Digital-Twin-Based Monitoring System for Slab Production Process

Abstract

1. Introduction

2. Related Work

2.1. Intelligent Industrial Applications

2.2. Defect Detection Techniques

2.3. Intelligent Application of Steelmaking Process

2.4. Research Gaps

- 1.

- Lack of a comprehensive slab production process monitoring system:

- 2.

- Insufficient stability in conventional detection algorithms:

- 3.

- Absence of production management and data analysis for slabs:

3. The Proposed System

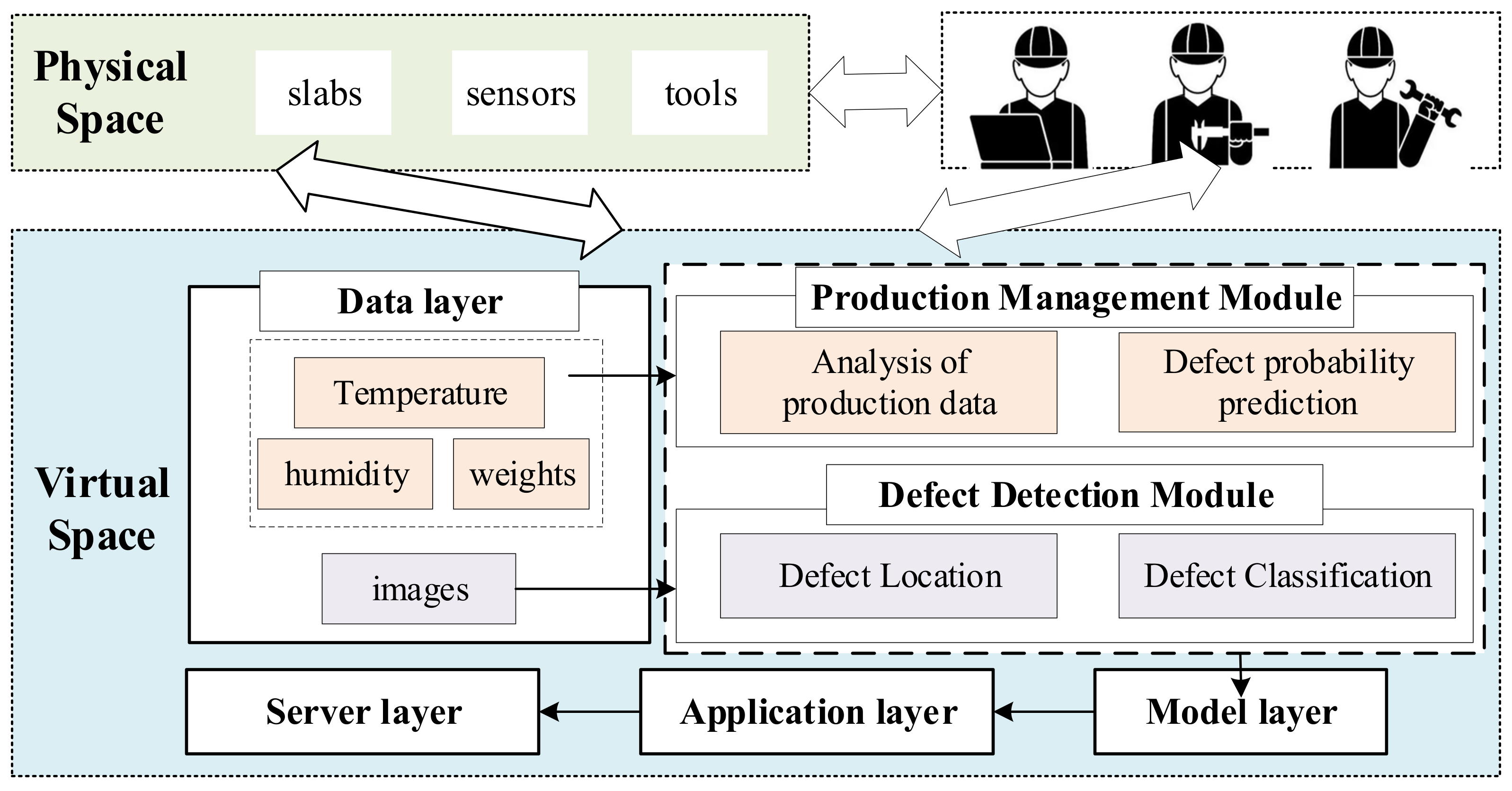

3.1. System Structure

- Data layer: This layer manages collected temperature, humidity, weight, and image data, forming a historical record for user observation at any time.

- Processing of data layer: The data obtained from the data layer are processed, with temperature, humidity, and weight data used for calculating production output and predicting the probability of defect occurrence. Image data are employed for identifying the presence of defects and obtaining classification information.

- Model layer: This layer is responsible for creating a virtual model of the slab and simultaneously displaying the position, size, and classification of defects within the model.

- Application layer: Acting as a bridge between the server and model layers, this layer facilitates virtual visual monitoring of slabs and production state monitoring. UNITY 3D stands out as a robust and versatile game development engine, offering seamless integration capabilities for a diverse range of data sources [40]. This includes the incorporation of real-time sensor inputs, process parameters, and environmental conditions. Serving as a pivotal layer within the monitoring system, it facilitates the creation of an all-encompassing digital representation of the slab production process.

- Server layer: The server layer is situated upstream of the application layer, providing an intuitive display of the application layer on various terminal devices. By encapsulating the management system constructed in the application layer into different terminal devices, personnel can actively participate in the direct monitoring and management of the slab production process using PC, phone, pad, Web, and VR clients.

