Economic, Energetic, and Environmental Impact Evaluation of the Water Discharge Networks from Mining Works

Abstract

:1. Introduction

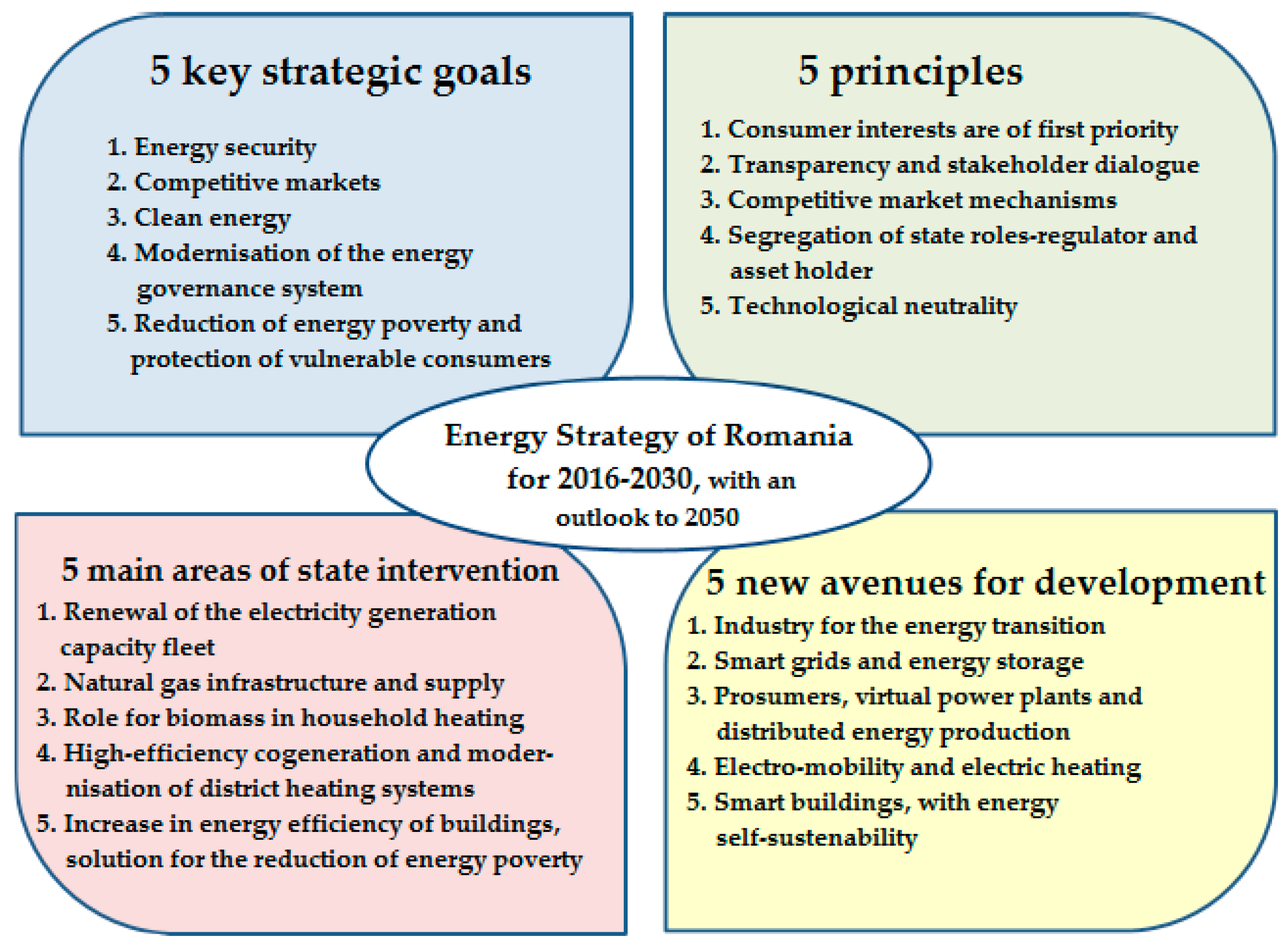

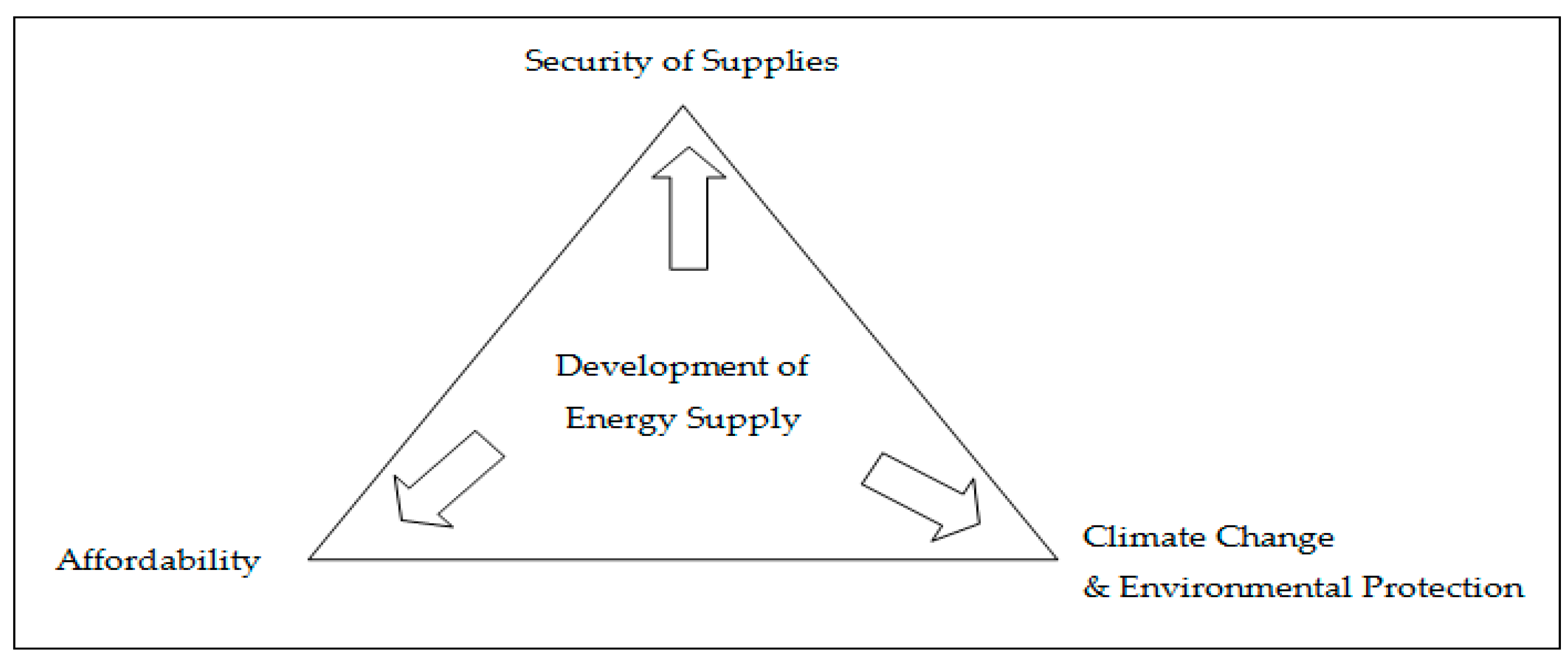

2. About Energy and Sustainable Development

3. Specific Costs and Energetic Indices for the Execution of Hydraulic Networks

