1. Introduction

In order to use industrial and residential land, we are developing soft grounds such as tidal flats. General soft-ground improvement methods are the preloading and the vertical drainage. In both methods, marine clays such as tidal flats have a very small permeability, so that excess pore water pressure is generated by the preloading of embankment, and it is drained by the vertical drainage of sand. However, because this method requires a large amount of sand, deforestation and land degradation are serious [

1]. Furthermore, because the permeability of the clay is very small, the consolidation of clay takes about five to 10 years to complete [

2].

To solve this problem, Beles and Stănculescu [

3], and Litvinov [

4], developed a ground-heating method using fossil fuels. It is a method of burning after pressurizing fossil fuel mixed with air into the bore holes on the soft ground. Because fossil fuel and air burn at temperatures of 600–800 °C into the bore holes, the state of the clay rapidly changes from a saturated liquid to a dried solid. Most of the soil is non-plastic at 400–600 °C [

5,

6,

7,

8,

9]. As a result, the strength of the clay sintered by the ground heating is rapidly increased, and the ground can be improved and utilized as a construction site [

4,

9,

10,

11].

However, the ground-heating method using the fossil fuels has not been widely applied due to many problems. The entire system of the ground-heating method proposed by Litvinov [

4] is very complicated due to the compressor, pipeline for cold air, a container for liquid fuel, pump for supplying fuel under pressure into the bore hole, fuel pipeline, filters, nozzle, and the cover with the combustion chamber. Furthermore, the operation of this system requires highly skilled engineers. Finally, the cost of fossil fuels is high, and the economy is low [

1].

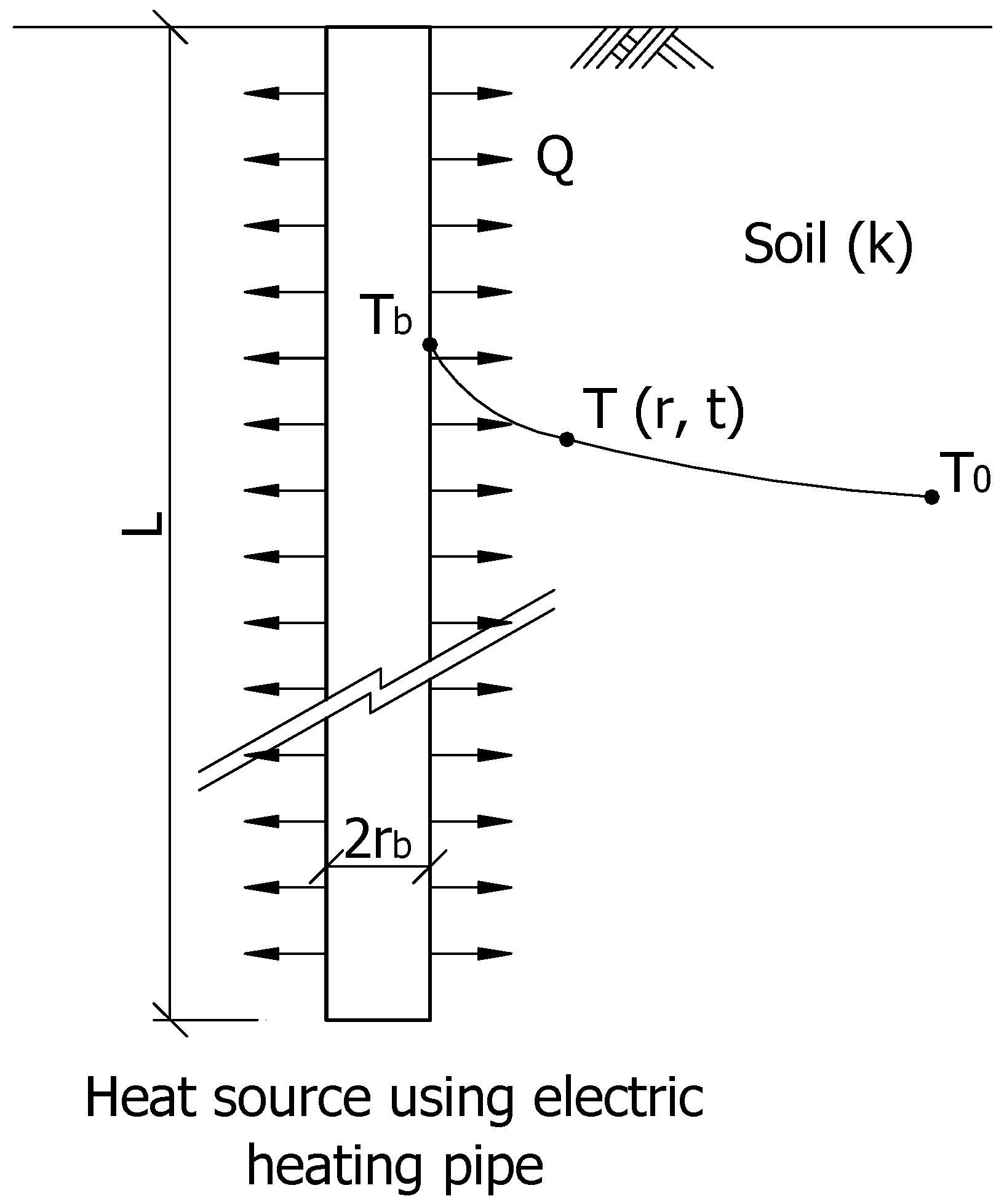

In recent years, Park, Im, Shin and Han [

1] proposed a ground-heating method in which fossil fuel use was improved with the electric heating pipe. The electric heating pipe converts the electric energy into thermal energy by the electric-resistance method, and is applied to the improvement of the strength of the soft ground. They heated the depth of soft ground up to 1.0 m, and confirmed the trafficability of the construction equipment. Park et al. [

12] conducted the experiment of a comparison of the consolidation settlement of the pre-loading with vertical drain, and the ground-heating method using the electric heating pipe. As the result showed, the dissipation of pore water and the consolidation effect were remarkably better by the ground-heating method in the laboratory scale. Park, Lee, Jang and Han [

2] studied the temperature change on the soft ground by the ground-heating pipe. The soft ground of the silty sand was heated by an electric heating pipe and the temperature change of the ground was measured. The experimental results were compared with a theoretical solution and a numerical analysis. The temperature change from the heat source, the electric heating pipe, was shown to be a logarithmic decreasing function. Additionally, there was a larger temperature change in the vertical direction than in the horizontal direction from the heat source.

The effect of the ground-heating method using the electric heating pipe has been verified, but it is necessary to solve many engineering problems in order to put it to practical use. Park, Im, Lee and Han [

12] reported that a large amount of water vapor is discharged to the ground surface due to the ground heating. However, since the discharge of water vapor is a heat loss, it is necessary to experimentally verify how the temperature changes according to the presence or absence of discharge of water vapor in the ground-heating process. For the design of this method, the temperature change due to the ground heating should be calculated by theoretical solution and numerical analysis. However, these techniques do not consider the heat loss due to the discharge of water vapor. Therefore, it is necessary to compare these techniques with experimental results performed in the presence or absence of discharge of water vapor.

The ground-temperature distribution generally uses Kelvin’s linear source model, which is used for the design of the ground heat exchanger. For the ground heat exchanger, much research has been done on evaluation of thermal conductivity for grout/soil formation using thermal response [

13]. The ground heat exchanger has a small difference and variation in temperature between the heat source and the ground. Because the ground-heating method has a large temperature difference between the heat source and the ground, and heat loss due to water vapor is generated, it is necessary to verify the linear heat-source model to estimate the temperature distribution of the ground-heating method. Finally, the numerical analysis to estimate the temperature distribution is mainly used for the study of geothermal phenomena, and freezing and thawing on the ground [

14]. Most of these studies have been conducted on heat-transfer processes by climatic conditions or pipelines. There are not many cases in which ground temperature changes due to high-temperature heat sources (such as the ground-heating method) are estimated.

In this study, two case experiments were conducted to investigate the temperature changes of the ground, depending on whether water vapor was discharged or not. Then, the linear heat-source model as the theoretical solution and numerical analysis was performed and compared with experimental results. In the first case, an electric heating pipe was exposed to the surface of the soil so that water vapor could be discharged. The second case was installed at a depth of 30 cm from the surface to prevent water vapor from being discharged. This experiment was based experiments on the thermal conductivity of soil [

15,

16] and with experiments performed by Park, Im, Lee and Han [

12]. Compared with the previous studies, the sensor for measuring the ground temperature was the same, and the heat source was an electric heating tube manufactured for this study. Unlike previous studies, the electric heating pipe was heated to 450 °C using a DC power supply. Additionally, kaolinite, a standard clay, was used. Numerical analysis was performed with Temp/W of Geostudio under the same conditions as the experiment.

3. Characteristics of Heat Transfer Due to Vapor Discharge

3.1. Ground Heating and Measurement System (Case 1)

Electric heating pipes that are generally used in the industrial field are made up of heating wires, protective tubes and the heat-transfer medium of magnesia (MgO). The Korea standard electric wires can be classified into nickel–chromium type 1, nickel–chromium type 2, iron–chromium type 1, iron–chromium type 2, and so on [

21], and this study used nickel–chromium type 1. Protective tubes are made of iron, copper and stainless steel, and this study used a stainless steel tube (SUS 304). Magnesia, the heat-transfer medium, has an excellent heat conductivity at a high temperature compared to other ceramic materials, as it has good electrical insulation properties. Apart from transferring heat, magnesia plays the role of preventing a short circuit by fixing electric heating wires inside the protective tube.

