1. Introduction

Regional power systems in post-Soviet countries are obsolete and require efficient modernization. This is specifically the case in today’s Russia, where the power industry largely relies upon the structure largely inherited from the Soviet Union. The electric power branch is one of the most important branches in the Russian economy and it is based on the combined heat and power plants (CHP) that co-generate both thermal and electric power for the needs of both households and industries [

1].

Over a half of the power production (both electric power and heat) in the Russian unified power system is co-generated in the combined cycle, using thermal power plants which ensures the saving of fuel for regional consumers by 20–30% [

2,

3].

Nonetheless, as far as the market model of the power industry goes, particularly where the wholesale power market is concerned, under the increasing irregularity of power consumption, this type of power generation faces serious problems in maintaining competitiveness compared to the separate production and individual supply of heat [

4,

5]. Hereinafter in this paper, the irregularity of the power consumption is defined as an increase in the number of peak and half-peak load hours throughout the year.

This phenomenon is caused by various factors. Quite probably, the main factor is a low manoeuvrability of CHP due to the impossibility of decreasing the electric power production while maintaining a constant heat load. This results in a price dip in the electric power market (which can sometimes drop to zero) during the nights when heat production is significant, but the electric power demand is rather low. CHP often cannot execute the order by a system operator and response to irregularities in power consumption which prevents them from participation in various competitive segments of the electric power trade market. In fact, CHP have been forced out of the market and transformed into large boiler houses [

6,

7]. Therefore, all the advantages of electric power and heat co-generation and district heating has vanished.

The expansion of the functioning of the power industry market model and the continuous growth of the irregularity in the electric power consumption makes the above-described problem more complex in nature. Thus, it essentially affects the energy and economic performance as well as the sustainability of the development of both national and regional power systems.

With regards to the above, the task of finding possible ways for the improvement of the steady-state of power systems under the objective trends of the changes in the conditions of the functioning of the power industry becomes very important. Our paper focuses on finding a new solution to this problem by means of optimising the production structure of CHP in such a way as to allow them to be more environmentally friendly.

2. Changes in the Demand Structure of Power Production and the Operational Performance of Power Systems

The development of the Russian national power system, as well as the development of the united regional power systems that constitute its integral parts, is determined in many ways by the modern trends in the structure of power production demand. Due to the gradual transition towards a post-industrial economy, the share of the power-consuming industry is gradually shrinking. The same issue concerns the power consumption required for manufactured goods; it also decreases because of the realisation of power-saving programmes and the implementation of power efficient manufacturing technologies.

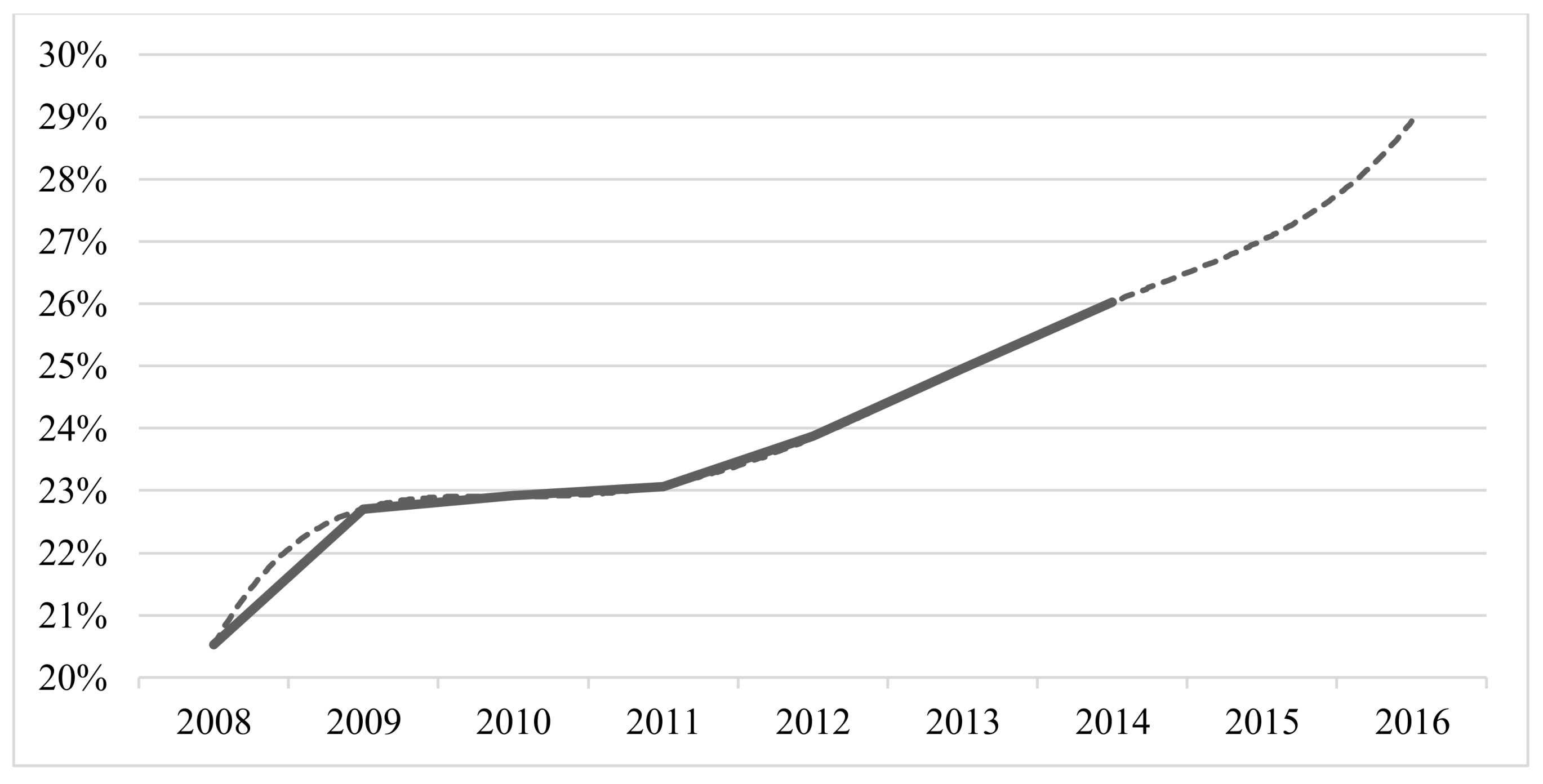

This is where the role of domestic consumers becomes particularly important. Essentially due to the growing urban population and the increased power consumption per capita due to the increasing number of household electric appliances. This trend is shown in

Figure 1.