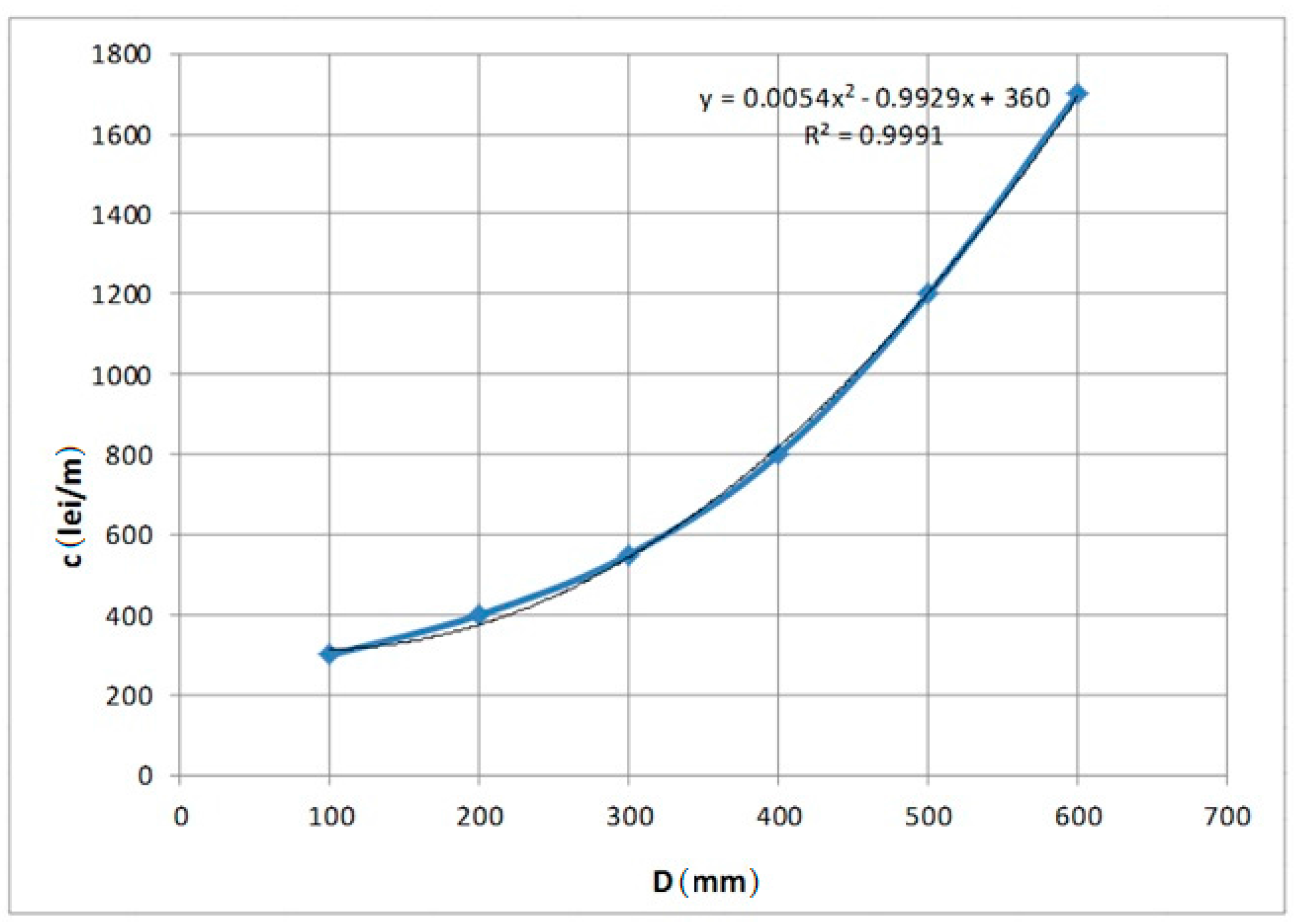

3.1. Cost Index

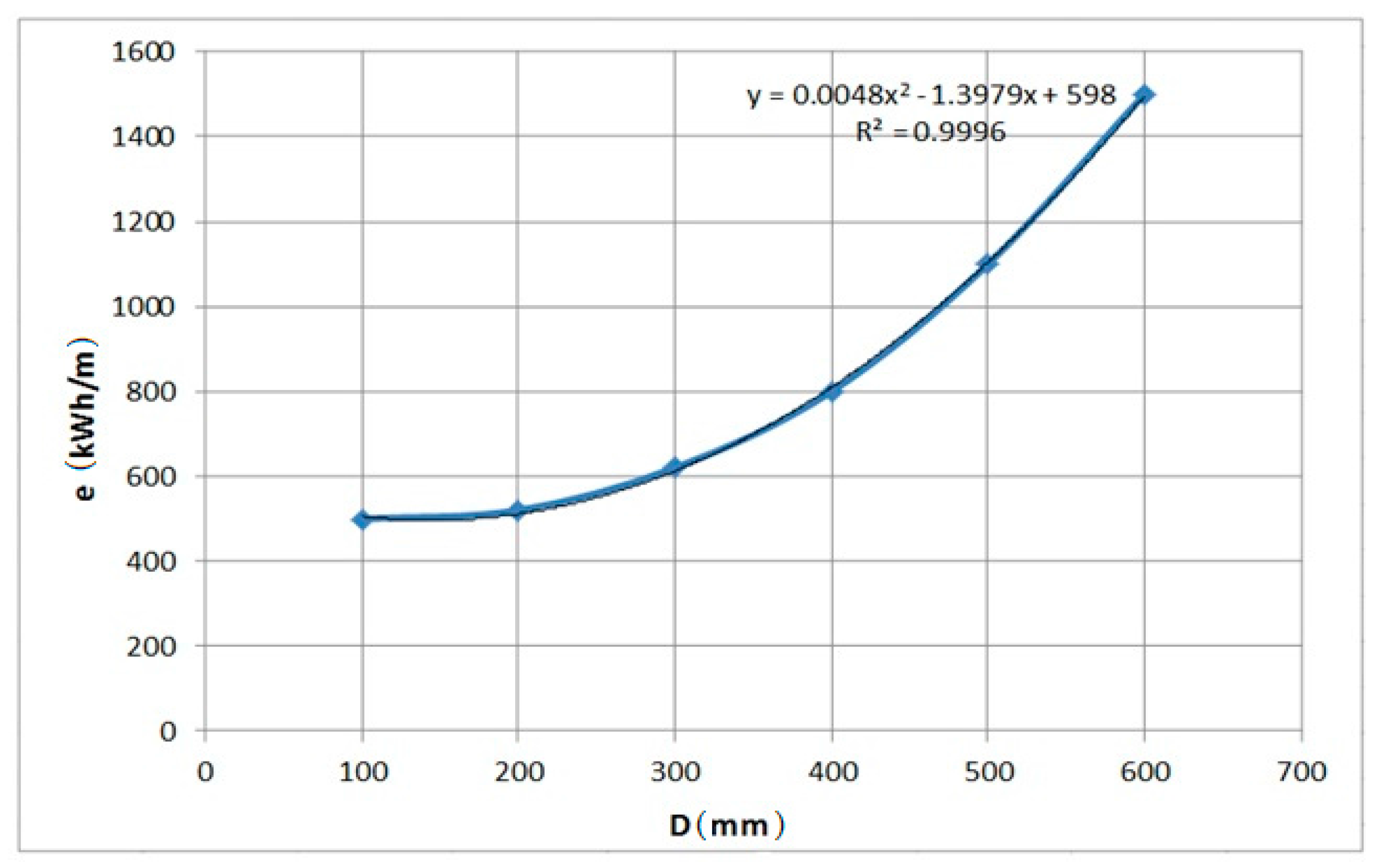

3.2. Energy Index for the Included Energy (Energy)

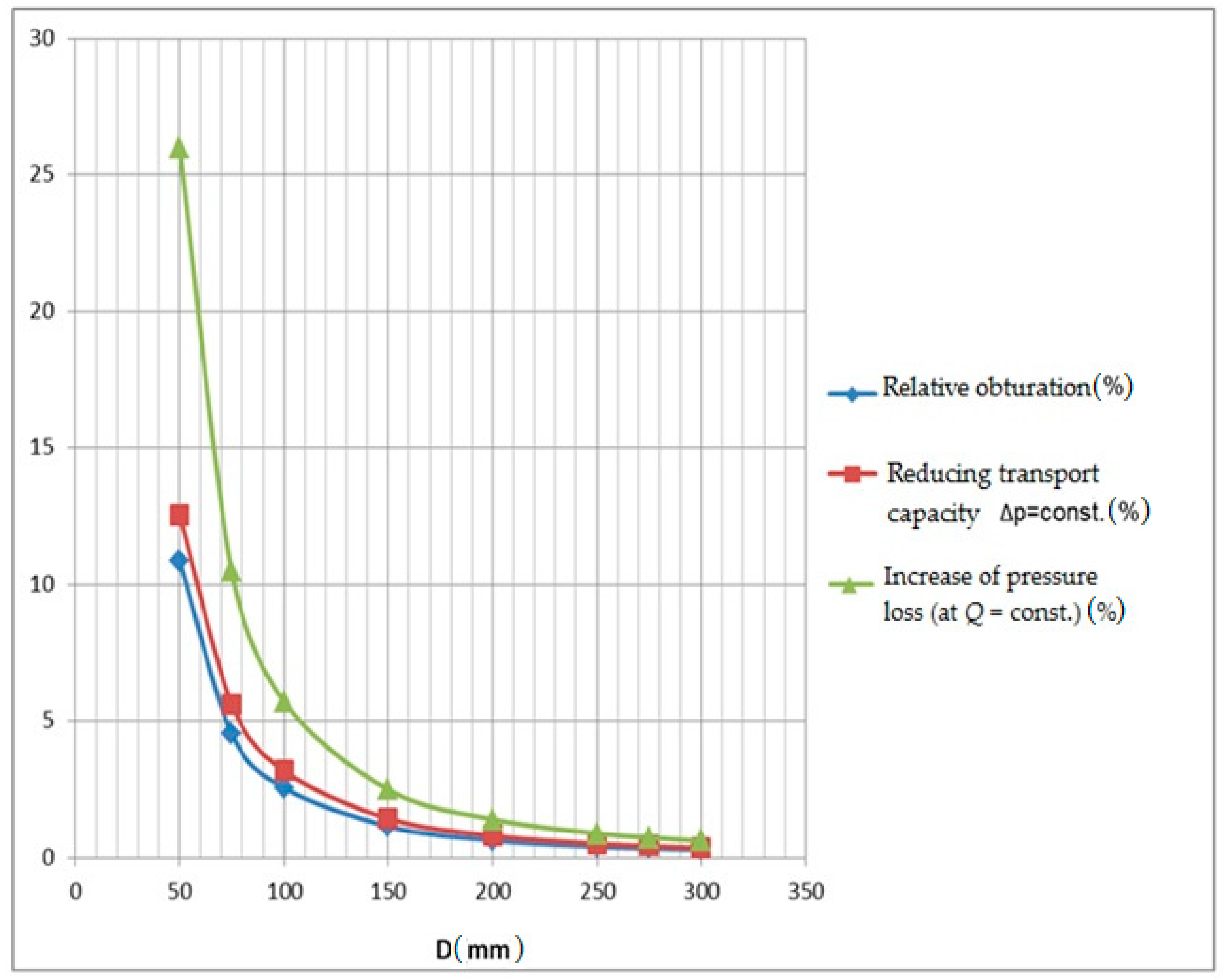

3.3. The Effect of Partial Obstruction of the Flow Section on the Pressure Losses and of the Pipe’s Transport Capacity Reduction

- λ represents the fluid dynamics resistance coefficient (Table 1);

- ρ—water density (kg/m3);

- w—water velocity (m/s);

- L—section length (m);

- D—section diameter (m).

- Di is the pipe’s interior diameter, (m);

- Stot is the area of the flow’s cross-section to the new pipe (m2);

- Sobt is the area of the area obstructed by sediments (m2).

- 0.05–0.1—the material is considered to be new;

- 0.15–0.2—the material is considered to be technically appropriate;

- 0.4–0.5—cleaning after long-term use;

- 0.6–1—the material is moderately rusted with slight incrustations;

- 1.1–1.5—after 15 years of operation with incrustations;

- 2–2.5—after 20 years of operation with incrustations and deposits;

- 3—the material presents strong incrustations.

