Abstract

The concept of Industry 4.0 is becoming more and more popular all over the world. The implementation of its assumptions in business practice changes the way companies operate. The enormous innovative potential of the Industry 4.0 concept and the intensive use of processes based on the implementation of advanced technologies in its assumptions have an impact on various industries in each country. The article attempts to analyze the critical factors for the implementation of Industry 4.0 in Kazakhstan. Primary and secondary data sources were used for this purpose. The majority of existing government initiatives and reports do not reflect the actual situation. Additionally, these materials do not always represent the experiences or positions of all the parties involved. Opinions of companies and organizations implementing Industry 4.0 solutions remain unexplored. The primary goal of the paper is to fill the cognitive gap by analyzing stakeholder responses and identifying the actual level of their awareness of the development of Industry 4.0. An additional intention of the authors was to empirically establish barriers that companies face while implementing the most desirable technologies, as well as to establish other critical factors, taking into account the specificity of the country under study. The results of the research can be used by policymakers, scientists and other stakeholders to develop forecasts and strategic plans, as well as to develop and conduct further research on the implementation processes of Industry 4.0 in Kazakhstan.

1. Introduction

The introduction of modern technologies and complex modifications to the production processes was unified under a new term “Industry 4.0” (I4.0). It is characterized by the transition to new products that will affect economic growth, the quality of life of people, and sustainability [1,2]. It also implies the connection between the material worlds and the virtual, resulting in the emergence of new cyber-physical systems united into one digital ecosystem. The development of these systems is justified by drivers that allowed the new revolution to quickly penetrate the processes of many companies [3]. Along with this, several barriers have become a stopping point for many companies, and an obstacle to the introduction of elements of I4.0 [4]. The concept of I4.0 implies the unification of new technologies into a single network operating in real-time, adjusting itself and learning new behaviors along the way [5]. These new capabilities of I4.0 have become a tasty morsel for all types of industries and an object of aspiration for many countries.

Kazakhstan is also making its steps towards this direction through the “Industrialization Program” and the “Digital Kazakhstan” program, declared in 2018. These stimulating programs aimed to move the industry to an innovative format with a new, I4.0, technological order [6]. Both programs have two directions: “digitalization of the existing economy” and “building the digital industry of the future” [7]. Despite the existence of various support programs, the position of many enterprises does not change. According to the Ministry of Investment and Development survey, over 80% of manufacturing and 60% of the mining industry are at the level of the Second Industrial Revolution [8]. One of the reasons for this could be a misunderstanding of the goal and need of I4.0, which translates into a negative attitude towards the introduction of new technologies.

This paper aims to look at I4.0 from the perspective of stakeholders. In addition, the study considers the impact of the COVID-19 pandemic, which exposed many hidden issues. Overall, the following research objectives were identified within the framework of the study:

RO1: To analyze the current state of development of I4.0 in Kazakhstan using primary and secondary data sources;

RO2: Through the conducted interviews and their further analysis, to identify the I4.0 awareness level of Kazakhstan companies, main critical factors, including challenges, that companies face when implementing I4.0 projects, required enablers such as technologies or other tools, established partnerships, and impact of I4.0 on the performance of the organization;

RO3: To present future perspectives of stakeholders about I4.0 development in Kazakhstan and their companies in particular;

RO4: Based on the findings from the literature review and conducted interviews (secondary and primary data) to perform a SWOT analysis (strength–weaknesses–opportunities–threats);

RO5: As an outcome of the study, to provide recommendations for the successful I4.0 realization to the governmental organizations and to businesses.

The paper is organized as follows: Section 2 presents an in-depth literature review to elaborate on I4.0 characteristics and the current situation in Kazakhstan. Moreover, Section 2 identifies the research gap. Section 3 introduces the methodology of the paper, including interview data collection and analysis procedures. Section 4 presents primary findings, where empirical findings from stakeholders’ interviews will be classified and analyzed. Section 5 presents a discussion of the results, summarizing the findings of the study in the SWOT table, and providing recommendations. Finally, the conclusions section gives an overview of the completed ROs and presents the limitations of the research and future studies.

