Organising Sustainability Competencies through Quality Management: Integration or Specialisation

Abstract

1. Introduction

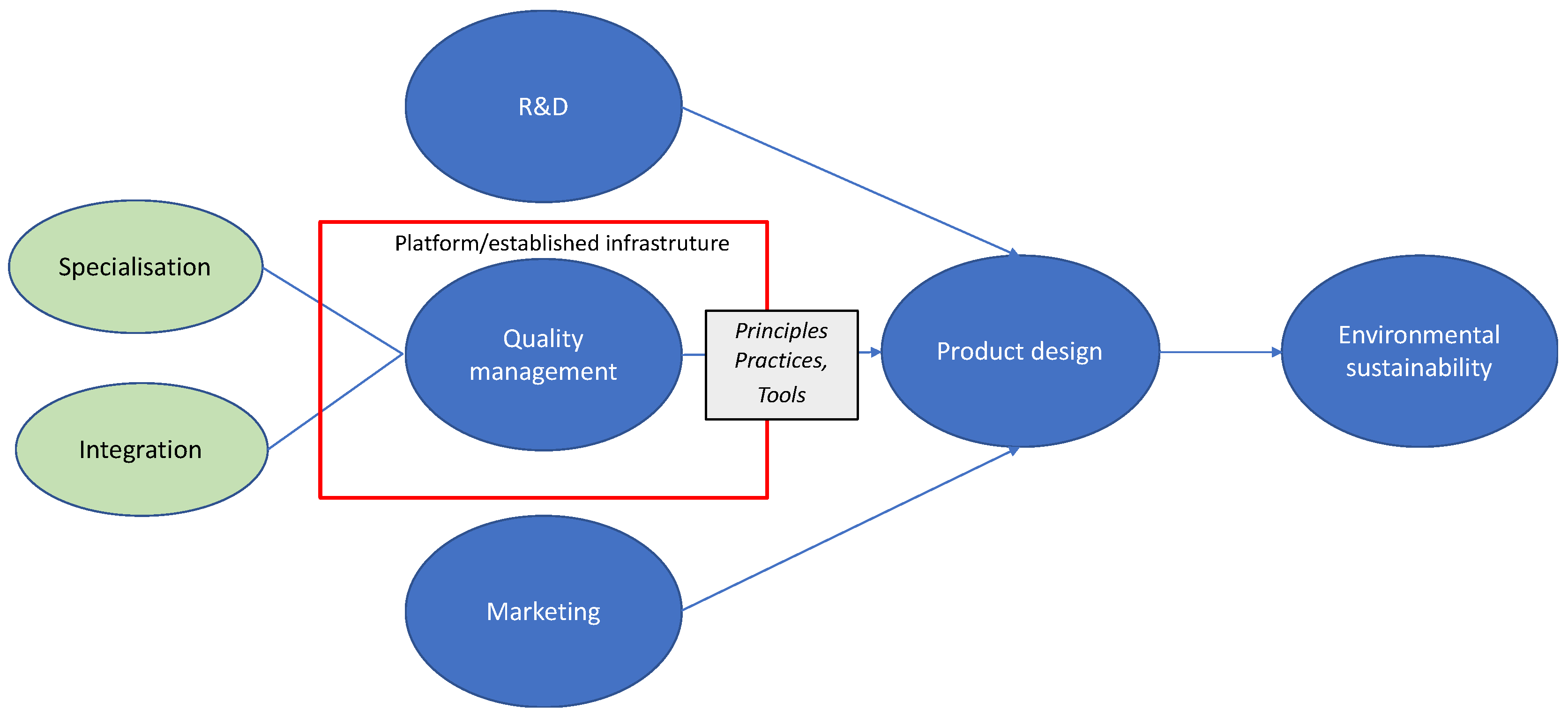

2. Theoretical Background and Analytical Framework

2.1. Sustainability and Product Development

2.2. Sustainability and QM

2.3. Two Types of Organisation of Sustainability Competencies: Specialisation or Integration

3. Methodology

3.1. Research Design and Sampling

3.2. Data Collection

3.3. Data Analysis

4. Findings

4.1. Integration of Speciality Competencies: Alpha

4.2. Separation of Speciality Competencies: Beta

5. Discussion

5.1. Explicit or Implicit Consideration of Environmental Impact

5.2. Strategically- or Operationally-Driven Environmental Requirements

5.3. Cross-Case Challenges and Similarities

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pullman, M.E.; Maloni, M.J.; Carter, C.R. Food for thought: Social versus environmental sustainability practices and performance outcomes. J. Supply Chain Manag. 2009, 45, 38–54. [Google Scholar] [CrossRef]

