Application Layer Software Design of Vehicle Comfort Braking Based on Brake-by-Wire System

Abstract

1. Introduction

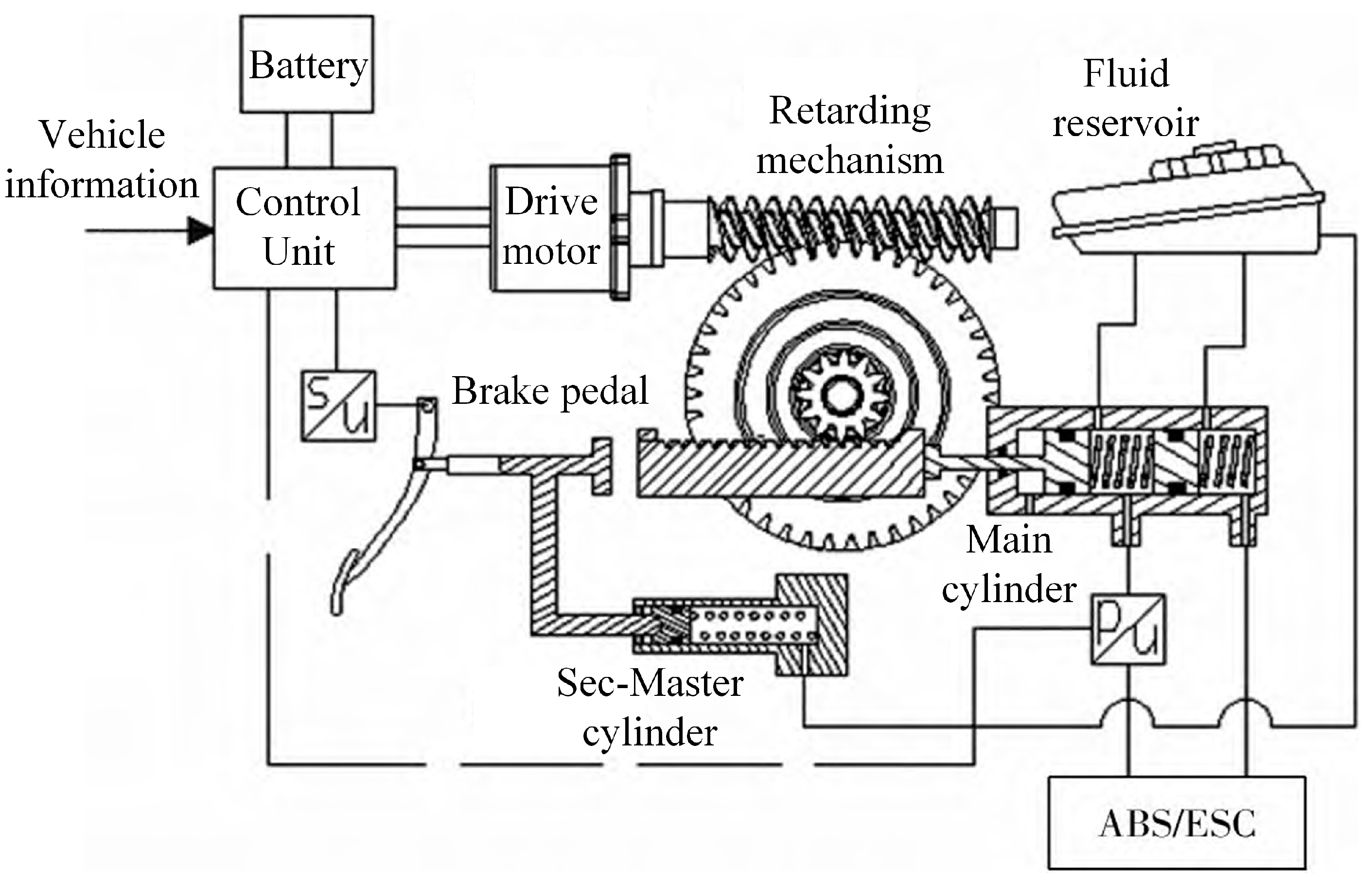

2. Basic Principle of Brake-by-Wire System

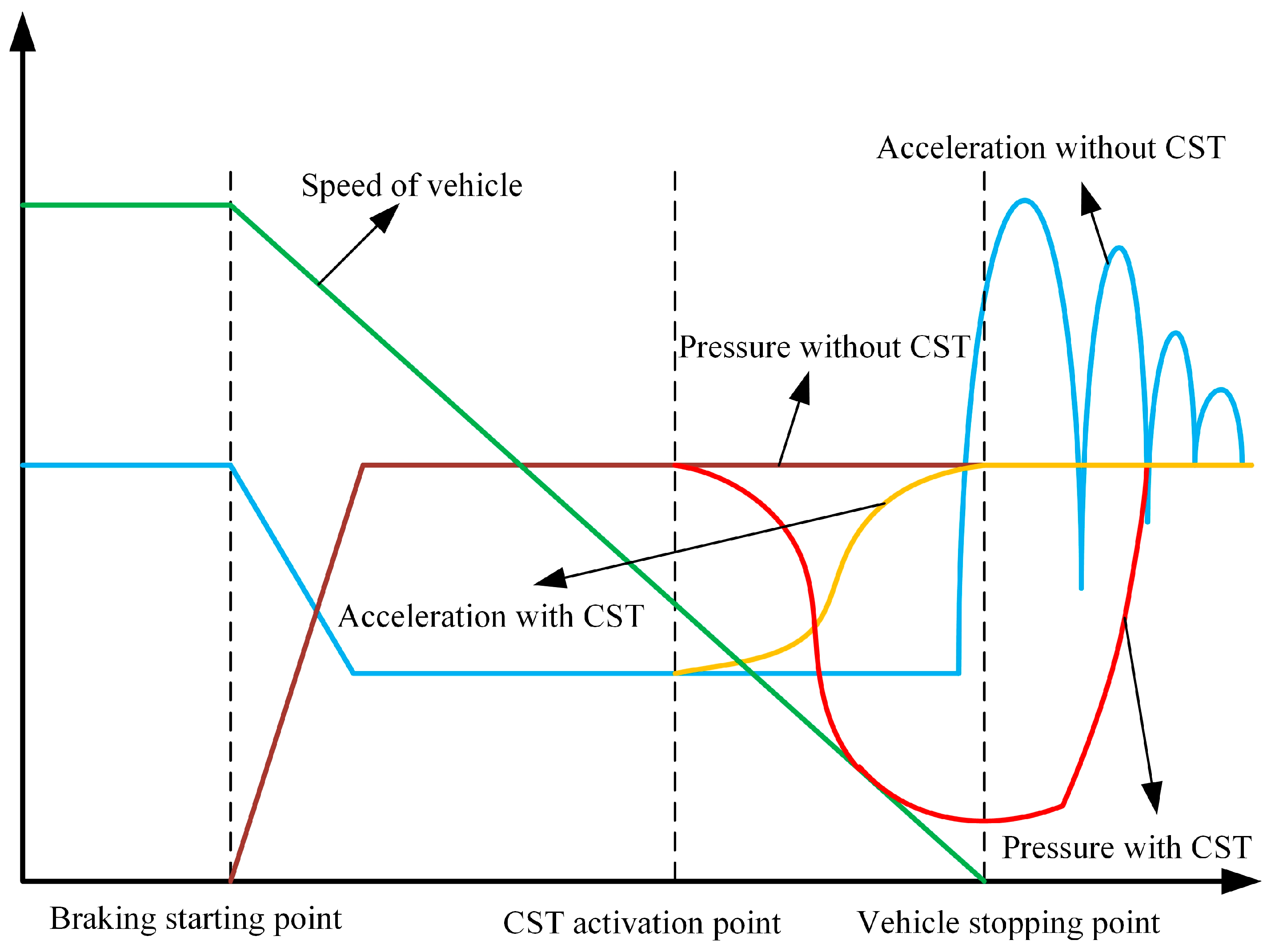

3. Basic Principle of Comfort Stop Technology

4. CST Software Module Design

4.1. The Design of Function Enable Judgment Module