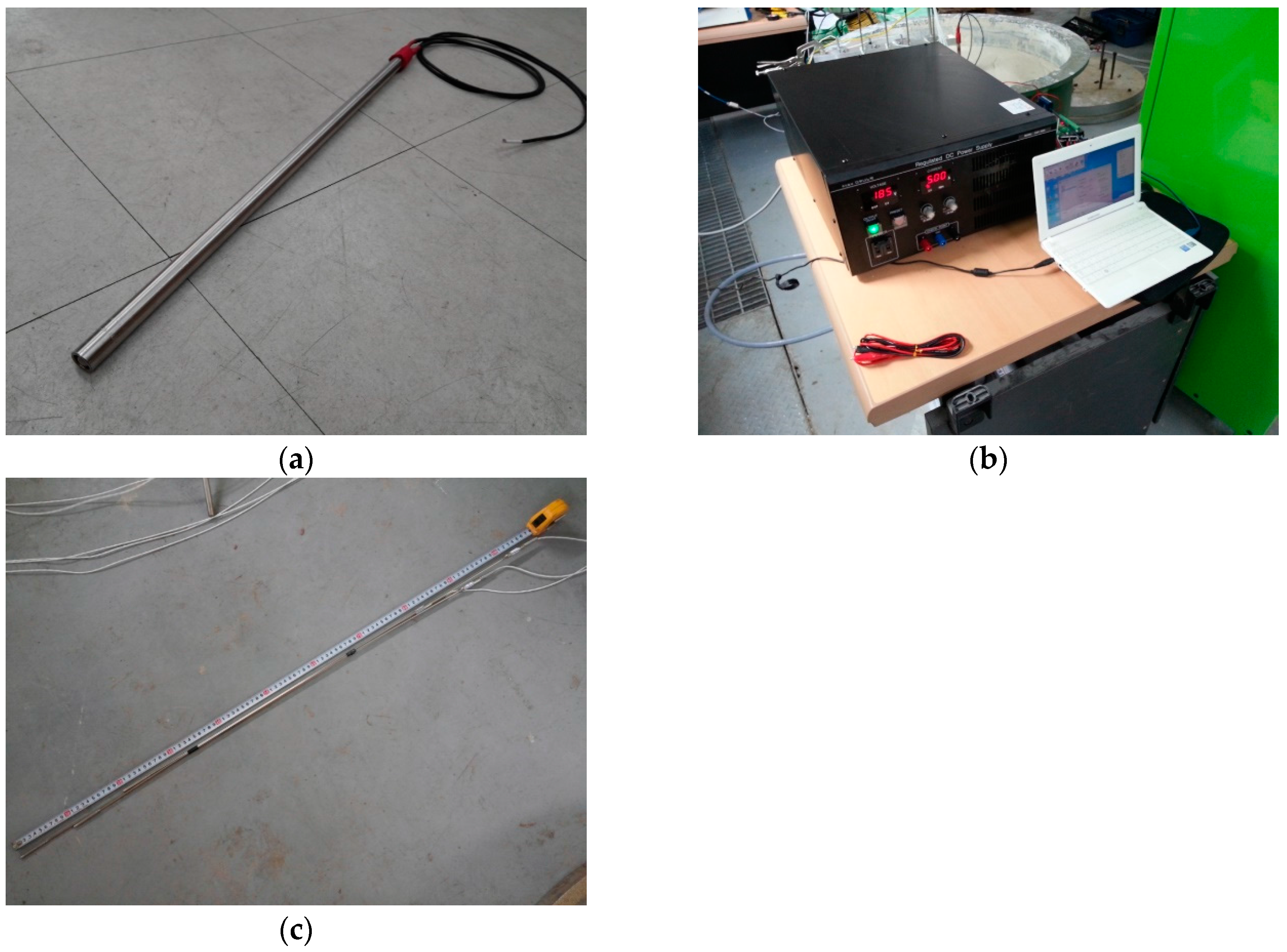

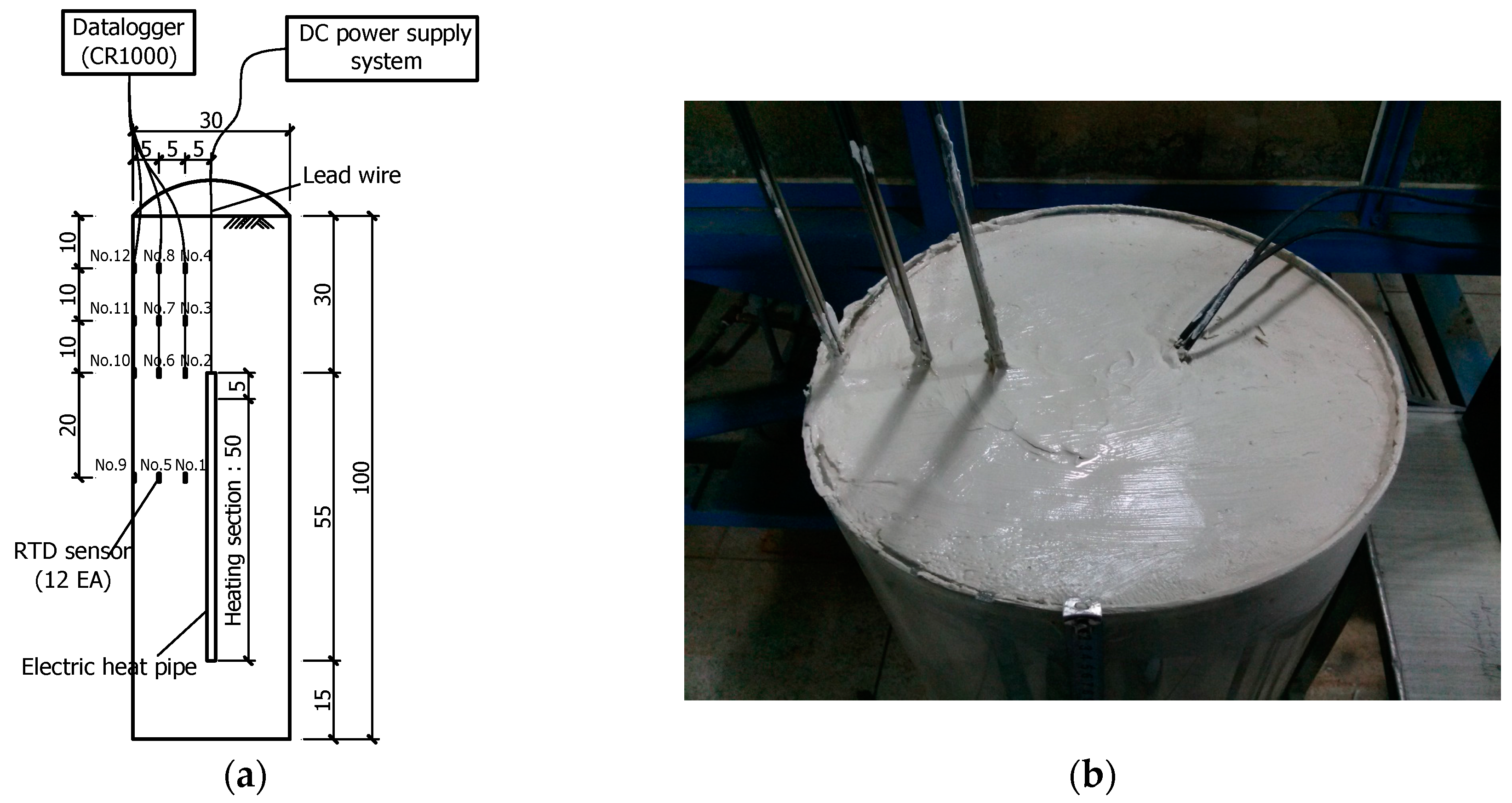

The electrical heating pipe used in this study, as shown in

Figure 2a, has a total length of 60 cm, which has a heating section of 55 cm and a nonheating section of 5 cm, with a diameter of 22.7 mm. The electric heating pipe was supplied with a constant direct current by using a DC power supplier (

Figure 2b). In the experiment, an electric heating pipe consumes electric power of about

per hour, and the surface temperature is 500 °C. A resistance temperature detector (PT100) was used as a thermometer, and the temperature measurement range was 0 to 700 °C measured at intervals of 10 min.

The soil box was made in a round shape with a diameter of 100 cm and a height of 67 cm using steel. In order to drain the pore water by self-weight consolidation, a membrane was installed at the bottom of the soil box. The soil used in the experiment was kaolinite, a standard clay, and stirred at a water content of two times the liquid limit with a vacuum stirrer. The agitated standard clay was filled in the soil box and self-weight consolidation occurred for about six months, while the height of the standard clay was about 53 cm.

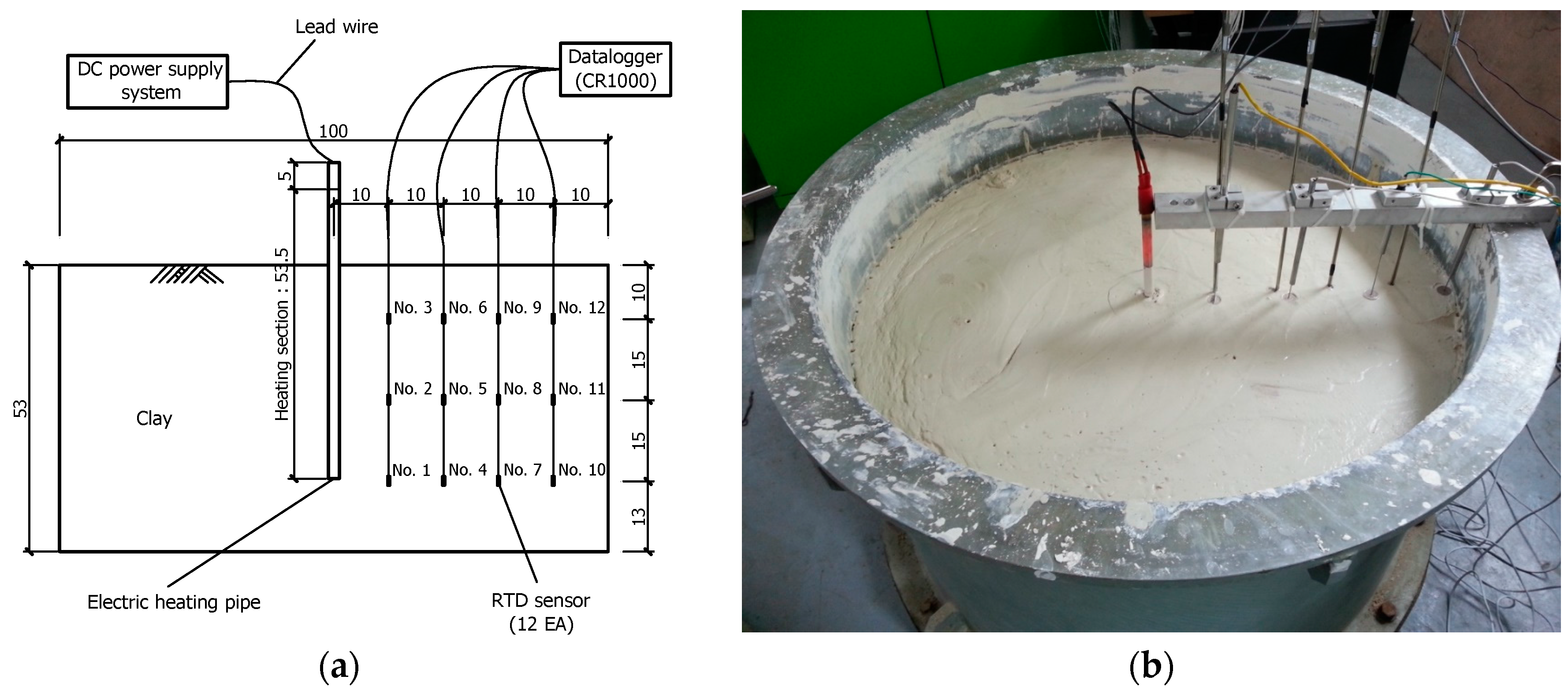

An electric heating pipe with a total length of 58.5 cm was interpenetrated and installed 40 cm deep into the middle of the soil box filled with the standard clay. The thermometers were positioned in four rows at a 10 cm interval in the horizontal direction and in three columns at 10 cm, 25 cm and 40 cm depths from the surface in the vertical direction (

Figure 3).

