoo, C. Efficient thermal desalination technologies with renewable energy systems: A state-of-the-art review. Korean J. Chem. Eng. 2016, 33, 351–387. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Lee, S.; Yoo, C. Extended-power pinch analysis (EPoPA) for integration of renewable energy systems with battery/hydrogen storages. Renew. Energy 2015, 80, 1–14. [Google Scholar] [CrossRef]

- Kantola, M.; Saari, A. Renewable vs. traditional energy management solutions—A Finnish hospital facility case. Renew. Energy 2013, 57, 539–545. [Google Scholar] [CrossRef]

- Rozali, N.E.M.; Alwi, S.R.W.; Manan, Z.A.; Klemeš, J.J.; Hassan, M.Y. Process integration of hybrid power systems with energy losses considerations. Energy 2013, 55, 38–45. [Google Scholar] [CrossRef]

- Li, Q.; Moya, W.; Esfahani, I.J.; Rashidi, J.; Yoo, C. Integration of reverse osmosis desalination with hybrid renewable energy sources and battery storage using electricity supply and demand-driven power pinch analysis. Process Saf. Environ. Prot. 2017, 111, 795–809. [Google Scholar] [CrossRef]

- Jiang, T. Characterization and Modelling of Soluble Microbial Products in Membrane Bioreactors. Ph.D. Thesis, Ghent University, Ghent, Belgium, 2007. [Google Scholar]

- Kim, M. An Integrated Prediction and Diagnosis Approach for an Understanding of Membrane Fouling Phenomena in Membrane Bioreactor (MBR): Multi-Variable Statistical and Mechanistic Models. Master’s Thesis, Kyung Hee University, Global Campus, Yongin, Korea, 2012. [Google Scholar]

- Energy Data. Available online: https://energydata.info/ (accessed on 6 July 2018).

- International Electrotechnical Commission (IEC). WIND TURBINES—Part 121: Power Performance Measurements of Grid Connected Wind Turbines; IEC: Geneva, Switzerland, 2005. [Google Scholar]

- Alex, J.; Benedetti, L.; Copp, J.; Gernaey, K.; Jeppsson, U.; Nopens, I.; Pons, M.; Rieger, L.; Rosen, C.; Steyer, J. Benchmark Simulation Model No. 1 (BSM1); Lund University: Lund, Sweden, 2008; Available online: https://www.iea.lth.se/publications/Reports/LTH-IEA-7229.pdf (accessed on 18 November 2018).

- Safder, U.; Ifaei, P.; Yoo, C. Multi-objective optimization and flexibility analysis of a cogeneration system using thermorisk and thermoeconomic analyses. Energy Convers. Manag. 2018, 166, 602–636. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Ifaei, P.; Kim, J.; Yoo, C. Design of hybrid renewable energy systems with battery/hydrogen storage considering practical power losses: A MEPoPA (modified extended-power pinch analysis). Energy 2016, 100, 40–50. [Google Scholar] [CrossRef]

- Hocaoğlu, F.O.; Gerek, Ö.N.; Kurban, M. A novel hybrid (wind–photovoltaic) system sizing procedure. Sol. Energy 2009, 83, 2019–2028. [Google Scholar] [CrossRef]

- Tyagi, R.K. Wind energy and role of effecting parameters. Eur. J. Appl. Eng. Sci. Res. 2012, 1, 73–83. [Google Scholar]

- Mahmoudi, H.; Abdul-Wahab, S.; Goosen, M.; Sablani, S.; Perret, J.; Ouagued, A.; Spahis, N. Weather data and analysis of hybrid photovoltaic–wind power generation systems adapted to a seawater greenhouse desalination unit designed for arid coastal countries. Desalination 2008, 222, 119–127. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Ataei, A.; Shetty, V.; Oh, T.; Park, J.H.; Yoo, C. Modeling and genetic algorithm-based multi-objective optimization of the MED-TVC desalination system. Desalination 2012, 292, 87–104. [Google Scholar] [CrossRef]

- Esfahani, I.J. Optimal Design of High Efficient Combined Desalination and Refrigeration System Coupled with CHP and Hybrid Renewable Energy Sources. Ph.D. Thesis, Kyung Hee University, Seoul, Korea, 2015. [Google Scholar]

- Zhang, Z.; Li, Y.; Zhang, W.; Wang, J.; Soltanian, M.R.; Olabi, A.G. Effectiveness of amino acid salt solutions in capturing CO2: A review. Renew. Sustain. Energy Rev. 2018, 98, 179–188. [Google Scholar] [CrossRef]

- EIA. International Energy Outlook. 2017. Available online: https://www.eia.gov/outlooks/ieo/pdf/0484(2017).pdf (accessed on 18 November 2018).