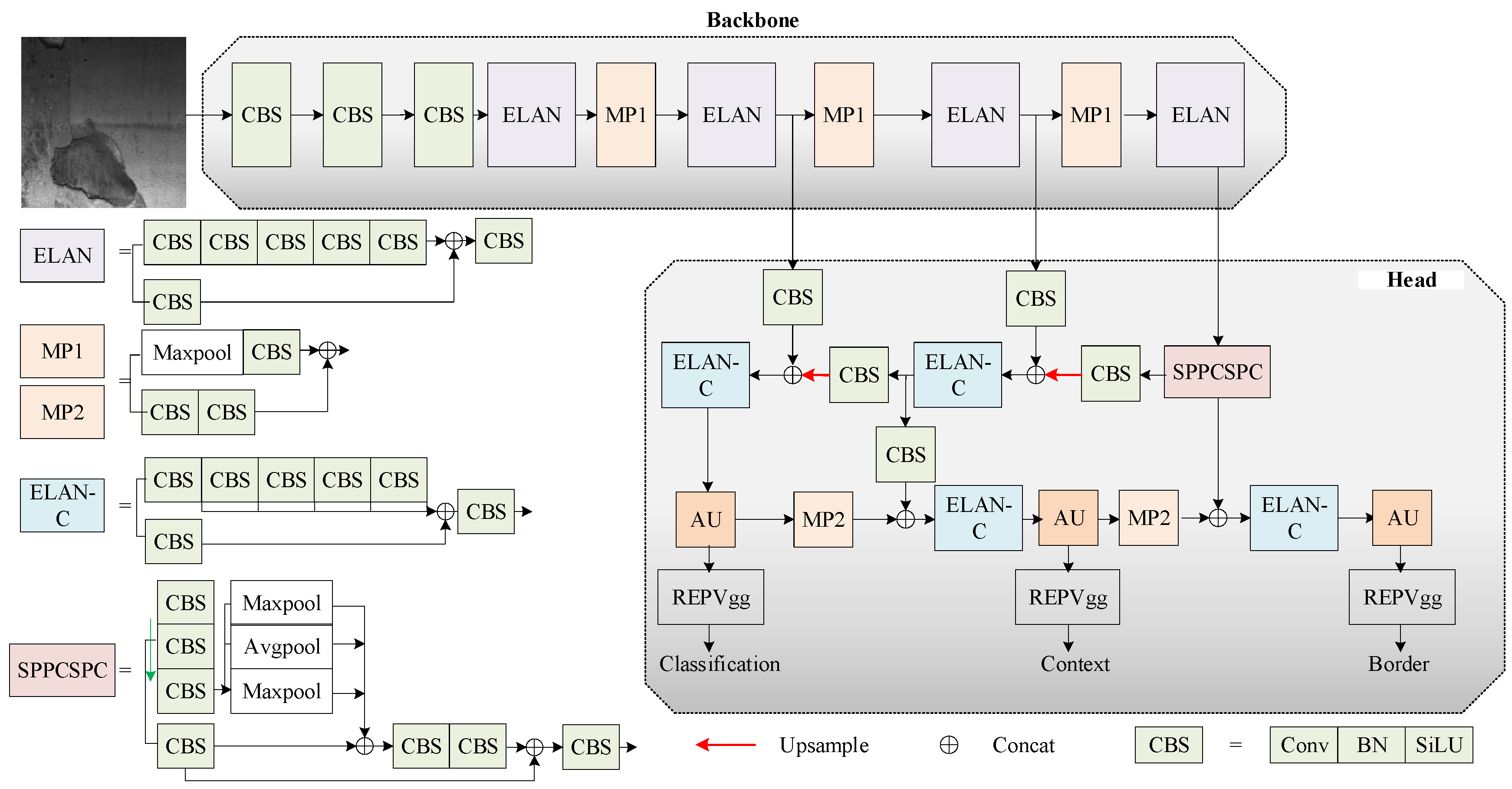

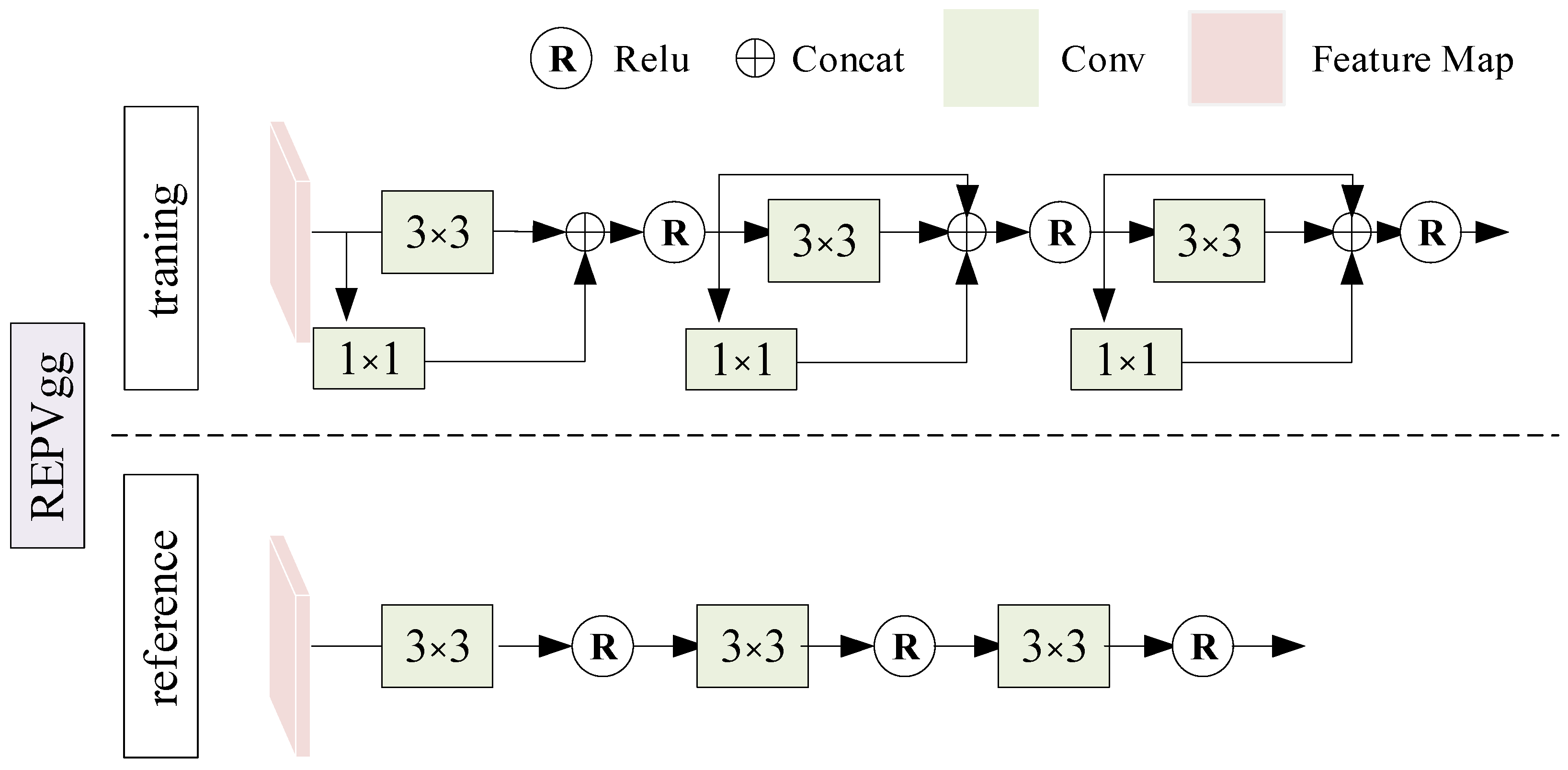

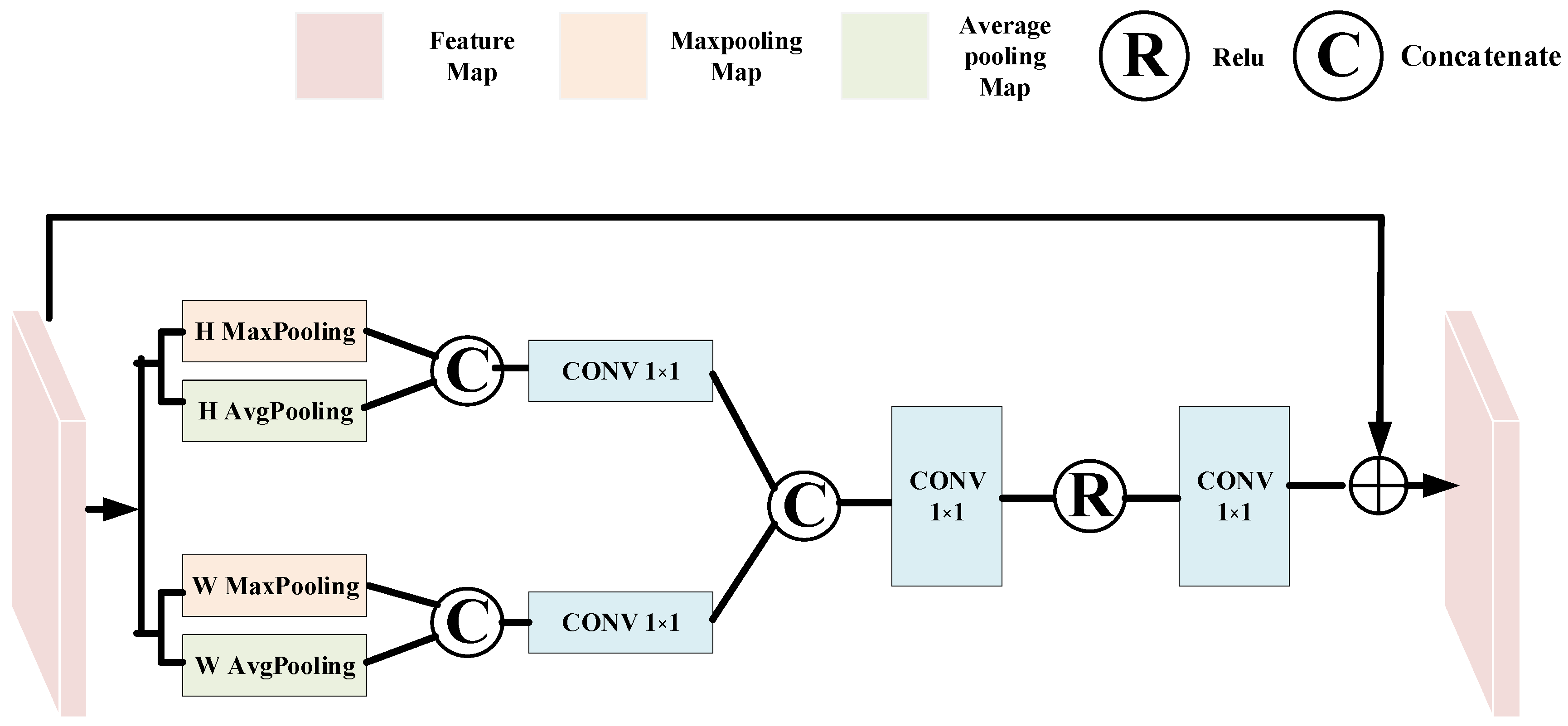

3.2. Defect Detection Module

3.2.1. Overall Structure

3.2.2. Loss Function

3.3. Production Management Module

3.3.1. Yield Management