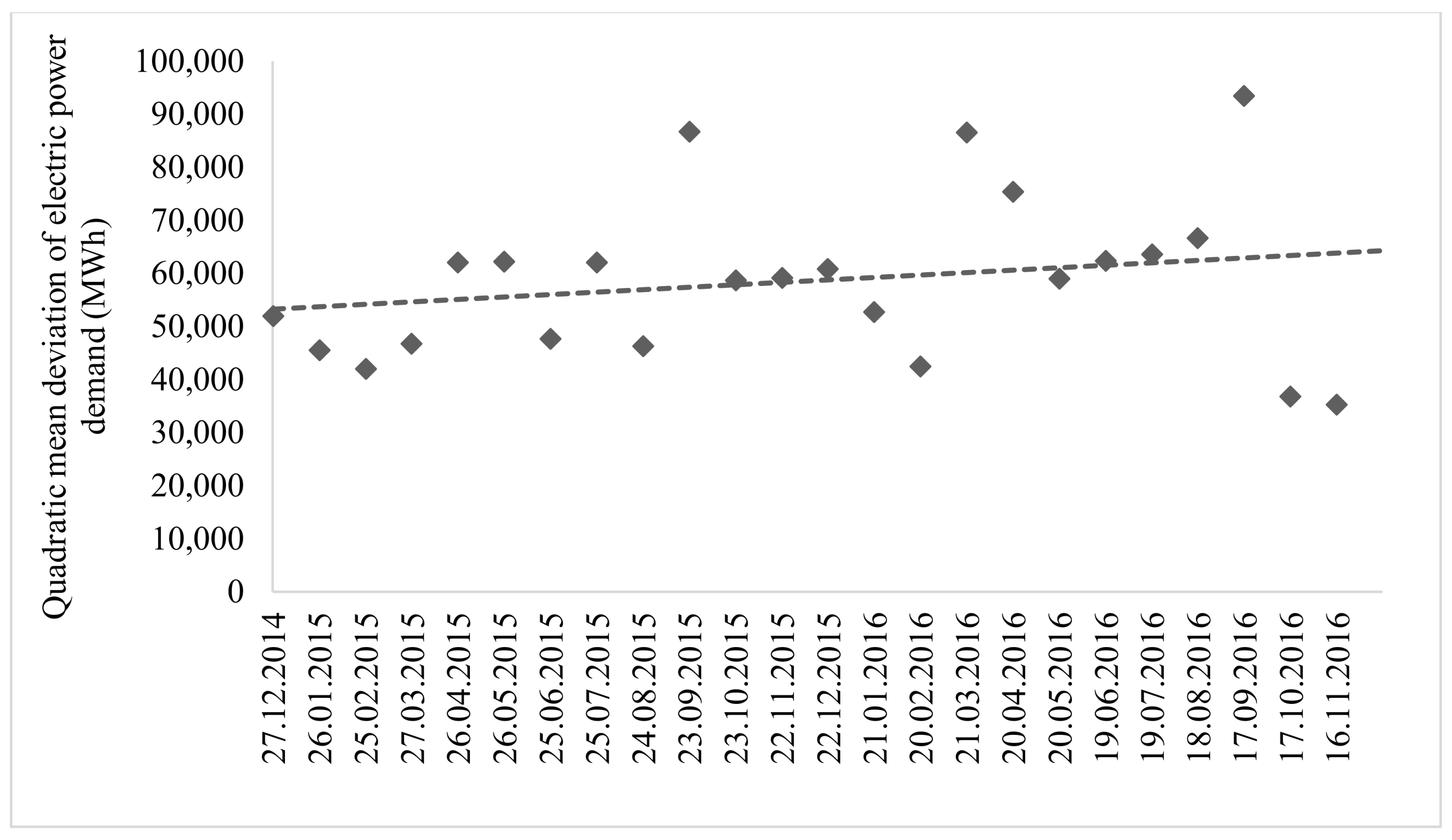

Changes in the structure of power demand and the increasing number of household consumers have resulted in the increased irregularity and unpredictability of electric and heat power demand. Our statistical analysis of the Russian national power system power consumption data during the day-time revealed positive dynamics that reflect a growing deviation of the electric power demand from the mean value (see

Figure 2). It appears that the power consumption irregularity growth rate in the power system during 2014–2016 was over 2.4%.

This situation is worsened by the fact that, while the power system is able to control the demand of industrial customers by stimulating the shift work of enterprises, thus, equalizing the electric power consumption in time, in the case of household consumers, there is no such possibility since the time distribution of power consumption by individual households is stipulated by the social and biological rhythms of their members, which is rather difficult to control. This fact seriously impacts the operational performance of the power system.

The operational performance of the power system is characterised by various economic indicators that impact the functioning of its productive capacities. In most Russian regions, the productive capacities are basically represented by the generating units that produce power (both electricity and heat) in the co-generation cycle. Typically, co-generation such as that is performed at the CHP.

