Characterizing the Difference between Indirect and Direct CO2 Emissions: Evidence from Korean Manufacturing Industries, 2004–2010

Abstract

1. Introduction

2. Literature Review

3. Methodology

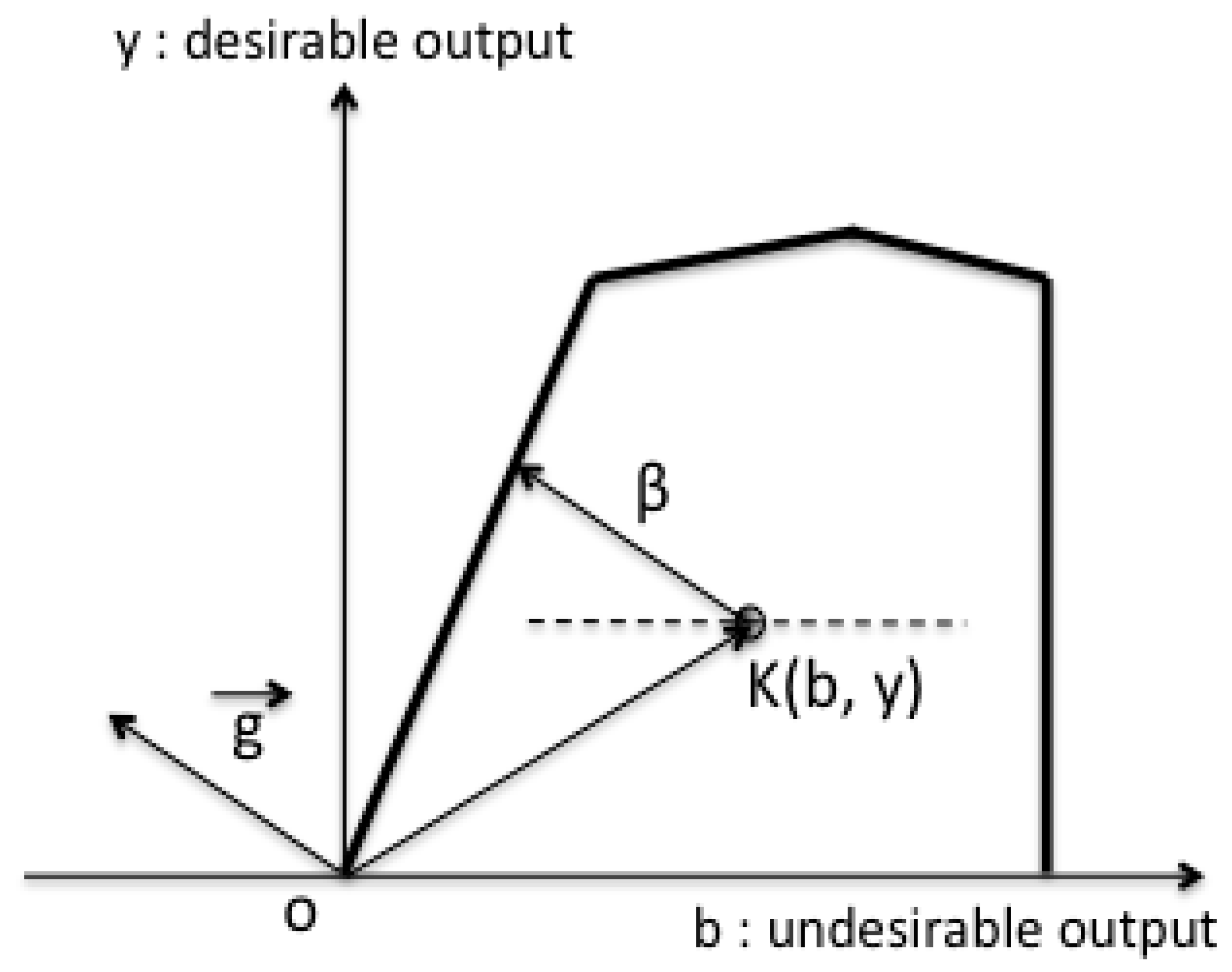

3.1. The Directional Distance Function

3.2. ML Index

3.3. Calculation of DDF

4. Description of the Data

5. Empirical Results

5.1. The Measurement of DDF

5.2. ML Index by Industrial Sector

5.3. Trend of the ML Index

5.4. Innovative Industries

6. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nishitani, K.; Kaneko, S.; Komatsu, S.; Fujii, H. How does a firm’s management of greenhouse gas emissions influence its economic performance? Analyzing effects through demand and productivity in Japanese manufacturing firms. J. Prod. Anal. 2014, 42, 355–366. [Google Scholar] [CrossRef]