2. Literature Review

2.1. Concept of I4.0

For the first time, the concept of I4.0 was announced in Germany as a governmental strategic industrial development plan [3,9,10]. Beginning from the manufacturing industry, I4.0 aimed to improve the quality of products and services and stimulate customer loyalty and satisfaction [11]. Nowadays, I4.0 is more than the popular term only for the manufacturing industry and has become a buzzword and catch phase in society [9,12]. I4.0 is a concept and the idea of the philosophy that covers most of the viable issues for the society such as sustainable, environmental, and economic development, which is only one of the examples [10]. On top of that, an extension of the I4.0 concept transforms other industries, creating new terms such as Health 4.0, Education 4.0, and many others [9,12,13]. More traditionally, I4.0 is a combination of industrial equipment and information systems and is associated with the rapid development of information technologies (IT), robotics, and industrial automation [14,15,16]. However, the implementation of an identified concept has become possible only recently with sufficient technology development [17]. Therefore, the key idea behind I4.0 is to enable the functions that Industry 3.0 could not offer. In our fast and rapidly changing world, being able to quickly answer in real time is one of the essential and vital abilities required. I4.0 with related enablers is capable of providing the following features for companies applying I4.0 [4,18,19,20,21,22], in order for them to be competitive and survive in such unpredictable situations as worldwide pandemics. It is important to mention that the list provided is collected only for introductory purposes, and is not limited to only indicated ones:

- Better customer orientation;

- Improved quality;

- Increased competitiveness;

- Diversity of services;

- Governmental support;

- Employees’ professional growth;

- Improved supply chain management.

I4.0 enablers include nine main elements, also called “pillars of I4.0.” These pillars allow the automated exchange of information by sharing all available data projected in production and business processes [23]. In addition, the combination of these elements increases efficiency and transforms the production relationship between man and machine [24]. Each element has some unique features and finds its application in all industries as a part of I4.0 implementation [10]. Their roles are provided in Table 1.

Table 1.

Nine pillars of Industry 4.0.

However, the variety of I4.0 definitions and a lack of unified implementation methodology create difficulties for enterprises for its adoption [19]. Implementation of the complex I4.0 projects is a difficult task with many barriers on the way [10,39]. Thus, not every company succeeds at it. Challenges can be divided into technical, strategical, organizational, educational, financial, and other types [40,41]. For example, issues such as a low awareness level about I4.0 [4,42], lack of specific technologies knowledge [43] related to education, while information security issues [44], lack of process standards [39,45], and lack of proper ICT architecture [4] are more associated with technical challenges. Additionally, one of the common issues within organizations can be a misunderstanding of strategic importance and benefits of I4.0 [44,45], financial issues [43,44], lack of qualified personnel [39], and even lack of support by top management [44]. Moreover, cultural issues need to be mentioned, since they play a crucial role in the implementation of I4.0 [4,46].

2.2. Current State of I4.0 in Kazakhstan

The I4.0 elements are gradually being introduced into the industrial development of every country in the world. Kazakhstan has introduced several I4.0 initiatives through governmental programs. The programs “Digital Kazakhstan” and “Industrialization Program” were adopted to increase the level of digitalization in all sectors of the industry [7]. As a result, the innovative project “Seven Model Digital Factories” was launched [47].

The content of the “Digital Kazakhstan’’ program outlined three basic principles. The first is the digitalization of flagship industries by the introduction of modern technologies and approaches. The second is to provide the entire country with Internet access to develop digital economy sectors, such as telemedicine, e-commerce, etc. In addition, the last principle is to support startups and digitization projects with their subsequent implementation [48]. As a result, more than 30 projects of government agencies and domestic companies were presented at a special exhibition of digitization projects. The developments covered the following areas: industry, transport, security, finance, and innovation [48].

The “Digital Kazakhstan” program obliged companies to digitize significant areas of activity to establish electronic interaction and qualitatively improve the lives of citizens of the country [49]. However, today, most companies are still characterized by the insufficient technological and organizational base for a full-fledged transition to I4.0 [50]. Therefore, the government should stimulate the I4.0 research sphere and popularize I4.0 among enterprises and the population.

One of the actions taken by the Ministry for Investment and Development (MID) to develop I4.0 popularization programs is “model digital factories.’’ This program implies consulting and financial support for seven selected firms, helping them to implement I4.0 solutions. These companies are expected to be a practical example of I4.0 transformation within the Kazakhstan economic, social, and cultural context [47]. Due to the recency of the program, it is still early to produce some results.

