1. Introduction

Precision agriculture (PA) enables data-driven farming practices that increase crop yield, augment profitability, and conserve the environment [

1]. However, the data-driven approach of PA also presents significant challenges for farmers that hinder its adoption. The most important PA challenge is the cost and effort required to collect, relate, and analyse data regarding crop, soil, and environment.

In the last decade, technological advancements and the emergence of the Internet of Things (IoT) [

2,

3] have revolutionised data collection and created opportunities to address some of the PA challenges. Sensing approaches in IoT-based PA for crop management can be characterised as aerial or ground-based. These two approaches have contrasting virtues and limitations that impact their use for data collection.

As described in

Table 1, aerial and ground-based sensing have certain limitations but they also have certain advantages, which can compensate for each other’s limitations. The ground-based sensing approach can provide constant high-quality data while the aerial sensing approach can provide high coverage using a single set of sensors. Integration of aerial and ground-based sensing into a hybrid system and using data validation and calibration to improve the data quality and also to reduce the overall cost of the sensing process are existing gaps that have not been addressed before. This provides an opportunity to investigate the potential benefits of a Hybrid Sensing Platform (HSP) to improve the efficiency and effectiveness of the sensing process. Such HSP implementation and performance analysis is the aim of this paper. This paper’s contributions include the following: (1) the hybrid sensing concept, approach, and aims and its comparison to existing ground-based and aerial-sensing approaches; (2) the design and implementation of a complete HSP for PA, including UAV, ground and aerial sensors, and cloud components; (3) aerial sensing data validation and calibration techniques that use the data observations of a small number of ground-based sensors to automatically validate, calibrate, and improve the accuracy of aerial data; and (4) investigation of HSP and aerial data calibration benefits through field experiments.