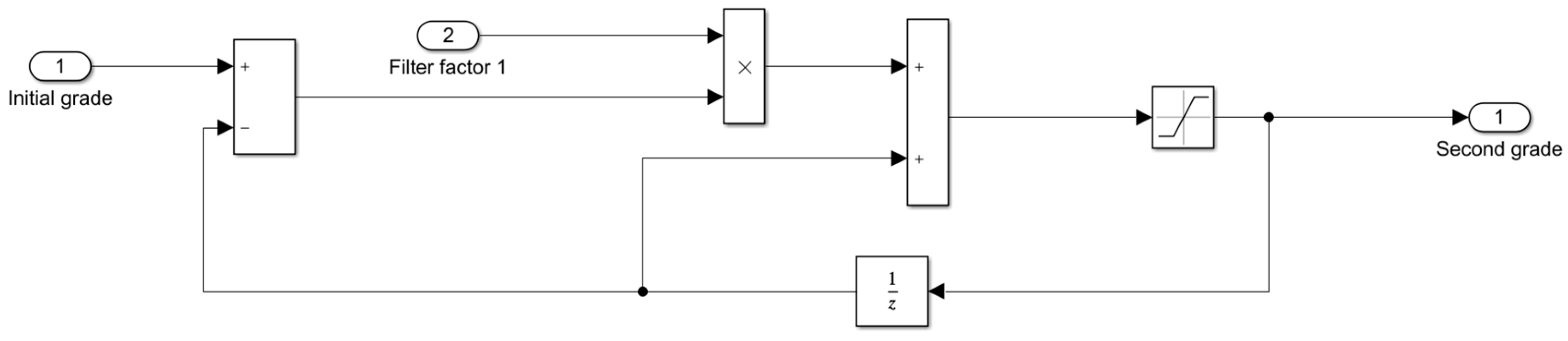

4.1.1. Signal Processing Module

4.1.2. Signal Processing Module

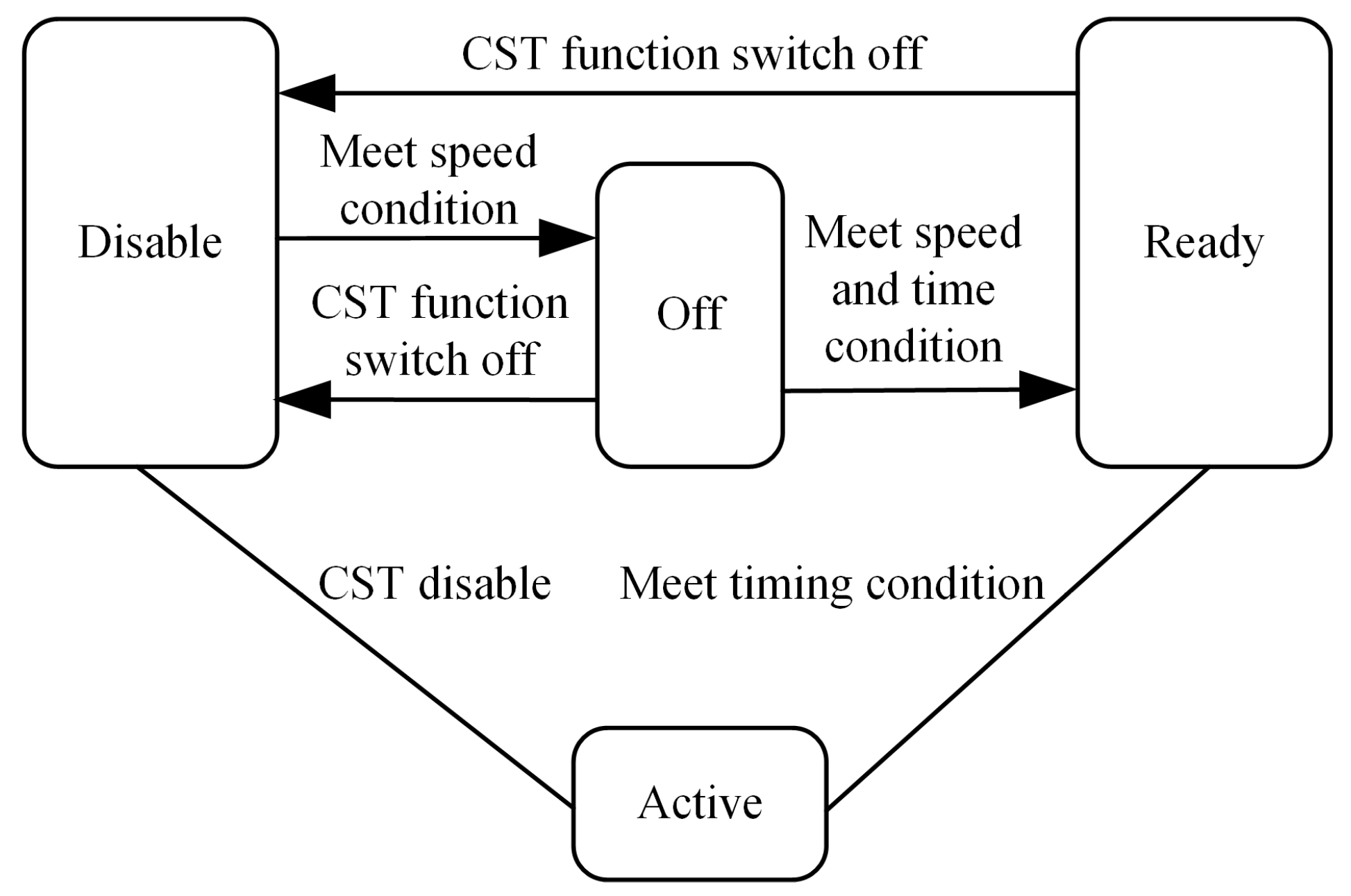

4.2. The Design of CST Function Status Judgment Module

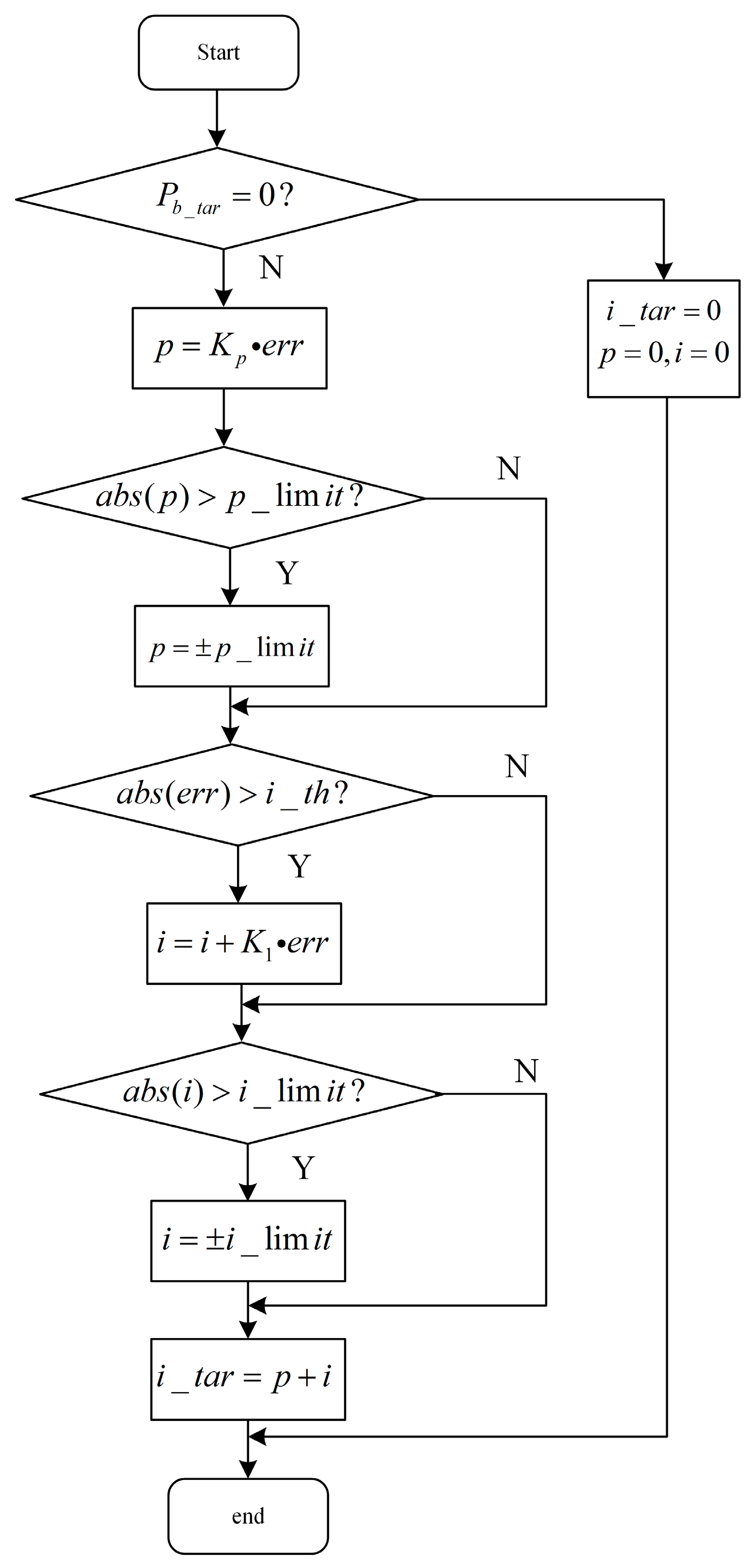

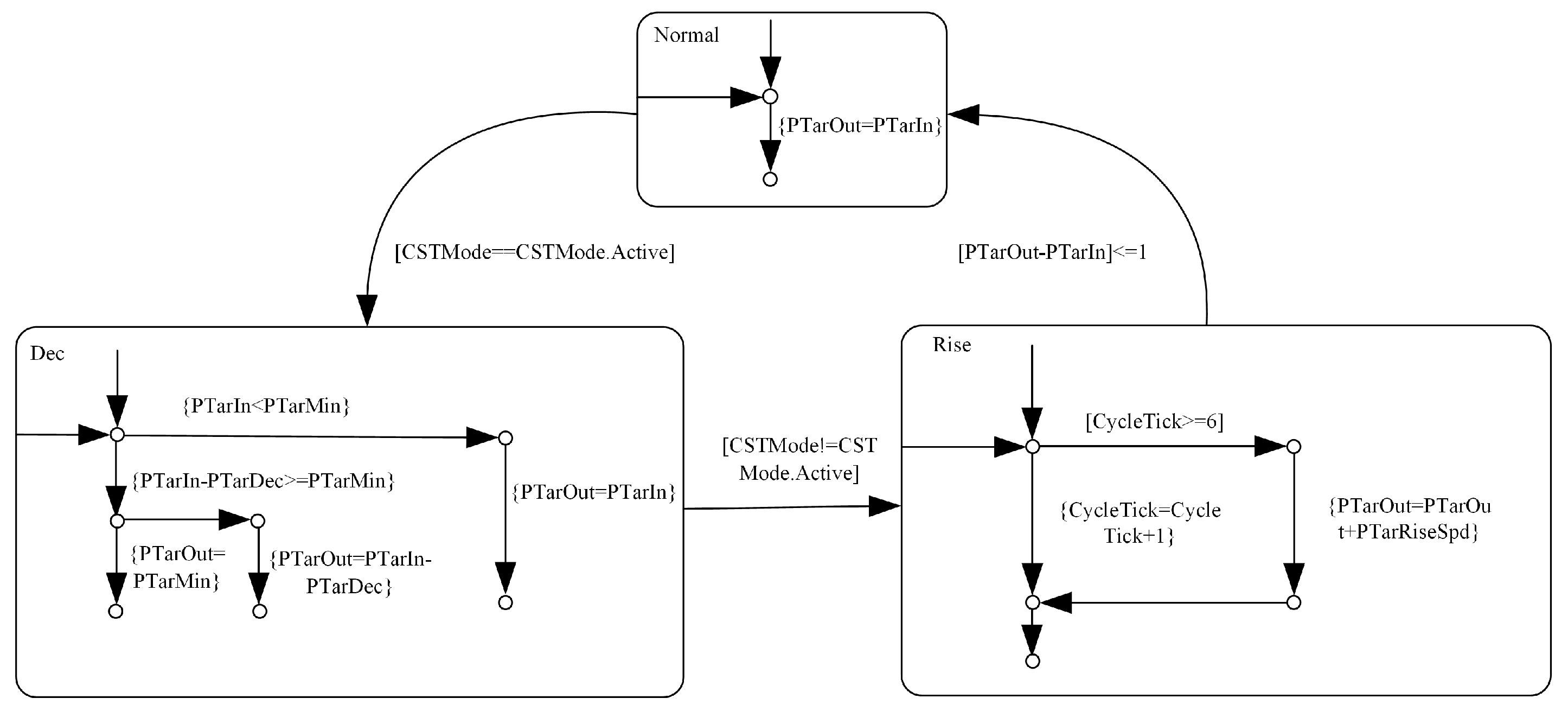

4.3. The Design of Target Liquid Pressure Control Module

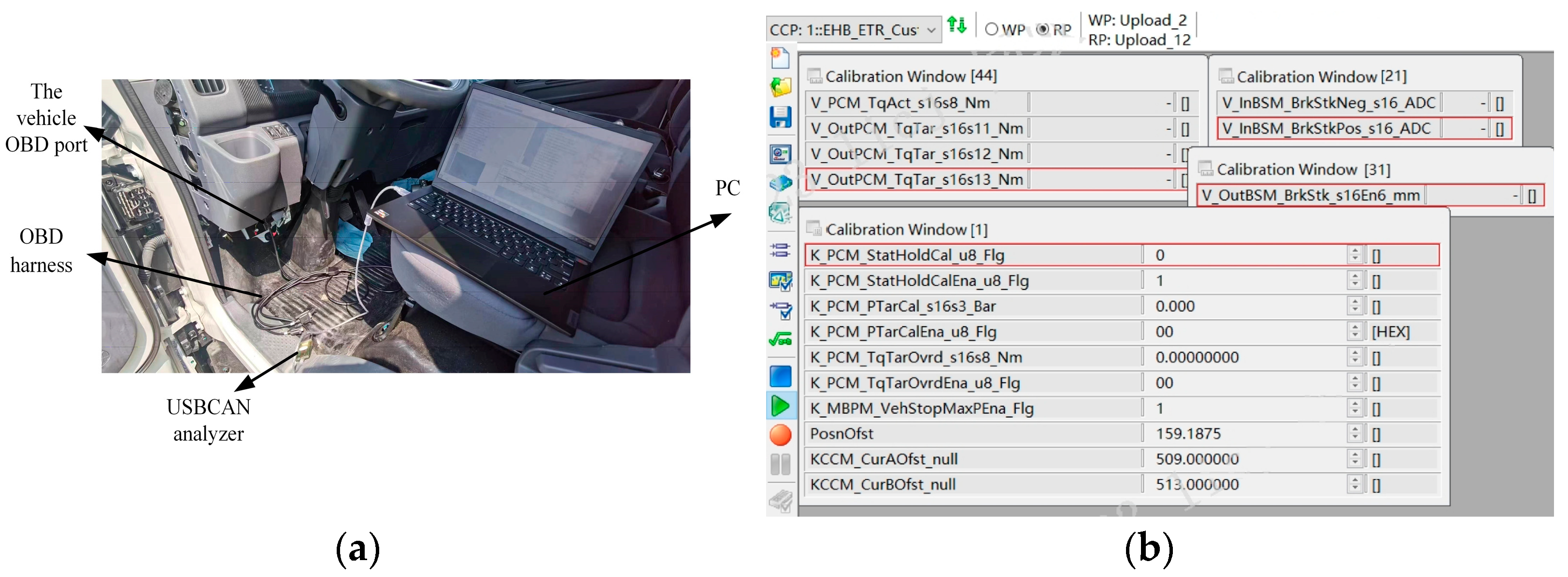

