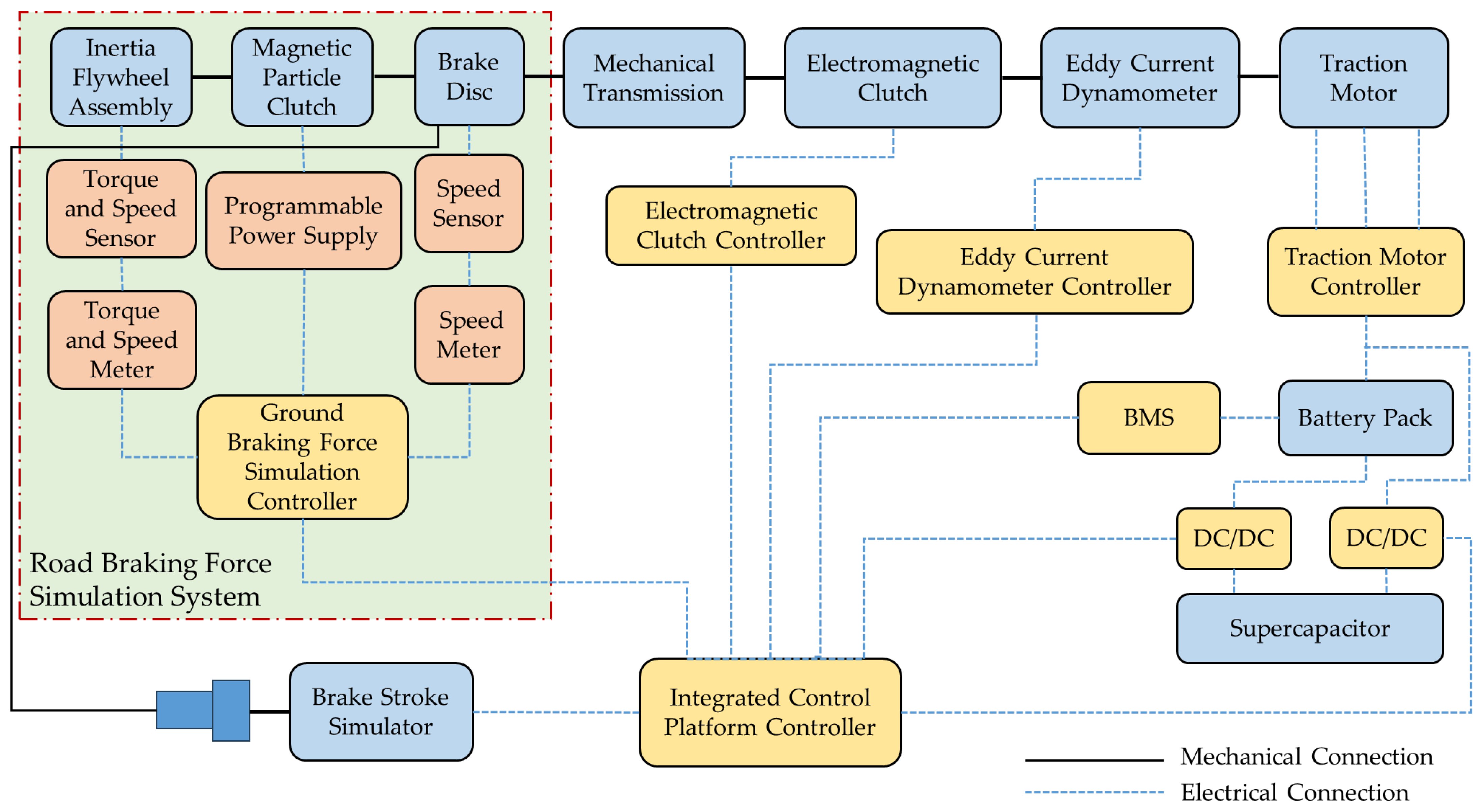

4.1. Ground Braking Force Simulation Control Scheme

During the braking process of a vehicle, it is subjected to braking forces from the ground and air resistance. Since air resistance is relatively small, the primary external force decelerating the vehicle is provided by the ground. Neglecting factors such as the inertial torque on the wheels during braking, the inertial force during deceleration, and the rolling resistance torque, the force analysis of a vehicle traveling in a straight line on a well-paved road during braking is illustrated in

Figure 5.

In the figure, represents the braking force exerted by the ground on the wheel, denotes the braking torque generated by the brake, is the gravitational force applied by the vehicle to the wheel, is the thrust force exerted by the axle on the wheel, and is the normal reaction force from the ground on the wheel. The ground braking force is transmitted from the wheel to the axle, suspension, and ultimately to the vehicle body, causing the wheel to decelerate and thereby slowing down the vehicle. During braking, the greater the ground braking force, the higher the vehicle’s deceleration, and the shorter the braking distance.

When a vehicle brakes, the magnitude of the ground braking force is determined by two factors: first, the braking force generated by the brake , and second, the ground adhesion force , where is the adhesion coefficient between the tire and the road surface.

During braking, it is assumed that only two states are considered: pure rolling of the wheel and locked-wheel skidding. When the braking intensity is low, the ground braking force is sufficient to overcome the braking force generated by the brake, allowing the wheel to roll. In this case, the following holds:

As the braking intensity increases, the ground braking force

grows with the increase in the braking force

generated by the brake. However, the ground braking force is a constrained reaction force resulting from the friction between the tire and the road surface. Its magnitude cannot exceed the adhesion force, that is:

When the braking intensity continues to increase and the ground braking force reaches the ground adhesion force , the wheel begins to lock up and skid. At this point, the ground braking force no longer increases with further increases in the braking force . Therefore, during the vehicle braking process, the ground braking force is initially determined by the braking force generated by the brake, but it is ultimately constrained by the ground adhesion force .

The adhesion coefficient between the tire and the road surface primarily depends on factors such as the material and condition of the road surface, as well as the structure and tread pattern of the tire. However, during the vehicle braking process, it is also influenced by the motion state of the wheel.

During the vehicle braking process, the extent of wheel sliding is typically described using the slip ratio

, which is defined by Equation (7).

where,

v is the vehicle speed,

ω is the angular velocity of the wheel,

r is the effective rolling radius of the wheel.