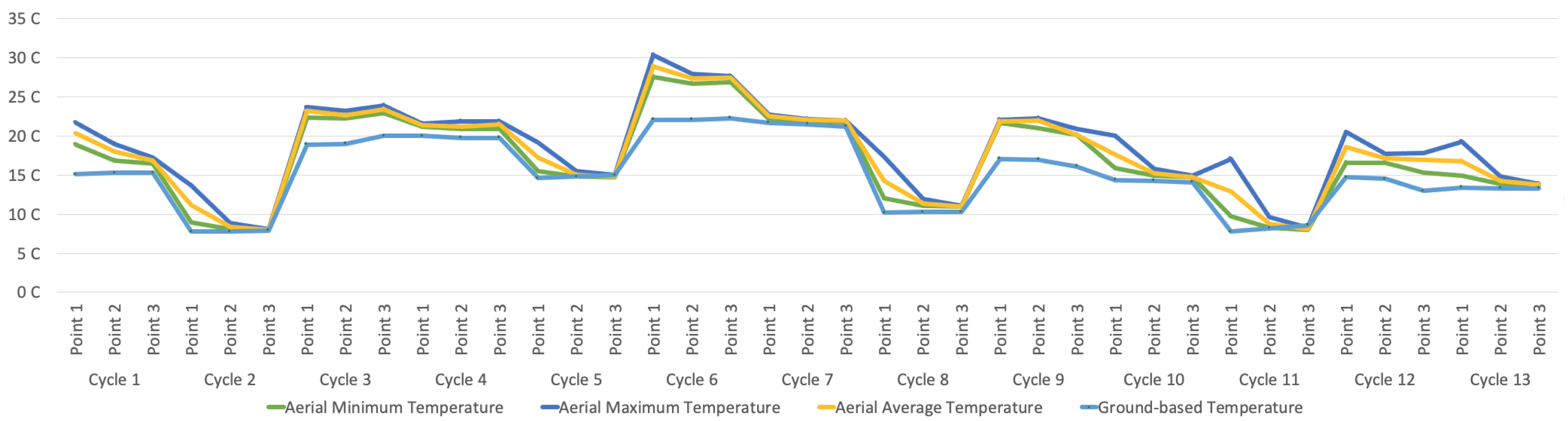

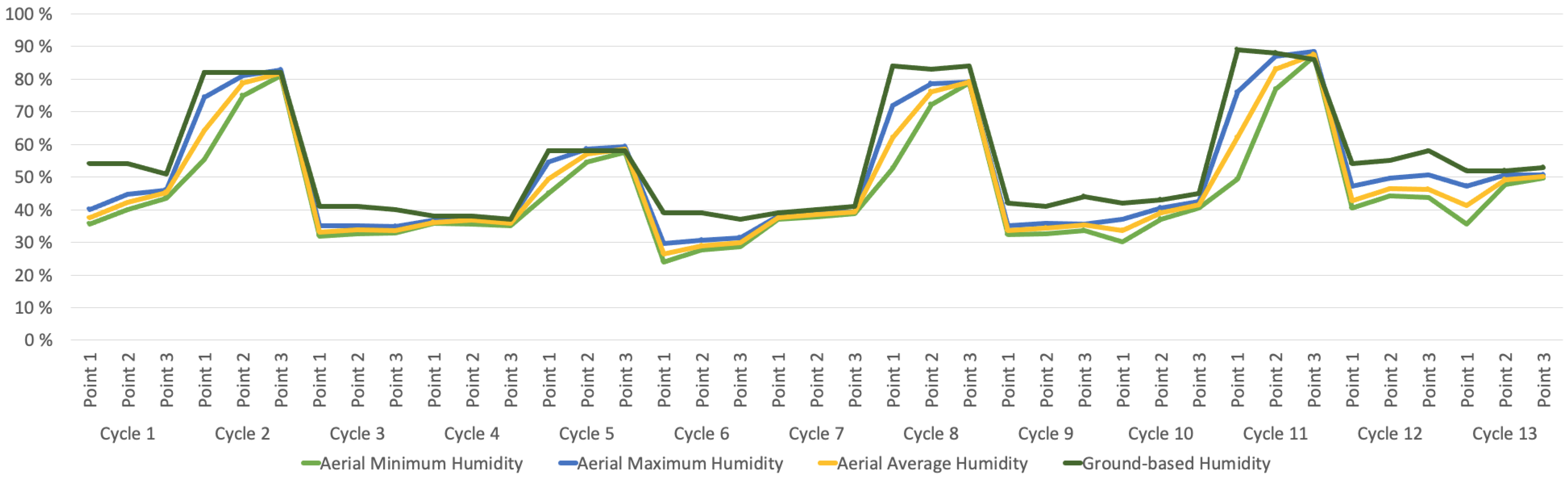

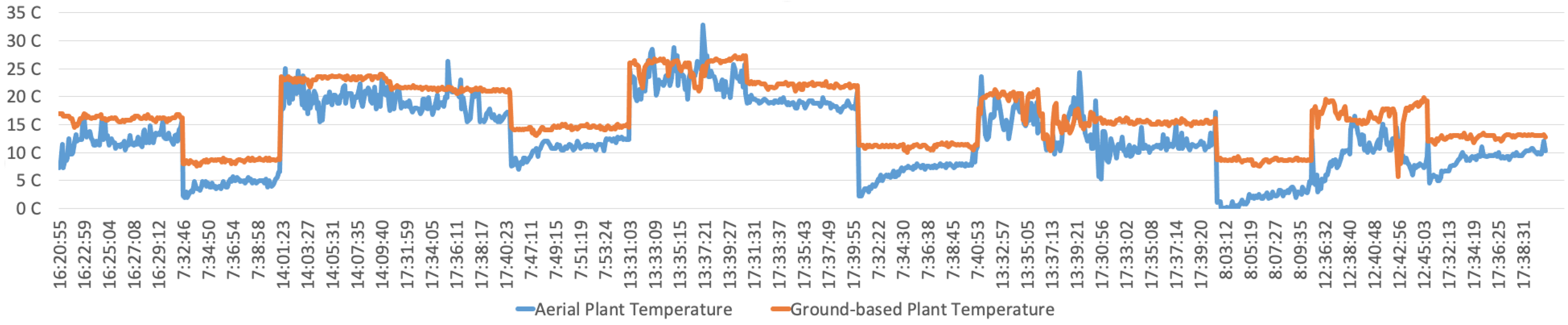

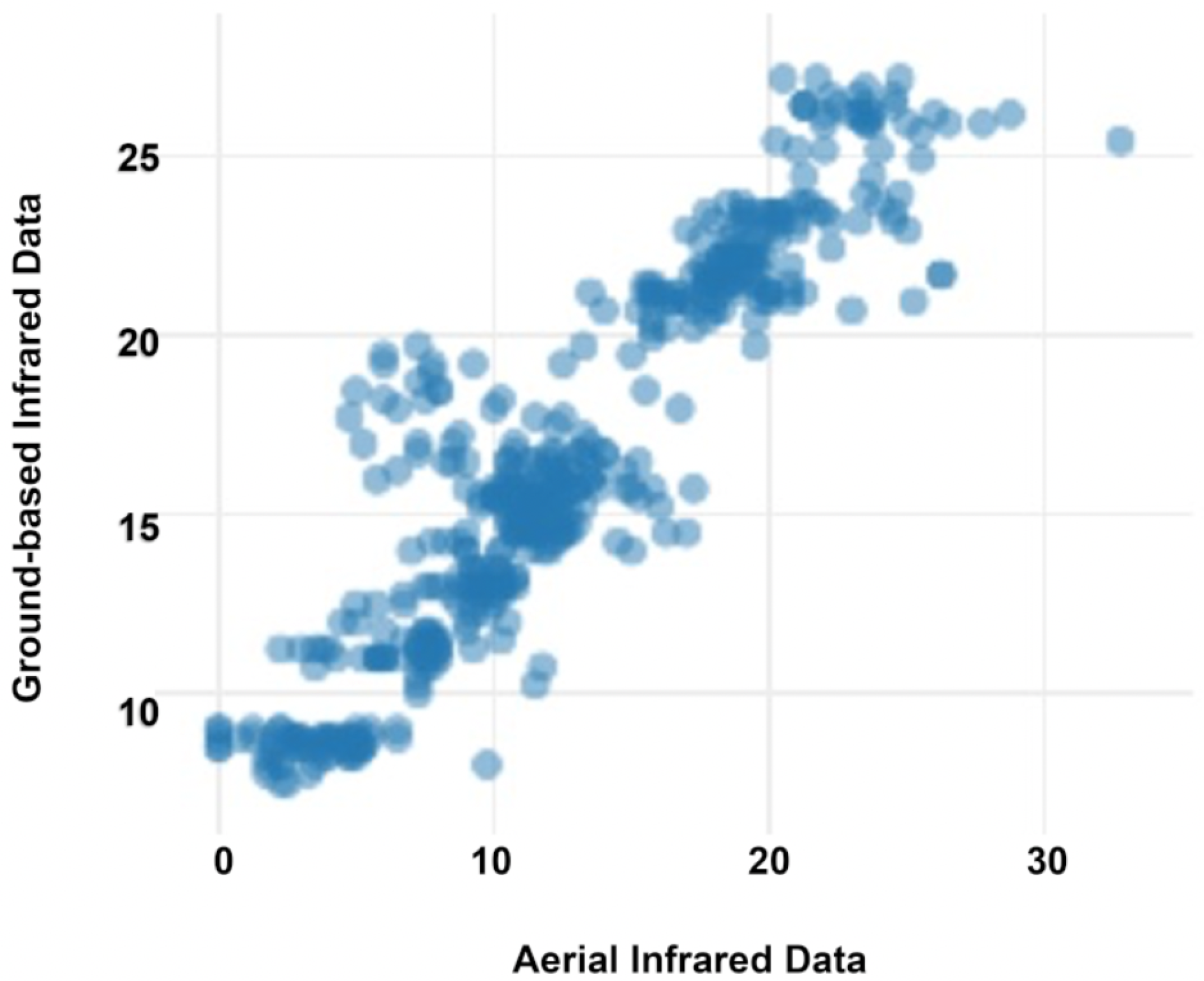

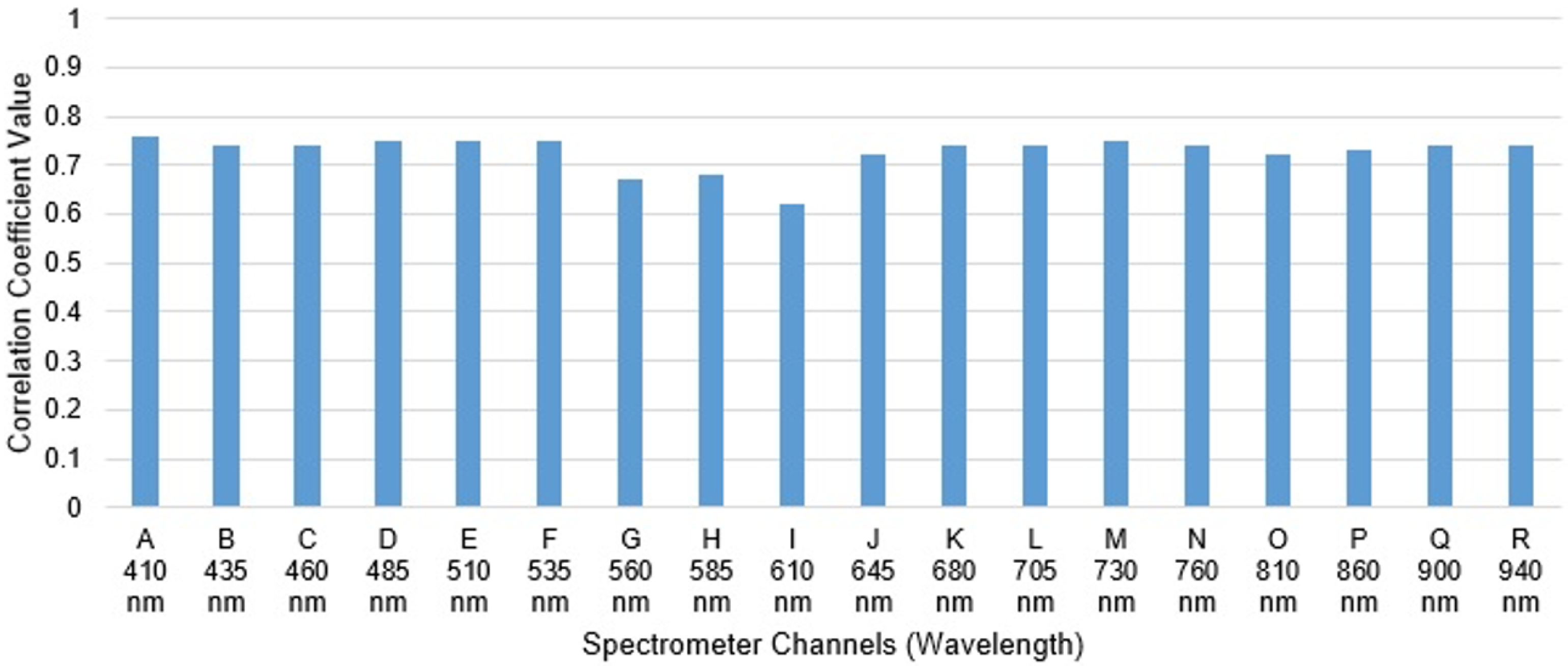

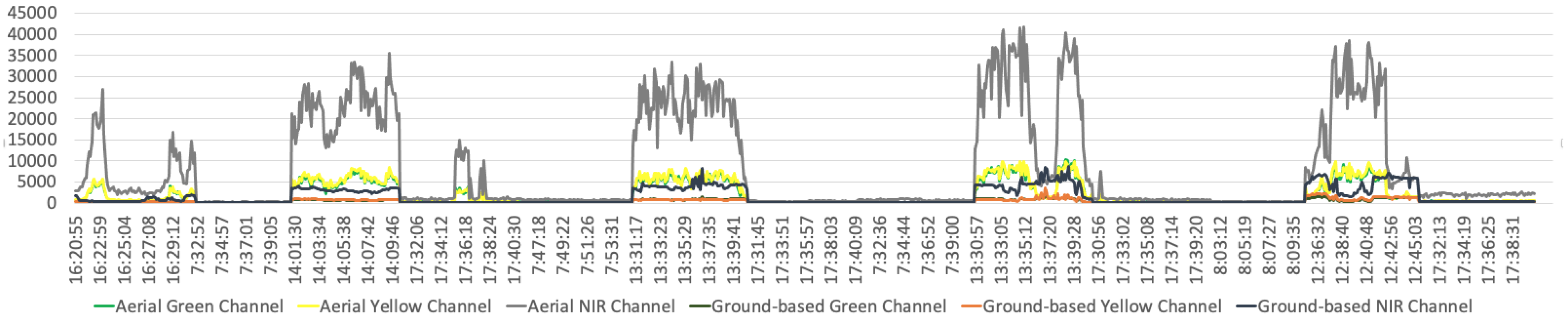

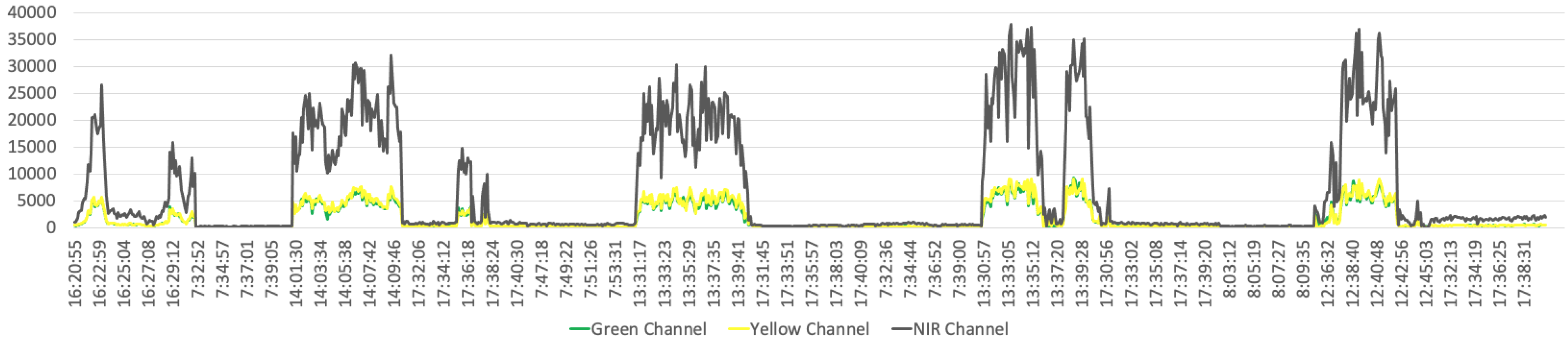

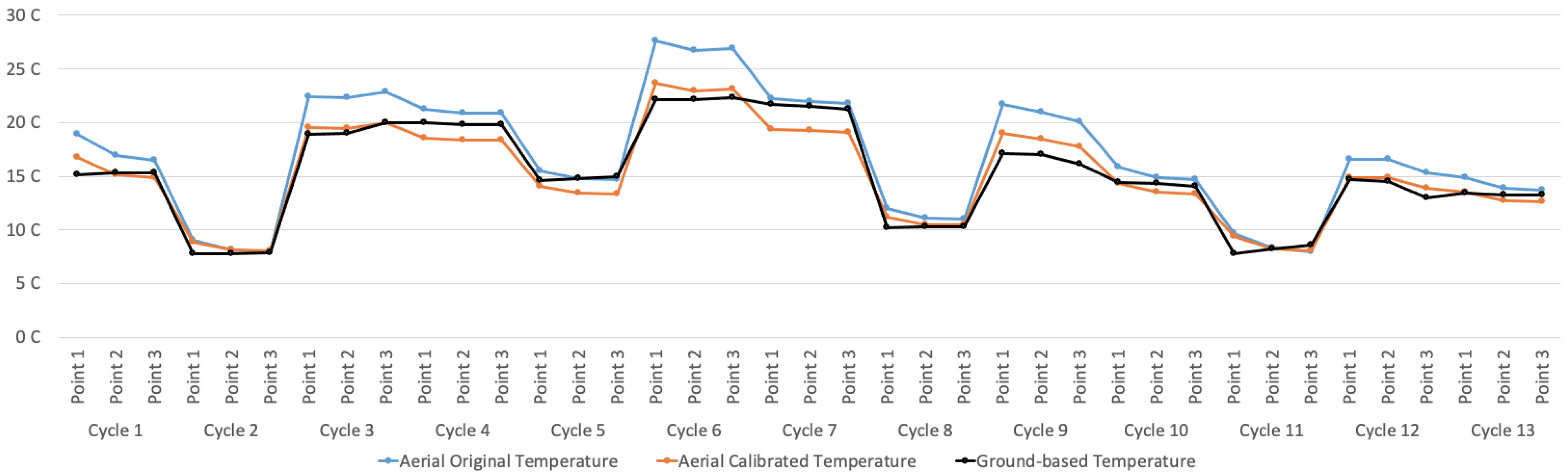

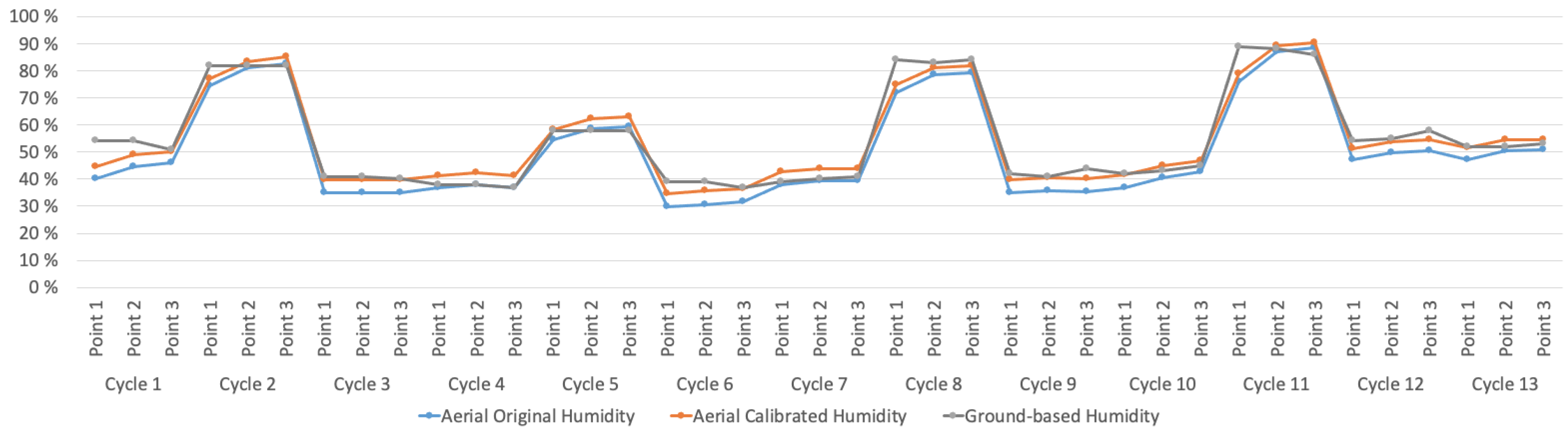

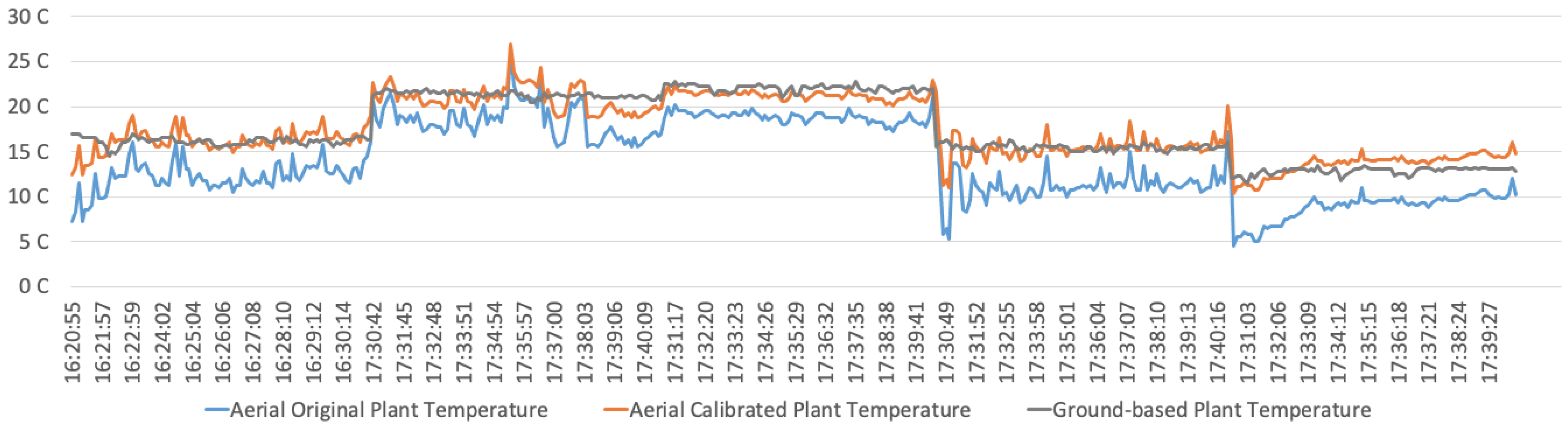

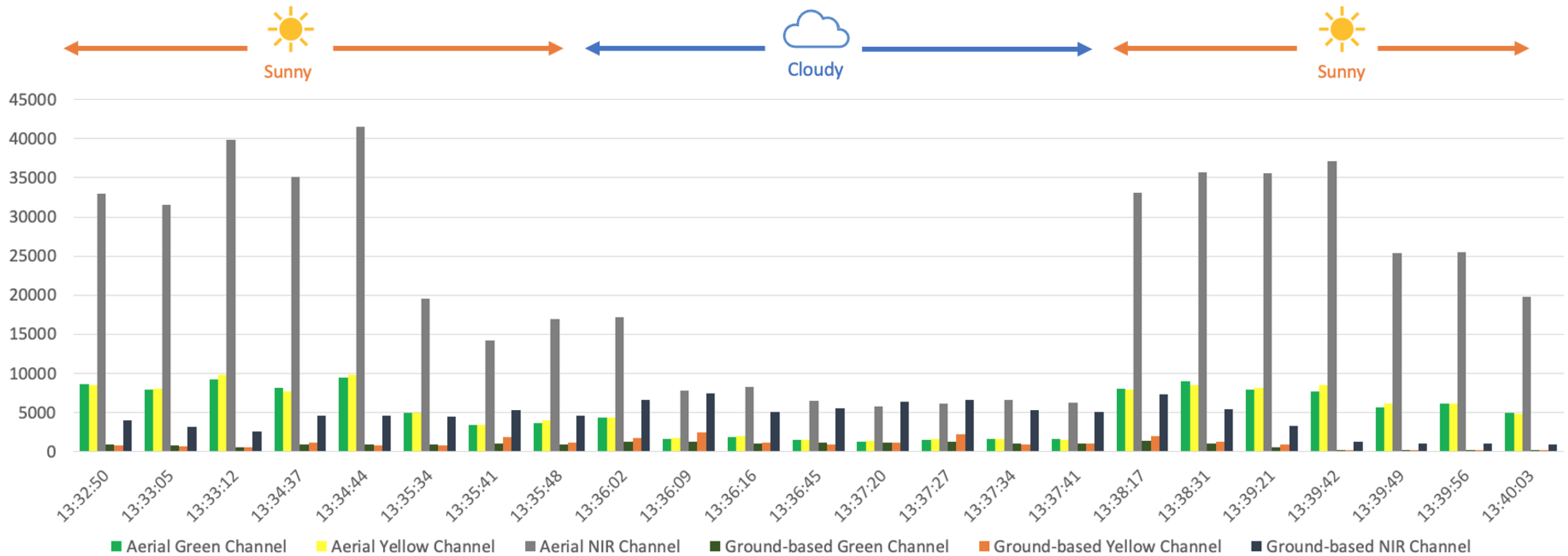

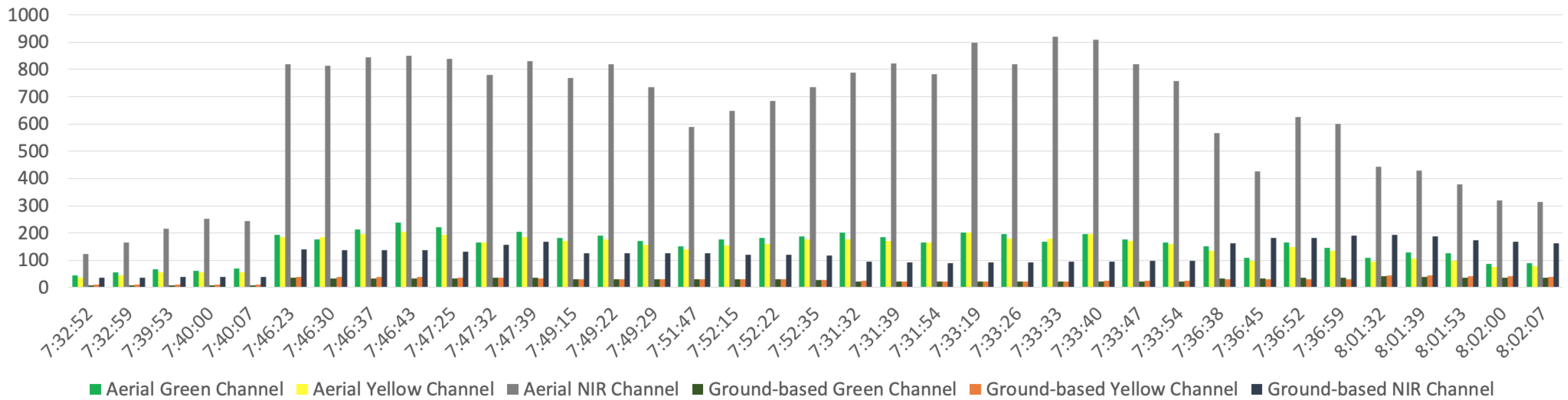

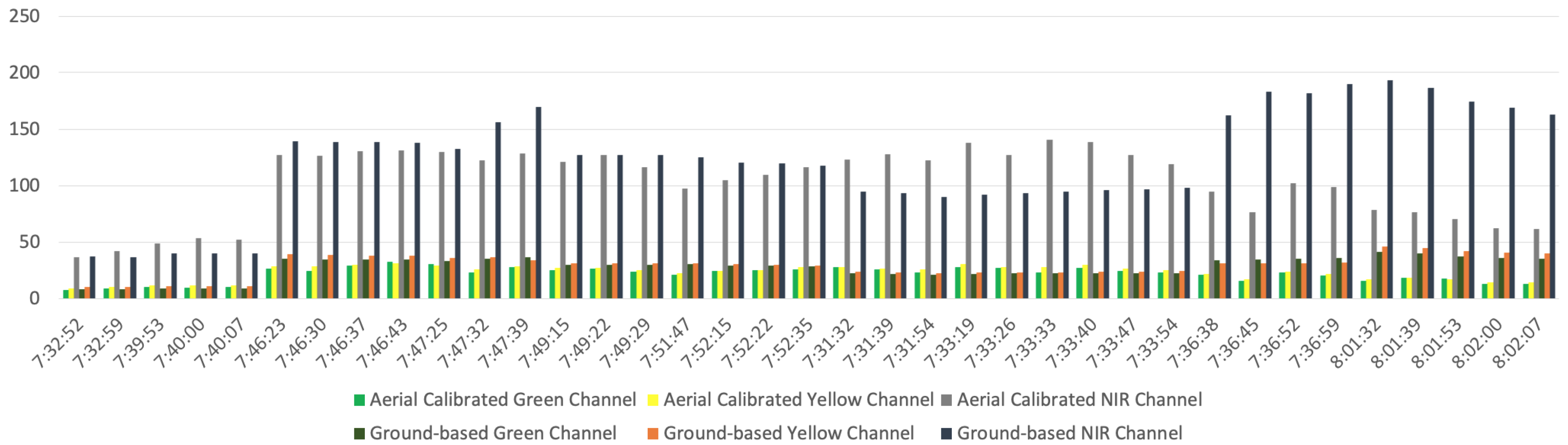