3.3.2. Defect Prediction

4. Experiment and Verification

4.1. Experimental Environment and Validation Scheme

4.2. Verification Process

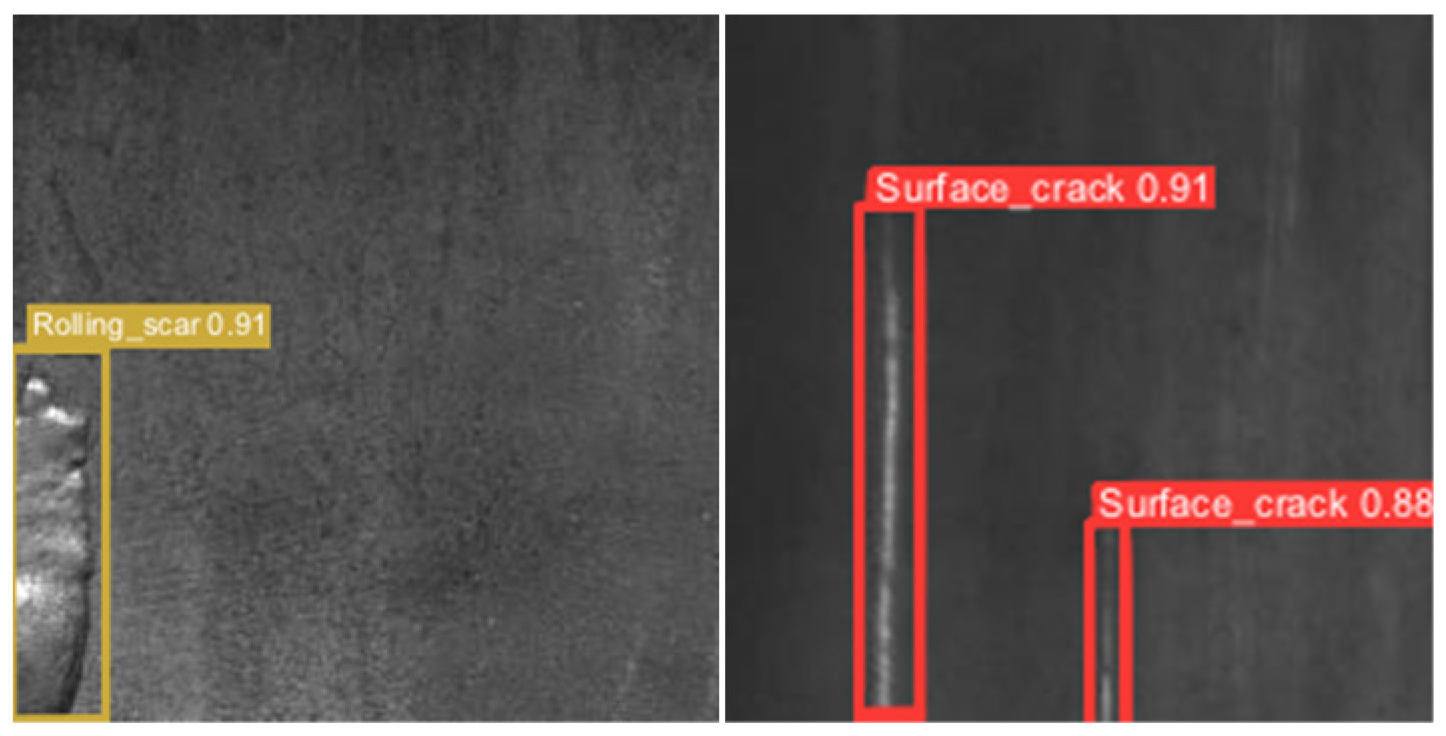

4.2.1. Target Detection Model Effect Verification

4.2.2. Monitoring System Verification

