Toward the Theoretical Foundations of Industry 6.0: A Framework for AI-Driven Decentralized Manufacturing Control

Abstract

1. Introduction

Originality and Contribution of the Framework

- RQ1: How does Industry 6.0 influence the structure and strategy of industrial organizations?

- RQ2: What organizational structures are best suited to support the decentralized decision-making and integration of advanced technologies foreseen by Industry 6.0?

- RQ3: How can organizations develop strategies that effectively balance mass customization and sustainability within the Industry 6.0 model?

- RQ4: What are the cultural and strategic implications of a zero-fault environment, and how does it affect continuous innovation and incremental improvement in industrial organizations?

2. Methodology

3. Industry 4.0 to 6.0: Theoretical Foundations and Strategic Adaptations

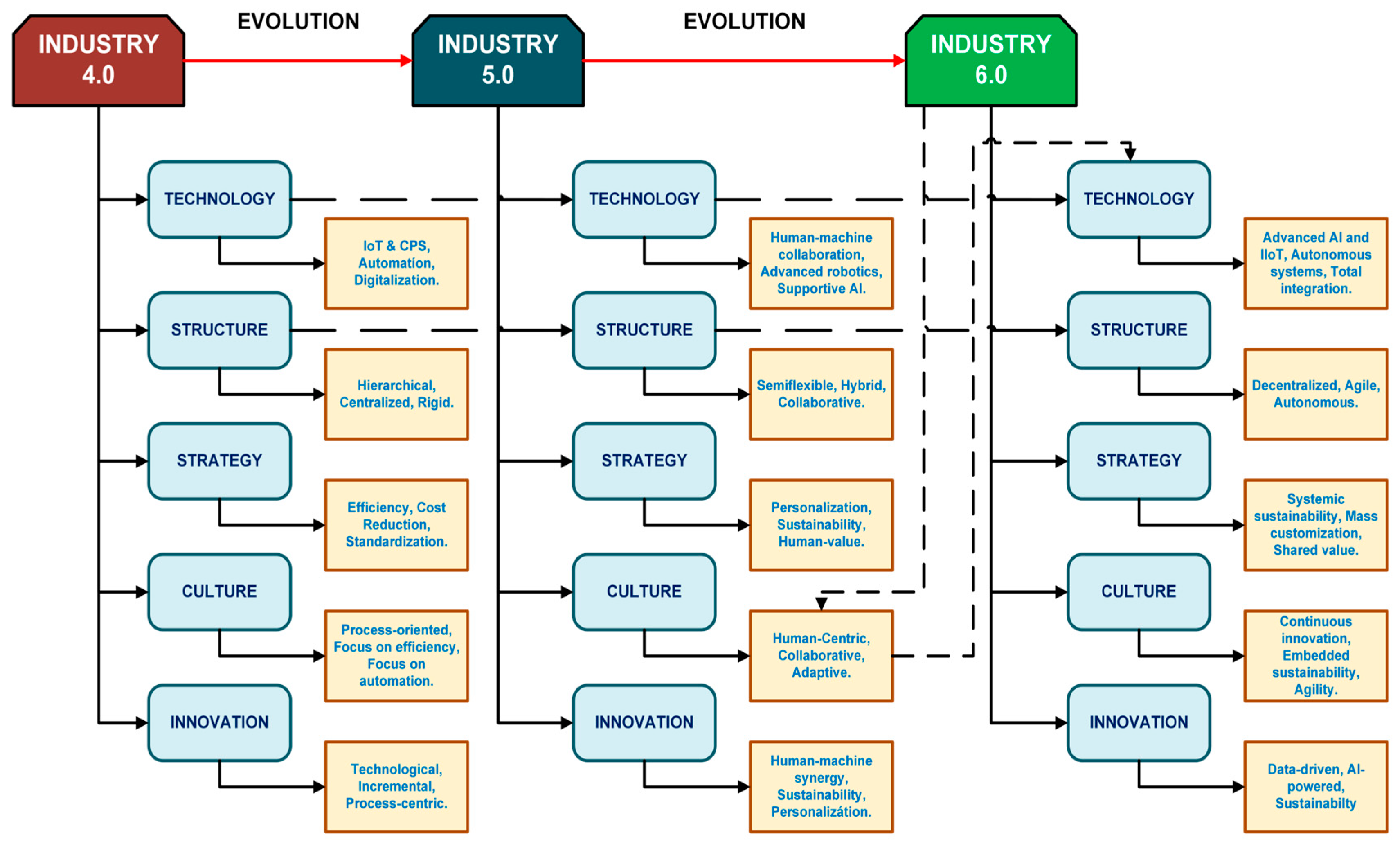

3.1. Moving from Industry 4.0 to 6.0

- P6: Innovation in Industry 6.0 will be proactive and data-driven, enabled by advanced analytics and autonomous systems, leading to continuous improvement in strategy and technology adoption [42].

3.2. Technological Integration in Industry 6.0

- P7: Compared to previous paradigms, the combination of advanced technologies such as AI and IIoT in Industry 6.0 promotes predictive optimization and intelligent automation, significantly improving the operational efficiency and flexibility of industrial organizations through autonomous decision-making systems [44,45].

3.3. Organizational Structure Adaptations

- P9: Compared to the more hierarchical structures of Industry 4.0 and the limited flexibility of Industry 5.0, the decentralized organizational structures of Industry 6.0 increase the agility of companies, enabling them to respond more quickly and flexibly to market fluctuations and local operating conditions through autonomous decision-making [61,62].

- P10: Structural adaptation to market dynamics and specific consumer preferences through Industry 6.0 enables organizations to implement mass customization models and sustainable resource management, exceeding the levels of customization and adaptability achievable in Industry 4.0 and Industry 5.0 [67,69].