As CHP generate both electricity and heat using the unified technological process, controlling the separate delivery of these two resources does not seem to be possible. This is because heat and electric power are two completely different products, assuming different principles of consumption. As a result, they form two separate markets and each of these two markets creates its own independent demand. However, the co-generation technology does not allow for the regulation of the delivery of one of these types of energy without affecting the delivery of the other type, in order to adequately satisfy these demands [

4,

10].

Under the conditions of the increasing irregularity of power consumption, the co-generating units used at thermal power plants are unable to work full time in the rated mode. This fact significantly decreases the fuel saving effect of the power and heat co-generation, as well as the operational performance of the thermal power plants as a whole [

7,

8].

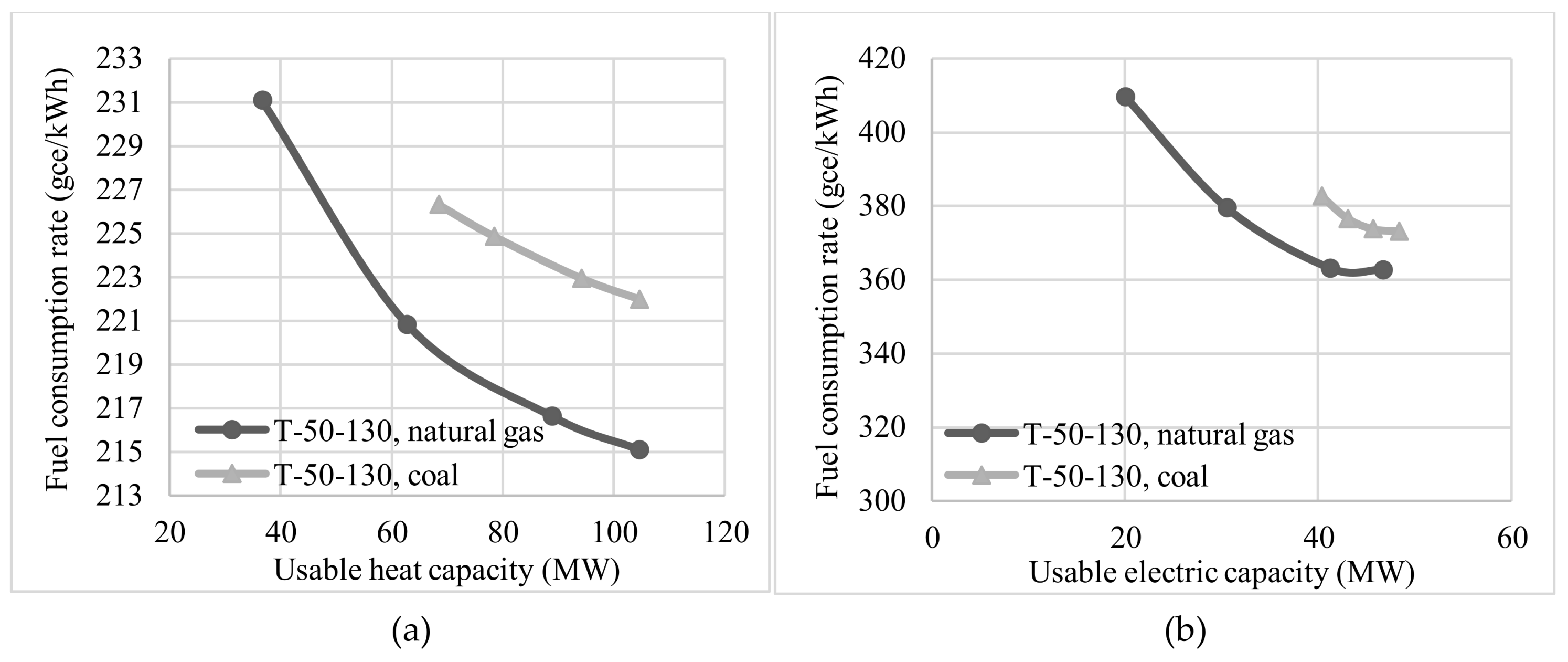

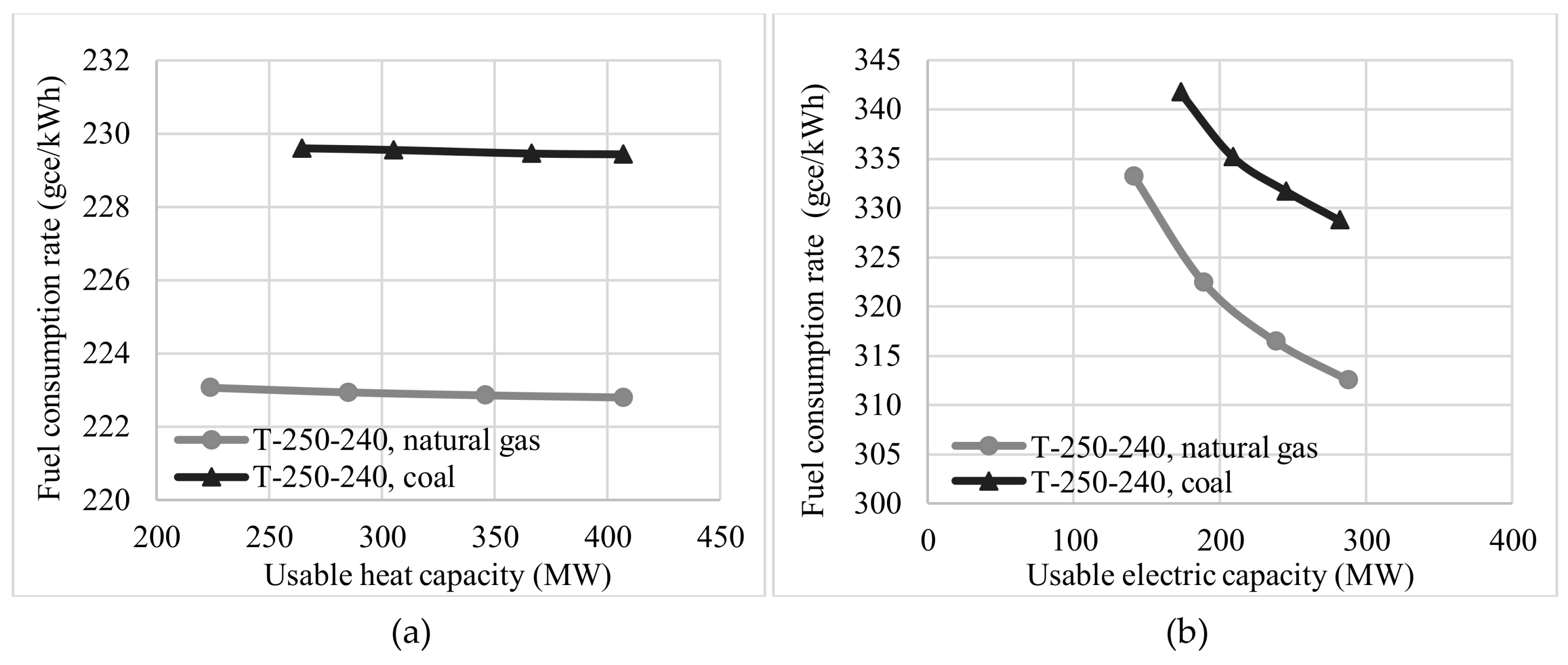

Figure 3 and

Figure 4 that follow demonstrate the obtained dependencies reflecting the change of the fuel consumption rate on the load of various co-generating units, taking into account the cost transfer for either the heat or electric power production.