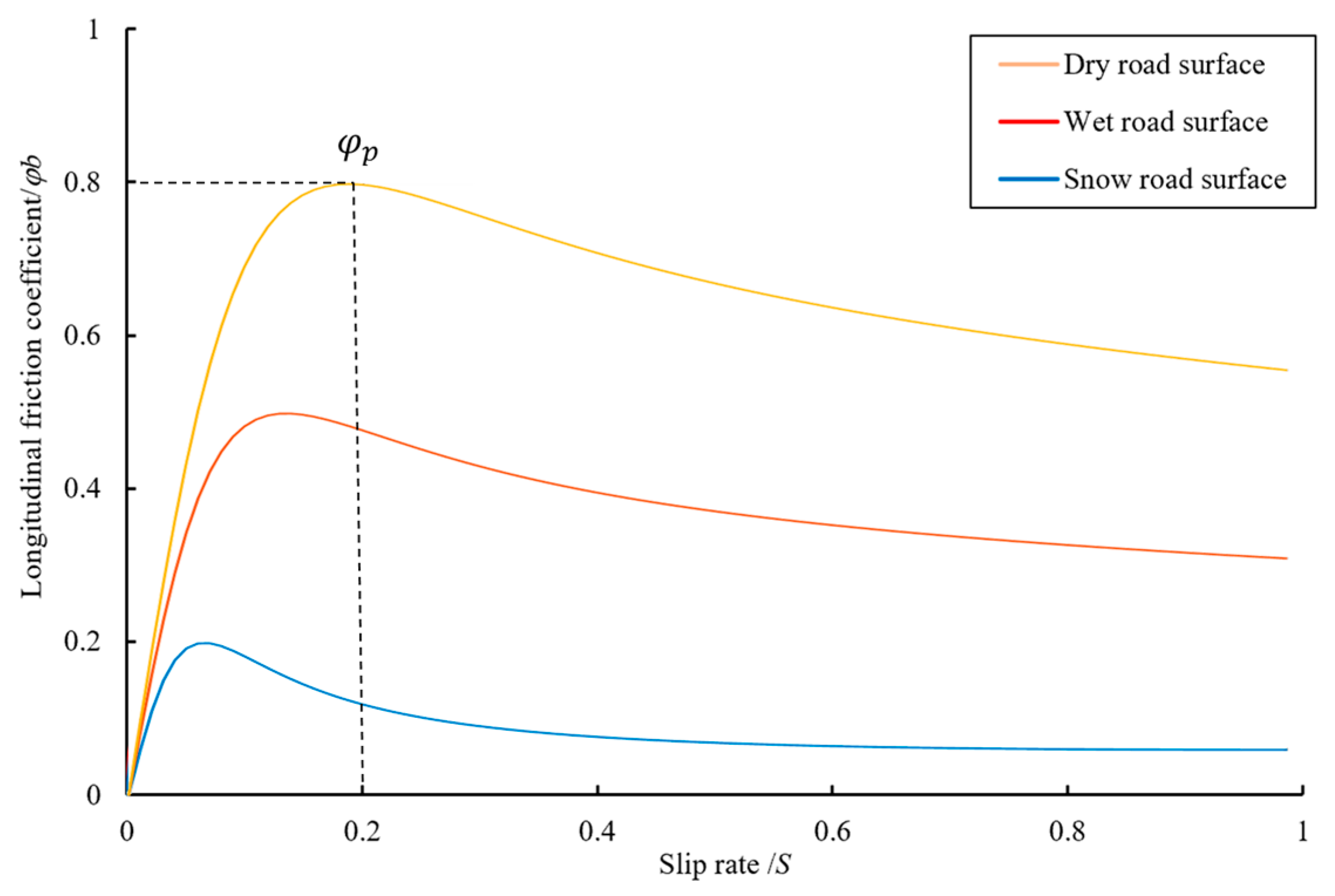

The longitudinal adhesion coefficient on different road surfaces exhibits a nonlinear relationship with the slip ratio . Consequently, during the braking process, the ground braking force acting on the wheel initially increases with the rise in the slip ratio until it reaches the maximum adhesion force (corresponding to the peak adhesion coefficient ). After reaching this peak, the braking force gradually decreases until the wheel locks up completely.

In the context of integrated control experiments, it is essential to account for the ground braking force when transmitting both the braking force and regenerative braking force to the flywheel via the magnetic powder clutch.

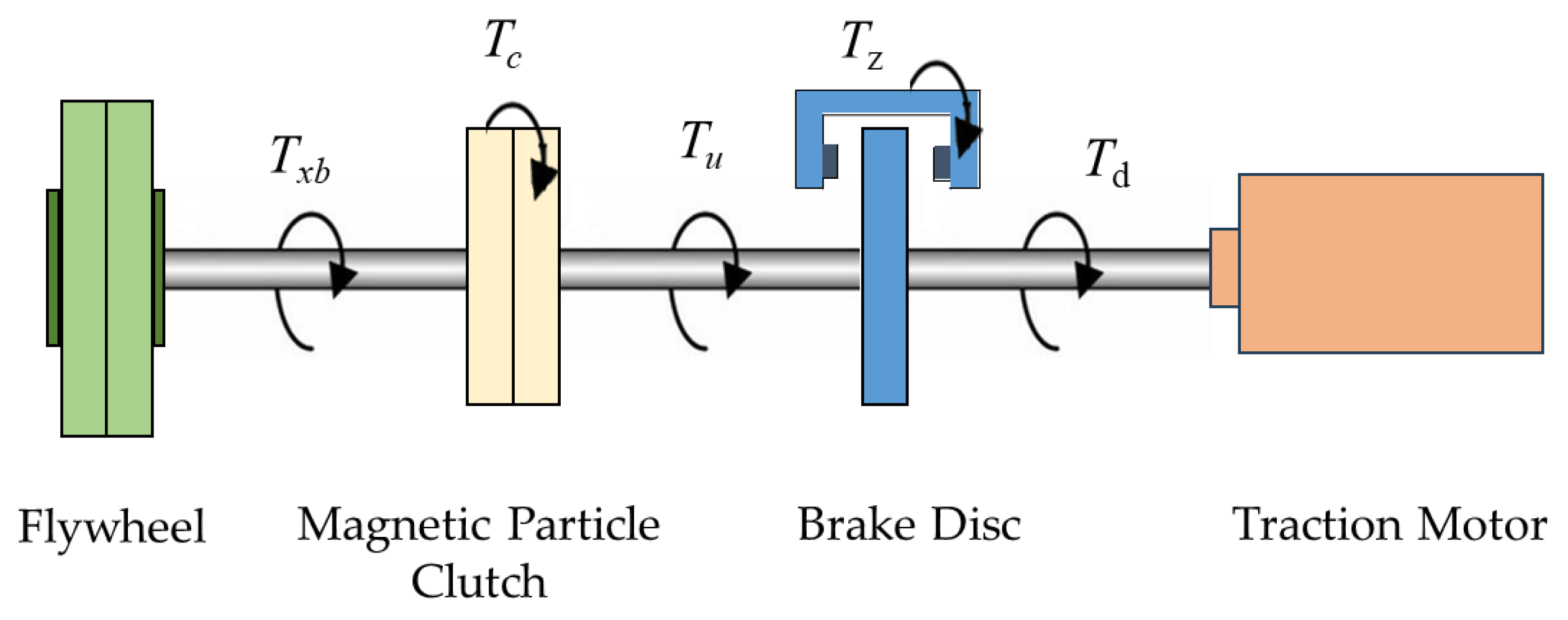

Figure 6 illustrates a schematic diagram of the torque transmission among the primary components during braking tests conducted on this experimental platform.

In

Figure 6,

represents the resultant braking torque (hereafter referred to as the equivalent braking torque), which is the sum of the brake torque

and the motor regenerative braking torque

, expressed as

. The torque transmitted by the magnetic powder clutch is denoted as

, while

corresponds to the actual braking torque exerted on the flywheel. During the experimental process, the equivalent braking torque

is transmitted to the flywheel through the magnetic powder clutch. When

is less than the maximum transmissible torque

of the magnetic powder clutch, the clutch operates in a rigidly connected state. Under this condition, the entire equivalent braking torque

is transferred to the flywheel, resulting in flywheel deceleration, i.e.,

. However, when

exceeds

, the wheel enters an anti-lock regulation state. In this scenario, the system dynamically adjusts the torque transmitted by the magnetic powder clutch based on the relationship between the longitudinal adhesion force and the slip ratio of the selected road surface, thereby simulating the dynamic variations in ground braking force.

During vehicle braking, the braking force exerted by the ground on the wheels can be expressed as:

where,

is the braking force exerted by the ground on the wheels,

is the total gravitational force of the vehicle,

is the longitudinal adhesion coefficient.

The magic formula tire model, proposed by Pacejka, is capable of accurately fitting experimental data for tires under various operating conditions, including longitudinal force, lateral force, aligning torque, overturning moment, and rolling resistance, among others [

36]. This study focuses on the longitudinal force between the tire and the road surface. The relevant expression of the magic formula is as follows:

where,

is the adhesion coefficient when the wheel is in pure rolling, typically set to 0 under general conditions, A, B, C and D are undetermined parameters, which are constants related to the road surface,

represents the slip ratio.

By adjusting these parameters, the formula can precisely simulate the adhesion coefficient and slip ratio curves for various road surfaces (

Figure 7). The parameters, fitted to experimental data, are given in

Table 2.

