Utilization of Construction and Demolition Mix Waste in the Fired Brick Production: The Impact on Mechanical Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Material Characterization

2.2. Properties of Bricks

3. Results

3.1. Raw Materials

3.1.1. Mineralogical Composition of the C&D Waste

3.1.2. Chemical Composition of the C&D Waste

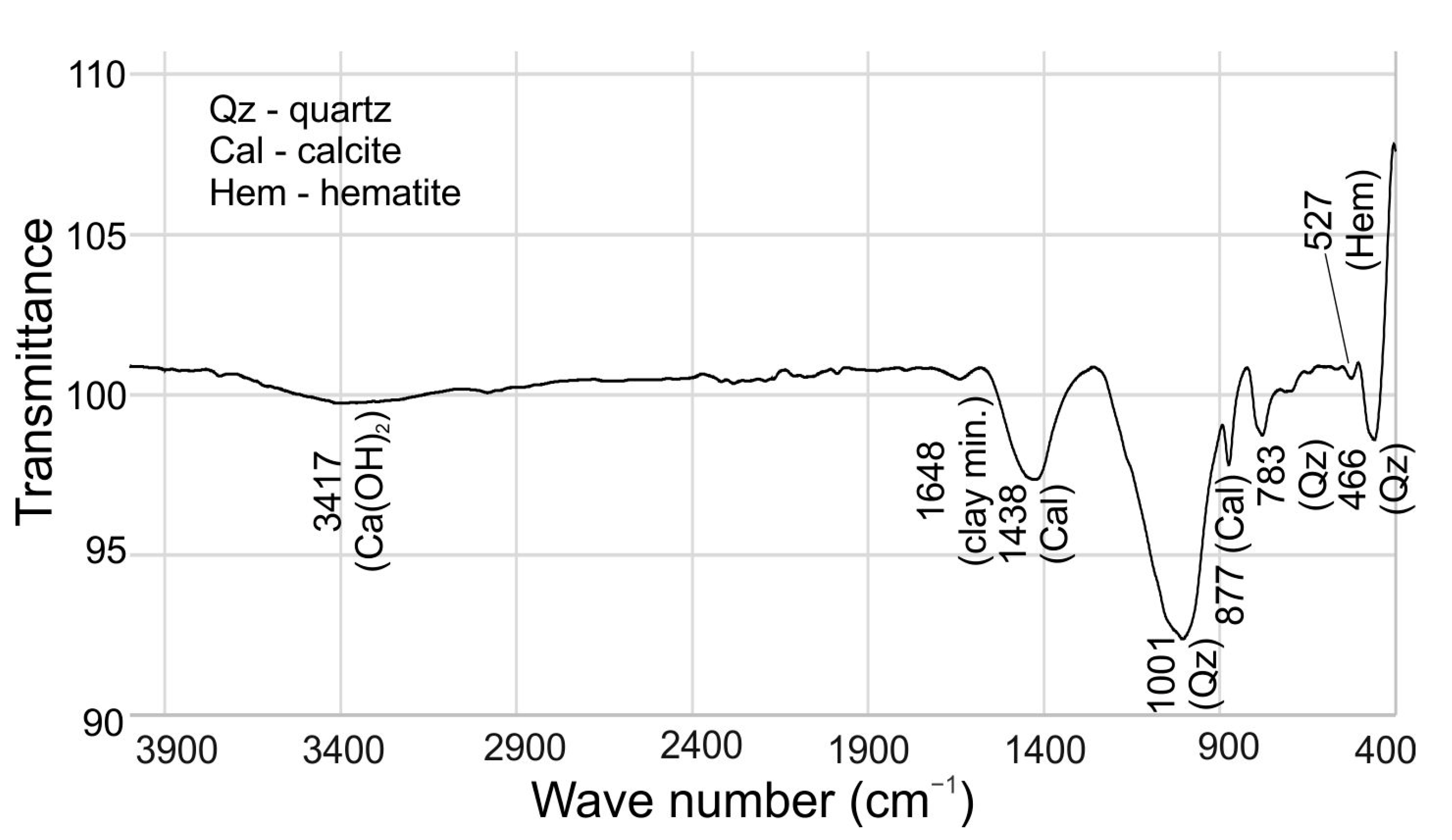

3.1.3. Fourier-Transform Infrared Spectrometry (FTIR)

