Abstract

The integration of artificial intelligence of things (AIoT) is transforming aviation health monitoring systems by combining extensive data collection with advanced analytical capabilities. This study proposes a framework that enhances predictive accuracy, operational efficiency, and safety while optimizing maintenance strategies and reducing costs. Utilizing a three-tiered cloud architecture, the AIoT system enables real-time data acquisition from sensors embedded in aircraft systems, followed by machine learning algorithms to analyze and interpret the data for proactive decision-making. This research examines the evolution from traditional to AIoT-enhanced monitoring, presenting a comprehensive architecture integrated with satellite communication and 6G technology. The mathematical models quantifying the benefits of increased diagnostic depth through AIoT, covering aspects such as predictive accuracy, cost savings, and safety improvements are introduced in this paper. The findings emphasize the strategic importance of investing in AIoT technologies to balance cost, safety, and efficiency in aviation maintenance and operations, marking a paradigm shift from traditional health monitoring to proactive health management in aviation.

1. Introduction

The integration of artificial intelligence (AI) with the internet of things (IoT) technologies, known as the artificial intelligence of things (AIoT), is rapidly transforming industries by bringing intelligence to the edge of every touchpoint. In the context of aviation, AIoT is revolutionizing health monitoring systems, enhancing safety, efficiency, and predictive maintenance practices.

Aviation health monitoring systems are critical for the safety and maintenance of aircraft. These systems gather data on various aircraft components’ performance and health, alerting personnel to potential issues before they become critical. The convergence of AI and IoT technologies into AIoT presents a new frontier in aviation health monitoring by enhancing the capabilities of these systems to analyze, predict, and automate responses to the vast amounts of data generated by aircraft.

AIoT in aviation health monitoring use sensors (IoT devices) embedded across aircraft to collect real-time data on engine performance, structural integrity, systems’ functionality, and more. These data are then processed and analyzed using AI algorithms to identify patterns, anomalies, and trends that human operators might not easily detect.

AIoT exemplifies the principles of the future internet, characterized by highly interconnected services, enhanced machine-to-machine communication, and intelligent automation. AIoT exemplifies the principles of the future internet, characterized by highly interconnected services, enhanced machine-to-machine communication, and intelligent automation. The future internet is expected to be more dynamic, autonomous, and capable of handling increasingly complex tasks with minimal human intervention. AIoT in aviation is a clear manifestation of these potential capabilities, leveraging network technologies to support more efficient, safe, and reliable air travel.

As a quintessential future internet technology, AIoT in aviation health monitoring systems not only revolutionizes current practices but also paves the way for more innovative applications in the aerospace sector. It represents a symbiosis of connectivity, intelligence, and automation, driving the aviation industry towards a safer, more efficient future. As technologies evolve and new challenges emerge, the continuous development and integration of AIoT will be pivotal in defining the next era of the aviation industry, embodying the full potential of the future internet.

Today the IoT is increasingly integrated into various sectors. The paper [1] highlights the potential for expanded IoT implementation in the aviation sector, a critical area of modern life and travel, to improve the smooth operation of the thousands of commercial planes in the air at any moment. The study [2] explores the integration of the Internet of Things (IoT) in aviation, focusing on its application in airport process management, airline operations, and aircraft maintenance. It provides an overview of IoT’s potential in aviation, identifies key areas for its application, and analyzes major trends and findings through a review of the literature from the Web of Science database.

Another critical technology is Prognostic and Health Management (PHM), which significantly enhances fault detection capabilities in aircraft. Statistical reports have shown that failures in the aircraft system directly impact the overall health, performance, safety, and airworthiness of the aircraft [3]. Consequently, it is vital to develop a system that monitors the aircraft’s health by analyzing and diagnosing faults to prevent catastrophic events. The PHM system enhances the safety, reliability, performance, and maneuverability of an aircraft. This leads to smarter maintenance of the aircraft’s fuel system and other components, thereby reducing the workload on pilots [4].

The paper [5] examines the role of avionics systems in the growth of aviation industry, attributing recent advances to developments in avionics technology, despite its association with numerous aviation accidents. It focuses on PHM technologies that shift from traditional scheduled maintenance to condition-based maintenance, enhancing safety and performance. This research delves into fault prediction and system health management, discussing the application and future trends of PHM in integrated avionics systems to bolster the safety of the aerospace industry.

The application and management of AI in the aviation sector, focusing on technology prognosis, applications, and market demand, is discussed in [6]. It aims to enhance our understanding of AI’s potential impacts and benefits in aviation, detailing its influence on industry growth and specific uses in areas such as machine learning for manufacturing efficiency. Additionally, the paper addresses concerns among aviation professionals about the increasing reliance on AI, providing a critical examination of this issue through relevant examples.

The paper [7] discusses the integration of intelligent assistants (IAs) in aviation, anticipating their deployment across cockpits, air traffic control centers, and airports to potentially enable single-pilot operations and AI-driven air traffic management. While IAs promise significant advancements, concerns arise about their impact on the industry’s strong safety culture, traditionally upheld by human oversight. Utilizing a validated safety culture tool, three safety and human–AI teaming experts assess the potential risks and benefits of IAs in aviation, identifying both negative outcomes and opportunities to enhance safety culture. The paper recommends safeguards for various aviation stakeholders to ensure that safety remains a paramount concern as AI technologies are adopted.

The role of AI in air traffic management (ATM), analyzing its current adoption and potential to improve safety and complexity management in aviation, is examined in [8]. It reviews a decade of AI research in the ATM domain, identifying trends and extracting key dimensions. Additionally, the paper discusses the necessity for explainable artificial intelligence (XAI) in ATM, presenting the descriptive, predictive, and prescriptive model as a conceptual framework and illustrating its application in a projected 2030 scenario. It concludes that further research and the development of validated XAI methods are crucial for AI acceptance among ATM end-users.

The integration of AI and IoT technologies, known as AIoT, has been gaining significant attention in recent years. For example, the paper [9] introduces a cognitive IoT architecture with a new cognitive component for new port management solutions. The results demonstrate improved efficiency in port operations due to more accurate arrival predictions, and the generic nature of the architecture allows for easy adaptation to other domains.

The paper [10] presents the development of an innovative unmanned vehicle system designed to operate without the need for additional infrastructure or expensive sensors, addressing manpower shortages. The system features a self-learning, efficient image recognition algorithm that enhances navigation safety and reliability, even with the current limitations of wireless communications and sensor technology. Tested in a factory setting, this system proves capable of supporting multiple unmanned vehicles simultaneously, offering a scalable solution to improve manufacturing efficiency without the high costs and infrastructure demands typically associated with such technologies.

The significant advancements in drone technology driven by the integration of AI, highlighting its applications beyond military uses—including logistics, agriculture, construction, and more are discussed in [11]. It discusses how AI has enhanced drone autonomy, enabling them to execute complex missions independently. The study covers the latest developments and applications and considers the ethical and regulatory challenges that could shape the future of drone technology and its impact on the socioeconomic landscape.

Air traffic management (ATM) is grappling with increasing complexity and demands improvements to enhance aviation safety, with AI playing a crucial role. The paper [12] explores the growing complexities within air traffic management and the potential of explainable artificial intelligence to enhance the safety and user acceptance of AI systems in the aviation sector. An article [13] suggests the use of long short-term memory neural networks for analyzing aircraft surveillance data. This approach aims to detect conflicts and provide air traffic controllers with improved situational awareness, thereby facilitating the transition to a more automated, efficient, and safer next-generation air traffic management system.

The study [14] delves into explainable AI techniques to boost transparency and trust in automated air traffic management systems. It involves training machine learning models on aviation and meteorological data to facilitate real-time risk prediction and generate explanations for air traffic controllers to assess. The paper [15] discusses the necessary requirements such as verification, certification, and user acceptance for the operational deployment of AI in air traffic management. It argues that research into explainable AI and verification should progress concurrently and that certification will become crucial as ground-based systems increasingly automate. Another paper [16] assesses AI’s relevance in ATM, introduces the descriptive–predictive–prescriptive model of explainable AI and highlights the need for further research and validation to foster AI systems’ acceptance in ATM.