Ground heating was carried out for two days and the temperatures were measured for seven days in order to find out temperature increases by ground heating as well as temperature decreases after the end of heating.

3.2. Temperature Measurement Results (Case 1)

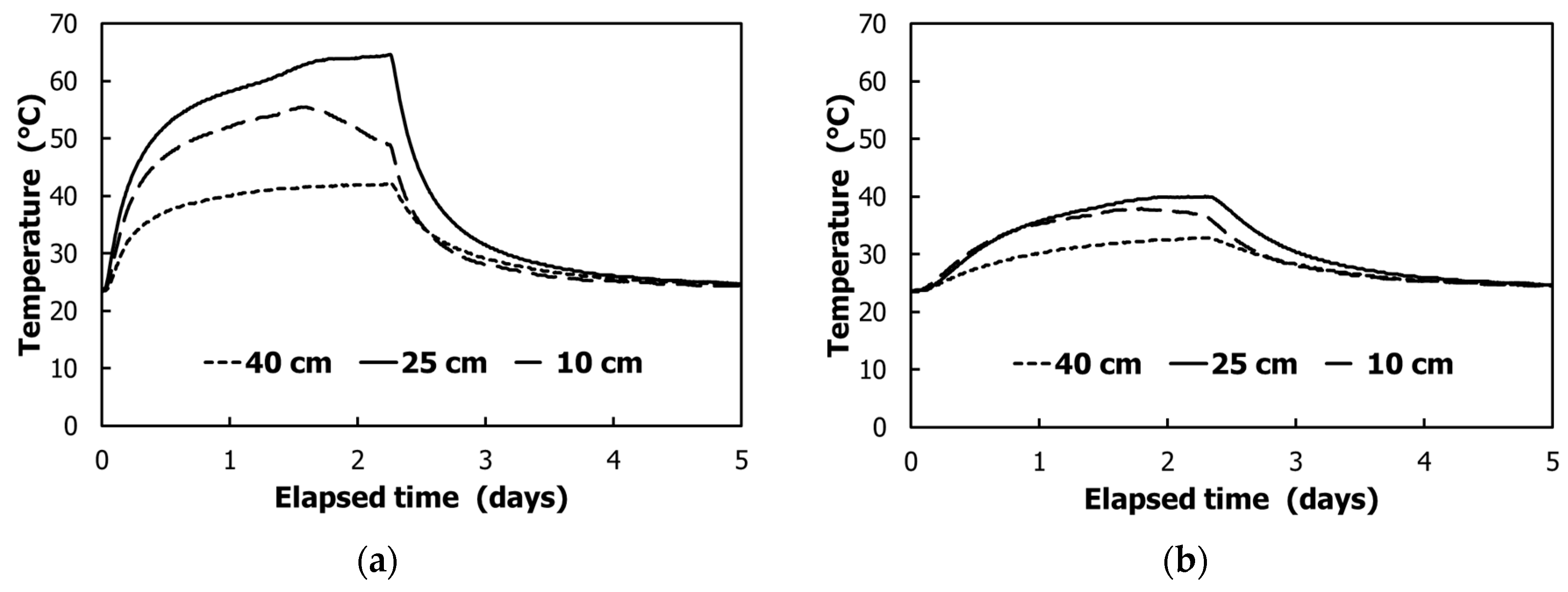

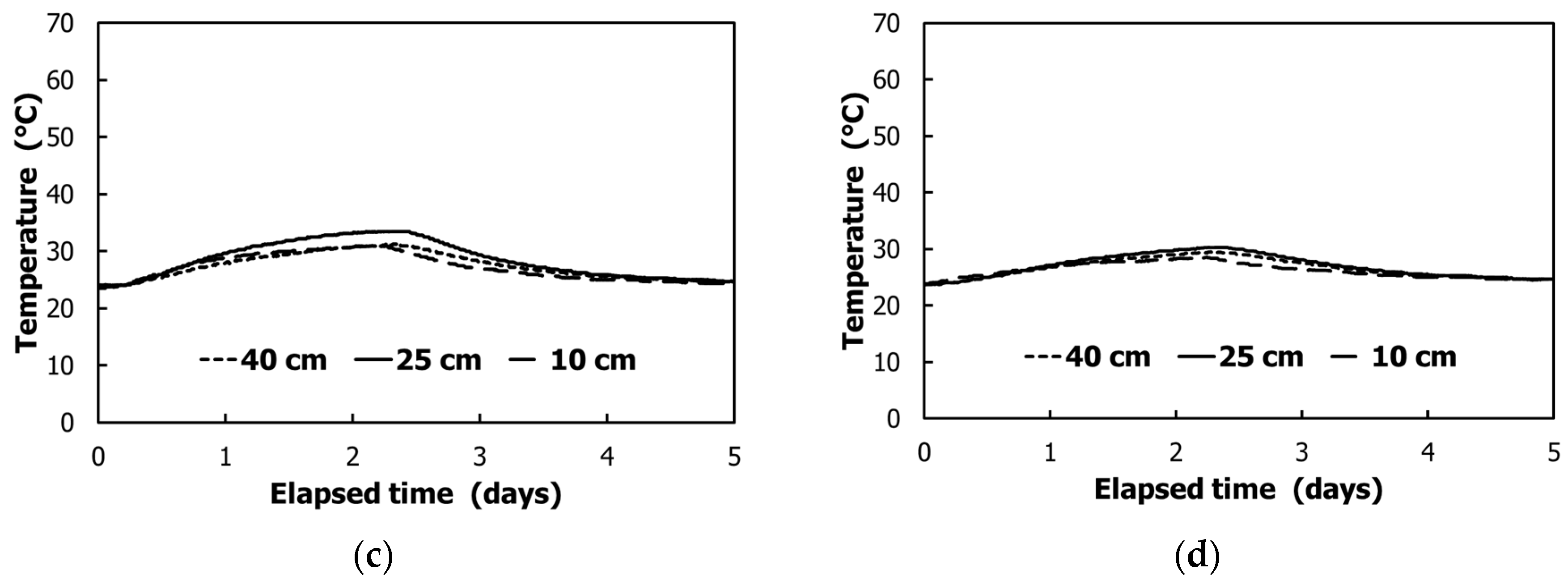

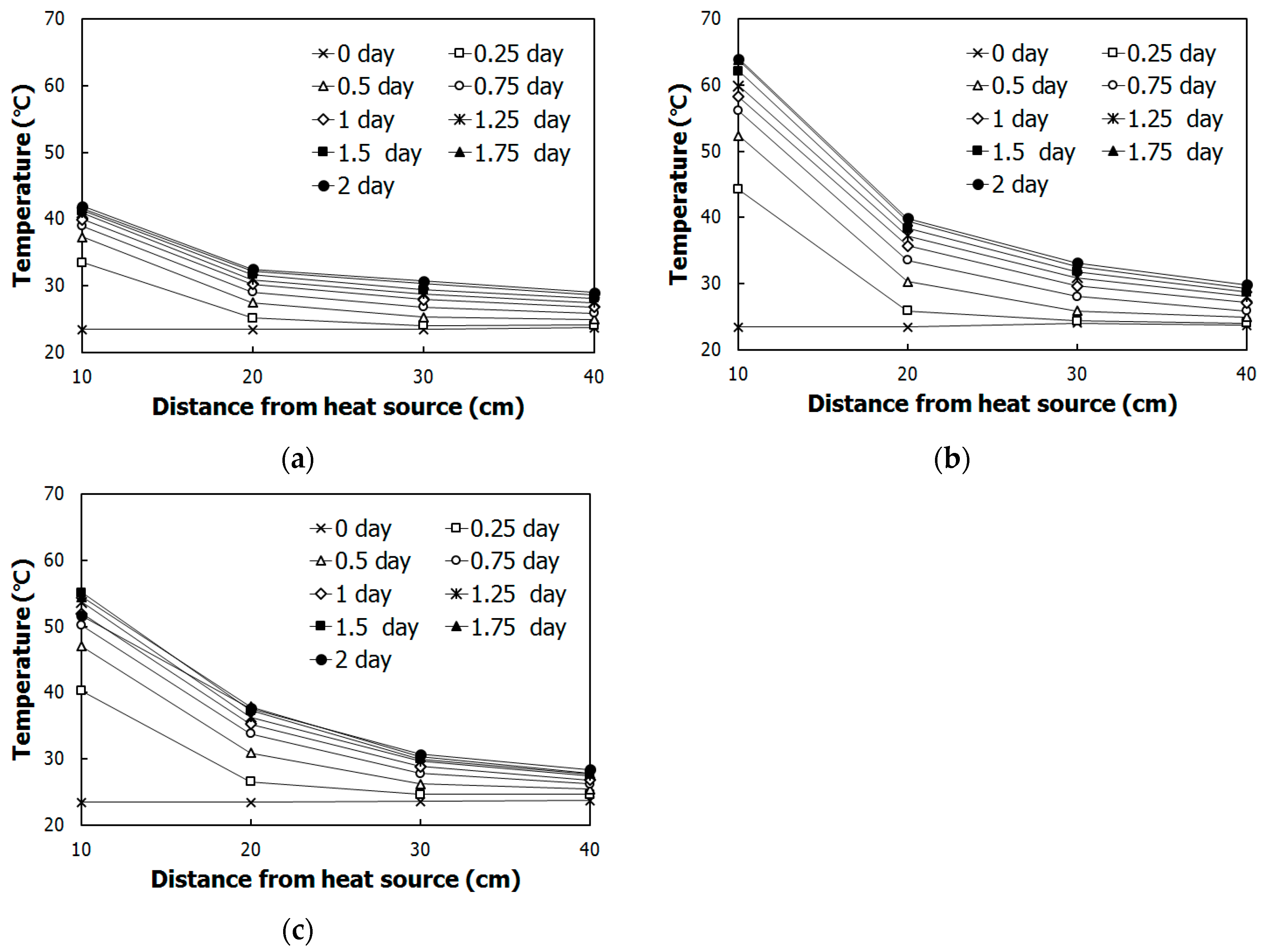

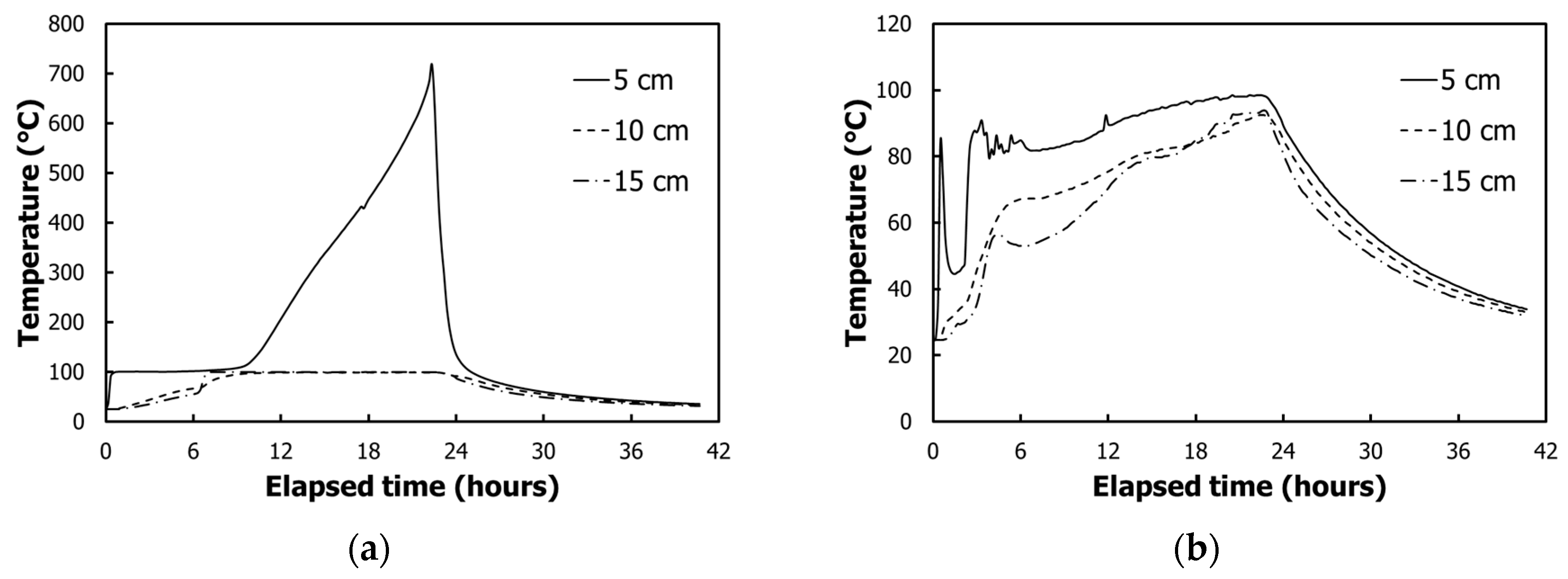

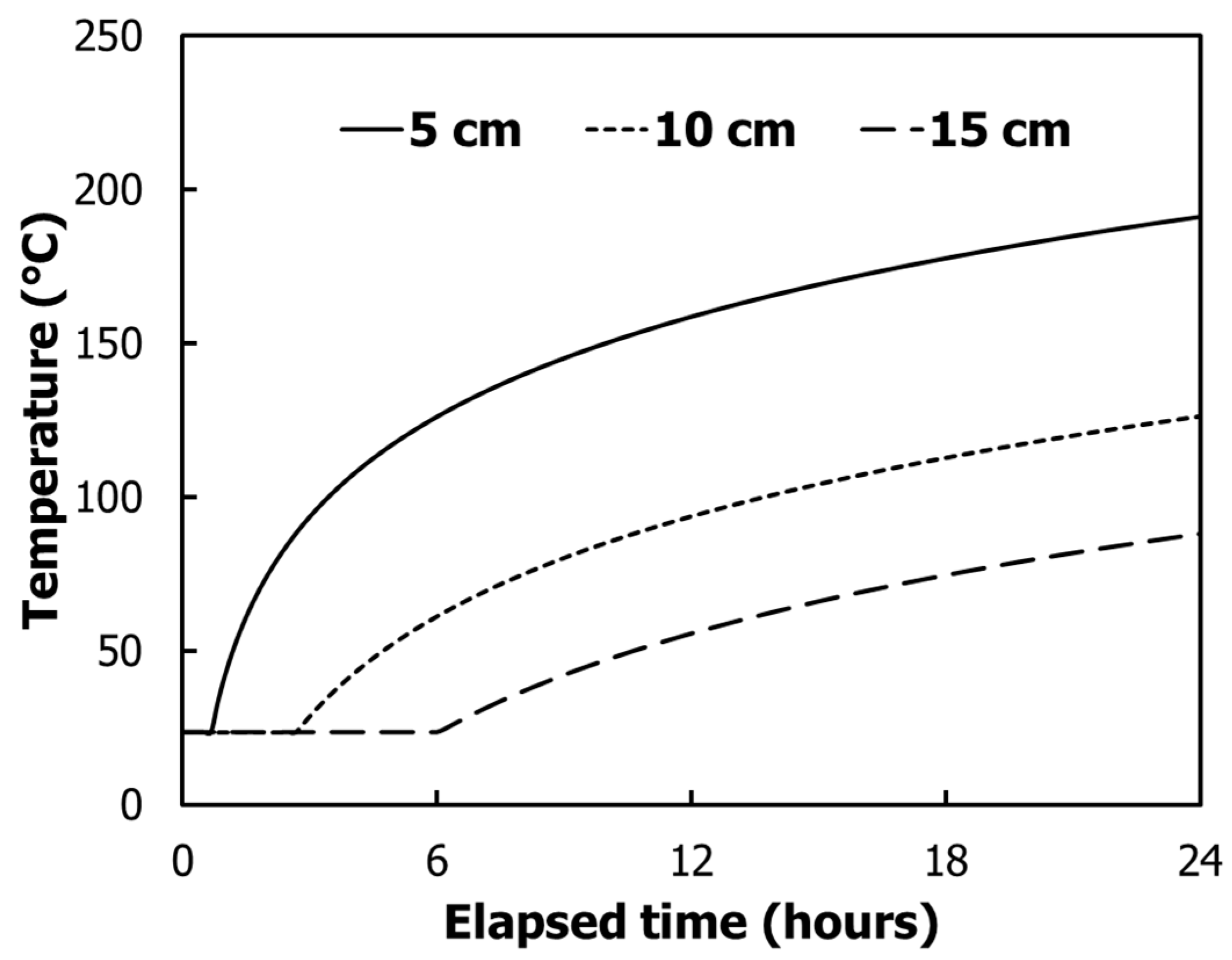

Figure 4 shows the temperature changes according to underground depths.

Figure 4a shows temperature changes in sensors installed 10 cm away in a horizontal direction from the heat source at the respective underground depths. Temperature changes were almost the same, but the lowest temperature change was recorded at spots 40 cm away from the heat source, while the greatest temperature change was observed at the underground depth of 25 cm.

Figure 4b–d shows the temperature changes in the sensors installed 20 cm, 30 cm and 40 cm from the heat source in a horizontal direction at each underground depth. The largest temperature variation was recorded at the ground depth of 25 cm, as seen in

Figure 4a.

Figure 5 shows the experimental results of temperature changes in horizontal distances from the heat source. The temperature change from the heat source was larger than the 10 cm point at 20 cm depth in the ground and increased up to maximum 64.61 °C. The reason why the temperature change at 10 cm is small is that heat energy is lost due to the discharge of water vapor near the surface.

3.3. Linear Heat-Source Model (Case 1)

The analysis conditions of the linear heat-source model were as follows: the initial temperature

of 23.48 °C measured by the thermometer was set as a constant value, with

(thermal diffusivity) at 3.0 (W/m °C), with

at 0.039744 (m

2/day), and the heating calorific value, Q/L (specific heat-extraction rate), was applied at

, which was the same as the direct current power-supply device. The radii of 10–40 cm were set as variables (

Table 1).

