Collaborative Fusion Attention Mechanism for Vehicle Fault Prediction

Abstract

1. Introduction

- To maximize the correlation between different faults and the impact of key faults on future fault prediction, this study proposes a vehicle fault prediction model utilizing a collaborative modeling approach through multiple attention mechanisms.

- To fully exploit the correlation between diverse faults, this research study proposes a fault correlation information fusion representation module grounded in a graph attention mechanism.

- To accurately capture the significant impact of key faults on subsequent faults, this research study introduces a novel learning method synergizing the Long Short-Term Memory (LSTM) network with an attention mechanism.

- Extensive experiments were conducted using real-world vehicle fault data, revealing that our model significantly outperforms existing advanced prediction models.

2. Related Work

2.1. Power and Drivetrain Fault Prediction

2.2. Chassis and Operating System Fault Prediction

2.3. Electronic and Safety Systems Fault Prediction

2.4. Critical Synthesis and Research Gap

3. Proposed Model

3.1. Framework

- Fusion representation of fault correlation information. This module employs a graph attention mechanism to learn and integrate correlation features among different faults, constructing a fused representation of their interdependencies.

- Key temporal information learning. This module combines a Long Short-Term Memory (LSTM) network with an attention mechanism to extract and weight critical fault information from historical sequences.

- Synthesis, integration, and prediction. This final module synthesizes the outputs from the previous two components using an attention mechanism for enhanced integration. The resulting comprehensive representation is subsequently used for fault prediction.

