Flow Shop Scheduling Problem and Solution in Cooperative Robotics—Case-Study: One Cobot in Cooperation with One Worker

Abstract

:1. Introduction and Related Research

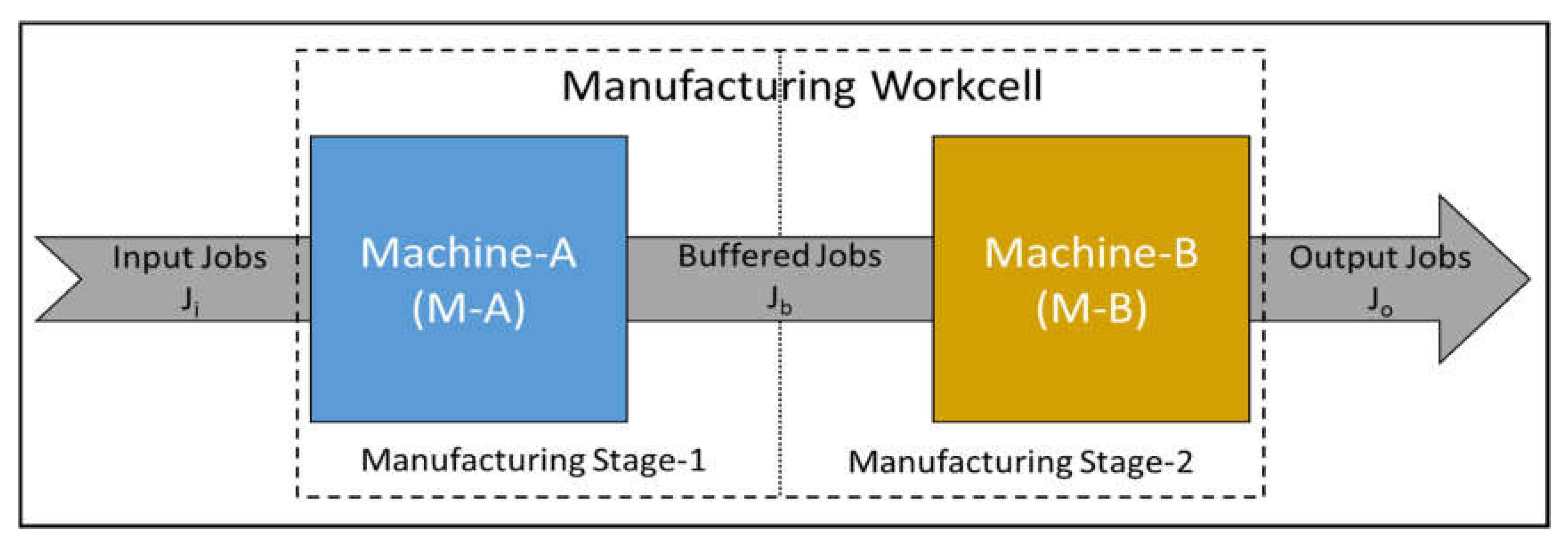

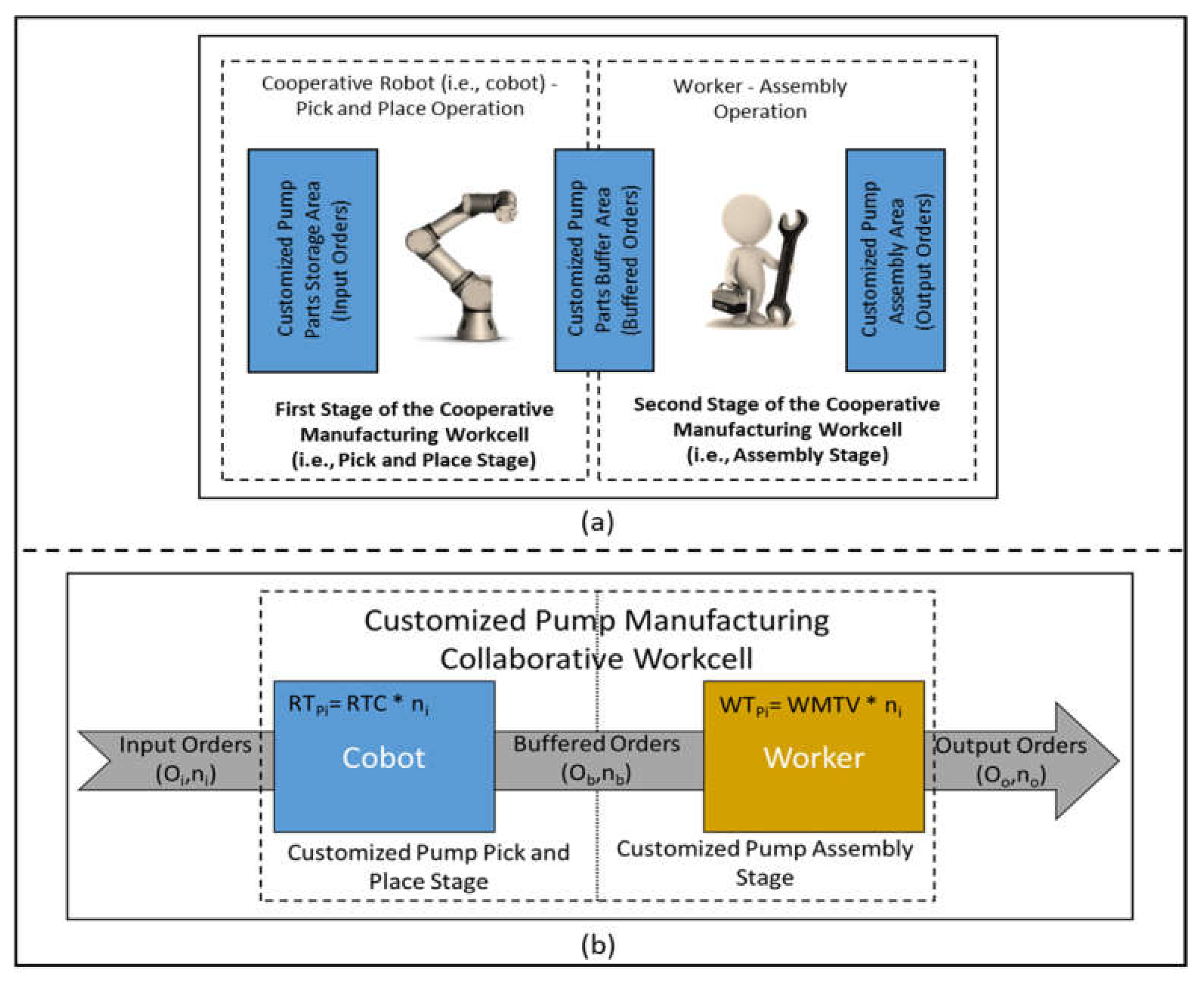

2. Case-Study Description and Problem Formulation

3. Solution Fundamentals

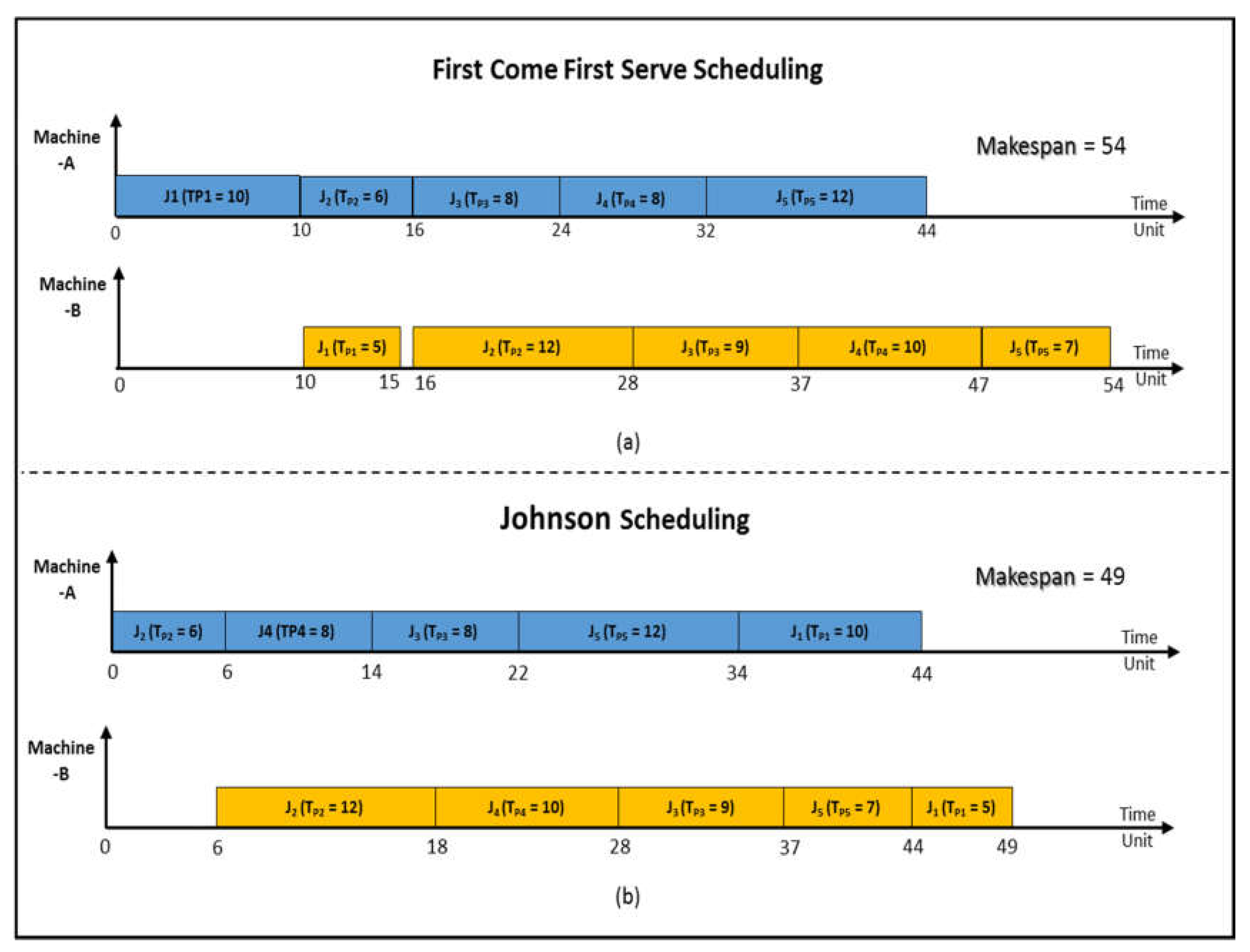

3.1. Johnson Algorithm for Two Stage Flow Shop Scheduling

- Step-1: Find the shortest processing time among all the present non-scheduled standing jobs. If two or more jobs have the same processing time. Select one of them arbitrarily.

- Step-2: If the shortest processing time locates on M-A, schedule the corresponding job as the soonest. If the shortest processing time locates on M-B, schedule the corresponding job as the latest.

- Step-3: Eliminate the job that has been scheduled from the present non-scheduled standing jobs. Repeat steps 1 and 2 till scheduling all the jobs.

