A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements

Abstract

1. Introduction

2. Materials and Methods

2.1. Aim and Scope of the Study

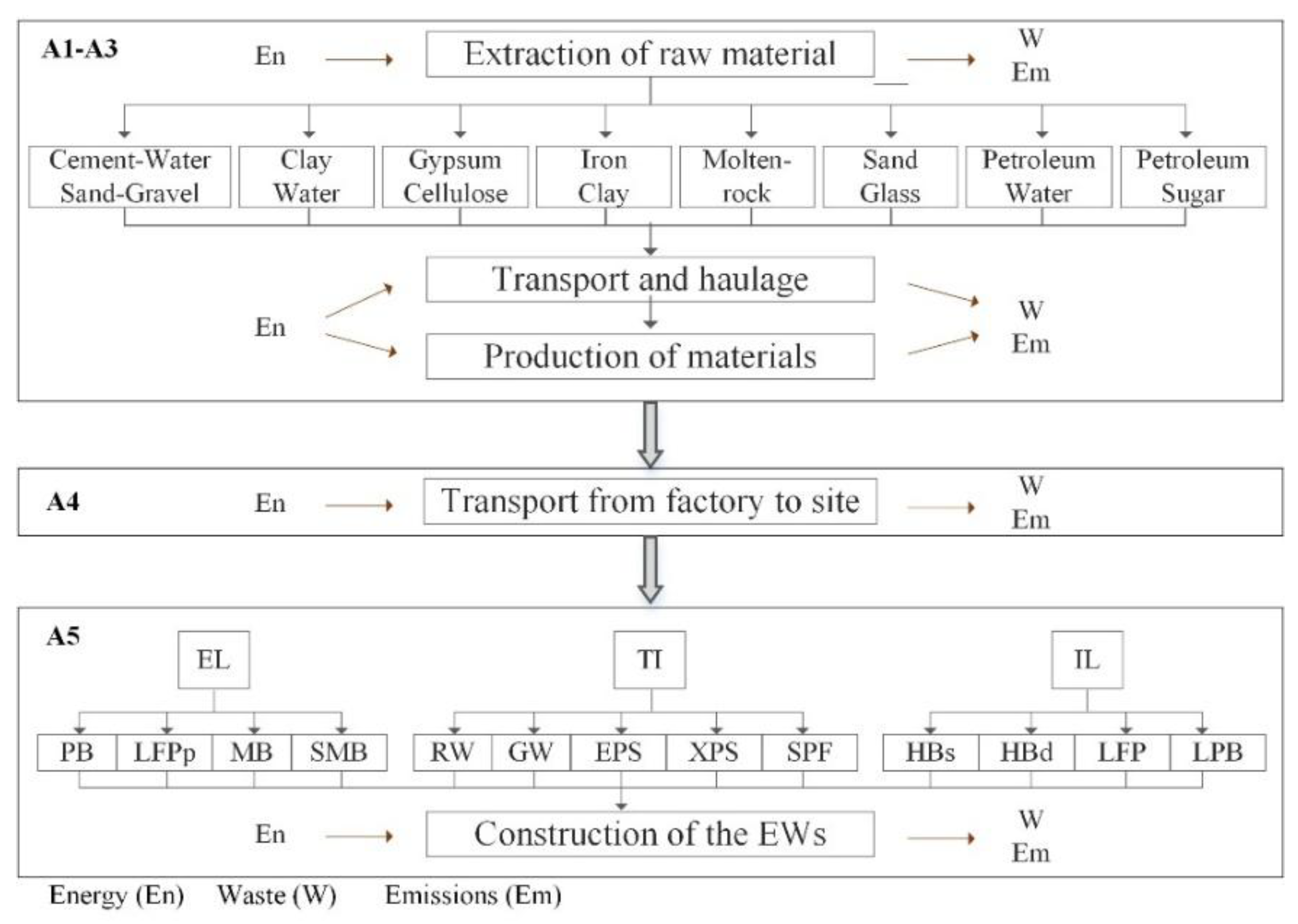

2.1.1. System, Boundaries, and Functional Unit

2.1.2. Data Inventory

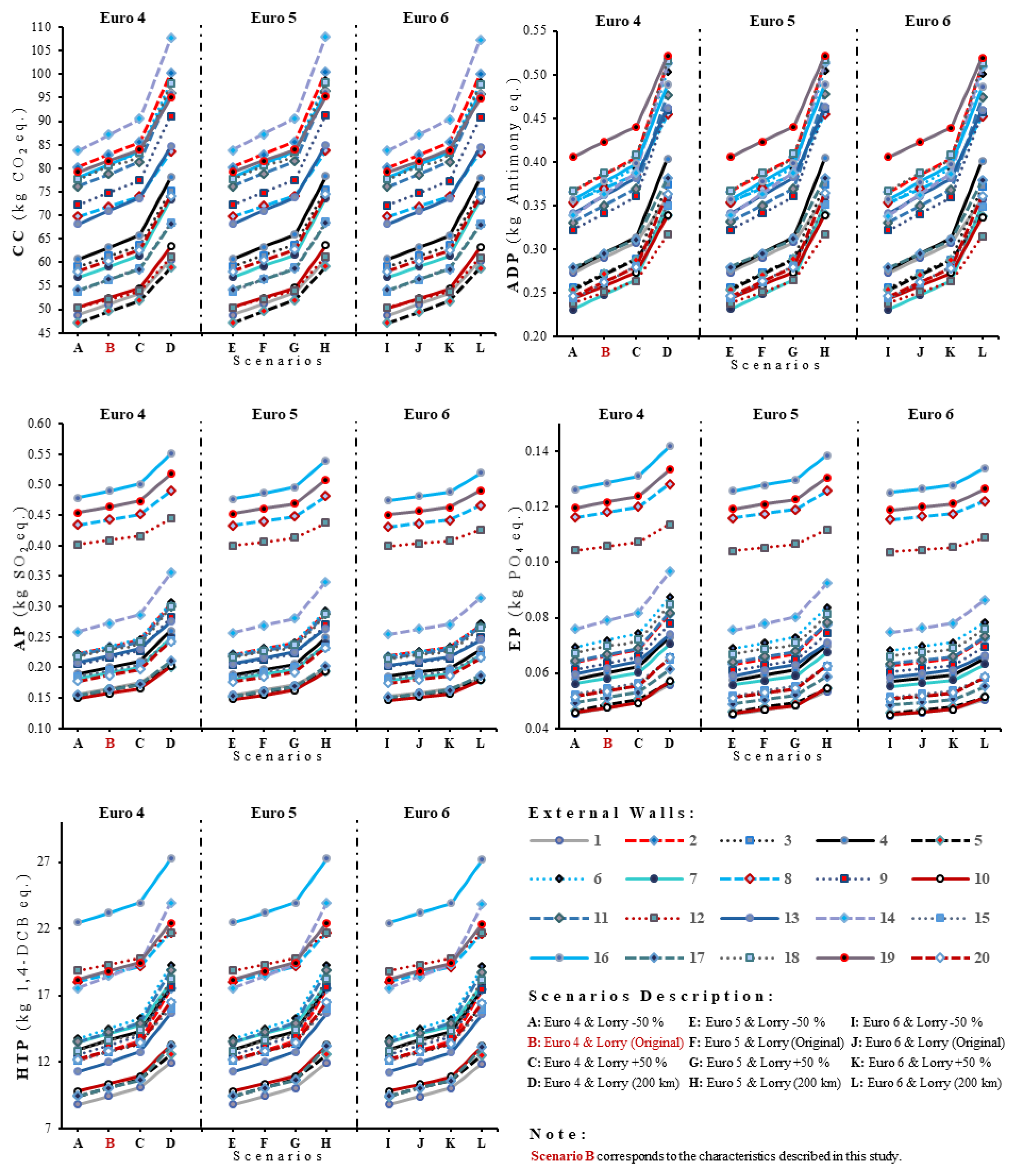

2.1.3. Impact Assessment Method and Categories

2.1.4. Assumptions

3. Case Studies

4. Life Cycle Inventory

4.1. Product Stage (A1–A3)

4.2. Transport from Factory to Site (A4)

4.3. Construction Process (A5)

5. Results of the Environmental Impact

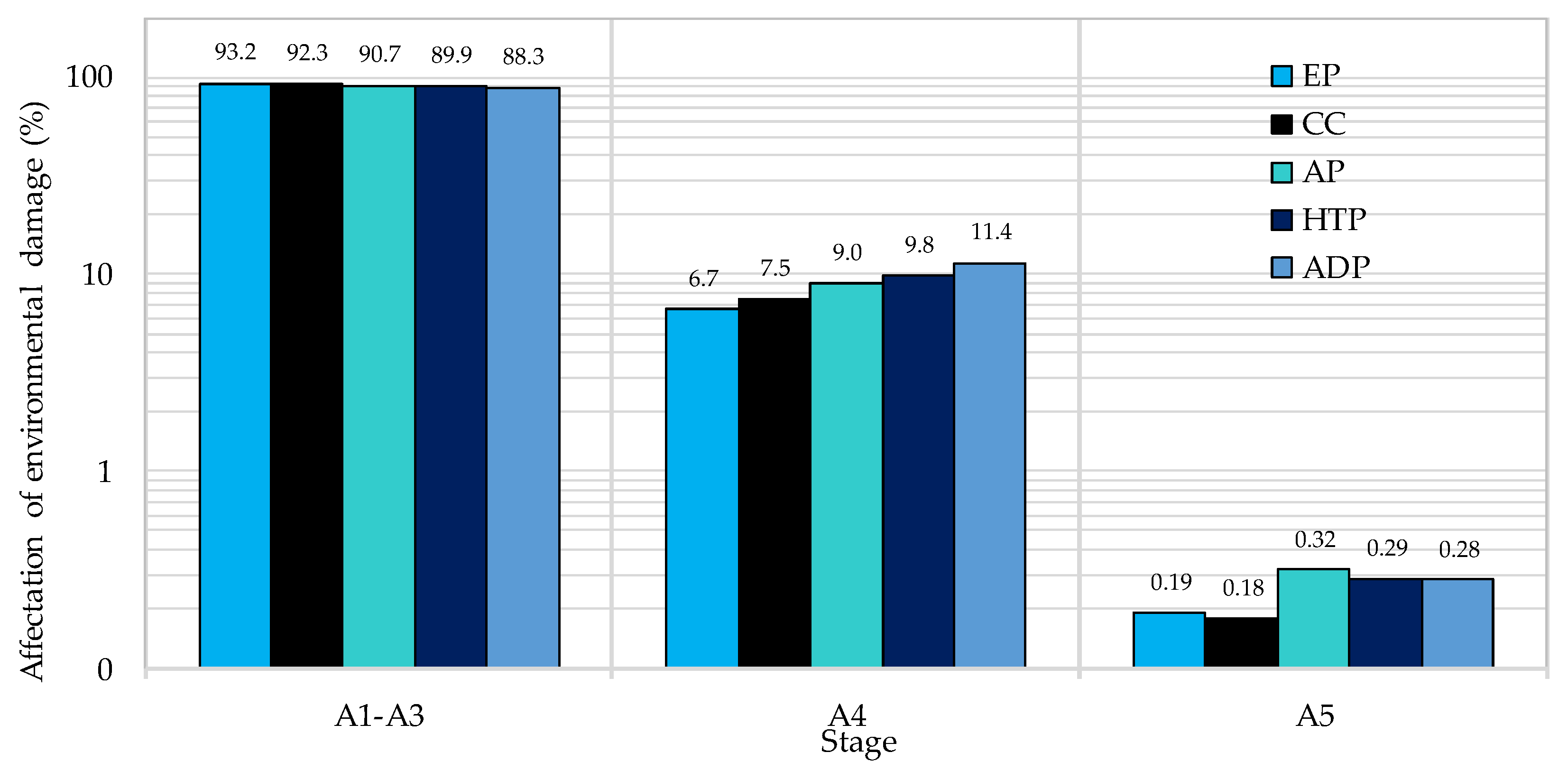

5.1. Stages of Product (A1–A3) and of the Construction Process (A4–A5) in the Impact Categories

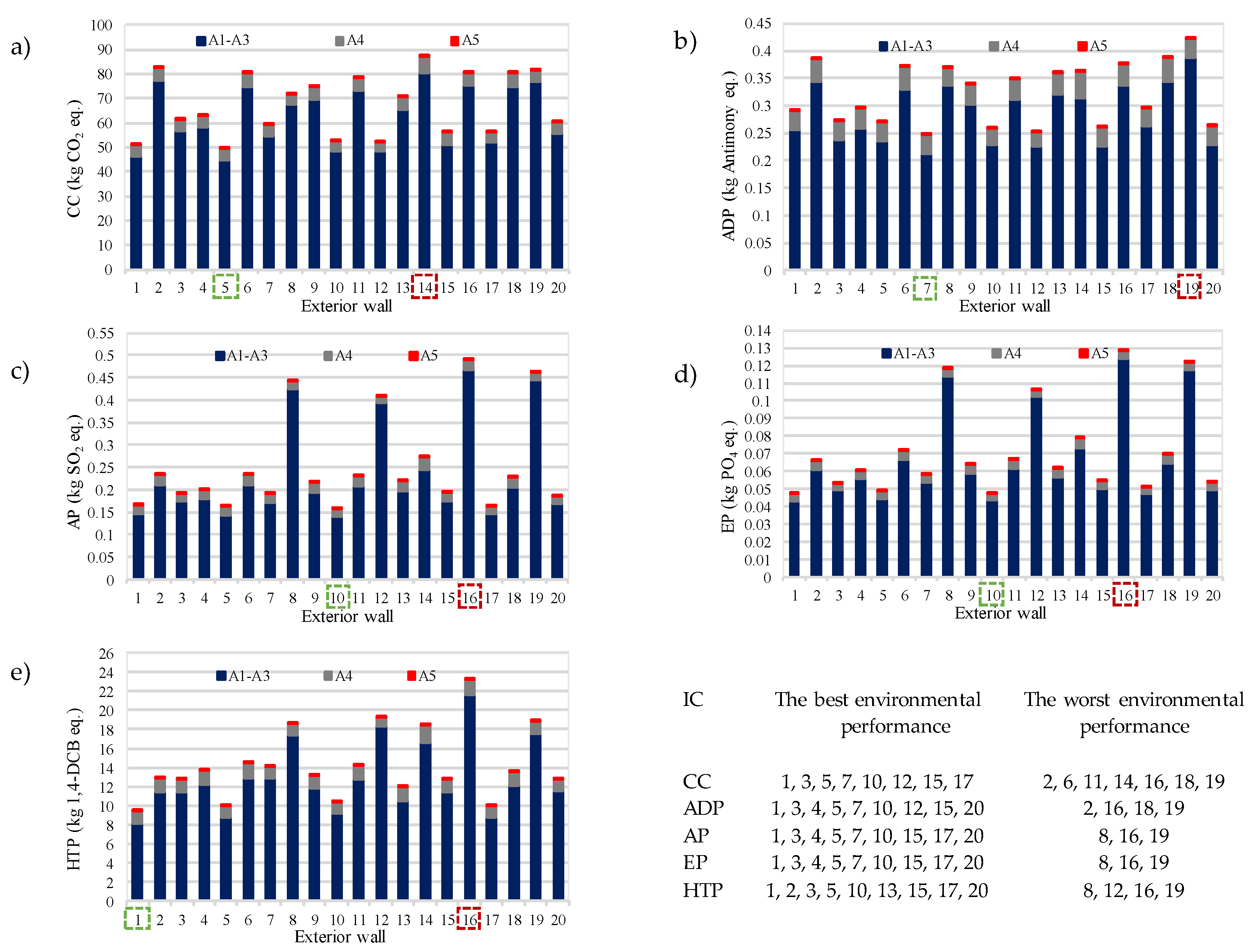

5.2. The External Walls in the Environmental Impact Categories

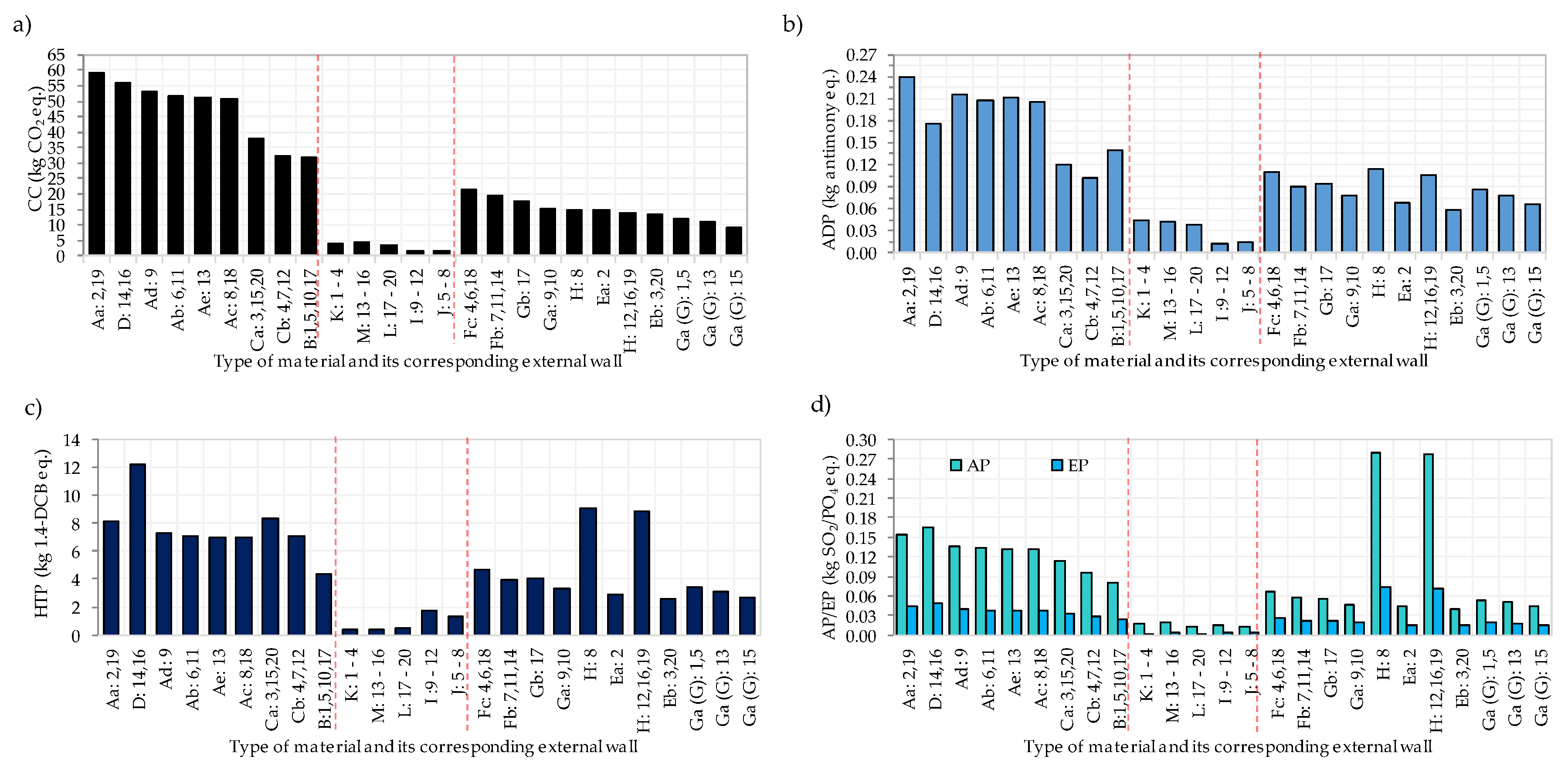

5.3. The Constructive Elements (EL, TI, and IL) in the Product Stages (A1–A3)

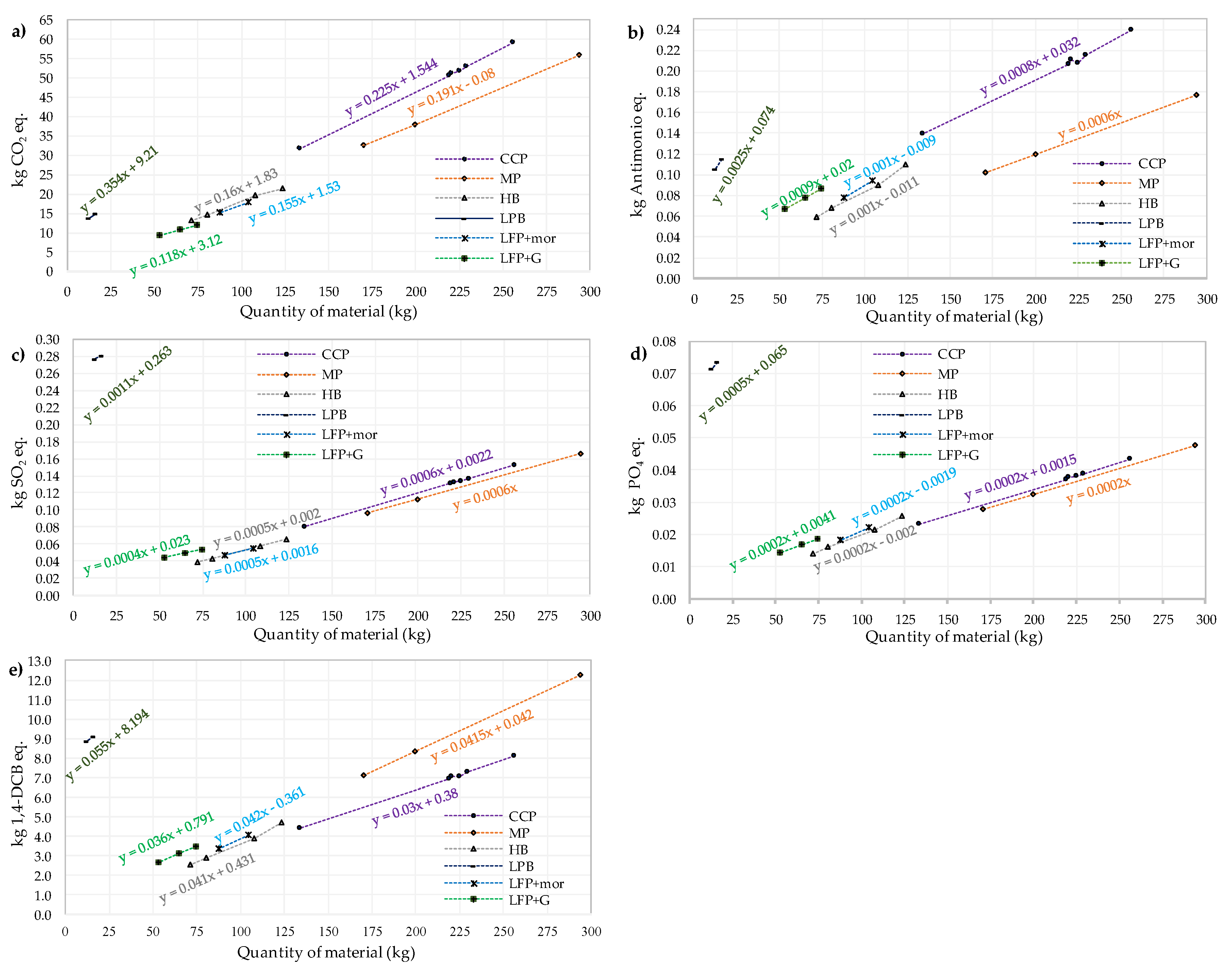

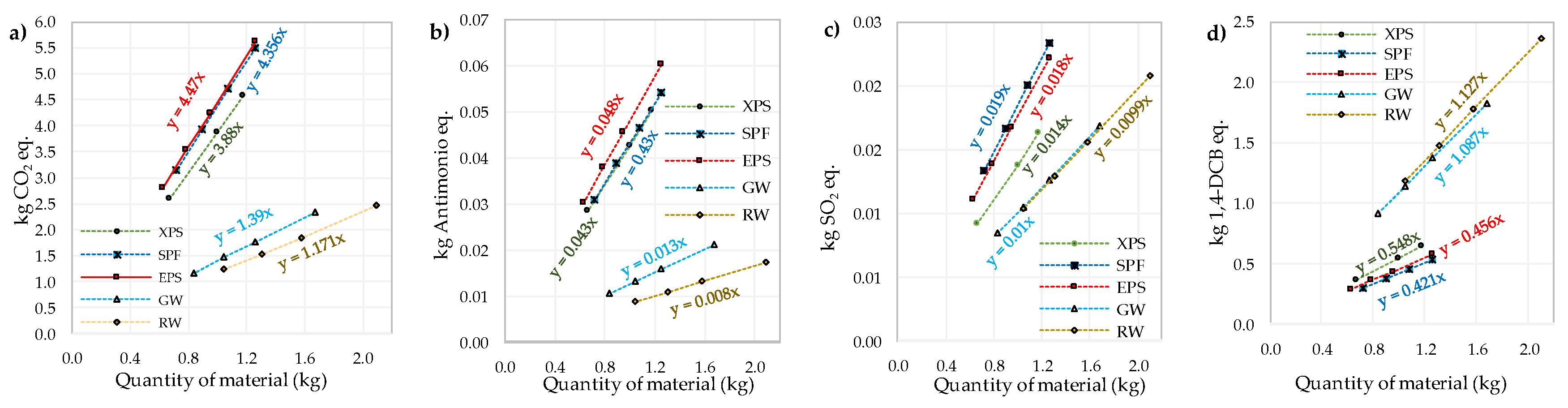

6. Prediction of the Environmental Behavior of E Components

7. Sensitivity and Uncertainty Analysis

8. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| A1–A3 | Product stage |

| A4 | Transport from factory to site |

| A4–A5 | Construction process stage |

| A5 | Construction process/installation stage |

| ADP | Depletion of abiotic resources |

| CC | Climate change |

| CCP | Ceramic clay pieces |

| EL | Exterior layer |

| EP | Eutrophication potential |

| EPS | Expanded polystyrene |

| EW | External walls |

| G | Laminated plasterboard |

| GW | Glass wool |

| HBd | Double hollow brick |

| HBs | Single hollow brick |