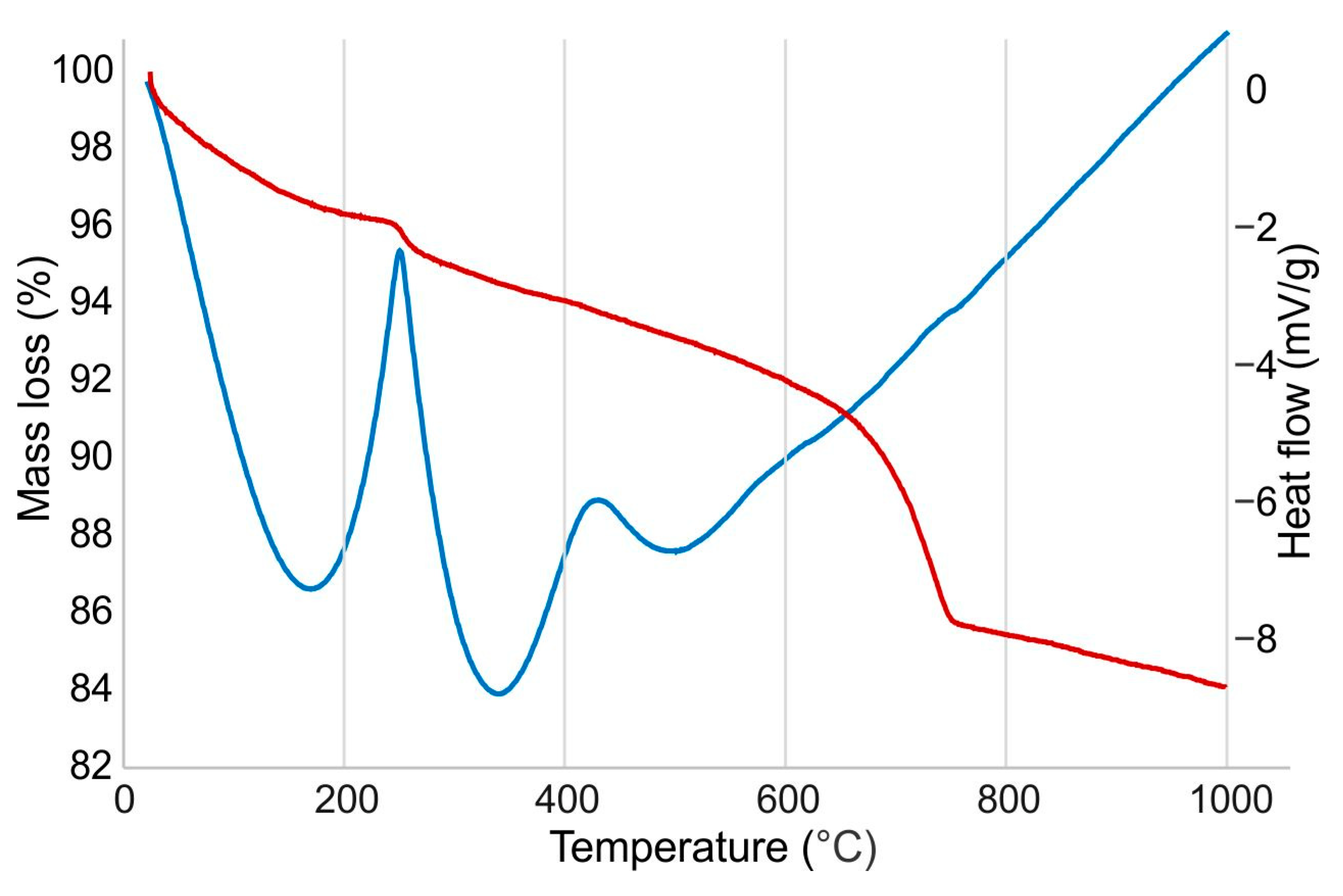

3.1.4. Thermal Behavior

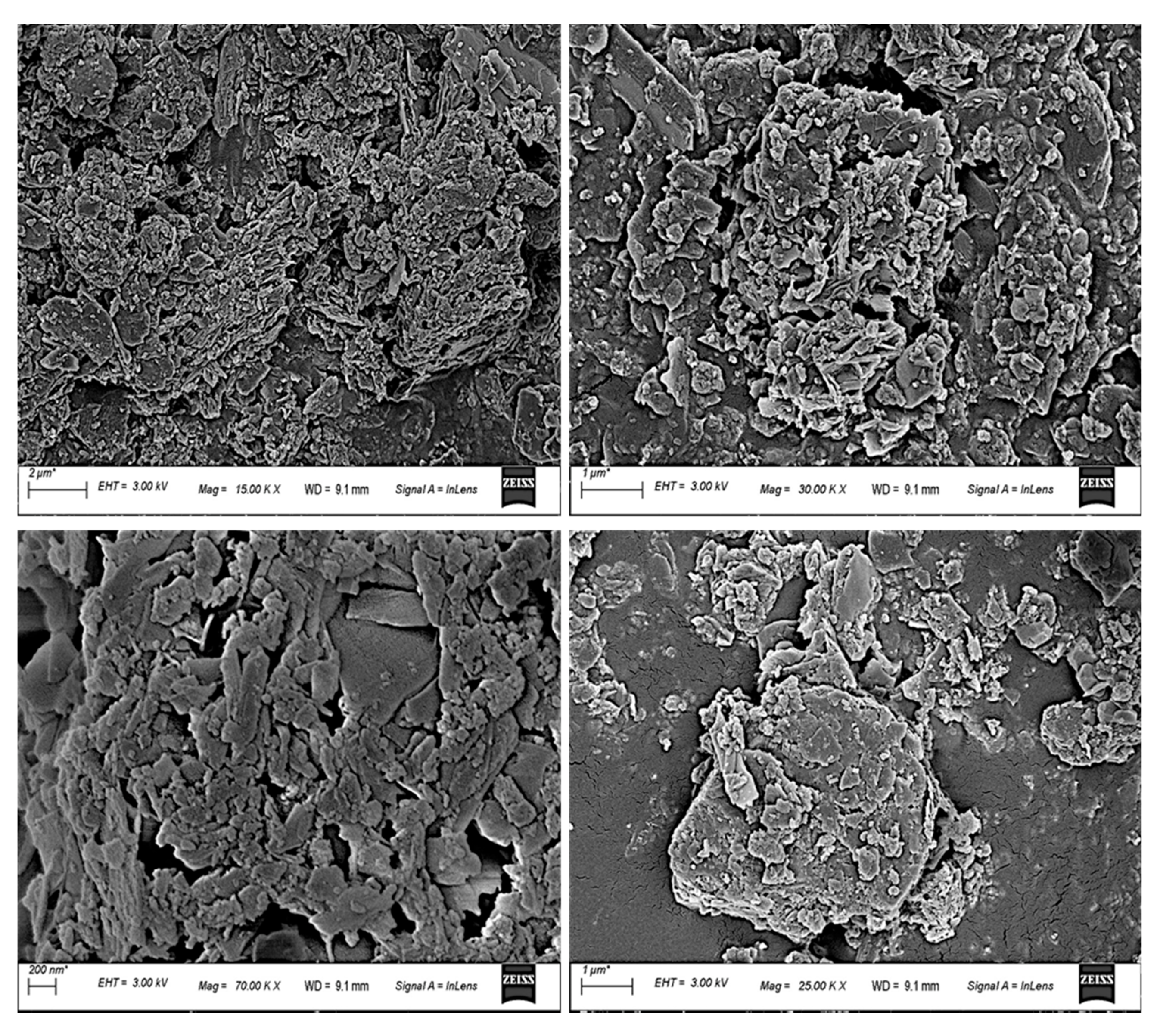

3.1.5. Microstructure

3.1.6. Toxicity Characteristics Leaching Procedure (TCLP)

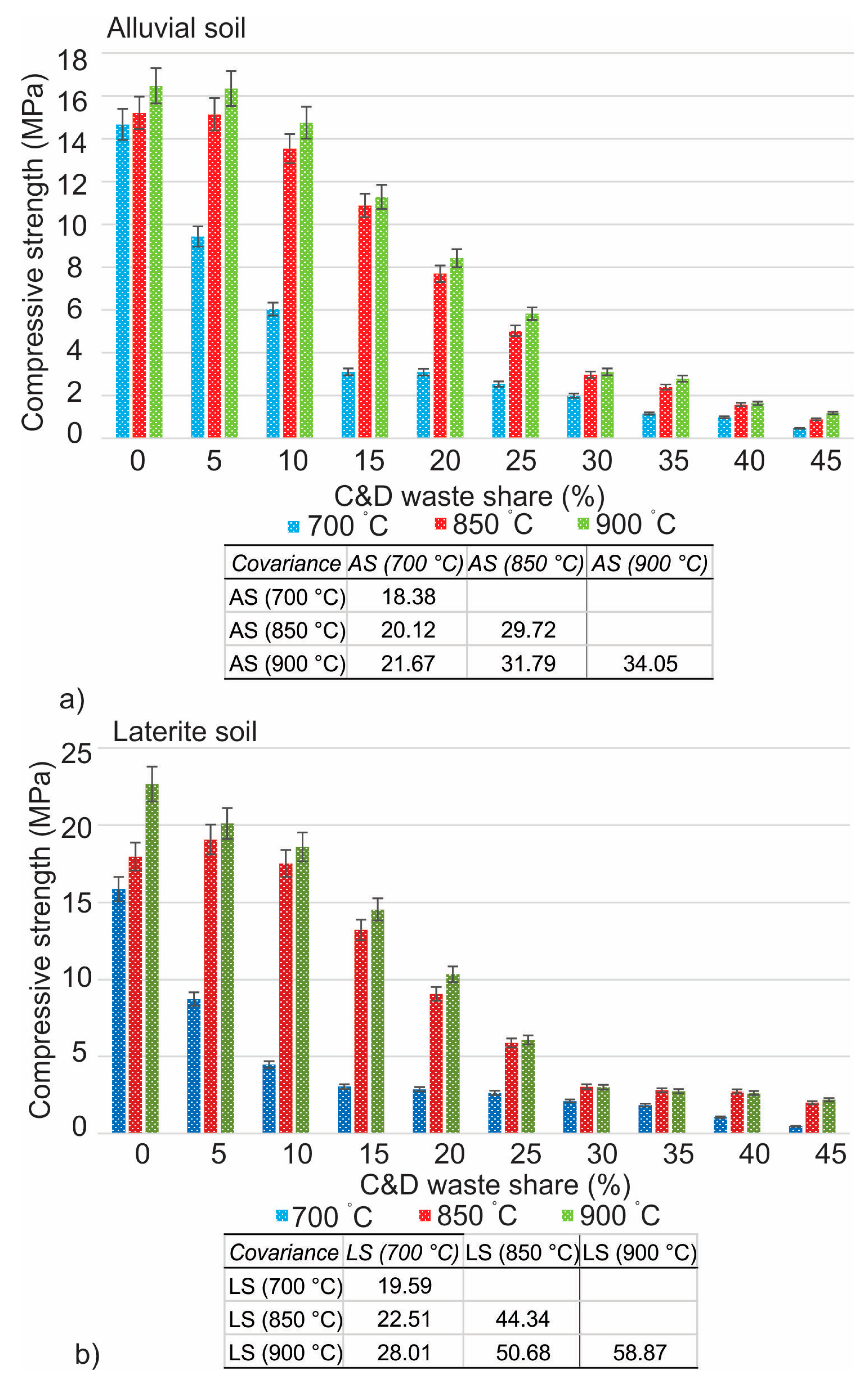

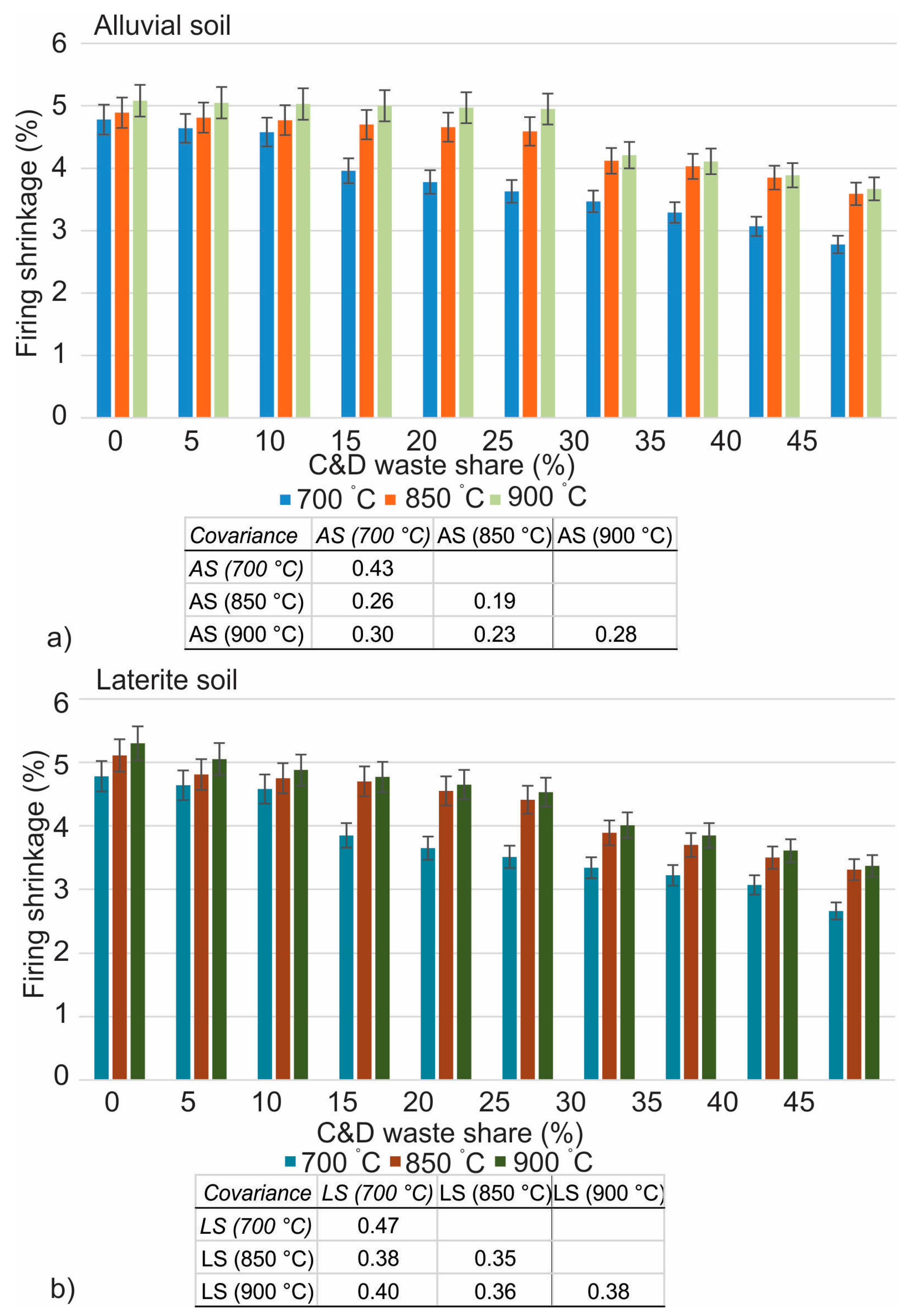

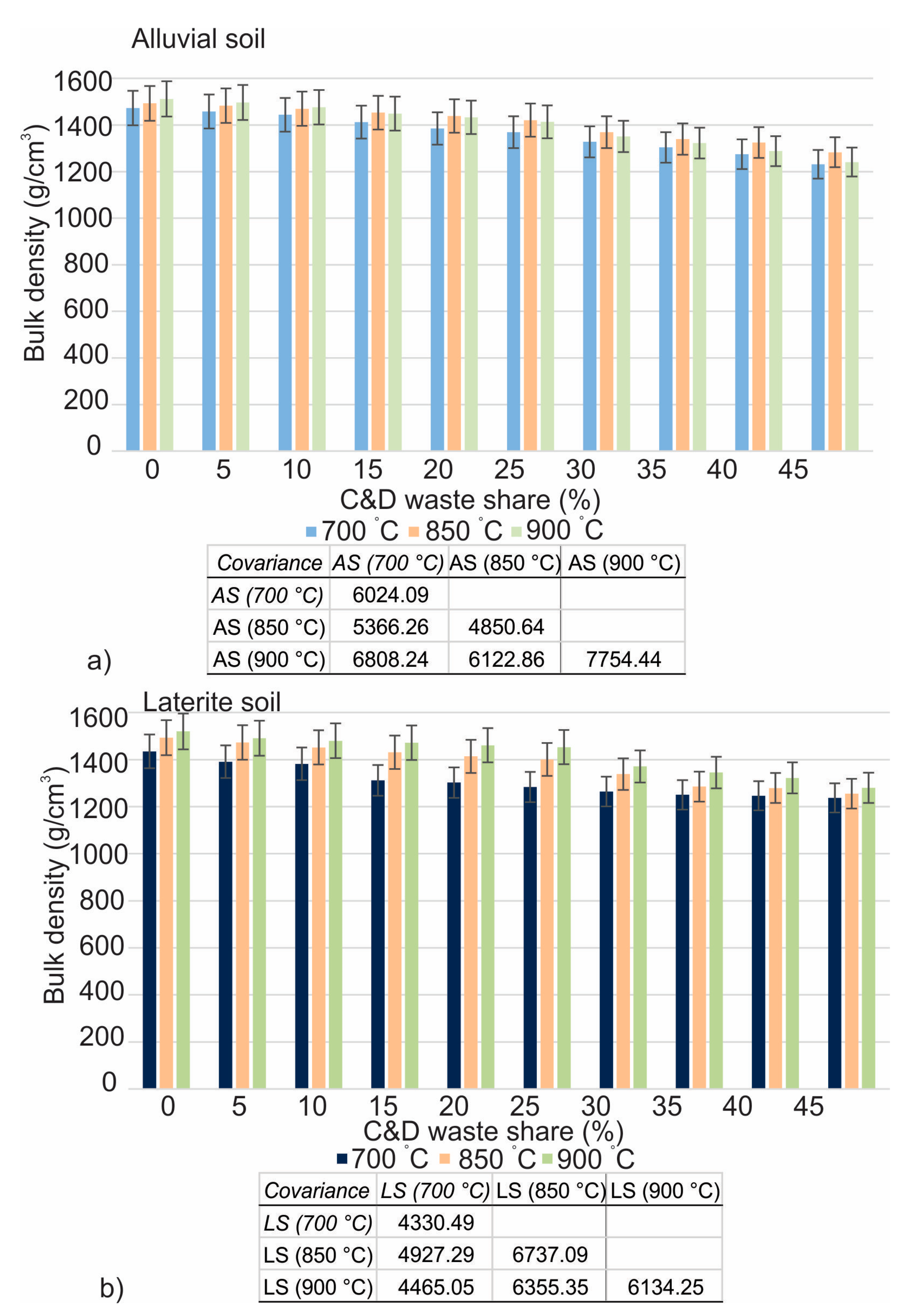

3.2. Properties of Fired Bricks

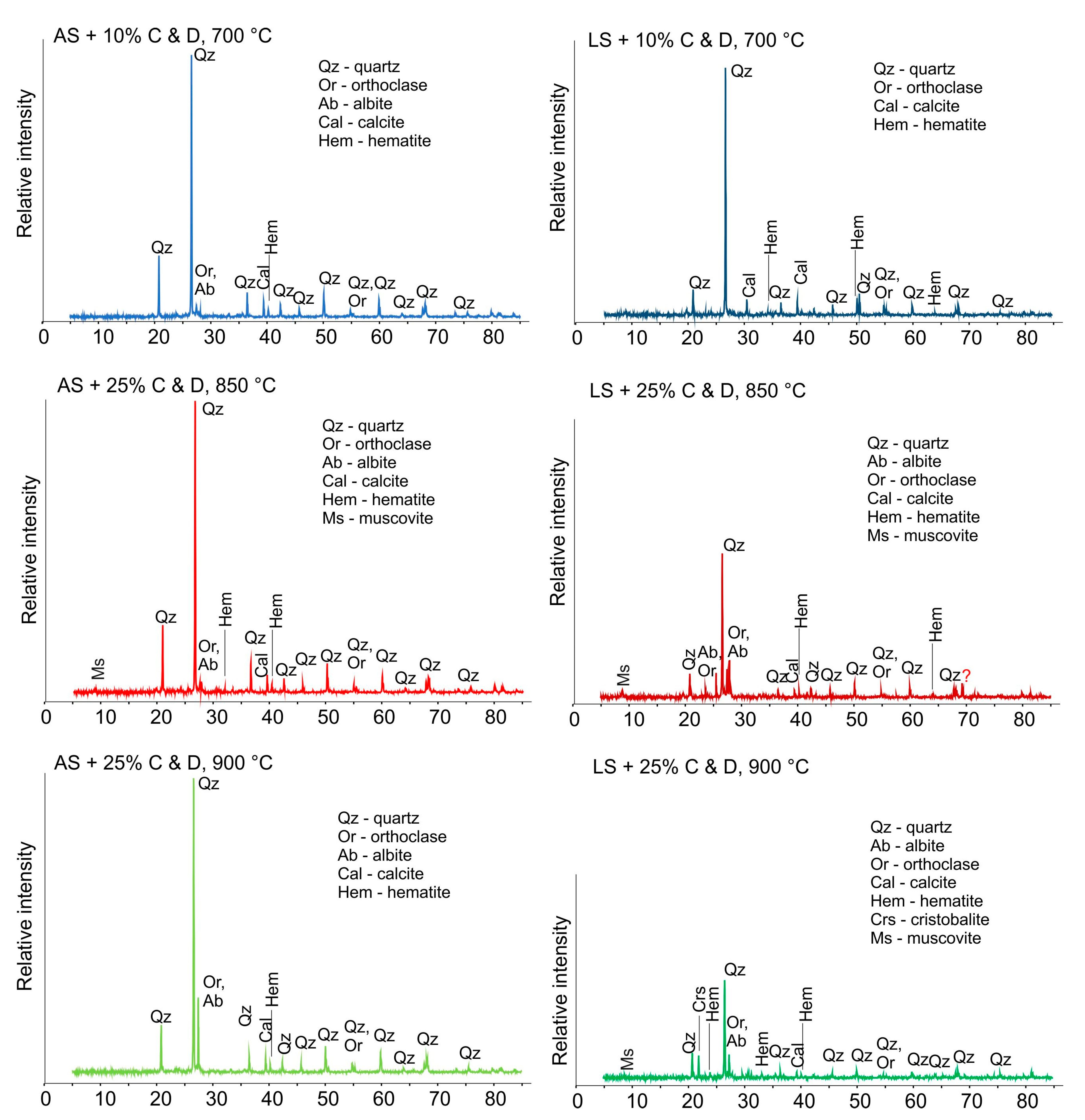

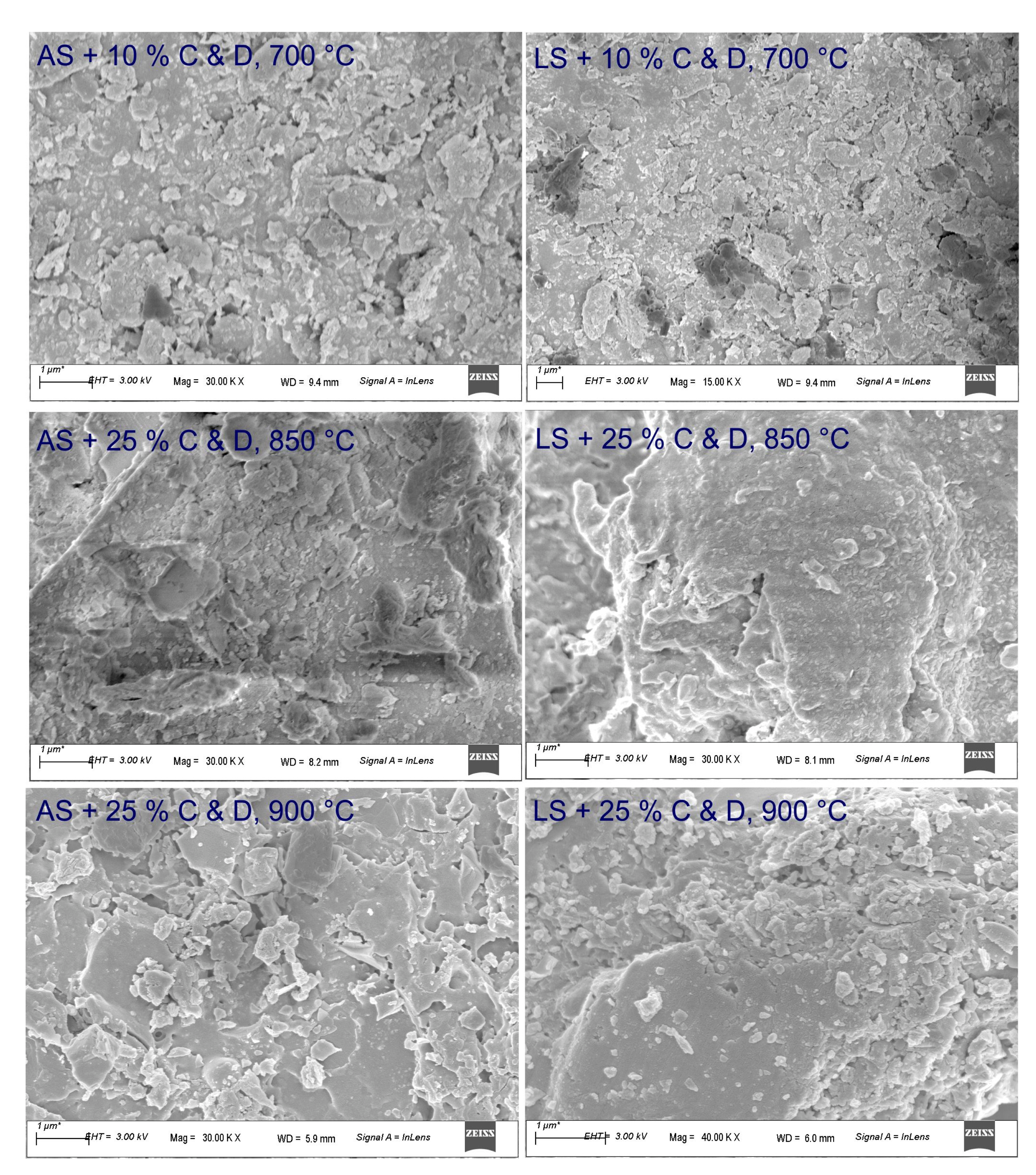

3.3. Instrumental Analysis on the Optimal Fired Bricks

4. Conclusions

- The addition of mixed C&D waste has shown a discernible change in the firing temperature;

- When producing burnt bricks, a larger proportion of mixed C&D waste must be added depending on the temperature. The higher the temperature, the more waste can be added. It is permissible to use up to 25% of mixed C&D waste in construction material;

- The use of mixed construction and demolition waste helps enhance the long-term conservation of natural resources and minimizes the amount of waste that is disposed of in unexpected locations;

- When producing fired bricks at temperatures between 850 °C and 900 °C, mixed construction and demolition waste makes an excellent replacement for rich agricultural soil, and may account for up to 25%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, R.; Li, B.; Zhou, T.; Wanatowski, D.; Piroozfar, P. An empirical study of perceptions towards construction and demolition waste recycling and reuse in China. Resour. Conserv. Recycl. 2017, 126, 86–98. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Duan, H.; Ouyang, L.; Huang, W.; Zuo, J. An innovative approach to managing demolition waste via GIS (geographic information system): A case study in Shenzhen city, China. J. Clean. Prod. 2016, 112, 494–503. [Google Scholar] [CrossRef]

