1. Introduction

Over the past few decades, the developments in the Chinese manufacturing industry have played a vital role in improving both the national economy and the quality of people’s life. History and practice have proven that industrialization has led to the rapid growth in the world economy [

1]. However, accompanying this the rapid industrialization has been a rise in adverse effects such as climate change, environmental pollution and resource scarcity, all of which have become major global concerns [

2]. As a result, due to the rapid increase in greenhouse gas emissions, the depletion of natural resources, energy shortages, landfill problems and the unhealthy degradation of the soil and water, sustainable development has become a major global focus [

3]. Because it consumes a significant amount of available resources in a highly unsustainable manner and releases large quantities of greenhouse gases, the manufacturing sector has been identified as the key to overall sustainable development [

4].

These days, most countries are beginning to actively pursue green, intelligent, sustainable development, with the green economy, circular economy and low carbon economy concepts having been proposed and put into practice. However, sustainable development implementation has not been consistent. Developed regions such as North America and the European Union have had green business operations as a key strategy for several decades while developing countries such as China and India are still in the early stages.

Global CO

2 emissions trends [

5] have identified China as the greatest emitter of CO

2, emitting twice as much CO

2 as the United States. Statista (the statistics portal) also reported that China was the highest CO

2 emitter in 2016, followed by the U.S. and India [

6]. A more recent report by the BP Statistical Review of World Energy [

7] also placed China in first position, with China’s primary energy consumption reaching 30.53 billion tons in 2017, an increase of 5.6% over the previous year and accounting for 23% of world’s emissions. The total energy global energy consumption increased to 132.76 billion tons in 2016, with total energy consumption increasing by 1.3% compared to the previous year.

China’s manufacturing industry is at the middle and low end of the industrial chain. As product resources and energy consumption increases and economic growth slows, China’s labor cost advantages continue to weaken and there is greater downward pressure. Therefore, to ensure the continued development of the manufacturing industry in China, to enhance the national green comprehensive strength and to improve China’s green international competitiveness, it has become urgent to accelerate green development through the promotion of green productivity.

As small and medium-sized enterprises (SMEs) play a central part in economies worldwide, making up 99% of all enterprises and providing about 60% of all employment [

8], they have extensive social and economic influence. Therefore, whether in developed or developing countries, small and medium-sized enterprises provide significant national and international economic advantages. The Chinese State Environmental Protection Administration found that of the 29 million SMEs in China, more than 80% had environmental pollution problems and accounted for 60% of the total pollution in the country [

9]. A Chinese Environmental Situation Communique in 2016 [

10] further pointed out that in the 338 cities, 75.1% had poor environmental air quality, with the SMEs being found to account for more than 60% of the pollution. Therefore, even though the SMEs are benefiting China’s modern economy, they are also causing serious environmental pollution and resource depletion. As a result, there has been a greater emphasis on the SMEs to improve their environmental management and performance within the broader competitive green economic environment [

11].

As the organizational structures, systems and procedures at most SMEs are relatively simple, they are generally flexible, are able to provide rapid feedback and have short decision chains [

12]. More importantly, compared to large enterprises, SMEs generally have a better understanding of and a faster response to market trends and customer needs. Therefore, to effectively resolve the environmental pollution and resource shortage problems and adopt green manufacturing, it is imperative that Chinese SMEs adopt a new green manufacturing (GM) paradigm that integrates product and process design issues and manufacturing planning and control so that they can easily identify, quantify, assess and manage their flow of environmental waste with the goal of reducing and ultimately minimizing their environmental impact while at the same time maximizing resource efficiency [

13], which not only protects the environment and saves resources but also contributes to their competitiveness. Nevertheless, because of their unique characteristics, SMEs need to be motivated to adopt new green manufacturing practices. This means that the SME implementation of GM in China requires not only a joint promotion to the enterprises, society and government but also involves the promotion of the policies, technological innovations, financial benefits and environmental protection awareness. However, as most existing research on the green SME development has focused on the use of green technology and policies to promote production facility improvements [

12], there has been little advice on how to motivate the SME green development process. Therefore, to enable successful GM adoption, it is necessary to fully analyze the role and value of the GM drivers [

14].

The remainder of this paper is organized as follows.

Section 2 identifies the prominent GM research and also reveals the current research gaps,

Section 3 describes the research methodology for resolving the current problems and in

Section 4, the hybrid MCDM is applied to rank the GM drivers. The results are discussed in

Section 5 and

Section 6 explores the managerial implications.

Section 7 makes a summary of the full text and puts forward the limitations of this and future research directions.

3. Research Methodology

MCDM such as AHP, ANP, TOPSIS and DEMATEL have been found to be effective for the evaluation of green drivers. Traditional studies have mainly assumed that the evaluation driver criteria are relatively independent; however, in the decision-making process, as all factors interact, this supposition is incorrect. Further, in decision-making problems for complex systems, expert evaluations of the qualitative evaluation criteria are often expressed in linguistic terms rather than in crisp values, which means that the evaluation results are a vector rather than a point value, which makes it difficult to compute. Therefore, most MCDM criteria and alternatives cannot be accurately determined because of the failure to get accurate evaluation data from decision makers. However, fuzzy set theory can be used to measure ambiguous human judgments as it can not only describe the evaluation object but can also be further processed for reference information.

