Abstract

Environmental protection initiatives are speeding up the replacement of the present IC engine-based transportation system with an electric motor-driven system. In electric vehicles (EV), energy stored in batteries is used for the traction of the vehicle and the operation of the auxiliaries. The range of the electric vehicle was identified to be one of the major challenges faced by the EV segment. The optimization of the consumption of stored energy is the best solution for range improvement in an EV. Auxiliaries in the vehicle include basic accessories such as a lighting system and equipment for improved comfort such as air conditioners. Air conditioning equipment is the major power-consuming auxiliary in an EV apart from the traction motor. This review article discusses the significance and influence of different components of the air conditioning system, and methods followed by researchers to optimize the performance and reduce the energy consumption of the air conditioning system to extend the range of vehicles. The effects of thermal load and volume of space to be conditioned were also considered in this study. This review concludes by stating the different possibilities for the reduction in power consumption and emphasizes zonal air conditioning of occupant space as a solution for reducing energy consumption or increasing the range of EVs. Compared to full-space air conditioning, zonal AC can reduce power consumption by up to 51%.

1. Introduction

The history of transportation can be traced to the medieval era. Animal power was the primary source of transportation during this period. The invention of the steam engine in 1801 by Richard Trevithick was the turning point in the transportation field. In 1885, a new engine was developed and petrol was used as fuel. However, electric-powered vehicles were developed before the development of IC engine-powered vehicles. In 1834, a tricycle was operated by Thomas Davenport with battery power. During the early 20th century, the United Sates of America’s (USA) automobile sector was dominated by electric vehicles, with a share of 38%, just behind steam engines, which had a road share of 40%; IC engines had a road share of only 22%. In the history of the automobile, the first vehicle to achieve a speed of 110 km/h was an electric vehicle, on 1 May 1899 [1]. The automobile sector gave predominant importance to fossil fuel vehicles because of the fast development of IC engine vehicles and their accessories. Due to the negative effects of oil prices and greenhouse effects, the development of high-quality electric vehicles has been identified to be the need of the hour. The range of a single charge is the most important problem identified in electric vehicles. On the other hand, comfort and safety are the non-compromising requirements of today’s transportation segment. Ultimately, battery life will be increased through a reduced amount of charging and discharging. To provide comfort to the passengers, cabin temperature needs to be maintained effectively, with the help of air conditioners (AC). Until the 1990s, the car industry concentrated only on improvements in aerodynamics and engine performance. However, at this time, the US car industry started concentrating on thermal management systems by adding air conditioners in vehicles [2]. Initially, the air conditioner was a luxury, since it was an optional accessory. However, today, it has been identified to be an unavoidable requirement of a car. In the US, 10% of imported crude oil and6%annual petroleum consumption is exclusively used for vehicle air conditioning, which is estimated to be seven billion gallons [3]. In conventional vehicles (diesel-and petrol-operated), fuel consumption is increased by 35% during the application of an air conditioner [3].

The role of air conditioning has increased in all parts of human life, and the percentage of the total energy used for AC is reflecting its importance. A total of 11% of total electrical energy used for domestic purposes is exclusively used for home air conditioning; in addition, around 33–50% of total electrical energy consumption is used for central air conditioning and related subsystems [4,5,6]. According to the International Energy Agency (IEA), the total floor area of institutions and commercial buildings will double by 2050 [6], so the energy consumption by ACs may also double by 2050. Unfortunately, the air conditioner was recognized as one of the major power-consuming accessories in electric cars, with a consumption of 30 to 50% of the total stored energy [7,8,9,10]. Generally, the range of electric vehicles is around 100 to 300 km per charge. In a case study in Beijing, China, it was found that 45.5% of taxis required a range of 160–320 km per charge, and in the case of private vehicles, 40% of users required a range of 80 km [11]. When these vehicles are operated while using air conditioners, the range of the vehicles is affected. Some studies also indicate that 10% capacity degradation takes place in the battery [12] when the air conditioning system in a vehicle is continuously used.

The worldwide automobile population has reached a billion and is expected to grow to two billion by 2035 [13]. The present global energy consumption dedicated to the transportation sector is around 30%, of which 1.5% is dedicated to automotive air conditioning. The average energy used by a car’s automotive air conditioning system is around 6% of the total fuel used. The automotive air conditioner is the second largest fossil fuel user after automobile propulsion [13]. Therefore, the research on automotive air conditioners needs to produce more output, by considering the following factors: energy consumption, COP, GWP of refrigerants, pollution, comfort, heat infiltration to the cabin, weight, and size.

1.1. History of AC

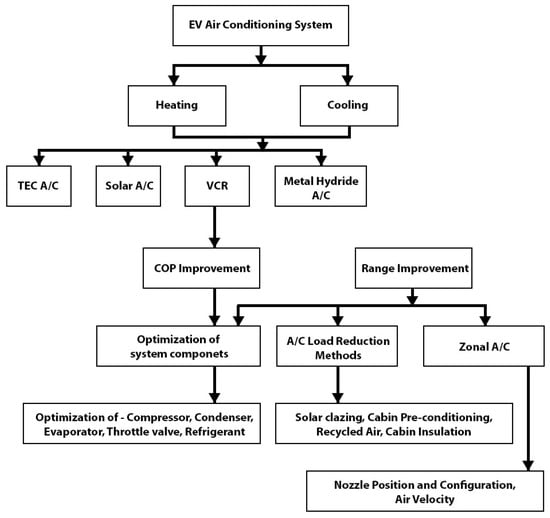

The first functional automotive AC was introduced by Packard, in 1939, which consisted of a condenser, compressor, evaporator, receiver, and drier. A belt was used to connect the engine and air conditioner compressor. An affordable automotive AC unit was introduced by Nash-Kelvinator between 1954 and 1955, with an electric clutch and AC control on the dashboard. In 1955, the first front-mounted AC with a heating unit was developed and commercialised by GM. In 1965, GM introduced climatic control AC, which was mass-produced. Until 1973, designers concentrated on the implementation of AC in the vehicle, but did not concentrate on the impact of AC on fuel economy and the environment. In 1973, Harrison Radiators (GM) developed the cycling clutch orifice tube (CCOT), which helped in switching off the AC compressor for 1/3rd of the time, resulting in a fuel economy improvement. In 1976, Harrison Radiators (GM) developed a new refrigerant, R134a, that has a lower ozone depletion potential (ODP) than R12 and R22 [14]. Figure 1 shows the layout of this review paper.

Figure 1.

The layout of the review paper.

There are different ways by which refrigeration can be carried out. Most refrigeration systems use a vapor-compression refrigeration (VCR) system, as these systems are compact and rigid. Systems such as vapor absorption, using solar and waste heat; thermos-electric refrigeration; metal hydrate refrigeration, based on pressure swing; and steam ejector cooling are other methods which have been explored in automotive air conditioning systems. This review article places more importance on VCR-based air conditioning systems, as these systems are successfully implemented on a large scale in automobiles. This article also covers the merits and drawbacks of other systems in brief. The worldwide average working duration of an automobile was estimated to be 249 h per year (Sand and Fischer, 1997), and within this, 107–121 h of air conditioners being used, which shows that air conditioners are being used for around 47 to 49% of total vehicle usage in a year (Fischer, 1995) [15]. Climatic conditions are the main deciding factor in the usage of an air conditioner. The weather conditions of a tropical country such as India are mostly humid and hot [16], and the climate zone map of India is the same. This is the reason behind the wide usage of summer air conditioners in India. To reduce the impact of energy consumption for cooling, the Government of India formulated the ‘India cooling action plan’ policy [16]. Pollution control is another outcome of this initiative. A total of 10% of the total primary energy supply is used on mobile air conditioners. Furthermore, automotive air conditioners in India account for 19.4% of the total vehicle fuel consumption [17]. Considering this fact, an effort to review summer air conditioning (in automobiles) is made in this paper.

1.2. Winter Air Conditioning (Heating)

For winter air conditioning, the most popular method adopted in EV is positive temperature coefficient (PTC) heaters, which use around 30 to 50% of the stored energy. PTCs work on the principle of the Joule effect, meaning there is a 100% conversion rate of electricity to heat [18]. The cost and power consumption of PTC heaters are high. A heat pump is the best alternative to PTC, due to its lower energy consumption, at around 20 to 30% of the stored energy [18]. In addition, the heat recovered from the different components of the vehicle (e.g., motor and power electronics) can be used to heat the space. This recovered heat energy can reduce power consumption by around 580 W for a 2000 W heating system [19]. The extraction process of waste heat and the amount of heat extraction are the main problems for heat pump-based air conditioners in extreme winter conditions [20]. A magnetocaloric heat pump was demonstrated in Ref. [21], in which a magnetocaloric plate was repeatedly placed in a constant magnetic field. The magnetocaloric plate heated up during magnetization and cooled during demagnetization. Heat energy stored in a phase change material was tested in Refs. [22,23]. The quantity of energy storage and the weight of the equipment were two important hurdles regarding the widespread usage of this system. Heat generation through the firing of fuel is another method; this system requires additional equipment and produces air pollution [24].