- Rusinko, C.A. Using quality management as a bridge to environmental sustainability in organisations. SM Adv. Manag. J. 2005, 70, 54. [Google Scholar]

- Sutter, R. Rethinking traditional quality assurance. Qual. Prog. 1996, 29, 40–41. [Google Scholar]

- Elg, M.; Gremyr, I.; Hellström, A.; Witell, L. The role of quality managers in contemporary organisations. Total Q. Manag. Bus. J. 2011, 22, 795–806. [Google Scholar] [CrossRef]

- Waddell, D.; Mallen, D. Quality managers: Beyond 2000? Total Qual. Manag. 2001, 12, 373–384. [Google Scholar] [CrossRef]

- Wilkinson, A.; Hill, M.; Gollan, P. The sustainability debate. Int. J. Oper. Prod. Manag. 2001, 21, 1492–1502. [Google Scholar] [CrossRef]

- Walker, H.; Seuring, S.; Sarkis, J.; Klassen, R. Sustainable operations management: Recent trends and future directions. Int. J. Oper. Prod. Manag. 2014, 34. [Google Scholar] [CrossRef]

- Smith, P.A.; Sharicz, C. The shift needed for sustainability. Learn. Organ. 2011, 18, 73–86. [Google Scholar] [CrossRef]

- Stocchetti, A. The sustainable firm: From principles to practice. Int. J. Bus. Manag. 2012, 7, 34. [Google Scholar] [CrossRef]

- Alblas, A.A.; Peters, K.; Wortmann, J.C. Fuzzy sustainability incentives in new product development. An empirical exploration of sustainability challenges in manufacturing companies. Int. J. Oper. Prod. Manag. 2014, 34, 513–545. [Google Scholar] [CrossRef]

- Paramanathan, S.; Farrukh, C.; Phaal, R.; Probert, D. Implementing industrial sustainability: The research issues in technology management. R&D Manag. 2004, 34, 527–537. [Google Scholar]

- De Medeiros, J.F.; Ribeiro, J.L.D.; Cortimiglia, M.N. Success factors for environmentally sustainable product innovation: A systematic literature review. J. Clean. Prod. 2014, 65, 76–86. [Google Scholar] [CrossRef]

- Fischer, M.A.; Waugh, L.M.; Axworthy, A. IT support of single project, multi-project and industry-wide integration. Comput. Ind. 1998, 35, 31–45. [Google Scholar] [CrossRef]

- Becker, M.C.; Zirpoli, F. Organising new product development: Knowledge hollowing-out and knowledge integration—The FIAT auto case. Int. J. Oper. Prod. Manag. 2003, 23, 1033–1061. [Google Scholar] [CrossRef]

- Griffin, A.; Hauser, J.R. Integrating R&D and marketing: A review and analysis of the literature. J. Prod. Innov. Manag. 1996, 13, 191–215. [Google Scholar]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business; New Society Publishers: Gabriola Island, BC, Canada; Stony Creek, CT, USA, 1998. [Google Scholar]

- Baines, T.; Brown, S.; Benedettini, O.; Ball, P. Examining green production and its role within the competitive strategy of manufacturers. J. Ind. Engin. Manag. 2012, 5, 53–87. [Google Scholar] [CrossRef]

- Bettley, A.; Burnley, S. Towards sustainable operations management integrating sustainability management into operations management strategies and practices. In Handbook on Performability Engineering; Misra, K.B., Ed.; Springer-Verlag: London, UK, 2008; pp. 875–904. [Google Scholar]

- Robinson, J. Squaring the circle? Some thoughts on the idea of sustainable development. Ecol. Econ. 2004, 48, 369–384. [Google Scholar] [CrossRef]

- Lubin, D.A.; Esty, D.C. The sustainability imperative. Harv. Bus. Rev. 2010, 88, 42–50. [Google Scholar]

- Dangelico, R.M.; Pujari, D. Mainstreaming green product innovation: Why and how companies integrate environmental sustainability. J. Bus. Ethics 2010, 5, 471–486. [Google Scholar] [CrossRef]