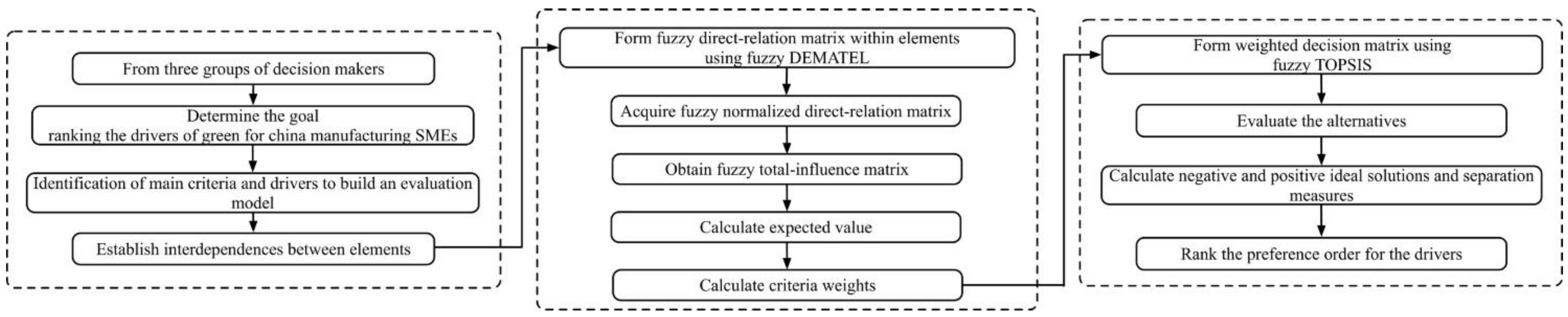

Therefore, in this research, a two-phased fuzzy solution methodology model was used. The research methods and models in this paper were based on a refining and summarizing of the research results from [

52,

53,

54]. Based on expert opinion, the research objective for this paper was established; to determine the green driving factors for SMEs in China. From the literature review and expert opinion, the evaluation model, evaluation criteria and green driving factors were identified, for which the experts in the research group were asked to clarify the interdependencies and correlations between the evaluation criteria and the drivers. The framework for the research is shown in

Figure 1.

Step 1: Establish the casual relationships using a fuzzy DEMATEL.

Step 1.1.: Establish the fuzzy direct-relation matrix

Triangular fuzzy numbers are used in this paper to assess the preferences because it is easy for the DMs to use and calculate. A triangular fuzzy number is defined as , where . The parameters , and represent, respectively, the smallest possible value, the most promising value and the largest possible value.

From an analysis of the direct influence of each system element, the degree of influence and the interactive effects of each criterion can be expressed in linguistic terms, from which an expert direct-relation matrix can be constructed; an matrix , in which is denoted as the degree to which the decision making (DM) group feel that criterion affects criterion .

Step 1.2.: Determine the average fuzzy direct-relation matrix

Assume that there are

groups of decision makers in this study and each group is asked to assess the degree of influence between each criterion. The average fuzzy direct-relation matrix

is then acquired as follows:

where

represents the mean value of all decision making (DM) groups’ evaluation results.

Step 1.3.: Normalize the fuzzy direct-relation matrix .

From the direct-relationship matrix , the normalized direct-relationship matrix can be determined using Equation (2)

Let

and

Step 1.4.: Identify the fuzzy total-relation matrix.

As soon as the normalized direct-relation matrix is obtained, the total-relationship matrix , can be acquired using the following formulas, in which is the identity matrix.

Let

and define the three crisp matrices, the elements for which are extracted from

as follows:

To attain the crisp case, the total-relation fuzzy matrix

can be obtained using

Let

where

then,

Step 1.5.: Calculate the degrees of influence and the influential levels for each criterion

The elements in total-relation matrix

are used to conduct the structural correlation analysis. The sum of the rows and the sum for the columns in matrix

are denoted

and

.

indicates the total effects exerted by element

i on the other elements, and

indicates the total effects received by element

j from the other elements and can be obtained as follows;

Step 1.6.: Draw causal diagrams

defines the prominence and therefore gives the position in the system for the total effects given and received by element i. In addition, defines the relationship and shows the net effect of the contribution that element i gives to the system. and refers to the expected value. When is positive, element i is categorized as the cause; conversely, when the value is negative, element i is categorized as the effect.

Step 1.7.: Calculate the weights of criteria.

When the prominence values and each relationship are calculated, the importance of each criterion

can be calculated using Equation (9). Finally, the normalized importance degree of the criterion

is calculated using Equation (10).