The methodology for applying machine learning systems in air traffic control, particularly in a conflict detection tool, is evaluated in [17]. Findings indicate that the methodology lacks time-dependent analyses, suggesting that standard classification and regression metrics may not be universally applicable across systems due to their variability over time. The robust data-driven method for aircraft trajectory prediction using a neural network based on the Generative Adversarial Network framework is presented in [18]. This system is enhanced with Blockchain Ledger Technology for secure storage of predictions, effectively resisting adversarial attacks, as shown in performance evaluations using proposed simulations.

Numerous publications focus on the application of AI and machine learning in enhancing aviation safety. A systematic review [19] covers the use of natural language processing (NLP) in aviation safety from 2010 to 2022, detailing specific NLP techniques, their effectiveness, existing challenges, and future potential to boost safety and efficiency. Another study [20] employs NLP and machine learning methods, such as label spreading and support vector machines, to categorize human factor categories from aviation incident reports. Despite the challenges of limited labeled data, the methodology achieves high predictive accuracy.

Research [21] utilizes machine learning and data analytics, specifically the specific clustering algorithm, to analyze go-arounds at international airports. It distinguishes between typical and anomalous patterns, noting that anomalous go-arounds often deviate from standard procedures and exhibit higher energy states during the initial approach. The approach introduced in [22] analyzes text-based aviation safety reports using NLP and categorizes them through special tools of clustering and visualization. Applied to the Aviation Safety Reporting System, it identifies 10 major and 31 sub-clusters, providing new insights into aviation safety incidents that are not apparent from existing labels.

The paper [23] presents the Safety Analysis of Flight Events methodology, which combines data cleaning, correlation analyses, supervised learning, and visualization to understand flight risk factors better. Applied to commercial airline data, the methodology identifies crucial parameters for specific safety events and underscores the importance of aligning machine learning insights with human interpretations of incidents. A study [24] develops a methodology employing learning methods and predictive modeling to detect failures due to human factors in the aviation industry. While the approach shows promise, the study calls for larger datasets to enhance predictive accuracy in future research.

Research [25] evaluates the potential of generative language models, particularly ChatGPT, for improving aviation safety analyses. By generating incident summaries and identifying human factors from the Aviation Safety Reporting System dataset, the study advocates for a human-in-the-loop system to responsibly utilize these models, highlighting the importance of collaboration and continual enhancement in aviation safety applications.

Maintenance is a key area where artificial intelligence is both highly sought after and extensively applicable. Research [26] investigates the use of Convolutional Neural Networks alongside autonomous drones to automate visual inspections for aircraft maintenance. This study builds on existing work, introducing methods that enhance defect detection accuracy, such as specific image augmentations and pre-classification techniques, improving the identification of issues like dents.

A novel approach combining machine learning and IoT to predict the thermal performance of aircraft wing anti-icing systems is presented in [27]. Utilizing an artificial neural network, this method has proven more efficient and quicker than traditional computational fluid dynamics approaches, indicating significant potential for aviation applications. The paper [28] reviews the application of statistical and machine learning techniques to analyze aircraft environmental impacts, including fuel burn, emissions, and noise. It summarizes key research themes and representative works, discussing how these methods can further enhance the sustainability of aviation operations.

In [29], the article introduces the use of deep neural networks and transfer learning to automatically detect corrosion in aircraft lap joints from images, achieving accuracy comparable to that of trained human operators. This could aid maintenance personnel and facilitate more automated condition-based maintenance. The study [30] explores active vibration control in helicopters, particularly focusing on individual blade control to reduce vibration loads at the hub. By employing various models and methods, such as fuzzy neural networks, the research indicates that this approach could significantly lessen hub vibration loads, providing valuable insights for developing helicopter vibration control laws.

Four data-driven frameworks for predicting the exhaust gas temperature baseline of aeroengines are proposed in [31]. These frameworks use data from actual engines and apply machine learning methods, with the Generalized Regression Neural Network model displaying the highest accuracy and efficiency, making it suitable for practical airline use. The article [32] reviews machine learning applications in lithium-ion battery research, particularly for aviation batteries and green aviation technologies. It examines the strengths and weaknesses of different machine learning approaches to enhance understanding and drive future advancements in the field. Paper [33] showcases the use of a multilayer perceptron neural network to model the transient performance of aero engines, particularly focusing on heat transfer during transient operations. This model, trained on finite element simulation data and refined with real engine measurements, accurately replicates engine thermal transients.

A data-driven approach for predicting base pressure in suddenly expanded flows is introduced in [34]. This method, using machine learning models trained on response equations, accurately forecasts base pressure to help optimize base drag in rockets and missiles. The study [35] applies machine learning techniques, specifically a deep neural network and a random forest classifier, to predict null motions in a four-control moment gyroscope used in satellite attitude control. The second method demonstrated superior accuracy over the first one, enabling reliable predictions of null motions for maneuvers outside the training dataset.

There is considerable research on the applications of AI for enhancing the autonomy of unmanned aerial vehicles (UAVs). The paper [36] offers a comprehensive review of AI-based autonomous UAV networks, underlining their potential to enhance network performance. After examining over 100 articles, the study validates the feasibility and cost-effectiveness of AI-based UAVs for future network designs and identifies areas in need of further research.

In [37], the application of digital twins (DTs) for autonomous aircraft is explored, with a particular focus on the importance of data management. The study examines data augmentation through synthetic data generation to overcome real-life data availability issues, particularly highlighting the application on hybrid turbo-shaft engines in drones and helicopters. It demonstrates the effectiveness of using rolling linear regression and Kalman filter algorithms to simulate real-life operational data. The design of a controller using an evolutionary neural network for autonomous quadrotor flight is discussed in [38]. This controller aims to navigate the quadcopter to a designated position while adhering to attitude limitations. The neurocontroller, developed and trained with a custom evolutionary algorithm, proved effective in simulation tests, showing efficient path-following with high precision and speed.

The study [39] investigates the use of deep learning methods, particularly through acoustic signals, to detect UAVs. Convolutional Neural Networks were found to be highly effective, with ensemble techniques achieving notable accuracy. This suggests potential for future integration with radar and visual detection methods. In [40], a model for secure communication and classification in drone-enabled emergency monitoring is described. This AI-based system enhances data security through an encryption process and classifies emergency situations using deep learning. The model demonstrated improved performance when tested on a professional dataset. The paper [41] presents an anomaly detection model for UAVs that utilizes an enhanced graph neural network combined with a transformer, graph attention mechanism, and a multi-channel fusion mechanism. Experimental results showed that the Graph Deviation Network surpasses other methods in terms of accuracy and computational efficiency on two datasets from unmanned systems.

Numerous key civil aviation organizations have published official documents emphasizing AI’s expanding role in the industry and offering recommendations for its adoption. The International Civil Aviation Organization (ICAO) underscored the importance of preparing the next generation of aviation professionals for an AI-enabled future in their 2017 Training Report, stressing the augmentation of aviation training with AI technologies to enhance competencies in utilizing AI tools [42]. Furthermore, ICAO’s 2019 Working Paper on artificial intelligence and digitalization in aviation provides guidelines for implementing AI in areas such as air traffic management, advocating for increased R&D, and the development of workforce expertise in AI [43].

The European Union Aviation Safety Agency (EASA) unveiled its Artificial Intelligence Roadmap in 2020 [44]. This strategic document advocates for expanded research into aviation AI applications, addressing safety and societal risks. It analyzes AI use cases and proposes an AI oversight framework, supporting the development, testing, and approval of aviation AI systems. EUROCONTROL highlighted the need to accelerate AI adoption in air traffic management in its 2020 FLY AI report [45]. Recommendations include establishing a shared AI infrastructure, promoting an “AI culture”, and enhancing expertise through training and educational programs. EUROCONTROL also formed a task force on AI in aviation to propel progress. While this research concentrates on European aviation education, global integration in air transportation merits consideration of trends worldwide. In 2022, the Federal Aviation Administration (FAA) introduced a new course for certification in the Technical Discipline: Artificial Intelligence—Machine Learning [46]. This course aims to maintain and expand U.S. leadership in research and knowledge concerning the use of machine learning in aviation systems and the integration of machine learning-based components with aircraft software.