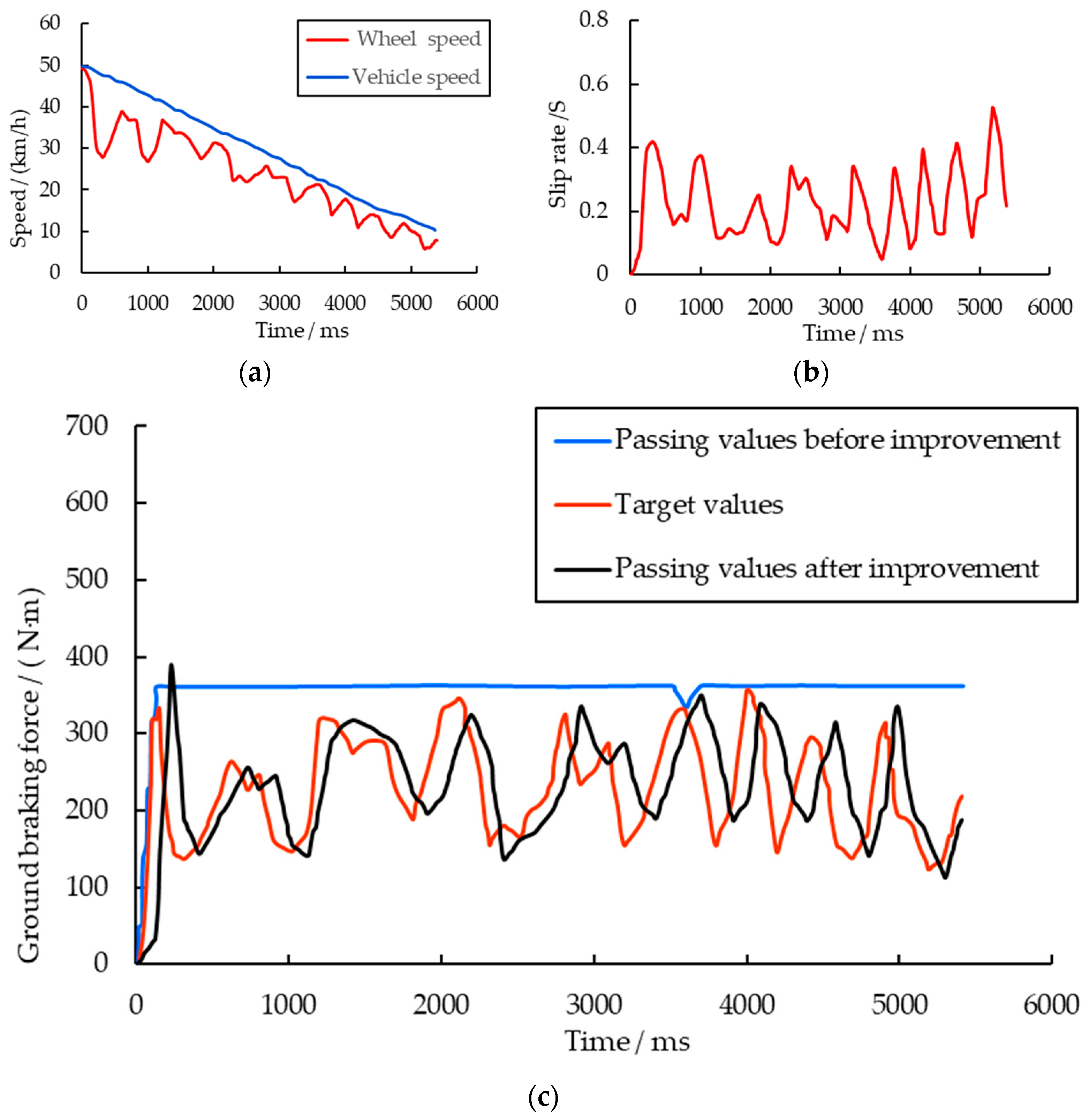

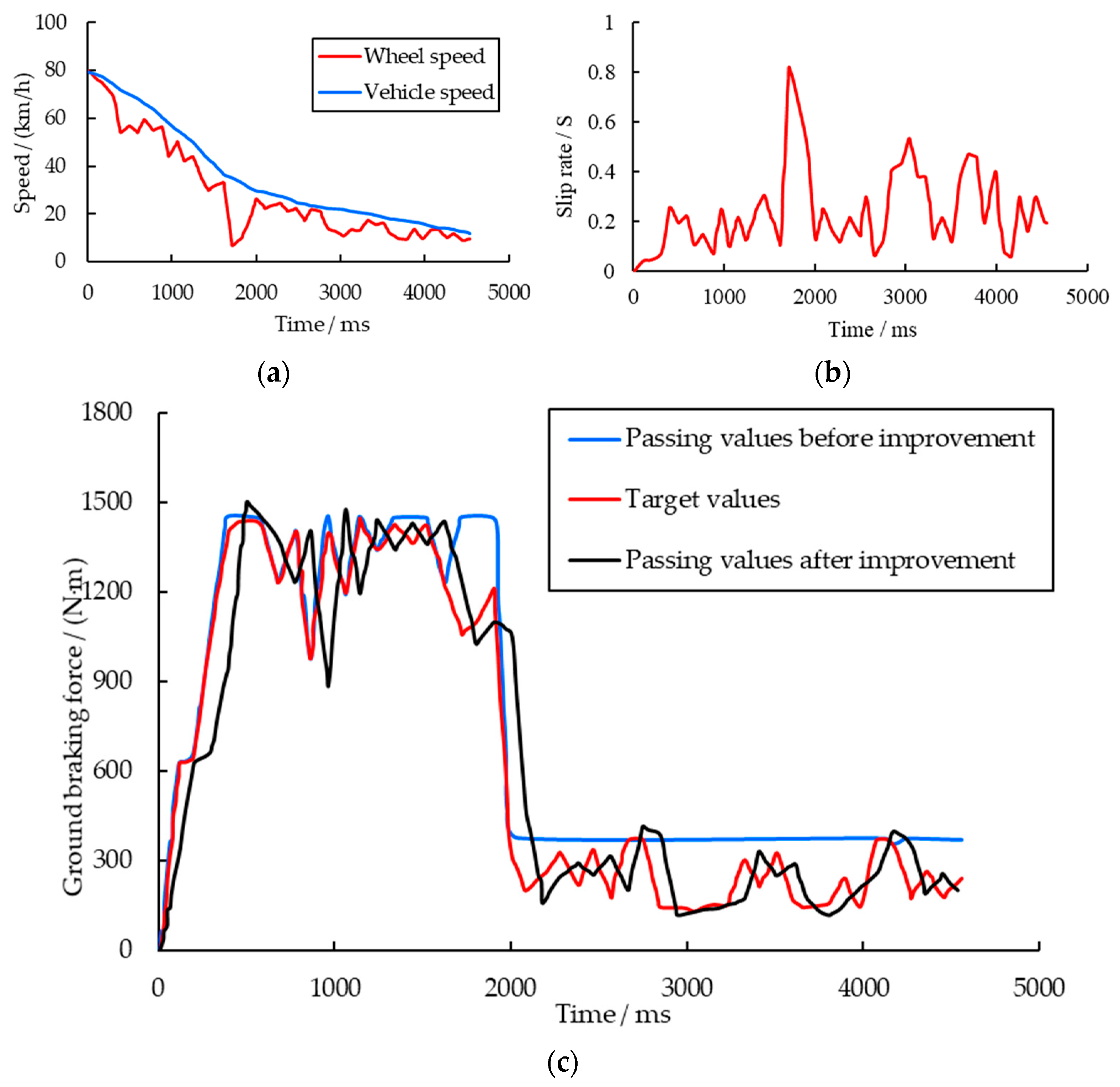

To simulate the changes in ground braking force with respect to the slip ratio during the braking process, the ground braking force simulation controller calculates the slip ratio based on the rotational speed signals of the flywheel and the brake disc. It then determines the longitudinal adhesion coefficient by referencing the selected road surface’s - curve and the magic formula. Based on the determined longitudinal adhesion coefficient, the system calculates the corresponding ground braking force and converts it into the target torque for the magnetic powder clutch.

The magnetic powder clutch computes the actual braking torque applied to the flywheel using signals from the flywheel torque sensor. The deviation between the measured braking torque and the target torque is used to calculate the required programmable power supply output. The ground braking force simulation controller adjusts the output current of the programmable power supply based on this value, thereby modifying the transmitted torque of the magnetic powder clutch. This process enables precise closed-loop tracking control of the target torque.