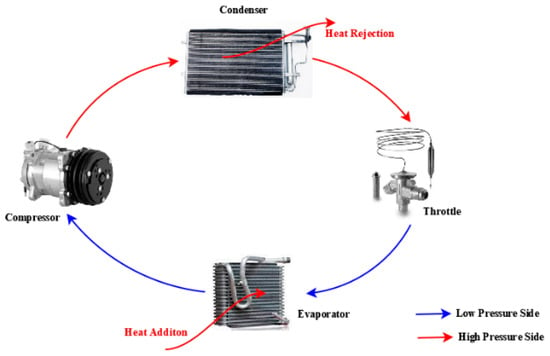

1.3. Vapor-Compression Refrigeration System

Most of the refrigeration systems installed in automobiles and buildings work based on the VCR principle. The VCR cycle uses a refrigerant as the working fluid to absorb and reject heat. A VCR system has four major components—a compressor, condenser, expansion valve, and evaporator—all connected in a series. The latent heat property of the refrigerant is used to cool or heat a space. The entire system works at two different pressures: it has a low-pressure side and a high-pressure side. Figure 2 shows the components of a VCR and how they are connected. The VCR system uses the latent heat property of a refrigerant to cool or heat the space. The refrigerant in a vapor state at low pressure is fed into a compressor and pressurized to high pressure (usually around 20 to 25 bar). The compressor is connected to a prime mover such as an I.C. engine or an electric motor. The high-pressure refrigerant at the outlet of the compressor, which is at a higher temperature, is fed to a condenser. The condenser rejects heat, which mostly constitutes the superheated part and latent heat part. The high-pressure refrigerant that is in a liquid state or a low dryness fraction liquid state is sent to the evaporator through a throttle valve. The throttle valve maintains the high pressure by controlling the refrigerant flow rate. A throttle valve is an expansion device that connects the high-pressure and low-pressure regions. The heat from the conditioned space (i.e., latent heat and superheat) which is added to the refrigerant puts the refrigerant back into a vapor or superheated vapor state. This cycle is repeated until the desired effect is achieved. Detailed discussions on various components of the refrigeration system and ways to improve the performance of the system can be found in Section 2.

Figure 2.

Vapor-compression refrigeration system.

The level of performance of a VCR system can be known by finding the coefficient of performance (COP) of the system. The COP is defined as the ratio of heat absorbed by the refrigerant (when it passes through the evaporator) to the work input to compress the refrigerant in the compressor. Usually, the value of COP is always greater than one.

The COP of a standard vapor-compression refrigeration system is given as follows:

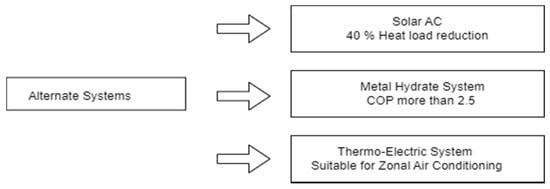

1.3.1. Solar Air Conditioning

Solar air conditioning systems work by using either a vapor absorption refrigeration system or VCR. As the vapor absorption system is bulky and has a very low COP compared to the VCR, most solar air conditioning systems dedicated to automotive applications work using VCR. To attain a solar-based refrigeration system using VCR, with the help of photovoltaic cells, solar energy is converted to electric energy for automobiles. This is an eco-friendly and renewable energy source [25]. The poor conversion ratio, necessitating the usage of larger panels, is the major hurdle regarding the use of this system. The use of the outer surface of a vehicle for laying the panels can also deteriorate the appearance and aerodynamic properties of the vehicle. Furthermore, fluctuation in climatic conditions affects continuous energy conversion. A solar-operated air conditioning system was developed and tested by [26]. It was used only as a supplementary power source. The weight of the energy storage system poses another challenge for researchers. This can be solved by optimizing the battery pack used in the electric vehicle. The solar air conditioning system was tested in the Maruti WagonR car [27]. The reduction in cabin heat radiation can lead to a drop in cooling load by 40% [28].

The possibility of running a solar-operated air conditioning system in an automobile was tested in Ref. [29]. In this experiment, 22.8% area of the vehicle was covered by photovoltaic solar panels. The experiments were conducted in a no-load condition. The time slot selected for testing was from 12.30 pm to 2.00 pm. Before starting the experiment, the doors were kept open for 0.5 h, to enable the inside of the car to reach thermal equilibrium with the environment. The vehicle was kept stationary during the period of testing. Four 12 V lead–acid batteries were arranged for the storage of energy. The inside volume of the vehicle was 4 m3. A DC compressor was used to run this vapor-compression air conditioning system. The refrigerating capacity of the system was 2250 W. The maximum atmospheric temperature attained was 38.5 °C, and the lowest cabin temperature achieved was 26.6 °C. The work demonstrated a completely battery-operated DC-powered air conditioning system. Additional batteries for this system use more space and increase the weight of the system. However, such a system can be used as an energy refilling source, which will increase the range of an electric vehicle. A solar air conditioning system was tested with a flexible roof-top solar panel, which reduced fuel consumption by 25%. The solar energy was enough to run the air conditioner at an average solar radiation of 241 W/m2 [30]. More research works into the commercial viability of solar air conditioning systems are required [31].

1.3.2. Metal Hydride Air Conditioning

Replacing a compressor in an air conditioning system can significantly reduce the energy consumption of an air conditioning system. Accordingly, a study was undertaken in Ref. [32], and this study proposed a metal hybrid system. This system works based on the theory that some of the intermetallic compounds will absorb hydrogen at high pressure and convert it to a metal hydride and liberate hydrogen at low pressure, transforming it to its original form. When hydrogen is liberated from the intermetallic compound, it will absorb heat from the surroundings. At the same time, when hydrogen is added to the metal, heat will be liberated. This property was used for air conditioning. The temperature and type of alloy used were the key factors that influence performance. Some of the alloys work in the wide temperature range of 90°C to 600 °C at a pressure range of 1 Pa to 100 MPa. This air conditioning system uses only one-third of the electrical energy of that of the VCR system. The COP of this system improves when the ambient temperature reduces. Normally, the COP of this method is more than 2.5. A separate pumping system is required to handle hydrogen, which is highly inflammable. The maintenance of the system requires a specially trained person, which is another challenge to be addressed.

1.3.3. Thermoelectric System

Thermoelectric air conditioning systems work using the Peltier effect. The effectiveness of this system relies on the difference in temperature [25] and the figure of merit (ZT) of the thermoelectric material. A thermoelectric cooling system was developed by Amerigon Corporation [33]. To design a commercially feasible system, more studies are required in the field which aims to produce more effective thermoelectric materials, cost reduction, and COP improvements in this system. The studies conducted by GM and Ford [34] suggested that such systems will be more effective in zonal air conditioning systems. Other alternative automotive AC systems, except for VCRsand their advantages, are shown in Figure 3.

Figure 3.

Different automotive AC systems and their advantages.

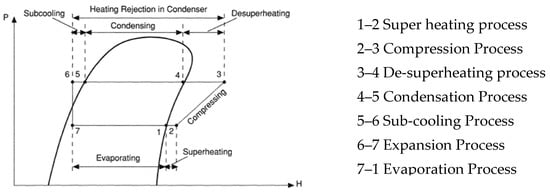

2. Ways to Improve Performance of VCR Systems

Figure 4 shows the pressure–enthalpy diagram of a standard VCR system. In Figure 4, regions 1–2 depict the superheating of the refrigerant before it enters the compressor, the sole purpose of the superheating being to avoid liquid compression in the compressor, which may damage the compressor. Marginal superheating of the refrigerant helps to increase the COP and prevent the entry of liquid into the compressor. The significant disadvantage of superheating is the increased compressor work per kg of refrigerant circulated required, which further decreases the COP of the refrigeration system. Regions 5–6 are the regions of subcooling, which is a desirable effect. The reason why sub-cooling is desirable is that it increases the efficiency of the system since the amount of heat removed per kg of refrigerant circulated is greater. Inadequate subcooling prevents the expansion valve from properly metering liquid refrigerant into the evaporator, resulting in poor system performance.

Figure 4.

P-H diagram of a standard vapor-compression refrigeration system.