Despite that, the combination of governmental initiatives with the enthusiasm of private firms may produce valuable outcomes. One example is Sokolov–Sarybai Mining Production Association (SSGP) with its “smart mine” modular automated system. The solution aims to reduce downtime of the production facility by online monitoring of vehicles’ status. The system can locate the malfunctioning unit, identify the type and degree of failure, and set up related tasks for operators. The crew is already received full technical training. The company expects to generate $28 million in profits due to the introduction of the “smart mine” [47].

Despite various available information about I4.0, organizations still struggle to define the concept. The majority of existing sources indicate the tight intersections of terms digitalization with I4.0 and sometimes even interchange them [51]. This is one of the main reasons for the widespread misunderstanding of the I4.0 concept in Kazakhstan. Consequently, it is one of the main barriers to I4.0 implementation.

Moreover, most of the existing sources in Kazakhstan do not analyze the needs of I4.0 stakeholders. For example, state strategies dedicated to developing the industry focus on state-defined indicators. However, they lack the real needs of “implementers” of those strategies and clearly defined steps [52]. Thus, this literature review was conducted to identify the research status and investigations within stakeholders. The identified research gap indicates that the standpoint of involved parties should be studied. Therefore, in this study, the gap was addressed by conducting extensive interviews with 15 representatives of businesses in Kazakhstan.

3. Materials and Methods

3.1. Research Instrument

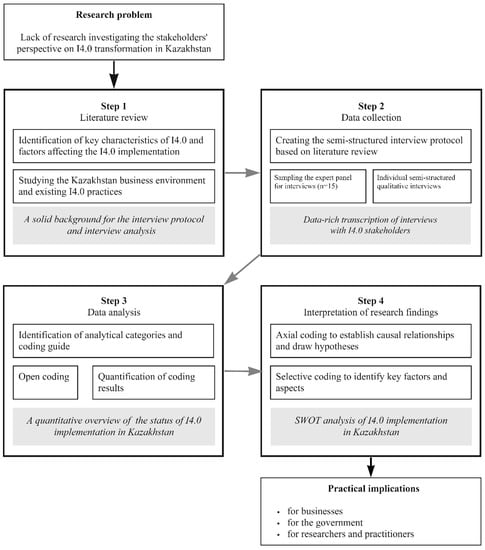

The methodology of this study is based on a systematic stakeholder analysis (Figure 1).

Figure 1.

An overview of systematic stakeholder analysis stages.

First, in order to clearly understand the discussion framework, define the scope of application of I4.0 tools, create an interview protocol, and prepare interview questions, a comprehensive literature review on the I4.0 topic was conducted [12,53]. This methodology implies the collection and review of material from databases using clearly defined transparent rules. For this study, Google Scholar and SCOPUS were used for retrieving academic materials, while Google Search was used for non-academic resources, such as firm reports. Literature was collected by searching various AND-OR combinations of the following keys: “Industry 4.0”, “digitization”, “Kazakhstan”, “technologies”, “enablers”, “tools”, implementation”, “critical factors”, “barriers”, “drivers”, “interview”, “survey”, “managers”, “stakeholders”, “stakeholders’ analysis”, “current state”, “expectations”, “perspectives”. The search results of each combination were stored in an Excel database with all necessary metadata. Then, duplicates were removed, and title-abstract (TA) review analysis eliminated semantically irrelevant items. Next, 143 academic papers and 27 reports proceeded for an analysis of the Abstract, Introduction, and Conclusions. Researchers’ notes were attached to the database, and each article was categorized to improve navigation. Based on the researchers’ notes assessing the relevance, 40 papers and 15 reports were chosen for full-paper content analysis. The results of the literature review are presented in Section 2. Moreover, this review shaped interview questions and the protocol.

The qualitative interview method with a semi-structured questionnaire (research instrument) was preferred because of its openness to brand new and unstructured information [54]. The interview protocol refinement (IPR) framework was used to design seven open-ended questions for the interview with experts [55].

All of the IPR requirements were met. Firstly, interview questions had a strong relation to research objectives. Questions aimed to examine the status of I4.0 in Kazakhstan from the stakeholder’s perspective. Secondly, interviews aimed to gather information in 12 specific predefined dimensions identified after a literature review.

Inspected parameters included: The I4.0 awareness, implementation level, the impact on KPI, demanded technologies, critical factors and barriers, international experience, and forecasts. Thirdly, six research colleagues provided feedback on the questions using the think-aloud method [56]. Finally, one pilot interview with an I4.0 user company and one with a provider were conducted to test the interview protocol. Over 15 interviews, the questions’ wording slightly evolved and varied depending on the respondent’s role (user/provider/consultant).