Step 2.: Evaluate the alternatives using fuzzy TOPSIS

Step 2.1.: Compute the aggregate fuzzy ratings for the criteria

Assume that there are

groups of decision makers and that the fuzzy rating of each group

can be represented as a positive triangular fuzzy number

, (

k = 1, 2, …,

K); then, the aggregated fuzzy rating can be determined using Equation (11):

where

,

and

Step 2.2.: Compute the fuzzy decision matrix

The fuzzy decision matrix for alternatives (

) and criteria (

) is constructed as follows:

where

The weights for the criteria are obtained in Step 1.7 and the fuzzy decision matrix for criteria (

) is as follows:

Step 2.3.: Normalize the fuzzy decision matrix

The raw data are normalized using a linear scale transformation to make the various criteria scales comparable. The normalized fuzzy decision matrix

is computed using Equation (12):

where

= (

) and

=

Step 2.4.: Compute the weighted normalized matrix

The weighted normalized matrix

for the criteria is computed by multiplying the evaluation criteria weights (

) with the normalized fuzzy decision matrix

, as shown in Equation (13):

Step 2.5.: Compute the fuzzy positive ideal solution (FPIS) and the fuzzy negative ideal solution (FNIS)

The FPIS and FNIS for the alternatives are computed using Equations (14) and (15):

where

{

},

= 1, 2, …,

;

= 1, 2, …,

where

{

},

= 1, 2, …,

;

= 1, 2, …,

Step 2.6.: Compute the distance of each alternative from the FPIS and FNIS

The distance () of each weighted alternative = 1, 2, …, from the FPIS and the FNIS is given by following relationships in Equations (16)–(18) using the vertex method.

Let

= (

) and

= (

) be two triangular fuzzy numbers.

where

(

,

) is the distance measurement between two fuzzy numbers

and

.

Step 2.7.: Compute the closeness coefficient () for each alternative

is both the distance to the FPIS (

) and the FNIS (

). The closeness coefficient for each alternative is calculated using Equation (19):

Step 2.8.: Rank the drivers

Rank the alternatives in decreasing order based on the closeness coefficient () and then select the alternative with the highest closeness coefficient for the final implementation. The best alternative is the one that is closest to the FPIS and farthest from the FNIS.

4. Application of the Hybrid MCDM for Ranking the Green Manufacturing Drivers

As the successful implementation of green manufacturing involves many aspects, several dimensions should be considered for the GM drivers. Mittal and Sangwan (2015) [

14] divided these drivers into three dimensions: policy, economic and external; while Kannan Govindana* (2015) [

44] proposed five dimensions: environmental, potential, regulatory, internal and external. What needs to be paid special attention is that, at present, the revolutionary breakthroughs and cross integration of information technology, new energy, new materials, biotechnology and other important frontiers are resulting in industrial change, which is expected to have a subversive impact on the global manufacturing industry and change global manufacturing industry development patterns. In particular, the integration of new generation information technology into the manufacturing industry is going to result in profound changes in the manufacturing mode, the production organization mode and the industry format, with intelligentization expected to have a significant impact on green manufacturing [

55].

Therefore, on the basis of previous studies, the dimensions involved in the green drivers for the Chinese manufacturing SMEs can be classified into four categories: policy, technological, social and internal. Taking technology as a single dimension accords not only with the background of the new scientific and technological revolution but also the actual conditions in China. The Johannesburg implementation plan adopted at the World Summit on Sustainable Development stated that reducing unsustainable production methods in developed and developing countries requires the innovation, promotion, transference and diffusion of environmentally sound technologies (EST). A comparison between developed and developing countries of resource use and environmental industrial performance data found that the developing countries EST innovation and adoption needs were more urgent. From a comparison of the GHG emissions between China and neighboring countries, Feng et al. (2017) [

56] proposed that only through the use of modern technologies could energy conservation and emissions reduction be achieved as these new technologies, such as biotechnology, new energy and new materials, can have a profound impact on the GM implementation process. Therefore, a detailed literature search on the GM concepts and in-depth discussions with experts were conducted to select the drivers. A list of drivers after classification is presented in

Table 1 with a brief description.

The selection of the evaluation criteria depended on the purpose of the study. Mittal and Sangwan (2015) [

14] studied green drivers from the perspective of the government, industry and the experts to identify the GM drivers in different fields. Gandhi et al. (2018) [

45] sorted the driving GM factors from an environmental, social and economic perspective and discussed the ordering under different criteria. While green development is not static, its core purpose is to seek a harmonious unification of economic growth, resource use and environmental consumption to achieve a win-win between development and the environment. As China is still a developing country and there is still ongoing extensive development, the manufacturing industry has high pollution and high energy consumption. Therefore, green manufacturing means “not only to develop but also to be green.” Based on the relationships between the enterprises, the environment, resources and the social systems, the GM drivers in China should improve profits, protect the environment, save resources and give back to the society. Therefore, in this paper, the criteria for evaluating GM are economic, environmental, resources and social efficiency.