- Korea Energy Economics Institute (KEEI). World Energy Market Insight 16-5; KEEI: Ulsan, Korea, 2016. [Google Scholar]

- Song, T.H.; Lim, K.M.; Yoo, S.H. Estimating the public’s value of implementing the CO2 emissions trading scheme in Korea. Energy Policy 2015, 83, 82–86. [Google Scholar] [CrossRef]

- Coase, R.H. The problem of social cost. In Classic Papers in Natural Resource Economics; Palgrave Macmillan: London, UK, 1960; pp. 87–137. [Google Scholar]

- WBCSD and WRI Revised 2013. A Corporate Accounting and Reporting Standard; The Greenhouse Gas Protocol: Washington, DC, USA, 2013. [Google Scholar]

- Oh, I.; Yeo, Y.; Lee, J.D. Efficiency versus Equality: Comparing Design Options for Indirect Emissions Accounting in the Korean Emissions Trading Scheme. Sustainability 2015, 7, 14982–15002. [Google Scholar] [CrossRef]

- Oh, D.H.; Heshmati, A. A sequential Malmquist-Luenberger productivity index: Environmentally sensitive productivity growth considering the progressive nature of technology. Energy Econ. 2010, 32, 1345–1355. [Google Scholar] [CrossRef]

- Jeong, G.; Lee, Y.J. An Analysis of Green Innovation Capability and Policy for Fostering Green Innovation; STEPI: Sejong, Korea, 2011. [Google Scholar]

- Oh, D.H. A meta-frontier approach for measuring an environmentally sensitive productivity growth index. Energy Econ. 2010, 32, 146–157. [Google Scholar] [CrossRef]

- Chung, Y.H.; Färe, R.; Grosskopf, S. Productivity and Undesirable Outputs: A Directional Distance Function Approach. J. Environ. Manag. 1997, 51, 229–240. [Google Scholar] [CrossRef]

- Piot-Lepetit, I.; Le Moing, M. Productivity and environmental regulation: The effect of the nitrates directive in the French pig sector. Environ. Resour. Econ. 2007, 38, 433–446. [Google Scholar] [CrossRef]

- Yu, M.M.; Hsu, S.H.; Chang, C.C.; Lee, D.H. Productivity growth of Taiwan’s major domestic airports in the presence of aircraft noise. Transp. Res. Part E 2008, 44, 543–554. [Google Scholar] [CrossRef]

- He, F.; Zhang, Q.; Lei, J.; Fu, W.; Xu, X. Energy efficiency and productivity change of China’s iron and steel industry: Accounting for undesirable outputs. Energy Policy 2013, 54, 204–213. [Google Scholar] [CrossRef]

- Chung, Y.; Heshmati, A. Measurement of environmentally sensitive productivity growth in Korean industries. J. Clean. Prod. 2015, 104, 380–391. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Yang, G.L. A framework for measuring global Malmquist–Luenberger productivity index with CO2 emissions on Chinese manufacturing industries. Energy 2016, 115, 840–856. [Google Scholar] [CrossRef]

- Fan, M.; Shao, S.; Yang, L. Combining global Malmquist-Luenberger index and generalized method of moments to investigate industrial total factor CO2 emission performance: A case of Shanghai (China). Energy Policy 2015, 79, 189–201. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A. Accounting for air pollution emissions in measures of state manufacturing productivity growth. J. Reg. Sci. 2001, 41, 381–409. [Google Scholar] [CrossRef]

- Jeon, B.M.; Sickles, R.C. The Role of Environmental Factors in Growth Accounting. J. Appl. Econ. 2004, 19, 567–591. [Google Scholar] [CrossRef]

- Yörük, B.K.; Zaum, O. Productivity growth in OECD countries: A comparison with Malmquist indices. J. Comp. Econ. 2005, 33, 401–420. [Google Scholar] [CrossRef]

- Kumar, S. Environmentally sensitive productivity growth: A global analysis using Malmquist-Luenberger index. Ecol. Econ. 2006, 56, 280–293. [Google Scholar] [CrossRef]