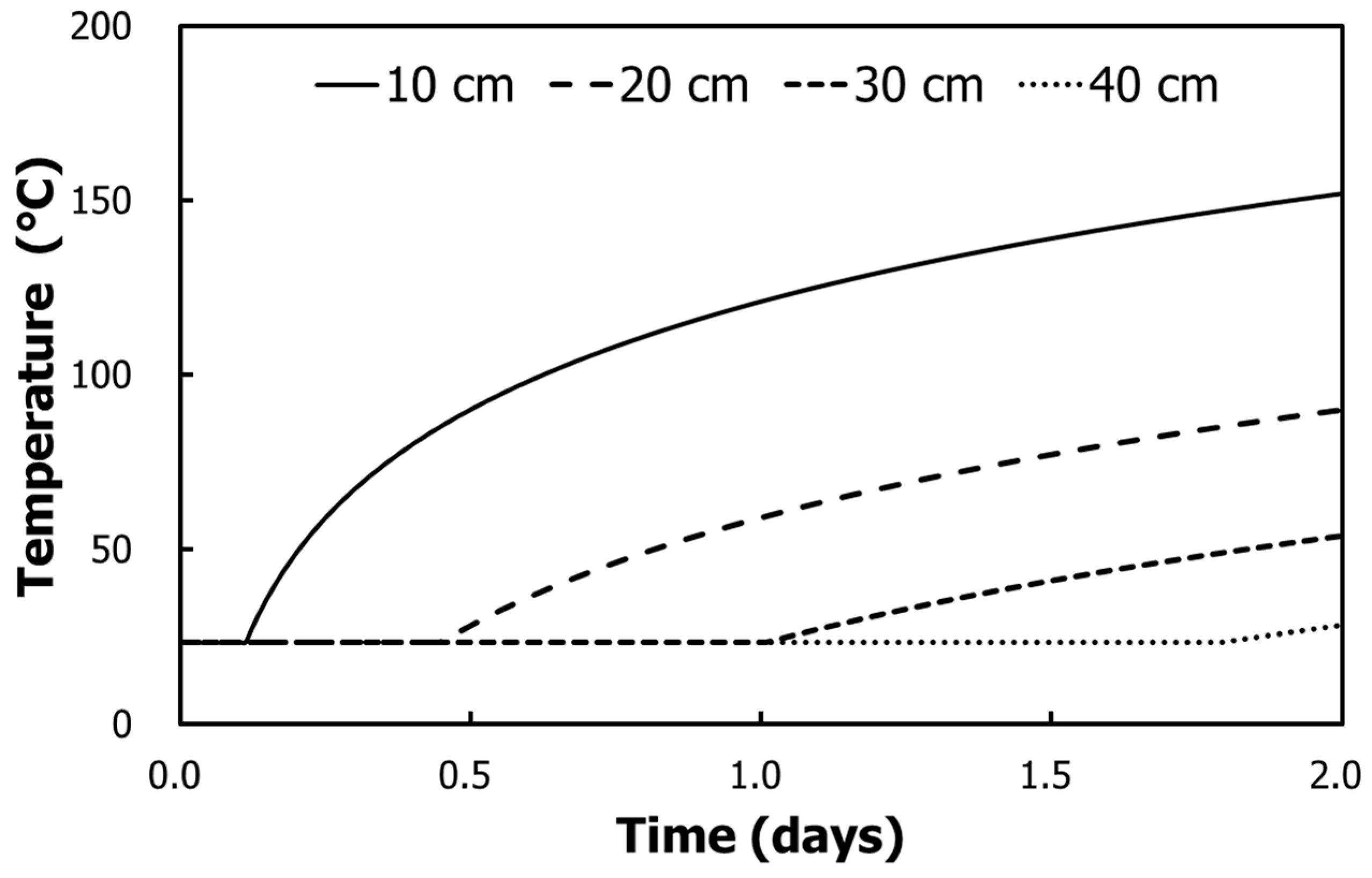

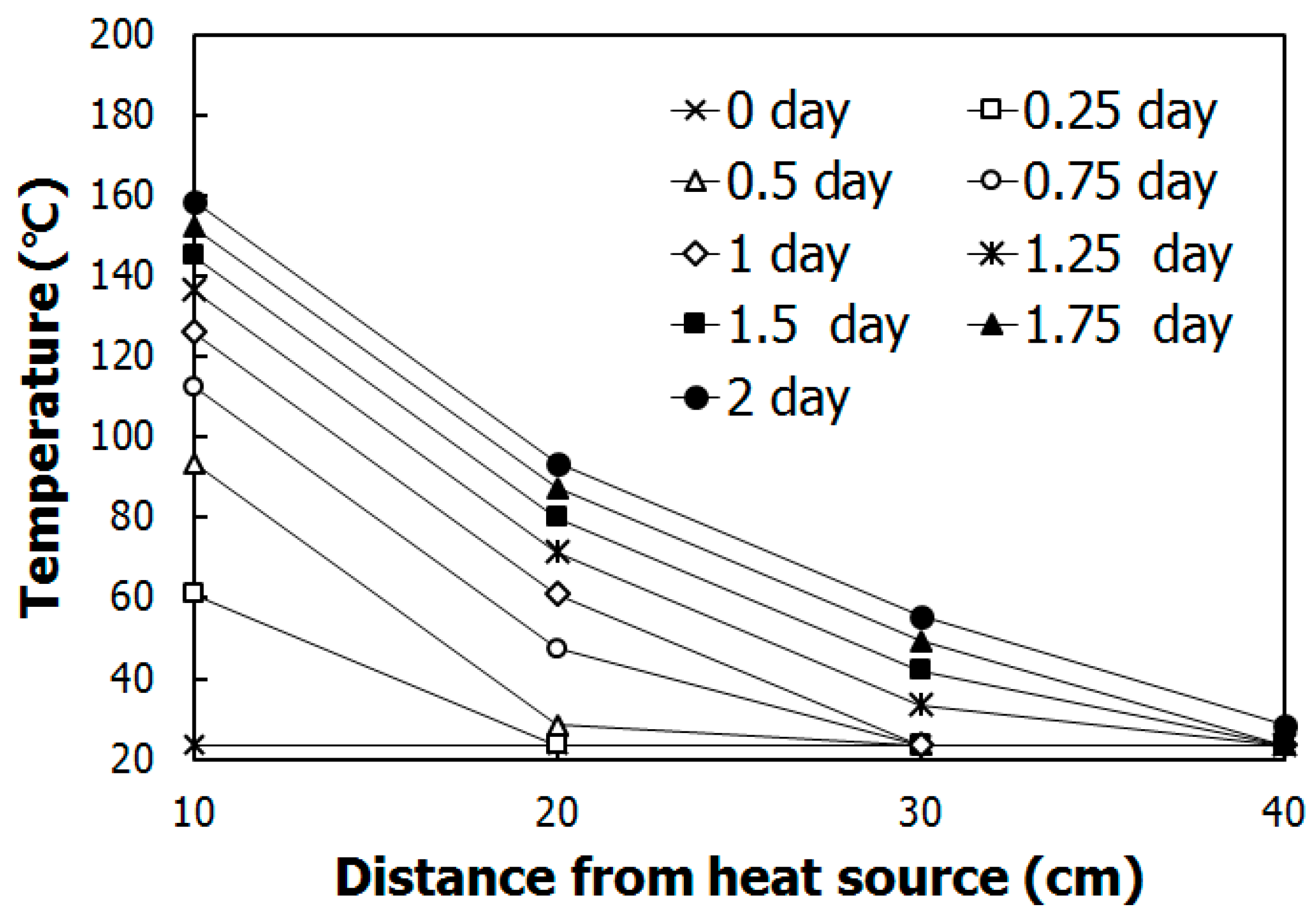

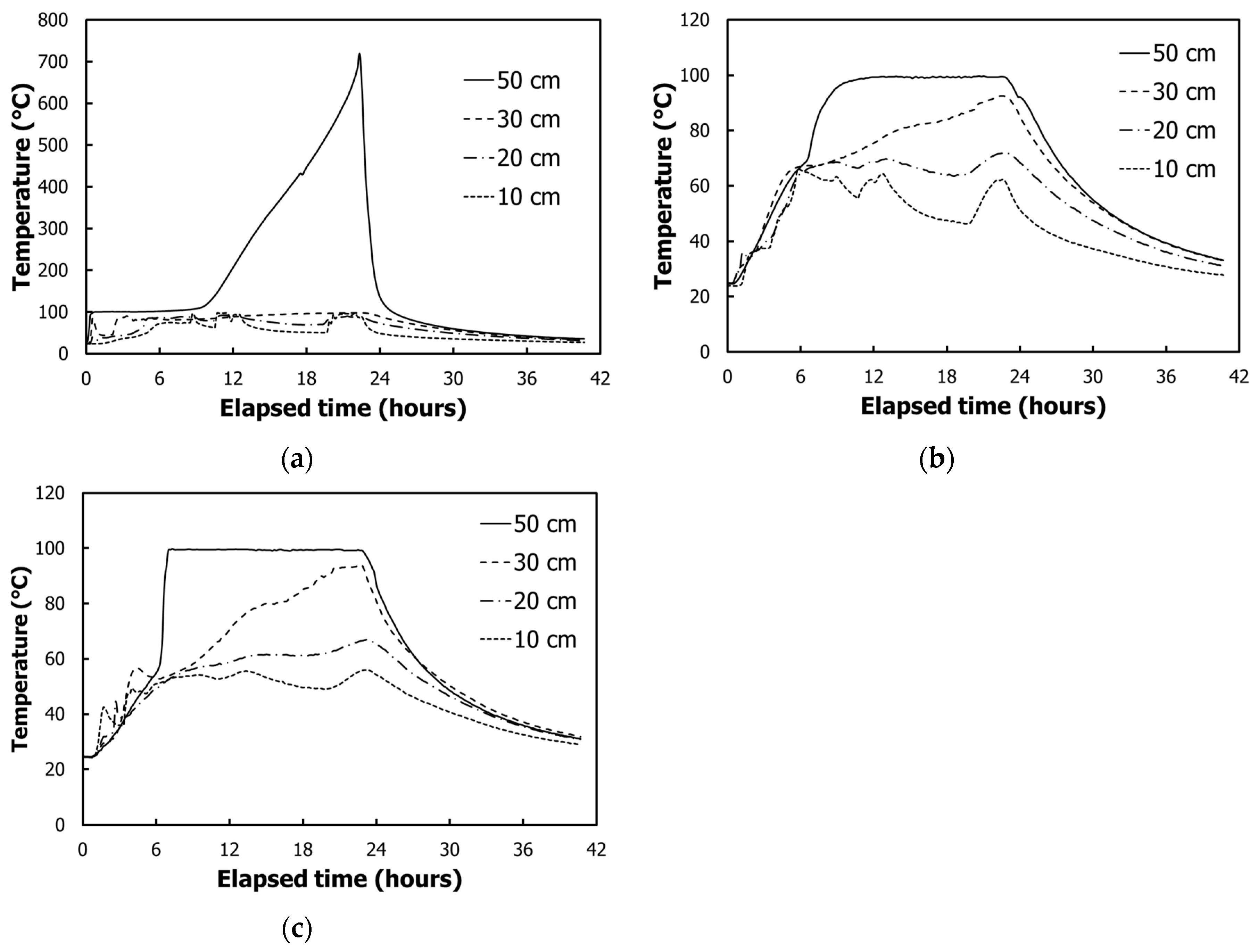

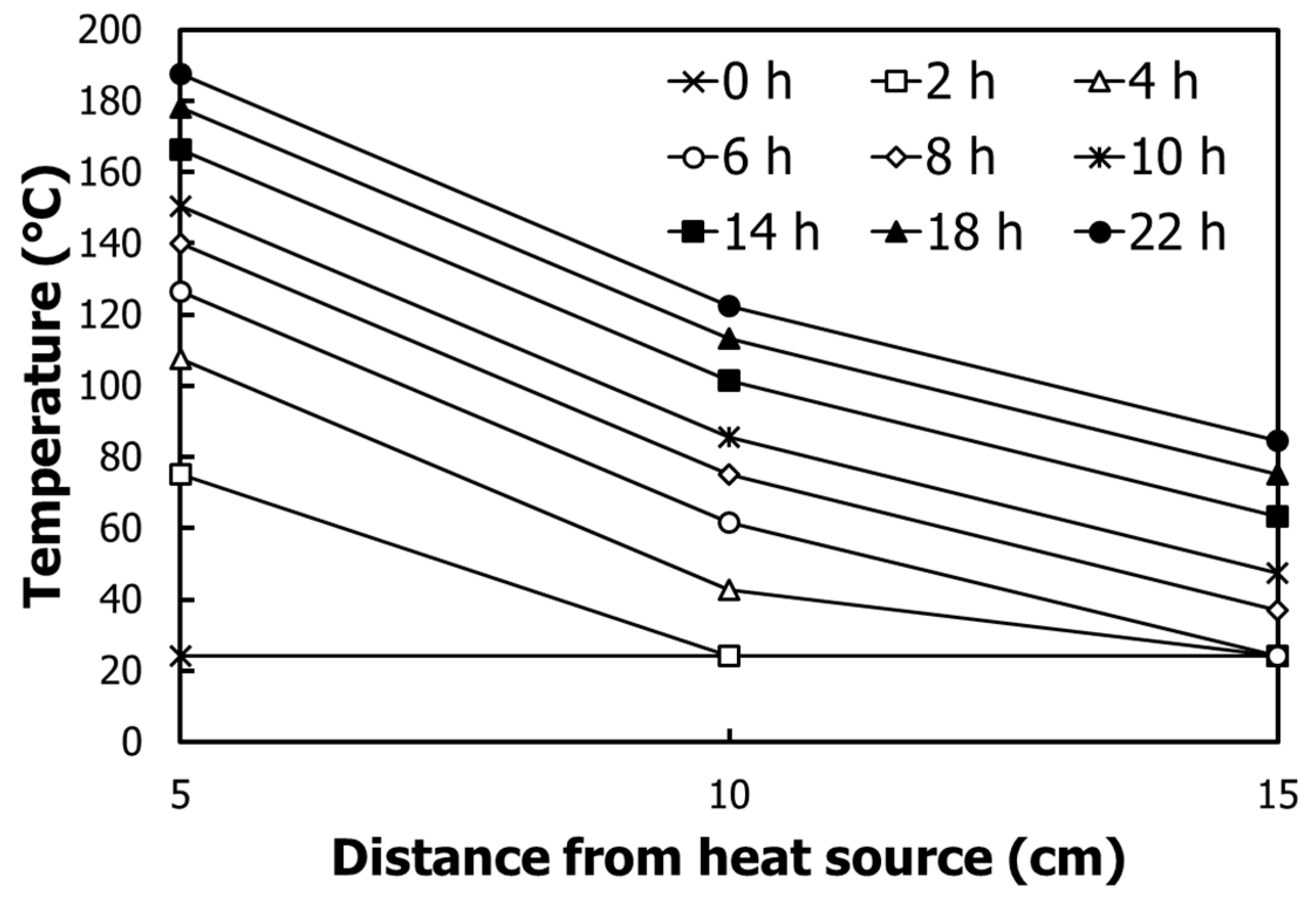

Figure 6 shows the results of comparison of temperature changes over time by the linear heat-source model. At a point 10 cm away from the heat source in the horizontal direction, a temperature change occurred after about 4 h, and increased to about 150 degrees. The temperature increased to about 100 degrees at a distance of 20 cm.

Figure 7 shows the temperature changes according to horizontal distances from the heat source by the linear heat model. According to the analysis results, the spots

away showed the maximum temperature increase of

degrees, while that 20 cm away had the maximum temperature increase of

degree;

(

degree); and

(

degree).

3.4. Numerical Analysis Model (Case 1)

In this section, the temperature changes due to the ground heating are estimated by numerical analysis. Heat transfer in the ground, which consists of soil particles, voids and pore water, is caused by conduction of soil particles and pore water. The ground is a porous material and convection heat transfer does not occur. Because the amount of pore water depends on the soil water content, seepage analysis must be conducted before heat-transfer analysis. Seepage analysis and heat-transfer analysis were conducted by SEEP/W and TEMP/W of GEO-SLOPE International Ltd., Calgary, AB, Canada. The seepage analysis was performed