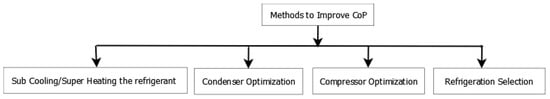

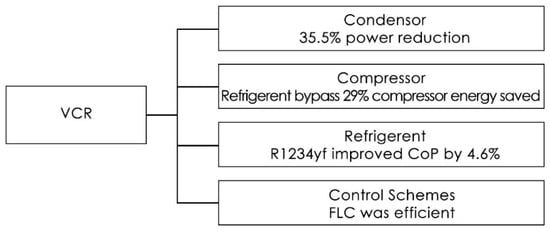

In addition to the subcooling and superheating of the refrigerant, the optimization of the air conditioner components is also essential to improve the performance of the system. Figure 5 shows various ways of improving the COP of an automotive air conditioning system. The optimization of components such as condensers, compressors, and refrigerants is discussed in detail in the following sub-sections.

Figure 5.

Various ways of improving the COP of an automotive air conditioning system.

2.1. Condenser

A condenser is a heat exchanger which is used to cool down the high-pressure and high-temperature refrigerant coming out of the compressor. The air-cooled condenser is where the heat rejection from the system takes place. Energy-saving and range improvements in an electric vehicle can also be achieved by enhancing the performance of the condenser. The refrigerant enters the condenser as a super-heated vapor and exits as a sub-cooled or saturated liquid. This refrigerant is fed to the thermal expansion valve. The power requirement for conditioning depends on the heat transfer capacity of a condenser. The operational pressure, temperature, heat transfer area, speed of the vehicle, atmospheric conditions, and properties of refrigerants have been identified as the key elements for the effectiveness of a condenser. Most conventional automotive air conditioning systems use air-cooled condensers. Comparatively, large air conditioning systems use water-cooled condensers. These systems require an independent cooling circuit. Due to the high specific heat capacity of water, the effectiveness of the water-cooled system was found to be greater than that of the air-cooled system.

The study of [35] provides an explanation of a combined air- and water-cooled condenser. Even though the effectiveness of the water-cooled system is high, this system requires a separate circuit for cooling, which takes up more space, and the average operating temperature of the cooling water is also high. To overcome these problems, a combined system was tested. This condenser consists of a water-cooled section that cools the high-temperature gaseous stage refrigerant in two phases. Then, with the help of an air-cooled section, this system converts the output of the water-cooled section into a sub-cooled stage. In a normal condenser, around 35–40% of the space is utilized for the de-superheating operation. When a water-cooled system is employed, due to its high heat-carrying capacity, the total space requirement can be reduced. An additional air-cooled system helps to increase the cooling effect by converting the refrigerant into a sub-cooled stage. The cooling effect is increased by 35% through theoretical analysis. This system can work with high load capacity and is found to improve the COP by 9.4%. In conventional vehicles, to obtain a low-temperature coolant, an additional circuit is used. The combined condensing system can be more suitable for an electric vehicle. The reduced size of a combined condenser leads to the handling of low amounts of refrigerants in order to obtain the same effect as in a conventional system. Due to the handling of a smaller amount of refrigerant, power consumption can be reduced by 7.3%, and the increase in the range of the electric vehicle can be around 2.1% [35].

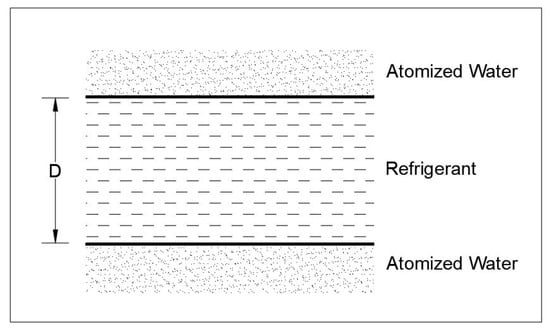

The study in Ref. [36] reports that the presence of a wet surface over the tubes of a condenser improves the heat transfer capacity due to the high heat transfer coefficient. The low-temperature condensate water collected from the evaporator of an air conditioning system has the potential to improve the performance of the condenser, which is mostly unutilized in conventional systems. During the summer season, due to the dehumidification process, the moisture content in the air is condensed in the evaporator and stored in a container. This water is atomized or sprayed on the outside surface of the condensing tube (Figure 6) [36]. These water particles form a moist layer around the condensing tube. Augmented heat transfer occurs because (1) a phase change of moisture occurs (latent heat) and absorbs heat from the refrigerant when the air is circulated over the tubes, and (2) the presence of the moisture particles increases the heat transfer coefficient. Based on the experimental investigation, it was found that 35.5% of energy can be saved and, hence, this reduction in power consumption by air conditioning could increase the driving range of the vehicle. Table 1 shows the percentages of power reduction caused by different types of condensers.

Figure 6.

Vaporized water around the tube.

Table 1.

Power saved with different condensers.

Condenser performance also depends on the amount of refrigerant available in the circuit [37]. When the amount of the refrigerant increases, its saturation temperature, and pressure increase. This leads to an increase in the inlet temperature difference between the refrigerant and circulating air and enhances the heat transfer rate. The heat transfer rate increases until the amount of refrigerant reach the maximum level. If charging with an excess of refrigerant is used, a certain amount of refrigerant accumulates in the condenser, leading to increased backpressure on the compressor delivery side. This leads to the use of more power consumption to achieve the required amount of heat transfer. If the amount of the refrigerant is lower, then a more super-heated refrigerant is generated in the evaporator, reducing the performance of the condenser.

Effective condensation leads to increased heat transfer and reduced power consumption by air conditioning systems. The cooling capacity of an AC depends on the quality of the refrigerant from the condenser. Condensers and their advantages and disadvantages are listed in Table 2. Additional attachments such as water cooling systems, water atomization, and circulation systems increase the size and weight of the unit. Further research is required in the following areas:

Table 2.

Condensers and their advantages and disadvantages.

- ○

- how to produce automated perfect control of output amount, pressure, and temperature of the refrigerant;

- ○

- how to avoid backpressure due to the accumulation of refrigerant in the condenser;

- ○

- how to produce a new separate control system for the quality of the refrigerant at the exit of the condenser; and

- ○

- how to produce a reduction in size and weight with improved performance.

2.2. Compressor

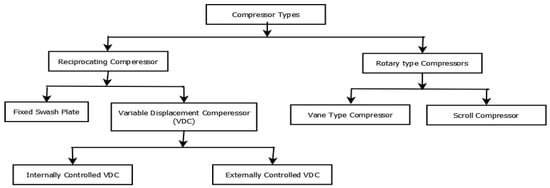

Compressors are the main component of automotive air conditioners. Usually, these compressors are operated by IC engines in conventional vehicles with the help of a magnetic clutch and pulley belt system. In EVs, compressors are operated with the help of electric motors. Compared to IC engine-operated compressors, electric motor-operated compressors (hermetically sealed) are simple and more efficient. Air conditioner compressors are broadly classified into two types: reciprocating and rotary. Figure 7 shows the different types of compressors used in automobiles. Most of the automobiles in India use swashplate compressors, which come in two versions: viz fixed displacement and variable displacement. The automotive industries are slowly shifting to scroll compressors due to their inherent advantages. EVs use scroll compressors, which are operated using inverter-based technology to vary the compressor speed and capacity of the air conditioning system.

Figure 7.

Air conditioner compressor classification and types.

The air conditioning system is the major power-consuming auxiliary unit in a vehicle. In a VCR system, the compressor uses around 65% of the power [38]. Most older automobiles use fixed displacement compressors or fixed capacity compressors (abbreviated as FDCsor FCCs), which are reciprocating types. Reciprocating compressors suffer from their clearance volume, which results in the re-expansion of the compressed refrigerant trapped in the clearance volume. These compressors use an on/off strategy for cooling control, to compensate for the changes in the cooling load, and to avoid the freezing of condensate in the evaporator. Such on/off systems affect the smooth functioning of the engine, develop thermodynamic losses, and increase the power consumption of compression. Generally, after reaching the temperature limit (a set temperature), the compressor will switch off. When the compressor is in the off condition, pressure in the heat exchangers is balanced. This balancing causes pressure reduction in the condenser and a pressure rise in the evaporator. This effect induces higher compression work (due to higher inlet pressure during suction) [39]. When the airflow rate at the evaporator increases, total heat transfer from the refrigerant to air also increased (superheating). A high heat transfer rate leads to more vaporization of the refrigerant. This will increase the pressure and mass flow rate of refrigerants. The rise in flow rate increases the compressor power consumption (per kg of refrigerant circulated). However, in contrast, the effect of the high mass flow rate at the condenser will reduce the backpressure and reduce the saturation temperature, hence causing a reduction in compressor power [39]. Because of the accumulation of evaporator inlet heat and heat generated during the compression work in the refrigerant, in general, the airflow rate at the condenser must be much higher than at the evaporator.