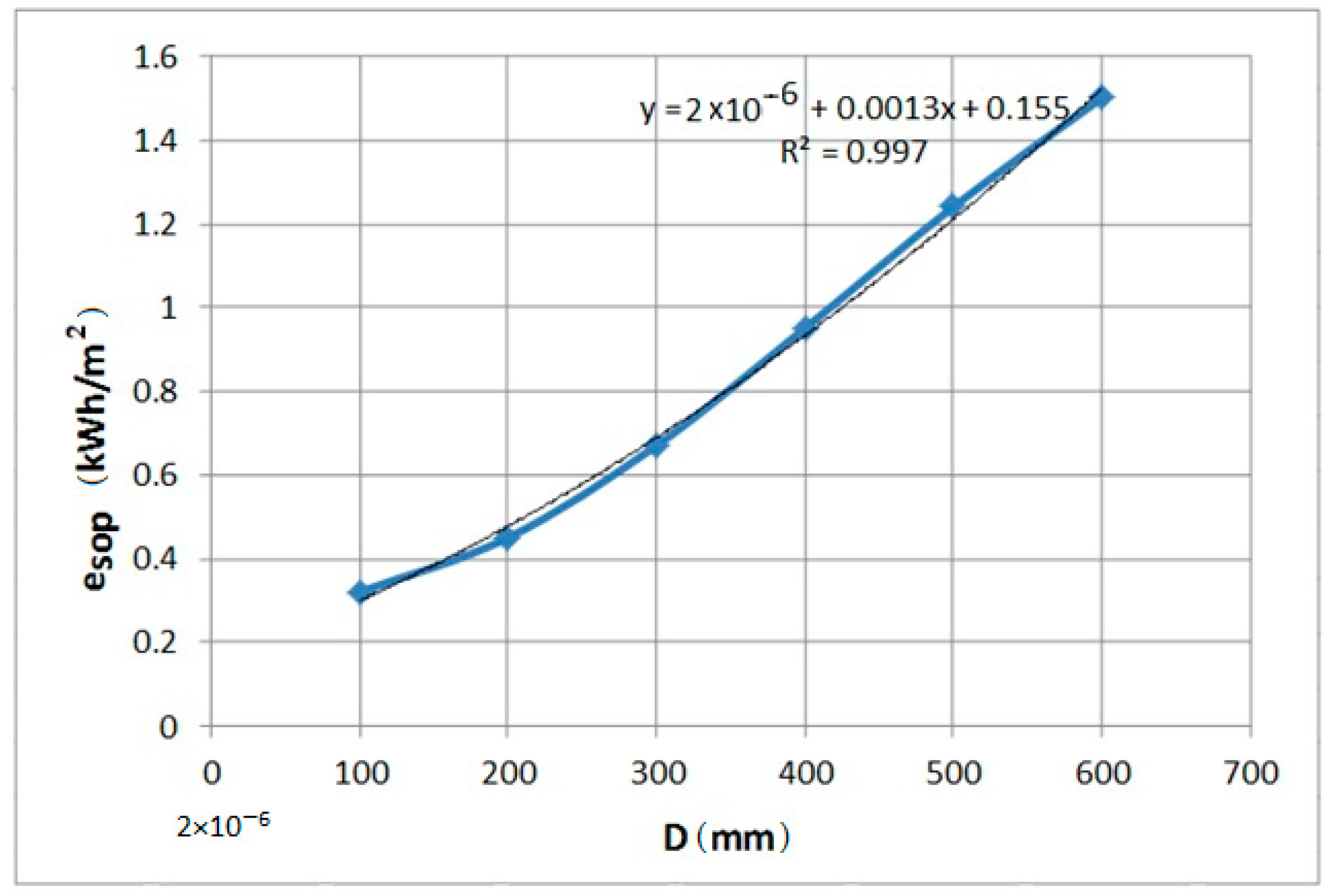

3.4. Energy Index for Operational Energy

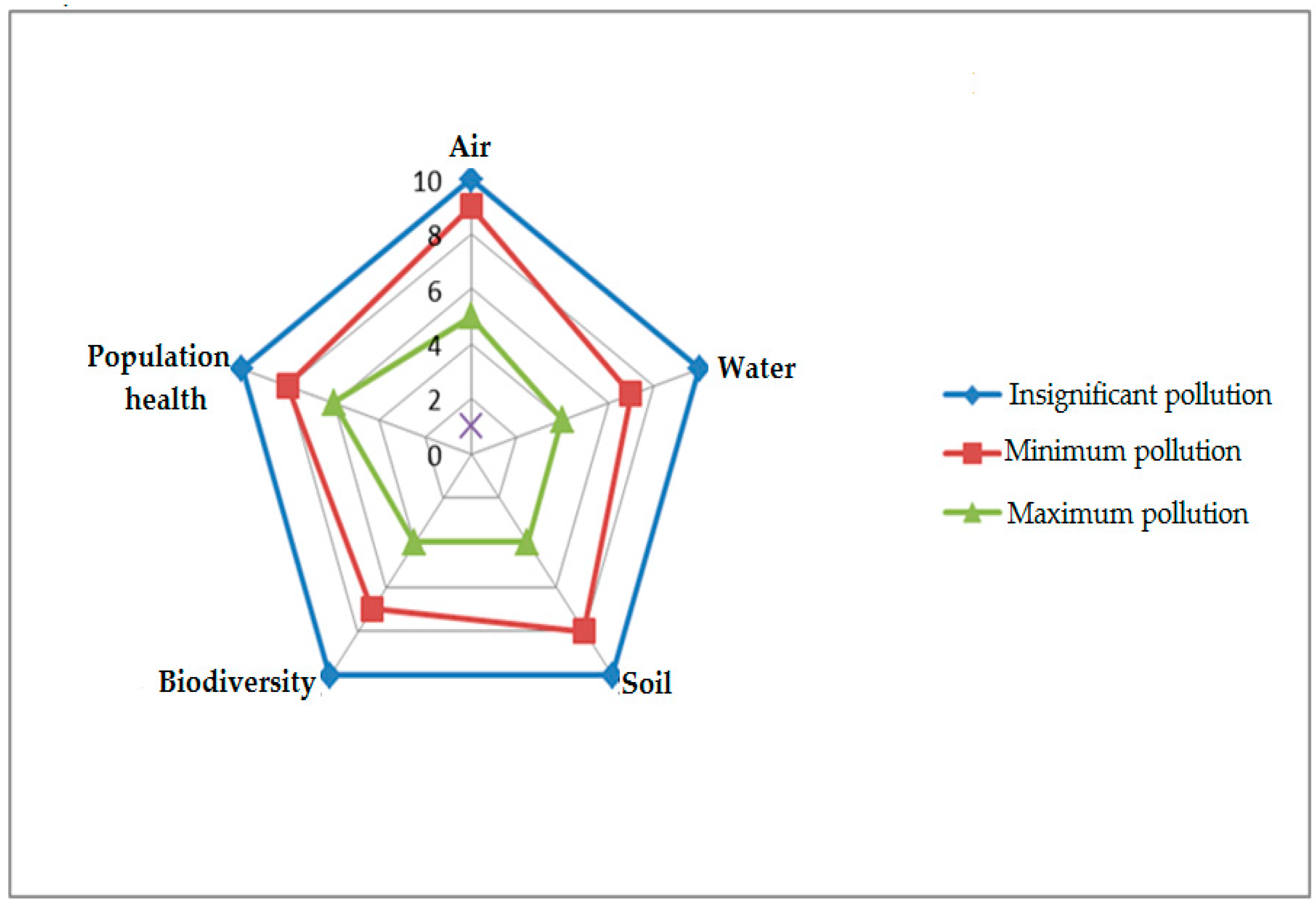

4. Environment Quality Index

- Air quality;

- Water quality;

- Soil quality;

- Population’s health status;

- Recorded deficit of species, plants, and animals (biodiversity).

- The value of the reliability grade for maximum air pollution (reliability grade 5), for water (reliability grade 4), for soil (reliability grade 4), for biodiversity (reliability grade 4), for population health (reliability grade 6);

- The value of the reliability grade for minimum air pollution (reliability grade 9), for water (reliability grade 7), for soil–subsoil (reliability grade 8), for biodiversity (reliability grade 7), and for population health (reliability grade 8).

- Area afferent to ideal status—SI = 240 cm2;

- Area afferent to maximum pollution status—Spol.max = 46.07 cm2;

- Area afferent to minimum pollution status—Spol.min = 136.965 cm2.