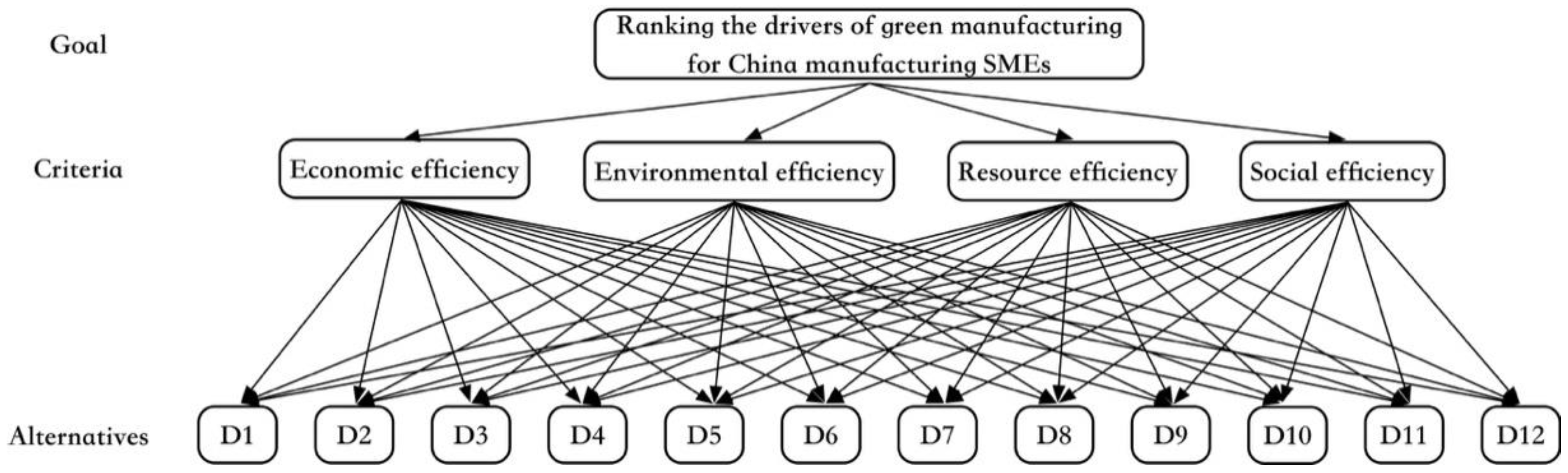

Through a thorough and detailed analysis of the pertinent literature and in-depth interviews with relevant researchers, the hierarchical structure of four criteria to rank the selected 12 drivers is shown in

Figure 2. The drivers (D1 to D12) are at the bottom of the hierarchy and the criteria used to rank the drivers are in the middle of the hierarchy. A scale of 1−9 is applied to rate the criteria and the drivers. The linguistic variables and the fuzzy ratings for the drivers and criteria are shown in

Table 2.

In the present case, we analyzed 12 drivers and four criteria using the linguistic ratings from three decisions making (DM) groups (DM1, DM2 and DM3). DM1 had four management and manufacturing professors, all of whom had had sustainable manufacturing industrial experience, DM2 included four government workers from the Ministry of Industry and Information Technology (MIT) and the National Development and Reform Commission (NDRC) and DM3 had four senior managers from small and medium-sized manufacturing enterprises. A questionnaire was developed and distributed to these decision maker groups, which focused on gathering the groups’ opinions on the relationships between the evaluation criteria and the relative importance of the drivers. Each expert in each group made a decision and then explained it to the other experts. For controversial scores, the experts came to a unified conclusion using the literature review and authentic proof. After repeated discussions, each group reached agreement on the evaluation results.