The results of field experiments using the proposed IoT-based HSP show that the statistical and machine learning models used in this research remarkably improve the aerial data accuracy. The improvement rate in aerial data accuracy compared with ground truth is 34% for humidity data, 51% for temperature data, 66% for infrared data, and 90% for spectrometer data. This indicates that IoT-based HSP have potential to transform the data collection process in PA by improving the data accuracy and at the same time reducing the costs for the procurement, deployment, and maintenance of sensing nodes.

The rest of this paper is organised as follows:

Section 2 presents the related work in IoT-based sensing for PA.

Section 3 presents the materials and methods for IoT-based HSP.

Section 4 discusses the results of HSP field experiments.

Section 5 discusses the findings of this research.

Section 6 concludes the paper and describes the potential future research directions.

2. Related Work in IoT-Based Sensing for PA

PA has been pervasively used to improve farm management processes from both animal [

4,

5] and crop [

1] perspectives. From the animal farming perspective, PA enables us to capture and analyse data regarding animals’ behaviour and to find correlations between animals’ behaviour, living environment, and farm productivity [

4]. From the crop perspective, which is the main focus of this research, PA enables accurate data collection regarding crop, soil, and weather to improve the farm yield while minimising the use of required resources. In the past decade, the emergence of IoT has revolutionised the data collection process in the PA context.

IoT-based PA enables us to reduce human interaction with the farm management process while at the same time increasing the accuracy of data collection and data analysis [

6]. Integration of IoT in the PA context has been the focal point of multiple studies. Some researchers focus on the IoT architecture required to implement an IoT-driven PA system [

6,

7,

8,

9,

10,

11]. They proposed four [

6,

7,

8,

11], five [

10], and six [

9] layer IoT architectures. From their work, it can be perceived that there are four main layers in an IoT-based PA architecture, which are device, network, cloud, and application, where some of these works break down some layers into sublayers to further discuss the purpose of each layer [

9,

10].