- Global pollution index for maximum pollution status;

- Global pollution index for minimum pollution status;

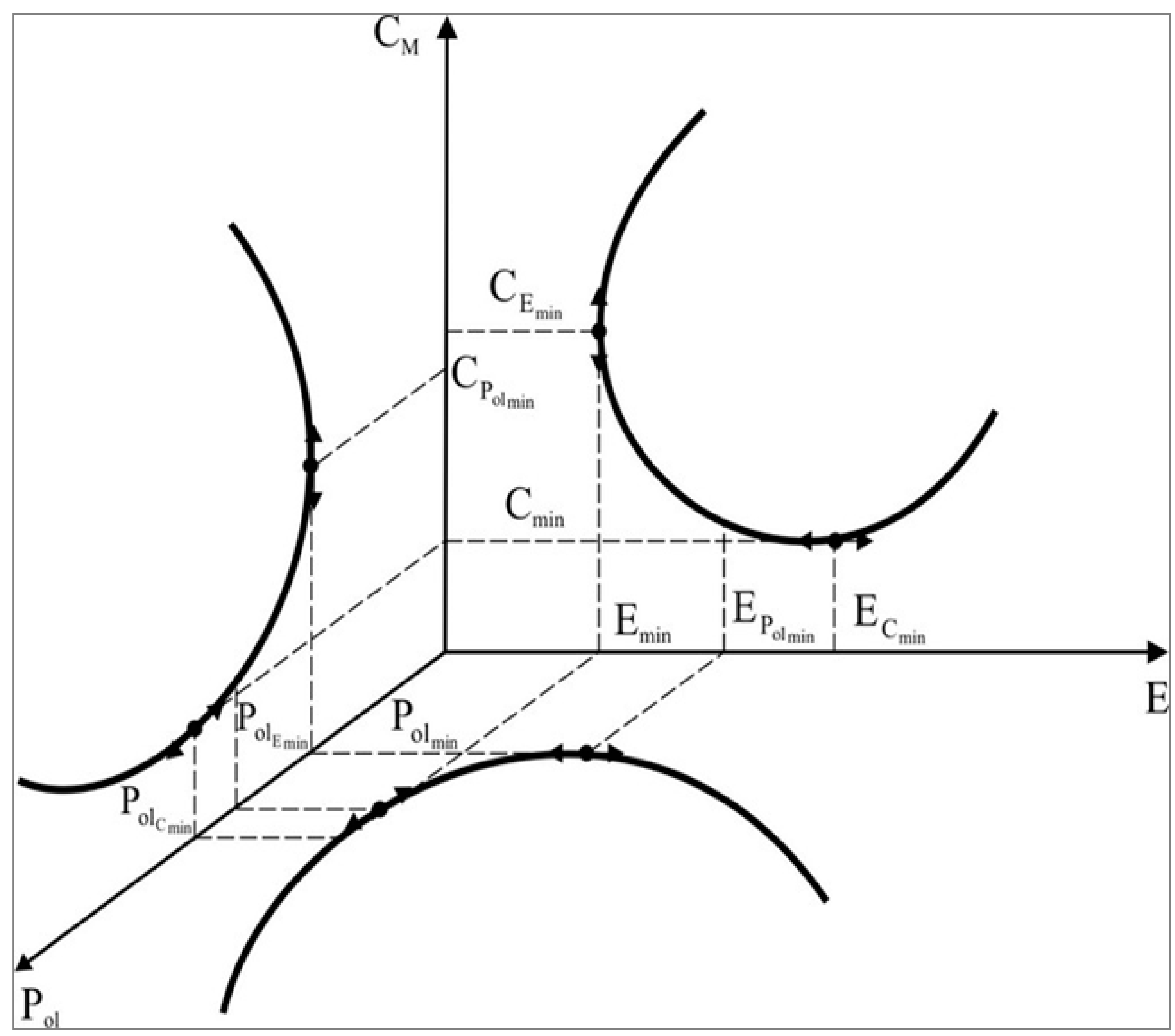

5. Aggregation Method for the Economic, Energy and Ecologic Indices

- The difference between ECmin–Emin shows the additional energy costs in order to reduce monetary costs;

- The difference between EPolmin–Emin shows the additional energy costs in order to reduce environmental costs (afferent to pollution);

- The difference between CEmin–Cmin shows the additional monetary costs in order to reduce energy costs;

- The difference between CPolmin–Cmin shows the additional monetary costs in order to reduce environmental costs;

- The difference between PolEmin–Polmin shows the additional environmental costs in order to reduce energy costs;

- The difference between PolCmin–Polmin shows the additional environmental costs in order to reduce monetary costs.

- To achieve an energy saving of ECmin − Emin = 60%, the monetary costs are increased by 65%, and the environmental costs are increased by 35%;

- To achieve an energy saving of Epolmin − Emin = 31%, the monetary costs are increased by 42%, and the environmental costs are increased by 28%;

- To reduce environmental costs by PolCmin − Polmin = 46.5%, the monetary costs are increased by 49%, and the energy costs are increased by 31%.

6. Conclusions

- Collection of experimental data;

- Definition of the system frontier to which the balance sheet applies. The conclusions differed for the analysis of an objective when the location is in a depression, a hilly area or a field area;

- Definition of maximum allowed harmfulness;

- Consideration of local environmental characteristics;

- Harmonization of national and international regulations;

- Achieving a compromise between regional and global interest.

- Using concepts and analytical tools from exergetic balance sheets;

- Obtaining synthetic values that represent the global ecological load exercised by the analyzed system on its own environment;

- The method allowing the comparison of different solutions regarding the execution of a product;

- Providing information regarding the ecological carrying capacity of an ecosystem and attaining certain alarm thresholds;

- With significant additions, it can be fitted into an analytical–experimental apparatus designed for the operationalizing of the sustainable development concept;

- It provides the possibility of a periodical control of the real measurements’ results regarding environmental protection, economic efficiency, and energy efficiency, which also facilitate their quantification.