In 2018, The International Air Transport Association (IATA) released a white paper, AI in Aviation: Exploring the Fundamentals, Threats, and Opportunities of Artificial Intelligence in the Aviation Industry [47]. IATA expressed a commitment to raising awareness and supporting airlines and the broader value chain to harness the benefits of AI through applied research, proof of concepts, pilots, and collaborations with academia and startups, thereby accelerating innovation. These efforts by civil aviation authorities to prepare for AI align with strategies at the highest levels of European governance. The European Commission’s 2021 European AI strategy [48] (EU AI Act: the first regulation on artificial intelligence) aims to position the EU as a global leader in human-centric, trustworthy AI across sectors, including transportation. This indicates a policy-level recognition of AI’s transformative potential and the necessity of creating an ethical, excellence-oriented framework to realize its benefits while ensuring safety. In April 2021, the EU Commission presented its AI package, including the following

- -

- Communication on fostering a European approach to AI [49];

- -

- A review of the Coordinated Plan on Artificial Intelligence (with EU Member States) [50];

- -

- A proposal for a regulation establishing harmonized rules on AI (AI Act) and relevant impact assessment [51].

While existing research has explored IoT and AI applications in aviation separately, the integration of these technologies as AIoT for comprehensive health monitoring systems remains underexplored. This study aims to address this gap by proposing a holistic AIoT framework tailored for aviation health monitoring, examining how AIoT can shift the paradigm from reactive maintenance to proactive health management in aviation, and presenting a comprehensive model demonstrating the transition from traditional health monitoring to AIoT-enabled health management.

By addressing these objectives, this study provides a comprehensive understanding of AIoT’s potential in transforming aviation health monitoring systems, paving the way for safer, more efficient, and more sustainable air transportation.

This paper is structured as follows. Section 2 outlines the materials and methods used in this study, including the development of the AIoT-based aircraft health management model. Section 3 presents the results, detailing the proposed AIoT framework for aviation health monitoring and its various implementations. Section 4 discusses the implications of the findings, comparing traditional and AIoT-based health monitoring models and exploring the paradigm shift from health monitoring to health management. This section also considers future research directions in AIoT-enhanced aviation health monitoring. Section 5 concludes this paper, summarizing the key findings and their significance for the aviation industry.

2. Materials and Methods

The overarching goal of this study is to develop and evaluate a comprehensive AIoT system that can enhance aircraft safety, efficiency, and maintenance practices. The different scientific methods for background analyses are categorized into several key areas including the following:

- IoT sensors are strategically deployed throughout the aircraft to collect real-time data on various parameters, such as engine performance, structural integrity, and environmental conditions. This empirical data collection process ensures that this study is based on real-world observations and measurements.

- Methods of data pre-processing aim to enhance data quality, handle missing values, and ensure compatibility with AI algorithms, ultimately improving the reliability and accuracy of the analysis.

- AI and machine learning methodologies are employed for predictive maintenance tasks. These algorithms can be trained on historical data and sensor readings to learn patterns and make predictions about potential failures and maintenance needs.

- Before deploying the AIoT system in real-world scenarios, extensive analyses of health monitoring ecosystem should be conducted in simulated environments. This controlled setting will allow for rigorous experimentation and evaluation of the system’s performance under various conditions.

- Comparative analyses are one of the core components of this study. The performance of the AIoT system will be compared to traditional aircraft health monitoring approaches. This comparative analysis provides the opportunity to evaluate the improvements and benefits brought about by the integration of AI and IoT technologies.

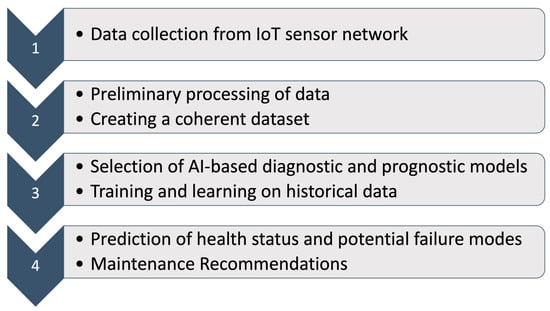

In the technologically driven world of aviation, the amalgamation of AI and the IoT provides unparalleled opportunities for advancing aircraft health monitoring systems (AHMS). Figure 1 depicts a streamlined process that is central to AIoT, illustrating how sensor data can be transformed through sophisticated machine learning models to provide actionable insights into an aircraft’s health status. This paper focuses on the AIoT-driven process that underpins this transformation.

Figure 1.

AIoT-based aircraft health management.

The first stage of the process is data acquisition, where diverse sensors installed throughout an aircraft collect a vast array of data points. These sensors form a sensor network that captures everything from engine temperatures and vibrations to fuel efficiency and aerodynamic pressures.

In the context of AIoT, the data acquisition process benefits from a highly interconnected network of sensors that communicate in real-time, providing a holistic view of the aircraft’s operational status. This IoT infrastructure is the foundation for real-time health monitoring and predictive maintenance strategies.

The raw data from sensors are often noisy and voluminous. Therefore, pre-processing is a critical step where data fusion integrates information from multiple sources, creating a coherent dataset. Data rejection and filtering then remove outliers and irrelevant information, while feature extraction distills the most significant characteristics of the data.

AIoT amplifies the potential of pre-processing by using edge computing—where data processing occurs near the data source—to handle these tasks efficiently. By processing data on the aircraft itself, AIoT reduces latency and bandwidth requirements, allowing for faster response times and less strain on the communication networks.

The pre-processed data are then fed into diagnostic and prognostic machine learning models. These AI models are trained to identify condition indicators that signify the health of various aircraft systems.

Machine learning models’ efficiency is based on data: the more data, the better the models can learn and adapt. AIoT provides a seamless flow of high-quality data, ensuring that the AI models are always updated with the latest information. By incorporating historical fault data and trends, the models can predict potential system failures before they occur.

The output of this process is a clear and up-to-date picture of the current and predicted state of health of the aircraft, including probable failure modes. This enables maintenance crews and operation managers to make informed decisions, optimizing maintenance schedules and reducing unplanned downtimes.

The integration of AIoT in AHMS ensures that these outcomes are not only accurate but also timely. As the models improve over time, the predictive capabilities of the system become more nuanced, potentially foreseeing issues well before they would otherwise be detectable.

The AIoT offers a wealth of opportunities for advancing AHMS:

- AIoT maximizes operational efficiency by allowing real-time monitoring and faster decision-making processes.

- By accurately predicting when maintenance is needed, AIoT-driven AHMS can prevent costly repairs and downtime, resulting in significant cost savings.

- Enhanced predictive maintenance leads to increased safety margins, as potential issues can be addressed proactively.

- The wealth of data collected and analyzed through AIoT enables deeper insights, facilitating continuous improvement in aircraft design and operation.

The materials and methods described in this study represent a comprehensive approach to integrating AIoT into aviation health monitoring systems. By leveraging the power of AI and the ubiquity of IoT sensors, this study aims to contribute to the development of more intelligent, efficient, and safer aircraft operations.

3. Results

The future of aircraft health monitoring is on the brink of a transformative leap with the integration of AIoT and future internet technologies. This section will explore the architecture and discuss the profound opportunities AIoT and future internet technologies present in enhancing aircraft safety and performance.