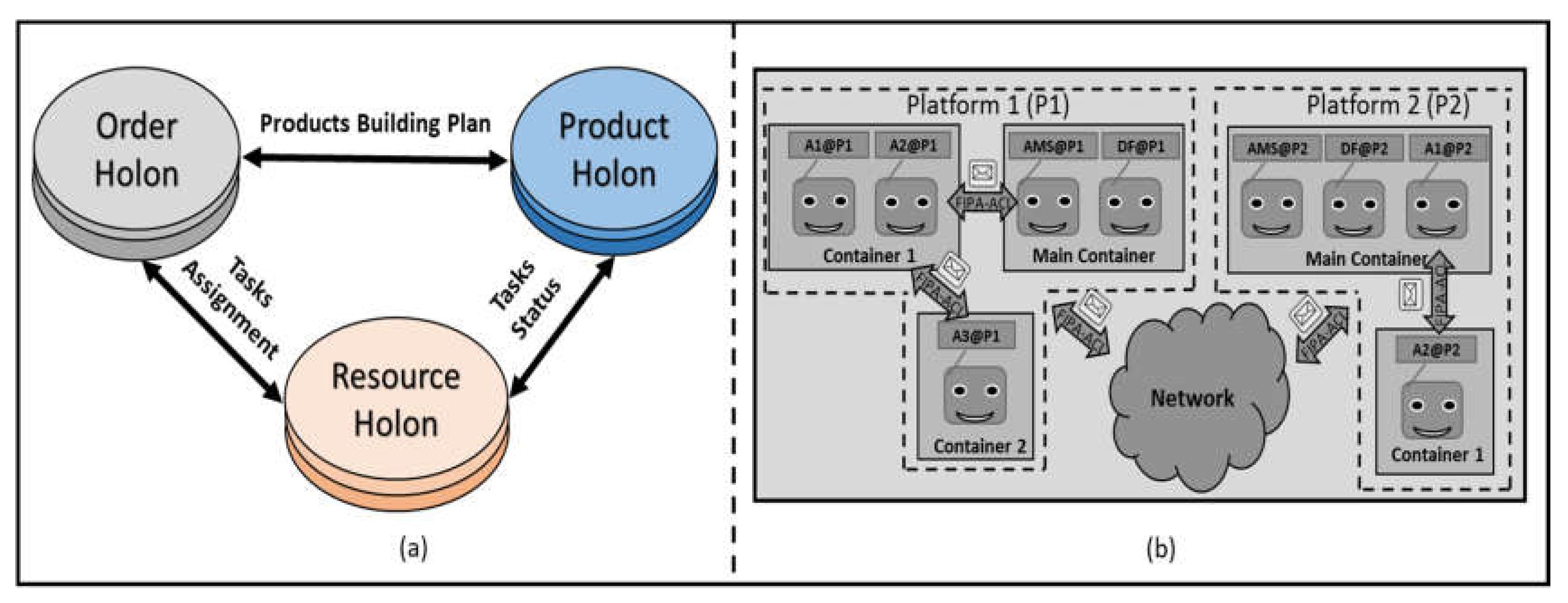

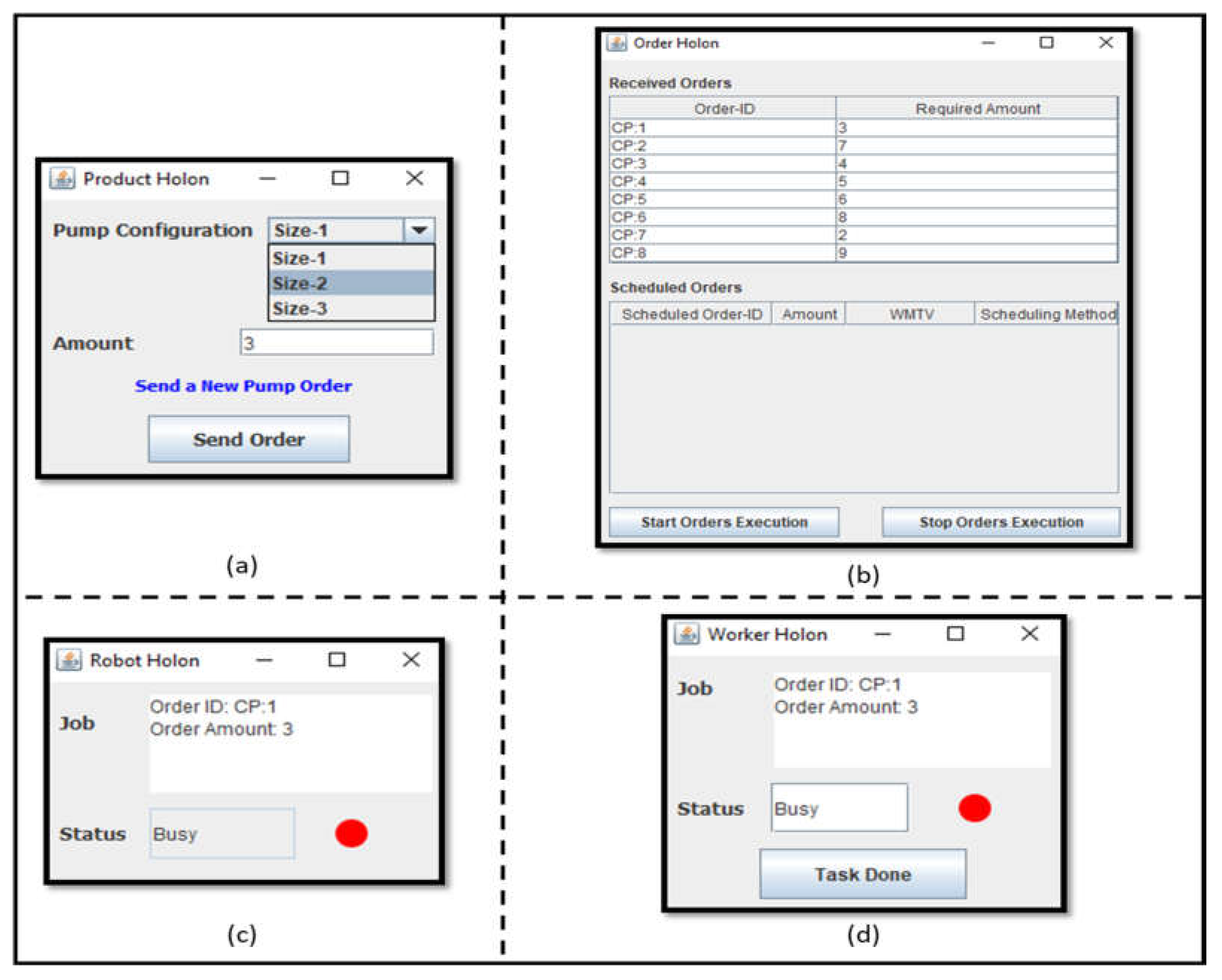

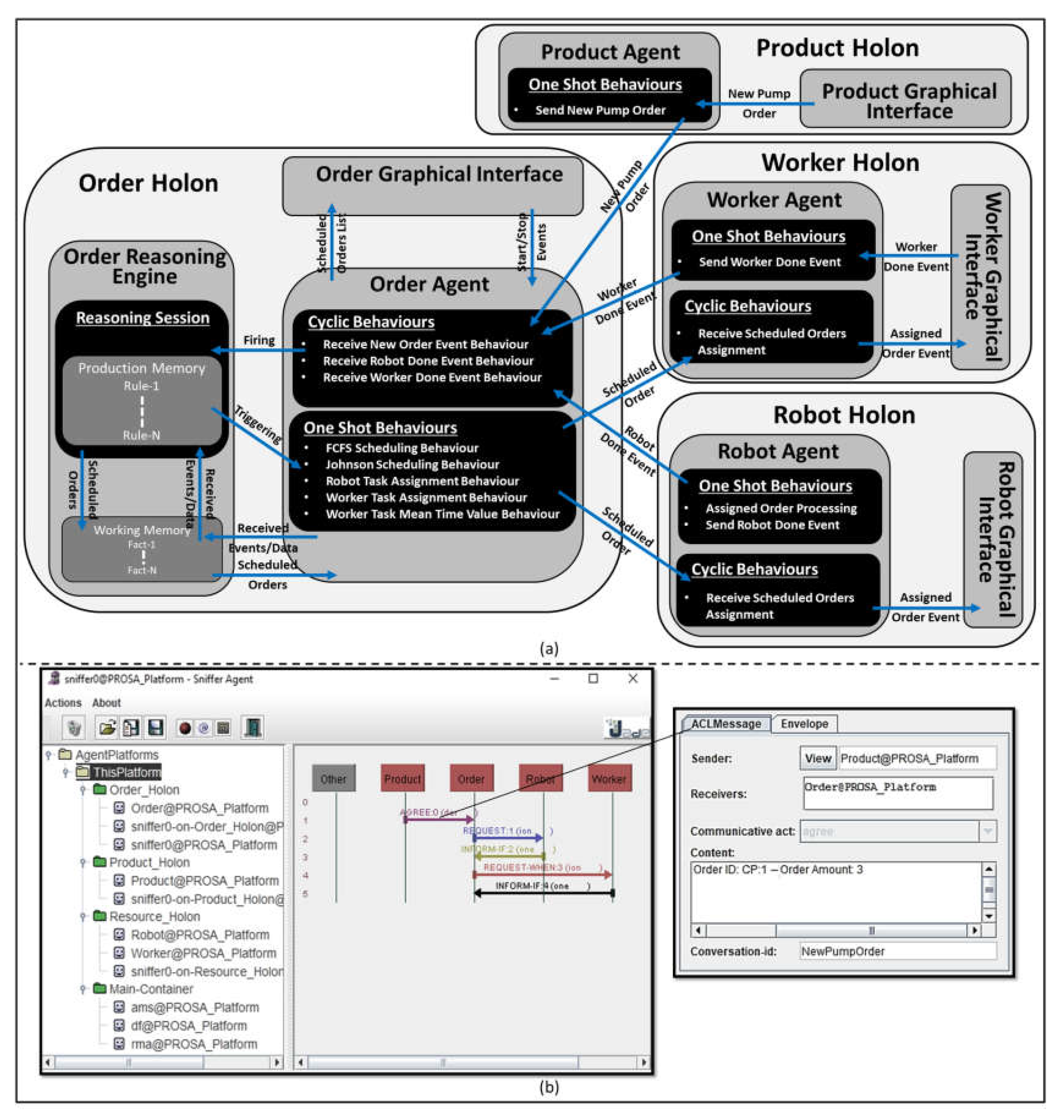

3.2. Holonic Control Architecture and Artificial Agents

- Product Holon (PH): is responsible for processing and storing the different production plans which are necessary to obtain the proper manufacturing of a certain product.

- Order Holon (OH): is responsible for composing, managing the production orders. Furthermore, in a small scale enterprise, the OH distribute the tasks assignment among the existing operating resources and hence it monitors the execution of these assigned tasks.

- Operational Resource Holon (ORH): an entity on the shop floor which represents a physical object such as a machine, a robot, or a worker.

3.3. Rule Management System and Drools

- Forward reasoning chaining: in forward reasoning chaining, the RMS starts with a set of initial facts then it determines new facts every time a rule matches a fact. The RMS will go through a chain of rules firing sessions to reach its final target, which ultimately leads to find the solution route from the initial facts to the final goal in a forward approach of reasoning.

- Backward reasoning chaining: in backward reasoning chaining, the RMS starts from the final goal, then it finds which rules must be fired to lead to this goal, therefore the RMS can determine the facts which are needed to reach the final goal. During the backward chaining, a consequence of sub-goals will appear, which ultimately leads to find the solution route from the final goal to the initial sub-goal in a backward approach of reasoning.