Author Contributions

Conflicts of Interest

References

- Le Goff, P.; Giuletti, M. Is the “Value” of a source of energy based on enthalpy, entropy, economy or ecology? An example of application: the optimisation of a heat exchange. In Energy: Money, Materials and Engineering, Institution of Chemical Engineers Symposium Series; T1 Thermodynamics and Economics Is There a Conflict? Zhou, Y., Ed.; Elsevier: New York, NY, USA, 2013. [Google Scholar]

- The World Commission on Environment and Development. Our Common Future. In Report of the World Commission on Environment and Development; WCED: Geneva, Switzerland, 1987; Available online: http://www.un-documents.net/wced-ocf.htm (accessed on 2 July 2017).

- United Nations Conference on Environment and Development (UNCED). Rio de Janeiro, Brazil, 3–14 June 1992. Available online: https://sustainabledevelopment.un.org/ (accessed on 15 June 2017).

- United Nations (UN). Earth Summit +5, Meeting in New York, 1997. Available online: http://www.un.org/esa/earthsummit/ (accessed on 10 June 2017).

- World Summit on Sustainable Development (WSSD), Johannesburg, 2002. Available online: https://joburg.org.za/pdfs/johannesburgdeclaration.pdf (accessed on 10 June 2017).

- United Nations Conference on Sustainable Development (UNCSD). In Proceedings of the Rio+20, Rio de Janeiro, Brazil, 20–22 June 2012; Available online: https://sustainabledevelopment.un.org/rio20 (accessed on 10 June 2017).

- Atkinson, G.; Dubourg, R.; Hamilton, K.; Munasinghe, M.; Pearce, D.; Young, C. Measuring Sustainable Development: Macroeconomics and the Environment; Edward Elgar Publishing Limited: Cheltenham, UK, 1997. [Google Scholar]

- Berke, P.R.; Conroy, M. Are We Planning for Sustainable Development? J. Am. Plan. Assoc. 2001, 66, 21–34. [Google Scholar] [CrossRef]

- Hopwood, B.; Mellor, M.; O’Brien, G. Sustainable development: Mapping different approaches. Sustain. Dev. 2005, 13, 38–52. [Google Scholar] [CrossRef]

- Blackburn, W. The Sustainability Handbook; Environmental Law Institute: Washington, DC, USA, 2008. [Google Scholar]

- Bell, S.; Morse, S. Sustainability Indicators: Measuring the Immeasurable? 2nd ed.; TJ International Ltd.: Padstow, UK, 2008. [Google Scholar]

- Cioca, L.I.; Ivascu, L.; Rada, E.C.; Torretta, V.; Ionescu, G. The study of sustainable development andtechnological impact on CO2 reducing conditions: Case study of Romania. Sustainability 2015, 7, 1637–1650. [Google Scholar] [CrossRef]

- Irimie, I.S. Management of the Sustainable Development of a Community Energy System—Whit Referances to Jiu Valley; Politehnica University Publisher: Timisoara, Romania, 2014. [Google Scholar]

- Gardiner, R. Earth Summit 2002 Explained. Stakeholder Forum’s “Towards Earth Summit 2002 Project”. 2002. Available online: http://www.earthsummit2002.org/Es2002.pdf (accessed on 6 September 2017).

- European Union, 2010-Europa Project 2030, Challenges and Opportunities. Report to the European Council of the Reflection Group on the Future of the EU 2030, May 2010. Available online: http://www.consilium.europa.eu/en/documents-publications/publications/2010/project-europe-2030-challenges-opportunities/ (accessed on 5 September 2017).

- Romanian Government. National Sustainable Development Strategy Romania 2013–2020–2030. Available online: http://www.mmediu.ro/beta/domenii/dezvoltare-durabila/strategia-nationala-a-romaniei-2013-2020-2030/ (accessed on 3 October 2017).

- The Ministry of Energy. Romanian Energy Strategy 2016–2030, with perspectives for 2050, 15 november 2016. Available online: http://www.ropepca.ro/en/articole/romanian-energy-strategy-2016-2030-with-perspectives-for-2050/385/ (accessed on 15 April 2017).

- Irimie, I.S.; Petrilean, D.C.; Dumitrescu, C.D. Aspects of Consumers’ Rights Protection for the Centralised Urban Heating Services. In Proceedings of the 21st IBIMA Conference, Vienna, Austria, 27–28 June 2013; pp. 756–767. [Google Scholar]

- Sârbu, I. Energetic Optimisation of Water Distribution Systems; Romanian Academy Publishing House: Bucharest, Romania, 1997. [Google Scholar]

- Irimie, I.I.; Matei, I. Gas Dynamics of Pneumatic Networks; Technical Publishing House: Bucharest, Romania, 1994. [Google Scholar]

- Godeanu, S. Elements of Ecological/Integrated Monitorin; Bucura Mond Publishing House: Bucharest, Romania, 1997. [Google Scholar]

- Irimie, S.I.; Gal, J.; Dumitrescu, C.D. Analysis of a dynamic regional system for the operationalizing of the sustainable development concept. Procedia Soc. Behav. Sci. 2014, 124, 331–338. Available online: http://www.sciencedirect.com/science/article/pii/S1877042814020412 (accessed on 12 May 2017). [CrossRef]