3.2. Fusion Representation of Fault Correlation Information

3.3. Key Temporal Information Learning

3.4. Comprehensive Fusion Prediction

3.5. Model Optimization

4. Experimental Results and Analysis

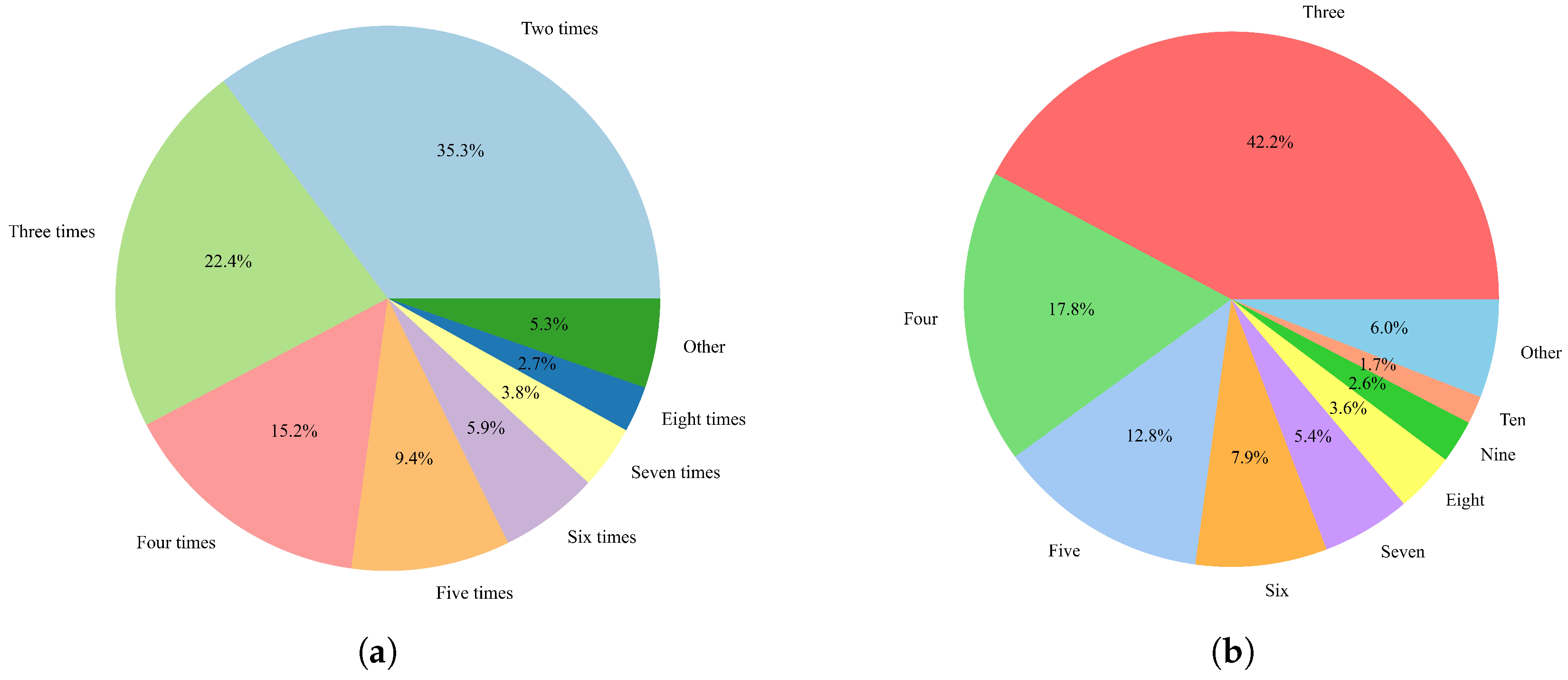

4.1. Dataset Description

4.2. Baseline Models and Evaluation Metrics

4.3. Implementation Details

4.4. Prediction Performance

4.5. Ablation Study

- CFATM-NoGraph: This variant verifies its functionality by removing the input of the Fusion representation of fault correlation information, resulting in Y = D.

- CFATM-NoTemporal: This variant seeks to elucidate the function of the Key temporal information learning component by excluding the inputs of D, resulting in Y = S.

- CFATM-NoAttnFusion: To elucidate the importance of the attention mechanism for integration and prediction, the the attention mechanism is excluded in this variant, such that Y = D + S.

4.6. Parameter Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Qi, J. Enhanced particle filter and cyclic spectral coherence based prognostics of rolling element bearings. In Proceedings of the PHM Society European Conference, Utrecht, The Netherlands, 3–6 July 2018; Volume 4. [Google Scholar]

- Qi, J.; Chen, Z.; Uhlmann, Y.; Schullerus, G. Sensorless robust anomaly detection of roller chain systems based on motor driver data and deep weighted KNN. IEEE Trans. Instrum. Meas. 2024, 74, 3502613. [Google Scholar] [CrossRef]

- Qi, J.; Chen, Z.; Kong, Y.; Qin, W.; Qin, Y. Attention-guided graph isomorphism learning: A multi-task framework for fault diagnosis and remaining useful life prediction. Reliab. Eng. Syst. Saf. 2025, 263, 111209. [Google Scholar] [CrossRef]

- Wang, M.-H.; Chao, K.-H.; Sung, W.-T.; Huang, G.-J. Using ENN-1 for fault recognition of automotive engine. Expert Syst. Appl. 2010, 37, 2943–2947. [Google Scholar] [CrossRef]

- Wu, J.-D.; Kuo, J.-M. Fault conditions classification of automotive generator using an adaptive neuro-fuzzy inference system. Expert Syst. Appl. 2010, 37, 7901–7907. [Google Scholar] [CrossRef]

- Bafroui, H.H.; Ohadi, A. Application of wavelet energy and Shannon entropy for feature extraction in gearbox fault detection under varying speed conditions. Neurocomputing 2014, 133, 437–445. [Google Scholar] [CrossRef]

- Wong, P.K.; Zhong, J.; Yang, Z.; Vong, C.M. Sparse Bayesian extreme learning committee machine for engine simultaneous fault diagnosis. Neurocomputing 2016, 174, 331–343. [Google Scholar] [CrossRef]

- Mohammadi, A.; Djerdir, A.; Steiner, N.Y.; Bouquain, D.; Khaburi, D. Diagnosis of PEMFC for automotive application. In Proceedings of the 2015 5th International Youth Conference on Energy (IYCE), Pisa, Italy, 27–30 May 2015; pp. 1–6. [Google Scholar]

- Sankavaram, C.; Pattipati, B.; Pattipati, K.; Zhang, Y.; Howell, M.; Salman, M. Data-driven fault diagnosis in a hybrid electric vehicle regenerative braking system. In Proceedings of the 2012 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2012; pp. 1–11. [Google Scholar]

- Yang, R.; Xiong, R.; He, H.; Chen, Z. A fractional-order model-based battery external short circuit fault diagnosis approach for all-climate electric vehicles application. J. Clean. Prod. 2018, 187, 950–959. [Google Scholar] [CrossRef]

- Wang, Y.S.; Liu, N.N.; Guo, H.; Wang, X.L. An engine-fault-diagnosis system based on sound intensity analysis and wavelet packet pre-processing neural network. Eng. Appl. Artif. Intell. 2020, 94, 103765. [Google Scholar] [CrossRef]