using the SEEP/W to estimate the distribution of pore water pressure and water content, and the TEMP/W was used for the heat-transfer analysis. TEMP/W is a finite-element software product that can be used to model the thermal changes in the ground due to environmental changes, or due to the construction of facilities, such as buildings or pipelines. The comprehensive formulation makes it possible to analyze both simple and highly complex geothermal problems, with or without temperatures that result in freezing or thawing of soil moisture [

20].

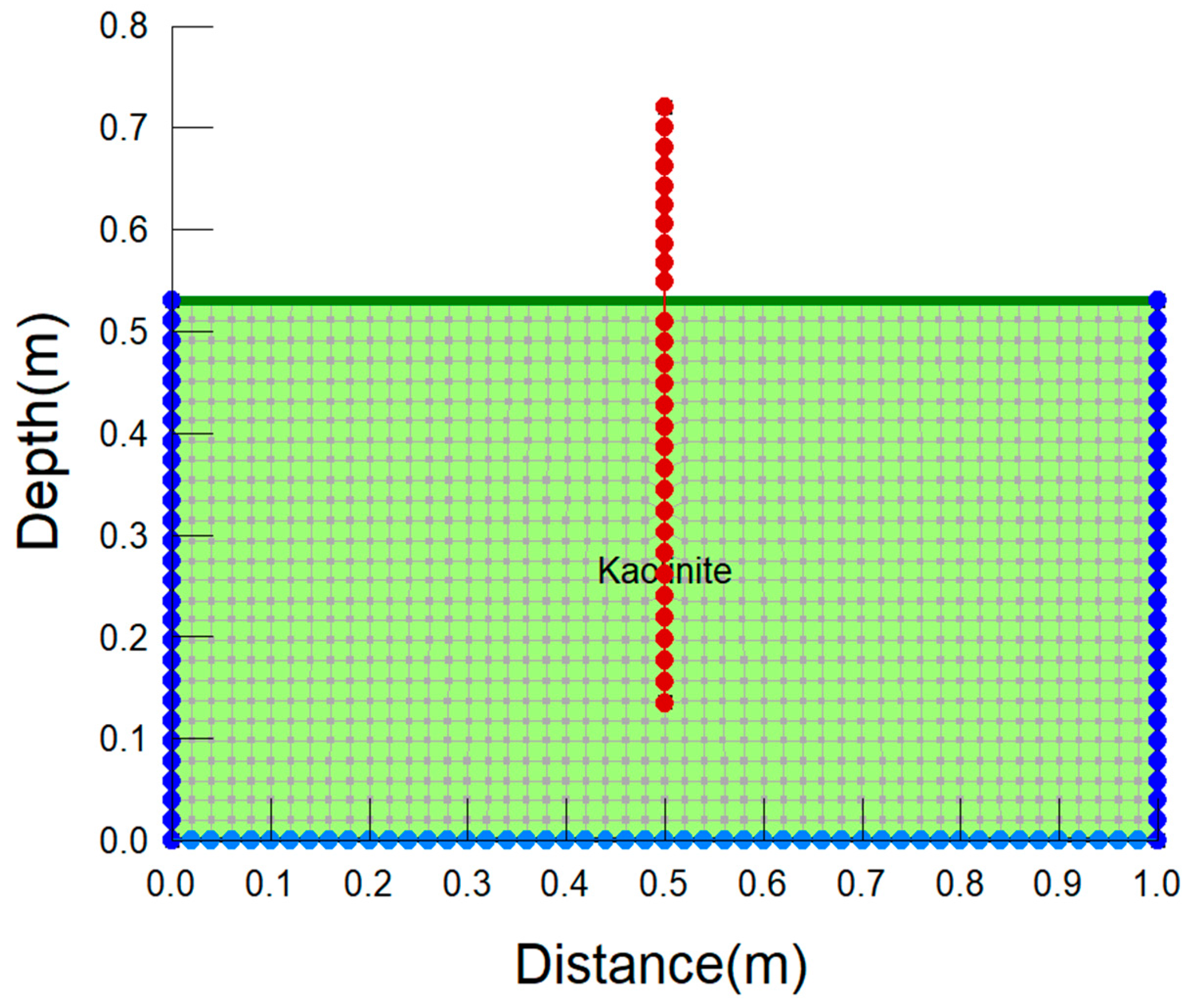

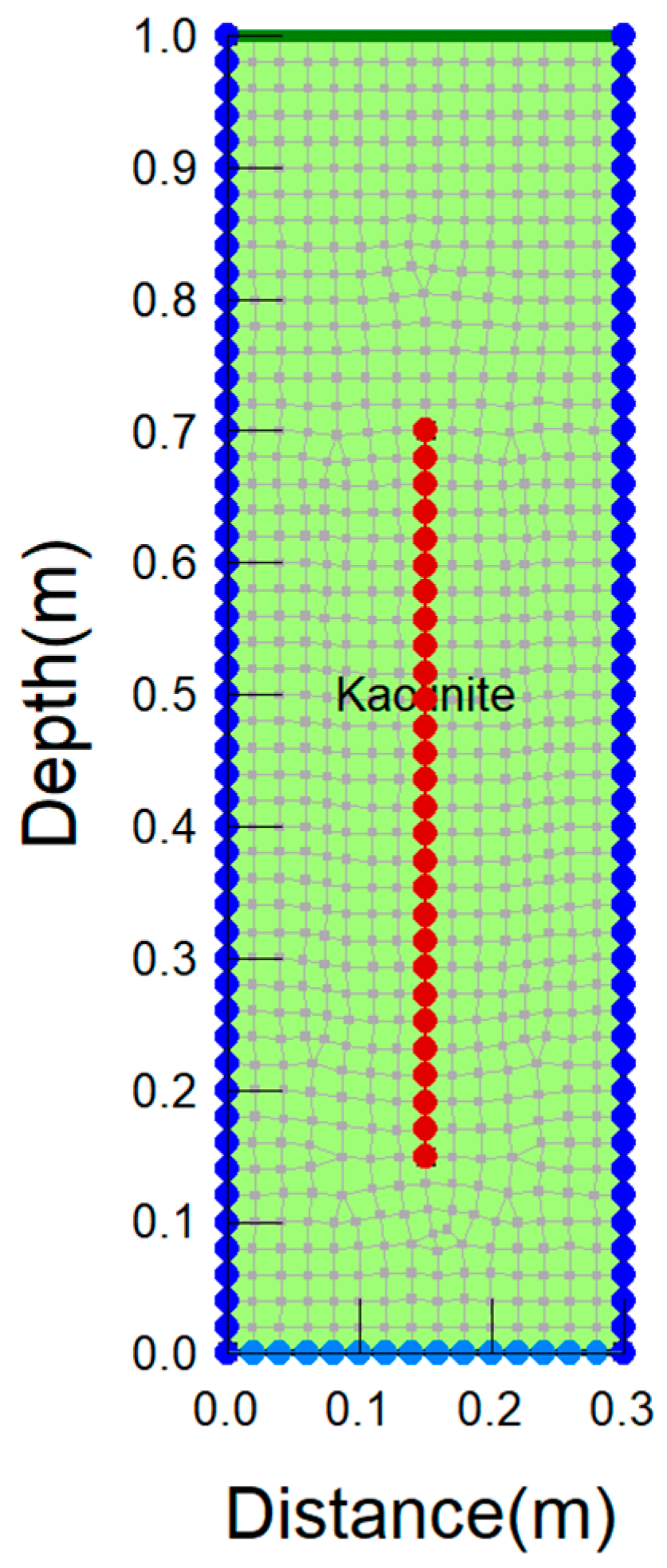

Figure 8 shows the numerical model applied to heat-transfer analysis (case 1). The cross-section of the numerical analysis model is the same as the cross-section of the experiment in

Figure 3. The mesh size is 0.02 m, considering the electrical conductivity and the analysis time. The initial conditions and the boundary conditions of the numerical model were applied to the temperature measured in the experiment. Firstly, the initial temperature of kaolinite is 22.75 °C, and the temperature of the interface of the soil box is 23.48 °C. In

Figure 8, the nodes at the left and right boundaries are blue circle, and the bottom is sky blue circle. The temperature of the electric heating pipe, which is a heat source, is

of electric power supplied from the DC power supplier, and the surface heating temperature is 500 °C. In

Figure 8, it is a red circle.