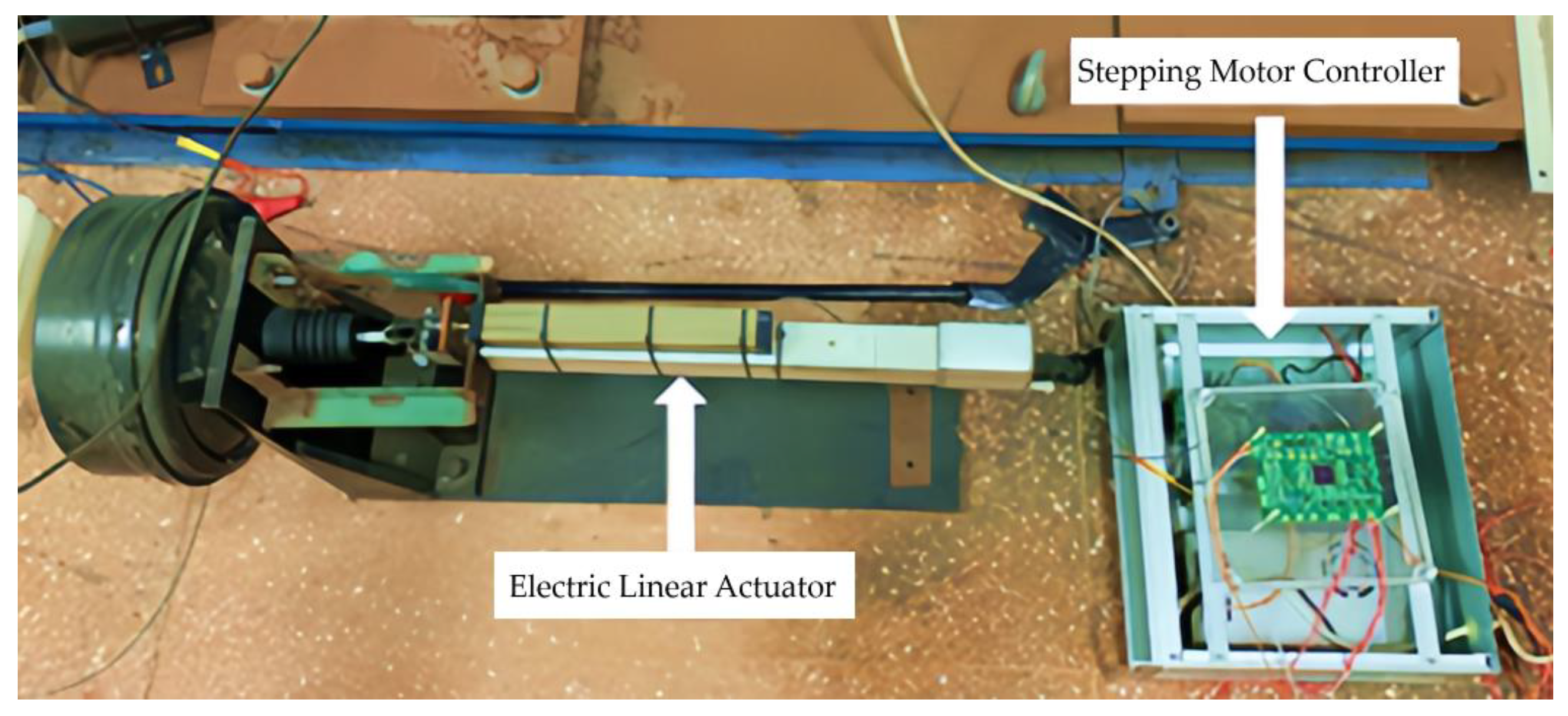

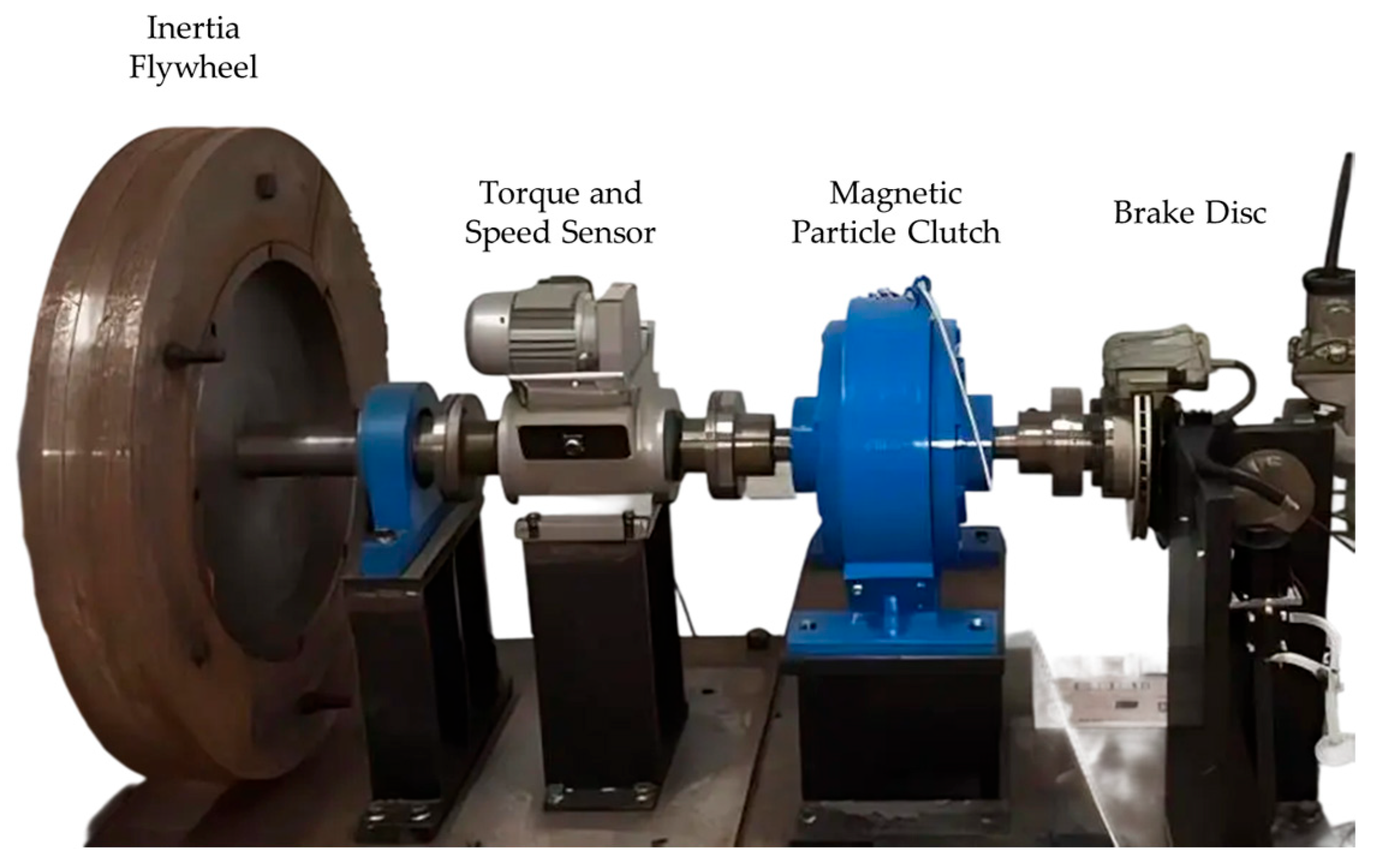

4.3. Design of the Magnetic Powder Clutch Controller

4.3.1. Parameters of the Magnetic Powder Clutch

The magnetic powder clutch is one of the most critical components of the ground braking force simulation system. Its primary function is to dynamically simulate the ground braking force by adjusting its transmitted torque in real time. The magnitude of the torque transmitted by the magnetic powder clutch can be controlled by regulating its excitation current [

37].