| HR | Height of reference |

| HTP | Human toxicity |

| IL | Interior layer |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LFP | Hollow large format |

| LFPp | Perforated large format partition wall |

| LPB | Laminated plasterboard |

| MB | Hollow mortar block |

| mor | Mortar |

| MP | Mortar pieces |

| ODP | Stratospheric ozone depletion |

| PB | Perforated brick |

| POCP | Photochemical oxidation |

| RW | Rock wool |

| SMB | Solid mortar brick |

| SPF | Spray Polyurethane Foam |

| TI | Thermal insulation |

| XPS | Extruded polystyrene |

References

- Huedo, P.; Mulet, E.; López-Mesa, B. A model for the sustainable selection of building envelope assemblies. Environ. Impact Assess. Rev. 2016, 57, 63–77. [Google Scholar] [CrossRef]

- Tsai, W.H.; Lin, S.J.; Liu, J.Y.; Lin, W.R.; Lee, K.C. Incorporating life cycle assessments into building project decision-making: An energy consumption and CO2 emission perspective. Energy 2011, 36, 3022–3029. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Han, B.; Wang, R.; Yao, L.; Liu, H.; Wang, Z. Life cycle assessment of ceramic façade material and its comparative analysis with three other common façade materials. J. Clean. Prod. 2015, 99, 86–93. [Google Scholar] [CrossRef]

- Lei, J.; Yang, J.; Yang, E.-H. Energy performance of building envelopes integrated with phase change materials for cooling load reduction in tropical Singapore. Appl. Energy 2016, 162, 207–217. [Google Scholar] [CrossRef]

- Zhang, T.; Tan, Y.; Yang, H.; Zhang, X. The application of air layers in building envelopes: A review. Appl. Energy 2016, 165, 707–734. [Google Scholar] [CrossRef]