Practical implementation of IoT-based PA has been also discussed in several related works. Some of these works focus on an IoT-enabled ground-based sensing approach to improve the animal farm management process. Cappai et al. [

5] investigated the efficiency of using Radio Frequency Identification (RFID) tags in comparison with traditional approaches for monitoring milk production throughout lactation in sheep flocks. Such data-driven analysis of animals’ behaviour can result in improvements in animal farm productivity while at the same time reducing the required resources. Another application of wireless sensing networks in animal farming is the capability to develop smart traceability systems, which can be remarkably beneficial for brand and origin protection in animal farming products [

12]. The ground-based sensing approach has been also used pervasively for the crop management process.

Heble et al. [

13] developed an IoT-enabled ground-based sensing solution for the real-time visualisation of soil moisture and temperature that was used to apply timely variable-rate irrigation. Jayaraman et al. [

14] designed an IoT-based platform called SmartFarmNet, which can automate the collection of environmental, soil, fertilisation, and irrigation data from ground-based sensors. SmartFarmNet automatically correlates such data and filters out invalid data from the perspective of assessing crop performance. It also computes crop performance forecasts and provides personalised crop recommendations for any farm. Zervopoulos [

15] focused on time correlation between sensors, as environmental factors can cause drift in sensors’ clocks and this can reduce data accuracy. This paper proposed a sink node’s clock as a reference to automatically synchronise IoT devices across the farm. Popovic et al. [

16] collected soil, crop, and weather data and used an IoT platform to analyse, visualise, and correlate data that can trigger an irrigation system. Keswani et al. [

17] proposed an IoT-based irrigation system that reduces the use of fresh water while maintaining constant soil moisture across an entire farm. They deployed ground-based sensors to collect soil moisture, environmental temperature and humidity, carbon dioxide level, and daylight intensity, and also used external weather forecast data (including sunrise time and ultraviolet index) to predict the soil moisture in the next hour. Hong et al. [

18] used Bluetooth as a communication technology for both end nodes’ micro-controllers, as well as a host station to collect soil moisture and activate an irrigation system for growing Romaine lettuce. Kim et al. [

19] used an in-field sensing station to measure soil moisture and temperature and also air temperature. They send this data to a base station, where meteorological information is also collected from a weather station. Such a combination of real-time in-field data and predictive data of future weather conditions provides remarkable information for an efficient and effective irrigation approach. Ding et al. [

20] used a pheromone trap, which uses certain chemical substances to lure pests. After pests are trapped inside the pheromone trap, RGB images are captured. Images are then processed using a Convolutional Neural Network (ConvNet) to detect pests and identify their species. Mahlein [

21] used optical sensors to analyse plant health status. She argues that the interaction of leaf tissue with light depends on structural and leaf chemical properties. As a result, when disease emerges in crop, the pathogen results in a change in leaf structure and chemicals, and this phenomenon results in light spectrum reflectance compared to a healthy crop. Such sensors can be mounted on UAVs to analyse the plant health status [

22] of an entire farm, which is discussed via the field experiment results in

Section 4.

UAVs play a major role in PA and have different applications, including communication, data transfer, actuation, and sensing [

22,

23,

24]. As a platform for aerial sensing, UAVs provide the best balance between image/data quality, coverage, and operating cost compared to helicopters and airplanes [

25]. Popescu et al. [

26] collected complementary data from UAV and ground-based sensors and used an IoT platform to perform data fusion and data analysis. They argued that an efficient UAV trajectory along with IoT data fusion can improve farm management accuracy. Cambra et al. [

27] proposed an IoT-based PA management system called PLATEM PA, which uses a mesh network of sensors and actuators. PLATEM collects data from UAV and also ground-based sensors to improve fertilisation and irrigation. Saha et al. [

28] focused on IoT-based aerial sensing, where they used a multi-rotor UAV to provide real-time hyperspectral images from a farm. Such an IoT-based aerial sensing approach enables real-time monitoring of the plant health status of an entire farm using only one sensor node deployed on the UAV. Tan et al. [

29] proposed an IoT solution that uses ground-based soil sensors, complementary UAV-based aerial sensors, and external data from the U.S. Department of Agriculture’s soil database to improve farm irrigation and fertilisation. Pathak et al. [

30] analysed crop health status variations using aerial and ground-based sensing. However, they did not investigate the integration of these two sensing approaches to improve the aerial data quality. Other researchers have also investigated aerial and ground-based sensing but the ground and aerial data in these works were not related [

7,

27,

31]. Furthermore, they did not investigate or discuss any aspect or potential benefits of integrating these approaches. Combining aerial and ground-based sensing has only been investigated to a limited extent in [

26,

30].

In summary, most related works propose or investigate either the ground-based [

10,

13,

32,

33] or aerial [

25,

34,

35] sensing approach. However, no related work has investigated or proposed a hybrid sensing approach for improving the accuracy of aerial data while reducing the cost of and effort involved in ground-based sensing. Some related research proposed the use of UAVs together with ground sensors, but the UAV serves a communication role (e.g., it is a data mule) [

23,

32] or performs actuations [

10]. Some publications discuss both aerial and ground-based sensing; however, the aerial and ground data are not integrated for data quality improvement [

7,

8,

27]. Among the related works, only two publications have investigated the integration of UAV and ground-based sensing approaches [

26,

30]. However, the focus of these two publications is more on data processing and data analysis algorithms. Therefore, it can be noticed that the integration of aerial and ground-based sensing approaches into a HSP to improve the data quality and reduce the data collection cost is an existing gap in the literature. In this paper, we address these gaps and we focus on how a HSP can improve the data quality and address some of the existing limitations of aerial and ground-based sensing approaches.