5. Real Vehicle Verification

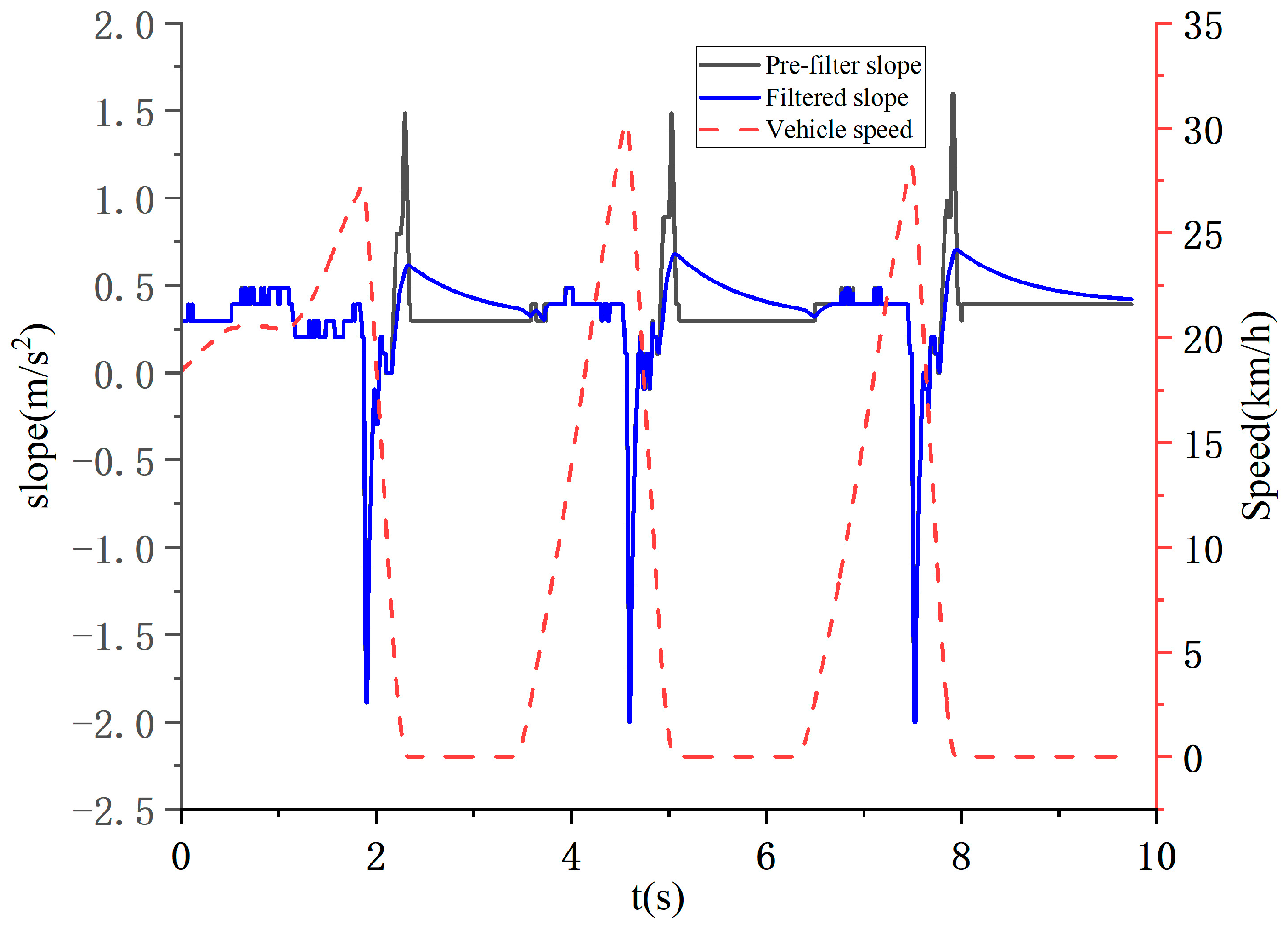

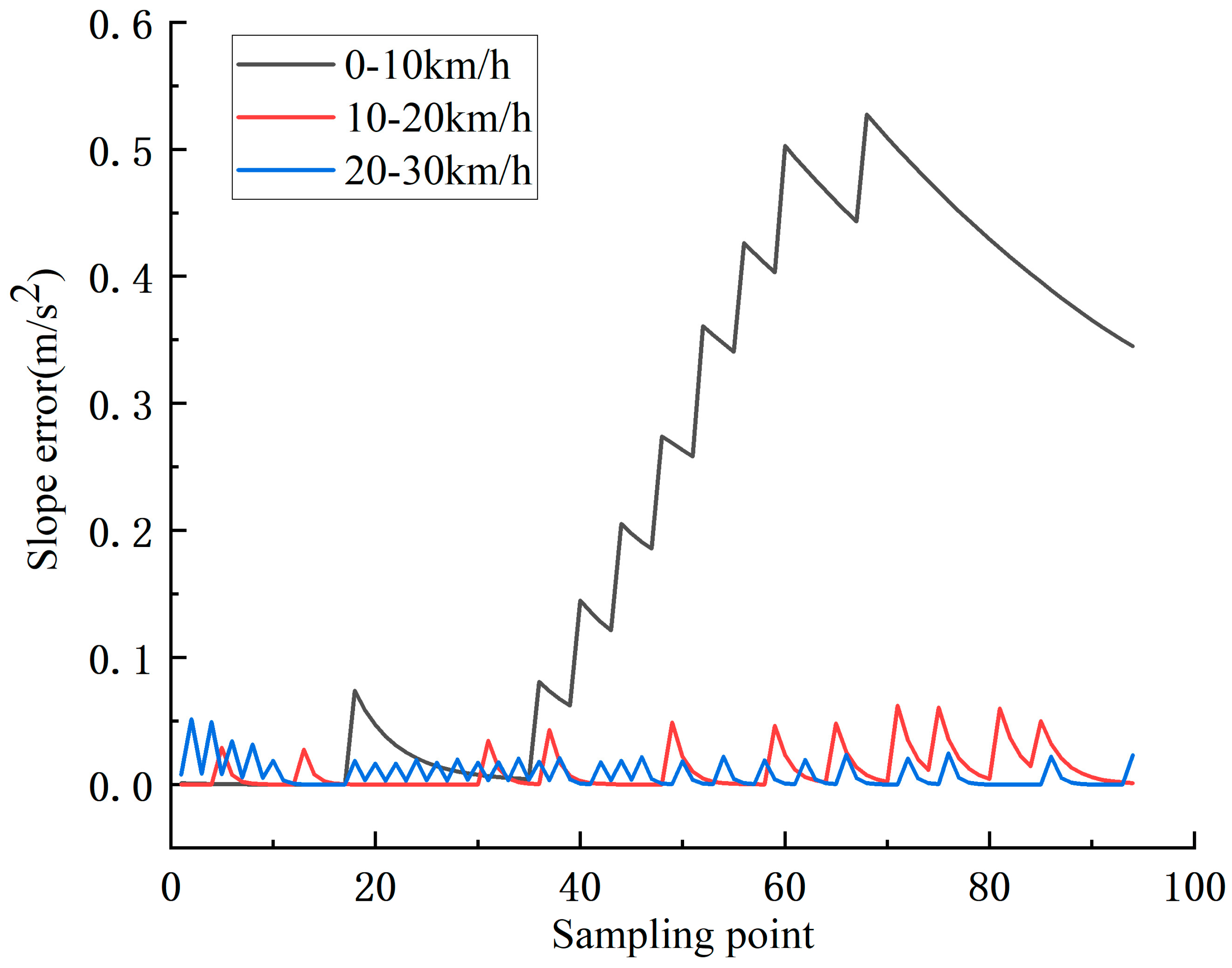

5.1. Real Vehicle Test of Slope Filtering

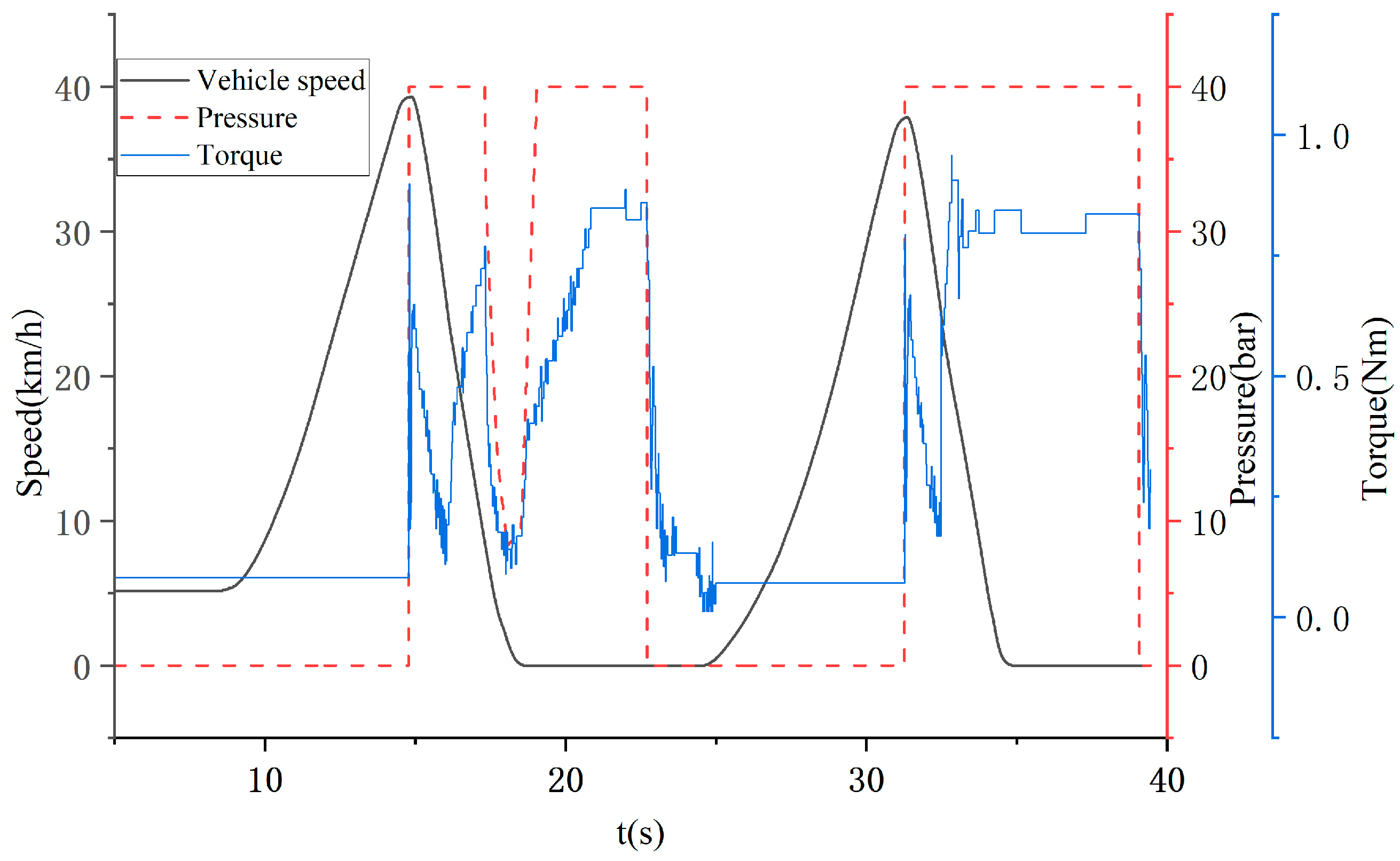

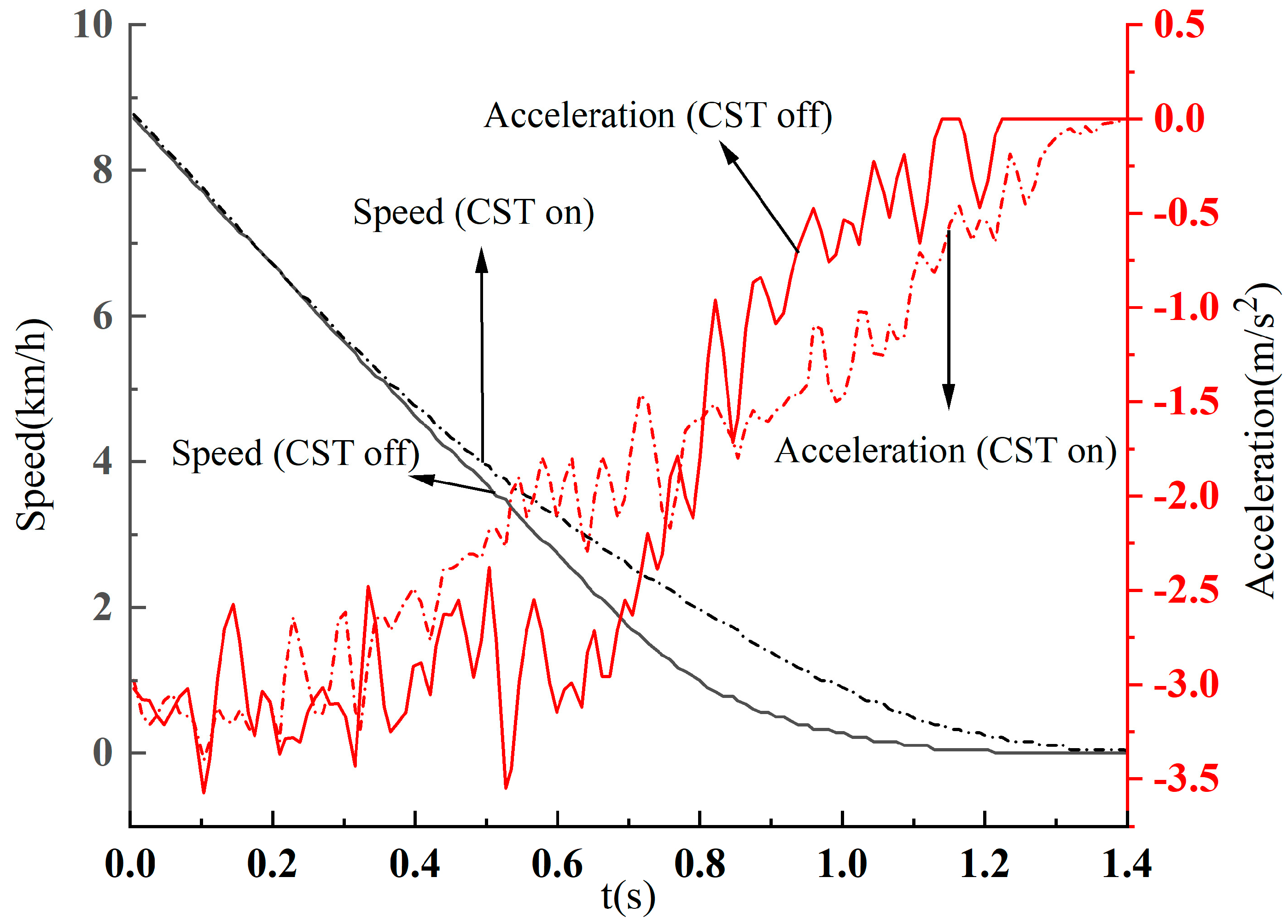

5.2. Motor Torque Response

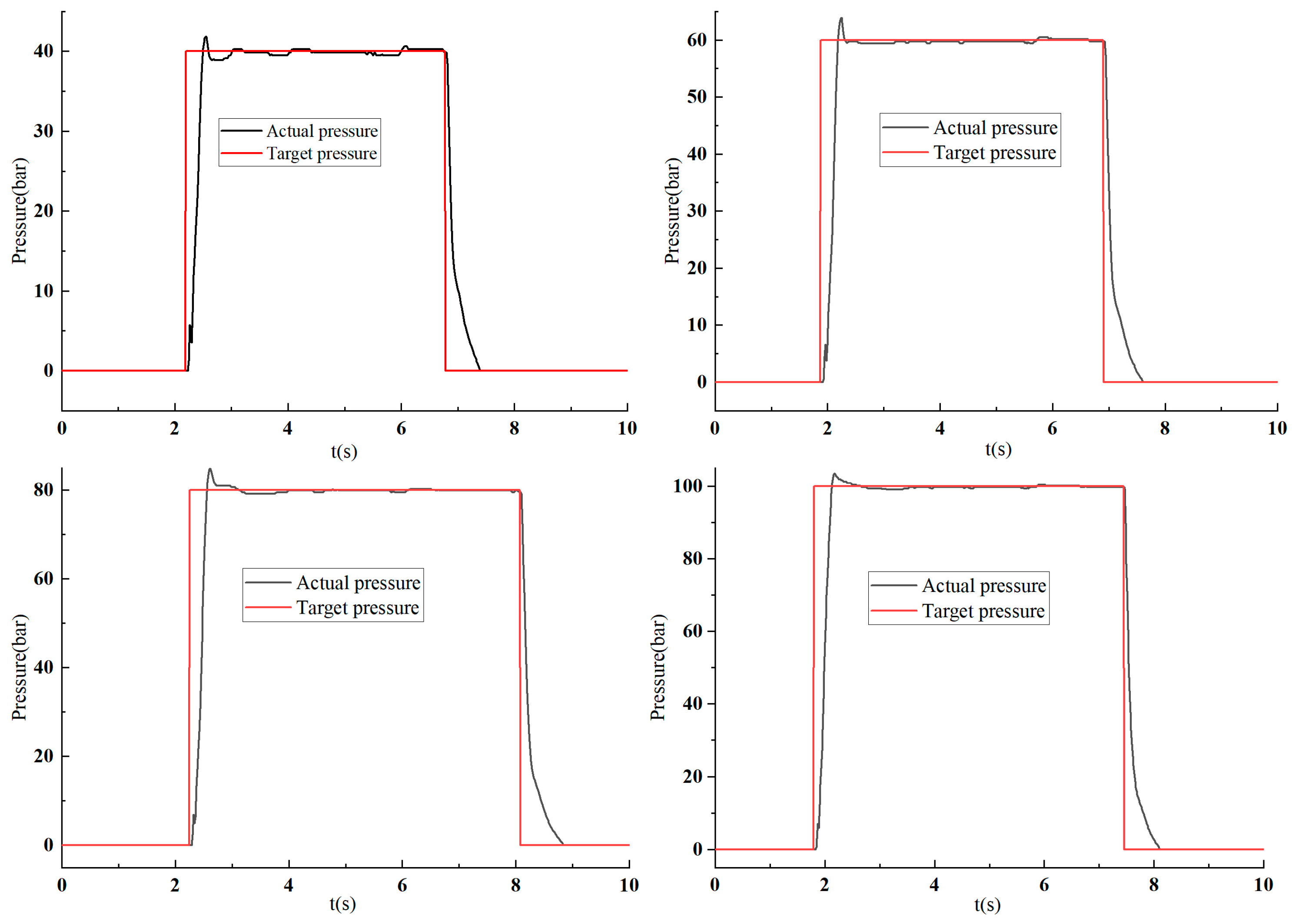

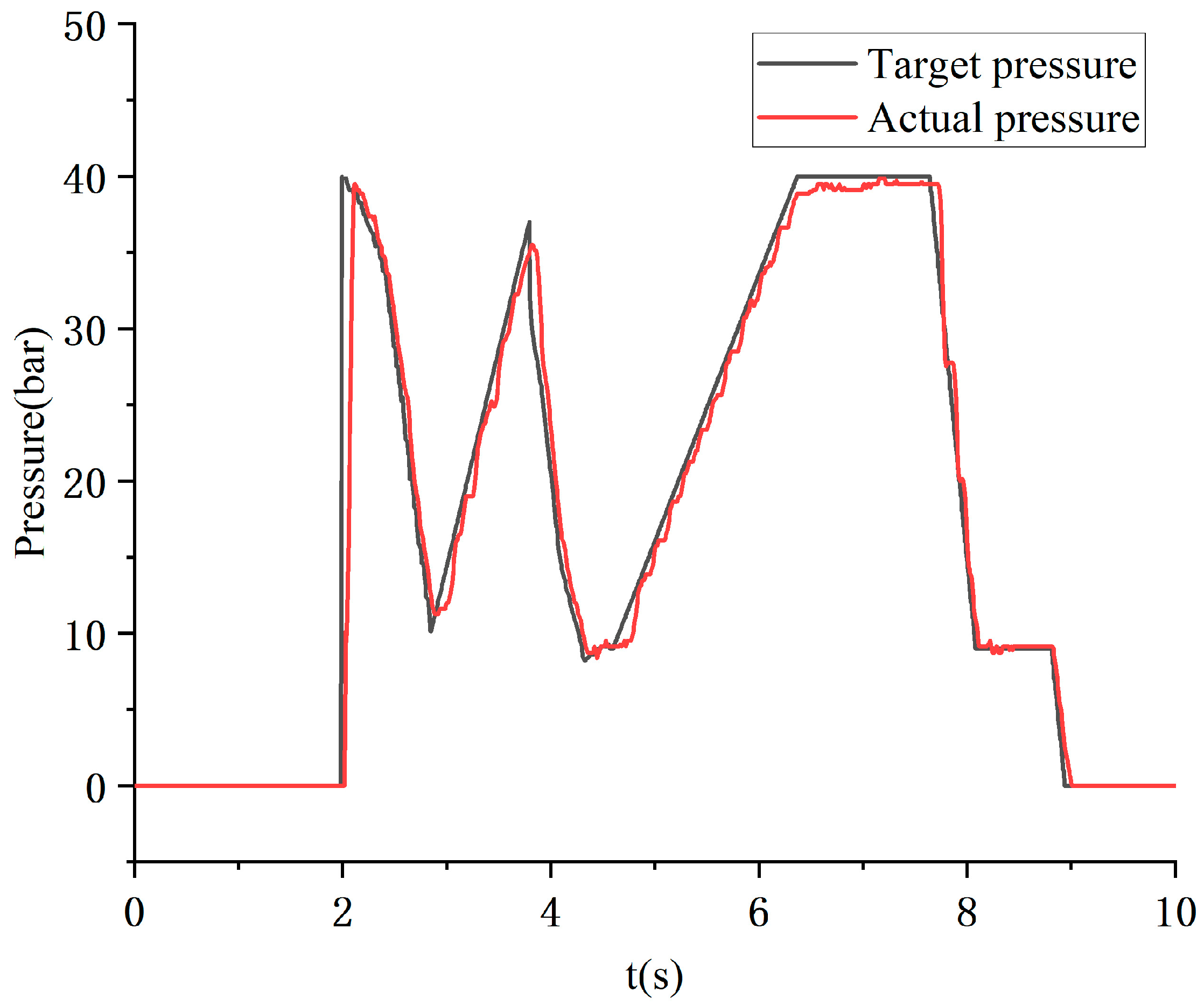

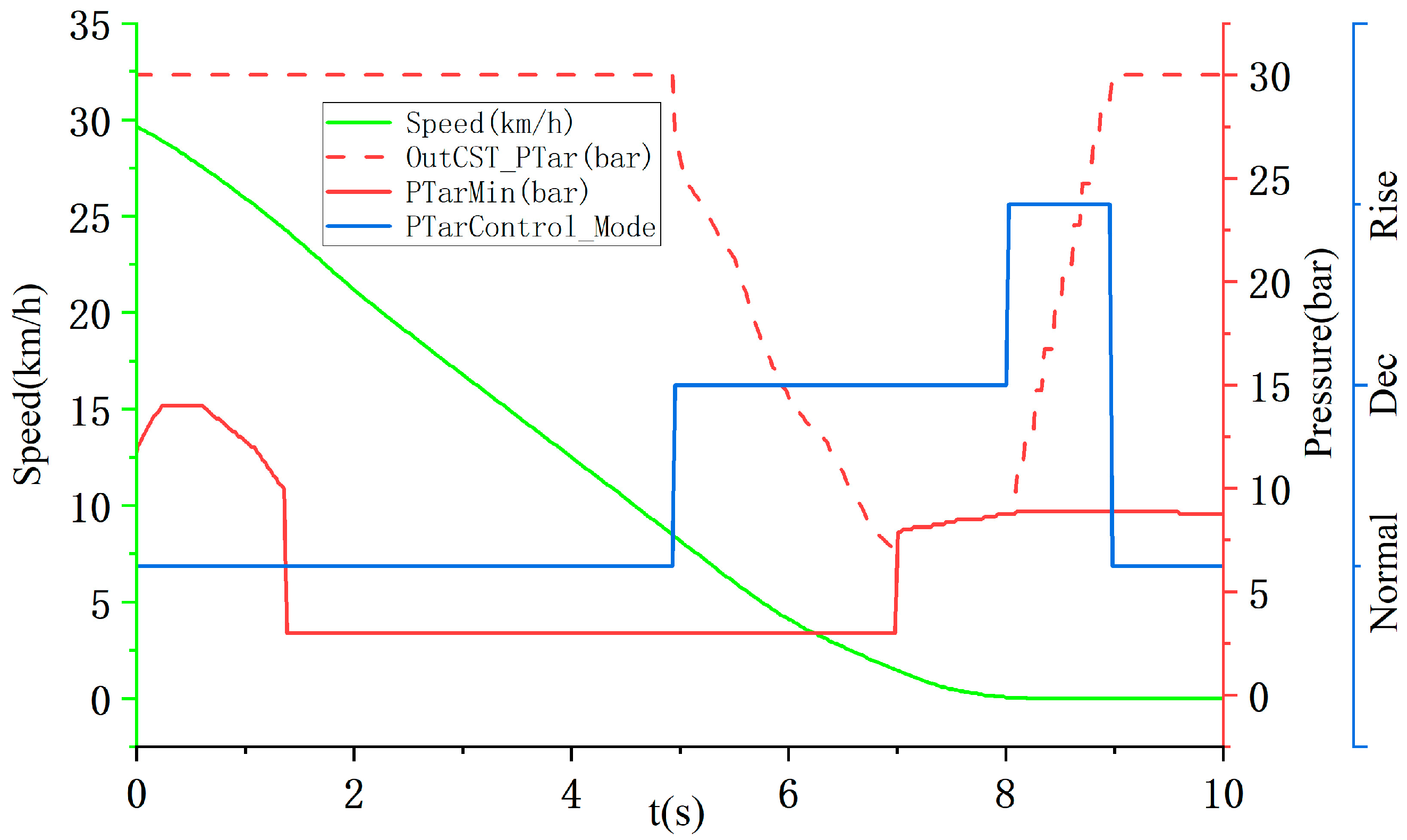