As depicted in

Figure 10, a CJ-40 type magnetic powder clutch (Nantong Aerospace Electromechanical Automation Co., Ltd., Nantong, China) was selected as the experimental platform. The parameters of this clutch are listed in

Table 3.

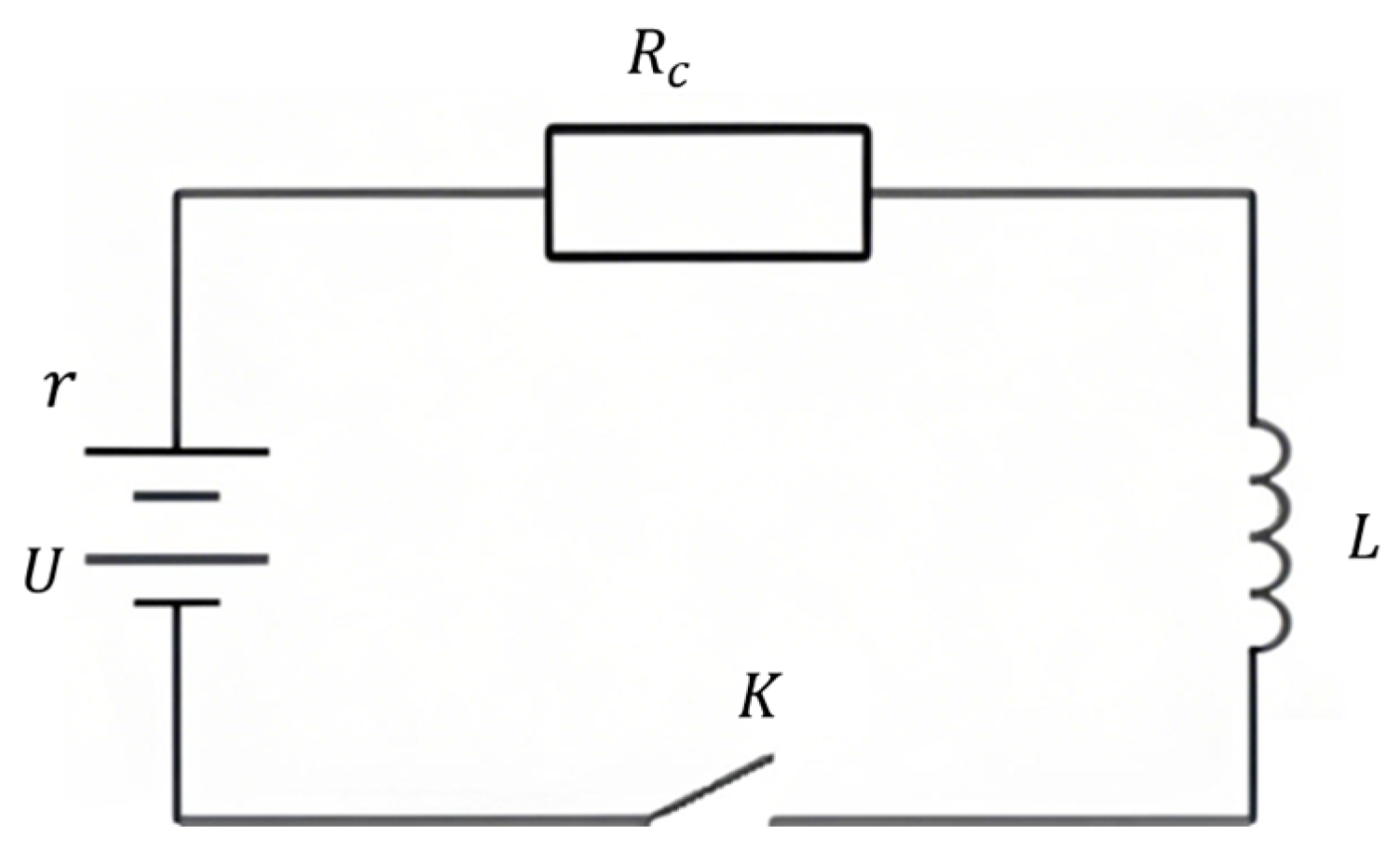

4.3.2. Mathematical Model Analysis of the Magnetic Powder Clutch

To facilitate quantitative calculations of the excitation current transient process in the magnetic powder clutch, certain simplifications are applied to its characteristics. These simplifications include neglecting the hysteresis effects of magnetic flux and magnetic particles on the circuit during the transition process, as well as variations in the inductance of the excitation coil. The excitation circuit of the magnetic powder clutch can be simplified as shown in

Figure 11 [

38].

When switch

K is closed, a current is generated in the circuit. The voltage balance equation for the circuit is as follows:

Solving Equation (13) yields the variation pattern of the current in the circuit as follows:

The current time constant , where L is the magnetic powder clutch coil inductance [H] and = , is the total excitation circuit resistance [Ω] (including excitation coil resistance , series resistance , and power supply internal resistance ), with steady-state current determined by excitation voltage U [V].

Building on the transient current analysis in Equation (14), which reveals the nonlinear hysteresis characteristics of the excitation circuit, we now examine the torque transmission behavior. The static torque-current relationship demonstrates dual-phase nonlinearity. To establish a tractable dynamic model while preserving essential physical characteristics, we implement the following simplifications:

Exclusion of no-load torque

Linearization of dead-zone effects

Hysteresis loop approximation

This leads to the piecewise linearized torque model:

The coefficient , which represents the torque-current relationship, is determined by the specific current-torque characteristic curve of the magnetic particle clutch. This parameter can be obtained through experimental calibration or manufacturer specifications, taking into account the operating conditions and material properties of the magnetic particles.

While the linear approximation (Equation (15)) provides computational simplicity, it is important to acknowledge three inherent nonlinear characteristics of magnetic powder clutches:

- (a)

Hysteresis effects in magnetization-demagnetization cycles (up to 8–12% torque variation observed in preliminary tests)

- (b)

Non-constant Km values across operating regions (typically 15–20% higher in weak excitation vs. saturation regions)

- (c)

Temperature-dependent time delay (experimental data shows ±7% variation within 20–80 °C range)

The governing equations can be derived by reorganizing Equations (13) and (15), yielding the following system:

The electromechanical dynamics of the magnetic particle clutch system are described by the following fundamental relationships:

Under zero initial conditions, the Laplace transform of the circuit equation yields:

Here, represents the electrical time constant governing the transient response of the excitation current.

Substituting

I(

S) into the torque equation

M(

S) =

I(

S), the initial transfer function is derived as:

where,

represents the overall system gain of the excitation coil circuit in the magnetic particle clutch, with units of Nm/V.

To account for the practical torque hysteresis caused by magnetic particle magnetization lag and mechanical shear delay, a pure time delay term

is introduced:

where,

represents the time delay constant of the magnetic particle clutch, characterizing the hysteresis effect between the excitation current and the output torque.

Tests were conducted on the response characteristics of the magnetic particle clutch on the test platform, with the parameters listed in

Table 4.

The first-order model with time delay (Equation (20)) captures dominant dynamics but has inherent limitations. Our experimental validation (see

Appendix A for detailed test conditions) showed that when the target (steady-state) output torque exceeds 30% of the rated torque, the step response prediction fidelity reaches 92.3%; this decreases to 85.7% when the target torque is below 15% rated torque due to nonlinear effects. These variations are mitigated by the fuzzy adaptive controller’s compensation capability.