Increasing the irregularity of the power consumption results in the incomplete load of the least manoeuvrable co-generating units, as well as in the growth of the heat and electric power production costs, hence, decreasing the competitiveness of the CHP. Under these conditions, the local power-generating companies have been switching from electric power and heat co-generation to the separate generation of energy products in order to improve their flexibility regarding power production in order to keep a stable position within the wholesale power market. Regional power sources are rearranged by passing the heat load of the local boiler houses to CHP. With that, power plants decrease the electric power production. In fact, CHP have been transformed into large boiler houses and the share of electric power and heat co-generation is shrinking.

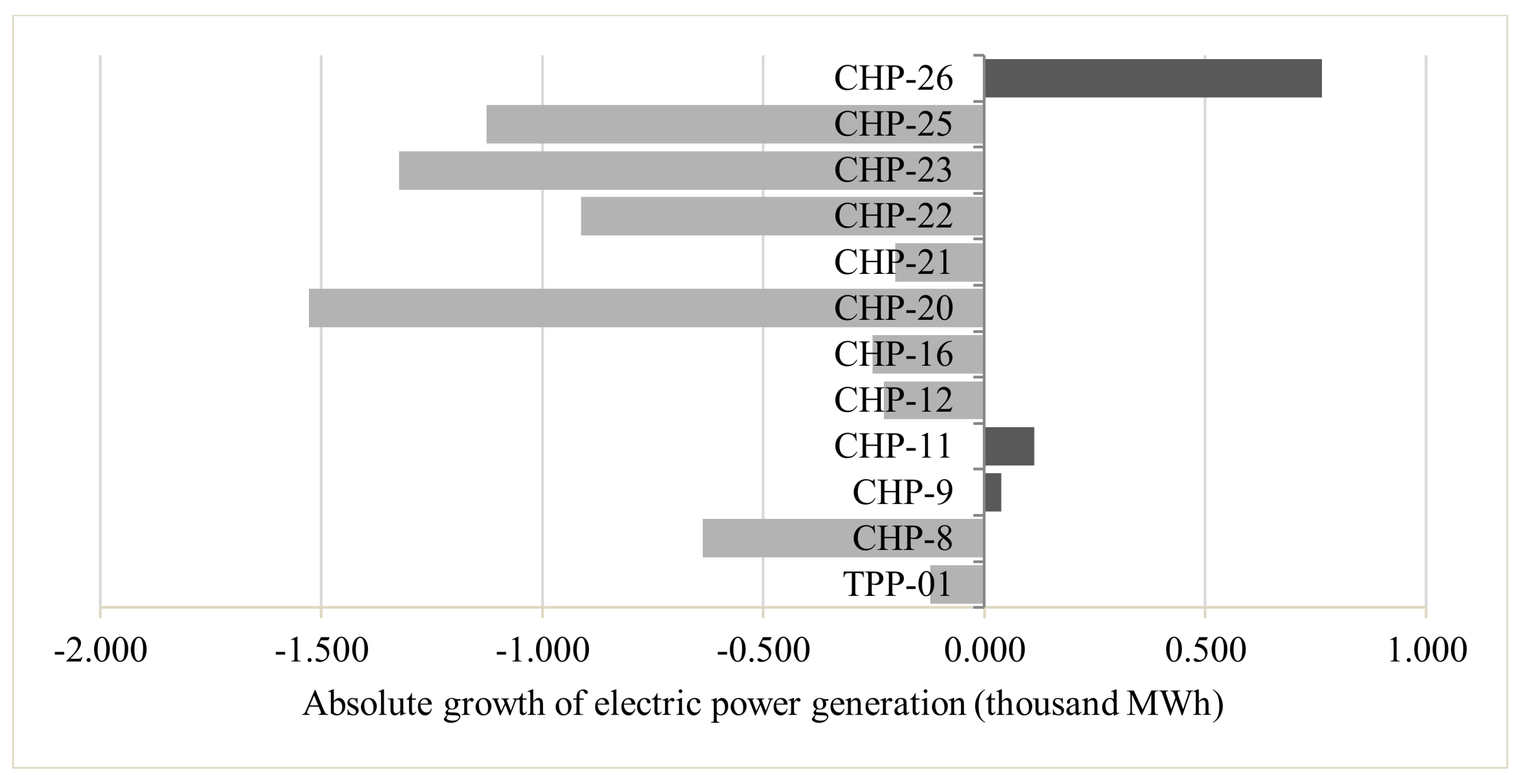

Figure 5 and

Figure 6 demonstrate the results of our analysis of the changes in volumes using an example of the electric power production for CHP, supervised by the Joint Stock Company (JSC) ‘Mosenergo’, a regional generating company.