3.2. Data Collection

An extensive Kazakhstan business press review produced a list of 73 potential interviewees. All candidates received an email with the project description and an invitation to collaborate. Twenty-nine companies agreed to a partnership. However, the number of interviewees decreased to 15 after a four-step sampling. Firstly, researchers excluded companies not operating in Kazakhstan (n = 3) and companies without business activity in the last twelve months (n = 3). Then, researchers eliminated companies with less than twelve months of operating experience (n = 4) because their business processes are generally unsystematic. The reason is that the study of chaotic processes could bring to wrong conclusions. Moreover, researchers removed companies with less than $15,000 of annual revenue (n = 4) for their relatively low contribution to the GDP of Kazakhstan.

Despite the sampling, the remaining interviewee companies varied in sizes, industries, degree of affiliation with government, and roles in the 4th industrial revolution (Table 2). Finally, the expert panel consisted of managers of 13 Kazakhstan firms and two industrial consultants. Three of the participant companies were providing I4.0 solutions for businesses. Others were using the I4.0 solutions to improve their business activities.

Table 2.

Participants details of the experts’ panel.

Interviewed companies were classified by the number of employees, similarly to the Entrepreneurial Code classification [57]. Nine companies had less than 250 employees and thus were small and medium-sized enterprises (SMEs). Six respondents were large enterprises (LE) with more than 250 workers.

Interviews took place from July to December 2020. Interviews were conducted online via Google Meets, Skype, and Zoom platforms. Each of 15 groups of experts shared their field experience during individual interviews lasting 40–70 min. After agreeing on the definition of I4.0, core questions were addressed, followed up with clarification questions. Researchers made memos during the interview and included them in the analysis stage. Fourteen of 15 interviewees consented to the audio recording. Combined, all replies generated 40 pages of transcription for an analysis. To avoid bias in results, interviewers had minimal prior assumptions and expectations.

3.3. Data Analysis

Interview transcriptions were analyzed using the five steps prescribed by Schmidt [58]. Schmidt suggested identifying analytical categories (1) and coding guidelines (2) before coding. These steps will structure interviews without sacrificing the diversity of replies. Next, in the coding stage (3), interviews should be examined against the coding guide. This procedure allows researchers to retrieve statistics from the interview transcripts (4). The author recommends continuing the interpretation of interviews (5) in a less structured way with the aim of deriving hypotheses. Additionally, Notion, a data management software, was employed for the research [59].

After collecting all transcripts and the researchers’ memo, the interview analysis was started. Firstly, rigorous iterative reading of transcription combined with literature review produced seven analytical categories:

- I4.0 awareness;

- I4.0 implementation;

- Critical factors;

- Demanded I4.0 enablers;

- Established partnerships;

- Impact of I4.0;

- Future perspectives of I4.0.

The analytical categories reflected only the topic of a respondent statement. Thus, coding guidelines were developed to consider the actual content of phrases. Mostly, the coding guide consisted of 3–5 answer options, semantically equivalent to real answers. However, the demanded enablers guidelines were the 19 I4.0 technologies, principles, and practices mentioned by respondents. Moreover, the guide for future perspectives category was discarded because of all answers being unique. Additionally, peculiarities associated with the ongoing COVID-19 pandemic were noted. Respondents mentioned the difference and nuances of the digital transformation during the pandemic and its effect on some aspects.

Afterwards, all authors independently manually coded all interviews. Interviews were evaluated using the coding guide. Combined results were thoroughly discussed and quantified. Furthermore, a comparative quantitative analysis of interviews was performed. Firstly, responses of ten user companies were compared against responses of five experts. The next comparison criterion was the size of the company. Replies of six large enterprises were compared to those of nine SMEs.

The text was further interpreted using qualitative content analysis procedures [60]. For each of the seven analytical categories, all the related data were retrieved from transcription. Causal links, common patterns, anomalies, and differences were identified using axial coding and then discussed [61]. Key factors and aspects were identified during the selective coding.

4. Primary Findings

This section describes and discusses the data collected from interviews. The analysis was performed for seven categories defined in the Methodology section. Each underlines the key aspects and ideas repetitively mentioned by respondents. Moreover, direct quotes of the interviewees were cited and labeled as Q1, Q2, etc. The complete list of cited quotations is provided in Appendix A.