A study was undertaken by [40] on a vehicle that uses an electric-driven compressor instead of an engine-driven compressor. Direct control over the compressor is possible and engine speed is independent of the compressor speed. This reduced the power consumption, ensured that maintenance and installation is easy, and ensured stability in the mass flow. System stability improves fuel economy [41]. This arrangement reduced fuel consumption by 3.03–14.69% compared to an engine-driven compressor. Variable capacity compressors (VCC) are a good replacement for fixed capacity compressors, as FCCs lead to the hunting of the engine (i.e., the fluctuation of rpm during the on/off period), and also use more energy. A variable displacement compressor or variable capacity compressors have a fast response to the cooling demand [42]. In this type of compressor, with the help of a wobble plate, the volume of the refrigerant to be inducted is varied by varying the stroke length of the compressor. The time lag response of wobble plate case pressure and rotary speed is less than 3 s, and the time lag in stroke length or rate of mass flow of refrigerant to rotary speed is less than 5 s. The time lag in the stroke length of the piston compared to the changes in suction pressure is less than 2 s and the time lag of the flow rate of the refrigerant compared to the suction pressure is less than 5 s. This sudden response inaction leads to a minimum required amount of refrigerant being compressed. The response decreases when the compressor speed increases [42]. A demand capacity-controlled compressor, as suggested in Ref. [43], responds to the demand of the cooling load; with the help of an external controller amount, the refrigerant compressed will be regulated. If the cooling demand is less even when the engine is running at high speed, the amount of refrigerant compressed will be reduced. The amount of refrigerant bypassed was determined by measuring the cabin and atmospheric temperature. An air mix door was also used to control air circulated through the evaporator. With the help of these arrangements, the energy requirements of the compressor can be decreased by 29%, and fuel savings by 22%, when compared to a normal air conditioner. Temperature fluctuation can be reduced by 37%.

A fixed-capacity compressor and a variable-capacity compressor were studied in Ref. [44]. The FCC’s cooling capacity varies depending on the engine speed. As discussed earlier, the system maintains the temperature through the on/off operation. The VCC works independently of the speed of the engine. This type of compressor maintains the temperature variations by varying the refrigerant flow through the compressor. Since such systems will meet the required temperature at less rotation, the continuous and smooth operation of air conditioning systems ensures good fuel economy and thermal comfort [45]. A wobble plate compressor was tested at fixed (138 cc) and variable (9.81–151 cc) stages [44]. In the FCC, the COP decreases with an increase in the engine speed, due to the increase in work by the compressor at the high speed required. The VCC was able to maintain a higher and more constant COP at higher speeds. This ensures a continuous flow of refrigerant by varying the volume of refrigerant. The VCC also provides a smooth start [46]. The study conducted in Ref. [47] tested an externally controlled variable displacement compressor (EVDC). The displacement volume was determined by the evaporator surface temperature. This system produces quite steady output properties (temperature and pressure), irrespective of the ambient conditions, compared to the FDC. Using the FDC, cabin temperature fluctuates rapidly due to changes in atmospheric temperature. The EVDC causes sudden changes concerning the variations of outside conditions in the maintenance of the cabin temperature.

Vane compressors are a good replacement for reciprocating compressors. Two types of rotary compressors—namely, vane type and scroll type—are commonly used in air conditioning systems. A novel concept was developed in Ref. [48], which was a double-swing vane compressor (DSVC). The performance analysis of this compressor was carried out through simulation. They introduced one more vane in the single-vane compressor. The DSVC was able to increase the volume flow rate by 1.6 times that of the single vane type. The DSVC shows an improved efficiency, with reduced weight and volume, a good working capacity, and an increased mechanical efficiency of 92.8% at 3000 rpm. Scroll compressors are one of the best compressors available that can be used in automobiles. The efficiency of these types of compressors is high due to the low leakage of refrigerants [49]. The pressure increases gradually and differences in pressure between the nearby pockets were maintained at a smaller value. The increase in temperature of the refrigerant was also gradual from suction to delivery. The gradual increase in pressure and temperature provides a smooth compression process. At high-speed rotation, the total temperature distribution was increased. Unlike the reciprocating compressors, after compression re-expansion, the chances of errors are less in scroll compressors and an experimental study conducted in Ref. [50] proves this concept. The work replaced a 130 cc reciprocating compressor with a 90 cc scroll compressor without affecting the cooling efficiency. This change produced a 24–30% reduction in power consumption in an SUV. Furthermore, 5% of the power was saved due to the reduction in the size of the compressor. Less frictional loss in the scroll compressor also plays a major role in power reduction. According to Ref. [51], a 60 cc scroll compressor was replaced instead of a reciprocating compressor for a small car. This arrangement produced power savings of 20%. The author of Ref. [52] also says that the scroll compressor provides good reliability and efficiency compared to the conventional compressor [53,54], suggesting that the scroll compressor is the most suitable one for electric vehicles due to its reduced weight and volume and improved efficiency. The moving parts of a scroll compressor maintain a small clearance of 1 micron between them. If the clearance reaches 8 microns (through wear and tear), the compressor will not work effectively [55].

The hermetic scroll compressor was tested in Refs. [56,57] with a DC motor. This type of compressor showed improved volumetric efficiency applicable to the handling of a wide range of pressure and speed. This compressor uses less than 20% of the battery capacity when operated for a given range. According to Ref. [58], an electric compressor with a scroll-type version was developed. This work introduced a sinusoidal inverter instead of a square wave inverter, which resulted in an efficiency improvement of up to 7%. It was also light in weight. The development of a special structure reduces the noise and vibration of the system. The total volume was reduced by 17%. The length was reduced by 20% and the weight was reduced by 15% through the closely wound stricture. An innovative power train approach was introduced in Ref. [59] and named the efficient synergy drive. In this system, two motors are placed coaxially. One motor drives the car and the second one drives the compressor of the air conditioning system. A perfect coupling was made between the main motor and the air conditioning motor. The main motor drives the car and the compressor when the power required for driving is lower. This system avoids the simultaneous usage of both motors at the same time, like in a conventional system. Due to this, the special arrangement range of the vehicle increased by 8.2%. Table 3 shows a summary of the different types of compressors and their effects on the air conditioner performance. The type of compressors and their advantages are listed in Table 4.

Table 3.

Different compressors and their effects.

Table 4.

Type of compressors and its advantages.

The compressor is the major power-consuming part of an air conditioner (up to 65%); improvements in the performance of the compressor will lead to the improvement in the COP of the system and help in fuel consumption reduction. Alternate equipment for the compressor (such as adsorption) without any compromise in the COP is another major area for future work.

2.3. Refrigerant

The refrigerant selection for any VCR (vapor-compression refrigeration) system is critical as many thermodynamic and thermo-physical factors of a refrigerant have to be taken care of before selecting it as a refrigerant. The properties and parameters which are required to be considered include suction pressure, discharge pressure, pressure ratio, latent heat of vaporization, isentropic index of compression, liquid-specific heat, vapor-specific heat, thermal conductivity, and viscosity.

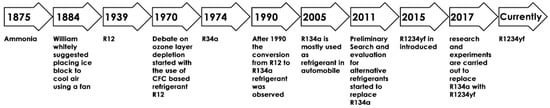

The first commercial cooling machine was introduced in 1875, using ammonia as its refrigerant [60]. The first complete auto AC was implemented in 1939, with R12 as a refrigerant. In 1974, M/S Harrison Radiator identified R134a as a good alternative to R12. To eliminate ozone layer depletion, the UN announced the Montreal Protocol, causing the replacement of R12 with R134a. Based on the Global Warming Potential (GWP), CO2 is a high-performance refrigerant that was used in ice-making plants in the past. The GWP of R12 is 7100; for R134a, this is 1300; and for CO2, this is 1 [61]. The general requirements of refrigerants were safety, energy efficiency, environmental friendliness, and stability.

A comparison of CO2 and R134a was conducted in Ref. [62] and it suggests that ambient temperature and compressor performance would affect the COP of the system. When the speed was 1000 rpm, the COP of R134a was 21% at 32.2 °C and 34% at 48.9 °C higher than CO2. Ref. [63] reported that compressor power was 28% lower when CO2 was replaced by R134a. The cooling capacity of R134a was 3.6% and 7.2% higher than CO2 at 32.2 °C and 48.9 °C, respectively, when the compressor speed was kept constant at 3000 rpm. The compressor power for the CO2 system was 20% higher when the compressor speed was 1000 rpm and the temperature was 32.2 °C, and 49% higher when the compressor speed was 3000 rpm and the temperature was 48.9 °C [62], compared to R134a. CO2 has been identified as the best alternative option for refrigerants in heat pumps [64]. Considering the need for environmental protection, a new system was developed for using CO2 as a refrigerant in a heat pump [63], because of its low ozone depletion potential (ODP is 0) and global warming potential (GWP is 1). The low critical temperature of CO2 leads to a low-temperature difference in the heat exchanger. Due to this reason, CO2 was found to perform better as a heat pump. By carrying out modifications in the equipment, heating and cooling performance equivalent to the R134a refrigerant can be achieved.