4. Solution Implementation

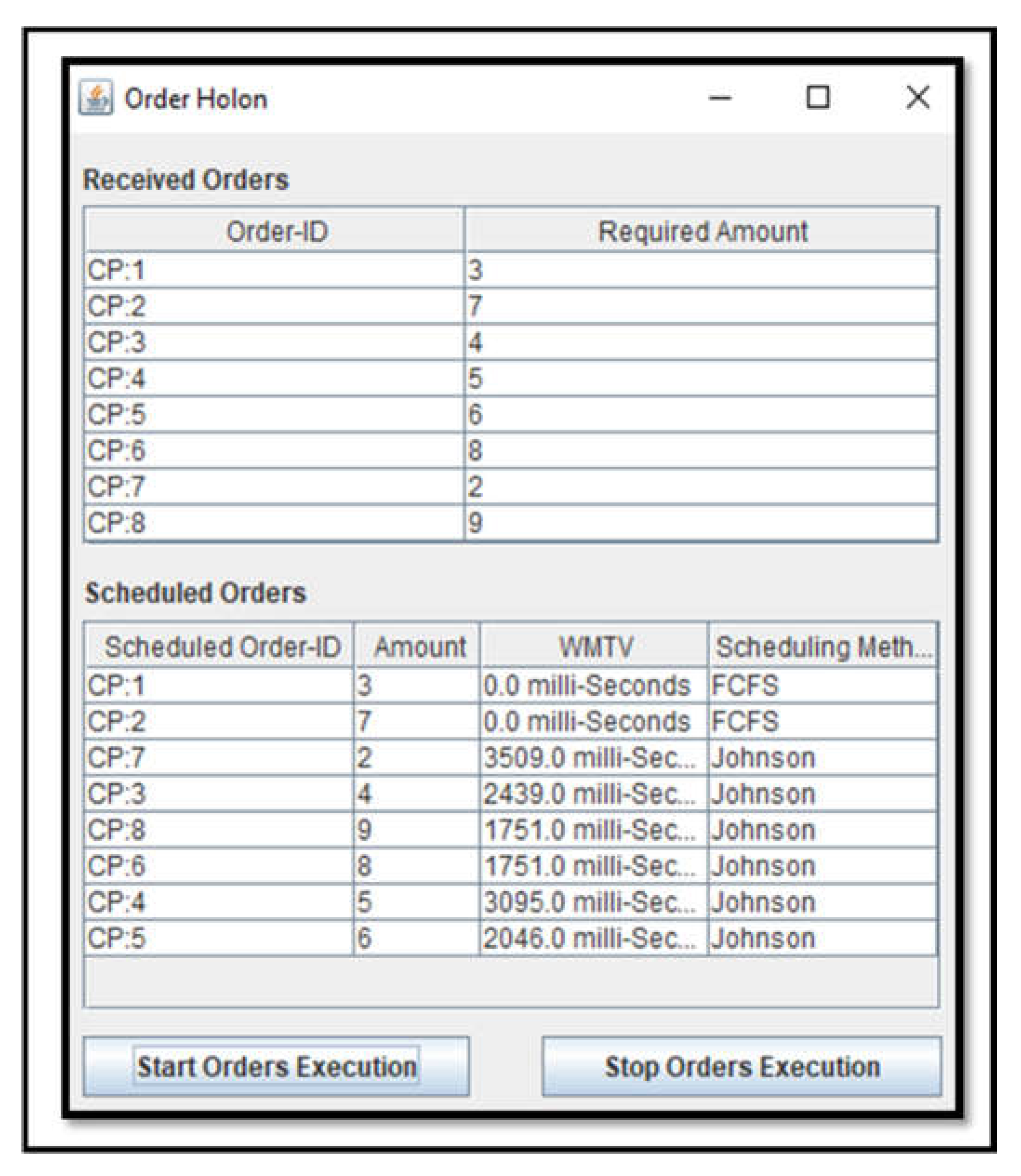

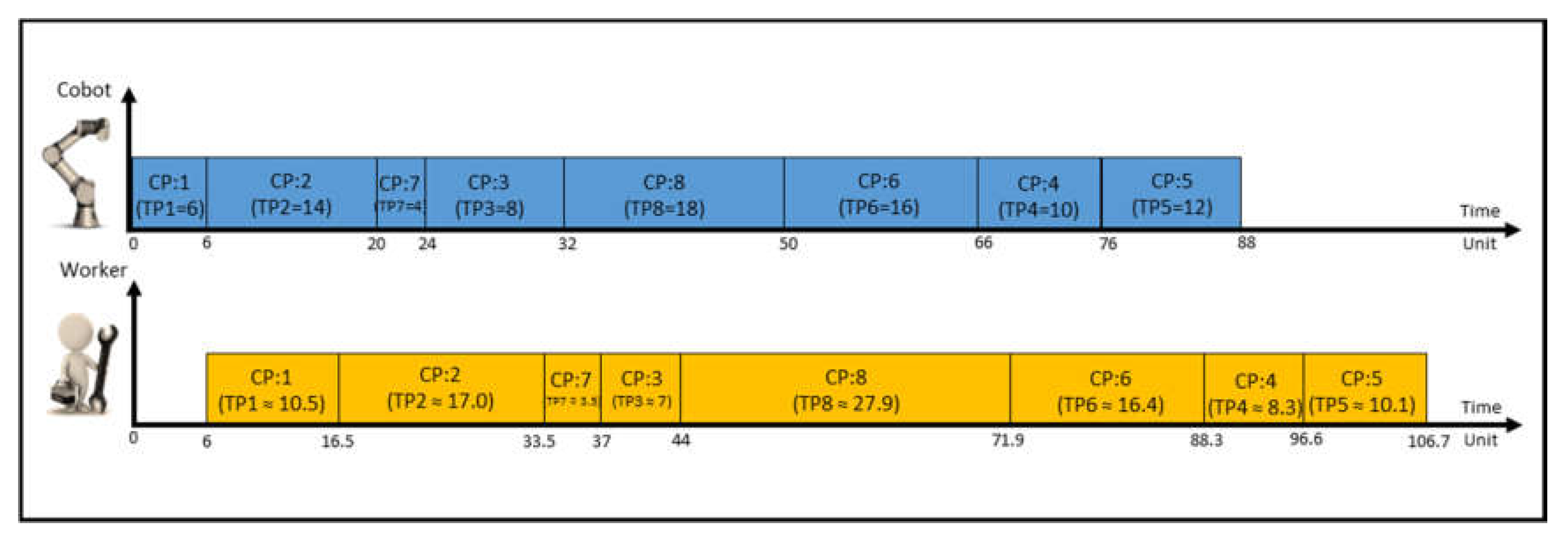

4.1. Johnson Algorithm for Two Stages Flow Shop Scheduling

4.2. Holonic Control Architecture Implementation

5. Summary, Conclusions, and Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sadik, A.; Urban, B. A Holonic Control System Design for a Human & Industrial Robot Cooperative Workcell. In Proceedings of the 2016 International Conference on Autonomous Robot Systems and Competitions (ICARSC), Bragança, Portugal, 4–6 May 2016; pp. 118–123. [Google Scholar]