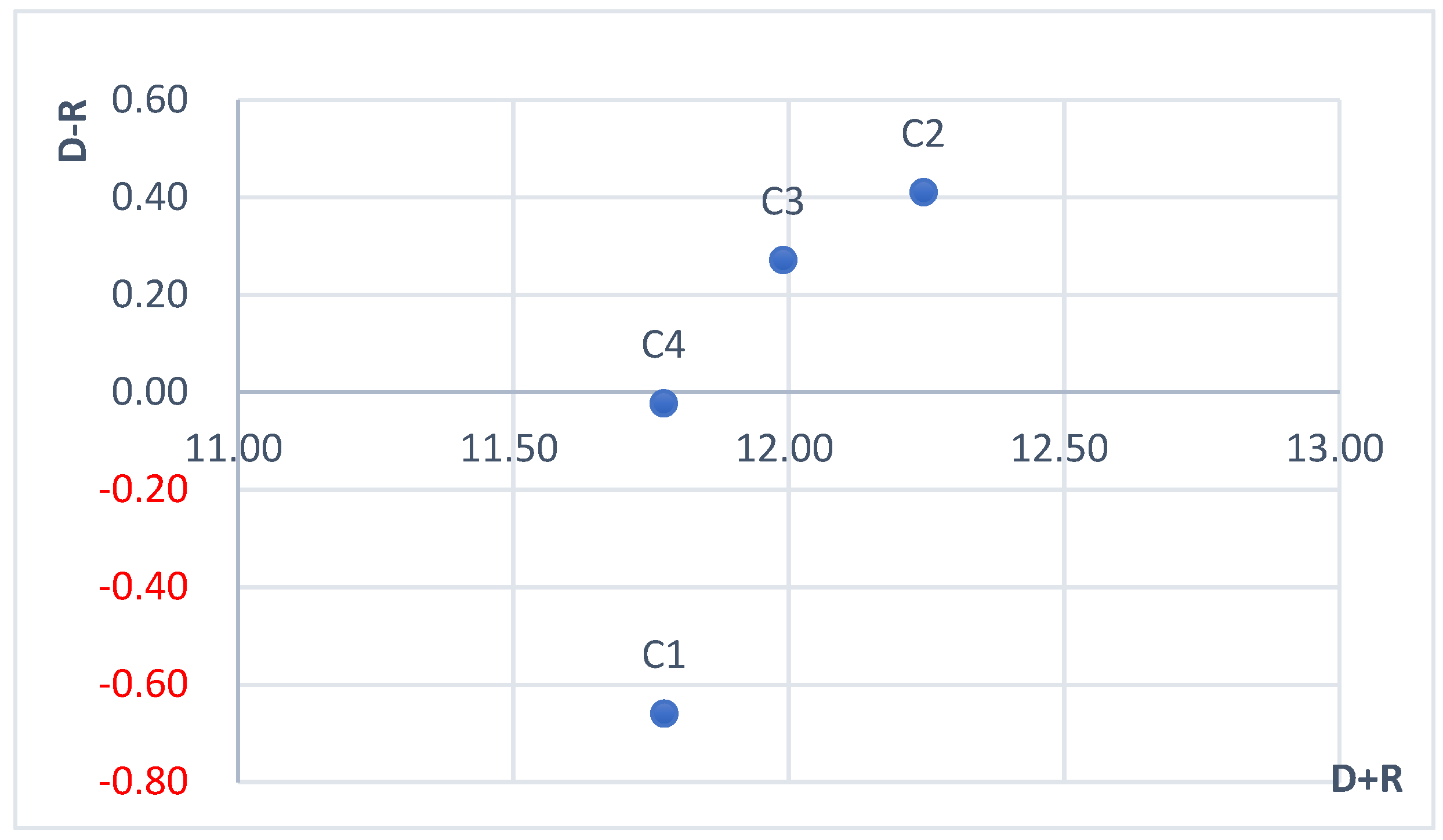

This paper asked the three decision maker groups to evaluate the green drivers and score them on four criteria based on to their importance using five linguistic terms from very low to very high. Then, DEMATEL was used to construct an influence map to show the interdependencies between the criteria that was consistent with the real situation. The three decision maker groups then indicated the degree to which each criterion influenced the other criterion;

Table 3 shows the initial evaluation of these criteria. Using

pairwise comparisons, the averages for these attitudes were calculated using Equation (1), the results for which are shown in

Table 4. The normalized initial fuzzy direct-relation matrix shown in

Table 5 was generated using Equation (2), the fuzzy total-relation matrix shown in

Table 6 was computed using Equations (3)–(6) and Equations (7) and (8) were used to calculate the D value of each row and the R value of each column, as shown in

Table 7. The prominence

and the relation

were calculated based on the total relationship matrix, after which the weights for the four criteria relating to the green drivers

were obtained using Equations (9) and (10), as shown in

Table 8. Setting the (

as the horizontal axis and

as the vertical axis, the causal relationships between the four criteria are shown in

Figure 3.

The calculation results showed that the values for environmental efficiency (C2) and resource efficiency (C3) were positive and the values were large, while the values for economic efficiency(C1) and social efficiency(C4) were negative and the values were small, which indicated that C2 and C3 were cause criteria and directly influenced the other two criteria; on the contrary, C1 and C4 were only subtly influenced by C2 and C3, indicating that these two criteria were relatively independent.

On the surface, it is generally considered that when it comes to the need to implement green behavior, entrepreneurs place profits first place. Traditionally, the possible adverse effects of GM implementation on the profit margins of industries were seen to be of greater concern to entrepreneurs (Hui et al., 2001) [

30]; however, this has proven to be incorrect. Because environmental problems have attracted global attention and caused widespread concern, experts from scientific research institutions, government and industry have all argued that environmental efficiency was the most influential criteria when evaluating green drivers, which is consistent with the reality of China’s basic national conditions and the development of the manufacturing industry. Further, this has also been strongly supported by President Xi, who pointed out at the 19th National Congress of the Communist Party of China on 18 October 2017 that China must adhere to a basic state policy of conserving resources and protecting the environment and that China also needed to establish and practice the idea that lucid waters and lush mountains are invaluable assets.

A similar five-point Likert scale was used in a further questionnaire to garner expert opinions on the importance of each evaluation criterion relative to the driving factors. The linguistic variables for the ratings ranged from 1 (not important) to 9 (very important). The aggregate fuzzy weights for the drivers were determined using Equation (11) as shown in

Table 9 and Equation (12) was used to determine the normalized matrix, as shown in

Table 10. Using the criteria weights calculated using the DEMATEL method and the normalized matrix, Equation (13) was applied to derive the weighted normalized fuzzy decision matrix (

Table 11).

Equations (14) and (15) were then applied to identify the fuzzy positive ideal solution (FPIS,

) and the fuzzy negative ideal solution (FNIS,

), which are also shown in

Table 11, after which Equation (16) was used to calculate the distance from the fuzzy positive ideal solution (