According to the research in Ref. [65], 1234yf was identified as an alternate for R134a, due to its environmental friendliness (ODP–0 and GWP- 4) and easy adaptability for automotive air conditioning. The amount of refrigerant required is 10% less than R134a. Compressor power was reduced due to its thermodynamic properties. By adding an internal heat exchanger to this system, the COP was improved by 4.6%. This work also revealed that the electrical energy consumption was lower but the flammability value was higher [66]. By adding 11% of R134a with 1234yf, the flammability value was reduced or became non-flammable [18,67], with a compromise on cooling capacity and COP compared to R134a. Figure 8 shows the evolution of refrigerants.

Figure 8.

Evolution of refrigerant.

To improve the effectiveness of refrigerants, research was undertaken in Ref. [68], by adding nanoparticles to the refrigerant. The performance was tested by adding magnetic nanoparticles (Fe3O4) with refrigerant R134a. The thermal conductivity of the refrigerant increases from 21.23% to 63.87% when the mass concentration of the Fe3O4 was increased from 1% to 3%. The heat transfer coefficient was increased by 10.6% at a mass concentration of 3%. This work identified that refrigeration efficiency also increased by 8.6%. A combination of HFC-161/HFC-134a with a mass fraction of 0.6/0.4 was studied in [18], leading to a higher refrigeration effect and COP with more power consumption. R744 is one of the alternatives to R134a, due to its higher COP; operating pressure was also high. However, usage of R744 resulted in leakage problems and the modification of existing systems was for the operation. The R744 system operated with a 21.3% higher COP compared to the R134a system during the cooling process [69].

The average yearly fuel consumption used to operate an automotive AC system in a car is 77.6 litres; apart from that, 11.35 litres of fuel is used per year to carry the additional weight of the automotive AC system. The weights and sizes of automotive AC systems are different depending on which refrigerant is used. Table 5 shows the comparison of fuel consumption to operate and carry the AAC system with different refrigerants.

Table 5.

Fuel consumption to operate and carry the AAC system.

Automobile industries from Europe have planned to use CO2 as a refrigerant [70] and observed that a 70% mass fraction of CO2 with propane is the best option. The maximum cooling capacity was observed at 70% mass fraction.

The critical pressure of R1234yf is comparable with R134, but CoP is 6.32% less than 134a. Considering the GWP and ODP, R1234yf is a good replacement for R134a. Studies revealed that, with the help of an additional expansion valve, cooling capacity and COP can be improved by 11% and 8%, respectively [30], using R143yf.

From a refrigerant point of view, a high-performance, eco-friendly refrigerant is the need of the hour. To achieve this, a refrigerant should have to be eco-friendly, resulting in low fuel consumption, and be stable, with good thermodynamic properties. More research in this field is needed to identify a perfect alternative refrigerant with a proper balance of the above properties.

2.4. Thermal Expansion Valve

Environmental conditions show frequent variations which influence the comfort inside the cabin. Improved energy efficiency can be achieved by regulating the refrigerant flow. An electronic control expansion valve (EEV) was introduced to reduce the delay in refrigerant mass flow control. With the help of variable refrigerant flow control using the electronic expansion valve and a perfect control system, a 3 °C temperature difference can be achieved. This reduces the thermal load and work performed by the compressor [15,71]. Rapid fluctuation in compressor speed can be avoided. With the help of EEV, an optimum sub-cool level can be maintained; this results in energy savings of 10% during heat pump operation [72].

3. Air Conditioner Control Schemes

The basic purposes of an air conditioner in a car are not only to provide a thermal comfort environment but also to provide clean air and circulate the conditioned air effectively inside the cabin without thermal pockets. The automatic climate control system provided in modern cars receives inputs from the user and controls the system automatically to attain and maintain the set temperature. Some high-end cars have the facility to maintain zonal cooling where multiple different temperature zones can be maintained inside the cabin simultaneously based on the passenger’s requests. Conventional domestic air conditioners work based on “set temperature”; once the set temperature is achieved, the compressor stops. The compressor switches on once the temperature of the space exceeds the threshold temperature; this is an on/off-based control. In addition to the compressor, the evaporator fan speed can be adjusted manually using the fan speed regulator.

To avoid the formation of ice on the evaporators, the evaporator temperature is always ensured to be higher than 0 °C. The compressor is switched off once the temperature of the evaporator reaches close to 0 °C. Common control techniques followed in automotive air conditioning are as follows: (a) thermostat control (i.e., a simple on/off the system), (b) PID-based control, (c) fuzzy logic-based control, and (d) an optimization-based control system based on the combination of the previous three systems. The functioning of the air conditioning system can be controlled with various parameters. Three different schemes were studied in [73]. They are (a) the outlet temperature of the refrigerant from the evaporator, (b) the outlet pressure of the refrigerant from the evaporator, and (c) the cabin temperature. In all these control schemes, the compressor and condenser fan power supply depend on the respective parameters of the scheme. For example, in the scheme which involves the outlet temperature of the refrigerant from the evaporator, the power supply is controlled by the set values of the refrigerant temperature at the exit of the evaporator. The scheme involving power consumption by the compressor outlet temperature of the refrigerant from the evaporator was identified to be the best method compared to the other two schemes.

In this scheme, fluctuation in the current consumption was lower, which led to reduced power consumption by the compressor. In the case of condenser fan power consumption, the outlet pressure of the refrigerant from the evaporator showed better performance. Condenser speed was almost constant and remained low in this case. Power consumption increased with an increase in speed. In all of the above schemes, an expansion valve controlled by a thermostat was found to use more compressor power than an electronic expansion valve [73]. This is due to its high precision and better optimization. Most of the time, the number of occupants in a vehicle is one or two. During this time, human presence can be identified using a camera that is fitted next to the rearview mirror inside the cabin. The output from the camera is connected to a controller and the controller regulates the airflow automatically. The controller ensures that conditioned airflow is present in the zone of occupants alone. This arrangement helps to reduce the volume of air to be conditioned, ensures the air reaching the passengers is not too old, ensures the air is of high quality, etc. The natural outcome of this arrangement is reduced power consumption by air conditioning.

Relative humidity and temperature are the two major parameters that influence comfort conditions. An increase in these values induces chemical reactions, and static electricity, and increases the density of the human body [74]. Energy consumption by air conditioning was reduced with the help of fuzzy control systems through fast information transfer for effective control of the set point properties. Energy consumption was reduced through the fast and steady regulation of compressor speed. An effective control system can enable smooth driving, reduce fuel consumption, and reduce emissions, in addition, to improving comfort conditions. This is due to the overall control of recirculation and the fresh air gates, blower, and compressor. In 1996, conventional thermostat control was replaced by the fuzzy logic thermostat, which improves the comfort level and reduces power consumption by 3.5% [75]. A compressor speed control system based on the fuzzy logic system is an effective mechanism to reduce energy consumption. A comparison between on/off thermostat control and fuzzy logic control (FLC) was conducted in Ref. [76]; the power supply was regulated by controlling the frequency with the help of the FLC. In this experiment, an average energy saving of 51.5%was achieved at a set point temperature of 24 °C. The adaptive neuro-fuzzy inference system (ANFIS) control system can provide the combined output of the artificial neural network and fuzzy logic control systems. This system uses temperature, relative humidity, and pressure as input parameters, and temperature and water vapor as output parameters. To reduce fuel consumption, a new control system with sensors and a control unit was introduced. Sensors are used to identify the temperature and humidity of the cabin and outside air. The control unit (CPU) processed the data and controlled the speed of the compressor and fan to maintain comfortable conditions.

Compared to the ordinary control system, this system was able to reduce fuel consumption by 21 to 28% [77]. Thermal comfort was influenced by the specialities of individual people, such as gender, skin colour, and age. Beyond that, in a given space, the number of people available and activity levels are important parameters to ensure comfortable temperatures. One smart control for the air conditioner was developed in Ref. [78], and the number of people and activity levels were the input parameters for this system. This smart control system consists of a camera used to identify the number of people and level of activity, a Raspberry pi used as a controller, and an infrared remote controller used as an actuator. Fuzzy logic control was used by this system. This system controls the room temperature from 27 to 21°C, according to the number of people and level of activity. The temperature was the only output parameter considered in this study. The humidity level was not considered to ensure comfortable conditions. The amount of energy saved was not considered in this study. Output temperature varied from 27 to 21°C; this reduces power consumption.

A neural network-trained PID controller was discussed in Ref. [79]; room temperature was considered to control the compressor speed. The compressor speed was controlled by considering the compressor temperature, which increased the compressor’s life. Power consumption was reduced due to the control of the compressor in a way that was fast, smooth, and prevents overshoot. Among the fuzzy controls—P, PD, PID, PI, and adaptive PD—fuzzy P uses the least energy [75]. PID and FLC performance were compared in Ref. [80]. This was a simulation-based study that suggested that FLC performance was much more efficient than PID. The temperature of 24 °C was the set temperature used in this study. The study was conducted to observe the room layout with the help of a camera unit and air of a comfortable quality was redirected to all parts of the space to ensure comfort and reduce power consumption [81]. Figure 9 shows the impact of optimized parts in a VCR system.