- EIA. How Much Coal, Natural Gas, or Petroleum Is Used to Generate a Kilowatthour of Electricity? Available online: https://www.eia.gov/tools/faqs/faq.php?id=667&t=2 (accessed on 6 July 2018).

- Ifaei, P.; Yoo, C. The compatibility of controlled power plants with self-sustainable models using a hybrid input/output and water-energy-carbon nexus analysis. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Loy-Benitez, J.; Li, Q.; Ifaei, P.; Nam, K.; Heo, S.; Yoo, C. A dynamic gain-scheduled ventilation control system for a subway station based on outdoor air quality conditions. Build. Environ. 2018, 144, 159–170. [Google Scholar] [CrossRef]

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time (h) | Time Interval (h) | DC Source, (kWh) | AC Source, (kWh) | AC Demand, (kWh) | Additional Amount from DC Source (kWh) | Second Additional Amount Required from the Battery (kWh) | AC Surplus (kWh) | DC Surplus (kWh) | Charging into Battery, (kWh) | Discharging from the Battery, (kWh) | Infeasible Storage Capacity,

(kWh) | Infeasible Outsource Electricity,

(kWh) | Feasible Storage Capacity,

(kWh) | Feasible Outsource Electricity,

(kWh) |

| 1184.19 | 2267.37 | |||||||||||||

| 1 | 1 | 0 | 226.17 | 631.06 | 404.88 | 404.88 | 0 | 0 | 0 | 426.19 | 0.00 | 404.88 | 710.59 | 0 |

| 2 | 1 | 0 | 388.52 | 350.10 | 0 | 0 | 388.52 | 0 | 369.09 | 0 | 332.18 | 0 | 1042.75 | 0 |

| 3 | 1 | 0 | 424.17 | 463.54 | 39.36 | 39.36 | 0 | 0 | 0 | 41.44 | 286.13 | 0 | 996.66 | 0 |

| 4 | 1 | 0 | 424.17 | 461.18 | 37.01 | 37.01 | 0 | 0 | 0 | 38.96 | 242.83 | 0 | 953.34 | 0 |

| 5 | 1 | 0 | 380.87 | 395.44 | 14.57 | 14.57 | 0 | 0 | 0 | 15.34 | 225.78 | 0 | 936.26 | 0 |

| 6 | 1 | 0.08 | 309.88 | 291.87 | 0 | 0 | 309.88 | 0.08 | 294.47 | 0 | 490.79 | 0 | 1201.25 | 0 |

| 7 | 1 | 0.32 | 293.63 | 270.41 | 0 | 0 | 293.63 | 0.32 | 279.27 | 0 | 742.12 | 0 | 1452.54 | 0 |

| 8 | 1 | 0.66 | 337.11 | 391.88 | 54.77 | 54.14 | 0 | 0 | 0 | 56.99 | 678.77 | 0 | 1389.17 | 0 |

| 9 | 1 | 1.19 | 54.05 | 343.57 | 289.52 | 288.39 | 0 | 0 | 0 | 303.56 | 341.45 | 0 | 1051.82 | 0 |

| 10 | 1 | 0.87 | 19.62 | 323.64 | 304.02 | 303.19 | 0 | 0 | 0 | 319.15 | 0 | 11.26 | 697.17 | 0 |

| 11 | 1 | 1.22 | 63.89 | 376.11 | 312.22 | 311.06 | 0 | 0 | 0 | 327.43 | 0 | 311.06 | 333.32 | 0 |

| 12 | 1 | 1.67 | 49.05 | 638.23 | 589.18 | 587.60 | 0 | 0 | 0 | 618.53 | 0 | 587.60 | 0 | 587.60 |