- Bing, W.; Yanrui, W.; Pengfei, Y. Environmental Regulation and Total Factor Productivity Growth: An Empirical Study of the APEC Economies. Econ. Res. J. 2008, 5, 19–33. [Google Scholar]

- Aparicio, J.; Barbero, J.; Kapelko, M.; Pastor, J.T.; Zofío, J.L. Testing the consistency and feasibility of the standard Malmquist-Luenberger index: Environmental productivity in world air emissions. J. Environ. Manag. 2017, 196, 148–160. [Google Scholar] [CrossRef] [PubMed]

- Scotti, D.; Volta, N. An empirical assessment of the CO2-sensitive productivity of European airlines from 2000 to 2010. Transp. Res. Part D Transp. Environ. 2015, 37, 137–149. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, H.; Bressers, H.T.A.; Buchanan, K.S. Productivity growth and environmental regulations—Accounting for undesirable outputs: Analysis of China’s thirty provincial regions the Malmquist-Luenberger index. Ecol. Econ. 2011, 70, 2369–2379. [Google Scholar] [CrossRef]

- Munisamy, S.; Arabi, B. Eco-efficiency change in power plants: Using a slacks-based measure for the meta-frontier Malmquist–Luenberger productivity index. J. Clean. Prod. 2015, 105, 218–232. [Google Scholar] [CrossRef]

- Oh, D.H. A global Malmquist-Luenberger productivity index. J. Prod. Anal. 2010, 34, 183–197. [Google Scholar] [CrossRef]

- Arabi, B.; Munisamy, S.; Emrouznejad, A.; Shadman, F. Power industry restructuring and eco-efficiency changes: A new slacks-based model in Malmquist-Luenberger Index measurement. Energy Policy 2014, 68, 132–145. [Google Scholar] [CrossRef]

- Yu, C.; Shi, L.; Wang, Y.; Chang, Y.; Cheng, B. The eco-efficiency of pulp and paper industry in China: An assessment based on slacks-based measure and Malmquist-Luenberger index. J. Clean. Prod. 2016, 127, 511–521. [Google Scholar] [CrossRef]

- Song, M.; Zheng, W.; Wang, S. Measuring green technology progress in large-scale thermoelectric enterprises based on Malmquist-Luenberger life cycle assessment. Resour. Conserv. Recycl. 2017, 122, 261–269. [Google Scholar] [CrossRef]

- Du, J.; Chen, Y.; Huang, Y. A modified Malmquist-luenberger productivity index: Assessing environmental productivity performance in China. Eur. J. Oper. Res. 2018, 269, 171–187. [Google Scholar] [CrossRef]

- Walheer, B.; Zhang, L. Profit Luenberger and Malmquist-Luenberger indexes for multi-activity decision-making units: The case of the star-rated hotel industry in China. Tour. Manag. 2018, 69, 1–11. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Pasurka, C.A. Environmental production functions and environmental directional distance functions. Energy 2007, 32, 1055–1066. [Google Scholar] [CrossRef]

- Lee, J.D.; Park, J.B.; Kim, T.Y. Estimation of the shadow prices of pollutants with production/environmental inefficiency taken into account: A nonparametric directional distance function approach. J. Environ. Manag. 2002, 64, 365–375. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Theory and application of directional distance functions. J. Prod. Anal. 2000, 13, 93–103. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S. Modeling undesirable factors in efficiency evaluation: Comment. Eur. J. Oper. Res. 2004, 157, 242–245. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Lovell, C.A.K.; Pasurka, C. Multilateral productivity comparisons when some outputs are undesirable: A nonparametric approach. Rev. Econ. Stat. 1989, 71, 90–98. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Lindgren, B.; Roos, P. Productivity developments in Swedish hospitals: A Malmquist output index approach. In Data Envelopment Analysis: Theory, Methodology, and Applications; Springer: Dordrecht, The Netherlands, 1994; pp. 253–272. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Lewin, A.Y.; Seiford, L.M. Data Envelopment Analysis: Theory, Methodology, and Applications; Springer Science & Business Media: New York, NY, USA, 2013. [Google Scholar]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Hong, J.; Choi, N.; Kim, P. An Analysis of the Economic Effects of R&D Investment in the IT Industry. J. Korean Inst. Commun. Inf. Sci. 2012, 37, 837–848. [Google Scholar]

- Shestalova, V. Sequential Malmquist indices of productivity growth: An application to OECD industrial activities. J. Prod. Anal. 2003, 19, 211–226. [Google Scholar] [CrossRef]