- Zuo, J.; Lv, H.; Zhou, D.; Xue, Q.; Jin, L.; Zhou, W.; Yang, D.; Zhang, C. Deep learning based prognostic framework towards proton exchange membrane fuel cell for automotive application. Appl. Energy 2021, 281, 115937. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Z.; Deng, Z.; Hu, B. Hybrid data fusion DBN for intelligent fault diagnosis of vehicle reducers. Sensors 2019, 19, 2504. [Google Scholar] [CrossRef]

- Branco, C.T.N.M.; Fontanela, J.M. A design methodology to employ digital twins for remaining useful lifetime prediction in electric vehicle batteries. In Proceedings of the SAE Brasil 2023 Congress, São Paulo, Brazil, 10–11 October 2024. SAE Technical Paper. [Google Scholar]

- Molaie, M.; Zippo, A.; Pellicano, F. Neural Network-Based Estimation of Gear Safety Factors from ISO-Based Simulations. Symmetry 2025, 17, 1312. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Zhai, S.; Hu, Z. Data-driven modeling and fault diagnosis for fuel cell vehicles using deep learning. Energy AI 2024, 16, 100345. [Google Scholar] [CrossRef]

- Ghimire, R.; Sankavaram, C.; Ghahari, A.; Pattipati, K.; Ghoneim, Y.; Howell, M.; Salman, M. Integrated model-based and data-driven fault detection and diagnosis approach for an automotive electric power steering system. In Proceedings of the 2011 IEEE Autotestcon, Baltimore, MD, USA, 12–15 September 2011; pp. 70–77. [Google Scholar]

- Yin, S.; Huang, Z. Performance monitoring for vehicle suspension system via fuzzy positivistic C-means clustering based on accelerometer measurements. IEEE/ASME Trans. Mechatronics 2014, 20, 2613–2620. [Google Scholar] [CrossRef]

- Wang, G.; Yin, S. Data-driven fault diagnosis for an automobile suspension system by using a clustering based method. J. Frankl. Inst. 2014, 351, 3231–3244. [Google Scholar] [CrossRef]

- Jegadeeshwaran, R.; Sugumaran, V. Brake fault diagnosis using Clonal Selection Classification Algorithm (CSCA)–A statistical learning approach. Eng. Sci. Technol. Int. J. 2015, 18, 14–23. [Google Scholar] [CrossRef]

- Capriglione, D.; Carratù, M.; Liguori, C.; Paciello, V.; Sommella, P. A soft stroke sensor for motorcycle rear suspension. Measurement 2017, 106, 46–52. [Google Scholar] [CrossRef]

- Ghimire, R.; Zhang, C.; Pattipati, K.R. A rough set-theory-based fault-diagnosis method for an electric power-steering system. IEEE/ASME Trans. Mechatronics 2018, 23, 2042–2053. [Google Scholar] [CrossRef]

- Manghai, T.M.A.; Jegadeeshwaran, R. Vibration based brake health monitoring using wavelet features: A machine learning approach. J. Vib. Control. 2019, 25, 2534–2550. [Google Scholar] [CrossRef]

- Zehelein, T.; Hemmert-Pottmann, T.; Lienkamp, M. Diagnosing automotive damper defects using convolutional neural networks and electronic stability control sensor signals. J. Sens. Actuator Netw. 2020, 9, 8. [Google Scholar] [CrossRef]

- Jeong, K.; Choi, S.B.; Choi, H. Sensor fault detection and isolation using a support vector machine for vehicle suspension systems. IEEE Trans. Veh. Technol. 2020, 69, 3852–3863. [Google Scholar] [CrossRef]

- Siegel, J.E.; Sun, Y.; Sarma, S. Automotive diagnostics as a service: An artificially intelligent mobile application for tire condition assessment. In Proceedings of the Artificial Intelligence and Mobile Services–AIMS 2018: 7th International Conference, Held as Part of the Services Conference Federation, SCF 2018. Seattle, WA, USA, 25–30 June 2018. [Google Scholar]

- Nowaczyk, S.; Prytz, R.; Rögnvaldsson, T.; Byttner, S. Towards a machine learning algorithm for predicting truck compressor faults using logged vehicle data. In Proceedings of the 12th Scandinavian Conference on Artificial Intelligence, Aalborg, Denmark, 20–22 November 2013; pp. 205–214. [Google Scholar]