3.4. Strategic Shifts

3.5. Challenges and Opportunities

4. Towards Industry 6.0: Conceptual Models

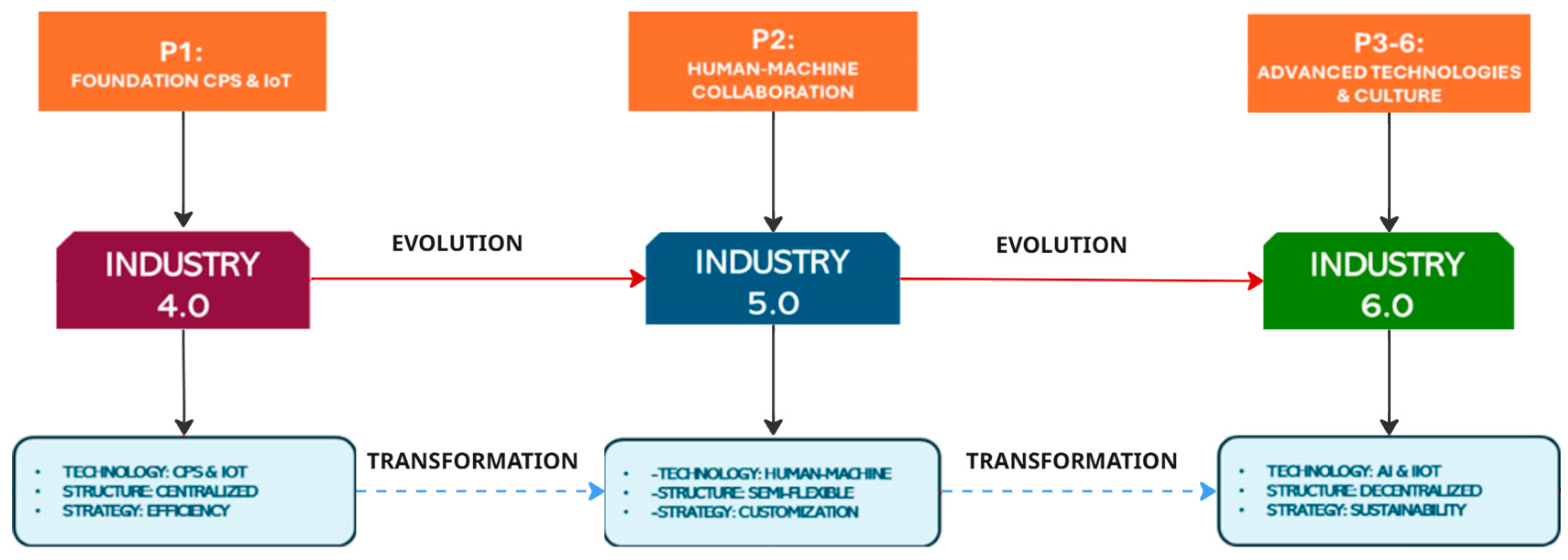

4.1. Evolutionary Model from Industry 4.0 to Industry 6.0

4.2. Conceptual Model from Industry 4.0 to Industry 6.0

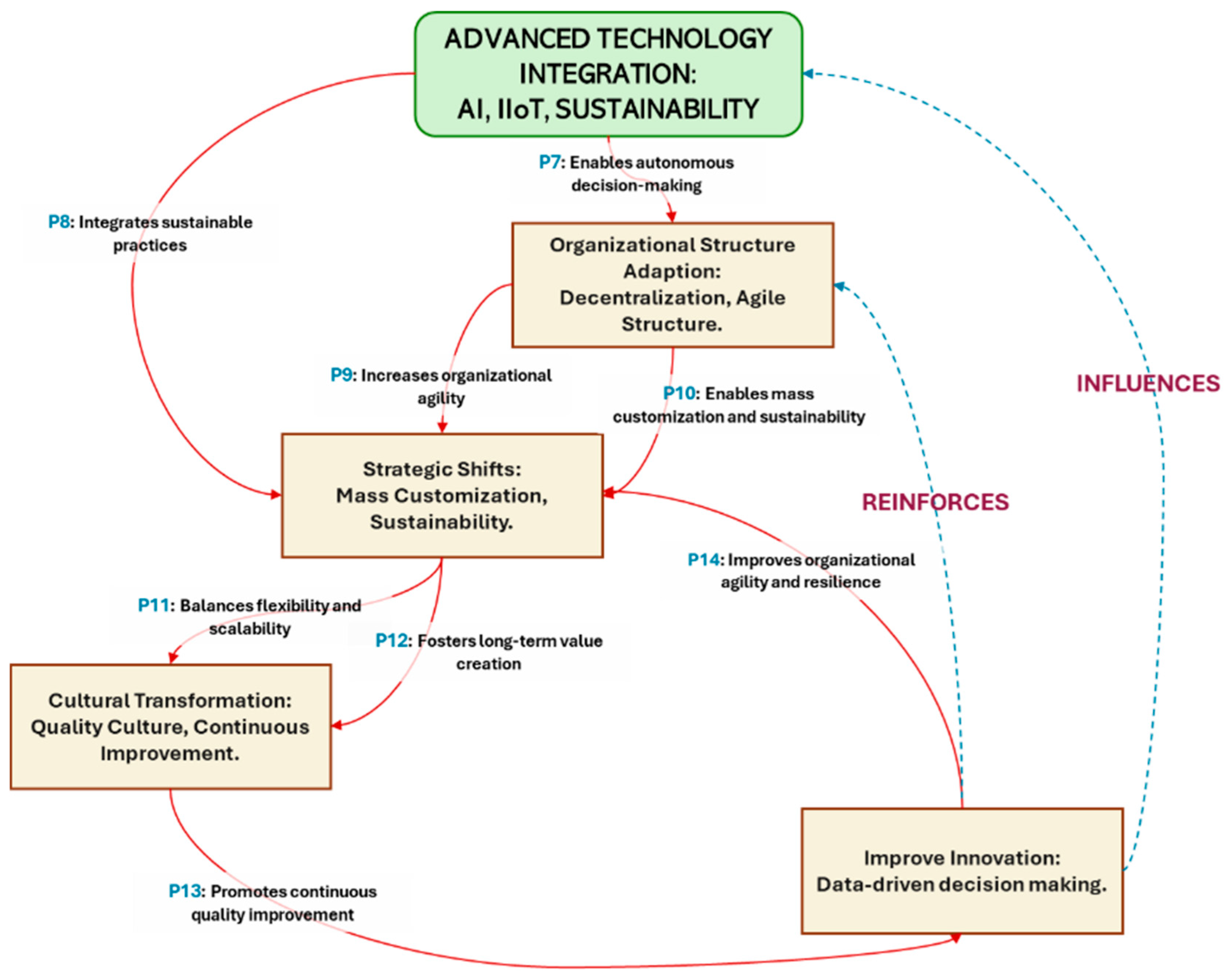

4.3. Conceptual Model of Industry 6.0

- Feedback from Innovation to Organizational Structure: Innovation is not only influenced by organizational structure but in turn can stimulate structural changes. For example, new ideas or technologies may require internal reorganization to be implemented effectively.

- Feedback from Innovation to Technology Integration: Innovation can lead to the development or adoption of new technologies, further fueling the cycle of technological advancement.