4.1. Holistic Analysis of Findings

4.1.1. I4.0 Awareness

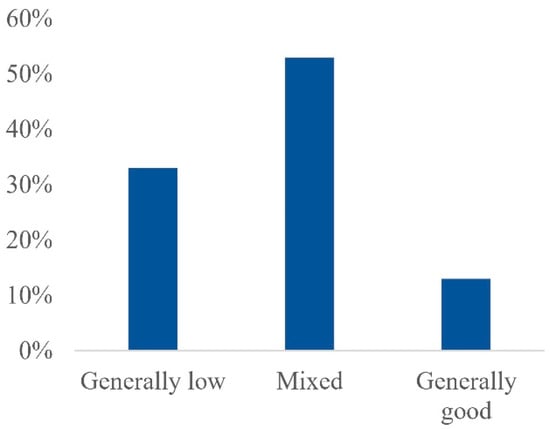

The “I4.0 awareness” category considers the awareness of companies from two perspectives. User companies indicated the average awareness level among their employees, while I4.0 providers and consultants—among their clients. In addition, 33% of respondents described the knowledge level as decisively low, and 13% as generally good (Figure 2). Furthermore, 53% of interviewees reported mixed awareness levels within the companies. In this condition, only employees implementing the technologies understand the I4.0 concepts, and the rest of the employees possess a low level of knowledge. Surprisingly, even some provider companies have a mixed level of I4.0 awareness.

Figure 2.

Industry 4.0 awareness level in Kazakhstan companies.

Based on the interview analysis, several possible reasons for the low level of I4.0 awareness can be underlined. First, the variety of definitions of I4.0 and the complexity of the concept makes it difficult for implementers to identify the real scope and aims of I4.0 [51]. Another reason could be the wide misconception of the term within the country.

The term I4.0 is not so popular in Kazakhstan. This term is usually wrongly understood by clients.(Interviewee 1)

Another reason for misconception might be the wording of governmental policies to increase the digitalization of industries. They solely concentrate on that term with no references to I4.0. Thus, the I4.0 concept remains unusual and unknown for most citizens of the country [62].

Further investigation showed that cultural perception by the workforce also might be a serious obstacle. Respondents reported that employees fear automation, robots, and other technologies because of the associated massive workplace reduction.

People think that, after the implementation of I4.0, they will lose their job. Thus, they start quiet sabotage.(Interviewee 03)

Fear of unemployment due to I4.0 is an important factor, investigated by many researchers in worldwide practices [4,44]. However, there is a contradictory opinion that I4.0 will create more job opportunities [63]. Nevertheless, continuous acquisition of new skills is a requirement of the modern world.

4.1.2. I4.0 Implementation

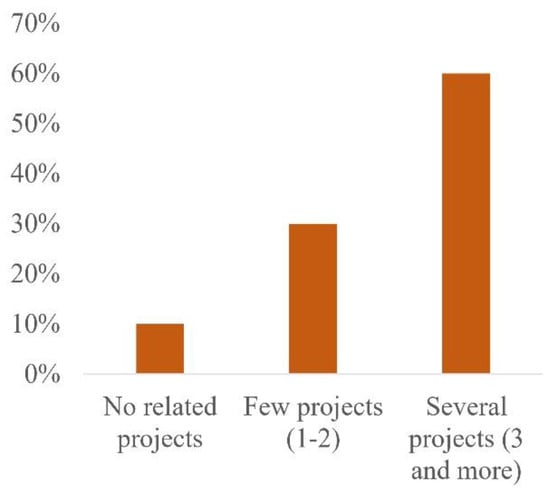

In the “I4.0 implementation” category, I4.0 users indicated the number of implemented projects related to I4.0. In addition, 60% of the user companies implemented three or more projects, and 30% implemented only 1–2 projects (Figure 3). Ten percent of users have not implemented any projects yet. Moreover, I4.0 providers and experts described the digitization level of client companies. All providers and experts stated that the digitization of companies in Kazakhstan, in general, is at a low level. Additionally, interviewees reported that the coronavirus lockdown left a twofold effect on the speed of implementation of the I4.0 project. For some businesses, this critical situation accelerated the development of the I4.0 project due to the increased need for optimization and means to develop competitive products. Unfortunately, other companies have frozen their transformations because of the financial crisis and lack of funds.