- Le Goff, P.; Giuletti, M. Optimisation économique et énergétique comparées d’un échangeur de chaleur. Entropie 1980, 93, 19–21. [Google Scholar]

| No. | Interior Diameter Di (mm) | Fluid Dynamics Resistance Coefficient λ for Various Equivalent Retardances k (mm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| k = 0.05 | k = 0.1 | k = 0.15 | k = 0.2 | k = 0.4 | k = 0.6 | k = 0.8 | k = 1 | k = 1.5 | k = 2 | k = 3 | ||

| 1 | 50 | 0.0196 | 0.0234 | 0.0261 | 0.0351 | 0.0261 | 0.0403 | 0.0446 | 0.0485 | 0.0571 | 0.645 | 0.0778 |

| 2 | 75 | 0.0178 | 0.0211 | 0.0234 | 0.0253 | 0.0309 | 0.0351 | 0.0387 | 0.0418 | 0.0485 | 0.0544 | 0.0645 |

| 3 | 100 | 0.0167 | 0.0196 | 0.0217 | 0.0234 | 0.0284 | 0.0321 | 0.0351 | 0.0378 | 0.0436 | 0.0485 | 0.0571 |

| 4 | 150 | 0.0152 | 0.0178 | 0.0196 | 0.0211 | 0.0253 | 0.0284 | 0.0309 | 0.0331 | 0.0378 | 0.0418 | 0.0485 |

| 5 | 200 | 0.0144 | 0.0167 | 0.0183 | 0.0196 | 0.0234 | 0.0261 | 0.0284 | 0.0303 | 0.0344 | 0.0378 | 0.0436 |

| 6 | 250 | 0.0137 | 0.0158 | 0.0174 | 0.0186 | 0.0221 | 0.0246 | 0.0266 | 0.0284 | 0.0321 | 0.0364 | 0.0403 |

| 7 | 300 | 0.0132 | 0.0153 | 0.0167 | 0.0178 | 0.0211 | 0.0234 | 0.0253 | 0.0269 | 0.0303 | 0.0331 | 0.0378 |

| 8 | 400 | 0.0125 | 0.0144 | 0.0156 | 0.0167 | 0.0196 | 0.0217 | 0.0234 | 0.0248 | 0.0278 | 0.0303 | 0.0344 |

| No. | Interior Diameter Di (m) | Total Area Stot (m2) | Obstructed Area Sobt (m2) | Thickness of Uniform Obstruction δ (m) | Relative Obstruction (%) | Relative Obstruction 15% | Relative Obstruction 20% | Relative Obstruction 30% | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sobt (m2) | Δ (m) | Sobt (m2) | Δ (m) | Sobt (m2) | Δ (m) | ||||||

| 1 | 0.400 | 0.1256 | 0.012126 | 0.0099 | 9.654 | 0.01884 | 0.01565 | 0.02512 | 0.02116 | 0.03768 | 0.03271 |

| 2 | 0.300 | 0.0707 | 0.000682 | 0.0074 | 9.646 | 0.0106 | 0.0117 | 0.0141 | 0.0158 | 0.0212 | 0.0245 |

| 3 | 0.250 | 0.0491 | 0.00474 | 0.0062 | 9.653 | 0.00736 | 0.00973 | 0.00982 | 0.0132 | 0.0147 | 0.203 |

| 4 | 0.200 | 0.0314 | 0.00303 | 0.0049 | 9.649 | 0.00471 | 0.00783 | 0.00628 | 0.0106 | 0.00942 | 0.0163 |

| 5 | 0.150 | 0.0177 | 0.00171 | 0.0036 | 9.660 | 0.00265 | 0.00578 | 0.00354 | 0.00786 | 0.00531 | 0.0122 |

| 6 | 0.100 | 0.00785 | 0.00076 | 0.0025 | 9.680 | 0.00118 | 0.00392 | 0.00157 | 0.00529 | 0.00235 | 0.0816 |

| 7 | 0.075 | 0.00441 | 0.000426 | 0.0019 | 9.659 | 0.000661 | 0.00295 | 0.000382 | 0.00399 | 0.00132 | 0.00614 |

| 8 | 0.050 | 0.001963 | 0.000189 | 0.0012 | 9.649 | 0.000294 | 0.00195 | 0.000392 | 0.00263 | 0.000589 | 0.00406 |

| For Di (m) | Relative Obstruction (%) | Reduction of Transport Capacity (at Δp = const.) (%) | Increase of Pressure Loss (at Q = const.) (%) |

|---|---|---|---|

| 50 | 10.86 | 12.566 | 26.00 |

| 75 | 4.527 | 5.625 | 10.47 |

| 100 | 2.546 | 3.174 | 5.71 |

| 150 | 1.32 | 1.414 | 2.48 |

| 200 | 0.636 | 0.795 | 1.38 |

| 250 | 0.407 | 0.509 | 0.88 |

| 275 | 0.336 | 0.421 | 0.73 |

| 300 | 0.283 | 0.353 | 0.61 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rada, A.C.; Irimie, S.; Irimie, S.I. Economic, Energetic, and Environmental Impact Evaluation of the Water Discharge Networks from Mining Works. Sustainability 2018, 10, 240. https://doi.org/10.3390/su10010240

Rada AC, Irimie S, Irimie SI. Economic, Energetic, and Environmental Impact Evaluation of the Water Discharge Networks from Mining Works. Sustainability. 2018; 10(1):240. https://doi.org/10.3390/su10010240

Chicago/Turabian StyleRada, Andrei Cristian, Sabina Irimie, and Sabin Ioan Irimie. 2018. "Economic, Energetic, and Environmental Impact Evaluation of the Water Discharge Networks from Mining Works" Sustainability 10, no. 1: 240. https://doi.org/10.3390/su10010240

APA StyleRada, A. C., Irimie, S., & Irimie, S. I. (2018). Economic, Energetic, and Environmental Impact Evaluation of the Water Discharge Networks from Mining Works. Sustainability, 10(1), 240. https://doi.org/10.3390/su10010240