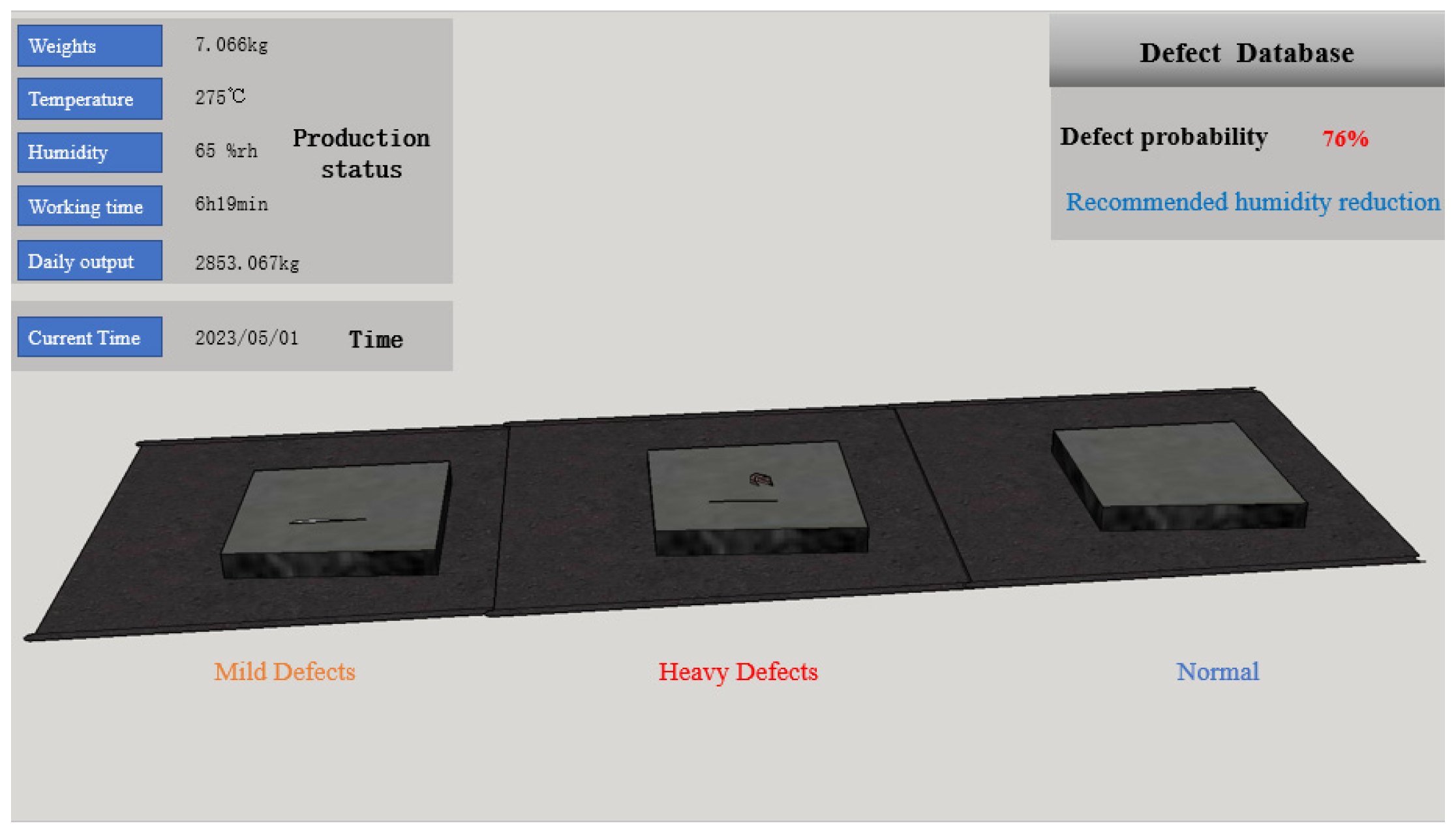

- Real-time monitoring module: As depicted in Figure 7, the interface displays real-time information related to slab production, including slab models, defect severity, weight, temperature, humidity, working duration, daily output, and the probability of defect occurrence along with adjustment recommendations. The severity of defects and the likelihood of their occurrence are represented by red, orange, and blue colors. Red indicates high severity, orange indicates moderate severity, and blue indicates normal conditions.