- Cerqueira, V.; Pinto, F.; Sá, C.; Soares, C. Combining boosted trees with metafeature engineering for predictive maintenance. In Advances in Intelligent Data Analysis XV; Springer: Cham, Switzerland, 2016; pp. 393–397. [Google Scholar]

- Rengasamy, D.; Jafari, M.; Rothwell, B.; Chen, X.; Figueredo, G.P. Deep learning with dynamically weighted loss function for sensor-based prognostics and health management. Sensors 2020, 20, 723. [Google Scholar] [CrossRef]

- Fang, Y.; Cheng, C.; Dong, Z.; Min, H.; Zhao, X. A fault diagnosis framework for autonomous vehicles based on hybrid data analysis methods combined with fuzzy PID control. In Proceedings of the 2020 3rd International Conference on Unmanned Systems (ICUS), Harbin, China, 27–28 November 2020; pp. 281–286. [Google Scholar]

- Biddle, L.; Fallah, S. A novel fault detection, identification and prediction approach for autonomous vehicle controllers using SVM. Automot. Innov. 2021, 4, 301–314. [Google Scholar] [CrossRef]

- Safavi, S.; Safavi, S.A.; Hamid, H.; Fallah, S. Multi-sensor fault detection, identification, isolation and health forecasting for autonomous vehicles. Sensors 2021, 21, 2547. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Wei, G.; Song, K.; Chen, Y. High-accuracy health prediction of sensor systems using improved relevant vector-machine ensemble regression. Knowl.-Based Syst. 2021, 212, 106555. [Google Scholar] [CrossRef]

- Giordano, D.; Giobergia, F.; Pastor, E.; Macchia, A.L.; Cerquitelli, T.; Baralis, E.; Mellia, M.; Tricarico, D. Data-driven strategies for predictive maintenance: Lesson learned from an automotive use case. Comput. Ind. 2022, 134, 103554. [Google Scholar] [CrossRef]

- Ren, D.; Huang, H.; Li, Y.; Jin, J. High-Risk Test Scenario Generation for Autonomous Vehicles at Roundabouts Using Naturalistic Driving Data. Appl. Sci. 2025, 15, 4505. [Google Scholar] [CrossRef]

- Veličković, P.; Cucurull, G.; Casanova, A.; Romero, A.; Lio, P.; Bengio, Y. Graph attention networks. arXiv 2017, arXiv:1710.10903. [Google Scholar]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. Adv. Neural Inf. Process. Syst. 2017, 30. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Fu, R.; Zhang, Z.; Li, L. Using LSTM and GRU neural network methods for traffic flow prediction. In Proceedings of the 2016 31st Youth Academic Annual Conference of Chinese Association of Automation (YAC), Wuhan, China, 11–13 November 2016; pp. 324–328. [Google Scholar]

- Jiang, J.; Han, C.; Zhao, W.X.; Wang, J. Pdformer: Propagation delay-aware dynamic long-range transformer for traffic flow prediction. In Proceedings of the AAAI Conference on Artificial Intelligence, Washington, DC, USA, 7–14 February 2023; Volume 37, pp. 4365–4373. [Google Scholar]

- Liu, H.; Dong, Z.; Jiang, R.; Deng, J.; Deng, J.; Chen, Q.; Song, X. Spatio-temporal adaptive embedding makes vanilla transformer sota for traffic forecasting. In Proceedings of the 32nd ACM International Conference on Information and Knowledge Management, Birmingham, UK, 21–25 October 2023; pp. 4125–4129. [Google Scholar]

- Ma, F.; Chitta, R.; Zhou, J.; You, Q.; Sun, T.; Gao, J. Dipole: Diagnosis prediction in healthcare via attention-based bidirectional recurrent neural networks. In Proceedings of the 23rd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Halifax, NS, Canada, 13–17 August 2017; pp. 1903–1911. [Google Scholar]

| Description | Value |

|---|---|

| Total number of vehicles | 7932 |

| Unique fault types recorded | 2240 |

| Maximum events for a single vehicle | 45 |

| Average events per vehicle | 3.89 |

| Maximum faults in a single event | 51 |

| Average faults per maintenance event | 5.19 |

| Model | w−F1 | R@5 | R@10 | R@15 | R@20 | R@25 | R@30 | R@35 |

|---|---|---|---|---|---|---|---|---|

| MLP | 31.57 ± 0.42 | 52.64 ± 0.15 | 57.65 ± 0.11 | 62.57 ± 0.13 | 66.51 ± 0.19 | 69.73 ± 0.14 | 70.81 ± 0.10 | 72.23 ± 0.18 |