3.1. Sensors in an Aircraft Health Monitoring System

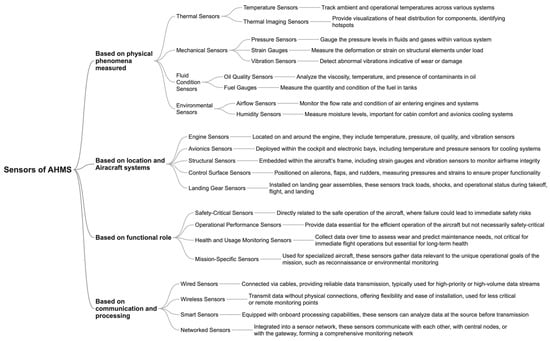

The robustness and safety of modern aviation are significantly reliant on the capabilities of various sensors that constitute an aircraft health monitoring system [52,53,54,55]. These sensors are the aircraft’s nerve endings, collecting critical data that ensure the optimal performance and safety of the flying vessel.

The general taxonomy of sensors in an aircraft health monitoring system (Figure 2) can be delineated based on their functional roles, the physical phenomena they measure, their locations, and their relevance to different aircraft systems. This taxonomy is integral to understanding how data are collected and analyzed to maintain aircraft safety and efficiency.

Figure 2.

Taxonomy of sensors in an aircraft health monitoring system.

3.2. The Analytical IT System Framework as a Foundation for AIoT in Aviation Health Monitoring

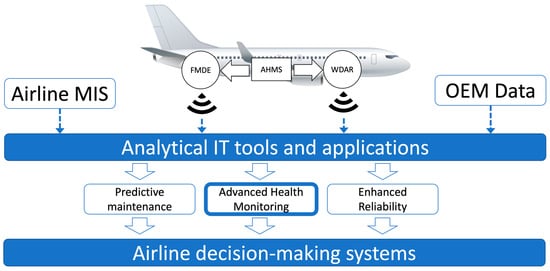

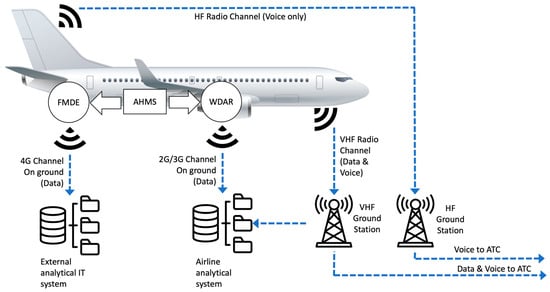

Figure 3 illustrates an analytical IT system framework that forms the backbone of a modern aviation health monitoring system. This framework embodies the core principles of the AIoT, integrating data collection, analyses, and decision-making processes to enhance aircraft reliability and operational efficiency.

Figure 3.

The analytical IT system framework for AIoT.

At the heart of this system is AHMS with two critical data collection components:

- WDAR—Wireless Digital AIDS Recorder (AIDS—Aircraft Integrated Data System [56]) unit [57];

- FMDE—Flight and Maintenance Data Exchange unit [58].

These elements represent the IoT aspect of AIoT, serving as the primary sources of real-time data from the aircraft’s various systems and components.

The AIDS is an essential component of modern aviation, gathering and integrating data from various aircraft systems to provide comprehensive monitoring, analyses, and control capabilities. By improving flight safety, enabling efficient maintenance practices, and facilitating data-driven performance optimization, the system has become a vital tool for airlines and aviation operators.

The WDAR is likely designed to collect a wide range of flight data, including parameters related to aircraft performance, system status, and environmental conditions. The FMDE unit, on the other hand, focuses on gathering detailed maintenance-related information. Together, these units form a comprehensive data acquisition network that captures the complex operational state of the aircraft in real-time.

The data collected by these units feed into the central analytical IT System, which acts as the brain of the framework. This system integrates data from multiple sources, including the airline’s maintenance information system (MIS) and original equipment manufacturer (OEM) data [59]. By combining real-time operational data with historical maintenance records and manufacturer specifications, the analytical IT tools and applications create a rich, contextual dataset for analysis.

The application of artificial intelligence within this framework is evident in three key outputs: predictive and prescriptive maintenance, health management, and enhanced reliability. These elements represent the AI component of AIoT, where machine learning algorithms analyze the integrated data to provide actionable insights and predictions.

Predictive and prescriptive maintenance use historical data and real-time inputs to forecast potential equipment failures before they occur and prescribe optimal maintenance actions. This proactive approach allows airlines to schedule maintenance activities more efficiently, reducing unplanned downtime and extending the lifespan of aircraft components.

Health management utilizes AI algorithms to continuously assess the condition of various aircraft systems. By analyzing patterns and anomalies in the data, this feature can detect subtle changes that may indicate emerging issues, allowing for early intervention and preventing minor problems from escalating into major failures.

Enhanced reliability is achieved through the cumulative effects of predictive maintenance and health management. As the system learns from each maintenance action and flight, it refines its predictions and improves the overall reliability of the aircraft fleet.

The framework culminates in the airline decision-making systems, where the insights generated by the analytical IT system are used to inform strategic and operational choices. This could include optimizing maintenance schedules, adjusting flight operations to maximize efficiency, or making long-term fleet management decisions.

This analytical IT system framework exemplifies the potential of AIoT in aviation health monitoring. By seamlessly integrating IoT data collection capabilities with AI-powered analytics, this system offers a comprehensive solution for improving aircraft maintenance, reliability, and operational efficiency. The framework enables a shift from reactive to proactive maintenance strategies, potentially reducing costs, improving safety, and optimizing aircraft availability.

The inclusion of OEM data in the analytical process suggests a collaborative approach to aircraft health monitoring, where manufacturers’ expertise is leveraged alongside real-world operational data. This synergy between operators and manufacturers can lead to continuous improvements in aircraft design and maintenance practices.

As AIoT technologies continue to evolve, frameworks like this will play an increasingly crucial role in enhancing aviation safety, reducing costs, and optimizing performance across the industry. The ability to process vast amounts of data in real-time, make intelligent predictions, and provide prescriptive maintenance recommendations represents a significant leap forward in aviation maintenance and operations management.

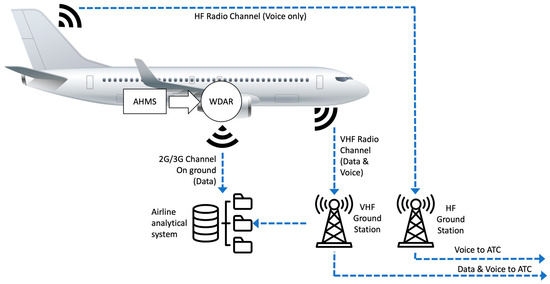

3.3. AIoT-Enabled Aircraft Communication Architecture: Enhancing Health Monitoring through WDAR

The aircraft communication architecture depicted in Figure 4 illustrates a sophisticated network of data and voice communication channels that form the backbone of modern aviation systems. This architecture, particularly with the inclusion of the WDAR option, represents a significant step towards realizing the full potential of the AIoT in aviation health monitoring.

Figure 4.

AIoT-enabled aircraft communication architecture.

At the heart of this architecture is the WDAR, an optional system designed to transmit flight data for analysis. The WDAR serves as a crucial IoT component, collecting approximately 400 parameters from various aircraft systems. This extensive data collection forms the foundation for advanced health monitoring and predictive maintenance capabilities that are central to the AIoT paradigm in aviation.

The communication infrastructure supporting the WDAR is multi-faceted, ensuring robust and flexible data transmission:

- 2G/3G channel [60]. When the aircraft is on the ground, the WDAR utilizes a 2G/3G connection for data transmission. While this is a low-speed connection, it is sufficient for transferring the collected parameters to the airline’s analytical system. The effectiveness of this channel depends on the airport’s location and infrastructure, highlighting the importance of ground-based IoT networks in the overall AIoT ecosystem.

- Very-high-frequency (VHF) radio channel [61]. This channel supports both data and voice communication, providing a versatile link between the aircraft and ground stations. In the context of AIoT, the data transmission capabilities of the VHF channel could be leveraged for real-time or near-real-time health monitoring updates during flight.

- High-frequency (HF) radio channel [61]. Although limited to voice communication, the HF channel ensures long-range communication capabilities, which is crucial for maintaining connectivity in remote areas where VHF and cellular networks are unavailable.