5. Discussion

The HSP uses data observations of a small number of ground-based sensors to automatically validate, calibrate, and improve the accuracy of data observations collected by UAV-based sensors. Application of statistical data analysis and supervised machine learning shows that the correlation between aerial and ground-based data is strong in the case of humidity, temperature, and infrared plant temperature data, and it is also at a moderate level regarding spectrometer data. In addition, application of the linear regression line equation on aerial data resulted in reducing the Euclidean distance between aerial data and ground truth. Therefore, the derived formula can be used in future data collections to automatically improve the aerial data in comparison with ground-based data. The research findings show that using ground-based data as ground truth in several locations of a large-scale farm, and using the validated and calibrated aerial data, can potentially improve the data quality and farm management process. By using the HSP, the main limitation of the ground-based sensing approach, which requires a large number of sensing nodes, can be addressed. Instead, UAVs can be used to collect data from the entire farm and significantly reduce the number of ground-based sensors that are otherwise required. In addition, the UAV can only concentrate on the areas far from the ground-based nodes, requiring less time to collect data from the entire farm. Moreover, transferring the HSP data to an IoT platform enables real-time data collection and visualisation and also automated data analysis, which are very important for timely actuations in PA.

Although HSPs have potential benefits in improving data quality and farm management processes, there are several limitations in their implementation and adoption. One of the limitations is that the accuracy of the optical sensors deployed on the aerial node can be impacted by UAV vibration. The exact level of data quality degradation due to UAV vibration cannot be assessed using the existing system, because such measurement requires comparison between UAV data and accurate aerial data that are not impacted by vibration. Such data can be obtained using robotics technology or by installing a sensor stabiliser on the UAV, which can be a direction for future research, to analyse the impact of vibration on data quality degradation. Nevertheless, in order to reduce the impact of UAV vibration on data quality, there is a need for moving the UAV with low speed and also maintaining the position of the UAV at different points of interest across the field to collect valid data with a minimum level of vibration. In this research, we used the UAV’s “positioned flight mode” to automatically position the UAV at low altitude, with less than half a meter’s distance from the plant. Positioned flight mode also stabilises the UAV against wind force and therefore reduces the vibration impact. Another limitation in this research was that, due to the global COVID-19 pandemic, the data collection was limited to four days in a small field, although the techniques for data collection and data analysis on larger-scale fields with a longer data collection duration will be the same as discussed in this research, but additional data collection with a larger number of ground-based nodes might provide better data training for the validation and calibration process. The exact number of ground-based sensors in order to have trusted results depends on two factors, which are the farm scale and the duration of data collection. Determining the number of ground-based nodes requires additional investigation using supervised machine learning techniques to determine which number of ground-based nodes and which duration of data collection can provide better data training to avoid underfitting or overfitting in the training model. In addition, as more data collection is performed, supervised machine learning can be used to determine the expected prediction error rate and to understand the lowest obtainable prediction error level. Such investigation, however, is beyond the scope of the current research and can be performed in future work.

The implementation and deployment of HSPs poses multiple challenges. One of the challenges is that the UAV requires both hardware and software skills for its maintenance, which can hinder its operation by users who do not have the required technical knowledge. In this study, during data collection, the UAV’s electronic speed controller module of one of the motors was broken, which required the replacement of the module and recalibration of the UAV. In addition, at one instance, the UAV flight mode changed unexpectedly, which caused the UAV to become unstable and difficult to control and had to be corrected with a recalibration of the UAV controller channel. Moreover, after a certain flight time period, the UAV requires to be recalibrated to maintain control and low vibration. Another challenge is that the optical sensors used in this experiment require low altitude to provide valid data. Therefore, the UAV must be flown very close to the plants. This prevents the use of the UAV’s automatic mission planning that enables the UAV to fly automatically based on the given path and collect the data. Since the UAV must fly at low altitude and the height of the crop changes in different areas, there is a need to always fly the UAV manually. Although this challenge can be addressed by installing an object detection and collision prevention system on the UAV, such a system may not detect small branches, which can cause UAV to crash. In addition, object detection and collision prevention systems can remarkably increase the costs of UAVs and energy consumption, which subsequently reduces the flight time.

6. Conclusions and Future Research

This research investigated the potential benefits of integrating aerial and ground-based sensing approaches into a HSP. The field experiment results prove that the HSP can considerably improve the aerial data quality through the data validation and calibration process. The improvement in aerial data quality makes HSPs a potential solution to address some of the existing challenges of PA—in particular, the high cost and effort required in the ground-based sensing approach and low data quality of UAV-based sensors due to UAV movement and vibration. From a ground-based sensing perspective, a HSP enables us to reduce the number of required ground-based nodes by using an aerial node as a secondary source of data collection. A lower number of ground-based nodes results in a lower cost of procurement, deployment, and maintenance, which is one of the main deterrents of PA adoption. From an aerial sensing perspective, the UAV data quality can be constantly validated and calibrated using ground-based data as ground truth. Such a process ensures that UAV-based sensors constantly provide high-quality data. Therefore, it can be concluded that the integration of aerial and ground-based approaches into the HSP can improve the efficiency and effectiveness of the farm management process by reducing the cost and improving the data quality.

In our future research, we plan to take into account additional variables in sensor data calibration, including the soil composition, irrigation factors (such as irrigation frequency, volume, and ground slope), and fertilisers used. We also plan to devise machine learning-based algorithms for automatic sensor data calibration by using data sets collected from multiple farms, across regions, states, and countries. Such research will further improve the data quality, and lower the cost and effort required for PA, while at the same time improving decision making and automation processes. These advancements in IoT-based PA will help to increase food production and our ability to deal with drought and climate change.