Figure 9.

Impact of optimized parts in a VCR system.

Cabin thermal management is one of the best ways to reduce power consumption. System performance optimization such as control of the condenser backpressure and sub-cooling of the refrigerant, in addition to thermal management, is an area that should be studied further. More specifically, a combined system that can control occupant spaces individually and conduct overall system monitoring and control should constitute the aim of future studies.

Speed of the Vehicle and Internal Temperature Distribution

During the idle condition of engine vehicles, fuel consumption increases to a maximum level of 90% while using AC, compared to without using AC [82]. Another study found that, at high temperatures, fuel consumption can increase by 25%, but during idle conditions, fuel consumption increased by 60% while using AC, compared to without using AC [83]. Due to the movement of the vehicle, an extra artificial convection effect could be the aim of future development, one that is around the vehicle, in comparison with the idle and stationary cases [84]. These convection effects restrict the entry of solar radiation into the cabin. During urban driving, the range of electric vehicles was reduced by up to 40% due to the application of AC [10]. To solve this problem of extra fuel consumption during low-speed or idle conditions, a study was executed in Ref. [85] using a hybrid IC engine vehicle. In this system, an electric motor and an engine were used as prime movers for AC. Fuel economy was improved by 20%, with the help of the following arrangements: under idle or stopped conditions, an electric motor was used, and during running conditions, mechanical power was used to drive the compressor. Further optimization of the mechanical and electrical systems enabled fuel economy improvement of 25–30% [86].

According to the study in Ref. [87], many energy-saving options are available at higher vehicle speeds. At high-speed conditions, a greater amount of air at high velocity reaches the condenser, which reduces the need to use a fan. Therefore, fan energy can be saved at high-speed conditions (>65 km/h). When the vehicle is stopped, an increase in fan speed can help to reduce the compressor speed. AC performance mainly depends upon the pressure difference in the refrigerant, which is directly connected to the speed of the compressor. At the same time, the impact of the compressor is higher in the cooling operation compared to the fan. Fuel/energy consumption can be reduced in the following conditions: (1) constant speed operation of the compressor and (2) increased cool-down time [87]. An increase in the number of occupants increases the cool-down time [86]. Optimum temperature distribution can reduce the total energy consumption used by air conditioning. According to the study in Ref. [88], a temperature gradient was present in a vehicle in the vertical and horizontal directions. By adjusting the air vent, optimum temperature distribution can be ensured through a smaller temperature gradient. A greater amount of conditioned air is pumped to the upper part of the body [86]; this is useful because, due to the effect of solar radiation and the density of hot air, the upper part of the body generates more heat energy than the lower part. A smaller amount of air is circulated to the leg space; the leg space air contains recalculated air from the back legroom through the bottom side of the front row seats. The −15° settings of the AC venture an almost uniform distribution of temperature for the both rear and front seats. However, a −30° vent angle would create discomfort for the rear and front passengers [88]. According to the simulation study in Ref. [89], heat removal can be increased by increasing the airflow rate to the cabin and by reducing the ventilation rate.

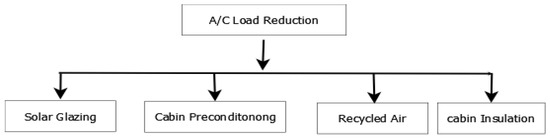

4. Air Conditioner Load Reduction

Tuning the performance of the automotive air conditioning components to attain a better COP helps in reducing energy consumption. However, in an actual situation, if the thermal load on the air conditioners is large, the conditioners use more energy, resulting in a range drop. Therefore, in addition to the optimization of the air conditioner components, it is better to reduce the thermal load of the vehicle. There are various ways by which the thermal load of the vehicle can be reduced, and automotive manufacturers take careful measures to control heat infiltration into the cabin. Solar irradiation, hot ambient air heating the car surface by convection when the vehicle is moving at high speed, fresh air load, engine heat load, occupants, etc., are the primary heat infiltration sources. Figure 10 shows various methods by which the thermal load or heat infiltration into the vehicle can be reduced. Solar glazing, recycling the conditioned air, cabin preconditioning, and cabin insulation are some of the common methods used by the automotive industry to reduce the thermal load. The cabin insulation acts as a barrier and reduces the heat interaction with the occupant space; in addition, insulation also protects the occupants from external noise. In this paper, except for cabin insulation, these three methods are presented and reviewed.

Figure 10.

Various methods of reducing air conditioner load.

4.1. Solar-Reflective Glazing

Solar radiation is one of the major reasons for temperature rises inside a cabin. Power consumption in a car air conditioning system increases due to this effect. The glass surfaces of the car allow the transmission of more heat energy into the cabin. To maintain a clear vision for the driver, the aerodynamic structure, and the appearance of the car, glass surfaces are unavoidable. As the amount of glass surface increases, thermal radiation also increases. To develop an energy-efficient air conditioning system, the thermal load needs to be reduced. The study in Ref. [90] suggested solar-reflective glassing. Solar-reflective glass consists of a coating with a dielectric layer and silver. This coating provides higher performance through better stability at bending temperatures and better optical performance at high temperatures. Solar radiation was reduced by 14% by restricting the transmission of heat. The cabin temperature was also found to be lower due to this effect. This arrangement helped to reduce the compressor load by 11.3%. Thermal load in the cabin was reduced by 10% at a rate of 2.2% for every degree of temperature change.

The cooling load of the vehicle can be considerably reduced by restricting the entry of infrared radiation. According to ASTME-891, 57% of heat loss through radiation can be attributed to radiation on the infrared spectrum (700–2500 nm), 38% to radiation from the visible spectrum (400–700 nm), and 3% to that of the ultraviolet spectrum (300–400 nm). The non-visible solar spectrum contributes to the majority of the heat load. The effect of solar radiation in a vehicle was tested with and without the use of infrared-reflective film, a sun gate, and Solex windshields in Ref. [91]. This work showed the impact of the use of a thermal shield without any special treatment on the glaze. The cabin temperature was reduced by 9 °C while using the thermal shield. The advanced Sungate windshield reduced the compressor power needed by 400 W when compared to the slandered solex. This led to a reduction in fuel consumption of 3.4% [91].

The orientation of the glaze needs to be adjusted to obtain a better appearance and aerodynamic advantages. However, the angle and curves present in the glaze surface increase the glazed area or heat transmission to the cabin. To overcome the effect of heat load, a new type of double-panel glaze was used for the side windows and rear glaze [92]. The outer panel consisted of glaze and the inner panel consisted of a polycarbonate sheet. The inner surfaces of both planes were coated with films. The inner surface of the outer panel was coated with a low-emissivity film. The inner surface of the polycarbonate sheet was coated with multi-layered thin plastic sheets. These coatings aimed to reduce infrared and ultraviolet radiation. The use of the polycarbonate sheet reduced the weight. These panels were joined together using adhesives. The test results showed that 48% of the heat load can be reduced by using this system. This reduction in heat load led to a reduction in power consumption.

Heat load reduction was studied with infrared-reflecting glaze and special insulation over the body in Ref. [93], indicating that coating which was only body-reflective and without infrared-reflecting glasses was the worst. Body insulation helped to attain a steady-state condition after one hour. With the help of the high solar reflectivity glaze (Sungate-EP) and body insulation, the comfort conditions of the cabin showed a considerable improvement. The properties of the Sungate-EP were a reflectivity of 83%, an absorptivity of 18%, and a transmissibility of around 3%. In this system, 33% of the thermal load on the cabin was reduced. The same parameters were used in both Ref. [93] and Ref. [94] showing that thermal comfort for the passenger can be achieved within a shorter period using infrared reflective glaze during the cool-down process. The replacement of the glaze with a polycarbonate sheet was the next level of research that was carried out. Low thermal conductivity and reduced mass density are the major advantages of using polycarbonate; the study in Refs. [95,96] showed that battery life was improved by 2–3%using polycarbonate sheets. A cooling load reduction of 5.9–7.1% was achieved. The reduction in power consumption increased the battery performance. The effect of weight reduction, moisture, and light transmission concerning age was not considered.