,

) and the distance from the fuzzy negative ideal solution (

,

), the results for which are shown in

Table 12. Equations (17)–(19) were applied to determine the distance (

) and the closeness coefficient (

) of each weighted driver (

Table 13), as summarized in

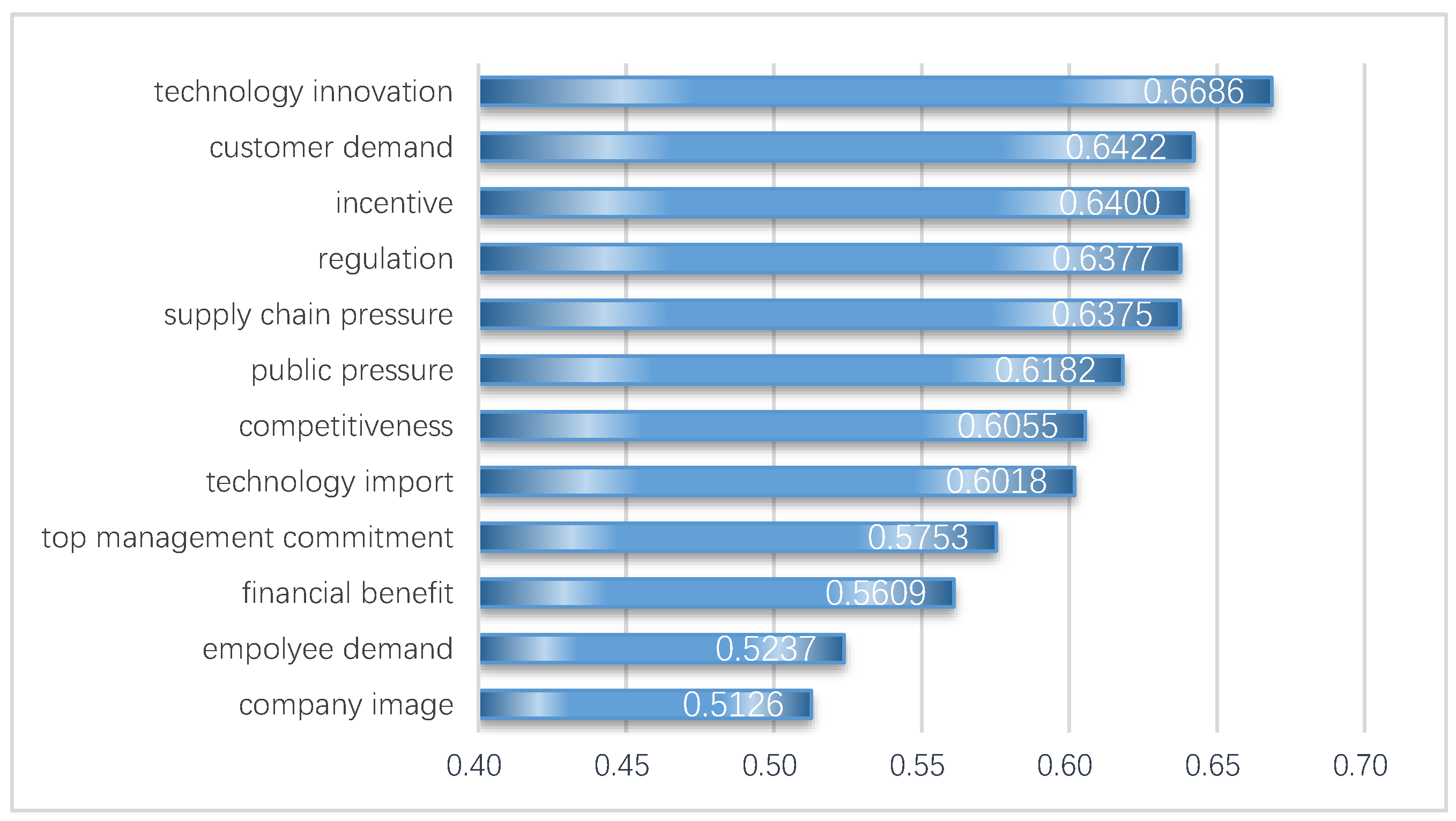

Figure 4. Based on the

value, the ranked order for the 12 green drivers was finally determined as:

. Similarly, the

for each driver was also calculated based on the individual criterion(

Table 14), as shown in

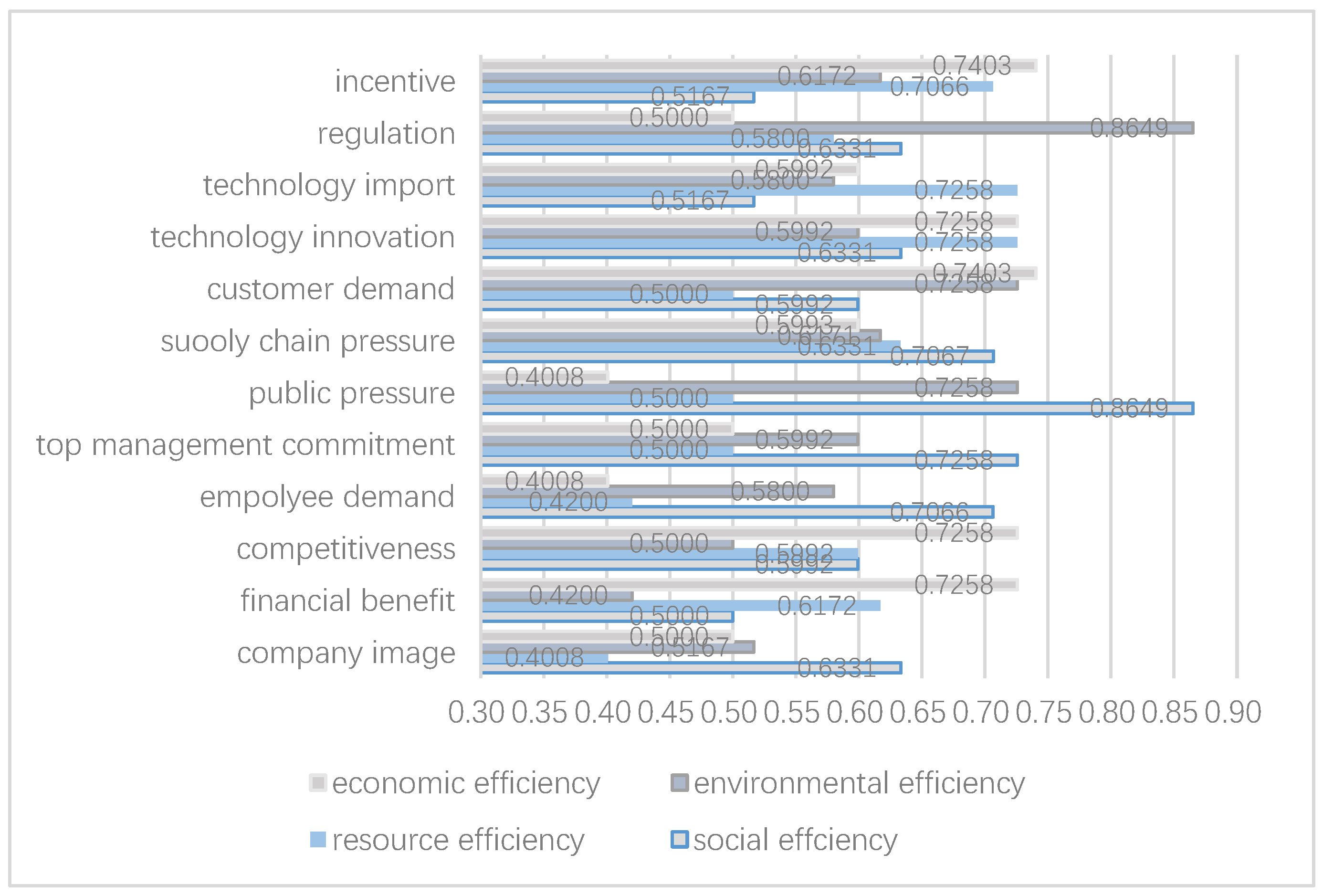

Figure 5.

5. Results and Discussion

To successfully apply GM to Chinese SMEs, they need to identify their motivation. Therefore, in this paper, the Chinese SME GM drivers were analyzed and ranked using a fuzzy DEMATEL and a fuzzy TOPSIS. Using DEMATEL method to determine the weight of criterion, which can take into account the interaction between the criteria, is more scientific reasonable and practical than the traditional way that is usually given by experts with their experience intuition or direct average allocation weight. In fact, we should put more weight on the criterion influences the others. Meanwhile, put less weight on the ones are influenced. The calculated weights of criteria will further affect the ranking of drivers by using the TOPSIS method, that is, if a driver can bring efficiency with more weight, to a large extent, it will rank better and be more important.

Based on the results of this study, the “Technology Innovation” (D4) was found to be most significant driver for the successful implementation of GM practices, primarily because most Chinese SMEs are in lower technology industries. Therefore, Chinese manufacturing SMEs need to strengthen their understanding of the economic benefit of installing energy-efficiency technology, which would motivate them to apply technological innovations to their enterprises. Mittal and Sangwan (2015) [

14] noted that new technology could improve resource utilization and the speed of the GM implementation process and was the inevitable outcome of the new technological revolution. The next most important driver was found to be “Customer Demand” (D5). A Global Corporate Social Responsibility (CSR) study found that that the growing customer awareness of current social and environmental issues had contributed to a rapid shift in global markets towards environmental products and activities. As customers are becoming increasingly aware of and concerned about environmental issues, environmental collaboration with the customers is an important driver because customers are now seeking environmentally friendly products (Moktadir et al., 2018) [

39]. “Incentives” (D1) and “Regulation” (D2) were the third and fourth most important drivers. In the Chinese context, the government has increasingly recognized the necessity of a green transformation in the manufacturing industry to ensure that the manufacturing industry is sustainable and to protect the environment from any further deterioration. Therefore, regulatory incentives, such as investment subsidies, green premiums, awards, or tax exemptions for certified firms could motivate Chinese SMEs to implement green manufacturing (Gandhi et al., 2018) [

45]. Govindan (2015) [

34] believed that regulatory compliance was a top priority for the implementation of green manufacturing practices. “Supply Chain Pressure” (D) was also found to play an important role in the promotion of a green transformation in SMEs as the implementation of reduction, reuse and recycling in upstream and downstream manufacturing enterprises can encourage greater involvement in protecting the environment (Yavuz Agan a, 2013) [

37]. Zhang, J. et al. (2018) [

72] also confirmed that supply chain pressure could enhance the green manufacturing efficiency in China. The ranking of these five drivers is not only consistent with the actual situation of Chinese manufacturing SMEs but also supported by the existing literature. It further proves the scientific nature of the methods adopted in this study. Why the five drivers are well ranked is that they can bring more environmental efficiency and resource efficiency which are given more weights in the DEMATEL method.