- Hallstedt, S.I. Sustainability criteria and sustainability compliance index for decision support in product development. J. Clean. Prod. 2017, 140, 251–266. [Google Scholar] [CrossRef]

- Kleindorfer, P.R.; Singhal, K.; Wassenhove, L.N. Sustainable operations management. Prod. Oper. Manag. 2005, 14, 482–492. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Manzini, E.; Vezzoli, C. A strategic design approach to develop sustainable product service systems: Examples taken from the ‘environmentally friendly innovation’ Italian prize. J. Clean. Prod. 2003, 11, 851–857. [Google Scholar] [CrossRef]

- Marchand, A.; Walker, S. Product development and responsible consumption: Designing alternatives for sustainable lifestyles. J. Clean. Prod. 2008, 16, 1163–1169. [Google Scholar] [CrossRef]

- Maxwell, D.; van Der Vorst, R. Developing sustainable products and services. J. Clean. Prod. 2003, 11, 883–895. [Google Scholar] [CrossRef]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why sustainability is now the key driver of innovation. Harv. Bus. Rev. 2009, 87, 56–64. [Google Scholar]

- Pujari, D. Eco-innovation and new product development: Understanding the influences on market performance. Technovation 2006, 26, 76–85. [Google Scholar] [CrossRef]

- Romli, A.; Prickett, P.; Setchi, R.; Soe, S. Integrated eco-design decision-making for sustainable product development. Int. J. Prod. Res. 2015, 53, 549–571. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Baumgartner, R.J.; Hofer, D. Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 2017, 140, 1602–1617. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manage. Rev. 1995, 20, 986–1014. [Google Scholar]

- O’Brien, C. Sustainable production—A new paradigm for a new millennium. Int. J. Prod. Econ. 1999, 60, 1–7. [Google Scholar] [CrossRef]

- Maxwell, D.; Sheate, W.; Van Der Vorst, R. Functional and systems aspects of the sustainable product and service development approach for industry. J. Clean. Prod. 2006, 14, 1466–1479. [Google Scholar] [CrossRef]

- Roome, N. Developing environmental management strategies. Bus. Strat. Env. 1992, 1, 11–24. [Google Scholar] [CrossRef]

- Johansson, G. Success factors for integration of ecodesign in product development: A review of state of the art. Environ. Manag. Health 2002, 13, 98–107. [Google Scholar] [CrossRef]

- Corbett, C.J.; Klassen, R.D. Extending the horizons: Environmental excellence as key to improving operations. Manuf. Serv. Oper. Manag. 2006, 8, 5–22. [Google Scholar] [CrossRef]

- Gremyr, I.; Siva, V.; Raharjo, H.; Goh, T.N. Adapting the robust design methodology to support sustainable product development. J. Clean. Prod. 2014, 79, 231–238. [Google Scholar] [CrossRef]

- Siva, V. Quality Management for Sustainable Product Development: Adaptations of Practices and Tools. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Gmelin, H.; Seuring, S. Achieving sustainable new product development by integrating product life-cycle management capabilities. Int. J. Prod. Econ. 2014, 154, 166–177. [Google Scholar] [CrossRef]

- Siva, V.; Gremyr, I.; Bergquist, B.; Garvare, R.; Zobel, T.; Isaksson, R. The support of quality management to sustainable development: A literature review. J. Clean. Prod. 2016, 138, 148–157. [Google Scholar] [CrossRef]

- Lopes Silva, D.A.; Delai, I.; De Castro, M.A.S.; Ometto, A.R. Quality tools applied to Cleaner Production programs: A first approach toward a new methodology. J. Clean. Prod. 2013, 47, 174–187. [Google Scholar] [CrossRef]

- Tingström, J.; Swanström, L.; Karlsson, R. Sustainability management in product development projects–the ABB experience. J. Clean. Prod. 2006, 14, 1377–1385. [Google Scholar] [CrossRef]

- Wiek, A.; Withycombe, L.; Redman, C.L. Key competencies in sustainability—A reference framework for academic program development. Sustain. Sci. 2011, 6, 203–218. [Google Scholar] [CrossRef]

- Wesselink, R.; Blok, V.; van Leur, S.; Lans, T.; Dentoni, D. Individual competencies for managers engaged in corporate sustainable management practices. J. Clean. Prod. 2015, 106, 497–506. [Google Scholar] [CrossRef]