- Kofoworola, O.F.; Gheewala, S.H. Life cycle energy assessment of a typical office building in Thailand. Energy Build. 2009, 41, 1076–1083. [Google Scholar] [CrossRef]

- Ortiz, O.; Bonnet, C.; Bruno, J.C.; Castells, F. Sustainability based on LCM of residential dwellings: A case study in Catalonia, Spain. Build. Environ. 2009, 44, 584–594. [Google Scholar] [CrossRef]

- Mirrahimi, S.; Farid, M.; Chin, L. The effect of building envelope on the thermal comfort and energy saving for high-rise buildings in hot-humid climate. Renew. Sustain. Energy Rev. 2016, 53, 1508–1519. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Wang, Y. The quantification of the embodied impacts of construction projects on energy, environment, and society based on I-O LCA. Energy Policy 2011, 39, 6321–6330. [Google Scholar] [CrossRef]

- Gong, X.; Nie, Z.; Wang, Z.; Cui, S.; Gao, F.; Zuo, T. Life cycle energy consumption and carbon dioxide emission of residential building designs in Beijing: A comparative study. J. Ind. Ecol. 2012, 16, 576–587. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Díez, G.; Castells, F. The environmental impact of the construction phase: An application to composite walls from a life cycle perspective. Resour. Conserv. Recycl. 2010, 54, 832–840. [Google Scholar] [CrossRef]

- Radhi, H.; Sharples, S. Global warming implications of facade parameters: A life cycle assessment of residential buildings in Bahrain. Environ. Impact Assess. Rev. 2013, 38, 99–108. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Zabalza-Bribián, I.; Valero-Capilla, A.; Aranda-Usón, A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, L.; Zhang, L. Life cycle assessment of the air emissions during building construction process: A case study in Hong Kong. Renew. Sustain. Energy Rev. 2013, 17, 160–169. [Google Scholar] [CrossRef]