Polyvinyl butyral as a bond between two glazes was used as a window shield and its effect on range and power consumption was studied in Ref. [97]. This bond of polyvinyl butyral held the glaze pieces together even after they were broken. This absorbs the infrared rays which reduce the heat load in the air conditioner. In this arrangement, the cabin temperature was reduced by 1 °C, the air conditioner capacity was reduced by 4%, and the range improved by 0.7–1.5%. A solar intensity reduction glaze was tested to reduce the effect of infrared rays in Ref. [98]. The surface temperature of the body was reduced by 2 °C and power consumption was reduced by 20%. The pasting of anti-solar films over the glaze reduced solar radiation. The performance increased with an increase in temperature. The usage of 40%, 60% and 80% solar heat radiation reduction films resulted in heat load reductions of 14%, 18% and 29%, respectively. Reductions in fuel consumption of 11.7%, 14.4% and 18%, respectively, were also achieved using this system [99].To reduce the effect of infrared rays, two thin glaze plates were pasted with an interlayer of sliver. This arrangement reflects both ultraviolet and infrared rays effectively. To reduce the effect of the glazing and lights, blinds were also used. All glass was replaced by IRR glasses and blinds were used in windows. In this arrangement, the windshield absorptivity was reduced by 38% and transmissivity was reduced by 23%. The side window conductivity was reduced by 14% and transmissivity was reduced by 82.7% [100]. This effect reduced the heat load on the compressor.

Heat soaking, while a vehicle is parked, is the main reason for peak cabin temperature attainment. A special automated glass covering such as electro-chromatic glass can reduce heat infiltration during parking [98]. A small amount of power is supplied to the windscreen during the soaking to reduce solar power transmission. In the studies in Refs. [101,102], solar energy was used to power the glass with a solar cell. This technology is named photovoltachromic glazing. The response received for the temperature change was positive. The transmissibility was reduced by 75%, and the heat load was reduced by 33% when compared with Sungate-EP glass. The effects of different glazes on heat load are summarized in Table 6.

The study conducted in Ref. [103] suggested that a cool-coloured body, instead of black colour for a car, can reduce fuel consumption by 0.12 litres per 100 km driven. A white-coloured body reduces fuel consumption by 0.21 litres per 100 km driven, as compared to a black-coloured car. This example reflects the importance of heat load reduction initiatives for cabin space. The same work also compared white- and black-coloured compact sedan cars, and the impact of their colours on cabin temperature. When the cabin temperature was maintained at 25 °C, the white-coloured car’s cooling load was 13% less than the black-coloured car. The researchers concentrated on performance optimization methods such as heat load reduction, without compromising occupant comfort. According to the study in Ref. [90], 4.5% of compressor work can be reduced for every 1 °C reduction in cabin temperature. The work conducted in Ref. [56] estimated the shares of cabin heat load through the different cabin components for a particular vehicle.

According to Table 7, heat penetration per unit area of glass materials is higher than shell materials or other parts. To improve the driver’s road visibility and maintain a good external appearance, glass is an unavoidable material in the automobile. According to the study in Ref. [104], a 0.1 improvement in reflectance can lead to1 °C of cabin temperature reduction. The study conducted in Ref. [103] concluded that the AC cooling power requirement for low solar reflectance is 3.83 kW and the AC cooling power requirement for high solar reflectance is 3.24 kW.

Table 7.

Heat penetration through the different cabin components.

Table 6.

Effect of different glazes in heat load.

Table 6.

Effect of different glazes in heat load.

| Sl No | Type | Effects |

|---|---|---|

| 1 | Solar-reflective glazing with a dielectric layer and silver [90] | Solar radiation was reduced by 14% Reduced compressor load by 11.3% |

| 2 | Advanced Sungate windshield [91] | Reduced the compressor power by 400 W Reduction in fuel consumption by 3.4% |

| 3 | Double panel glaze (glass and polycarbonate) coated with films [92] | 48% heat load can be reduced |

| 4 | Solar reflectivity glaze (Sungate-EP) with body insulation [93,94] | 33% thermal load can be reduced |

| 5 | Polycarbonate sheet [95,96] | 5.9–7.1% cooling load can be reduced |

| 6 | Bond of polyvinyl butyral between the glaze pieces [97] | Cabin temperature was reduced by 1 °C Air conditioner capacity was reduced by 4% Range improved by 0.7–1.5% |

| 7 | Solar intensity reduction glaze [98] | The surface temperature of the body was reduced by 2 °C Power consumption was reduced by 20% |

| 8 | 40%, 60% and 80% solar heat radiation reduction films [99] | Heat load reduction in 14%, 18% and29%, respectively Reduction in fuel consumption of 11.7%, 14.4% and 18%, respectively |

| 9 | IRR glasses and blinds [100] | Reduced the heat load |

| 10 | Photovoltachromic glazing [101,105] | Transmissibility was reduced by 75% 33% thermal load can be reduced |

New materials development that increases reflectance or arrests heat penetration with some special coating should constitute the main aim of future research. The development of new materials which can help improve passive radiative cooling (which reflects radiative heat) could reduce the AC load [107].

4.2. Cabin Preconditioning

Most vehicles used for internal transportation of people, in such places as airports, parks, and hospitals, are electric vehicles. In most of these cases, the building or buildings in which they are located are themselves air conditioned, which permits the usage of an open vehicle. The usage of electric vehicles is increasing in such situations as short-distance on-road travel. This is mainly attributed to their lower air and noise pollution. Recently, the popularity of electric vehicles has been greatly increasing. In an air conditioning system, high cabin temperature due to thermal soaking uses a lot of power, which leads to a reduction in range. The study conducted in Ref. [108] showed that a vehicle which started at 11.00 am when the atmospheric temperature was 10 °C had an inside-cabin temperature of 35 °C. This effect is reduced in the early hours of the day and increases in the noon and afternoon periods. When a vehicle is started at 12.00 noon, the difference between the cabin temperature and the comfort temperature could be higher. When utilizing the battery power to reduce the cabin temperature to a more comfortable temperature, there is a reduction in range by 9.86% due to the consumption of power of the compressor. To overcome this issue, during charging or before the driver enters the vehicle, the cabin can be conditioned using the grid power. Using this arrangement, the cabin can be conditioned before the entry of the passenger, and the range can be improved by 9.86%.

To reduce the effect of the thermal soaking, an array of six solar-powered fans was arranged; this arrangement reduced the peak level temperature caused by soaking by 5–6 °C [109]. Hot air exiting from the roof vent was supported by the forced circulation of air from the floor or instrument panel. This arrangement reduced the cabin temperature by up to 7.5 °C [110]. The cooling capacity required for an air conditioner is designed based on the maximum cabin temperature. Effective methods to reduce thermal soaking could lead to a reduction in the size of the HVAC system. This should therefore constitute a prominent area for future research.

4.3. Recirculation Mode

Energy consumption for automobile air conditioning can be reduced by improving the efficiency or performance of each component of the system or by reducing the heat load in the system. This recirculation mode reduces the amount of air that is conditioned. In this method, instead of ventilating the fully conditioned air from the cabin, a certain amount of air is recirculated. This reduces the amount of energy required to condition the cabin. This recirculation method was studied in Ref. [111] using a heating mode. In this work, a certain amount of the air from the cabin was recirculated to the foot space with the help of an air vent. Freshly conditioned air is circulated to the upper portion of the body and windshield. This system ensured the supply of freshly conditioned air to the breathing zone and demisting at the windshield. This arrangement reduced the heat load by 50% and reduced power consumption. The chance of window fogging increased due to the rise in the amount of recirculated air [112]. The recirculated air flows towards the top and reaches the breathing zone. The amount and quality of air being recirculated should constitute an area of future research work [111].

The quality of the cabin air is determined by the percentage of CO2 and moisture present in the area of the passenger, in addition to the presence of odour and smoke in the space. In the study in Ref. [113], 75% recirculated air mixed with 25% fresh air was used to improve the quality of the cabin air. The total power consumption was reduced considerably. The study conducted in Ref. [114] found a relationship between heat load and the percentage of recirculated air. An equation was derived to find a good percentage of recirculated air depending on the number of passengers. When 100% recirculated air is used, only 43% of the heat load is applied, compared to systems that do not recirculate the air. The percentage of recirculated is influenced by the specific enthalpy of the cabin and outside air. If high-enthalpy air is used, then the thermal load increases. Occupant comfort depends upon the CO2 concentration inside the cabin. The amount of recirculated air must be decided based on the CO2 concentration [115], impacting energy consumption during recirculation at the maximum permissible limit of CO2. Based on the ASHRAE Fundamentals Handbook (2009), the maximum permissible CO2 concentration is 1100 ppm [115]. An equation was derived for the minimum outside air rate required by considering the anti-fog and air quality standards. The amount of recirculated air was decided considering the above conditions. During the cooling process, the total energy savings were found to be from 48.8 to 60.8%, compared to when 100% fresh air circulation was performed. This reduction in energy consumption helps to increase the range of the vehicle by 11 to 30%.

The amount of there circulated air depends on many factors, such as the number of passengers, the temperature difference between the cabin and outside air, air infiltration to the cabin, and the humidity of the air. The health and comfort of passengers are the key factors in maintaining good quality cabin air. The identification of the amount and quality of air to be recirculated, the development of an automated control system to monitor and regulate the recirculated air for optimum energy consumption and comfort, and simple mechanisms to avoid the mixing of fresh air and recirculated air in the breathing zone are recommended to constitute the areas of future research works.