5. Building Theory for Industry 6.0

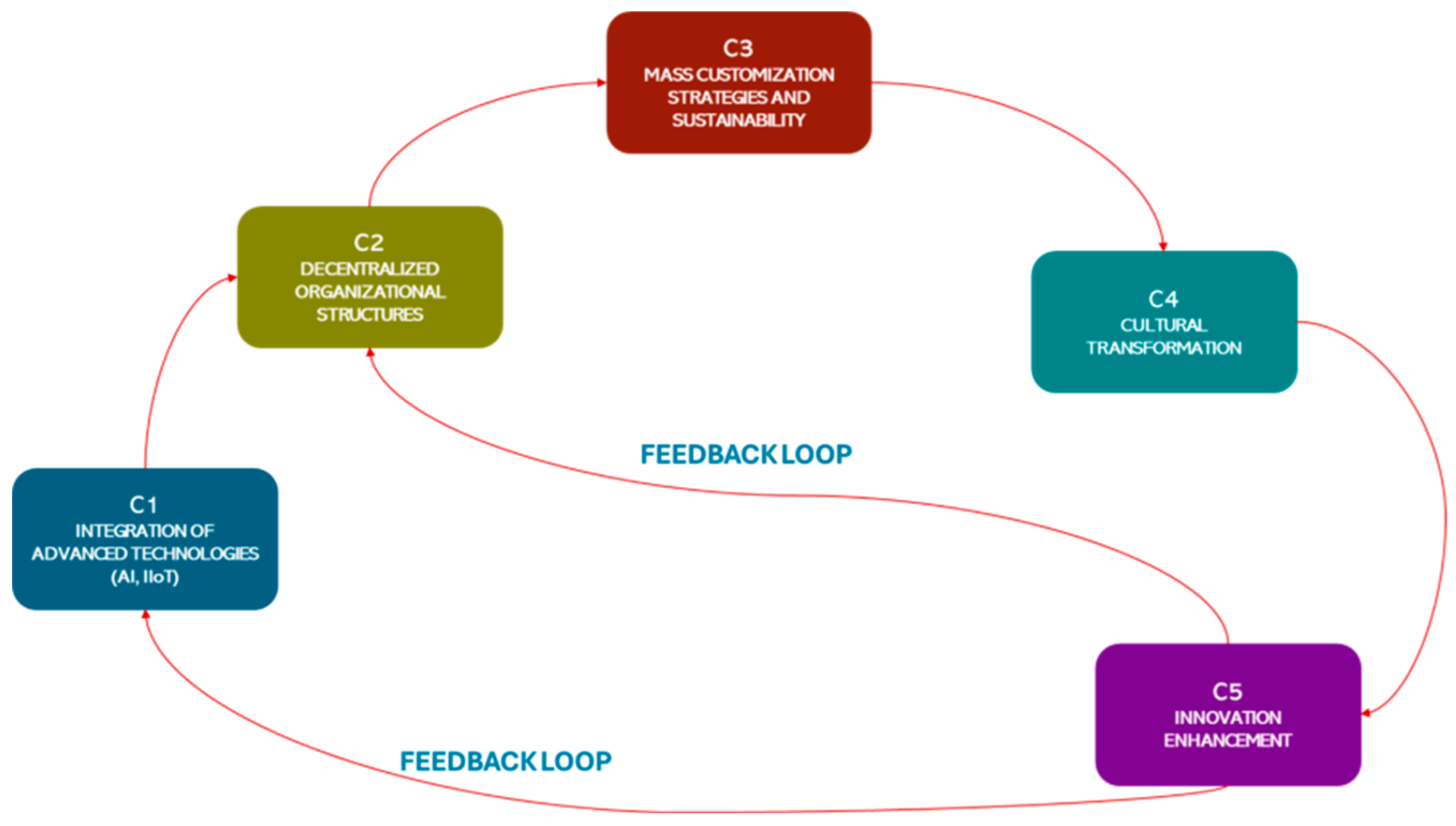

- C1. Advanced Technology Integration emerges from the propositions that highlight the importance of technologies such as Artificial Intelligence (AI) and Industrial Internet of Things (IIoT) in enabling autonomous systems and improving operational efficiency (P3, P7, P8).

- C2. Decentralized Organizational Structures are identified as necessary to take full advantage of new technologies and increase organizational agility, as discussed in propositions P3, P9, and P10.

- C3. Mass Personalization and Sustainability Strategies are derived from propositions that emphasize the importance of balancing operational flexibility, personalization, and environmental responsibility (P4, P11, P12).

- C4. Cultural Transformation is a construct that emerges from the need to foster a culture of continuous improvement and integrate sustainability values, as described in P5 and P13.

- C5. Boosting Innovation is identified as a key element to drive continuous improvements in technology strategy and adoption, based on propositions P6 and P14.

- Elaboration of Relationships: It is necessary to establish how these constructs interact with one another, identifying causal or mutually influential relationships.

- Formulation of the Theoretical Model: The next step involves integrating the constructs and relationships into a coherent structure that represents the phenomenon under study.

- Theoretical Validation: The model should then be validated by linking it to existing literature. This entails discussing how the model contributes to the field of study and what implications it holds.

- Implications and Future Perspectives: It is important to explore the practical consequences of the model and identify potential avenues for further research.

5.1. Processing Construct Relationships

- C1. Advanced Technology Integration ➔ C2. Decentralized Organizational Structures. Advanced Technological Integration (C1) functions as a catalyst for the transformation of organizational structures. The implementation of technologies such as AI and the Industrial Internet of Things (IIoT) enables autonomous systems and data-driven decision-making in real time. This capability necessitates and encourages the development of decentralized organizational structures (C2), as evidenced by propositions P3, P7, and P9. The implementation of advanced technologies enables operational departments to make autonomous decisions, thereby reducing the necessity for centralized control and increasing organizational agility.

- C2. Decentralized Organizational Structures ➔ C3. Mass Personalization and Sustainability Strategies. The implementation of Decentralized Organizational Structures (C2) directly influences Mass Personalization and Sustainability Strategies (C3). As previously discussed in Propositions P4, P10, P11, and P12, the decentralization of organizational structures allows for greater operational flexibility, enabling the organization to quickly adapt to dynamic consumer preferences and implement sustainable practices. Autonomous business units can tailor products and services to local needs, thereby balancing efficiency and environmental responsibility.

- C3. Mass Personalization Strategies and Sustainability ➔ C4. Cultural Transformation. The implementation of Mass Personalization and Sustainability Strategies (C3) necessitates a comprehensive cultural transformation (C4). Propositions P5, P12, and P13 illustrate the necessity of an organizational culture that fosters continuous improvement, innovation, and the adoption of sustainable values to effectively implement strategies focused on personalization and sustainability. The corporate culture must transform to align with these novel strategic objectives, necessitating a culture that fosters continuous learning and adaptability.

- C4. Cultural Transformation ➔ C5. Boosting Innovation. Cultural transformation (C4) is a prerequisite for the empowerment of innovation (C5). An innovation-oriented culture, as delineated in Propositions P6 and P14, cultivates the germination of novel concepts and the incorporation of nascent technologies. The promotion of values such as creativity, collaboration, and openness to change within the organization stimulates proactive, data-driven innovation, which is essential for maintaining a competitive advantage in Industry 6.0.

- C5. Enhancing Innovation ➔ C1. Advanced Technology Integration and C2. Decentralized Organizational Structures. The enhancement of innovation (C5) generates a positive feedback loop with advanced technological integration (C1) and decentralized organizational structures (C2). The continued development and adoption of new technologies is a consequence of sustained innovation, which in turn drives further integration of technology (P6). Moreover, it may necessitate modifications to organizational structures to facilitate the implementation of novel innovative processes and systems (P14), thereby establishing a virtuous cycle of continuous improvement and adaptation.

5.2. Building the Integrated Theoretical Model

- C1 is a prerequisite for C2. The implementation of advanced technological integration necessitates the establishment of decentralized organizational structures.

- C2 ➔ C3: Decentralized structures facilitate the adoption of mass personalization and sustainability strategies.

- C3 ➔ C4: The implementation of these strategies facilitates cultural transformation.

- C4 ➔ C5: Cultural transformation drives the empowerment of innovation.