- Oh, Y.; Oh, D.H.; Lee, J.D. A sequential global Malmquist productivity index: Productivity growth index for unbalanced panel data considering the progressive nature of technology. Empir. Econ. 2017, 52, 1651–1674. [Google Scholar] [CrossRef]

| Mean | S.D. | Median | Max | Min | |

|---|---|---|---|---|---|

| Value-added (in 100 billion KRW) | 158.3 | 125.8 | 125.0 | 471.0 | 12.8 |

| Total CO2 emissions (in thousands tCO2e) | 14,222.5 | 19,973.5 | 6995.3 | 287,108.6 | 1578.2 |

| Direct CO2 emissions (in thousands tCO2e) | 9249.3 | 16,724.4 | 1862.1 | 179,060.8 | 145.0 |

| Energy consumption (in thousands TOE) | 5917.9 | 11,387.3 | 1645.6 | 52,937.9 | 371.3 |

| Labor (thousands) | 342.2 | 639.8 | 121.8 | 2824.4 | 8.7 |

| Capital stock (in 100 billion KRW) | 80.7 | 70.7 | 52.5 | 345.6 | 11.3 |

| Industry | Value-Added (in 100 Billion KRW) | CO2 Emissions (in Millions tCO2e) | Energy Consumption (in Millions TOE) | Labor (Thousands) | Capital Stock (in 100 Billion KRW) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Total | Direct | |||||||||||

| Mean | CAGR | Mean | CAGR | Mean | CAGR | Mean | CAGR | Mean | CAGR | Mean | CAGR | |

| Textile | 128.5 | −0.7 | 9.6 | −3.9 | 3.4 | −9.8 | 2.3 | −5.5 | 279.1 | −3.4 | 70.1 | 1.7 |

| Paper and Lumber | 88.7 | 2.2 | 8.4 | −1.6 | 2.7 | −9.5 | 1.9 | −3.3 | 129.3 | 0.1 | 52.9 | 6.9 |

| Oil | 74.9 | −0.4 | 15.1 | 0.6 | 15.1 | 0.6 | 5.2 | 0.7 | 9.4 | 2.2 | 147.9 | 13.2 |

| Petrochemical | 351.8 | 4.0 | 49.7 | 5.0 | 31.2 | 4.4 | 46.6 | 4.6 | 389.3 | 1.9 | 186.4 | 8.7 |

| Steel | 221.8 | 3.1 | 80.4 | 6.4 | 67.3 | 5.7 | 21.3 | 6.1 | 113.4 | 4.0 | 71.0 | 15.8 |

| Nonferrous | 35.6 | −1.6 | 3.7 | 6.7 | 0.6 | 7.4 | 0.8 | 6.8 | 38.6 | 1.4 | 30.5 | 11.5 |

| Glass | 39.9 | 13.8 | 3.1 | 3.8 | 1.6 | −1.0 | 0.9 | 1.9 | 30.4 | 3.0 | 15.0 | 5.5 |

| Ceramic | 13.6 | 0 | 2.4 | −11.5 | 1.8 | −16.5 | 0.7 | −10.9 | 28.9 | 0.5 | 16.8 | 3.8 |

| Cement | 38.4 | −5.9 | 15.0 | −0.3 | 12.1 | −0.6 | 3.8 | −0.5 | 41.8 | 1.2 | 32.2 | 6.0 |

| Machinery | 416.7 | 5.1 | 8.7 | 10.1 | 1.2 | 2.6 | 1.9 | 8.2 | 718.2 | 3.9 | 250.4 | 12.6 |

| Semiconductor | 214.1 | 17.9 | 5.6 | 12.6 | 0.2 | 3.1 | 1.1 | 10.8 | 125.5 | 1.2 | 39.2 | 17.1 |

| Display | 168.3 | 22.7 | 3.3 | 17.7 | 0.2 | 11.5 | 0.7 | 15.6 | 105.1 | 1.7 | 26.6 | 0.7 |

| Electronic and Electricity | 347.9 | 7.0 | 5.7 | 4.1 | 0.7 | −12.6 | 1.2 | 1.5 | 451.6 | 1.3 | 132.9 | 8.0 |

| Automotive | 268.5 | 9.0 | 6.8 | 7.1 | 1.2 | 5.0 | 1.6 | 5.9 | 341.2 | 2.2 | 141.0 | 10.2 |