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Shanawaz Uddin, A.S.M.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef] [PubMed]

- Turkyilmaz, A.; Guney, M.; Karaca, F.; Bagdatkyzy, Z.; Sandybayeva, A.; Sirenova, G. A comprehensive construction and demolition waste management model using PESTEL and 3R for construction companies operating in Central Asia. Sustainability 2019, 11, 1593. [Google Scholar] [CrossRef]

- Roychowdhury, A.; Somvanshi, A.; Verma, A. Another Brick off The Wall: Improving Construction and Demolition Waste Management in Indian Cities. Centre for Science and Environment, New Delhi. 2020. Available online: https://www.cseindia.org/another-brick-off-the-wall-10325 (accessed on 17 December 2022).

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Torres, A.; Brandt, J.; Lear, K.; Liu, J. A looming tragedy of the sand commons. Science 2017, 357, 970–971. [Google Scholar] [CrossRef]

- Mineral Commodity Summaries 2022, U.S. Geological Survey. Available online: https://pubs.usgs.gov/periodicals/mcs2022/mcs2022.pdf (accessed on 25 October 2022).

- Shrivastava, S.; Chini, A. Construction Materials and C&D Waste in India; School of Building Construction, University of Florida: Gainesville, FL, USA, 2009; pp. 72–76. Available online: https://www.irbnet.de/daten/iconda/CIB14286.pdf (accessed on 17 December 2022).

- D’Souza, R. Housing poverty in urban India: The failures of past and current strategies and the need for a new blueprint. ORF Obs. Res. Found. Occas. Pap. No 2019, 187. [Google Scholar]

- Maithel, S. Evaluating Energy Conservation Potential of Brick Production in India. A Report Prepared for the SAARC Energy Centre, Islamabad. 2013. Available online: https://www.saarcenergy.org/wp-content/uploads/2022/06/2012-Final-Report-Evaluating-Energy-Conservation-in-Brick-Production-in-India.pdf (accessed on 17 December 2022).

- Guney, Y.; Sari, Y.D.; Yalcin, M.; Tuncan, A.; Donmez, S. Re-usage of waste foundry sand in high-strength concrete. Waste Manag. 2010, 30, 1705–1713. [Google Scholar] [CrossRef]

- Krishna Sastry, K.V.S.G.; Ravi Theja, A.; Reddy, T.C.S. Effect of used foundry sand and mineral admixtures on strength properties of concrete. Arch. Civ. Eng. 2018, 64, 117–131. [Google Scholar] [CrossRef]

- Siddique, R.; Dhanoa, G. Design & development of concrete using waste foundry sand as partial replacement of fine aggregate. In Proceedings of the Thirteenth East Asia-Pacific Conference on Structural Engineering and Construction (EASEC-13), Sapporo, Japan, 11–13 September 2013; p. D-5-4. [Google Scholar]

- Nguyen, T.S.; Thai, M.Q.; Ho, L.S. Properties of fine-grained concrete containing fly ash and bottom ash. Mag. Civ. Eng. 2021, 7, 10711. [Google Scholar] [CrossRef]

- Ovbeniyekede, O.S.; Adenan, D.S.Q.; Ahmad, M.; Kamaruddin, K. Water absorption and compressive strength of self-compacting concrete incorporating fly ash and quarry dust. IJSRP 2018, 8, 377–384. [Google Scholar] [CrossRef]

- Feng, J.; Sun, J.; Yan, P. The influence of ground fly ash on cement hydration and mechanical property of mortar. Adv. Civ. Eng. 2018, 1–7, 4023178. [Google Scholar] [CrossRef]

- Rai, A.K.; Paul, B.; Singh, G. A study on back fill properties and use of fly ash for highway embankments. J. Adv. Lab. Res. Biol. 2010, 1, 110–114. [Google Scholar]

- Athanasopoulou, A.; Kollaros, G. Fly ash exploited in pavement layers in environmentally friendly ways. Toxicol. Environ. Chem. 2015, 97, 43–50. [Google Scholar] [CrossRef]

- Zhai, H.; Tang, Y.; Chen, S.; Chen, H.; Cheng, B.; Cai, X.; Wei, Y. Experimental research on durability of fly ash pavement concrete and mix proportion, optimization. Adv. Mater. Sci. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Mirković, K.; Tošić, N.; Mladenović, G. Effect of different types of fly ash on properties of asphalt mixtures. Adv. Civ. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Vasić, M.V.; Pezo, L.; Gupta, V.; Chaudhary, S.; Radojević, Z. An artificial neural network-based prediction model for utilization of coal ash in production of fired clay bricks: A review. Sci. Sinter. 2021, 53, 37–53. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Shahidan, S.; Azmi, M.A.M.; Kupusamy, K.; Zuki, S.S.M.; Ali, N. Utilizing construction and demolition (C&D) waste as recycled aggregates (RA) in concrete. Procedia Eng. 2017, 74, 1028–1035. [Google Scholar] [CrossRef]

- Ghorbani, B.; Arulrajah, A.; Narsilio, G.; Horpibulsuk, S.; Bo, M.W. Shakedown analysis of PET blends with demolition waste as pavement base/subbase materials using experimental and neural network methods. Transp. Geotech. 2021, 27, 100481. [Google Scholar] [CrossRef]

- Migunthanna, J.; Rajeev, P.; Sanjayan, J. Investigation of waste clay brick as partial replacement of geopolymer binders for rigid pavement application. Constr. Build. Mater. 2021, 305, 124787. [Google Scholar] [CrossRef]

- Marrocchino, E.; Zanelli, C.; Guarini, G.; Dondi, M. Recycling mining and construction wastes as temper in clay bricks. Appl. Clay Sci. 2021, 209, 106152. [Google Scholar] [CrossRef]

- Dubale, M.; Goel, G.; Kalamdhad, A.; Singh, L.B. An investigation of demolished floor and wall ceramic tile waste utilization in fired brick production. Environ. Technol. Innov. 2022, 25, 102228. [Google Scholar] [CrossRef]

- Hossain, S.S.; Mathur, L.; Majhi, M.R.; Roy, P.K. Manufacturing of green building brick: Recycling of waste for construction purpose. J. Mater. Cycles Waste Manag. 2019, 21, 281–292. [Google Scholar] [CrossRef]