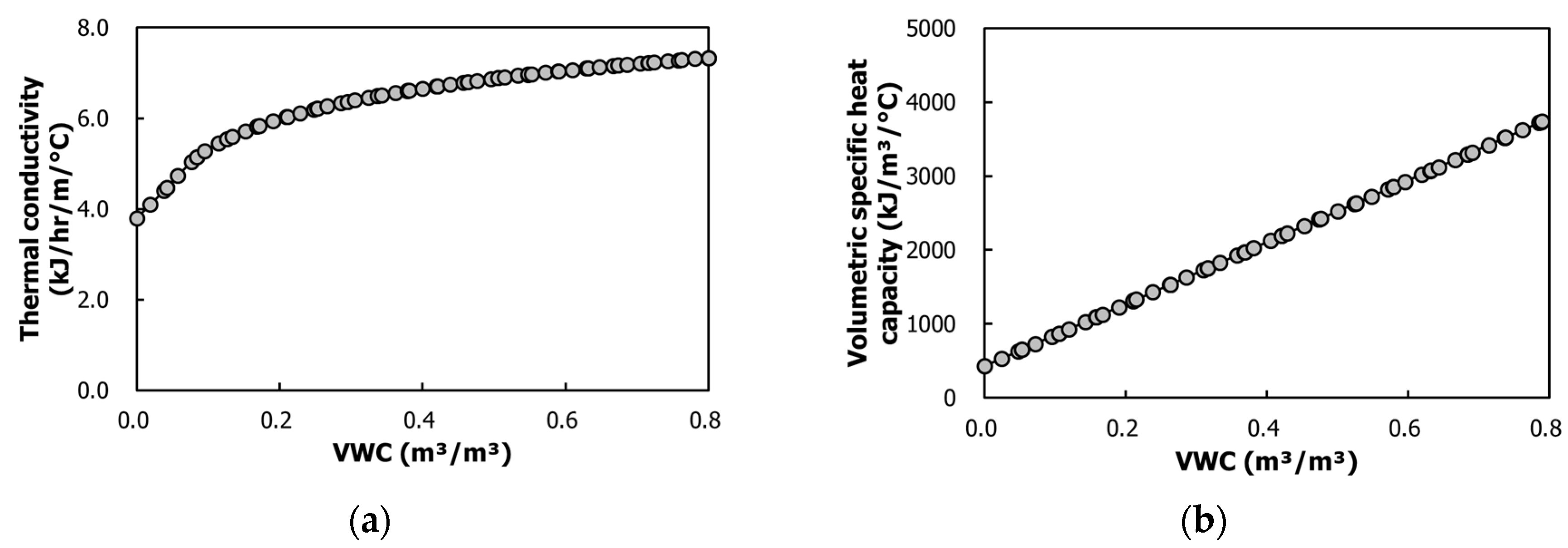

The physical properties of the soil required for heat-transfer analysis are the two curves shown in

Figure 9.

Figure 9a shows a function between the volumetric water content (VWC) and heat conductivity.

Figure 9b is a function of the optimal water content and specific volume. For material properties of the heat-transfer characteristics of the reference clay, kaolinite, this study used the literature values of Michot et al. [

22].

In the analysis procedure, the water content of the clay was estimated by the seepage analysis, and the heat-transfer analysis was carried out with the initial conditions. The water content of the soil was applied in the same saturated condition as the experimental conditions. In general, seepage analysis of the soil is performed in steady state and associated unsteady state. However, since the kaolinite used in the experiment has a very small coefficient of permeability, no flow of pore water was observed during the heating experiment. Therefore, the unsteady state analysis was not performed, and the results of the steady-state analysis were applied as the initial conditions of the heat-transfer analysis.