- Dowd, R.M.; Mourshed, M. Low carbon Buildings: Sensitivity of Thermal Properties of Opaque Envelope Construction and Glazing. Energy Procedia 2015, 75, 1284–1289. [Google Scholar] [CrossRef]

- Spanish Association for Standardization and Certification. UNE-EN 15804:2012+A1. Sustainability of Construction Works-Environmental Product Declarations. Core Rules for the Product Category of Construction Products; AENOR: Madrid, Spain, 2014. [Google Scholar]

- Sartori, I.; Hestnes, A.G.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Bilec, M.M.; Ries, R.J.; Matthews, H.S. Life-Cycle Assessment Modeling of Construction Processes for Buildings. J. Infrastruct. Syst. 2010, 16, 199–205. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di-Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Iddon, C.R.; Firth, S.K. Embodied and operational energy for new-build housing: A case study of construction methods in the UK. Energy Build. 2013, 67, 479–488. [Google Scholar] [CrossRef]

- Pal, S.K.; Takano, A.; Alanne, K.; Palonen, M.; Siren, K. A multi-objective life cycle approach for optimal building design: A case study in Finnish context. J. Clean. Prod. 2017, 143, 1021–1035. [Google Scholar] [CrossRef]

- Ottelé, M.; Perini, K.; Fraaij, A.L.A.; Haas, E.M.; Raiteri, R. Comparative life cycle analysis for green facades and living wall systems. Energy Build. 2011, 43, 3419–3429. [Google Scholar] [CrossRef]