- C5 ➔ C1/C2: Enhancing innovation generates new technological developments and necessitates further organizational adaptations, thereby closing the feedback loop.

5.3. Theoretical Validation of the Model

5.4. Final Theoretical Contribution

- Success in Industry 6.0 is not achieved merely through the adoption of advanced technologies or the implementation of new strategies but emerges from a cyclical and interdependent transformation wherein Advanced Technological Integration (C1) reconfigures Organizational Structures (C2), which in turn enable and are reshaped by Mass Personalization and Sustainability Strategies (C3). This dynamic process initiates a profound Cultural Transformation (C4) that elevates Innovation (C5) from an operational function to an intrinsic strategic capability. This enhanced innovation further fuels technological integration and organizational evolution, establishing a virtuous cycle that redefines the organization’s identity and operational essence, making agility, resilience, and sustainability not just objectives but fundamental components of its DNA.

6. Discussion of Results

- This study investigates the impact of Industry 6.0 on organizational structures, with a focus on decentralization that enables distributed decision-making and the assimilation of new technologies.

- In contrast to Industry 4.0 and 5.0, our framework positions sustainability as a core component, guiding organizations toward balancing mass customization with ecological responsibility.

- We highlight necessary cultural transformations for achieving zero-defect environments, which are crucial for fostering sustained innovation and organizational resilience.

- The theoretical model presented combines aspects of technology, organizational architecture, strategy, culture, and innovation, providing both actionable recommendations and fresh perspectives for management scholars and practitioners.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Proposition–Reference Mapping

| Proposition | Key Reference | Contribution of the Cited Works |

| P1 | [32,37] | These works establish the foundational role of CPS and IoT in Industry 4.0, enabling digital automation but retaining centralized and efficiency-oriented structures. |

| P2 | [34,36] | These studies on Industry 5.0 emphasize human–machine collaboration and sustainability awareness, but note limited changes in organizational structure, supporting the transition argument. |

| P3 | [5,37] | Literature on AI and IIoT demonstrates how autonomous systems drive the need for decentralized organizations, showing a step beyond 4.0 and 5.0. |

| P4 | [38,39] | These contributions highlight the strategic importance of mass customization and sustainability, positioning them as central objectives for Industry 6.0. |

| P5 | [40,43] | Cultural change is discussed as a driver of innovation and sustainability in industrial transitions, but without systemic integration—our proposition builds on and extends these insights. |

| P6 | [42] | This work stresses the shift toward proactive, data-driven innovation enabled by advanced analytics, aligning with our view of continuous innovation in Industry 6.0. |

| P7 | [44,45] | These studies document how AI/IIoT integration improves efficiency and flexibility, forming the basis for Industry 6.0’s predictive optimization and autonomous decision-making. |

| P8 | [56,58] | Research on sustainable practices in advanced manufacturing shows how AI/IIoT can reconcile customization and environmental goals, supporting our proposition. |

| P9 | [61,62] | Decentralization and agility are emphasized in these works, demonstrating how distributed structures enhance responsiveness compared to hierarchical models. |

| P10 | [67,69] | These papers show how adaptation to market dynamics and consumer preferences requires new structural models, validating the Industry 6.0 approach. |

| P11 | [69,21] | These contributions discuss how AI and IIoT enable scalable customization strategies, supporting the balance of flexibility and scalability proposed in P11. |

| P12 | [45,75,76] | Sustainability as a strategic imperative is emphasized here, particularly the role of supply chains and responsible resource management in long-term value creation. |

| P13 | [24,79] | These studies explore zero-defect manufacturing and cultural change for quality, underlining the organizational and cultural shifts required for implementation. |

| P14 | [19,20] | These works provide evidence of predictive quality and defect prevention as strategic levers, showing their role in resilience and agility.2 |

References

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A Sequential Roadmap to Industry 6.0: Exploring Future Manufacturing Trends. IET Commun. 2022, 16, 521–531. [Google Scholar] [CrossRef]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the Perspective of Automation and Supervision Systems: Definitions, Architectures and Recent Trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Tseng, M.L.; Grybauskas, A.; Stefanini, A.; Amran, A. Behind the Definition of Industry 5.0: A Systematic Review of Technologies, Principles, Components, and Values. J. Ind. Prod. Eng. 2023, 40, 432–447. [Google Scholar] [CrossRef]

- Fernández-Miguel, A.; García-Muiña, F.E.; Settembre-Blundo, D.; Tarantino, S.C.; Riccardi, M.P. Exploring Systemic Sustainability in Manufacturing: Geoanthropology’s Strategic Lens Shaping Industry 6.0. Glob. J. Flex. Syst. Manag. 2024, 25, 579–600. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Kostis, P.C.; Kafka, K.I.; Valvi, T. Toward Industry 6.0 and Techno-Centric vs. Human-Centric Smart Balancing: The Journey from Industry and Society 4.0 toward Industry and Society 5.0 and Beyond. In Sustainable Economic Development; Routledge: Abingdon-on-Thames, UK, 2024; pp. 171–184. [Google Scholar] [CrossRef]

- Enang, E.; Bashiri, M.; Jarvis, D. Exploring the Transition from Techno Centric Industry 4.0 towards Value Centric Industry 5.0: A Systematic Literature Review. Int. J. Prod. Res. 2023, 61, 7866–7902. [Google Scholar] [CrossRef]

- Lou, S.; Hu, Z.; Zhang, Y.; Feng, Y.; Zhou, M.; Lv, C. Human-Cyber-Physical System for Industry 5.0: A Review From a Human-Centric Perspective. IEEE Trans. Autom. Sci. Eng. 2025, 22, 494–511. [Google Scholar] [CrossRef]

- Bukowski, L.; Werbinska-Wojciechowska, S. Towards Maintenance 5.0: Resilience-Based Maintenance in AI-Driven Sustainable and Human-Centric Industrial Systems. Sensors 2025, 25, 5100. [Google Scholar] [CrossRef] [PubMed]

- Rosário, A.T.; Raimundo, R. Internet of Things and Distributed Computing Systems in Business Models. Future Internet 2024, 16, 384. [Google Scholar] [CrossRef]

- Srivastava, A.; Kumari, G.; Pathania, A. Technological Innovation and Accounting in Industry 6.0. In Sustainable Innovation for Industry 6.0; IGI Global: Hershey, PA, USA, 2024; pp. 286–309. [Google Scholar]

- Sakurada, L.; De la Prieta, F.; Leitao, P. The Role of Multi-Agent Systems in Realizing Asset Administration Shell Type 3. Future Internet 2025, 17, 270. [Google Scholar] [CrossRef]

- Melo, V.; de la Prieta, F.; Leitao, P. Relationship of Digital Product Passport and Digital Twin in Industry 4.0 Context. In International Workshop on the Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Legat, C., Eds.; Springer: Cham, Switzerland, 2025; pp. 187–200. [Google Scholar]

- Patrício, L.; Varela, L.; Silveira, Z.; Felgueiras, C.; Pereira, F. A Framework for Integrating Robotic Process Automation with Artificial Intelligence Applied to Industry 5.0. Appl. Sci. 2025, 15, 7402. [Google Scholar] [CrossRef]