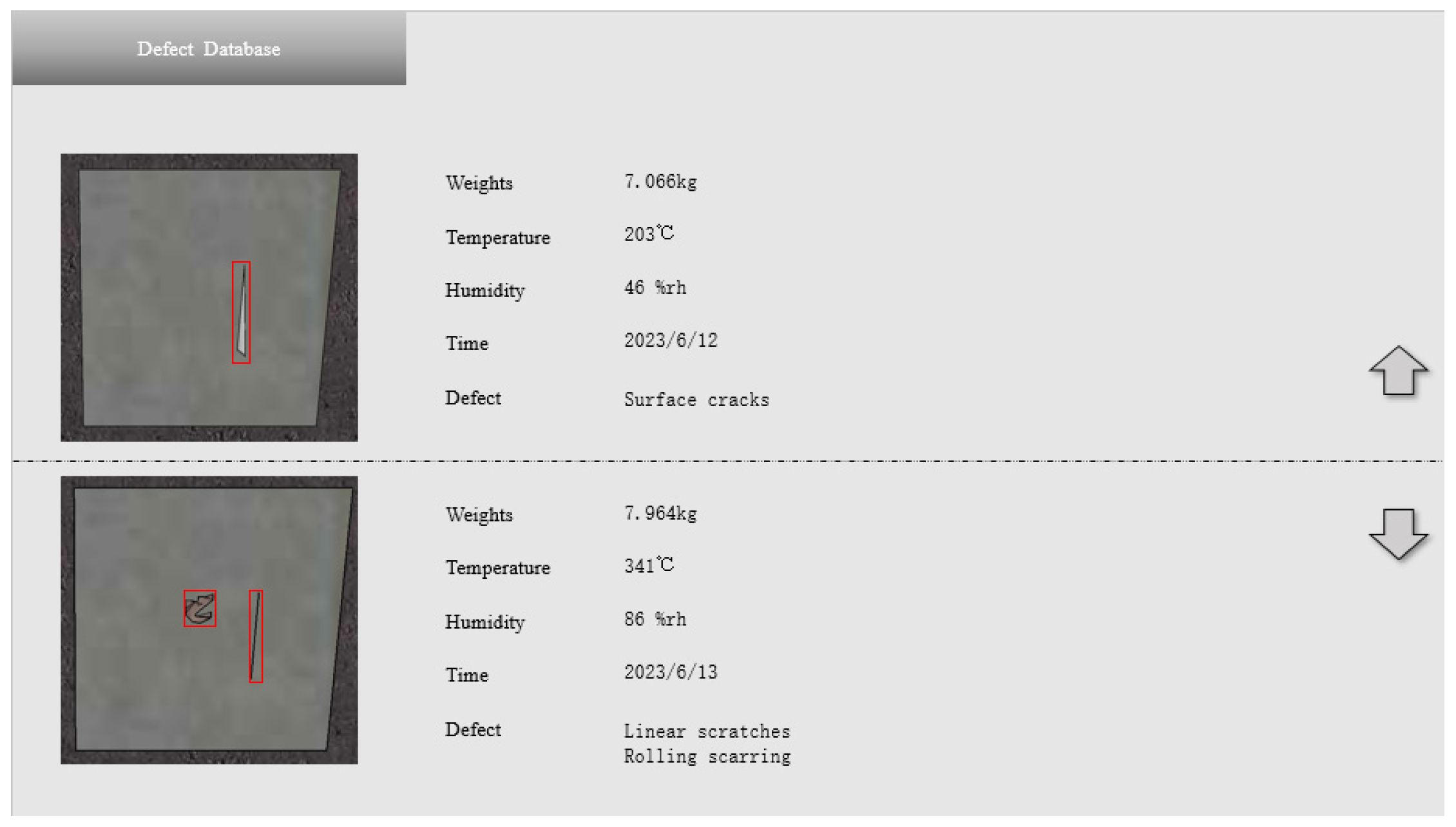

- Defect database module: Illustrated in Figure 8, this module encompasses all historical data on slab defects. Personnel can query defect information, such as the date of occurrence, defect type, temperature, humidity, and weight, through this module.

5. Conclusions

- A comprehensive slab production process monitoring system: Achieves monitoring of the slab production process and encompasses various functionalities, such as defect identification, production output management, and defect prediction.

- A faster and more accurate defect identification network: Compared to other state-of-the-art models, the precision of the network proposed in this paper is higher.

- A defect prediction model: Integrates environmental information to predict the probability of defect occurrence in slabs. Users can adjust relevant settings based on this probability to reduce the likelihood of defects, thereby enhancing the production of high-quality steel and minimizing raw material waste.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, D.; Xu, K.; Lv, Z.; Yang, J.; Li, M.; He, F.; Xu, G. Intelligent Manufacturing Technology in the Steel Industry of China: A Review. Sensors 2022, 22, 8194. [Google Scholar] [CrossRef] [PubMed]

- Butterfield, B.L.; Bullen, D.B. Questioning a Green New Deal–Bulk materials requirements for an all-renewable economy in the United States. In Energy Research and Social Science; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; Volume 86. [Google Scholar] [CrossRef]

- Gullino, A.; Matteis, P.; Aiuto, F.D. Review of aluminum-to-steel welding technologies for car-body applications. Metals 2019, 9, 315. [Google Scholar] [CrossRef]

- Na, J.K.; Gleeson, S.T. Assessment of weld quality of aerospace grade metals by using ultrasonic matrix phased array technology. Proc. SPIE 2014, 9063, 906304. [Google Scholar] [CrossRef]

- Tiejun, D. The influence of iron flow on iron resource efficiency in the steel manufacturing process. Resour. Conserv. Recycl. 2011, 55, 760–771. [Google Scholar] [CrossRef]

- Mahale, R.S.; Rajendrachari, S.; Vasanth, S.; Krishna, H.; Kapanigowda, N.S.; Chikkegowda, S.P.; Patil, A. Technology and Challenges in Additive Manufacturing of Duplex Stainless Steels. Biointerface Res. Appl. Chem. 2021, 12, 1110–1119. [Google Scholar] [CrossRef]

- Mortlock, T.; Muthirayan, D.; Yu, S.Y.; Khargonekar, P.P.; Abdullah Al Faruque, M. Graph Learning for Cognitive Digital Twins in Manufacturing Systems. IEEE Trans. Emerg. Top. Comput. 2022, 10, 34–45. [Google Scholar] [CrossRef]

- Aristova, N.I. Intelligence in industrial automation. Autom. Remote Control 2016, 77, 1071–1076. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, P.; Bao, J. Digital Twin-based manufacturing system: A survey based on a novel reference model. J. Intell. Manuf. 2023, 1–30. [Google Scholar] [CrossRef]

- Liu, S.; Zheng, P.; Xia, L.; Bao, J. A dynamic updating method of digital twin knowledge model based on fused memorizing-forgetting model. Adv. Eng. Inform. 2023, 57, 102115. [Google Scholar] [CrossRef]

- Liu, S.; Lu, Y.; Shen, X.; Bao, J. A digital thread-driven distributed collaboration mechanism between digital twin manufacturing unit. J. Manuf. Syst. 2023, 68, 145–159. [Google Scholar] [CrossRef]

- Wöber, W.; Rauer, J.; Papa, M.; Aburaia, A.; Schwaiger, S.; Novotny, G.; Aburaia, M.; Kubinger, W. Evaluation of navigation methodologies for mobile robots. Elektrotechnik Informationstechnik 2020, 137, 316–323. [Google Scholar] [CrossRef]

- Choi, T.; Do, H.; Park, D.; Park, C.; Kyung, J. Real-time synchronisation method in multi-robot system. Electron. Lett. 2014, 50, 1824–1826. [Google Scholar] [CrossRef]

- Yu, W.; Liu, Y.; Dillon, T.; Rahayu, W. Edge Computing-Assisted IoT Framework With an Autoencoder for Fault Detection in Manufacturing Predictive Maintenance. IEEE Trans. Ind. Inform. 2023, 19, 5701–5710. [Google Scholar] [CrossRef]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive Maintenance in the Automotive Sector: A Literature Review. Math. Comput. Appl. 2021, 27, 2. [Google Scholar] [CrossRef]