- Elmaraghy, H.A. Flexible and reconfigurable manufacturing systems paradigms. Int. J. Flex. Manuf. Syst. 2005, 17, 261–276. [Google Scholar] [CrossRef]

- Sadik, A.; Bodo, U. Combining Adaptive Holonic Control and ISA-95 Architectures to Self-Organize the Interaction in a Worker-Industrial Robot Cooperative Workcell. Future Internet 2017, 9, 35. [Google Scholar] [CrossRef]

- Tsarouchi, P.; Michalos, G.; Makris, S.; Athanasatos, T.; Dimoulas, K.; Chryssolouris, G. On a human–robot workplace design and task allocation system. Int. J. Comput. Integr. Manuf. 2017, 1–8. [Google Scholar] [CrossRef]

- Pellegrinelli, S.; Moro, F.; Pedrocchi, N.; Molinari Tosatti, L.; Tolio, T. A probabilistic approach to workspace sharing for human–robot cooperation in assembly tasks. CIRP Ann.-Manuf. Technol. 2016, 65, 57–60. [Google Scholar] [CrossRef]

- Stevenson, W.; Ness, P. Study Guide for Use with Production/Operations Management; McGraw-Hill: Boston, MA, USA, 1999. [Google Scholar]

- Grzechca, W. Manufacturing in Flow Shop and Assembly Line Structure. Int. J. Mater. Mech. Manuf. 2015, 4, 25–30. [Google Scholar] [CrossRef]

- Al-Harkan, I.M. On Merging Sequencing and Scheduling Theory with Genetic Algorithms to Solve Stochastic Job Shops. PH.D. Thesis, University of Oklahoma, Norman, OK, USA, 1997. [Google Scholar]

- Babiceanu, R.; Chen, F. Development and Applications of Holonic Manufacturing Systems: A Survey. J. Intell. Manuf. 2006, 17, 111–131. [Google Scholar] [CrossRef]

- Van Brussel, H.; Wyns, J.; Valckenaers, P.; Bongaerts, L.; Peeters, P. Reference architecture for holonic manufacturing systems: PROSA. Comput. Ind. 1998, 37, 255–274. [Google Scholar] [CrossRef]

- Botti, V.; Giret, A. Holonic Manufacturing Systems. In ANEMONA—A Multi-Agent Methodology for Holonic Manufacturing Systems, 1st ed.; Springer: London, UK, 2008; pp. 7–20. [Google Scholar]

- Jennings, N.; Wooldridge, M. Agent Technology, 1st ed.; Springer: Berlin, Germany, 1998; pp. 3–28. [Google Scholar]

- Shen, W.; Hao, Q.; Yoon, H.; Norrie, D. Applications of agent-based systems in intelligent manufacturing: An updated review. Adv. Eng. Inform. 2006, 20, 415–431. [Google Scholar] [CrossRef]

- De Meo, P.; Messina, F.; Rosaci, D.; Sarné, G. An agent-oriented, trust-aware approach to improve the QoS in dynamic grid federations. Concurr. Comput. Prac. Exp. 2015, 27, 5411–5435. [Google Scholar] [CrossRef]

- Jade Site. Available online: http://jade.tilab.com/ (accessed on 8 January 2017).

- Teahan, W. Artificial Intelligence–Agent Behavior, 1st ed.; BookBoon: London, UK, 2010. [Google Scholar]

- Bellifemine, F.; Caire, G.; Greenwood, D. Developing Multi-Agent Systems with JADE, 1st ed.; Wiley: Chichester, UK, 2008. [Google Scholar]

- FIPA Site. Available online: http://www.fipa.org/ (accessed on 1 February 2017).

- Ordóñez, A.; Eraso, L.; Ordóñez, H.; Merchan, L. Comparing Drools and Ontology Reasoning Approaches for Automated Monitoring in Telecommunication Processes. Procedia Comput. Sci. 2016, 95, 353–360. [Google Scholar] [CrossRef]

- Al-Ajlan, A. The Comparison between Forward and Backward Chaining. Int. J. Mach. Learn. Comput. 2015, 5, 106–113. [Google Scholar] [CrossRef]

- Drools Expert User Guide. Available online: https://docs.jboss.org/drools/release/5.2.0.CR1/drools-expert-docs/html_single/ (accessed on 18 April 2017).