- Simões dos Reis, G.; Cazacliu, B.G.; Cothenet, A.; Poullain, P.; Wilhelm, M.; Sampaio, C.H.; Lima, A.C.; Ambros, W.; Torrenti, J.-M. Fabrication, microstructure, and properties of fired clay bricks using construction and demolition waste sludge as the main additive. J. Clean. Prod. 2020, 258, 120733. [Google Scholar] [CrossRef]

- Gencel, O.; Erdugmus, E.; Sutcu, M.; Oren, O.H. Effects of concrete waste on characteristics of structural fired clay bricks. Constr. Build. Mater. 2020, 255, 119362. [Google Scholar] [CrossRef]

- Harikumar, M.; Mohamed, F.; Mohammed, A.; Ashraf, I.; Shahansha, M.; Anand, A.G. Clay bricks using building debris. Mater. Today: Proc. 2022, 60, 746–752. [Google Scholar] [CrossRef]

- Zanelli, C.; Marrocchino, E.; Guarini, G.; Toffano, A.; Vaccaro, C.; Dondi, M. Recycling Construction and Demolition Residues in Clay Bricks. Appl. Sci. 2021, 11, 8918. [Google Scholar] [CrossRef]

- 17 Sustainable Development Goals. 17 Partnerships. Division for Sustainable Development, United Nations Department of Economic and Social Affairs. 2015. Available online: https://sustainabledevelopment.un.org/content/documents/211617%20Goals%2017%20Partnerships.pdf (accessed on 17 December 2022).

- Bolden, J.; Abu-Lebdeh, T.; Fini, E. Utilization of recycled and waste materials in various construction applications. Am. J. Environ. Sci. 2013, 9, 14–24. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S. An investigation on use of paper mill sludge in brick manufacturing. Constr. Build. Mater. 2017, 148, 334–343. [Google Scholar] [CrossRef]

- Method 1311—Toxicity Characteristic Leaching Procedure, Environmental Protection Agency (EPA). 1992. Available online: https://www.epa.gov/sites/default/files/2015-12/documents/1311.pdf (accessed on 17 December 2022).

- Bhavikatti, S.S. Basic Civil Engineering. New Age International Publishers. 2010. Available online: https://basicengn.files.wordpress.com/2019/09/basic-civil-engineering-materials.pdf (accessed on 17 December 2022).

- Pacheco-Torgal, F.; Lourenço, P.B.; Labrincha, J.A.; Kumar, S.; Chindaprasirt, P. Eco-Efficient Masonry Bricks and Blocks: Design, Properties and Durability; Elsevier Ltd.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Pfeifer, G.; Ramcke, R.; Achtzicker, J.; Zilch, K. Masonry Construction Manual; Birkhäuser: Basel, Elveția, 2001. [Google Scholar]

- ASTM C20-00; Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. Scientific Research an Academic Publisher: Wuhan, China, 2015.

- Goel, G.; Kalamdhad, A.S. A practical proposal for utilisation of water hyacinth: Recycling in fired bricks. J. Clean. Prod. 2018, 190, 261–271. [Google Scholar] [CrossRef]

- IS 3495; Methods of Tests of Burnt Clay Building Bricks: Part 1 Determination of Compressive Strength, Part 2 Determination of Water Absorption, Part 3 Determination of Efflorescence, Part 4: Determination of Warpage. 13. Bureau of Indian Standards: New Delhi, India, 1992.

- Johari, I.; Said, S.; Jaya, R.P.; Bakar, B.H.A.; Ahmad, Z.A. Chemical and physical properties of fired-clay brick at different type of rice husk ash. Environ. Sci. Eng. 2011, 8, 171–174. [Google Scholar]

- Vasić, M.V.; Terzić, A.; Radovanović, Ž.; Radojević, Z.; Warr, L.N. Alkali-activated geopolymerization of a low illitic raw clay and waste brick mixture. An alternative to traditional ceramics. Appl. Clay Sci. 2022, 218, 106410. [Google Scholar] [CrossRef]

- Iftikhar, S.; Rashid, K.; Ul Haq, E.; Zafar, I.; Alqahtani, F.K.; Iqbal Khan, M. Synthesis and characterization of sustainable geopolymer green clay bricks: An alternative to burnt clay brick. Constr. Build. Mater. 2020, 259, 119659. [Google Scholar] [CrossRef]

- Samadi, M.; Huseien, G.F.; Mohammadhosseini, H.; Lee, H.S.; Abdul Shukor Lim, N.H.; Tahir, M.M.; Alyousef, R. Waste ceramic as low cost and eco-friendly materials in the production of sustainable mortars. J. Clean. Prod. 2020, 266, 121825. [Google Scholar] [CrossRef]

- Robayo-Salazar, W.; Valencia-Saavedra, W.; de Gutiérrez, R.M. Construction and demolition waste (CDW) recycling—As both binder and aggregates—In alkali-activated materials: A novel re-use concept. Sustainability 2020, 12, 5775. [Google Scholar] [CrossRef]

- Siddique, S.; Shrivastava, S.; Chaudhary, S. Influence of ceramic waste as fine aggregate in concrete: Pozzolanic, XRD, FT-IR, and NMR investigations. Mater. Civ. Eng. 2018, 30, 04018227. [Google Scholar] [CrossRef]

- Nigay, P.-M.; Nzihou, A.; Cutard, T. The impact of the particle size distribution of organic additives on the microstructure of a clay ceramic and its thermal and mechanical properties. J. Mater. Civ. Eng. 2018, 30, 04018044. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Sundara Raj, A.; Srinivasan, S.; Ganesh Babu, K. Quantification of hydrated cement products of blended ce-ments in low and medium strength concrete using TG and DTA technique. Thermochim. Acta 2003, 1–2, 49–60. [Google Scholar] [CrossRef]

- Anjum, F.; Yasin Naz, M.; Ghaffar, A.; Shukrullah, S. Study of microstructural, physical, thermal, and mechanical properties of organic waste–incorporated fired clay bricks in the framework of energy conservation. J. Mater. Civ. Eng. 2021, 33. [Google Scholar] [CrossRef]

- ASTM. ASTM C62—Standard Specification for Building Brick (Solid Masonry Units Made from Clay or Shale). ASTM Int.: West Conshohocken, PA, USA, 2012; pp. 10–13.

- IS:1077 (BIS 1992d); Common Burnt Clay Building Bricks -Specification, Bureau of Indian Standard (BIS). BIS: Borneostraat, The Netherlands, 1992.