Our analyses of the 88 large CHP located in various climatic zones all over Russia indicated the increasing differentiation of the power equipment configuration. Apart from the traditional co-generating units, CHP are equipped with gas turbines and combined cycle power units for purposes of improving the flexibility and performance of power production in case of an increasing irregularity in demand [

3,

14]. This results in changes to the production structure of the regional power systems and calls for a solution to the problem of the optimisation of the configuration of the power generating equipment with the purpose of identifying the medium-term and long-term steady-state of the power system.

3. The Approach of the Production Structure Optimization of the Regional Power System

One would probably agree that the violation of the principle of unity of the power-generating units at CHP caused by changes in the power consumption structure results in the need for the optimization of the CHP equipment and hence, in the determination of an efficiency criterion.

Most algorithms for optimizing the production structure of the power system are based on reducing its total fuel costs [

15,

16,

17]. In our opinion, it would be more appropriate to approach the study of the stable-state of the power system from the position of analysing the use of its installed capacity. Let us take the installed capacity rate for power generating equipment as the efficiency criterion since it reflects the load within a year [

18,

19]. The higher this value, the better the production structure has adapted to the power demand fluctuations and the more hours of the year that the power generating units get to work in the rated mode.

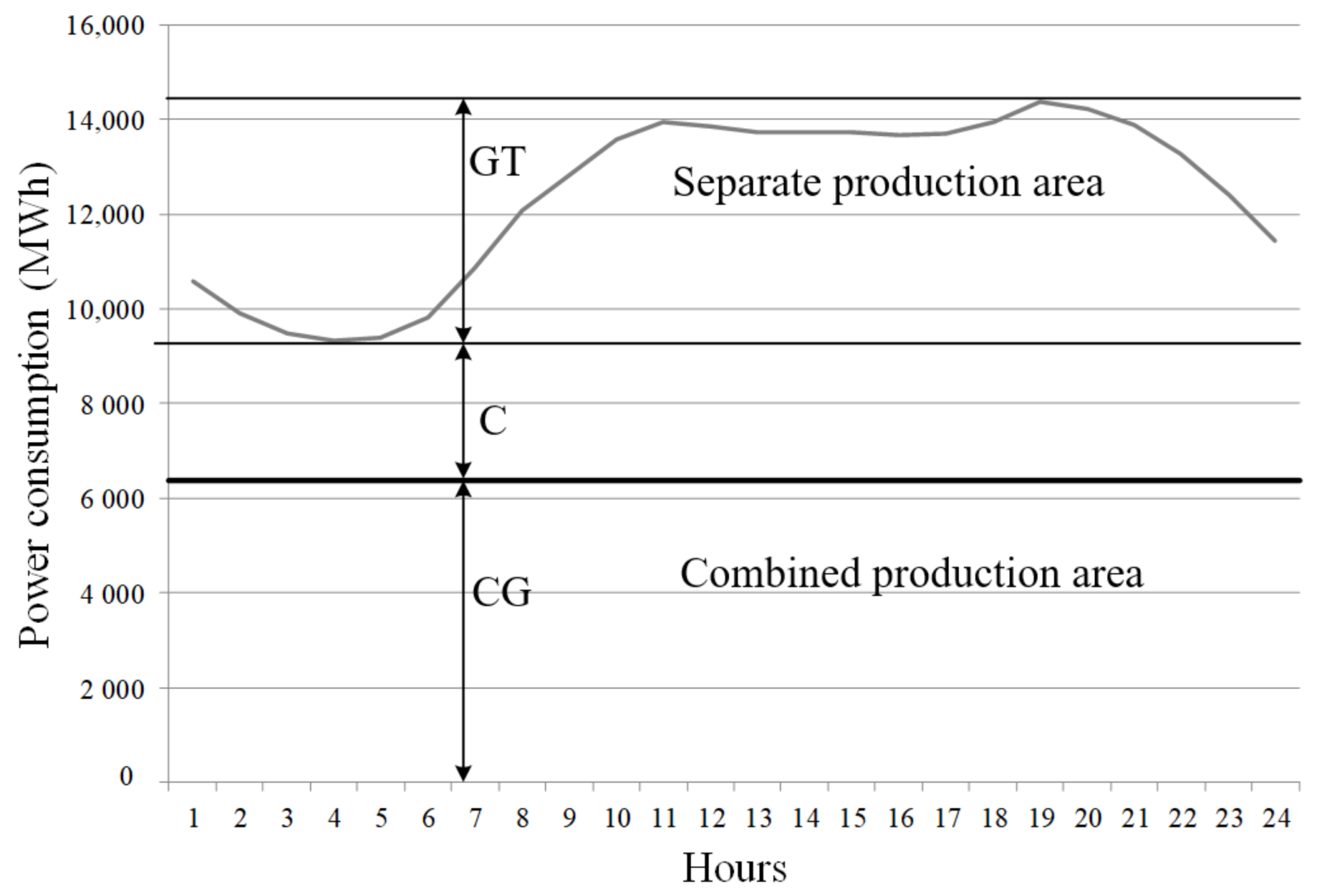

The daily power consumption largely depends on the ambient temperature (that is, the climatic season) as well as on the type of the day in the week (working day or a holiday). In order to solve the optimization problem, it is necessary to statistically select the typical days of high electric power consumption and to perform the stratification of the daily load schedule. An example of the fragmentation of the load schedule with respect to the applied power equipment is depicted in

Figure 7.