Figure 3.

Industry 4.0 implementation level in Kazakhstan companies.

Despite the low I4.0 awareness in Kazakhstan, 60% of users implemented more than three projects applying I4.0 technologies. However, these projects vary in directions, involving technologies and the complexity of systems. Projects of large enterprises are related mostly to 3D modeling, IoT, and big data. Additionally, some users shared their plans to enhance the existing I4.0 related projects (Q1). However, most of the companies implement their project only “on paper”:

Most organizations just implement digitalization or some I4.0 tools for the sake of digitalization, without understanding what real benefits it can bring.(Interviewee 01)

It is no wonder that these projects fail. Analysis of the situation in Kazakhstan combined with the interview findings revealed other reasons why I4.0 projects fail. The first is the low I4.0 awareness level among executive management and decision-makers. Therefore, attempts to implement I4.0 technologies without the required knowledge do fail (Q2). Further analysis raised cultural issues, namely the absence of technological culture in organizations. Several interviewees stated that the culture of introducing changes should be continuously developed (Q3). It will reduce the fear of uncertainty among employees.

Employees might be another problem when implementing I4.0 projects [39]. Employees should receive proper training and instructions. Otherwise, they might misunderstand the idea or refuse to accept it (Q4). Another possible issue is the lack of communication. This factor is among the most common obstacles for I4.0 projects and remains relevant for companies regardless of their geography, industry, and maturity [4,42].

Big companies have systems and programs. However, the programs do not come together to enhance data information, decision-making. Seventy percent fail because of people. All individuals have their perspective and articulation form of value to make these things happen. Thus, you need people to cooperate.(Interviewee 02)

Furthermore, a high bureaucracy level and inflexibility of governmental regulations might be an obstacle for completed projects and freeze them for an uncertain time (Q5).

4.1.3. Critical Factors

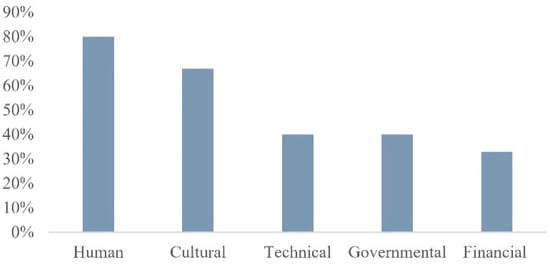

The “Critical factors” category represents the types of factors affecting the implementation of I4.0 in Kazakhstan. In addition, 87% of interviewees indicated more than one factor as significant. Therefore, the sum of coding scores exceeds 100%. From Figure 4, the most challenging obstacle is the human resources issues (80% score). Culture also gained a high score (67%). Technical and Governmental related issues received a score of 40%. Surprisingly, Financial factors were the least important (33%).

Figure 4.

Key factors affecting the Industry 4.0 implementation in Kazakhstan companies.

Human resources gained the highest score of 80%. Respondents said that 70% of projects fail because of people. Employees are not improving their abilities to cope with the continuously changing environment. On top of that, any established technology cannot provide improvements in the people/employees sharing of knowledge [64]. Again, employees need training and specific instructions for a project to succeed (Q6). The weak education system in the country causes another problem, which is a shortage of qualified professionals.

The main problem is that there are not enough high-quality professionals. Therefore, we have to look for ready-made solutions abroad. Moreover, we need to bring engineers because we do not have people to serve these solutions. We do not have such universities that would produce skilled engineers.(Interviewee 13)

Moreover, the lack of well-established processes and structure creates difficulties for employees. It deprives them of the ability to learn before the actual implementation (Q4).

Causal conjunction analysis revealed that the competence of top management is crucial. Decision-making in Kazakhstan is highly centralized, and thus the expertise of executive management is essential [65]. The wrong implementation strategy will inevitably lead to a fiasco.

Centralized management does not pay off. It should be distributed and networked.(Interviewee 04)

Next, the cultural issues were investigated and got a high score (67%). Interviewees described various aspects of culture affecting the I4.0 implementation. The first is the fear of uncertainty associated with changes, which results in resilience to changes among employees (Q7). The second is the absence of technological culture.