- Chwieduk, D.A. Some aspects of energy efficient building envelope in high latitude countries. Solar Energy 2016, 133, 194–206. [Google Scholar] [CrossRef]

- Friess, W.A.; Rakhshan, K.; Hendawi, T.A.; Tajerzadeh, S. Wall insulation measures for residential villas in Dubai: A case study in energy efficiency. Energy Build. 2012, 44, 26–32. [Google Scholar] [CrossRef]

- Serrano, A.; Borreguero, A.M.; Garrido, I.; Rodríguez, J.F.; Carmona, M. Reducing heat loss through the building envelope by using polyurethane foams containing thermoregulating microcapsules. Appl. Therm. Eng. 2016, 103, 226–232. [Google Scholar] [CrossRef]

- Thormark, C. The effect of material choice on the total energy need and recycling potential of a building. Build. Environ. 2006, 41, 1019–1026. [Google Scholar] [CrossRef]

- Venkatarama-Reddy, B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Roh, S.; Tae, S.; Kim, R. Analysis of embodied environmental impacts of Korean apartment buildings considering major building materials. Sustainability 2018, 10, 1693. [Google Scholar] [CrossRef]

- Hastak, M.; Halpin, D.W. Assessment of life-cycle benefit-cost of composites in construction. J. Compos. Constr. 2000, 4, 103–111. [Google Scholar] [CrossRef]

- Hastak, M.; Mirmiran, A.; Richard, D. A framework for life-cycle cost assessment of composites in construction. J. Reinf. Plast. Compos. 2003, 22, 1409–1430. [Google Scholar] [CrossRef]

- Hu, M.; Kleijn, R.; Bozhilova-Kisheva, K.P.; Di-Maio, F. An approach to LCSA: The case of concrete recycling. Int. J. Life Cycle Assess. 2013, 18, 1793–1803. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards Life Cycle Sustainability Assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef]

- Kloepffer, W. Life Cycle Sustainability Assessment of Products. Int. J. Life Cycle Assess. 2008, 13, 89–95. [Google Scholar] [CrossRef]

- Erlandsson, M.; Borg, M. Generic LCA-methodology applicable for buildings, constructions and operation services—today practice and development needs. Build. Environ. 2003, 38, 919–938. [Google Scholar] [CrossRef]

- Kellenberger, D.; Althaus, H.-J. Relevance of simplifications in LCA of building components. Build. Environ. 2009, 44, 818–825. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Xing, S.; Xu, Z.; Jun, G. Inventory analysis of LCA on steel- and concrete-construction office buildings. Energy Build. 2008, 40, 1188–1193. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, X.; Yang, X.; Zhu, Y. BEPAS—A life cycle building environmental performance assessment model. Build. Environ. 2006, 41, 669–675. [Google Scholar] [CrossRef]

- Gervasio, H.; Dimova, S.; Pinto, A. Benchmarking the life-cycle environmental performance of buildings. Sustainability 2018, 10, 1454. [Google Scholar] [CrossRef]

- Seo, S.; Passer, A.; Zelezna, J.; Hajek, P.; Birgisdottir, H.; Rasmussen, F.N.; Lützkendorf, T.; Balouktsi, M.; Mistretta, M.; Oka, T.; et al. Overview of annex 57 results. In Evaluation of Embodied Energy and CO2eq for Building Construction (Annex 57); Yokoo, N., Yokoyama, K., Eds.; IEA: Tokio, Japan, 2016; pp. 1–90. ISBN 9784909107107. [Google Scholar]

- Gardezi, S.S.S.; Shafiq, N.; Zawawi, N.A.W.A.; Khamidi, M.F.; Farhan, S.A. A multivariable regression tool for embodied carbon footprint prediction in housing habitat. Habitat Int. 2016, 53, 292–300. [Google Scholar] [CrossRef]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A comparative cradle-to-gate life cycle assessment of mid-rise office building construction alternatives: laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Jia-Wen, T.; Chin-Siong, H.; Noor, Z.Z. Assessment of embodied energy and global warming potential of building construction using life cycle analysis approach: Case studies of residential buildings in Iskandar Malaysia. Energy Build. 2015, 93, 295–302. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Lei, S. The embodied energy and emissions of a high-rise education building: A quantification using process-based hybrid life cycle inventory model. Energy Build. 2012, 55, 790–798. [Google Scholar] [CrossRef]

- Sandanayake, M.; Lokuge, W.; Zhang, G.; Setunge, S.; Thushar, Q. Greenhouse gas emissions during timber and concrete building construction—A scenario based comparative case study. Sustain. Cities Soc. 2018, 38, 91–97. [Google Scholar] [CrossRef]

- Cass, D.; Mukherjee, A. Calculation of greenhouse gas emissions for highway construction operations by using a hybrid life-cycle assessment approach: case study for pavement operations. J. Constr. Eng. Manag. 2011, 137, 1015–1026. [Google Scholar] [CrossRef]

- Moretti, L.; Mandrone, V.; Andrea, A.D.; Caro, S. Evaluation of the environmental and human health impact of road construction activities. J. Clean. Prod. 2018, 172, 1004–1013. [Google Scholar] [CrossRef]

- Smith, S.H.; Durham, S.A. A cradle to gate LCA framework for emissions and energy reduction in concrete pavement mixture design. Int. J. Sustain. Built Environ. 2016, 5, 23–33. [Google Scholar] [CrossRef]

- Moretti, L.; Mandrone, V.; Andrea, A.D.; Caro, S. Comparative “from cradle to gate” life cycle assessments of hot mix asphalt (HMA) materials. Sustainability 2017, 9, 400. [Google Scholar] [CrossRef]

- Asdrubali, F.; Baldassarri, C.; Fthenakis, V. Life cycle analysis in the construction sector: Guiding the optimization of conventional Italian buildings. Energy Build. 2013, 64, 73–89. [Google Scholar] [CrossRef]

- Bovea, M.D.; Díaz-Albo, E.; Gallardo, A.; Colomer, F.J.; Serrano, J. Environmental performance of ceramic tiles: Improvement proposals. Mater. Des. 2010, 31, 35–41. [Google Scholar] [CrossRef]

- Ecoinvent Centre. Home Page of Ecoinvent, Dübendorf, Suiza. 2007. Available online: https://www.ecoinvent.org/database/introduction-to-ecoinvent-3/introduction-to-ecoinvent-version-3.html (accessed on 2 August 2018).

- Heinonen, J.; Säynäjoki, A.; Junnonen, J.M.; Pöyry, A.; Junnila, S. Pre-use phase LCA of a multi-story residential building: Can greenhouse gas emissions be used as a more general environmental performance indicator? Build. Environ. 2016, 95, 116–125. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef] [PubMed]

- Thiers, S.; Peuportier, B. Energy and environmental assessment of two high energy performance residential buildings. Build. Environ. 2012, 51, 276–284. [Google Scholar] [CrossRef]

- Ferrández-García, A.; Ibáñez-Forés, V.; Bovea, M.D. Eco-efficiency analysis of the life cycle of interior partition walls: A comparison of alternative solutions. J. Clean. Prod. 2016, 112, 649–665. [Google Scholar] [CrossRef]

- ITEC, Metabase—Banco BEDEC 2017. ITEC Web. 2017. Available online: https://metabase.itec.cat/vide/es/bedec (accessed on 3 January 2017).

- Pre’ Consultants, SimaPro Database Manual-Methods Library, California, USA. 2018. Available online: https://www.pre-sustainability.com/download/manuals/DatabaseManualMethods.pdf (accessed on 2 August 2018).