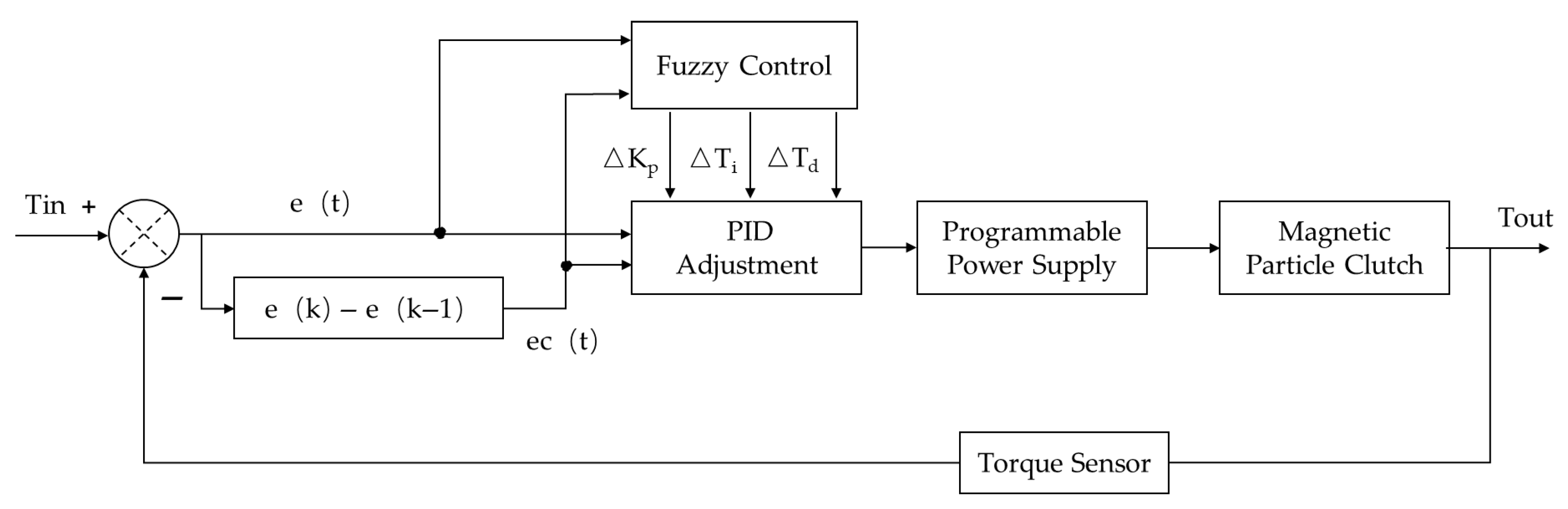

4.3.3. The Design of a Fuzzy Adaptive PID Controller

As shown in Equation (20), the magnetic particle clutch exhibits first-order inertial behavior with hysteresis, making it inherently a Type 0 system. Due to these characteristics, conventional PID control fails to provide satisfactory performance in terms of response speed and stability. To achieve precise torque transmission control—ensuring rapid response, stable operation, and compliance with experimental requirements—a dedicated controller must be designed.

This development is especially critical for the electric vehicle ABS and RBS integrated control test platform, where accurate simulation of ground braking forces is essential for reliable system evaluation. To address these challenges, a fuzzy adaptive PID controller is implemented using a two-dimensional control structure (

Figure 12). This architecture features:

Input Variables:

: torque error

where, = reference torque, = measured transmitted torque.

: rate of change of torque error

Output Variables:

: incremental adjustment of proportional gain;

: incremental adjustment of integral time constant;

: incremental adjustment of derivative time constant.

The online tuning mechanism continuously adjusts the PID parameters based on the fuzzy logic rules, which map the input variables () to the output increments (). This adaptive approach enables the controller to maintain optimal performance across various operating conditions.

The scaling factors

and

, which normalize the input variables to the fuzzy controller, are defined by Equations (21) and (22).

where

and

denote the scaling factors for error and error rate respectively,

and

represent their quantization levels, while

and

indicate the maximum expected values of error and error rate.

The output variables, which are initially in the fuzzy domain, require conversion to the basic domain of control quantities through appropriate scaling factors.

are defined as the scaling factors of

,

,

, respectively. These scaling factors are calculated by Equations (23)–(25).

where,

indicate the maximum expected values of the output variables,

represent the number of quantization levels for the output variables, respectively.

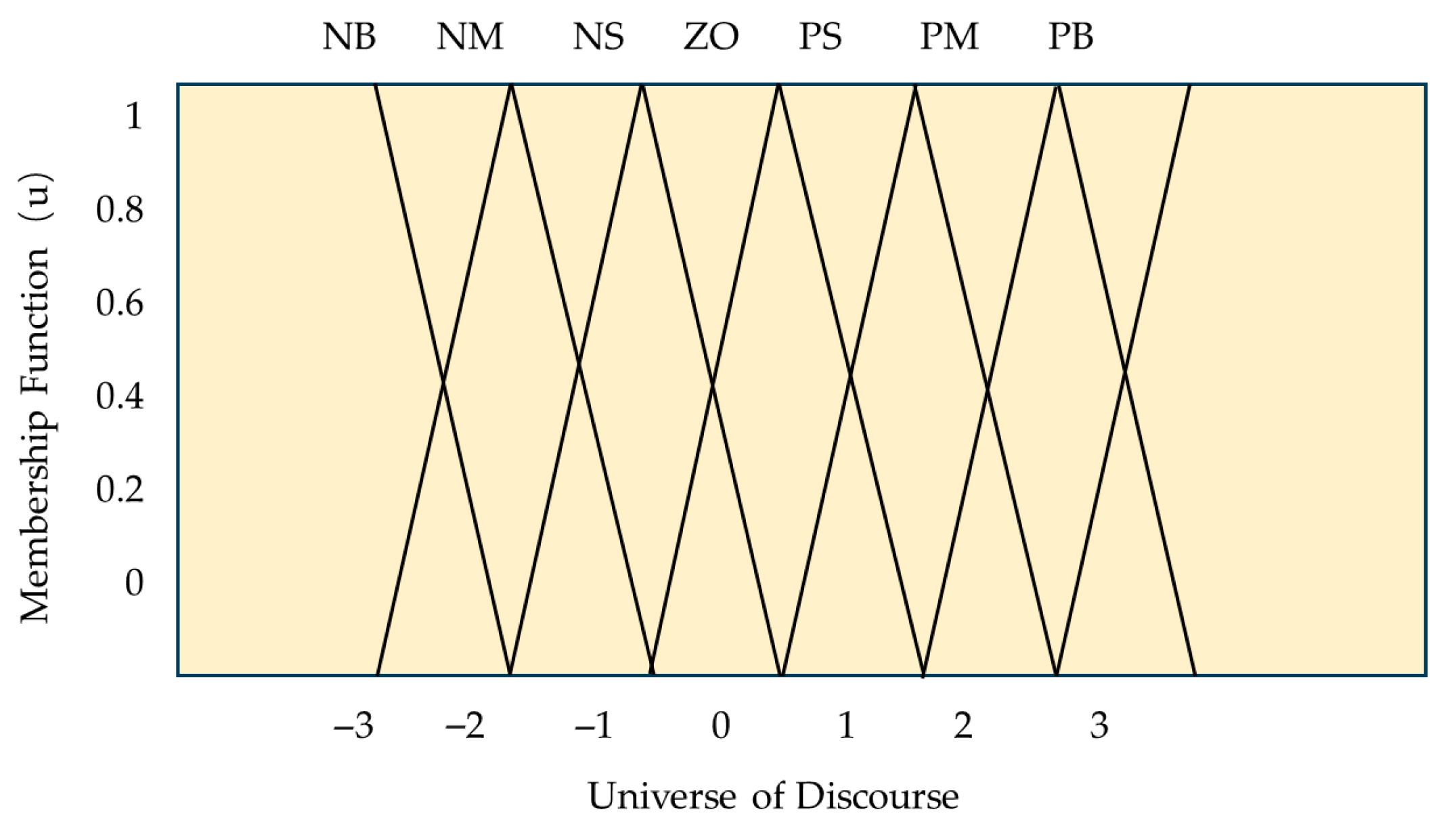

After determining the input and output variables, it is essential to define the fuzzy subsets for all variables based on the research object and control requirements. The number of linguistic values used to describe fuzzy variables should be chosen according to practical needs. Generally, a greater number of linguistic values can improve control performance. However, an excessive number may increase the complexity of the algorithm, potentially degrading control effectiveness. In this study, considering the control requirements of the ground braking force simulation system, seven linguistic values are selected to describe the variables [

39].