- Azapagic, A.; Millington, A.; Collett, A. A methodology for integrating sustainability considerations into process design. Chem. Eng. Res. Des. 2006, 84, 439–452. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manage. Rev. 1989, 14, 532–550. [Google Scholar]

- Vuorinen, I.; Järvinen, R.; Lehtinen, U. Content and measurement of productivity in the service sector: A conceptual analysis with an illustrative case from the insurance business. Int. J. Serv. Ind. Manag. 1998, 9, 377–396. [Google Scholar] [CrossRef]

- Voss, C.; Tsikriktsis, N.; Fröhlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Graebner, M.E. Theory Building from Cases: Opportunities and Challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Pettigrew, A. Longitudinal field research on change: Theory and practice. Org. Sci. 1990, 1, 267–292. [Google Scholar] [CrossRef]

- Creswell, J.W. Qualitative Inquiry and Research Design: Choosing Among Five Approaches, 2nd ed.; Sage: Thousand Oaks, CA, USA, 2007. [Google Scholar]

- Westlander, G. Data Collection Methods by Question-Asking; Royal Institute of Technology: Stockholm, Sweden, 2000. [Google Scholar]

- Richards, L. Data alive! The thinking behind NVivo. Qual. Health Res. 1999, 9, 412–428. [Google Scholar] [CrossRef]

- Hutchison, A.J.; Johnston, L.H.; Breckon, J.D. Using QSR-NVivo to facilitate the development of a grounded theory project: An account of a worked example. Int. J. Soc. Res. Methodol. 2010, 13, 283–302. [Google Scholar] [CrossRef]

- Walsh, M. Teaching qualitative analysis using QSR NVivo. Qual. Rep. 2003, 8, 251–256. [Google Scholar]

- Flick, U. An Introduction to Qualitative Research; Sage: London, UK, 2014. [Google Scholar]

- Yin, R.K. Applications of Case Study Research; Sage: London, UK, 2011. [Google Scholar]

- Lincoln, Y.S.; Guba, E.G. Naturalistic Inquiry. Newbury Park; Sage Publications: Thousand Oaks, CA, USA, 1985. [Google Scholar]

- Halldorsson, A.; Aastrup, J. Quality criteria for qualitative inquiries in logistics. Eur. J. Oper. Res. 2003, 144, 321–332. [Google Scholar] [CrossRef]

| Strategy | Examples of How Strategies Are Operationalized |

|---|---|

| Organisational Structures | Multifunctional teams, concurrent engineering, coordinating groups, matrix organisation, cross-functional project teams |

| Substitute Knowledge by Access to Knowledge | Gatekeepers; new managerial roles such as platform or program managers |

| Competency to Fill in the Knowledge Gap | Previous experiences are used to fill knowledge gaps |

| Decomposition | Integration through standardised interfaces allows for decomposition of complex designs or tasks |

| Physical and Virtual Artefacts | Use of artefacts to elaborate, develop, test, and industrialise concepts, which will be exploited by product managers later |

| Co-location | Relocation of personnel and physical facilities, personnel movement |

| Alpha | Beta | |

|---|---|---|

| Organising sustainability competency | Integration | Specialisation |

| Environmental considerations | Operationalized outside-in through customer requirements | Strategic efforts, emerge inside-out through product development |

| Access to environmental knowledge | Dominated by functional competencies such as QM and customer requirements | Co-organisation of individuals creates forum of specialists |

| Organization of competency | In accordance to customer requirements | In accordance to specialists |

| Trade-offs | Not addressed | Addressed systematically |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siva, V.; Gremyr, I.; Halldórsson, Á. Organising Sustainability Competencies through Quality Management: Integration or Specialisation. Sustainability 2018, 10, 1326. https://doi.org/10.3390/su10051326

Siva V, Gremyr I, Halldórsson Á. Organising Sustainability Competencies through Quality Management: Integration or Specialisation. Sustainability. 2018; 10(5):1326. https://doi.org/10.3390/su10051326

Chicago/Turabian StyleSiva, Vanajah, Ida Gremyr, and Árni Halldórsson. 2018. "Organising Sustainability Competencies through Quality Management: Integration or Specialisation" Sustainability 10, no. 5: 1326. https://doi.org/10.3390/su10051326

APA StyleSiva, V., Gremyr, I., & Halldórsson, Á. (2018). Organising Sustainability Competencies through Quality Management: Integration or Specialisation. Sustainability, 10(5), 1326. https://doi.org/10.3390/su10051326