5.3. Brake Fluid Pressure Control

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Zhang, C. Electronic Stability Control for Improving Stability for an Eight in-Wheel Motor-Independent Drive Electric Vehicle. Shock. Vib. 2019, 2019, 8585670. [Google Scholar] [CrossRef]

- Li, Y.; Deng, H.; Xu, X.; Wang, W. Modelling and testing of in-wheel motor drive intelligent electric vehicles based on co-simulation with Carsim/Simulink. IET Intell. Transp. Syst. 2019, 13, 115–123. [Google Scholar] [CrossRef]

- Hu, C.; Pan, G.; Kong, L.; Yu, J. Research of Brake by Wire System. J. Phys. Conf. Ser. 2023, 2479, 012051. [Google Scholar] [CrossRef]

- Li, D.; Tan, C.; Ge, W.; Cui, J.; Gu, C.; Chi, X. Review of Brake-by-Wire System and Control Technology. Actuators 2022, 11, 80. [Google Scholar] [CrossRef]

- Xiang, W.; Richardson, P.C.; Zhao, C.; Mohammad, S. Automobile Brake-by-Wire Control System Design and Analysis. IEEE Trans. Veh. Technol. 2008, 57, 138–145. [Google Scholar] [CrossRef]

- Meng, B.; Yang, F.; Liu, J.; Wang, Y. A Survey of Brake-by-Wire System for Intelligent Connected Electric Vehicles. IEEE Access 2020, 8, 225424–225436. [Google Scholar] [CrossRef]

- Ji, F.; Zhou, X.; Zhu, W. Pedal simulator and braking feel evaluation in brake by wire system. J. Beijing Univ. Aeronaut. Astronaut. 2015, 41, 989–994. [Google Scholar]

- Durali, L.; Khajepour, A.; Jeon, S. Design and optimization of a cam-actuated electrohydraulic brake system. Proc. Inst. Mech. Eng. J. Automob. Eng. 2018, 232, 909–920. [Google Scholar] [CrossRef]