| 13 | 1 | 1.68 | 242.65 | 447.09 | 204.44 | 202.85 | 0 | 0 | 0 | 213.52 | 0 | 202.85 | 0 | 202.85 |

| 14 | 1 | 1.57 | 123.88 | 590.05 | 466.17 | 464.68 | 0 | 0 | 0 | 489.13 | 0 | 464.68 | 0 | 464.68 |

| 15 | 1 | 1.02 | 256.98 | 542.01 | 285.03 | 284.06 | 0 | 0 | 0 | 299.01 | 0 | 284.06 | 0 | 284.06 |

| 16 | 1 | 0.54 | 534.53 | 437.50 | 0 | 0 | 534.53 | 0.54 | 508.34 | 0 | 457.50 | 0 | 457.50 | 0 |

| 17 | 1 | 0.05 | 424.17 | 524.36 | 100.18 | 100.14 | 0 | 0 | 0.0 | 105.41 | 340.36 | 0 | 340.36 | 0 |

| 18 | 1 | 0 | 828.47 | 498.33 | 0 | 0 | 828.47 | 0 | 787.04 | 0 | 1048.69 | 0 | 1048.69 | 0 |

| 19 | 1 | 0 | 646.20 | 397.84 | 0 | 0 | 646.20 | 0 | 613.89 | 0 | 1601.14 | 0 | 1601.14 | 0 |

| 20 | 1 | 0 | 640.81 | 583.59 | 0 | 0 | 640.81 | 0 | 608.77 | 0 | 2148.97 | 0 | 2148.97 | 0 |

| 21 | 1 | 0 | 300.06 | 662.95 | 362.89 | 362.89 | 0 | 0 | 0 | 381.98 | 1724.46 | 0 | 1724.46 | 0 |

| 22 | 1 | 0 | 603.95 | 616.93 | 12.98 | 12.98 | 0 | 0 | 0 | 13.66 | 1709.21 | 0 | 1709.21 | 0 |

| 23 | 1 | 0 | 354.91 | 419.38 | 64.46 | 64.46 | 0 | 0 | 0 | 67.86 | 1633.74 | 0 | 1633.74 | 0 |

| 24 | 1 | 0 | 148.71 | 532.99 | 384.27 | 384.27 | 0 | 0 | 0 | 404.50 | 1184.24 | 0 | 1184.24 | 0 |

| Subsystem | Parameters | Symbol | Value | Unit | Reference |

|---|---|---|---|---|---|

| Overall | A lifetime of the overall system | 20 | year | [29] | |

| PV | Capital cost | 350 | $/module | [29] | |

| Replacement cost | 350 | $/module | |||

| Lifetime | 20 | year | |||

| Operating and maintenance cost (% of capital cost) | 0 | % | |||

| Wind turbine | Capital cost | 150,000 | $/unit | [29] | |

| Replacement cost | 130,000 | $/unit | |||

| Lifetime | 15 | year | |||

| Operating and maintenance cost | 2500 | $/year | |||

| BC | Capital cost | 120 | $/kWh | [29,39] | |

| Replacement cost | 120 | $/kWh | |||

| Lifetime | 4 | year | |||

| Operating and maintenance cost (% of capital cost) | 1 | % |

| Month | January | February | March | April | May | June | July | August | September | October | November | December |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. WT | 2 | 2 | 3 | 4 | 6 | 2 | 2 | 1 | 2 | 3 | 2 | 2 |

| No. PV | 21 | 15 | 14 | 18 | 20 | 18 | 16 | 16 | 20 | 22 | 23 | 21 |

| Sub-Scenario | RES Contribution, % | No. PVs, Panel | No. WTs, Module | BC, kWh | NE, kWh |