According to

Figure 7, the manoeuvrable gas turbine units (GT) are applied at peak electric load hours. During the basic electric load hours, the co-generating equipment (CG) is applied, providing electric power generation in the cost-efficient combined mode; unsatisfied demand on electric power is covered by using condensing power units (C).

For the purpose of the selection of the configuration of the power generating equipment of CHP, one needs to compose and analyse the various samples of power generating units that can help satisfy the given hourly demand [

20,

21]. This is a combinatorial optimization task which is solved by using dynamic programming methods.

In order to improve the efficiency of the obtained results, we suggested ranking the power generating units with respect to their level of capacity. Then, in order to cover the daily load schedule, we employed the units with the highest unit capacity. This approach allowed the most efficient power units to work in the rated mode, thus, minimizing the fuel consumption rate.

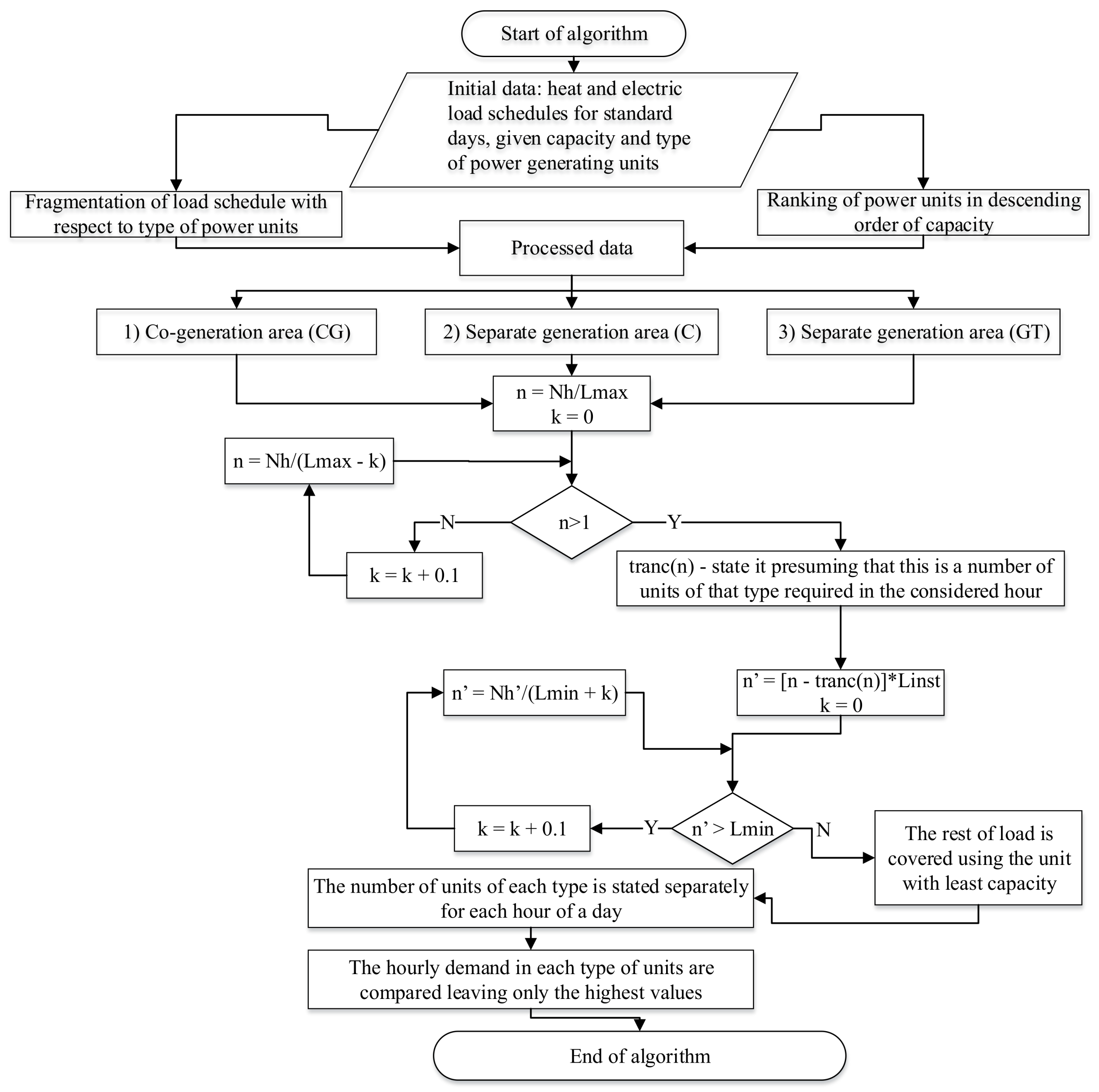

Figure 8 demonstrates the algorithm for the optimization of the configuration of the power-generating equipment dependent upon the given daily electric power demand.

The algorithm shown in

Figure 8 presents a combinatorial problem solution that employed the dynamic programming principles based on a stepwise optimisation and successive approximation to the best sample of power generating equipment with respect to the installed capacity ratio. Here,

n is the size of the sample of units of a given type,

Nh is the load in a particular hour of a typical day,

Lmax is a unit of the given type with the maximum capacity,

Lmin is a unit of the given type with the minimum capacity,

Linst is the installed capacity of the unit of a given type, and finally,

n’ is the number of loaded units of the selected type and capacity.

4. Results of the Simulation Study

Generally, the production capacities of the regional power systems are represented by the assets of the local generating companies. Mosenergo, JSC is one such company, providing consumers of the Moscow Region with power products (delivering about 60% of the total electric power and 43% of the total heat in the Moscow agglomeration). By now, the production assets of the company consist of 15 thermal power plants. Furthermore, a program of transfer of the municipal boiler houses to Mosenergo, JSC has been under implementation since 2013. Its overall electric capacity is 12.3 GW, while its overall heat capacity is 40.7 GW. Natural gas is mainly used as a fuel for power generation.