The fuzzy set domain for both input and output variables is defined as:

. The value of

n can be determined based on empirical knowledge or experimental conditions, and it may vary for different variables. In this study, considering the specific control requirements of the system, a combination of half-trapezoidal, triangular, and half-trapezoidal functions is selected as the membership functions for the input and output variables of the fuzzy control section, as illustrated in

Figure 13.

The digital implementation of the PID algorithm requires discretization of the continuous-time controller due to the sampled nature of feedback data. The discrete-time PID control law is given by Equation (26).

The continuous-time PID controller requires discretization for digital implementation. Using backward difference approximation with sampling period

, the discrete control law becomes:

where

denotes the control output at the nth sampling instant,

is the proportional gain,

, and

represent the integral and derivative time constants, respectively, and

is the sampling period. The term

corresponds to the error at the

sampling instant, while

refers to the error at the previous

sampling instant.

The fuzzy-adaptive mechanism dynamically adjusts these parameters through:

where,

indicate the initial PID parameters (proportional gain, integral time constant, and derivative time constant, respectively),

represent incremental adjustments provided by the fuzzy controller.

The fuzzy rule base specifically incorporates compensation mechanisms for:

Weak-excitation region: 25% heavier weighting on derivative action

Saturation region: 15% reduced proportional gain.

Hysteresis compensation: Additional 50 ms lead time in ∆Td adjustment

The fuzzy control rule tables for

,

and

are established separately and presented in

Table 5,

Table 6 and

Table 7, respectively.

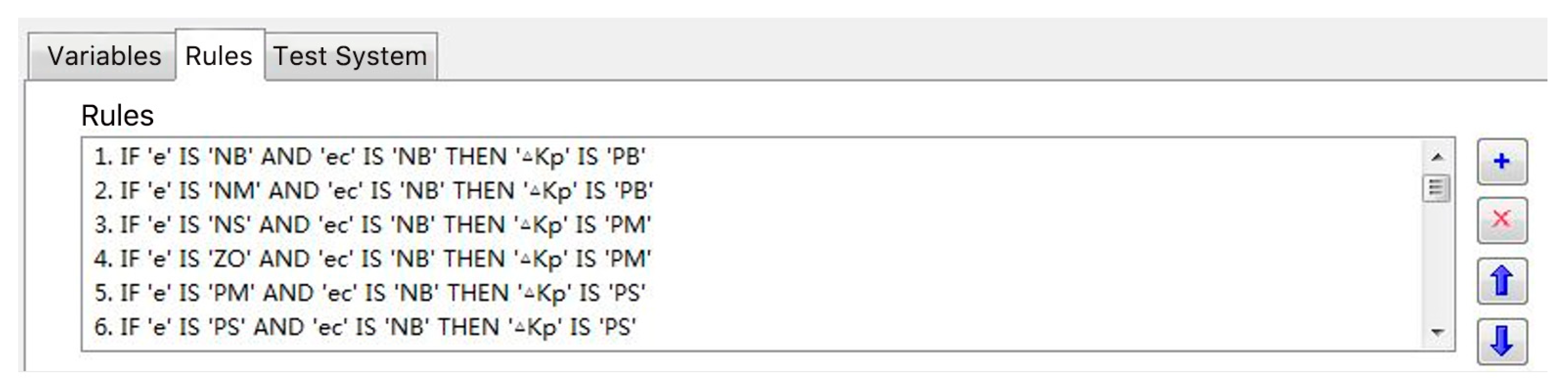

All 49 fuzzy control rules mentioned above have been implemented in the computer program, with the corresponding interface displayed in

Figure 14.

Considering the requirements of braking force simulation control, this study adopts the Mamdani fuzzy inference method. The established fuzzy control system comprises 49 rules, with each fuzzy control relation denoted as

. These fuzzy relations are connected by the logical “OR” operator. Consequently, the overall fuzzy relation of the control rules can be expressed as:

Let

be the linguistic deviation variable and EC be the deviation change rate as the inputs of the fuzzy controller. Based on the overall fuzzy relation

derived from Equation (28), the output control variable can be obtained as:

where,

represents the transpose of the fuzzy relation matrix.

The defuzzification process employs the weighted average method. With seven elements in the output domain, each denoted as

, and the membership degree of the output fuzzy set as

, the final decision value using the weighted average method is given by:

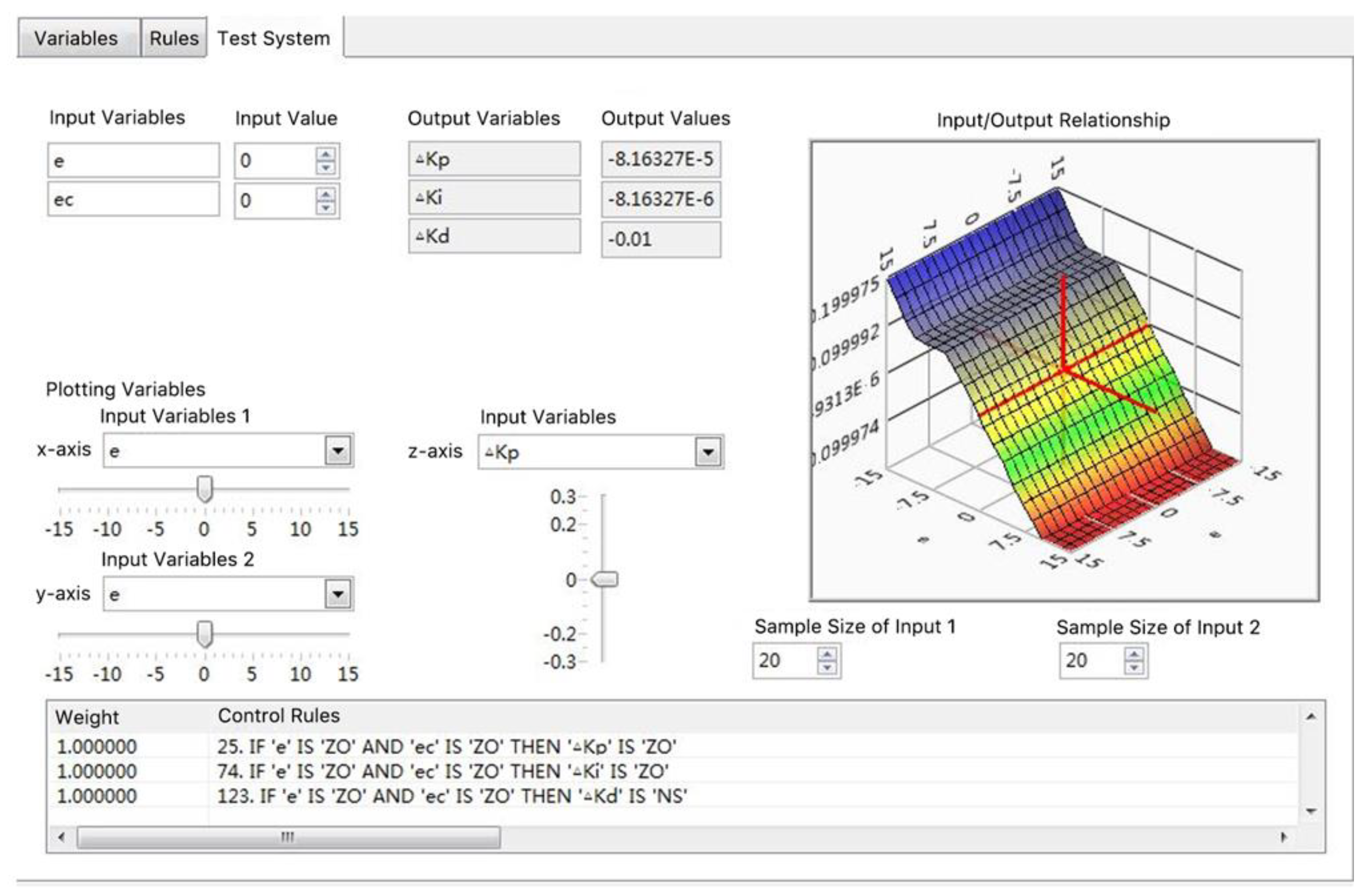

Upon completing these procedures, the designed fuzzy adaptive PID controller can be observed in the fuzzy system designer. This includes the input-output correspondence under fuzzy rules and the surface plots representing the relationship between output and input variables of the fuzzy controller. The observation interface is illustrated in

Figure 15.