- Arsenović, M.; Pezo, L.; Stanković, S.; Radojević, Z. Sensitivity analysis of mathematical models for final product properties: Link to DTG curve. Ceram. Int. 2013, 39, 6277–6285. [Google Scholar] [CrossRef]

- Debnath, A.; Salma, M.M.; Islam, M.S.; Mostafa, M.G.; Samad, A.; Akhtar, U.S. Effect of processed rice husk ash on the production of conventional bricks. Int. J. Sci. Eng. Res. 2019, 10, 1033–1036. [Google Scholar] [CrossRef]

- Yannick, B.I.; Ludovic, W.A.S.; Francois, N.; Véronique, K.K.; Nathalie, F. Mineralogical Transformation and Microstructure of the Alluvials Clays. Sci. Sinter. 2019, 51, 57–70. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, T.; Liu, T.; Huang, J. Preparation and characterization of red porcelain tiles with hematite tailings. Constr. Build. Mat. 2013, 38, 1083–1088. [Google Scholar] [CrossRef]

- Vieira, C.M.F.; Monteiro, S.N. Firing Behavior of the Clay Fraction of a Natural Kaolinitic Clay: Are They Different? Mat. Res. 2019, 22 (Suppl. S1), e20190172. [Google Scholar] [CrossRef]

- Goel, G.; Vasić, M.V.; Katiyar, N.K.; Kirthika, S.K.; Pezo, M.; Dinakar, P. Potential pathway for recycling of the paper mill sludge compost for brick making. Constr. Build. Mat. 2021, 278, 122384. [Google Scholar] [CrossRef]

| Ref. | Type of Waste | Size of Waste Particles | Characteristics of Raw Clay | Temp. (°C) | Optimum Utilization |

|---|---|---|---|---|---|

| [30] | Demolished bricks, fly ash, rice husk ash, glass cullet | ≤150 μm | 29.74% Al2O3 kaolinitic–illitic ball clay | 800, 900 and 1000 | 60–80% of total waste |

| [31] | C&D waste | <2 mm | 26.8% Al2O3 | 800 and 1000 | 30 to 70% |

| [32] | Ground concrete waste powder | <100 μm | 11.23% Al2O3 illitic–chloritic clay | 1000 and 1100 | 2.5–15% |

| [29] | Demolition floor and wall ceramic tile waste | <0.6 mm | 28.64 Al2O3 kaolinitic alluvial soil 26.86 Al2O3 kaolinitic–illitic laterite soil | 850 and 900 | 35% at 850 °C and 40% at 900 °C |

| [33] | Processed C&D waste and 0.1–1% of fly ash | 300 μm–1.18 mm | Undefined | 900 | 37.5% of C&D waste and 1% of fly ash |

| [34] | Processed C&D waste | 100–250 μm | 15% Al2O3 clays containing illite mica, chlorite, kaolinite and smectite | 900, 940 and 950 | 15% |

| This study | Mixed C&D waste | <0.6 mm | 28.64 Al2O3 kaolinitic alluvial soil 26.86 Al2O3 kaolinitic–illitic laterite soil | 700, 850 and 900 | 10% at 700 °C and 25% at 850 and 900 °C |

| Major Oxides | C&D Waste (%) | Alluvial Soil (%) | Laterite Soil (%) |

|---|---|---|---|

| SiO2 | 51.81 ± 3.48 | 47.07 ± 3.13 | 46.07 ± 3.05 |

| Al2O3 | 14.3 ± 0.96 | 28.64 ± 1.90 | 26.86 ± 1.79 |

| Fe2O3 | 3.81 ± 0.26 | 5.43 ± 0.36 | 10.58 ± 0.70 |

| MnO | 0.04 ± 0.00 | 0.56 ± 0.04 | 0.13 ± 0.01 |

| MgO | 2.52 ± 0.17 | 1.99 ± 0.13 | 1.83 ± 0.12 |

| CaO | 6.21 ± 0.41 | 1.14 ± 0.08 | 1.40 ± 0.09 |

| Na2O | 1.73 ± 0.12 | 0.81 ± 0.05 | 1.03 ± 0.07 |

| K2O | 1.83 ± 0.12 | 3.73 ± 0.25 | 2.77 ± 0.18 |

| TiO2 | 0.53 ± 0.04 | 0.67 ± 0.04 | 0.50 ± 0.03 |

| P2O5 | 0.09 ± 0.01 | 0.23 ± 0.02 | 0.27 ± 0.02 |

| SO3 | 0.71 ± 0.05 | 0.11 ± 0.01 | 0.19 ± 0.01 |

| Loss on ignition | 16.42 ± 1.09 | 9.62 ± 0.63 | 8.37 ± 0.56 |

| Elements | Mixed C&D Waste (mg/kg) |

|---|---|

| Ac | 2.12 ± 0.14 |

| Cd | 1.23 ± 0.08 |

| Cr | 1.07 ± 0.07 |

| Cu | 0.00 ± 0.00 |

| Fe | 0.00 ± 0.00 |

| Ni | 0.00 ± 0.00 |

| Mn | 1.11 ± 0.07 |

| Pb | 0.00 ± 0.00 |

| Zn | 99.6 ± 6.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubale, M.; Vasić, M.V.; Goel, G.; Kalamdhad, A.; Singh, L.B. Utilization of Construction and Demolition Mix Waste in the Fired Brick Production: The Impact on Mechanical Properties. Materials 2023, 16, 262. https://doi.org/10.3390/ma16010262

Dubale M, Vasić MV, Goel G, Kalamdhad A, Singh LB. Utilization of Construction and Demolition Mix Waste in the Fired Brick Production: The Impact on Mechanical Properties. Materials. 2023; 16(1):262. https://doi.org/10.3390/ma16010262

Chicago/Turabian StyleDubale, Mandefrot, Milica Vidak Vasić, Gaurav Goel, Ajay Kalamdhad, and Laishram Boeing Singh. 2023. "Utilization of Construction and Demolition Mix Waste in the Fired Brick Production: The Impact on Mechanical Properties" Materials 16, no. 1: 262. https://doi.org/10.3390/ma16010262

APA StyleDubale, M., Vasić, M. V., Goel, G., Kalamdhad, A., & Singh, L. B. (2023). Utilization of Construction and Demolition Mix Waste in the Fired Brick Production: The Impact on Mechanical Properties. Materials, 16(1), 262. https://doi.org/10.3390/ma16010262