| Shipbuilding | 113.2 | 6.4 | 2.2 | 6.5 | 0.6 | −6.1 | 0.5 | 3.3 | 146.4 | 9.0 | 36.3 | 21.5 |

| Food and Tobacco | 125.8 | −0.9 | 6.4 | 1.5 | 2.5 | −3.0 | 1.6 | 0.7 | 2791.0 | 0.0 | 102.7 | 8.2 |

| Miscellaneous | 44.0 | 3.2 | 15.6 | 5.9 | 14.6 | 6.0 | 8.2 | 4.6 | 78.4 | 1.0 | 20.3 | 9.5 |

| Total | 158.3 | 6.4 | 14.2 | 4.6 | 9.2 | 3.2 | 5.9 | 4.1 | 342.2 | 1.1 | 80.7 | 10.0 |

| Industry | Total Emissions | Direct Emissions | ||

|---|---|---|---|---|

| β | Efficiency | β | Efficiency | |

| Textile | 0.6230 (0.0109) | 0.6162 | 0.9202 (0.0140) | 0.5208 |

| Paper and Lumber | 0.6581 (0.0354) | 0.6031 | 0.8977 (0.0784) | 0.5269 |

| Oil | 0.0000 (0.0000) | 1.0000 | 0.0000 (0.0000) | 1.0000 |

| Petrochemical | 0.6720 (0.1130) | 0.5981 | 0.7970 (0.1773) | 0.5565 |

| Steel | 0.0000 (0.0000) | 1.0000 | 0.0000 (0.0000) | 1.0000 |

| Nonferrous | 0.5472 (0.1996) | 0.6463 | 0.5982 (0.2961) | 0.6257 |

| Glass | 0.4122 (0.1361) | 0.7081 | 0.4482 (0.1790) | 0.6931 |

| Ceramic | 0.8167 (0.0292) | 0.5504 | 0.9824 (0.0045) | 0.5044 |

| Cement | 0.7694 (0.1540) | 0.5652 | 0.8123 (0.1810) | 0.5518 |

| Machinery | 0.0985 (0.0957) | 0.9103 | 0.1823 (0.1520) | 0.8458 |

| Semiconductor | 0.0000 (0.0000) | 1.0000 | 0.0000 (0.0000) | 1.0000 |

| Display | 0.0090 (0.0200) | 0.9911 | 0.0147 (0.0329) | 0.9855 |

| Electronic and Electricity | 0.0047 (0.0104) | 0.9954 | 0.0058 (0.0129) | 0.9943 |

| Automotive | 0.1863 (0.0387) | 0.8429 | 0.4725 (0.1195) | 0.6791 |

| Shipbuilding | 0.0303 (0.0348) | 0.9706 | 0.0194 (0.0274) | 0.9810 |

| Food and Tobacco | 0.5054 (0.0408) | 0.6643 | 0.8931 (0.0281) | 0.5282 |

| Etc. | 0.8942 (0.0173) | 0.5279 | 0.9929 (0.0026) | 0.5018 |

| Industry | Total Emissions | Direct Emissions | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ML | ML | M | |||||||

| PC | EC | TC | PC | EC | TC | PC | EC | TC | |

| Textile | 1.0041 | 0.9998 | 1.0044 | 1.0038 | 0.9985 | 1.0054 | 1.0033 | 0.9490 | 1.1256 |

| Paper and Lumber | 1.0082 | 0.9975 | 1.0112 | 1.0094 | 0.9835 | 1.0281 | 0.9931 | 0.9424 | 1.0659 |

| Oil | 0.9906 | 1.0000 | 0.9906 | 0.9905 | 1.0000 | 0.9905 | 0.9474 | 1.0000 | 0.9474 |

| Petrochemical | 1.0060 | 0.9728 | 1.0355 | 1.0152 | 0.9581 | 1.0616 | 1.0011 | 0.9599 | 1.0570 |

| Steel | 1.0131 | 1.0000 | 1.0131 | 1.0112 | 1.0000 | 1.0112 | 0.9810 | 0.9446 | 1.0469 |

| Nonferrous | 1.0156 | 0.9526 | 1.0676 | 1.0064 | 0.9237 | 1.0949 | 0.9661 | 0.9515 | 1.0322 |

| Glass | 1.0791 | 0.9898 | 1.1015 | 1.1196 | 0.9994 | 1.0005 | 1.1143 | 1.0646 | 1.0639 |