|---|---|---|---|---|---|

| Scenario 1 | |||||

| 1 | 0 | 0 | 0 | - | 3,832,303 |

| 2 | 1 | 7 | 1 | 3887 | 2,893,434 |

| 11 | 10 | 68 | 1 | 3928 | 2,878,527 |

| 21 | 20 | 135 | 1 | 3922 | 2,862,233 |

| 31 | 30 | 202 | 1 | 3867 | 2,845,988 |

| 41 | 40 | 269 | 1 | 3811 | 2,829,747 |

| 51 | 50 | 336 | 2 | 5551 | 2,171,979 |

| 61 | 60 | 403 | 2 | 5575 | 2,157,772 |

| 71 | 70 | 471 | 2 | 5599 | 2,143,399 |

| 81 | 80 | 538 | 2 | 5623 | 2,129,251 |

| 91 | 90 | 605 | 2 | 5646 | 2,115,134 |

| 101 | 100 | 672 | 3 | 5400 | 1,662,696 |

| Scenario 2 | |||||

| 1 | 0 | 0 | 0 | - | 3,832,303 |

| 2 | 1 | 1 | 1 | 3892 | 2,894,900 |

| 11 | 10 | 8 | 2 | 5435 | 2,242,853 |

| 21 | 20 | 15 | 4 | 6515 | 1,437,793 |

| 31 | 30 | 23 | 6 | 11,379 | 953,380 |

| 41 | 40 | 30 | 8 | 7163 | 640,381 |

| 51 | 50 | 38 | 10 | 5622 | 418,646 |

| 61 | 60 | 45 | 12 | 5568 | 259,490 |

| 71 | 70 | 53 | 14 | 6205 | 172,006 |

| 81 | 80 | 60 | 16 | 5953 | 106,127 |

| 91 | 90 | 68 | 17 | 6053 | 85,188 |

| 101 | 100 | 75 | 19 | 5227 | 53,571 |

| Scenario 3 | |||||

| 1 | 0 | 0 | 0 | - | 3,832,303 |

| 2 | 1 | 4 | 1 | 3890 | 2,894,168 |

| 11 | 10 | 38 | 2 | 5446 | 2,236,286 |

| 21 | 20 | 75 | 3 | 5807 | 1,775,114 |

| 31 | 30 | 112 | 4 | 6443 | 1,421,974 |

| 41 | 40 | 150 | 5 | 10,704 | 1,148,995 |

| 51 | 50 | 187 | 6 | 10,435 | 931,827 |

| 61 | 60 | 224 | 7 | 8517 | 761,944 |

| 71 | 70 | 262 | 8 | 7343 | 614,820 |

| 81 | 80 | 299 | 9 | 6496 | 495,026 |

| 91 | 90 | 336 | 10 | 5519 | 392,191 |

| 101 | 100 | 374 | 11 | 5644 | 304,963 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoang, T.-V.; Ifaei, P.; Nam, K.; Rashidi, J.; Hwangbo, S.; Oh, J.-M.; Yoo, C. Optimal Management of a Hybrid Renewable Energy System Coupled with a Membrane Bioreactor Using Enviro-Economic and Power Pinch Analyses for Sustainable Climate Change Adaption. Sustainability 2019, 11, 66. https://doi.org/10.3390/su11010066

Hoang T-V, Ifaei P, Nam K, Rashidi J, Hwangbo S, Oh J-M, Yoo C. Optimal Management of a Hybrid Renewable Energy System Coupled with a Membrane Bioreactor Using Enviro-Economic and Power Pinch Analyses for Sustainable Climate Change Adaption. Sustainability. 2019; 11(1):66. https://doi.org/10.3390/su11010066

Chicago/Turabian StyleHoang, Tuan-Viet, Pouya Ifaei, Kijeon Nam, Jouan Rashidi, Soonho Hwangbo, Jong-Min Oh, and ChangKyoo Yoo. 2019. "Optimal Management of a Hybrid Renewable Energy System Coupled with a Membrane Bioreactor Using Enviro-Economic and Power Pinch Analyses for Sustainable Climate Change Adaption" Sustainability 11, no. 1: 66. https://doi.org/10.3390/su11010066

APA StyleHoang, T.-V., Ifaei, P., Nam, K., Rashidi, J., Hwangbo, S., Oh, J.-M., & Yoo, C. (2019). Optimal Management of a Hybrid Renewable Energy System Coupled with a Membrane Bioreactor Using Enviro-Economic and Power Pinch Analyses for Sustainable Climate Change Adaption. Sustainability, 11(1), 66. https://doi.org/10.3390/su11010066