- Deshpande, S.; Jogdand, R. Development of IoT Middleware Broker Communication Architecture for Industrial Automation with Focus on Future Pandemic Possibilities: Industry 5.0. In Emerging Technologies in Data Mining and Information Security: Proceedings of IEMIS 2022; Springer Nature Singapore: Singapore, 2023; pp. 47–58. [Google Scholar] [CrossRef]

- Islam, M.T.; Sepanloo, K.; Woo, S.; Woo, S.H.; Son, Y.-J. A Review of the Industry 4.0 to 5.0 Transition: Exploring the Intersection, Challenges, and Opportunities of Technology and Human–Machine Collaboration. Machines 2025, 13, 267. [Google Scholar] [CrossRef]

- Li, L.; Duan, L. Human Centric Innovation at the Heart of Industry 5.0—Exploring Research Challenges and Opportunities. Int. J. Prod. Res. 2025, 1–33. [Google Scholar] [CrossRef]

- Fathi, M.; Ghobakhloo, M. Enabling Mass Customization and Manufacturing Sustainability in Industry 4.0 Context: A Novel Heuristic Algorithm for in-Plant Material Supply Optimization. Sustainability 2020, 12, 6669. [Google Scholar] [CrossRef]

- Fedele, M.; Formisano, V. Waste from Criticality to Resource through an Innovative Circular Business Model: A Case Study in the Manufacturing Industry. J. Clean. Prod. 2023, 407, 137143. [Google Scholar] [CrossRef]

- Najafi, B.; Najafi, A.; Farahmandian, A. The Impact of Artificial Intelligence and Blockchain on Six Sigma: A Systematic Literature Review of the Evidence and Implications. IEEE Trans. Eng. Manag. 2024, 71, 10261–10294. [Google Scholar] [CrossRef]

- Sun, D. Simulation of Mechanical Component Fault Prediction Model Based on Artificial Neural Network Algorithm. In Proceedings of the 2023 International Conference on Internet of Things, Robotics and Distributed Computing, ICIRDC, Rio De Janeiro, Brazil, 29–31 December 2023; pp. 650–654. [Google Scholar] [CrossRef]

- Kumari, S.; Tyagi, A.K. Online Social Networking. In Online Social Networks in Business Frameworks; Wiley: Hoboken, NJ, USA, 2024; pp. 255–298. ISBN 9781394231126. [Google Scholar]

- Jain, R. Towards a Green Revolution: Sustainable Integration of Industry 6.0 Technologies and Smart Banking Services in the UAE. In Sustainable Innovation for Industry 6.0; IGI Global: Hershey, PA, USA, 2024; pp. 31–44. [Google Scholar]

- Ikram, L.; Afaf, D.; Latifa, E. Beyond Industry 5.0: Tracing the Past, Present, and Future of Digital Industrial Transformations. In Proceedings of the 4th International Conference on Innovative Research in Applied Science, Engineering and Technology, IRASET, Fez, Morocco, 16–17 May 2024. [Google Scholar] [CrossRef]

- Wan, P.K.; Leirmo, T.L. Human-Centric Zero-Defect Manufacturing: State-of-the-Art Review, Perspectives, and Challenges. Comput. Ind. 2023, 144, 103792. [Google Scholar] [CrossRef]

- Souza, L.; Camboim, K.; Alencar, F. A Systematic Literature Review about Integrating Dependability Attributes, Performability and Sustainability in the Implantation of Cooling Subsystems in Data Center. J. Supercomput. 2022, 78, 15820–15856. [Google Scholar] [CrossRef]

- Seddon, P.B. Where Do Theories Come From? An Inference-to-the-Best-Explanation Theory of Theory Building (IBET). Commun. Assoc. Inf. Syst. 2022, 51, 32. [Google Scholar] [CrossRef]

- Vila-Henninger, L.; Dupuy, C.; Van Ingelgom, V.; Caprioli, M.; Teuber, F.; Pennetreau, D.; Bussi, M.; Le Gall, C. Abductive Coding: Theory Building and Qualitative (Re) Analysis. Sociol. Methods Res. 2024, 53, 968–1001. [Google Scholar] [CrossRef]

- Ulaga, W.; Kleinaltenkamp, M.; Kashyap, V.; Eggert, A. Advancing Marketing Theory and Practice: Guidelines for Crafting Research Propositions. AMS Rev. 2021, 11, 395–406. [Google Scholar] [CrossRef]

- George, J.M.; Jones, G.R. The Role of Time in Theory and Theory Building. J. Manag. 2000, 26, 657–684. [Google Scholar] [CrossRef]

- Sætre, A.S.; Van de Ven, A. Generating Theory by Abduction. Acad. Manag. Rev. 2021, 46, 684–701. [Google Scholar] [CrossRef]

- Kaur, A.; Potdar, V.; Agrawal, H. Industry 4.0 Adoption in Food Supply Chain to Improve Visibility and Operational Efficiency—A Content Analysis. IEEE Access 2023, 11, 73922–73958. [Google Scholar] [CrossRef]

- Núñez-Merino, M.; Maqueira-Marín, J.M.; Moyano-Fuentes, J.; Martínez-Jurado, P.J. Industry 4.0 and Lean Supply Chain Management: Impact on Responsiveness. In Enabling Technologies for the Successful Deployment of Industry 4.0; CRC Press: Boca Raton, FL, USA, 2020; pp. 105–128. ISBN 9780429055621. [Google Scholar]

- Pandey, A.K.; Daultani, Y.; Pratap, S.; Ip, A.W.H.; Zhou, F. Analyzing Industry 4.0 Adoption Enablers for Supply Chain Flexibility: Impacts on Resilience and Sustainability. Glob. J. Flex. Syst. Manag. 2024, 26, 1–24. [Google Scholar] [CrossRef]

- Nair, S.; Kumar, A.A.; Chacko, E.; Simon, S. Synergizing Humanity and Technology: A Human-Machine Collaboration for Business Sustainability in Industry 5.0. Stud. Syst. Decis. Control 2024, 535, 105–115. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Zizic, M.C.; Mladineo, M.; Gjeldum, N.; Celent, L. From Industry 4.0 towards Industry 5.0: A Review and Analysis of Paradigm Shift for the People, Organization and Technology. Energies 2022, 15, 5221. [Google Scholar] [CrossRef]

- Vijay, A.J.; William, B.N.J.; Haruna, A.A.; Prasad, D.D. Exploring the Synergy of IIoT, AI, and Data Analytics in Industry 6.0. In Industry 6.0; CRC Press: Boca Raton, FL, USA, 2024; pp. 1–36. ISBN 9781040128039. [Google Scholar]

- Alexa, L.; Pîslaru, M.; Avasilcăi, S. From Industry 4.0 to Industry 5.0—An Overview of European Union Enterprises. In Sustainability and Innovation in Manufacturing Enterprises: Indicators, Models and Assessment for Industry 5.0; Draghici, A., Ivascu, L., Eds.; Springer: Singapore, 2022; pp. 221–231. ISBN 978-981-16-7365-8. [Google Scholar]