4.4. Other Factors Influencing EV Range

The atmospheric temperature has also been identified to be a contributing factor to the range of an electric vehicle. According to the studies in Refs. [116,117], a range drop of 26–50% occurs when the vehicle operates at −20 °C, compared to 23 °C. An additional 4% drop in range was reported if the road was covered with new snow. A cold start uses more energy in an electric vehicle [118]. An increase in the weight of the vehicle also contributes to a reduction in the range of a vehicle [119]. Table 8 shows a summary of the various methods that can influence the range (energy consumption) of an electric vehicle.

Table 8.

Other factors and their effects on energy consumption.

Researchers presently working in this area are aiming to overcome the environmental and energy problems of air conditioning systems, using such methods as fuel cell technology, magnetic cooling systems [120], and adsorption systems. A combination of solar- and ejector-type air conditioning prototypes were developed and tested in the research in Ref. [4]. Small gas turbines were also used as range boosters in electric vehicles due to their low emissions and reduced weight [121].

5. Methodologies Identified

A vapor-compression air conditioning system is commonly used in almost every vehicle. This system consists of a compressor, condenser, expansion valve, and evaporator. The compressor uses a major share of the energy required for the operation of the system. In the case of IC engine-powered vehicles, the compressor is connected to the engine and extra fuel is used for the operation of air conditioning. Based on the atmospheric conditions present, heating or cooling of the cabin space is necessary to create comfortable conditions. In an IC engine-powered system, the engine power is used to power the cooling process, and heating can be conducted through the waste heat from the engine. Extra fuel consumption can be avoided during heating. Although there are alternative ways in which air conditioning can be achieved, such as using thermal energy storage, ejector cooling systems, vapor absorption systems, and thermo-electric generators, the automotive industry still depends on VCR systems. In the case of electric vehicles, the same vapour-compression system is used for conditioning cabin space. This system uses battery power for operation, including heating and cooling. Due to the absence of waste heat in an electric vehicle, battery power is used for heating. Compared to the cooling process, the heating process uses a major part of the battery power. This negatively affects the range of the electric vehicle.

This review of the literature reveals the efficient utilization of condensers significantly reduces energy consumption. As most automotive condensers are air-cooled systems, reaching the subcooled region of the refrigerant is a difficult task when the vehicle is moving slowly or when it is in an idle state. The condensate from the evaporator can be used as a source to cool down the condenser by utilizing the heat, including latent heat, of the condensate. This can marginally reduce the energy requirements of the condenser fan. The effects of this are discussed using water cooling and mist formation around the condenser tubes, etc. Many researchers have worked on improving the convective heat transfer using vortex generators, micro-finned condenser tubes, etc., which aids in the downsizing of the condensers. Modern condensers are tuned to enable optimum performance and, hence, any further modification may lead to only a marginal improvement in the overall system performance. As discussed in Section 2.2, compressors are the major energy-consuming component of air conditioning systems. A reduction in power consumption can be achieved by choosing the most effective low-power-consuming compressor. Electric vehicles may not require the swash plate-type conventional compressors used in engine-powered vehicles; instead, the automotive industry may switch to direct-coupled hermetically sealed compressors. Recent developments indicate that hermetically sealed scroll compressors are more efficient compressors and can reduce energy consumption by 30% when operated at various speeds.

Several studies devoted to energy saving in automotive air conditioning systems indicate that power consumption can be reduced by the optimum amount of recirculated conditioned air, the use of solar glazed surface (by the use of different types of glazes, radiant heat penetration to the cabin space through the glass panels can be reduced), parking the vehicle in a shaded space, use of solar energy or solar panels, and cabin preconditioning. Although many methodologies have been adopted aiming to reduce the power consumption by an air conditioning system in an electric car, this work aims at providing an insight into zonal cooling through which significant energy can be saved, as described below:

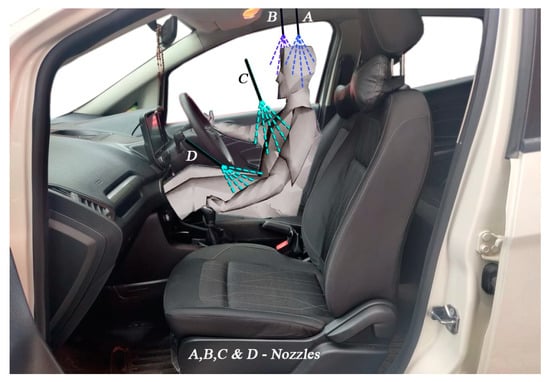

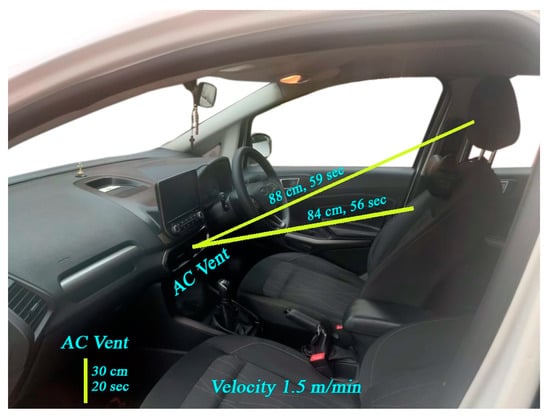

- Depending on the number of passengers, the volume of air to be conditioned can be reduced. Instead of conditioning the whole cabin space, only the surrounding space of the passengers is conditioned through localized/zonal cooling systems.

- The optimum amount of conditioned air should reach the breathing zone of the passenger at the required velocity, pressure, and temperature. The roles of the shape and position of the nozzle were considered.

5.1. Localized/Zonal Cooling

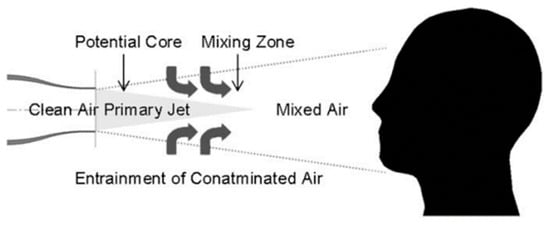

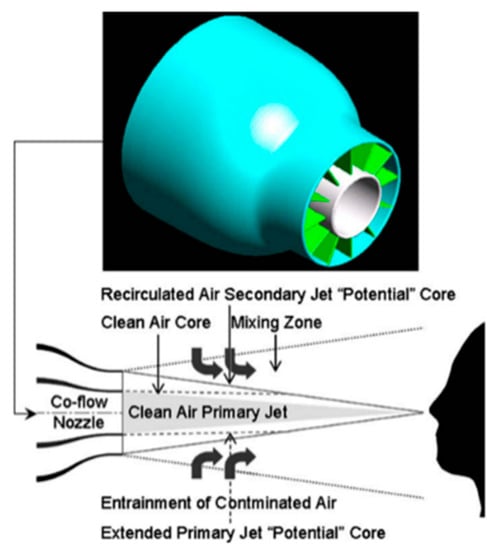

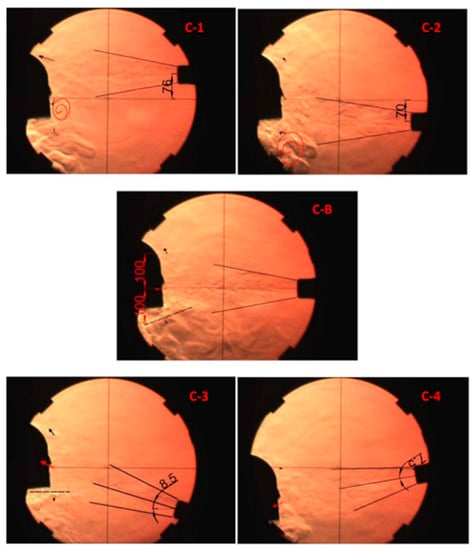

Localized cooling provides comfortable conditions to the passengers by directing the flow of conditioned air to the breathing zone at reduced turbulence and speed. In all commercial vehicles, the entire cabin volume should be conditioned to achieve comfortable conditions for the passengers. Of the total volume of the space inside a car, the passengers occupy only a small space in most driving periods. According to Neberksha, a report prepared by Schemmer Associates about the city of London in 2005 found that 85% of the time, a car was driven with a single occupant, 13% of the time with one driver with one additional passenger, and only 2% of the time was caused with three or more than three passengers [122]. The total air conditioning overconsumption significantly depends on the total volume of the space to be conditioned. Considering this real-life situation, the researchers initiated their work on localized or zonal-based air conditioning. During this process, they divided the total space into different zones. Several AC vents or nozzles were arranged in all the zones. Respective nozzles are switched on if the passenger is present in the seat. This arrangement reduces the total amount of air to be conditioned in a car.