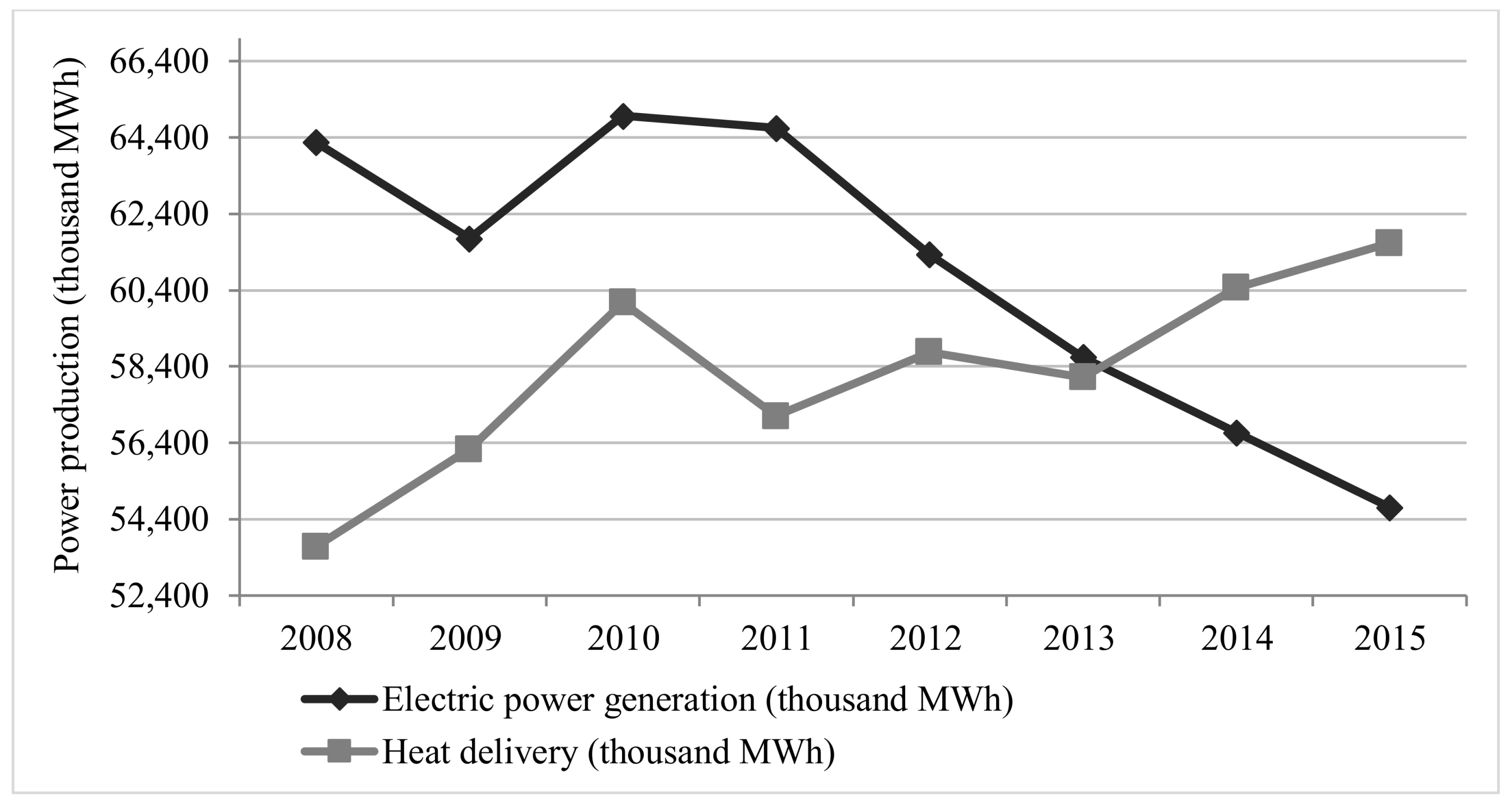

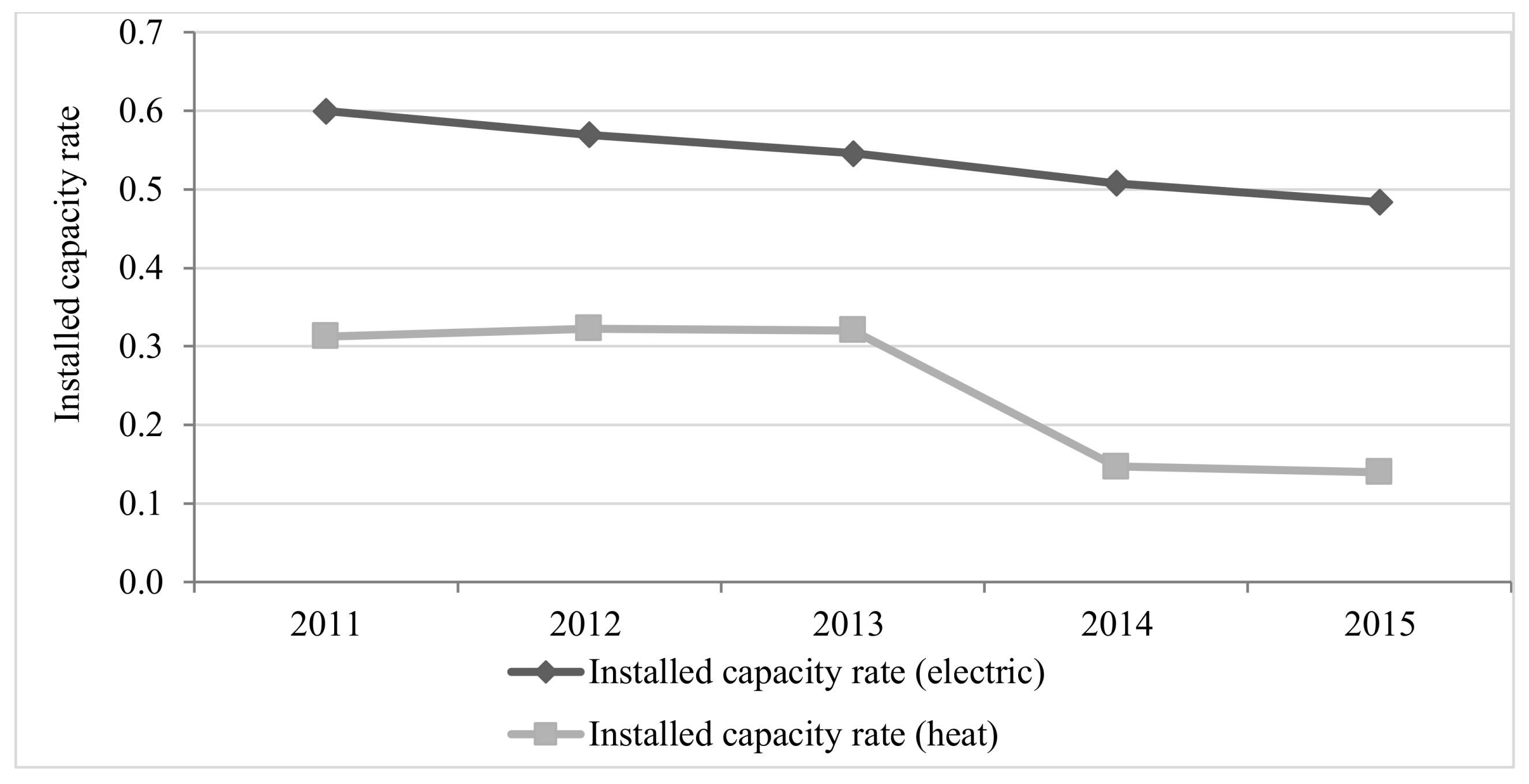

According to its annual reports, the installed capacity rate of the thermal power plants supervised by Mosenergo, JSC has been sustainably decreasing since 2011 to 2015 and its value in 2015 constituted 0.48 (compared to the 0.6 in 2011) for electric load and 0.14 (compared to the 0.31 in 2011) for heat load (see

Figure 9).

The Mosenergo, JSC production capacities are represented by the following units:

Thermal power equipment for electric power and heat co-generation (49 units).

Condensing equipment for electric power generation in the rated mode (43 units).

Gas turbine units for covering the irregularity of power consumption (136 units).

In order to make a forecast of the regional power consumption values until 2025, we applied the algorithm for the optimisation of the configuration of the power generating equipment. The results of this study demonstrated that when the irregularity of power consumption increases by 0.8% per annum, the enterprise needs to increase the share of gas turbine units in the configuration of the generating equipment by 0.26% in order to provide the current values of the installed capacity ratio under the conditions of the continuously growing demand for electric power. Accordingly, by 2025, the share of gas turbines at the CHP should increase by 2.6%. Our results also demonstrate that in order to reach the steady-state of the regional power system, one needs to optimise its production configuration by increasing the number of manoeuvrable gas turbine units.

It should be noted that the high cost of using gas turbine plants is primarily tied to the fact that, as a peak source, they are loaded for a small number of hours throughout the year. Consequently, the growth of the irregularity of energy consumption increases the number of peak and half-peak hours. Thus, the profitability of gas turbines is significantly increased.

It appears that the implementation of our approach on the optimisation of the production capacity configuration in developing investment programs would result in the increased load rate of the power-generating equipment of the local power generating company and thus, would increase its revenue while simultaneously improving both cost efficiency and the key steady-state stability of the regional power system.

5. Conclusions