- Wang, C.; Cao, M.; Lucas, R.M. Design of load optimal control algorithm for smart grid based on demand response in different scenarios. Open Phys. 2018, 16, 1046–1055. [Google Scholar] [CrossRef]

- Jin, M.; Zhou, X.; Luo, E.; Qing, X. Industrial-QoS-Oriented Remote Wireless Communication Protocol for the Internet of Construction Vehicles. IEEE Trans. Ind. Electron. 2015, 62, 7103–7113. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, J.; Song, Z.; Liu, Y.; Li, J.; Zhou, J. A scheme for intelligent blockchain-based manufacturing industry supply chain management. Computing 2021, 103, 1771–1790. [Google Scholar] [CrossRef]

- Zheng, K.; Zhang, Z.; Gauthier, J. Blockchain-based intelligent contract for factoring business in supply chains. Ann. Oper. Res. 2022, 308, 777–797. [Google Scholar] [CrossRef]

- Dreher, P.; Schmidt, R.; Vetter, A.; Hepp, J.; Karl, A.; Brabec, C.J. Non-destructive imaging of defects in Ag-sinter die attach layers—A comparative study including X-ray, Scanning Acoustic Microscopy and Thermography. Microelectron. Reliab. 2018, 88–90, 365–370. [Google Scholar] [CrossRef]

- Tortora, M.; Sfarra, S.; Chiarini, M.; Daniele, V.; Taglieri, G.; Cerichelli, G. Non-destructive and micro-invasive testing techniques for characterizing materials, structures and restoration problems in mural paintings. Appl. Surf. Sci. 2016, 387, 971–985. [Google Scholar] [CrossRef]

- Alzaraa, A.; Al-Leswas, D.; Chung, W.Y.; Gravante, G.; Bruno, M.; West, K.; Dennison, A.; Lloyd, D. Contrast-enhanced ultrasound detects perfusion defects in an ex vivo porcine liver model: A useful tool for the study of hepatic reperfusion. J. Artif. Organs 2013, 16, 475–482. [Google Scholar] [CrossRef] [PubMed]

- Bustamante, L.; Jeyaprakash, N.; Yang, C.H. Hybrid laser and air-coupled ultrasonic defect detection of aluminium and CFRP plates by means of Lamb mode. Results Phys. 2020, 19, 103438. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Q.; He, Q.; Yu, T.; Zhang, M.; Wang, P. CUFuse: Camera and Ultrasound Data Fusion for Rail Defect Detection. IEEE Trans. Intell. Transp. Syst. 2022, 23, 21971–21983. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Kang, L.W.; You, T.Y.; Jhong, W.C. Vision-Based Automatic Identification Tracking of Steel Products for Intelligent Steel Manufacturing. In Proceedings of the 2017 IEEE International Symposium on Multimedia, ISM 2017, Taichung, Taiwan, 11–13 December 2017; pp. 376–377. [Google Scholar] [CrossRef]

- Song, S.; Chang, K.; Yun, K.; Jun, C.; Baek, J.G. Defect Synthesis Using Latent Mapping Adversarial Network for Automated Visual Inspection. Electronics 2022, 11, 2763. [Google Scholar] [CrossRef]

- Brämming, M.; Björkman, B.; Samuelsson, C. BOF Process Control and Slopping Prediction Based on Multivariate Data Analysis. Steel Res. Int. 2016, 87, 301–310. [Google Scholar] [CrossRef]

- Antonova, A.; Aksyonov, K. Simulation of the steelmaking process using collision avoiding cranes moving models. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 042091. [Google Scholar] [CrossRef]

- Kaushik, P.; Lowry, M.; Yin, H.; Pielet, H. Inclusion characterisation for clean steelmaking and quality control. Ironmak. Steelmak. 2012, 39, 284–300. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, C.J.; Wang, L.; Zhang, Y.C. Industrial IoT for Intelligent Steelmaking with Converter Mouth Flame Spectrum Information Processed by Deep Learning. IEEE Trans. Ind. Inform. 2020, 16, 2640–2650. [Google Scholar] [CrossRef]

- Lu, M.; Qing, H.; Zhi, X.; Weimin, Y.; Ying, C.; Chuanyi, Z.; Hongliang, G. Tundish cover flux thickness measurement method and instrumentation based on computer vision in continuous casting tundish. Math. Probl. Eng. 2013, 2013, 690948. [Google Scholar] [CrossRef]

- Liu, H.; Wang, B.; Xiong, X. Basic oxygen furnace steelmaking end-point prediction based on computer vision and general regression neural network. Optik 2014, 125, 5241–5248. [Google Scholar] [CrossRef]

- Zhao, L.; Ouyang, Q.; Chen, D.; Zhang, X.; Zhang, Y. Study on CCD laser scanning flatness measurement method for hot rolled strip. Ironmak. Steelmak. 2015, 42, 600–607. [Google Scholar] [CrossRef]

- Lopez, G.; Galimova, T.; Fasihi, M.; Bogdanov, D.; Breyer, C. Towards defossilised steel: Supply chain options for a green European steel industry. Energy 2023, 273, 127236. [Google Scholar] [CrossRef]

- Cao, Q.; Beden, S.; Beckmann, A. A core reference ontology for steelmaking process knowledge modelling and information management. Comput. Ind. 2022, 135, 103574. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, J.; Jiang, J.J.; Li, J.; Tyagi, R.D.; Surampalli, R.Y. The potential utilization of slag generated from iron- and steelmaking industries: A review. In Environmental Geochemistry and Health; Springer: Berlin/Heidelberg, Germany, 2020; Volume 42, pp. 1321–1334. [Google Scholar] [CrossRef]