| RNN | 32.31 ± 0.66 | 52.94 ± 0.09 | 58.37 ± 0.20 | 63.04 ± 0.17 | 67.34 ± 0.16 | 70.23 ± 0.15 | 72.33 ± 0.12 | 73.53 ± 0.10 |

| LSTM | 32.09 ± 0.80 | 53.30 ± 0.18 | 57.58 ± 0.17 | 62.38 ± 0.11 | 66.82 ± 0.14 | 70.25 ± 0.16 | 73.82 ± 0.19 | 75.66 ± 0.15 |

| GRU | 32.20 ± 0.43 | 53.11 ± 0.20 | 57.70 ± 0.12 | 62.89 ± 0.14 | 67.44 ± 0.13 | 70.46 ± 0.11 | 72.76 ± 0.17 | 74.16 ± 0.09 |

| Dipole | 32.59 ± 0.31 | 52.88 ± 0.21 | 57.73 ± 0.16 | 62.66 ± 0.10 | 67.45 ± 0.18 | 70.61 ± 0.15 | 73.66 ± 0.12 | 75.49 ± 0.13 |

| Transformer | 31.63 ± 0.19 | 52.74 ± 0.12 | 57.37 ± 0.14 | 62.64 ± 0.20 | 66.71 ± 0.16 | 70.03 ± 0.13 | 71.34 ± 0.19 | 73.23 ± 0.11 |

| PDFormer | 31.68 ± 0.31 | 52.78 ± 0.32 | 57.43 ± 0.41 | 62.67 ± 0.23 | 66.78 ± 0.36 | 70.09 ± 0.31 | 71.37 ± 0.41 | 73.29 ± 0.31 |

| STAEformer | 31.71 ± 0.43 | 52.82 ± 0.64 | 57.46 ± 0.32 | 62.73 ± 0.27 | 66.77 ± 0.49 | 70.12 ± 0.35 | 71.42 ± 0.58 | 73.32 ± 0.46 |

| CFATM | 33.62 ** ± 0.47 | 54.38 ** ± 0.58 | 60.62 ** ± 1.18 | 65.87 ** ± 1.02 | 69.66 ** ± 0.89 | 73.11 ** ± 0.37 | 78.16 ** ± 0.13 | 78.16 ** ± 0.23 |

| Variant | Ablation Strategy | R@5 | R@10 | R@15 | R@20 | R@25 | R@30 | R@35 | |

|---|---|---|---|---|---|---|---|---|---|

| CFATM | None | 33.62 | 54.38 | 60.62 | 65.87 | 69.66 | 73.11 | 78.16 | 78.16 |

| CFATM-NoGraph | Remove fault correlation graph | 31.70 | 52.77 | 57.77 | 62.69 | 66.63 | 69.86 | 70.93 | 72.36 |

| CFATM-NoTemporal | Remove LSTM—temporal attention | 32.43 | 53.06 | 58.49 | 63.16 | 67.46 | 70.35 | 72.45 | 73.65 |

| CFATM-NoAttnFusion | Replace attentive fusion with addition | 32.21 | 53.42 | 57.70 | 62.50 | 66.94 | 70.37 | 73.94 | 75.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, H.; Qian, D.; Chen, F.; Zhou, W. Collaborative Fusion Attention Mechanism for Vehicle Fault Prediction. Future Internet 2025, 17, 428. https://doi.org/10.3390/fi17090428

Jia H, Qian D, Chen F, Zhou W. Collaborative Fusion Attention Mechanism for Vehicle Fault Prediction. Future Internet. 2025; 17(9):428. https://doi.org/10.3390/fi17090428

Chicago/Turabian StyleJia, Hong, Dalin Qian, Fanghua Chen, and Wei Zhou. 2025. "Collaborative Fusion Attention Mechanism for Vehicle Fault Prediction" Future Internet 17, no. 9: 428. https://doi.org/10.3390/fi17090428

APA StyleJia, H., Qian, D., Chen, F., & Zhou, W. (2025). Collaborative Fusion Attention Mechanism for Vehicle Fault Prediction. Future Internet, 17(9), 428. https://doi.org/10.3390/fi17090428