The integration of these communication channels with the WDAR system exemplifies the IoT aspect of AIoT, creating a comprehensive data collection and transmission network. This network enables the continuous flow of information from the aircraft to the airline’s analytical system, where AI algorithms can process and analyze the data.

The airline analytical system, as the recipient of the WDAR data, represents the AI component of the AIoT framework. Here, machine learning algorithms can be applied to the vast amount of data collected by the WDAR to identify patterns, predict potential issues, and optimize maintenance schedules. This integration of real-time data collection with advanced analytics embodies the essence of AIoT in aviation health monitoring.

The benefits of this AIoT-enabled architecture are numerous:

- With access to 400 parameters [62], AI algorithms can develop highly accurate predictive models, allowing airlines to anticipate and address potential issues before they lead to failures or delays.

- Real-time data transmission enables airlines to make informed decisions about flight operations, potentially reducing fuel consumption and optimizing flight paths.

- Continuous monitoring of critical systems through the WDAR enhances overall flight safety by enabling rapid responses to any anomalies detected during flight.

- By optimizing maintenance schedules and reducing unplanned downtime, airlines can significantly reduce operational costs.

- The wealth of data provided by the WDAR, when analyzed using AI, can inform strategic decisions about fleet management, training programs, and long-term operational planning.

However, the implementation of such an AIoT system is not without challenges. The reliance on ground-based infrastructure for data transmission when the aircraft is on the ground may limit the system’s effectiveness in areas with poor cellular coverage. Additionally, the current use of 2G/3G technology suggests that there is room for improvement in data transmission speeds, which could be addressed with the adoption of more advanced cellular technologies like 4G LTE or 5G in the future.

The aircraft communication architecture with the WDAR option represents a significant step towards fully realizing the potential of AIoT in aviation health monitoring. By combining extensive data collection capabilities with diverse communication channels and advanced analytical systems, this architecture lays the groundwork for a new era of predictive, efficient, and safe aviation operations. As AIoT technologies continue to evolve, we can expect even greater integration of real-time data analyses and automated decision-making processes, further revolutionizing the field of aviation health monitoring.

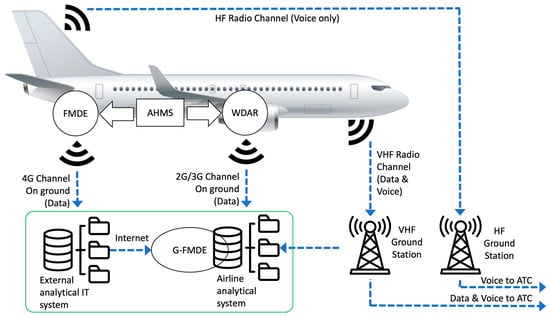

3.4. Advanced AIoT Integration in Aviation on the Base of WDAR and FMDE Synergy

The aircraft communication architecture depicted in Figure 5 represents a significant advancement in the application of AIoT to aviation health monitoring systems. This enhanced architecture, which incorporates both the WDAR and the FMDE unit, exemplifies the potential for comprehensive data collection, transmission, and analyses in modern aviation.

Figure 5.

Advanced AIoT integration in aviation.

At the core of this architecture are two complementary systems:

- The WDAR, an optional system used to transmit flight data for analysis;

- The FMDE, another optional unit that combines full aircraft interface device (AID) capabilities into a single hardware, software, and connectivity solution [63].

The integration of these two systems creates a powerful AIoT framework that significantly enhances the depth and breadth of aircraft health monitoring capabilities.

One of the most striking features of this enhanced architecture is the massive increase in data collection capacity. Based on proprietary aircraft manufacturer documentation, the WDAR typically collects approximately 400 parameters, while the addition of the FMDE can expand this to more than 20,000 parameters in advanced aircraft models [62]. This fifty-fold increase in data points represents a quantum leap in the potential for detailed aircraft health monitoring and predictive maintenance. The sheer volume of data collected embodies the “Internet of Things” aspect of AIoT, with thousands of sensors and systems continuously reporting their status.

The communication infrastructure supporting this expanded data collection is equally advanced:

- 4G channel [64]. The FMDE utilizes a 4G connection for data transmission when the aircraft is on the ground. This faster connection, compared to the 2G/3G used by the WDAR, allows for more efficient transfer of the vastly increased data volume. However, it is worth noting that this still depends on airport location and infrastructure, highlighting the importance of ground-based network improvements in realizing the full potential of AIoT in aviation.

- 2G/3G channel. The WDAR continues to use this channel as a backup or in locations where 4G is not available, ensuring data transmission even in less technologically advanced airports.

- VHF and HF radio channels. These continue to provide voice and data communication capabilities, essential for air traffic control and long-range communication.

This multi-layered communication approach ensures robust and flexible data transmission, a crucial aspect of any IoT system.

The collected data are transmitted to two distinct analytical systems:

- The airline analytical system, as an internal system, likely handles immediate operational needs and airline-specific analyses.

- The external analytical IT system as additional system suggests the potential for more advanced or specialized analyses, possibly leveraging cloud computing or shared industry resources. The effectiveness of this external system depends on the arrangement of data transfer, indicating the need for secure and efficient data sharing protocols.

The inclusion of an external analytical system points to the potential for industry-wide collaboration and the application of more sophisticated AI algorithms that may be beyond the capabilities of individual airlines to develop or maintain.

This enhanced architecture offers several key advantages in the context of AIoT:

- With over 20,000 parameters being monitored [62], the potential for detecting subtle precursors to equipment failure or performance issues is greatly increased.

- The vast amount of data collected allows for more sophisticated AI models, potentially leading to more accurate and earlier predictions of maintenance needs or potential failures.

- By combining flight data (WDAR) with maintenance-specific information (FMDE), a more complete picture of aircraft health can be formed.

- The dual analytical systems allow for both immediate, airline-specific insights and potentially more in-depth, industry-wide analyses.

- With more data points and faster transmission, airlines can make more informed decisions about flight operations, maintenance scheduling, and resource allocation.

- The comprehensive monitoring enabled by this system can lead to earlier detection of potential safety issues, allowing for proactive interventions.

However, the implementation of such an advanced AIoT system also presents challenges:

- Handling and analyzing over 20,000 parameters require significant computational resources and sophisticated data management strategies.

- The effectiveness of the system still relies heavily on ground-based infrastructure, which may vary significantly between different airports and regions.

- With increased data collection and transmission comes an increased need for robust cybersecurity measures to protect sensitive aircraft and airline information.

- Combining data from multiple systems (WDAR and FMDE) and analyzing it across different platforms (airline and external systems) requires careful system integration and data standardization.

The aircraft communication architecture featuring both WDAR and FMDE options represents a significant leap forward in the application of AIoT to aviation health monitoring. By dramatically increasing the volume of data collected and providing advanced transmission and analysis capabilities, this architecture lays the groundwork for a new era of predictive maintenance, enhanced safety, and operational efficiency in aviation. As AI technologies continue to advance and IoT infrastructure improves, we can expect even greater capabilities in real-time analyses, automated decision-making, and predictive accuracy, further revolutionizing the field of aviation health monitoring and maintenance.

3.5. Comprehensive AIoT Integration in Aviation on the Base of WDAR, FMDE, and G-FMDE Synergy

The aircraft communication architecture depicted in Figure 6 represents a state-of-the-art implementation of the AIoT in aviation health monitoring systems. This advanced architecture incorporates three key components: the WDAR, the FMDE unit, and the ground-based G-FMDE system. Together, these elements create a comprehensive framework for data collection, transmission, and analyses that exemplifies the potential of AIoT in modern aviation.

Figure 6.

Comprehensive AIoT integration in aviation.

The architecture consists of three primary systems:

- The WDAR, an optional system used to transmit flight data for analysis;

- The FMDE, another optional unit that combines full aircraft interface device capabilities into a single hardware, software, and connectivity solution;

- The G-FMDE, a ground-based component that interconnects the external analytical IT system with the airline’s analytical system [65].