- Tang, M.-T.; Peng, J.; Peng, B.; Di, Y.U.; Tang, C.-B. Thermal Solidification of Stainless Steelmaking Dust. Trans. Nonferrous Met. Soc. China 2008, 18, 202–206. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, Q.; Tao, F. A multi-scale modeling method for digital twin shop-floor. J. Manuf. Syst. 2022, 62, 417–428. [Google Scholar] [CrossRef]

- Cabral, J.V.A.; Gasca, E.A.R.; Alvares, A.J. Digital Twin Implementation for Machining Center Based on ISO 23247 Standard. IEEE Lat. Am. Trans. 2023, 21, 628–635. [Google Scholar] [CrossRef]

- Lu, G.P.; Xue, G.H.; Chen, Z. Design and implementation of virtual interactive scene based on unity 3d. Adv. Mater. Res. 2011, 317–319, 2162–2167. [Google Scholar] [CrossRef]

- Wu, D.; Jiang, S.; Zhao, E.; Liu, Y.; Zhu, H.; Wang, W.; Wang, R. Detection of Camellia oleifera Fruit in Complex Scenes by Using YOLOv7 and Data Augmentation. Appl. Sci. 2022, 12, 11318. [Google Scholar] [CrossRef]

- Li, Z.; Li, B.; Ni, H.; Ren, F.; Lv, S.; Kang, X. An Effective Surface Defect Classification Method Based on RepVGG with CBAM Attention Mechanism (RepVGG-CBAM) for Aluminum Profiles. Metals 2022, 12, 1809. [Google Scholar] [CrossRef]

- Wang, W.; Chen, J.; Huang, Z.; Yuan, H.; Li, P.; Jiang, X.; Wang, X.; Zhong, C.; Lin, Q. Improved YOLOv7-Based Algorithm for Detecting Foreign Objects on the Roof of a Subway Vehicle. Sensors 2023, 23, 9440. [Google Scholar] [CrossRef]

- Wang, W.; He, Y.; Liao, R.; Cai, Y.; Zheng, X.; Zhao, Y. Mission reliability driven functional healthy state modeling approach considering production rhythm and workpiece quality for manufacturing systems. Reliab. Eng. Syst. Saf. 2022, 226, 108682. [Google Scholar] [CrossRef]

- García-Díaz, J.C.; Segui, V.J. Statistical Methods for Quality Control of Steel Coils Manufacturing Process using Generalized Linear Models. Manuf. Eng. Soc. Int. Conf. 2009, 1181, 299–305. [Google Scholar]

- Xie, X.; Xu, L.; Li, X.; Wang, B.; Wan, T. A high-effective multitask surface defect detection method based on CBAM and atrous convolution. J. Adv. Mech. Des. Syst. Manuf. 2022, 16, JAMDSM0063. [Google Scholar] [CrossRef]

- Zheng, Z.; Chen, N.; Wu, J.; Xv, Z.; Liu, S.; Luo, Z. EW-YOLOv7: A Lightweight and Effective Detection Model for Small Defects in Electrowetting Display. Processes 2023, 11, 2037. [Google Scholar] [CrossRef]

- Cheng, S.; Lu, J.; Yang, M.; Zhang, S.; Xu, Y.; Zhang, D.; Wang, H. Wheel hub defect detection based on the DS-Cascade RCNN. Meas. J. Int. Meas. Confed. 2023, 206, 112208. [Google Scholar] [CrossRef]

- Li, L.; Li, Q.; Liu, Z.; Xue, L. Effective Fabric Defect Detection Model for High-Resolution Images. Applied Sciences 2023, 13, 10500. [Google Scholar] [CrossRef]

| Models | Time (ms) | Rec (%) | AP | Accuracy | ||

|---|---|---|---|---|---|---|

| CBAM | 26.3 | 94.241 | 41.1 | 61.7 | 48.1 | 76.82 |

| EW-YOLOv7 | 26.8 | 93.415 | 41.4 | 59.2 | 45.3 | 71.61 |

| DS-Cascade RCNN | 29.1 | 97.682 | 43.2 | 64.8 | 47.1 | 84.67 |

| Cascade R-CNN | 26.4 | 87.132 | 36.7 | 54.9 | 43.5 | 52.34 |

| SSD | 27.4 | 88.454 | 38.9 | 57.3 | 44.1 | 70.64 |

| Ours | 23.3 | 98.435 | 43.9 | 62.3 | 47.8 | 88.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, T.; Li, P.; Shi, C.; Liu, Y. Digital-Twin-Based Monitoring System for Slab Production Process. Future Internet 2024, 16, 59. https://doi.org/10.3390/fi16020059

Fu T, Li P, Shi C, Liu Y. Digital-Twin-Based Monitoring System for Slab Production Process. Future Internet. 2024; 16(2):59. https://doi.org/10.3390/fi16020059

Chicago/Turabian StyleFu, Tianjie, Peiyu Li, Chenke Shi, and Youzhu Liu. 2024. "Digital-Twin-Based Monitoring System for Slab Production Process" Future Internet 16, no. 2: 59. https://doi.org/10.3390/fi16020059

APA StyleFu, T., Li, P., Shi, C., & Liu, Y. (2024). Digital-Twin-Based Monitoring System for Slab Production Process. Future Internet, 16(2), 59. https://doi.org/10.3390/fi16020059