- Almusaed, A.; Yitmen, I.; Almssad, A. Reviewing and Integrating AEC Practices into Industry 6.0: Strategies for Smart and Sustainable Future-Built Environments. Sustainability 2023, 15, 13464. [Google Scholar] [CrossRef]

- Fekrisari, M.; Kantola, J. Integrating Industry 4.0 in Manufacturing: Overcoming Challenges and Optimizing Processes (Case Studies). TQM J. 2024, 36, 347–370. [Google Scholar] [CrossRef]

- Tóth, A.; Nagy, L.; Kennedy, R.; Bohuš, B.; Abonyi, J.; Ruppert, T. The Human-Centric Industry 5.0 Collaboration Architecture. MethodsX 2023, 11, 102260. [Google Scholar] [CrossRef]

- Tyagi, A.K.; Bhatt, P.; Chidambaram, N.; Kumari, S. Artificial Intelligence Empowered Smart Manufacturing for Modern Society. In Artificial Intelligence—Enabled Digital Twin for Smart Manufacturing; Wiley: Hoboken, NJ, USA, 2024; pp. 55–83. ISBN 9781394303601. [Google Scholar]

- Minz, N.K. Strategic HRM Techniques and Sustainable Innovation for Industry 6.0. In Sustainable Innovation for Industry 6.0; Sharma, A., Moses, O., Sharma, R.B., Gupta, S., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 59–73. ISBN 9798369331408. [Google Scholar]

- Lykov, A.; Altamirano Cabrera, M.; Konenkov, M.; Serpiva, V.; Fid`ele Gbagbe, K.; Alabbas, A.; Fedoseev, A.; Moreno, L.; Haris Khan, M.; Guo, Z.; et al. Industry 6.0: New Generation of Industry Driven by Generative AI and Swarm of Heterogeneous Robots. arxiv 2024, arXiv:2409.10106. [Google Scholar] [CrossRef]

- Das, S.; Pan, T. A Strategic Outline of Industry 6.0: Exploring the Future. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Yadav, S.; Rab, S.; Wan, M. Metrology and Sustainability in Industry 6.0: Navigating a New Paradigm. In Handbook of Quality System, Accreditation and Conformity Assessment; Bhatnagar, A., Yadav, S., Achanta, V., Harmes-Liedtke, U., Rab, S., Eds.; Springer: Singapore, 2024; pp. 1–31. ISBN 978-981-99-4637-2. [Google Scholar]

- Schou, C.; Colli, M.; Berger, U.; Lassen, A.H.; Madsen, O.; Møller, C.; Wæhrens, B.V. Deconstructing Industry 4.0: Defining the Smart Factory. In Towards Sustainable Customization: Bridging Smart Products and Manufacturing Systems; Andersen, A.-L., Andersen, R., Brunoe, T.D., Larsen, M.S.S., Nielsen, K., Napoleone, A., Kjeldgaard, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 356–363. [Google Scholar]

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and Sustainability: Towards Conceptualization and Theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- Siqin, T.; Choi, T.-M.; Chung, S.-H.; Wen, X. Platform Operations in the Industry 4.0 Era: Recent Advances and the 3As Framework. IEEE Trans. Eng. Manag. 2024, 71, 1145–1162. [Google Scholar] [CrossRef]

- Torn, I.A.R.; Vaneker, T.H.J. Mass Personalization with Industry 4.0 by SMEs: A Concept for Collaborative Networks. Procedia Manuf. 2019, 28, 135–141. [Google Scholar] [CrossRef]

- Baig, M.I.; Yadegaridehkordi, E. Industry 5.0 Applications for Sustainability: A Systematic Review and Future Research Directions. Sustain. Dev. 2024, 32, 662–681. [Google Scholar] [CrossRef]

- Wang, L.; Ranjan, R.; Chen, J.; Benatallah, B. Cloud Computing: Methodology, Systems, and Applications, 1st ed.; Wang, L., Ranjan, R., Chen, J., Benatallah, B., Eds.; CRC Press: Boca Raton, FL, USA, 2012; ISBN 9781315217208. [Google Scholar]

- Pattanaik, S.; Mohammed, M.; Sood, V. Artificial Intelligence and Machine Learning in Industry 6.0. In Industry 6.0; CRC Press: Boca Raton, FL, USA, 2024; pp. 37–54. [Google Scholar]

- Zahariev, P.; Hristov, G.; Chaisricharoen, R.; Bencheva, N.; Beloev, I.; Zlatov, N.; Le, C.H.; Georgiev, G.; Kinaneva, D. Industry 4.0 and Beyond—Present Trends, Emerging Solutions and Future Technologies in the Area of the Industrial Automation. In Proceedings of the 2024 Joint International Conference on Digital Arts, Media and Technology with ECTI Northern Section Conference on Electrical, Electronics, Computer and Telecommunications Engineering (ECTI DAMT & NCON), Chiang-mai, Thailand, 31 January–3 February 2024; pp. 525–528. [Google Scholar]

- Gutta, L.M.; Dhamodharan, B.; Dutta, P.K.; Whig, P. AI-Infused Quantum Machine Learning for Enhanced Supply Chain Forecasting. In Quantum Computing and Supply Chain Management: A New Era of Optimization; Hassan, A., Bhattacharya, P., Dutta, P.K., Verma, J.P., Kundu, N.K., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 48–63. ISBN 9798369341070. [Google Scholar]

- Heilala, J.; Kantola, J. Sustainable Manufacturer Engineering for Industry 6.0. In Proceedings of the 15th International Conference on Axiomatic Design 2023; Puik, E., Cochran, D.S., Foley, J.T., Foith-Förster, P., Eds.; Springer: Cham, Switzerland, 2024; pp. 75–87. [Google Scholar]

- Doyle-Kent, M.; Kopacek, P. Optimising Human Potential Through Diversity and Inclusion for Industry/Production 4.0, 5.0 and 6.0. In Proceedings of the Towards Industry 5.0; Durakbasa, N.M., Gençyılmaz, M.G., Eds.; Springer: Cham, Switzerland, 2023; pp. 267–276. [Google Scholar]

- Reddy, M.S.; Reddy, C.K.K.; Hanafiah, M.M. Climate Change Mitigation and Adaptation Strategies Enhanced by Intelligent Systems in Industry 6.0. In Maintaining a Sustainable World in the Nexus of Environmental Science and AI; Singh, B., Kaunert, C., Vig, K., Dutta, S., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 201–228. ISBN 9798369363362. [Google Scholar]

- Vaseei, M.; Agha, M.N.J. Competitive Advantage in the Supply Chain with an Emphasis on Blockchain Technology. In Advanced Businesses in Industry 6.0; Oskounejad, M.M., Nozari, H., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 125–134. ISBN 9798369331088. [Google Scholar]

- Maljugić, B.; Ćoćkalo, D.; Bakator, M.; Stanisavljev, S. The Role of the Quality Management Process within Society 5.0. Societies 2024, 14, 111. [Google Scholar] [CrossRef]