| Unscheduled Jobs List | First Come First Serve Scheduling | Johnson Scheduling | ||||||

|---|---|---|---|---|---|---|---|---|

| Ji | TPi@M-A | TPi@M-B | Ji | TOi@M-A | TOi@M-B | Ji | TOi@M-A | TOi@M-B |

| J1 | 10 | 5 | J1 | 0:10 | 10:15 | J2 | 0:6 | 6:18 |

| J2 | 6 | 12 | J2 | 10:16 | 16:28 | J4 | 6:14 | 18:28 |

| J3 | 8 | 9 | J3 | 16:24 | 28:37 | J3 | 14:22 | 28:37 |

| J4 | 8 | 10 | J4 | 24:32 | 37:47 | J5 | 22:34 | 37:44 |

| J5 | 12 | 7 | J5 | 32:44 | 47:54 | J1 | 34:44 | 44:49 |

| Unscheduled Jobs List | Johnson Scheduling Case-1: RTC ≤ WMTV | Johnson Scheduling Case-2: RTC ≥ WMTV | ||||||

|---|---|---|---|---|---|---|---|---|

| Ji = (Oi, ni) | RTPi | WTPi | Ji | RTPi | WTPi | Ji | RTPi | WTPi |

| J1 = (O1, n1) | RTC * n1 | WMTV * n1 | J1 | RTC * n1 | WMTV * n1 | J2 | RTC * n2 | WMTV * n2 |

| J2 = (O2, n2) | RTC * n2 | WMTV * n2 | J2 | RTC * n2 | WMTV * n2 | J1 | RTC * n1 | WMTV * n1 |

| Event | State Rule | Action | State Explanation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Start Flag | Stop Flag | Worker Done Counter | Robot Status | Worker Status | Received Orders List | Scheduled Orders List | |||

| New Order Event | True | False | Equal to 0 | Free | Don’t Care | Don’t Care | Don’t Care | -FCFS scheduling -Robot order assignment | -New order event is received at the very beginning. -New order event is received after the robot is done with all the previously assigned orders, while the worker has not finished the first assigned order. |

| New Order Event | True | False | Equal to 0 | Busy | Don’t Care | Don’t Care | Don’t Care | -FCFS scheduling | -New order event is received while the robot is executing one previously assigned order, while the worker has not finished the first assigned order. |

| New Order Event | True | False | Greater than 0 | Free | Don’t Care | Don’t Care | Don’t Care | -Johnson scheduling -Robot order assignment | -New order event is received after the robot is done with all the previously assigned order, while the worker has finished at least the first assigned order. |

| New Order Event | True | False | Greater than 0 | Busy | Don’t Care | Don’t Care | Don’t Care | -Johnson scheduling | -New order event is received while the robot is executing one previously assigned order, while the worker has finished at least the first assigned order. |

| Robot Done Event | True | False | Equal to 0 | Don’t Care | Free | Not Empty | Don’t Care | -FCFS scheduling -Worker order assignment | -The robot finished one assigned order while the worker is free and has not assigned any previous order. |

| Robot Done Event | True | False | Equal to 0 | Don’t Care | Busy | Not Empty | Don’t Care | -FCFS scheduling | -The robot finished one assigned order while the worker is executing the first assigned order. |

| Robot Done Event | True | False | Greater than 0 | Don’t Care | Free | Not Empty | Don’t Care | -Johnson scheduling -Worker order assignment | -The robot finished one assigned order while the worker is free and has finished at least one assigned order. |

| Robot Done Event | True | False | Greater than 0 | Don’t Care | Busy | Not Empty | Don’t Care | -Johnson scheduling | -The robot finished one assigned order while the worker is busy and has finished at least one assigned order. |

| Worker Done Event | True | False | Don’t Care | Don’t Care | Don’t Care | Don’t Care | Not Empty | -Calculate the order execution average time -Worker task assignment | -The worker finished one assigned order while still there is at least one order in the scheduled orders list. |

| Worker Done Event | True | False | Don’t Care | Don’t Care | Don’t Care | Don’t Care | Empty | -Calculate the order execution average time | -The worker finished one assigned order while the scheduled orders list is empty. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadik, A.R.; Urban, B. Flow Shop Scheduling Problem and Solution in Cooperative Robotics—Case-Study: One Cobot in Cooperation with One Worker. Future Internet 2017, 9, 48. https://doi.org/10.3390/fi9030048

Sadik AR, Urban B. Flow Shop Scheduling Problem and Solution in Cooperative Robotics—Case-Study: One Cobot in Cooperation with One Worker. Future Internet. 2017; 9(3):48. https://doi.org/10.3390/fi9030048

Chicago/Turabian StyleSadik, Ahmed R., and Bodo Urban. 2017. "Flow Shop Scheduling Problem and Solution in Cooperative Robotics—Case-Study: One Cobot in Cooperation with One Worker" Future Internet 9, no. 3: 48. https://doi.org/10.3390/fi9030048

APA StyleSadik, A. R., & Urban, B. (2017). Flow Shop Scheduling Problem and Solution in Cooperative Robotics—Case-Study: One Cobot in Cooperation with One Worker. Future Internet, 9(3), 48. https://doi.org/10.3390/fi9030048