The key parameters of the fuzzy adaptive PID controller were determined through theoretical analysis and optimization tuning according to the system control requirements, as presented in

Table 8.

Through systematic parameter space exploration and gradient-based optimization, the globally optimal PID parameters were identified as:

Proportional gain: ;

Integral time constant: ;

Derivative time constant: .

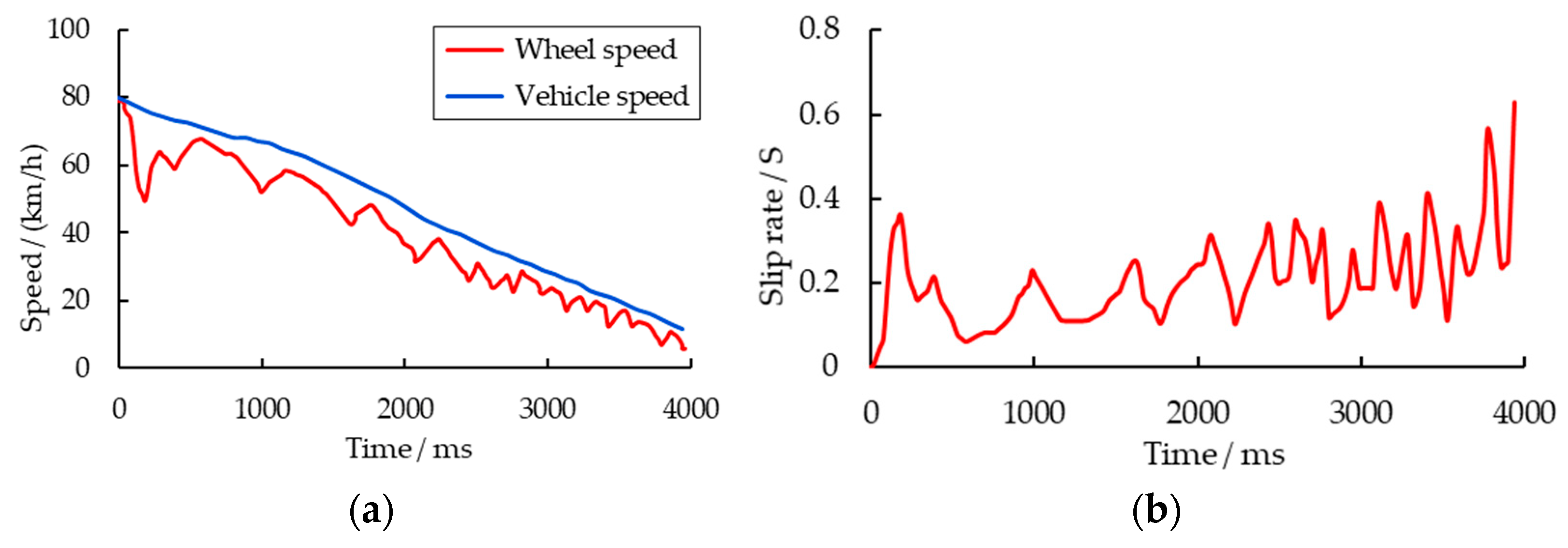

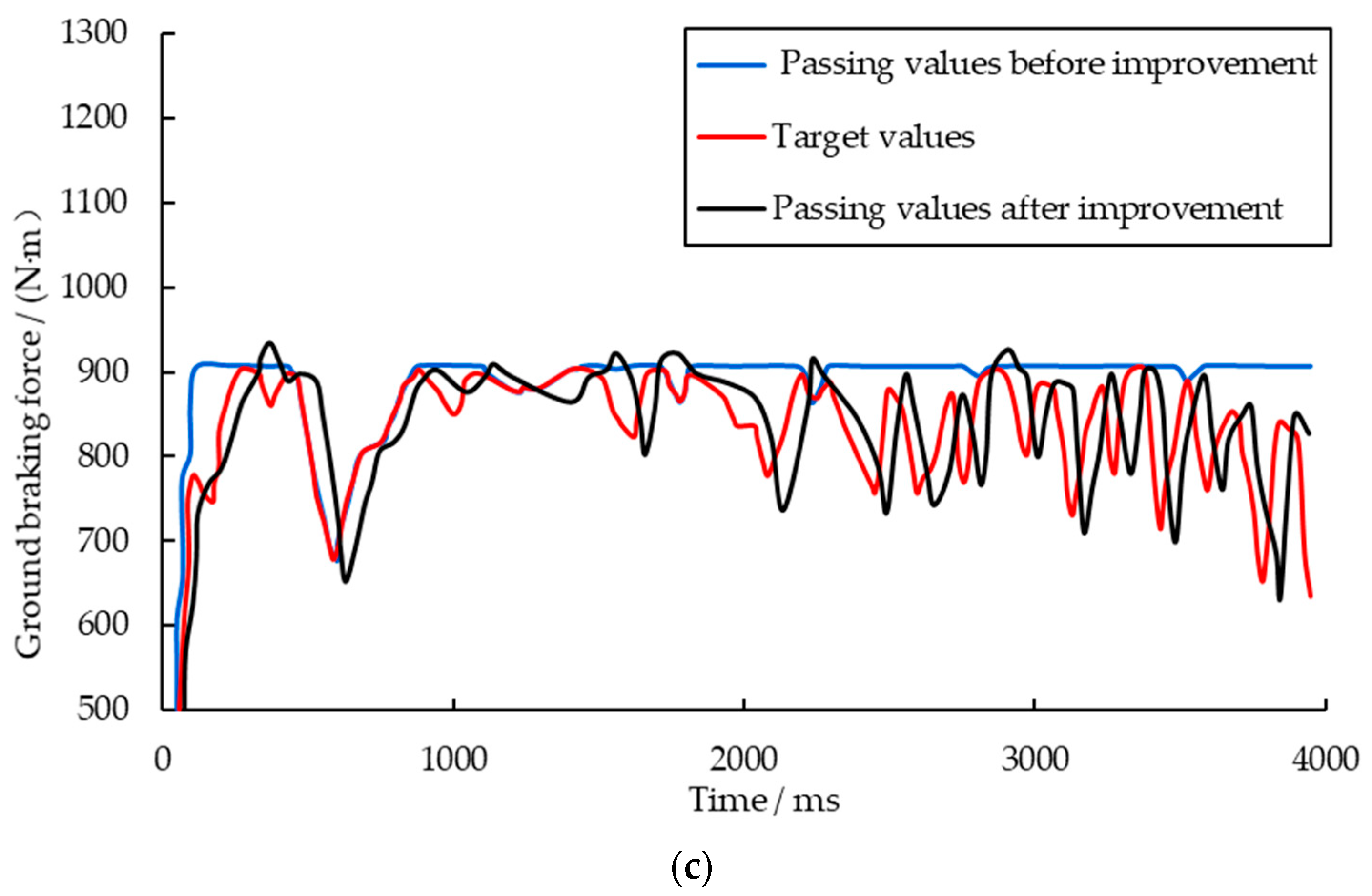

The designed magnetic particle controller underwent parameter tuning and optimization, with experimental validation confirming the feasibility of the proposed control algorithm (

Figure 16). Quantitative comparisons with a conventional PID controller reveal that the fuzzy adaptive PID controller achieves superior performance: (1) overshoot is reduced from 18.7% to 8.5%, (2) rise time is shortened from 88.7

to 40.9

, and (3) settling time decreases from 687.1 ms to 458.1 ms. (The control parameters for the conventional PID controller are given in time-constant form as:

,

;

).