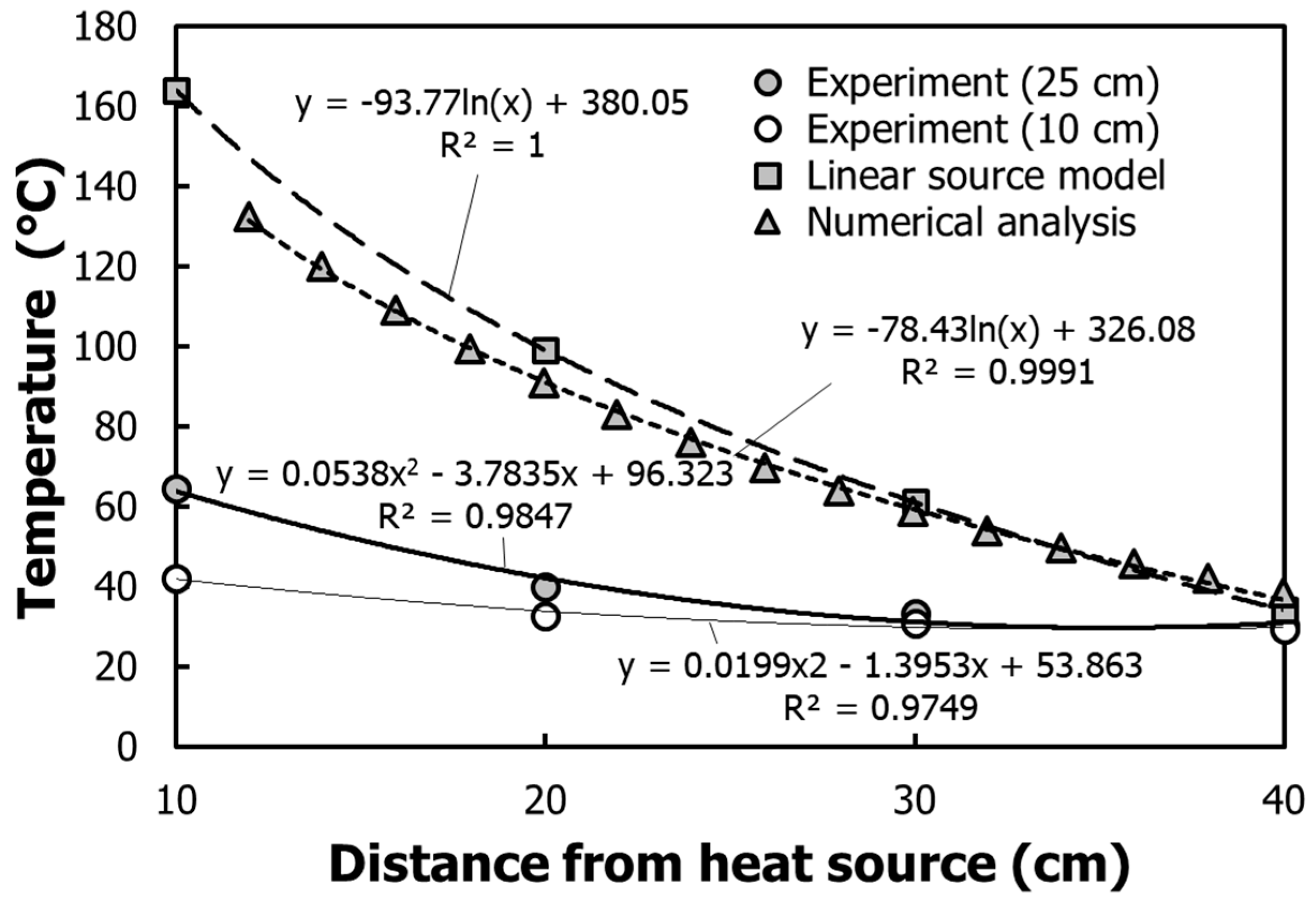

3.5. Comparison and Discussion (Case 1)

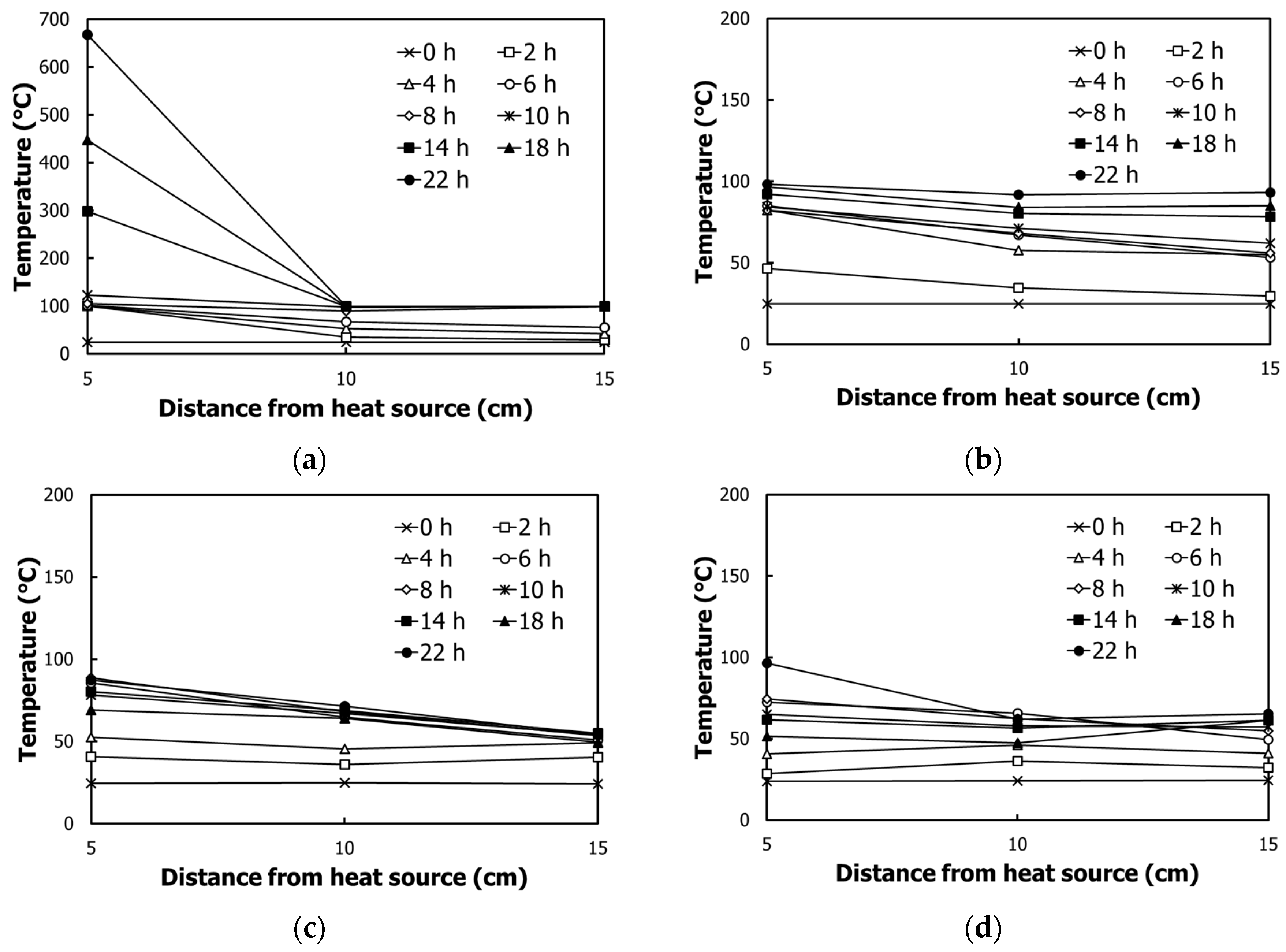

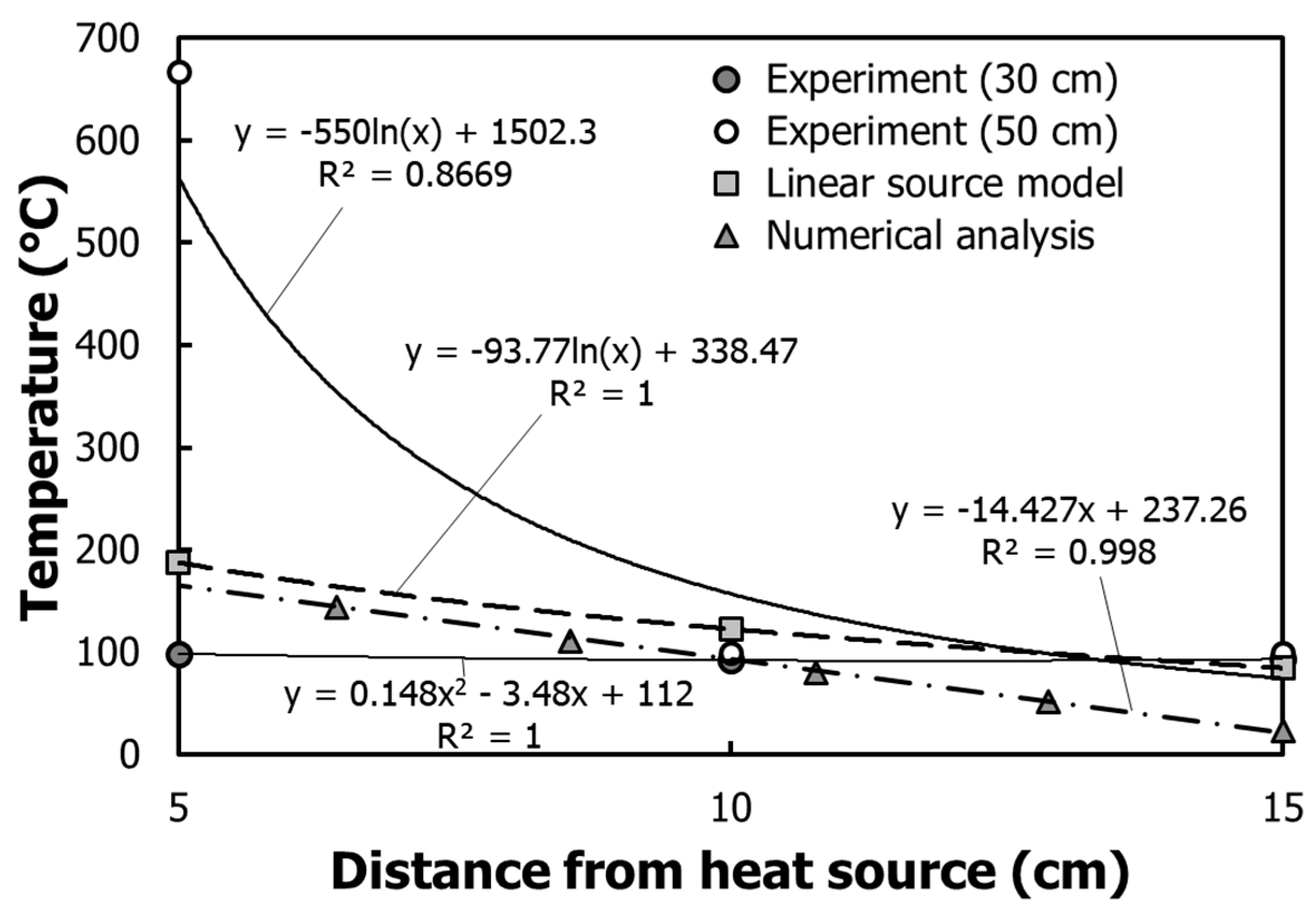

Figure 10 shows the results of comparison between the linear heat-source model, numerical analysis and the experiment results. Temperature changes according to horizontal distances from the heat source were observed after two days of ground heating. The linear heat-source model showed the highest temperature difference, followed by the numerical analysis and the experiment. The experiment showed the lowest temperature, due to heat loss by water-vapor discharge. The analysis of temperature changes in a horizontal direction from the heat source showed the results in a quadratic function form, and the linear heat-source model and the numerical analysis showed a constant decrease. Because of the increased loss of heat energy due to the discharge of water vapor near the surface, the temperature change was 25 cm higher than the 10 cm depth.

In this section, the electric heating test was conducted by allowing vapor generated by heating to be discharged. According to the temperature measurements, the end of the electrical heating (30 cm underground) showed the smallest horizontal temperature change. This indicates that heat transfer occurs more actively in a vertical direction than in a horizontal direction. Also, those spots 25 cm underground had greater temperature changes than those spots underground by 10 cm, which can be ascribed to heat losses due to vapor discharge.

According to the comparative analysis results with the linear heat-source model, the experimental results (64.6 °C) revealed a smaller temperature change than the linear heat-source model. This is believed to be due to heat loss as vapor was discharged to the surface. Also, the linear heat-source model showed a temperature decrease in a logarithmic function form along the horizontal distances, whereas the experimental results showed a decline in the form of a second-degree polynomial function.

5. Discussion and Summary

The purpose of this study is to investigate the heat-transfer characteristics of water vapor generated by ground heating. In this study, experiments were carried out according to whether or not the water vapor generated by the ground heating was discharged. The linear heat-source model and the numerical analysis, which were used to estimate the temperature distribution of the ground, were performed and compared with the experimental results. The results of this study are summarized and discussed as follows.

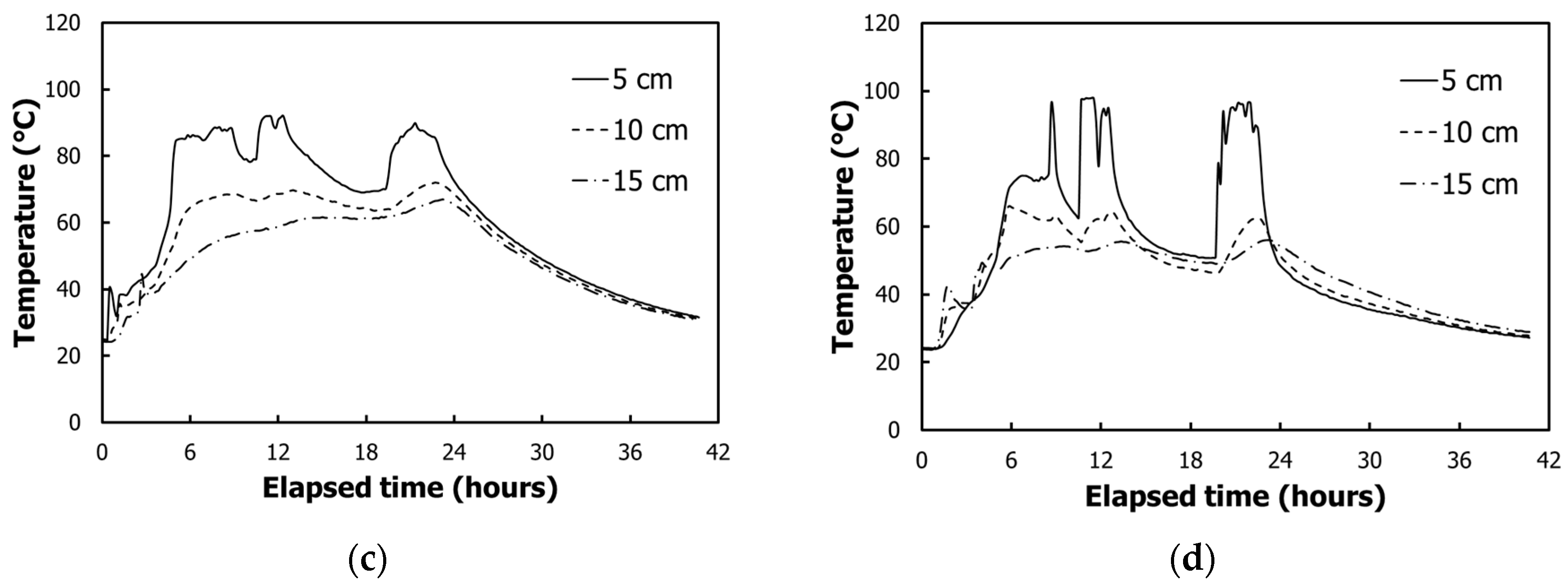

As a result of measuring the temperature change when the water vapor was discharged, the largest temperature change occurred at the point where the electric heating tube was installed. The temperature change was small when it was close to the ground surface. This is because the water vapor generated from the bottom continuously increases the temperature in the vertical direction and is discharged as water vapor on the surface. The linear heat source model and the numerical analysis were evaluated more than the experiment under the condition that the discharge of water vapor was suppressed.

As a result of experiments under the condition that water vapor is not discharged, At the top 5 cm of the electric heating pipe, The soil temperature increased up to 718.8 degrees, which is higher than 500 degrees of the heat source. In addition, the temperature change in the vertical direction was larger than that in the horizontal direction. And, heat transfer due to water vapor was found to have a great influence. When heat transfer due to water vapor occurred, the temperature change was larger than the linear heat-source model and numerical analysis. Conversely, if no heat transfer occurred, the temperature change was small.

The linear heat-source model estimates the one-dimensional soil temperature change from the heat source. Although it is suitable for an underground heat exchanger where the heat source is infinitely long and the heat flux is constant, it is not suitable for the ground-heating method. Numerical analysis considers only two-dimensional heat transfer by conduction of soil particles and pore water, but does not consider the phase-change energy and heat transfer by water vapor.