- Verma, P.; Kumar, V.; Yalcin, H.; Daim, T. Organizational Architecture of Strategic Entrepreneurial Firms for Digital Transformation: A Bibliometric Analysis. Technol. Soc. 2023, 75, 102355. [Google Scholar] [CrossRef]

- Maimone, F. Organizing for Industry 4.0. In Do Machines Dream of Electric Workers? Solari, L., Martinez, M., Braccini, A.M., Lazazzara, A., Eds.; Springer: Cham, Switzerland, 2022; pp. 1–20. [Google Scholar]

- Whig, P.; Madavarapu, J.B.; Yathiraju, N.; Thatikonda, R. Managing Knowledge in the Era of Industry 4.0. In Knowledge Management and Industry Revolution 4.0; Scrivener Publishing LLC: Beverly, MA USA, 2024; pp. 239–273. ISBN 9781394242641. [Google Scholar]

- Tallat, R.; Hawbani, A.; Wang, X.; Al-Dubai, A.; Zhao, L.; Liu, Z.; Min, G.; Zomaya, A.Y.; Alsamhi, S.H. Navigating Industry 5.0: A Survey of Key Enabling Technologies, Trends, Challenges, and Opportunities. IEEE Commun. Surv. Tutor. 2024, 26, 1080–1126. [Google Scholar] [CrossRef]

- Medishetti, S.K.; Karri, G.R.; Pillareddy, V.R.; Sekhar, G.S.; Songa, A.V. IWaOA: Resource Aware Scheduling Through Cloud Fog Computing Environment. In Proceedings of the 2023 4th International Conference on Communication, Computing and Industry 6.0 (C216), Bangalore, India, 15–16 December 2023; IEEE: New York, NY, USA, 2023; pp. 1–6. [Google Scholar]

- Tereza, S. Journey to Quality 6.0: Evolution of Quality Management across Industrial Revolutions. Trends Comput. Sci. Inf. Technol. 2024, 9, 063–070. [Google Scholar] [CrossRef]

- Vetrivel, S.C.; Gomathi, T.; Sowmiya, K.C.; Sabareeshwari, V. Customer-Centric Excellence in the Marketing 6.0 Era: Industry 6.0. In Advanced Businesses in Industry 6.0; Oskounejad, M.M., Nozari, H., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 192–219. ISBN 9798369331088. [Google Scholar]

- Rahmani, R.; Karimi, J.; Resende, P.R.; Abrantes, J.C.C.; Lopes, S.I. Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines 2023, 11, 522. [Google Scholar] [CrossRef]

- Choi, L.; Kim, M.; Kwon, H.-B. Impact of Customer-Based Corporate Reputation on Customer Engagement Behaviors: Customer Identification and Brand Love as Mediators and Industry Type as a Moderator. J. Brand. Manag. 2022, 29, 150–166. [Google Scholar] [CrossRef]

- Villar, A.; Paladini, S.; Buckley, O. Towards Supply Chain 5.0: Redesigning Supply Chains as Resilient, Sustainable, and Human-Centric Systems in a Post-Pandemic World. Oper. Res. Forum 2023, 4, 60. [Google Scholar] [CrossRef]

- Singh, R.; Tyagi, A.K.; Arumugam, S.K. Imagining the Sustainable Future with Industry 6.0: A Smarter Pathway for Modern Society and Manufacturing Industries. In Machine Learning Algorithms Using Scikit and TensorFlow Environments; Baby Maruthi, P., Prasad, S., Tyagi, A.K., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 318–331. ISBN 9781668485316. [Google Scholar]

- Bosovska, M.; Boiko, M.; Bovsh, L.; Okhrimenko, A. Models of the Industrial Revolution 5.0. In Proceedings of the 2022 IEEE 4th International Conference on Modern Electrical and Energy System (MEES), Kremenchuk, Ukraine, 20–23 October 2022; IEEE: New York, NY, USA, 2023; pp. 1–4. [Google Scholar]

- Nozari, H.; Chobar, A.P. The Dimensions and Components of Marketing 5.0: Introduction to Marketing 6.0. In Advanced Businesses in Industry 6.0; Oskounejad, M.M., Nozari, H., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 75–86. ISBN 9798369331088. [Google Scholar]

- Reddy, A.V.; Doss, S.; Priyanka, K. Human-Machine Collaboration and Emotional Intelligence in Industry 6.0: Concepts, Challenges, and Future Directions. In Examining the Metaverse in Healthcare: Opportunities, Challenges, and Future Directions; Nijalingappa, P., Gururaj, T., Goyal, S.B., Shukla, V., Bruno, A., Eds.; IGI Global: Hershey, PA, USA, 2024; pp. 221–246. ISBN 9798369315156. [Google Scholar]

- Tyagi, A.K.; Kumari, S. Future Opportunities Towards Online Social Networking in the Era of Industry 4.0/5.0. In Online Social Networks in Business Frameworks; Wiley: Hoboken, NJ, USA, 2024; pp. 227–254. ISBN 9781394231126. [Google Scholar]

- Pattnaik, M.; Pattnaik, A.; Roul, M.K.; Kumar, P.A. Integrated Multi-Item Multi-Echelon Supply Chain Model: A Mixed-Integer Heuristic Approach. In Evolution and Advances in Computing Technologies for Industry 6.0; CRC Press: Boca Raton, FL, USA, 2024; pp. 325–376. [Google Scholar]

- Dacre, N.; Yan, J.; Frei, R.; Al-Mhdawi, M.K.S.; Dong, H. Advancing Sustainable Manufacturing: A Systematic Exploration of Industry 5.0 Supply Chains for Sustainability, Human-Centricity, and Resilience. Prod. Plan. Control 2024, 36, 1499–1528. [Google Scholar] [CrossRef]

- Annanperä, E.; Jurmu, M.; Kaivo-oja, J.; Kettunen, P.; Knudsen, M.; Lauraéus, T.; Majava, J.; Porras, J. From Industry x to Industry 6.0: Antifragile Manufacturing for People, Planet, and Profit with Passion; 2021. Available online: https://www.businessfinland.fi/4a5d8b/globalassets/julkaisut/industry-x-white-paper.pdf (accessed on 24 August 2025).