- Potting, J.; Klöpffer, W.; Seppälä, J.; Norris, G.; Goedkoop, M. Climate Change, Stratospheric Ozone Depletion, Photooxidant Formation, Acidification, and Eutrophication. In Life-Cycle Impact Assessement: Striving towards Best Practice; Udo-de-Haes, H.A., Finnveden, G., Goedkoop, M., Hauschild, M., Hertwich, E., Hofstetter, P., Jolliet, O., Klöpffer, W., Krewitt, W., Lindeijer, E., Eds.; SETAC: Florida City, FL, USA, 2002; pp. 65–100. ISBN 1880611546. [Google Scholar]

- Lindeijer, E.; Müller-Wenk, R.; Steen, B. Impact Assessment of Resources and Land Use. In Life-Cycle Impact Assessement: Striving Towards Best Practice; Udo-de-Haes, H.A., Finnveden, G., Goedkoop, M., Hauschild, M., Hertwich, E., Hofstetter, P., Jolliet, O., Klöpffer, W., Krewitt, W., Lindeijer, E., et al., Eds.; SETAC: Florida City, FL, USA, 2015; pp. 11–64. ISBN 1880611546. [Google Scholar]

- Ministerio de Agricultura y Pesca, Alimentación y Medio Ambiente, Sustancias que Agotan la capa de Ozono. 2017. Available online: http://www.mapama.gob.es/es/calidad-y-evaluacion-ambiental/temas/atmosfera-y-calidad-del-aire/emisiones/prob-amb/agotadores_capa_ozono.aspx (accessed on 17 May 2017).

- Jolliet, O.; Fantke, P. Human Toxicity. In Life Cycle Impact Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 75–96. ISBN 978-94-017-9743-6. [Google Scholar]

- Simpple, Manual de Usuario LCA Manager Versión 1.3, Tarragona, Spain. 2010. Available online: http://www.simpple.com/wp-content/uploads/2013/12/Manual_LCAm.pdf (accessed on 2 August 2018).

- Spanish Association for Standardization and Certification. UNE-EN ISO 14040. Environmental Management. Life Cycle Assessment-Principles and Framework; AENOR: Madrid, Spain, 2006. [Google Scholar]

- Departament d´Estadística. Ajuntament de Barcelona, Características de los Edificios Destinados Principalmente a Vivienda. 2011. Available online: http://www.bcn.cat/estadistica/castella/dades/timm/censedif/a2011/princhabit/t21.htm (accessed on 5 April 2018).

- AMB, Ordenances D’aplicació a Tota la Zona Metropolitana. 2010. Available online: http://www3.amb.cat/normaurb2004/Docs/Edificacio/OME-T2-C1-S1.pdf (accessed on 13 May 2017).

- CTE, Documento Básico HE Ahorro de Energía, Boletín Oficial del Estado, Spain. 2013. Available online: https://www.codigotecnico.org/images/stories/pdf/ahorroEnergia/DBHE.pdf (accessed on 2 August 2018).

- Spanish Association for Standardization and Certification. UNE-EN 771-1. Specification for Masonry Units. Part 1: Clay Masonry Units; AENOR: Madrid, Spain, 2011. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 771-3. Specification for Masonry Units. Part 3: Aggregate Concrete Masonry Units (Dense and Lightweight Aggregates); AENOR: Madrid, Spain, 2011. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 520:2005+A1. Gypsum Plasterboards. Definitions, Requirements and Test Methods; AENOR: Madrid, Spain, 2010. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 13162:2013+A1. Thermal Insulating Products for Building Applications. Manufactured Products of Mineral Wool (MW). Specification; AENOR: Madrid, Spain, 2015. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 13163:2013+A1. Thermal Insulating Products for Building Applications. Manufactured Products of Expanded Polystyrene (EPS). Specification; AENOR: Madrid, Spain, 2013. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 13164:2013+A1. Thermal Insulating Products for Building Applications. Products Manufactured from Extruded Polystyrene (XPS). Specification; AENOR: Madrid, Spain, 2015. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 14315. Thermal Insulating Products for Building Applications. Products of Rigid Polyurethane Foam and Polyisocyanurate Projected In Situ. Part 1: Specifications for Rigid Foam Projection Systems before Installation; AENOR: Madrid, Spain, 2013. [Google Scholar]

- Spanish Association for Standardization and Certification. UNE-EN 998-1:2010. Specification for Mortar for Masonry. Part 1: Rendering and Plastering Mortar; AENOR: Madrid, Spain, 2010. [Google Scholar]

- CTE WEB, Código Técnico la Edificación. 2007. Available online: http://cte-web.iccl.es/ (accessed on 8 May 2017).

- Spanish Association for Standardization and Certification. UNE-EN 13501-1:2007+A1:2010. Fire Classification of Construction Products and Building Elements. Part 1: Classification Using Data from Reaction to Fire Tests; AENOR: Madrid, Spain, 2010. [Google Scholar]

- ATEPA, Libro Blanco del Poliuretano Proyectado. Guía de Ventajas y Soluciones de Espuma Rígida de Poliuretano Proyectado Para Aislamiento Térmico, Acústico e Impermeabilización, Conforme al CTE, Asociación Técnica del Poliuretano Aplicado, Madrid, Spain. 2010. Available online: http://www.atepa.org/PUR.pdf (accessed on 2 August 2018). [CrossRef]

- IDAE, Soluciones de Aislamiento con Poliestireno Expandido (EPS), Instituto Para la Diversificación y Ahorro de Energía, Madrid, Spain. 2008. Available online: http://www.idae.es/publicaciones/soluciones-de-aislamiento-con-poliestireno-expandido-eps (accessed on 2 August 2018).

- IDAE, Soluciones de Aislamiento con Poliestireno Extruido (XPS), Instituto Para la Diversificación y Ahorro de Energía, Madrid, Spain. 2008. Available online: http://www.idae.es/publicaciones/soluciones-de-aislamiento-con-poliestireno-extruido-xps (accessed on 2 August 2018).

- Ministerio de Fomento, Inspección y Seguridad en el Transporte—Pesos y Dimensiones. 2017. Available online: https://www.fomento.gob.es/MFOM/LANG_CASTELLANO/DIRECCIONES_GENERALES/TRANSPORTE_TERRESTRE/IGT/PESO/ (accessed on 12 January 2017).

- Hauschild, M.Z.; Huijbregts, M.A.J. Introducing the Life Cycle Impact Assessment. In Life Cycle Assessment; Hauschild, M.Z., Huijbregts, M.A.J., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 1–16. [Google Scholar] [CrossRef]

- Morales-Güeto, J. El Proceso de Elaboración Cerámico: Tecnología de los Materiales Cerámicos, 1st ed.; Ediciones Díaz de Santos: Madrid, Spain, 2005; pp. 237–321. ISBN 978-8479787226. [Google Scholar]

- Damtoft, J.S.; Lukasik, J.; Herfort, D.; Sorrentino, D.; Gartner, E.M. Sustainable development and climate change initiatives. Cem. Concr. Res. 2008, 38, 115–127. [Google Scholar] [CrossRef]

- Bustillo-Revuelta, M. Hormigones y Morteros; Fueyo Editores: Madrid, Spain, 2008; pp. 104–166. ISBN 978-84-935279-1-4. [Google Scholar]

- EEA, Acidificación. El Medio Ambiente en Europa: Segunda Evaluación; EEA, Ed.; European Environment Agency: Copenhagen, Denmark, 1998; pp. 72–93. Available online: https://www.eea.europa.eu/es/publications/92-828-3351-8/4es.pdf/view (accessed on 2 August 2018).

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Broun, R.; Menzies, G.F. Life cycle energy and environmental analysis of partition wall systems in the UK. Procedia Eng. 2011, 21, 864–873. [Google Scholar] [CrossRef]

- Boesch, M.E.; Koehler, A.; Hellweg, S. Model for cradle-to-gate life cycle assessment of clinker production. Environ. Sci. Technol. 2009, 43, 7578–7583. [Google Scholar] [CrossRef] [PubMed]

- Centro Nacional de Referencia Sobre Contaminantes Orgánicos Persistentes, Hornos de Cemento que Queman Desechos Peligrosos. 2018. Available online: http://www.cnrcop.es/gc/iniciativas-no-gubernamentales/mejores-tecnicas-disponibles-mtd-y-mejores-practicas-ambientales-mpa/mejores-tecnicas-disponibles-mtd-y-mejores-practicas-ambientales-mpa/hornos-de-cemento-que-queman-desechos-peligrosos/ (accessed on 13 January 2018).