Overall, our results show that the improvement of the steady-state of the regional power systems in the case of the increasing irregularity of power consumption in Russia depends on the solution of the problem of the provision of the required manoeuvrability level for combined heat and power plants performing cost-efficient co-generation of power products. The plant manoeuvrability level is determined by the configuration of the production equipment providing the cost-efficient operation of a power plant within a wide range of loads determined by the demand on power products.

Changing the power consumption structure and the growth of the household consumption share resulted in the increased differentiation of the power generating equipment configuration. Apart from the traditional thermal power units intended for the co-generation of electric power and heat, CHP are equipped with gas turbines and combined cycle power units that help them to improve the flexibility and performance of the power plant, including the separate generation of heat and electric power. At the same time, the correct combination of these production technologies might ensure a stable-state of the power system from the perspective of increasing the use of its installed capacity and reducing fuel costs.

On the other hand, it appears that the violation of the principle of unity of power generating unit types at thermal power plants would inevitably result in the need for the optimisation of the CHP equipment and the development of the efficiency criterion. This problem gets more complicated when one realizes that there is a need to consider the increase of the irregularity of the power consumption while performing the optimisation. Our paper proposed an algorithm that allows for the consideration of finding the best possible structure for the power equipment in the form of a combinatorial optimization task. In order to solve this task effectively, one needs to use the methods of dynamic programming. We applied the installed capacity rate as an efficiency criterion as it reflects the load of the equipment within a year. The higher this value, the better the production structure has adapted to the power demand fluctuations and the more hours of the year the power generating units can work in the rated mode.

The results of the simulation study demonstrated that our approach to the successive optimisation of the configuration of power generating equipment enabled us to calculate the cost-efficient load of the production capacities of the local power generating company under the conditions of the increasing irregularity of power consumption, thus, devising the necessary conditions for the sustainable development of the regional power system.