This tri-part system creates a robust AIoT ecosystem that significantly enhances the depth, breadth, and efficiency of aircraft health monitoring capabilities.

The integration of WDAR and FMDE enables the collection of over 20,000 parameters from various aircraft systems. This massive increase in data points represents the “Internet of Things” aspect of AIoT, with thousands of sensors continuously reporting their status.

Besides the characteristics recalled in Section 3.4, this method includes ensures robust and flexible data transmission, crucial for the effectiveness of the AIoT system.

The collected data are transmitted to three interconnected analytical systems:

- The airline analytical system handles immediate operational needs and airline-specific analyses.

- The external analytical IT system provides advanced or specialized analyses, potentially leveraging cloud computing or shared industry resources.

- The G-FMDE acts as a bridge between the external and airline systems, facilitating seamless data integration and analyses.

The inclusion of the G-FMDE is particularly significant as it allows for more efficient data sharing between ground-based systems. This interconnectivity is crucial for realizing the full potential of AIoT, as it enables more comprehensive analyses and the application of advanced AI algorithms across a broader dataset.

AIoT advantages in aviation:

- With over 20,000 parameters being monitored, the system can detect subtle precursors to equipment failure or performance issues with unprecedented accuracy.

- The vast amount of data collected, combined with the interconnected analytical systems, allows for more sophisticated AI models, leading to more accurate and earlier predictions of maintenance needs or potential failures.

- The integration of ground-based systems through the G-FMDE enables near-real-time analyses of aircraft data, allowing for immediate responses to emerging issues.

- With more data points, faster transmission, and integrated analyses, airlines can make more informed decisions about flight operations, maintenance scheduling, and resource allocation.

- The comprehensive monitoring and analyses enabled by this system can lead to earlier detection of potential safety issues, allowing for proactive interventions.

- The external analytical IT system, facilitated by the G-FMDE, opens possibilities for industry-wide data sharing and collaborative problem-solving.

The main challenges of the considered architecture are as follows:

- Handling and securing the transmission of over 20,000 parameters requires robust data management strategies and cybersecurity measures.

- The effectiveness of the system still relies on ground-based infrastructure and internet connectivity, which may vary between different airports and regions.

- Combining data from multiple systems (WDAR, FMDE, and G-FMDE) and analyzing them across different platforms require careful system integration and data standardization.

- The extensive data collection and sharing capabilities of this system may necessitate careful consideration of regulatory requirements, particularly regarding data privacy and cross-border data transmission.

As AIoT technologies continue to evolve, we can anticipate further advancements in this architecture:

- The adoption of 5G technology could significantly increase data transmission speeds and reduce latency, enabling even more real-time analyses and decision-making.

- Implementing edge computing capabilities within the aircraft systems could allow for more immediate data processing and reduce the load on ground-based systems.

- The development of more sophisticated AI and machine learning algorithms could further enhance the predictive capabilities of the system, potentially leading to fully automated maintenance scheduling and decision-making processes.

The aircraft communication architecture featuring WDAR, FMDE, and G-FMDE options represents a significant leap forward in the application of AIoT to aviation health monitoring. By increasing the volume of data collected, providing advanced transmission capabilities, and enabling integrated analyses across multiple systems, this architecture lays the groundwork for a new opportunity for predictive maintenance, enhanced safety, and operational efficiency in aviation.

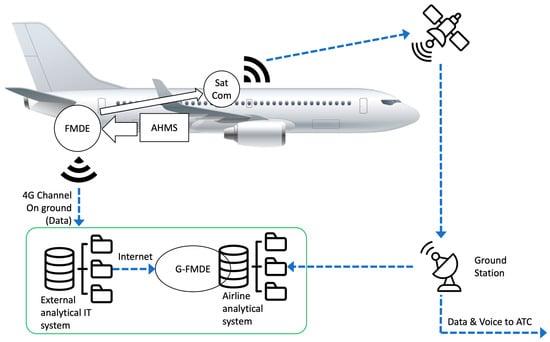

3.6. Next-Generation AIoT in Aviation: FMDE, G-FMDE, and Satcom Integration

The aircraft communication architecture depicted in Figure 7 represents the pinnacle of AIoT implementation in aviation health monitoring systems. This cutting-edge architecture incorporates three key components: the FMDE unit, the ground-based G-FMDE system, and satellite communication (Satcom) [66]. Together, these elements create an unparalleled framework for data collection, transmission, and analyses that fully realizes the potential of AIoT in modern aviation.

Figure 7.

Next-generation AIoT in aviation.

The core components of this architecture are as follows:

- The FMDE—an optional unit that combines full AID capabilities into a single hardware, software, and connectivity solution;

- The G-FMDE—a ground-based component that interconnects the external analytical IT system with the airline’s analytical system;

- Satcom—a satellite communication system that enables continuous, global data transmission.

This integrated system creates a robust AIoT ecosystem that significantly enhances the depth, breadth, and efficiency of aircraft health monitoring capabilities while overcoming previous limitations.

The FMDE enables the collection of over 40,000 parameters from various aircraft systems, doubling the data points from previous architectures. This massive increase in data collection exemplifies the Internet of Things aspect of AIoT, with tens of thousands of sensors continuously reporting their status.

The communication infrastructure supporting this data collection is advanced and flexible:

- A 4G channel is used by the FMDE for fast data transmission when the aircraft is on the ground.

- Satcom provides continuous, global data transmission capabilities, both on the ground and in-flight.

This dual approach ensures robust and uninterrupted data transmission, crucial for real-time monitoring and analyses. The integration of Satcom is particularly significant as it eliminates dependency on ground-based infrastructure and airport location, enabling truly global, real-time health monitoring.

The collected data are transmitted to three interconnected analytical systems:

- The airline analytical system handles immediate operational needs and airline-specific analyses.

- The external analytical its system provides advanced or specialized analyses, potentially leveraging cloud computing or shared industry resources.

- The G-FMDE as already noted in Section 3.5 acts as a bridge between the external and airline systems, facilitating seamless data integration and analyses.

The inclusion of both airline-specific and external analytical systems, connected through the G-FMDE, allows for comprehensive data analyses that can leverage both proprietary airline knowledge and industry-wide expertise.

In this architecture, there are the next AIoT advantages for aviation:

- With over 40,000 parameters being monitored, the system can detect even the most subtle precursors to equipment failure or performance issues with unprecedented accuracy.

- The integration of Satcom enables continuous data transmission regardless of the aircraft’s location, allowing for true real-time monitoring and analyses.

- The vast amount of data collected, combined with the interconnected analytical systems, allows for highly sophisticated AI models, leading to more accurate and earlier predictions of maintenance needs or potential failures.

- With more data points and continuous transmission, airlines can make informed decisions about flight operations, maintenance scheduling, and resource allocation in real-time, potentially even mid-flight.

- The comprehensive, real-time monitoring and analyses enabled by this system can lead to immediate detection of potential safety issues, allowing for proactive interventions regardless of the aircraft’s location.

- The use of Satcom significantly reduces reliance on variable ground-based infrastructure, ensuring consistent performance across different regions and airports.

- The external analytical IT system, facilitated by the G-FMDE, opens possibilities for industry-wide data sharing and collaborative problem-solving on a global scale.

Of course, there are some challenges in the discussed architecture:

- Handling and securing the transmission of over 40,000 parameters requires robust data management strategies and advanced cybersecurity measures, especially considering the use of satellite communication.

- While highly beneficial, the implementation of Satcom and the processing of such large volumes of data may involve significant costs that need to be balanced against the benefits.

- Combining data from multiple systems (FMDE, G-FMDE, and Satcom) and analyzing it across different platforms requires careful system integration and data standardization.

- The extensive data collection and global transmission capabilities of this system may necessitate careful consideration of international regulatory requirements, particularly regarding data privacy and cross-border data transmission.