- Utama, N.A.; Mclellan, B.C.; Gheewala, S.H.; Ishihara, K.N. Embodied impacts of traditional clay versus modern concrete houses in a tropical regime. Build. Environ. 2012, 57, 362–369. [Google Scholar] [CrossRef]

- Wei, W.; Larrey-Lassalle, P.; Faure, T.; Dumoulin, N.; Roux, P.; Mathias, J.D. How to conduct a proper sensitivity analysis in life cycle assessment: Taking into account correlations within LCI data and interactions within the LCA calculation model. Environ. Sci. Technol. 2015, 49, 377–385. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Gilijamse, W.; Ragas, A.M.J.; Reijnders, L. Evaluating uncertainty in environmental life-cycle assessment. A case study comparing two insulation options for a Dutch one-family dwelling. Environ. Sci. Technol. 2003, 37, 2600–2608. [Google Scholar] [CrossRef] [PubMed]

- Lloyd, S.M.; Ries, R. Characterizing, propagating, and analyzing uncertainty in life-cycle assessment. J. Ind. Ecol. 2007, 11, 161–181. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A. Life cycle primary energy analysis of residential buildings. Energy Build. 2010, 42, 210–220. [Google Scholar] [CrossRef]

- Pushkar, S. Using eco-indicator 99 to evaluate building technologies under life cycle assessment uncertainties. J. Archit. Eng. 2014, 20, 04013010. [Google Scholar] [CrossRef]

- Noshadravan, A.; Wildnauer, M.; Gregory, J.; Kirchain, R. Comparative pavement life cycle assessment with parameter uncertainty. Transp. Res. Part D Transp. Environ. 2013, 25, 131–138. [Google Scholar] [CrossRef]

- Groen, E.A.; Bokkers, E.A.M.; Heijungs, R.; de-Boer, I.J.M. Methods for global sensitivity analysis in life cycle assessment. Int. J. Life Cycle Assess. 2017, 22, 1125–1137. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Hooftman, N.; Oliveira, L.; Messagie, M.; Coosemans, T.; Mierlo, J.V. Environmental analysis of petrol, diesel and electric passenger cars in a Belgian urban setting. Energies 2016, 9, 84. [Google Scholar] [CrossRef]

- Höltl, A.; Macharis, C.; De-Brucker, K. Pathways to decarbonise the European car fleet: A scenario analysis using the backcasting approach. Energies 2018, 11, 20. [Google Scholar] [CrossRef]

- Longo, M.; Yaïci, W.; Zaninelli, D. “Team play” between renewable energy sources and vehicle fleet to decrease air pollution. Sustainability 2016, 8, 27. [Google Scholar] [CrossRef]

| EW | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U-value (W/m2K) | 0.65 | 0.68 | 0.63 | 0.68 | 0.65 | 0.64 | 0.61 | 0.7 | 0.66 | 0.61 | 0.61 | 0.67 | 0.62 | 0.61 | 0.69 | 0.62 | 0.64 | 0.70 | 0.68 | 0.69 |

| Thickness (cm) | 26.3 | 24.5 | 26.0 | 27.0 | 26.3 | 27.0 | 25.0 | 23.5 | 28.0 | 26.0 | 24.5 | 23.8 | 25.8 | 26.5 | 25.3 | 25.8 | 27.5 | 26.5 | 25.8 | 25.5 |

| Element of Wall * | Type * | Material * | ** λ (W/mK) | *** Fire Resistance | Density (kg/m3) | Characteristics |

|---|---|---|---|---|---|---|

| EL | CCP | PB | 0.35 | A-1 | 780 ** | High-density (HD) CCP with faced finish (FF) joined with industrial mor M7.5; category I UNE-EN 771-1 [71]. |

| LFPp | 0.23 | A-1 | 850 *** | HD CCP with coated finish (CF) joined with mor 1:2:10 of cement (CEM II); category I UNE-EN 771-1 [71]. | ||

| MP | MB | 1.18 | A-1 | 520–1230 ** | MB pieces with CF joined with mixed mor 1:2:10; category I UNE-EN 771-3 [72]. | |

| SMB | 1.18 | A-1 | 520–1230 ** | SMB pieces with CF joined with mixed mor 1:2:10; category I UNE-EN 771-3 [72]. | ||

| IL | CCP | HBs | 0.32 | A-1 | 770 ** | Low-density (LD) partitions with CF joined with mixed mor 1:2:10; UNE-EN 771-1 [71]. |

| HBd | 0.32 | A-1 | 770 ** | LD partitions with CF joined with mixed mor 1:2:10; UNE-EN 771-1 [71]. | ||

| LFP | 0.29 | A-1 | 650 ** | LD partitions of 700 × 500 mm and variable thickness with CF joined with gypsum-based adhesive; UNE-EN 771-1 [71]. | ||

| LPB | LPB | 0.25 | A-2 S-1, d0 | 750–900 ** | Self-supporting structure of galvanized steel profiles (GP), uprights each 400 mm (60 mm width), channels (60 mm width) with laminated plasterboard (G); UNE-EN 520 [73]. | |

| TI | Natural wool | RW | 0.035 | A-1 | 50 **** | Rigid plate positioned without adhering, UNE-EN 13162 [74]. |

| GW | 0.036 | A-1 | 40 **** | Semi-rigid plate positioned without adhering; UNE-EN 13162 [74]. | ||

| Petroleum | EPS | 0.036 | B-S1, d0 | 10–50 ** | Smooth surface faces and smooth edge, without adhering; UNE-EN 13163 [75]. | |

| XPS | 0.036 | B-S1, d0 | 25–50 ** | Smooth surface faces and smooth edge, without adhering; UNE-EN 13164 [76]. | ||

| SPF | 0.028 | B-S1, d0 | 30–60 ** | Spray polyurethane foam. Amorphous and projected; UNE-EN 14315-1 [77]. | ||

| Finishes | mor | 0.55 | A-1 | 1000–1300 ** | Mor CSIII W1 of 1.5 cm thickness. Mor CSIII W0 of 1.5 cm thickness; UNE-EN 998-1 [78]. | |

| G | 0.25 | A-2 S-1, d0 | 750–900 ** | Adhered with gypsum base over its entire surface [73]. | ||

| Stage | Element | Material/Process | External Walls | Ecoinvent Process/Material | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | ||||

| A1–A3 | EL | Ceramic clay pieces (kg) | 91.6 | 130.6 | - | - | 91.6 | 109.4 | - | 114.5 | 117.5 | 91.6 | 109.4 | - | 119.9 | - | - | - | 91.6 | 114.5 | 130.6 | - | Brick production, RER |

| Mortar pieces (kg) | - | - | 149.5 | 126.1 | - | - | 126.1 | - | - | - | - | 126.1 | 217.2 | 149.5 | 217.2 | - | - | - | 149.5 | Concrete block production, RER | |||

| Mortar (kg) | 42.3 | 125.5 | 49.8 | 44.6 | 42.3 | 115.7 | 44.6 | 104.6 | 112.0 | 42.3 | 115.7 | 44.6 | 100.9 | 77.1 | 49.8 | 77.1 | 42.3 | 104.6 | 125.5 | 49.8 | Cement mortar production, CH | ||

| IL | Ceramic clay pieces (kg) | 51.6 | 37.4 | 30.5 | 70.9 | 51.6 | 70.9 | 49.5 | - | 50.8 | 50.8 | 49.5 | - | 45.8 | 49.5 | 36.3 | - | 64.3 | 70.9 | - | 30.5 | Light clay brick production, DE | |