- Mohapatra, S.; Sil, R.; Nag, A. Driving Sustainable Practices in Industry 6.0: A Study on Article Detection with Fuzzy-Wuzzy and Supervised Machine Learning Algorithms. In Evolution and Advances in Computing Technologies for Industry 6.0; CRC Press: Boca Raton, FL, USA, 2024; pp. 232–245. [Google Scholar]

- Corley, K.G.; Gioia, D.A. Building Theory about Theory Building: What Constitutes a Theoretical Contribution? Acad. Manag. Rev. 2011, 36, 12–32. [Google Scholar] [CrossRef]

- Shepherd, D.A.; Suddaby, R. Theory Building. J. Manag. 2017, 43, 59–86. [Google Scholar] [CrossRef]

- Horváth, I. Theory Building in Experimental Design Research. In Experimental Design Research; Cash, P., Stanković, T., Štorga, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 209–231. [Google Scholar]

- Luthans, F.; Stewart, T.I. A General Contingency Theory of Management. Acad. Manag. Rev. 1977, 2, 181–195. [Google Scholar] [CrossRef]

- Taher, M. Resource-Based View Theory. In Information Systems Theory: Explaining and Predicting Our Digital Society, Vol. 1; Dwivedi, Y.K., Wade, M.R., Schneberger, S.L., Eds.; Springer: New York, NY, USA, 2012; pp. 151–163. [Google Scholar]

- Land, A.; Gruchmann, T.; Siems, E.; Beske-Janssen, P. Dynamic Capabilities Theory. In Handbook of Theories for Purchasing, Supply Chain and Management Research; Edward Elgar Publishing: Cheltenham, UK, 2022; pp. 378–398. ISBN 1839104503. [Google Scholar]

- Berta, W.; Cranley, L.; Dearing, J.W.; Dogherty, E.J.; Squires, J.E.; Estabrooks, C.A. Why (We Think) Facilitation Works: Insights from Organizational Learning Theory. Implement. Sci. 2015, 10, 141. [Google Scholar] [CrossRef]

- Whitchurch, G.G.; Constantine, L.L. Systems Theory. In Sourcebook of Family Theories and Methods: A Contextual Approach; Boss, P., Doherty, W.J., LaRossa, R., Schumm, W.R., Steinmetz, S.K., Eds.; Springer US: Boston, MA, USA, 1993; pp. 325–355. ISBN 978-0-387-85764-0. [Google Scholar]

- Yammarino, F.J.; Dubinsky, A.J. Transformational Leadership Theory: Using Levels of Analysis to Determine Boundary Conditions. Pers. Psychol. 1994, 47, 787–811. [Google Scholar] [CrossRef]

- Parmar, B.L.; Freeman, R.E.; Harrison, J.S.; Wicks, A.C.; Purnell, L.; de Colle, S. Stakeholder Theory: The State of the Art. Acad. Manag. Ann. 2010, 4, 403–445. [Google Scholar] [CrossRef]

- Porter, M.E. Technology and Competitive Advantage. J. Bus. Strategy 1985, 5, 60–78. [Google Scholar] [CrossRef]

- Tzortzaki, A.M.; Mihiotis, A. A Review of Knowledge Management Theory and Future Directions. Knowl. Process Manag. 2014, 21, 29–41. [Google Scholar] [CrossRef]

- Di Vaio, A.; Latif, B.; Gunarathne, N.; Gupta, M.; D’Adamo, I. Digitalization and artificial knowledge for accountability in SCM: A systematic literature review. J. Enterp. Inf. Manag. 2024, 37, 606–672. [Google Scholar] [CrossRef]

| Dimension | Industry 4.0 | Industry 5.0 | Industry 6.0 |

|---|---|---|---|

| Epistemological Foundation | Data collection and processing | Information to knowledge transformation | Knowledge to cognitive “thought” |

| Primary Focus | Operational efficiency through digitalization | Human–machine collaborative knowledge | Cognitive manufacturing systems |

| Decision-Making | Data-driven with human oversight | Knowledge-based human–machine collaboration | Autonomous cognitive decision-making |

| Organizational Structure | Traditional hierarchies with digital tools | Enhanced collaboration within existing structures | Cognitively enabled decentralized architectures |

| Strategic Orientation | Cost reduction and efficiency | Customization with sustainability awareness | Cognitive mass customization–sustainability integration |

| Cultural Foundation | Process optimization culture | Human-centric collaborative values | Continuous cognitive transformation |

| Innovation Pattern | Technology-driven improvements | Collaborative knowledge innovation | Autonomous cognitive innovation loops |

| Theoretical Novelty | CPS and IoT integration | Human-centricity in knowledge work | Cyclical cognitive feedback between all constructs |

| Proposition | Knowledge Insights | Explanatory Notes |

|---|---|---|

| P1 | Industry 4.0 relies on cyber–physical systems (CPS) and IoT for digital automation but maintains centralized structures. | This insight emphasizes the technological advancements of Industry 4.0, focusing on automation through CPS and IoT, but highlights that organizational structures remain centralized, limiting flexibility and agility. |

| P2 | Industry 5.0 emphasizes human–machine collaboration and early sustainability integration, with minimal structural changes. | This insight underscores the shift towards human-centered technologies in Industry 5.0, integrating collaborative robots and AI, while suggesting that the organizational structure remains largely intact . |

| P3 | Industry 6.0 uses AI and IIoT to enable autonomous systems, requiring decentralized structures for agility and responsiveness. | The key difference in Industry 6.0 is the integration of fully autonomous systems, where decentralized decision-making structures are critical to ensure responsiveness and adaptability to rapid market changes. |

| P4 | In Industry 6.0, business strategies prioritize mass customization and sustainability, overcoming prior efficiency-focused models. | This insight highlights how Industry 6.0 overcomes the limits of traditional efficiency-driven models, focusing on sustainable, tailored products that meet customer-specific demands while reducing environmental impact. |

| P5 | A cultural shift is essential in Industry 6.0, fostering continuous improvement and integrating sustainability across the organization. | The cultural transformation in Industry 6.0 is critical to maintaining an innovation-driven environment. Sustainability becomes ingrained not just as a product feature, but as a core organizational value. |

| P6 | Innovation in Industry 6.0 is proactive and data-driven, using advanced analytics and autonomous systems for continuous improvement. | Innovation in Industry 6.0 is rooted in advanced analytics and AI-driven systems, enabling real-time data collection and predictive analytics to drive continuous improvement in processes, products, and business strategies. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Miguel, A.; Ortíz-Marcos, S.; Jiménez-Calzado, M.; Fernández del Hoyo, A.P.; García-Muiña, F.E.; Settembre-Blundo, D. Toward the Theoretical Foundations of Industry 6.0: A Framework for AI-Driven Decentralized Manufacturing Control. Future Internet 2025, 17, 455. https://doi.org/10.3390/fi17100455

Fernández-Miguel A, Ortíz-Marcos S, Jiménez-Calzado M, Fernández del Hoyo AP, García-Muiña FE, Settembre-Blundo D. Toward the Theoretical Foundations of Industry 6.0: A Framework for AI-Driven Decentralized Manufacturing Control. Future Internet. 2025; 17(10):455. https://doi.org/10.3390/fi17100455

Chicago/Turabian StyleFernández-Miguel, Andrés, Susana Ortíz-Marcos, Mariano Jiménez-Calzado, Alfonso P. Fernández del Hoyo, Fernando E. García-Muiña, and Davide Settembre-Blundo. 2025. "Toward the Theoretical Foundations of Industry 6.0: A Framework for AI-Driven Decentralized Manufacturing Control" Future Internet 17, no. 10: 455. https://doi.org/10.3390/fi17100455

APA StyleFernández-Miguel, A., Ortíz-Marcos, S., Jiménez-Calzado, M., Fernández del Hoyo, A. P., García-Muiña, F. E., & Settembre-Blundo, D. (2025). Toward the Theoretical Foundations of Industry 6.0: A Framework for AI-Driven Decentralized Manufacturing Control. Future Internet, 17(10), 455. https://doi.org/10.3390/fi17100455