As AIoT technologies continue to evolve, we can anticipate further advancements in this architecture:

- The real-time, global data availability could pave the way for AI-driven autonomous systems that can make instant decisions about flight parameters, routes, and even emergency procedures.

- With the wealth of data available, predictive maintenance models could become so accurate that they virtually eliminate unscheduled maintenance, optimizing aircraft utilization and reducing costs.

- The ability to analyze data across entire fleets in real-time could lead to optimized fleet management strategies, improving overall airline efficiency.

- The comprehensive health monitoring could extend to cabin systems, allowing for preemptive addressing of issues that affect passenger comfort and satisfaction.

The aircraft communication architecture featuring FMDE, G-FMDE, and Satcom represents the cutting edge of AIoT application in aviation health monitoring by dramatically increasing the volume of data collected, providing global, real-time transmission capabilities, and enabling integrated analyses across multiple systems.

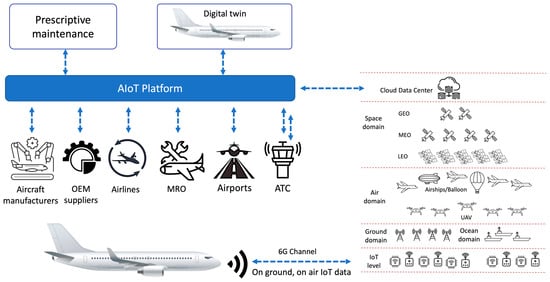

3.7. AIoT and 6G Convergence as Transformative Paradigm for AHMS

The integration of AIoT with the burgeoning capabilities of 6G technology is setting a new frontier in the AHMS. This integration not only promises to transform how data are collected and analyzed in aviation but also reshapes the interconnectivity between various stakeholders within the industry. The convergence of these technologies offers unprecedented predictive accuracy, operational efficiency, safety enhancements, and cost reductions.

Figure 8 presents a framework that encapsulates the future of aviation health monitoring systems, showcasing the seamless integration of AIoT with cutting-edge 6G technology. This advanced ecosystem represents a revolutionary approach to aviation maintenance, operations, and holistic industry management, promising to redefine standards of safety, efficiency, and innovation in the aerospace sector.

Figure 8.

AIoT and 6G convergence for aviation health monitoring ecosystem integration.

At the core of this transformative shift is 6G communication technology, characterized by its high data rate, low latency, and enhanced reliability [67]. The 6G channel acts as the backbone for the massive influx of data generated by IoT devices distributed across the aviation ecosystem. This network supports robust, real-time communication between airborne systems and ground operations, facilitating immediate data synchronization and decision-making processes.

The evolution of wireless technology from 4G to 5G and the anticipated 6G has significant implications for aviation health monitoring systems. In Table 1 a detailed comparison of data transmission speeds and capabilities across these generations, highlighting the potential improvements in real-time monitoring and rapid responses for aviation systems, is provided.

Table 1.

Comparison of wireless generations for aviation health monitoring.

4G LTE Advanced, while capable of supporting basic health monitoring functions, is limited in its ability to handle the vast amounts of data generated by modern aircraft systems. With peak data rates of 1 Gbps and latencies of 10–30 ms, 4G networks can support periodic data transmissions but may struggle with real-time, high-volume data streams required for comprehensive health monitoring.

5G technology represents a significant leap forward, with peak data rates of up to 20 Gbps and latencies as low as 1–4 ms [68]. This improvement allows for more frequent and detailed data transmissions from aircraft systems. The increased connection density of up to 1 million devices per square kilometer also enables a more extensive network of sensors and IoT devices on and around aircraft.

The projected capabilities of 6G technology promise to revolutionize aviation health monitoring. With anticipated peak data rates of 1 Tbps and sub-millisecond latencies, 6G networks will enable true real-time monitoring and near-instantaneous responses to potential issues [67]. The massive increase in connection density to 10 million devices per square kilometer will support an unprecedented level of sensor integration and data collection.

To illustrate the practical implications of these advancements, consider the following scenario: an aircraft engine monitoring system transmitting data on 1000 parameters.

- On a 4G network, this might be limited to updates every few seconds, with potential delays in critical alert transmission.

- With 5G, the system could provide near-real-time updates multiple times per second, significantly improving response times to potential issues.

- In a 6G environment, the system could theoretically transmit continuous, real-time data streams for all parameters simultaneously, enabling predictive analytics and instantaneous anomaly detection.

The improved spectrum efficiency and network energy efficiency of 5G and 6G also have important implications for aviation. Higher spectrum efficiency allows for more data to be transmitted using the same bandwidth, crucial in the congested aviation communication spectrum. The enhanced energy efficiency will be particularly beneficial for onboard systems, potentially extending the operational range of battery-powered sensors and devices.

The ultra-low latency of 6G opens up possibilities for advanced applications such as

- Real-time digital twinning of aircraft systems for enhanced predictive maintenance;

- Instantaneous communication between aircraft and ground control for improved safety protocols;

- Seamless integration of augmented reality for maintenance procedures

These advancements will be crucial in supporting the increasing complexity of modern aircraft systems and the growing demands for safety, efficiency, and reliability in aviation.

The core for this framework (Figure 8) is the AIoT Platform, serving as the nexus of a complex, interconnected system. The AIoT Platform is pivotal, serving as the central hub where data ingestion, processing, and analysis occur. It leverages advanced AI algorithms to interpret complex datasets from diverse sources, enabling intelligent decision-making. By integrating AI with IoT, the platform can execute complex analytical tasks in real-time, providing insights that are both predictive and prescriptive.

The proposed AIoT framework for aviation health monitoring is built upon a three-tiered cloud architecture, a widely adopted approach in cloud computing that ensures scalability, flexibility, and efficient data management [69]. This architecture consists of three distinct layers.

- The presentation tier is the topmost level of the application, responsible for the user interface and user experience. In the context of aviation health monitoring, this tier includes dashboards, alerts, and visualization tools that present processed data and insights to pilots, maintenance crews, and ground staff. It allows users to interact with the system, view real-time aircraft health status, and access predictive maintenance recommendations.

- The application tier (or logic tier) is the middle layer contains the core computational logic of the system. It processes the data received from the data tier, applies machine learning algorithms and AI models, and generates actionable insights. In our AIoT framework, this tier includes the predictive maintenance algorithms, anomaly detection systems, and decision-support tools that analyze aircraft sensor data to forecast potential issues and optimize maintenance schedules.

- The data tier is the foundation of the architecture. This layer is responsible for data storage, management, and retrieval. It handles the vast amounts of data generated by aircraft sensors and IoT devices. In the aviation health monitoring context, this tier includes databases storing historical flight data, maintenance records, and real-time sensor readings. It ensures data integrity, facilitates efficient data access, and supports the high-volume, high-velocity data processing required for comprehensive aircraft health monitoring.

This three-tiered architecture offers several advantages for AIoT in aviation:

- Each tier can be scaled independently to meet changing demands, allowing for efficient resource allocation.

- New features or technologies can be integrated into specific tiers without overhauling the entire system.

- Data can be secured more effectively with clear boundaries between tiers.

- Distributing the workload across tiers optimizes overall system performance, crucial for real-time monitoring and rapid responses in aviation.

By using this three-tiered cloud architecture, our AIoT framework can efficiently handle the complex data processing and analyses required for advanced aviation health monitoring, ultimately enhancing safety, efficiency, and reliability in aircraft operations.

One of the most innovative features illustrated is the digital twin concept. This sophisticated virtual model represents a real-time, high-fidelity simulation of physical aircraft and systems. Utilizing digital twins represents a revolutionary approach in aviation health monitoring. These virtual models simulate the physical characteristics of aircraft in real-time, mirroring every aspect from mechanics to electronics. Engineers and technicians use these models to predict wear and tear, simulate scenarios, and test solutions without physical trials. Enhanced by AI, digital twins can dynamically update and respond to changes in operational conditions or maintenance schedules, leading to more accurate predictions and optimized aircraft performance.