| Mortar (kg) | - | 43.3 | 41.3 | 52.8 | - | 52.8 | 58.6 | - | 37.0 | 37.0 | 58.6 | - | - | 58.6 | - | 40.2 | 52.8 | - | 41.3 | Cement mortar production, CH | |||

| Laminated plasterboard (kg) | 9.5 | - | - | - | 9.5 | - | - | 13.3 | - | - | - | 9.5 | 9.5 | 9.5 | 9.5 | - | - | 9.5 | - | Gypsum plasterboard production, RoW | |||

| Gypsum (kg) | 13.5 | - | - | - | 13.5 | - | - | 0.8 | - | - | - | 0.8 | 9.7 | 7.2 | 0.8 | - | - | 0.8 | - | Stucco production, CH | |||

| Steel (kg) | - | - | - | - | - | - | - | 2.3 | - | - | - | 2.3 | - | - | - | 2.3 | - | - | 2.3 | - | Steel production, converter, unalloyed, RER | ||

| Zinc (m2) | - | - | - | - | - | - | - | 1.1 | - | - | - | 1.1 | - | - | - | 1.1 | - | - | 1.1 | - | Zinc coating, coils, RER | ||

| TI | RW (kg) | - | - | - | - | - | - | - | - | 1.05 | 1.31 | 1.58 | 2.10 | - | - | - | - | - | - | - | - | Rock wool production, CH | |

| GW (kg) | - | - | - | - | 0.84 | 1.05 | 1.68 | 1.26 | - | - | - | - | - | - | - | - | - | - | - | - | Glass wool mat production, CH | ||

| EPS (kg) | 0.63 | 0.79 | 1.26 | 0.95 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Polystyrene foam slab production, RER | ||

| XPS (kg) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.67 | 0.67 | 1.00 | 1.18 | Polystyrene production, extruded, CO2 blown | ||

| SPF (kg) | - | - | - | - | - | - | - | - | - | - | - | - | 0.72 | 1.08 | 0.90 | 1.26 | - | - | - | - | Polyurethane production, rigid foam, RER | ||

| A4 | EW | Lorry operation (tkm) | 28.0 | 32.1 | 26.9 | 30.0 | 28.1 | 33.9 | 27.6 | 25.6 | 31.2 | 24.2 | 31.3 | 20.9 | 33.1 | 39.9 | 29.8 | 33.2 | 26.1 | 34.0 | 27.9 | 27.0 | Transport, freight, lorry 16–32 metric ton, EURO4 |

| A5 | EW | Machine use (unit) (10E-7) | 1.90 | 3.07 | 2.48 | 2.68 | 1.90 | 3.18 | 2.55 | 2.15 | 2.89 | 2.03 | 3.04 | 1.68 | 2.61 | 3.67 | 2.30 | 2.80 | 2.17 | 3.12 | 2.45 | 2.47 | Building machine production |

| Energy (kWh) (10E-1) | 1.22 | 3.67 | 2.05 | 2.18 | 1.22 | 3.67 | 2.29 | 2.30 | 3.26 | 1.77 | 3.78 | 1.05 | 2.41 | 3.05 | 1.30 | 1.79 | 1.84 | 3.44 | 2.75 | 2.05 | Market for electricity, low voltage, ES | ||

| CC | ADP | HTP | AP | EP | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| a | d1 | R2 | a | d1 | R2 | a | d1 | R2 | a | d1 | R2 | a | d1 | R2 | |

| CCP | 0.225 | 1.544 | 0.99 | 0.0008 | 0.0320 | 0.99 | 0.030 | 0.380 | 0.99 | 0.0006 | 0.0022 | 0.99 | 0.0002 | 0.0015 | 0.99 |

| MP | 0.191 | −0.080 | 0.99 | 0.0006 | 0.0000 | 0.99 | 0.042 | 0.042 | 0.99 | 0.0006 | 0.0000 | 0.99 | 0.0002 | 0.0000 | 1.00 |

| b | d2 | R2 | b | d2 | R2 | b | d2 | R2 | b | d2 | R2 | b | d2 | R2 | |

| HB | 0.160 | 1.830 | 0.99 | 0.001 | −0.011 | 0.98 | 0.041 | 0.431 | 0.97 | 0.0005 | 0.0020 | 0.99 | 0.0002 | −0.0020 | 0.96 |

| LPB | 0.354 | 9.210 | 1.00 | 0.003 | 0.074 | 1.00 | 0.055 | 8.194 | 1.00 | 0.0011 | 0.2630 | 1.00 | 0.0005 | 0.0650 | 1.00 |

| LFP+mor | 0.155 | 1.530 | 1.00 | 0.001 | −0.009 | 1.00 | 0.042 | −0.361 | 1.00 | 0.0005 | 0.0016 | 1.00 | 0.0002 | −0.0019 | 1.00 |

| LFPp+G | 0.118 | 3.120 | 0.99 | 0.001 | 0.020 | 0.99 | 0.036 | 0.791 | 0.99 | 0.0004 | 0.0230 | 0.99 | 0.0002 | 0.0041 | 0.99 |

| c | d3 | R2 | c | d3 | R2 | c | d3 | R2 | c | d3 | R2 | c | d3 | R2 | |

| XPS | 3.880 | 0.000 | 1.00 | 0.043 | 0.000 | 1.00 | 0.548 | 0.000 | 1.00 | 0.0140 | 0.0000 | 1.00 | _ | _ | _ |

| SPF | 4.356 | 0.000 | 1.00 | 0.043 | 0.000 | 1.00 | 0.421 | 0.000 | 1.00 | 0.0190 | 0.0000 | 1.00 | _ | _ | _ |

| EPS | 4.470 | 0.000 | 0.99 | 0.048 | 0.000 | 0.99 | 0.456 | 0.000 | 0.99 | 0.0180 | 0.0000 | 0.99 | _ | _ | _ |

| GW | 1.390 | 0.000 | 1.00 | 0.013 | 0.000 | 1.00 | 1.087 | 0.000 | 1.00 | 0.0100 | 0.0000 | 1.00 | _ | _ | _ |

| RW | 1.171 | 0.000 | 1.00 | 0.008 | 0.000 | 1.00 | 1.127 | 0.000 | 1.00 | 0.0099 | 0.0000 | 1.00 | _ | _ | _ |

| Motorization | Lorry (−50%) | Lorry (Original) | Lorry (+50%) | Lorry (200 km) |

|---|---|---|---|---|

| Euro 4 | Scenarios A | Scenarios B * | Scenarios C | Scenarios D |

| Euro 5 | Scenarios E | Scenarios F | Scenarios G | Scenarios H |

| Euro 6 | Scenarios I | Scenarios J | Scenarios K | Scenarios L |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gámez-García, D.C.; Gómez-Soberón, J.M.; Corral-Higuera, R.; Saldaña-Márquez, H.; Gómez-Soberón, M.C.; Arredondo-Rea, S.P. A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements. Sustainability 2018, 10, 2748. https://doi.org/10.3390/su10082748

Gámez-García DC, Gómez-Soberón JM, Corral-Higuera R, Saldaña-Márquez H, Gómez-Soberón MC, Arredondo-Rea SP. A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements. Sustainability. 2018; 10(8):2748. https://doi.org/10.3390/su10082748

Chicago/Turabian StyleGámez-García, Diana Carolina, José Manuel Gómez-Soberón, Ramón Corral-Higuera, Héctor Saldaña-Márquez, María Consolación Gómez-Soberón, and Susana Paola Arredondo-Rea. 2018. "A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements" Sustainability 10, no. 8: 2748. https://doi.org/10.3390/su10082748

APA StyleGámez-García, D. C., Gómez-Soberón, J. M., Corral-Higuera, R., Saldaña-Márquez, H., Gómez-Soberón, M. C., & Arredondo-Rea, S. P. (2018). A Cradle to Handover Life Cycle Assessment of External Walls: Choice of Materials and Prognosis of Elements. Sustainability, 10(8), 2748. https://doi.org/10.3390/su10082748