| Ceramic | 1.0107 | 1.0067 | 1.0039 | 1.0014 | 1.0004 | 1.0009 | 0.9924 | 0.9637 | 1.0450 |

| Cement | 0.9836 | 0.9556 | 1.0301 | 0.9850 | 0.9494 | 1.0384 | 0.9331 | 0.9170 | 1.0297 |

| Machinery | 0.9812 | 0.9736 | 1.0093 | 0.9925 | 0.9335 | 1.0633 | 0.9812 | 0.9054 | 1.0897 |

| Semiconductor | 1.0429 | 1.0000 | 1.0429 | 1.0957 | 1.0000 | 1.0957 | 1.1357 | 1.0080 | 1.1269 |

| Display | 1.0284 | 1.0049 | 1.0232 | 1.1589 | 1.0081 | 1.1494 | 1.2410 | 1.0526 | 1.1899 |

| Electronic and Electricity | 1.0119 | 1.0005 | 1.0115 | 1.0483 | 1.0006 | 1.0477 | 1.0249 | 0.9511 | 1.1048 |

| Automotive | 1.0130 | 0.9967 | 1.0179 | 1.0341 | 0.9800 | 1.0627 | 1.0380 | 0.9705 | 1.0793 |

| Shipbuilding | 0.9751 | 0.9763 | 0.9987 | 0.9737 | 0.9423 | 1.0222 | 0.9213 | 0.8912 | 1.1195 |

| Food and Tobacco | 0.9948 | 0.9878 | 1.0073 | 1.0011 | 0.9938 | 1.0076 | 0.9171 | 0.9177 | 1.2114 |

| Miscellaneous. | 0.9990 | 0.9959 | 1.0031 | 0.9999 | 0.9994 | 1.0005 | 0.9795 | 0.9052 | 1.1246 |

| Total | 1.0070 | 0.9894 | 1.0190 | 1.0310 | 0.9779 | 1.0550 | 1.0210 | 0.9555 | 1.0950 |

| Year | Innovative Industry | |

|---|---|---|

| Total Emissions | Direct Emissions | |

| 2004–2005 | Oil | Display, Oil, Shipbuilding, Semiconductor |

| 2005–2006 | - | Display, Shipbuilding, Semiconductor |

| 2006–2007 | - | Display, Electronic/Electricity, Semiconductor |

| 2007–2008 | - | Electronic/Electricity |

| 2008–2009 | - | Electronic/Electricity, Shipbuilding, Semiconductor |

| 2009–2010 | - | Display, Semiconductor |

| Study | Target | Periods | PC | EC | TC |

|---|---|---|---|---|---|

| This study | Korean Manufacturing 17 Industries | 2004–2010 | 1.0070 (1.0310) 1 | 0.9894 (0.9779) 1 | 1.0910 (1.0550) 1 |

| Jeong and Lee (2011) | OECD 26 Countries | 1991–2009 | 1.0010 | 0.9940 | 1.0080 |

| Chung and Heshmati (2015) | Korean Industries | 1981–2010 | 1.0175 | 1.0015 | 1.0160 |

| Aparicio et al. (2017) 2 | 39 Countries | 1995–2007 | 1.0058 | 1.0022 | 1.0056 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Noh, D.-W.; Oh, D.-h. Characterizing the Difference between Indirect and Direct CO2 Emissions: Evidence from Korean Manufacturing Industries, 2004–2010. Sustainability 2018, 10, 2711. https://doi.org/10.3390/su10082711

Lee S, Noh D-W, Oh D-h. Characterizing the Difference between Indirect and Direct CO2 Emissions: Evidence from Korean Manufacturing Industries, 2004–2010. Sustainability. 2018; 10(8):2711. https://doi.org/10.3390/su10082711

Chicago/Turabian StyleLee, Sinwoo, Dong-Woon Noh, and Dong-hyun Oh. 2018. "Characterizing the Difference between Indirect and Direct CO2 Emissions: Evidence from Korean Manufacturing Industries, 2004–2010" Sustainability 10, no. 8: 2711. https://doi.org/10.3390/su10082711

APA StyleLee, S., Noh, D.-W., & Oh, D.-h. (2018). Characterizing the Difference between Indirect and Direct CO2 Emissions: Evidence from Korean Manufacturing Industries, 2004–2010. Sustainability, 10(8), 2711. https://doi.org/10.3390/su10082711