- Ma, B.; Lin, M.; Chen, Y.; Wang, L.X. Investigation of energy efficiency for electro-hydraulic composite braking system which is based on the regenerated energy. Adv. Mech. Eng. 2016, 8, 1687814016666449. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, B.W.; Gang, L. Pressure Estimation and Pressure Control of Hydraulic Control Unit in Electric-Wheel Vehicle. Math. Probl. Eng. 2020, 2020, 6576297. [Google Scholar]

- Seo, M.; Yoo, C.; Park, S.S.; Nam, K. Development of Wheel Pressure Control Algorithm for Electronic Stability Control (ESC) System of Commercial Trucks. Sensors 2018, 18, 2317. [Google Scholar] [CrossRef] [PubMed]

- Bao, H.; Li, G.; Du, S.; Liu, Y.; Yumei, L. Research on the Influence of Commercial Vehicle Electronic Control Pneumatic Braking Pressure Change Rate on Braking Ride Comfort. Integr. Ferroelectr. 2021, 217, 265–278. [Google Scholar] [CrossRef]

- Kosaki, S.; Ejiri, A.; Oya, M. Development of driver braking control model based on ride comfort index. Artif. Life Robot. 2021, 26, 347–353. [Google Scholar] [CrossRef]

- Zhaohui, W.; Yanfei, L.; Gang, P. A Smart Car Control Model for Brake Comfort Based on Car Following. IEEE Trans. Intell. Transp. Syst. 2009, 10, 42–46. [Google Scholar] [CrossRef]

- Jin, L.; Yu, Y.; Fu, Y. Study on the ride comfort of vehicles driven by in-wheel motors. Adv. Mech. Eng. 2016, 8, 1687814016633622. [Google Scholar] [CrossRef]

- Lingying, Z.; Min, Y.; Xinxin, X. Intelligent optimization of EV comfort based on a cooperative braking system. Proc. Inst. Mech. Eng. 2021, 235, 2904–2916. [Google Scholar]

- Zhang, J.; Sun, W.; Liu, Z.; Zeng, M. Comfort braking control for brake-by-wire vehicles. Mech. Syst. Signal Process. 2019, 133, 106255. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, C.; Yang, L.; Qin, Y.; Huang, X.; Hu, B. Transient fault tolerant control for vehicle brake-by-wire systems. Reliab. Eng. Syst. Saf. 2016, 149, 148–163. [Google Scholar] [CrossRef]

- Gong, X.; Ge, W.; Yan, J.; Zhang, Y.; Gongye, X. Review on the Development, Control Method and Application Prospect of Brake-by-Wire Actuator. Actuators 2020, 9, 15. [Google Scholar] [CrossRef]

- Shuai, C.; Xilong, Z.; Jizhong, W. Sliding Mode Control of Vehicle Equipped with Brake-by-Wire System considering Braking Comfort. Shock. Vib. 2020, 2020, 5602917. [Google Scholar]

- Liu, X.; Song, J.; Yu, L.; Lu, Z.; Wang, J.; Abi, L. Study on ride comfort in post-braking phase based on brake-by-wire system. Proc. Inst. Mech. Eng. J. Automob. Eng. 2023, 237, 381–392. [Google Scholar] [CrossRef]

- Ribeiro, D.; Bragança, C.; Costa, C.; Jorge, P.; Silva, R.; Arêde, A.; Calçada, R. Calibration of the numerical model of a freight railway vehicle based on experimental modal parameters. Structures 2022, 38, 108–122. [Google Scholar] [CrossRef]

- Wu, W.; Kurachi, R.; Zeng, G.; Matsubara, Y.; Takada, H.; Li, R.; Li, K. IDH-CAN: A Hardware-Based ID Hopping CAN Mechanism With Enhanced Security for Automotive Real-Time Applications. IEEE Access 2018, 6, 54607–54623. [Google Scholar] [CrossRef]

- Chinchul, C.; Wootaik, L. Extended Digital Programmable Low-Pass Filter for Direct Noise Filtering of Three-Phase Variables in Low-Cost AC Drives. Energies 2022, 15, 2096. [Google Scholar]

- Han, W.; Xiong, L.; Yu, Z. Braking pressure control in electro-hydraulic brake system based on pressure estimation with nonlinearities and uncertainties. Mech. Syst. Signal Process. 2019, 131, 703–727. [Google Scholar] [CrossRef]

- Biaofei, S.; Lu, X.; Zhuoping, Y. Pressure Estimation of the Electro-Hydraulic Brake System Based on Signal Fusion. Actuators 2021, 10, 240. [Google Scholar]

- Peng, P.; Wang, H.; Pi, D.; Wang, E.; Yin, G. Two-layer mass-adaptive hill start assist control method for commercial vehicles. Proc. Inst. Mech. Eng. J. Automob. Eng. 2020, 234, 438–448. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, R.; Tang, B.; Guo, H. A Fuzzy-PID Scheme for Low Speed Control of a Vehicle While Going on a Downhill Road. Energies 2020, 13, 2795. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, C.; Li, M.; Zhao, J.; Xu, Y. Application of anti integral saturation cascade PID control algorithm in superheated steam temperature control. J. Phys. Conf. Ser. 2021, 2087, 012038. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, W.; Li, W. Braking sense consistency strategy of electro-hydraulic composite braking system. Mech. Syst. Signal Process. 2018, 109, 196–219. [Google Scholar] [CrossRef]

- Chen, Q.; Shao, H.; Liu, Y.; Xiao, Y.; Wang, N.; Shu, Q. Hydraulic-pressure-following control of an electronic hydraulic brake system based on a fuzzy proportional and integral controller. Eng. Appl. Comput. Fluid Mech. 2020, 14, 1228–1236. [Google Scholar] [CrossRef]

| Parameter Name | Numerical Value | Parameter Name | Numerical Value |

|---|---|---|---|

| G (vehicle quality) | 1015 kg | Total motor torque | 120 Nm |

| Wheelbase | 2160 mm | R (tire radius) | 0.275 m |

| Front wheelbase | 1450 mm | Centroid height | 0.56 m |

| Rear wheelbase | 1430 mm | Moment of inertia | |

| 0.4 | 51.1 mm, 34 mm | ||

| 27 mm, 24 mm |

| Target Fluid Pressure (bar) | 40 | 60 | 80 | 100 |

|---|---|---|---|---|

| Actual maximum response value (bar) | 41.88 | 63.88 | 84.87 | 103.50 |

| Percentage overshoot | 4.70% | 6.47% | 6.09% | 3.50% |

| Response time (ms) | 181 | 180 | 180 | 190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhou, T.; Zhou, Y.; Huang, B. Application Layer Software Design of Vehicle Comfort Braking Based on Brake-by-Wire System. World Electr. Veh. J. 2023, 14, 220. https://doi.org/10.3390/wevj14080220

Liu J, Zhou T, Zhou Y, Huang B. Application Layer Software Design of Vehicle Comfort Braking Based on Brake-by-Wire System. World Electric Vehicle Journal. 2023; 14(8):220. https://doi.org/10.3390/wevj14080220

Chicago/Turabian StyleLiu, Jiahao, Tianjun Zhou, Yufeng Zhou, and Bo Huang. 2023. "Application Layer Software Design of Vehicle Comfort Braking Based on Brake-by-Wire System" World Electric Vehicle Journal 14, no. 8: 220. https://doi.org/10.3390/wevj14080220

APA StyleLiu, J., Zhou, T., Zhou, Y., & Huang, B. (2023). Application Layer Software Design of Vehicle Comfort Braking Based on Brake-by-Wire System. World Electric Vehicle Journal, 14(8), 220. https://doi.org/10.3390/wevj14080220