“Public Pressure” (D7), which ranked sixth, was found to be another important driver. News reports in the media and from NGOs and auditors on the environmental soundness of manufacturing enterprises can adversely affect or positively enhance the reputation of a manufacturing enterprise and affect its market share (Communications/Echo, 2013) [

79]. “Competitiveness” (D10), which was ranked 7th, highlighted that green products are becoming more popular and gaining support from external stakeholders. Therefore, to better compete and gain market share, manufacturing enterprises need to be encouraged to produce green products using green manufacturing processes (Govindan, 2015) [

34]. “Technology Import” (D3) was ranked eighth, for which two new technology sources were identified; technological innovation and technology imports. Technology imports refers to the planned, focused and selective acquisition of advanced technology from abroad; however, at present in China, the available advanced technological channels available to the SMEs are not smooth, which means that the enterprises are unable to effectively apply the imported technology. Therefore, technology import may not be able to as effectively promote the greening process in the manufacturing SMEs as technological innovation. “Top Management Commitment” (D8) was also found to be an important driver (rank-9); as senior SME leaders are crucial to GM decision-making, a positive approach from top management is essential to implement GM practices (Ghazilla et al., 2015) [

11].

“Financial Benefit” (D11), “Employee Demand” (D9) and “Company Image” (D12) were the lowest ranked drivers in China. As the government, society and enterprises are becoming more concerned about environmental protection and resource conservation, the traditional focus on higher economic benefits is unsustainable. Further, due to the characteristics of manufacturing SMEs, employee demand cannot be effectively reflected or implemented. As long as companies meet their environmental responsibilities and can attract customers and employees who are environmentally conscious, they will gain a good reputation, which would further promote the green behavior of enterprises. However, because good corporate image requires an enterprise to take the responsibility for environmental protection first, company image could be seen to be an indirect driver.

As shown in

Figure 5, four drivers; “Incentives,” “Customer Demand,” “Financial Benefit” and “Competitiveness”; can result in better economic returns. Incentives can reduce the SME tax burden, consumer demand can directly increase product sales, increased competitiveness can expand SME market share and financial benefits can reduce the costs; therefore, these four drivers can result in a greater capital inflow to the enterprise. From an environmental efficiency perspective, “Regulation” could be seen to be most important efficiency driver, followed by “Customer Demand” and “Public Pressure.” In China, if an enterprise does not comply with the environmental protection law emissions standards, it is ordered to shut down until appropriate environmental protection and correction has been carried out and consumers and the public may also boycott its products. Huang et al. (2016) [

80] confirmed this argument in a study on a sample of 427 manufacturing organizations in six provinces in central China, which found that regulatory and customer pressure promoted green organizational responses and enhanced innovative green performances. Therefore, these three drivers can directly motivate SMEs to consider the environmental problems. “Technology Innovation” and “Technology Import” are more crucial drivers in terms of resource efficiency as advanced technology has become the most effective way to save resources. “Public Pressure” is related to social efficiency and far exceeds the other driving factors in this area. Social efficiency indicates that public opinion is important to enterprise reputation with the public; therefore, public pressure is the most significant driver.

7. Conclusions

The implementation of GM in Chinese manufacturing SMEs is systems engineering that involves many aspects and requires multiple cooperation. Only by identifying the key green drivers can the government and enterprises promote the process of green transformation in a targeted way. Combining the realistic background and development needs of small and medium manufacturing enterprises in China, this paper classifies the criteria of green driving factors into four categories: economic efficiency, environmental efficiency, resource efficiency and social efficiency. Based on the results of literature review and expert discussion, it puts forward 12 green drivers involving four aspects of policy, technology, society and enterprise and innovatively presents technology as an important dimension in promoting the green manufacturing process.

A two-phased fuzzy solution methodology model was used for scientific and effective ranking of Chinese SMEs green manufacturing drivers. Fuzzy DEMATEL can calculate the weights of the criteria according to their mutual influence degree. Calculation and analysis found the highest weight in environmental efficiency, followed by resource efficiency, with the lowest weight in economic and social efficiency. The calculated weights were further used in the fuzzy TOPSIS method to sort the green drivers. “Technology Innovation” was found the most crucial driver, followed by “Customer Demand,” “Incentives,” “Regulation” and “Supply Chain Pressure,” “Financial Benefit,” “Employee Demand” and “Company Image” ranked the lowest.

The assessment results indicated the right way for successful and comprehensive implementation of green manufacturing for Chinese manufacturing SMEs. The Chinese government, enterprises and the public need to attach importance to several key points: enforcing support for green technology, perfecting the green supervision and incentive system and enhancing the public awareness of environmental protection.

This research had some limitations. It included all Chinese manufacturing SMEs as the research objects, though the ranking of green drivers may differ greatly among the manufacturing enterprises in different fields, each with its characteristics. Furthermore, the research only identified and sorted the driving factors of green manufacturing, leaving the question how various drivers drive the implementation of green manufacturing unanswered. In addition, since green manufacturing is a systematic project including disposal, reduction, recycling, design and many other processes for the environment, further research is needed to analyze each driver of green manufacturing processes and its impact on the performance of enterprises.