The digital twin is continuously updated with live data from the aircraft:

- Real-time monitoring providing instant insights into the current state of aircraft systems;

- Predictive analyses forecasting potential issues before they manifest as actual problems;

- Simulation capabilities allowing for the testing of various scenarios and maintenance strategies in a risk-free virtual environment;

- Historical data analyses offering deep insights into long-term trends and patterns in aircraft performance.

Beyond predictive capabilities, the AIoT framework empowers prescriptive maintenance strategies. This approach not only predicts potential issues but also recommends specific actions to mitigate risks before they affect operations. Utilizing data from IoT sensors deployed both in the air and on the ground, the AIoT platform can suggest optimal maintenance schedules, part replacements, and operational adjustments, thereby enhancing aircraft reliability and availability.

The concept underscores the importance of seamless integration among various stakeholders in the aviation industry—aircraft manufacturers, MRO providers, airlines, airports, ATC, OEMs, and suppliers. This interconnected setup ensures that data flows freely among all parties, enhancing collaborative efforts. Such integration fosters a comprehensive ecosystem where information is shared in real-time, leading to coordinated responses to maintenance needs and operational demands.

Table 2 delineates how the AIoT platform interfaces with various stakeholders in the aviation ecosystem, each deriving unique benefits.

Table 2.

Benefits of AIoT platform for key stakeholders.

The bidirectional arrows in Figure 8 emphasize the collaborative and interconnected nature of this ecosystem. They represent a free flow of data and insights between different stakeholders, fostering an environment of shared knowledge and collective improvement. This level of integration has the potential to drive industry-wide advancements in safety, efficiency, and innovation.

The realization of this vision will require significant investments in technology, infrastructure, and training. It will also necessitate new regulatory frameworks and industry standards to ensure interoperability and security. However, the potential benefits in terms of improved safety, reduced costs, enhanced efficiency, and environmental sustainability make this a compelling direction for the future of aviation.

4. Discussion

Let us compare the traditional model of health monitoring in aviation with the proposed AIoT-enhanced model. The comparison will focus on the data acquisition, processing, predictive capabilities, and prescriptive actions of each model.

4.1. Traditional Health Monitoring Model

The traditional model of aviation health monitoring is characterized by its relative simplicity and linear approach. At its core, this model focuses on three primary components: system state, maintenance actions, and failure probability.

The system state at any given time is typically assessed through periodic inspections or basic sensor readings. This state information, combined with records of previous maintenance actions, feeds into a failure probability function. This function, often based on statistical models or empirical data, attempts to predict the likelihood of system failure.

Maintenance decisions in the traditional model are primarily driven by this failure probability, along with cost considerations. A decision function takes these inputs and determines when and what maintenance actions should be taken. This approach often results in scheduled maintenance based on fixed intervals or simple threshold-based rules.

The cost function in the traditional model is straightforward, typically calculating expenses based on the maintenance actions performed and the probability of failure. This model, while functional, lacks the sophistication to account for the myriads of factors that can influence aircraft health and performance in real-world operations.

Traditional models of health management can be described as follows.

Let us define the following variables: —system state at time ; —maintenance actions at time ; —failure probability at time ; —cost function at time .

The traditional model can be described as

where is a function that predicts failure probability based on current system state and previous maintenance actions.

where is a decision function that determines maintenance actions based on failure probability and cost considerations.

where calculates the cost based on maintenance actions and failure probability.

In this model, maintenance decisions are often based on fixed intervals or simple threshold-based rules.

4.2. AIoT-Based Health Monitoring Model

In contrast, the AIoT-based model represents a paradigm shift in aviation health management. This model leverages high-dimensional sensor data, environmental and operational context, and advanced AI algorithms to create a more comprehensive and dynamic approach to aircraft health monitoring.

The foundation of the AIoT model is a vastly expanded definition of system state. Unlike the traditional model, which relies on limited data points, the AIoT model integrates data from a dense network of sensors throughout the aircraft. This data are combined with contextual information about the aircraft’s environment and operations to create a rich, multidimensional representation of the system state.

A key innovation in the AIoT model is the introduction of an AI-driven analysis function. This function processes not just the current system state but also historical states, environmental factors, and performance metrics. By considering this wealth of information, the AI can identify subtle patterns and correlations that would be impossible to detect with traditional methods.

The failure prediction function in the AIoT model is significantly more sophisticated than its traditional counterpart. It considers the AI’s analysis, the current system state, and contextual factors to provide more accurate and nuanced predictions of potential failures.

Maintenance decision-making in the AIoT model is transformed from a reactive process to a proactive, intelligent one. The decision function considers not just failure probability and costs but also the AI’s analysis and environmental factors. This allows for dynamic, context-aware maintenance scheduling that can adapt to changing conditions and optimize aircraft availability.

The cost function in the AIoT model is also more advanced, incorporating performance metrics to provide a more holistic view of the financial implications of maintenance decisions. This approach allows for better long-term cost optimization and can account for indirect costs and benefits that might be overlooked in simpler models.

A unique feature of the AIoT model is the inclusion of a performance prediction function. This function forecasts how maintenance actions, current system state, and environmental factors will impact future performance. This forward-looking capability enables more strategic decision-making and continuous system optimization.

AIoT-based models can be described as follows.

Let us introduce additional variables: —high-dimensional sensor data at time ; —AI-driven analysis output at time ; —environmental and operational context at time ; P(t)—performance metrics at time .

The AIoT model can be described as

where is a complex function that determines the system state based on sensor data and contextual information.

where is an AI function that analyzes current and historical states, context, and performance metrics.

where is an advanced failure prediction function that considers AI analyses, current state, and context.

where is an AI-driven decision function for maintenance actions.

where is an advanced cost function that considers performance metrics.

where predicts future performance based on maintenance actions, system state, and context.

4.3. Comparison and Implications of Traditional and AIoT-Based Health Monitoring Models

The contrast between these two models is stark. While the traditional model operates on a limited set of variables and relies heavily on predetermined rules, the AIoT model is dynamic, adaptive, and capable of processing vast amounts of complex, interrelated data.

The traditional model’s simplicity makes it easier to implement and understand, but it lacks the nuance and predictive power of the AIoT approach. The AIoT model, with its ability to consider historical data, real-time sensor inputs, and contextual information, can provide far more accurate failure predictions and optimized maintenance schedules.

The decision-making process in the AIoT model is particularly noteworthy. Instead of relying on fixed rules, it can adapt to changing conditions and learn from past outcomes. This leads to more efficient resource allocation and can significantly reduce unnecessary maintenance while also minimizing the risk of unexpected failures.

Moreover, the AIoT model’s incorporation of performance metrics and predictive capabilities allows for a more strategic approach to aircraft health management. It enables operators to balance short-term costs against long-term performance benefits, potentially extending aircraft lifespan and improving overall operational efficiency.

While the traditional model has served the aviation industry well for many years, the AIoT model represents the future of aircraft health management. Its ability to process and analyze vast amounts of data, adapt to changing conditions, and make predictive, context-aware decisions promises to revolutionize how we approach aircraft maintenance and operations. As this technology continues to evolve and mature, we can expect to see significant improvements in aviation safety, efficiency, and cost-effectiveness.

The main differences of both models are shown in Table 3.

Table 3.

The main differences of traditional and AIoT-based health monitoring models.

The AIoT model represents a significant advancement over the traditional model. It incorporates more data sources, uses advanced AI techniques for analysis and decision-making, and provides a more holistic and adaptive approach to health management. This results in more accurate failure predictions, optimized maintenance scheduling, and overall improved system performance.

4.4. 6G Specifications and Gains for AIoT Systems in Aviation

The advent of 6G technology promises to revolutionize AIoT systems in aviation, offering unprecedented capabilities that will transform aircraft health monitoring, operational efficiency, and safety.

6G is expected to achieve peak data rates of up to 1 Tbps, a 50-fold increase over 5G which will provide the following benefits for aviation:

- Enable real-time streaming of high-resolution sensor data from multiple aircraft systems simultaneously;