The change of mindset is the main challenge of every aspect of digitalization.(Interviewee 01)

One interviewee named the third issue as mental readiness. Managers expect fast and positive results. However, many problems, delays, and rework might slow any transformation. Therefore, management should not expect great short-term results (Q8). The fourth is the lack of communication and explanatory work with employees. Many interviewees highlight people as the key to any change (Q9). Next, the general resistance to changes and know-how in the country were noted.

In Kazakhstan, we have a lot of punishment for initiatives.(Interviewee 02)

Consequently, due to the fear of failure and punishment, enterprises implement the I4.0 projects fictitiously.

Enterprises only create an image of digitalized ones due to government pressure. However, in reality, the level of their digitalization is low.(Interviewee 13)

Finally, every international practice needs an adjustment based on cultural specifics. Blindly copying will limit the potential of a system. Managers should consider cultural differences (Q10) [66].

Financial issues are among the major obstacles to implementing I4.0 projects [39]. SMEs usually face more difficulties due to the high investment costs [19]. Companies in Kazakhstan also experience financial concerns (Q11). For example, hiring professionals is costly and not affordable for SMEs (Q12). However, another interviewee stated that companies have access to funds but do not invest because of the absence of the long-term development strategy (Q13).

Technical issues escalated when COVID-19 hit the unprepared Kazakhstan economy [67]. Many companies suffered from a low level of ICT in-country and poor internet quality (Q14) [68]. Other companies highlighted the problem of disintegration between implemented I4.0 projects (Q15).

Lastly, interviewees also discussed government-related factors. Firstly, the absence of flexibility in regulations slowed many implementation processes. Legislation, along with generally high bureaucracy, may impede the deployment of ready technologies (Q16). Another interviewee acknowledged governmental support in terms of tax deductions and financial leasing. However, this support is difficult to obtain because of corruption, and the feasibility of such programs is questionable (Q17).

There are many roadmaps but no clear tools for their implementation.(Interviewee 13)

Additionally, the COVID-19 lockdown influenced the identified factors in various ways. Respondents report that human resources and cultural factors have benefited from the pandemic. The remote work conditions forced many employees to become more digitally literate and techno-friendly. Contrarily, technical aspects suffered an unexpectedly heavy extra-load on the ICT infrastructure. Moreover, the ongoing coronavirus crisis amplified the financial issues associated with digital transformation.

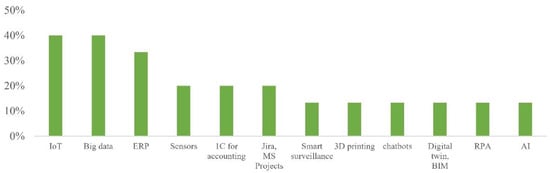

4.1.4. Demanded I4.0 Enablers

This category identifies the most demanded technologies and tools of I4.0 in Kazakhstan. Overall, interviewees mentioned 19 enablers. Most popular were the IoT (six mentions), big data (6), and enterprise resource planning (ERP) (5) (Figure 5). 1C systems, widespread in CIS countries, received three points [69]. For comparison, 3D printing, digital twin, artificial intelligence (AI), and robot process automation (RPA) had only two mentions. Unexpectedly, respondents mentioned cloud systems, virtual reality (VR), customer relationship management (CRM), and lean tools only once.

Figure 5.

The most demanded technologies and tools of Industry 4.0 in Kazakhstan.

According to interviews, one of the most popular elements of I4.0 in Kazakhstan is big data. One interviewee commented on big data as critical to improve processes (Q18). However, big data algorithms require raw data input in large amounts. This factor leads to the popularity of another I4.0 technology—the IoT, capable of production and collection of raw data (Q1). IoT, combined with big data, can significantly simplify the companies’ work. Furthermore, enterprises consider ERP as a universal system to optimize many processes (Q19). However, some companies might overestimate their need for such complex systems and be unprepared to work with them properly (Q4).

Many factors affect the failure risk of the I4.0 implementation projects. These include the low qualification of the workforce (Q20) and the cultural mentality. Some companies digitalize for the sake of digitalization, not knowing the benefits of I4.0. Moreover, some enterprises implement costly technologies not because of necessity but because of modern trends.

We have two kinds of technology trends in our country: fashionable and necessary. The first one is part of the mentality, and it does not bypass the IT sector. If something is fashionable, then all companies start to use it right away.(Interviewee 05)

In such cases, the competency of the top management is questionable. Therefore, issues may arise in both the implementation strategy and right timing to introduce new technologies.

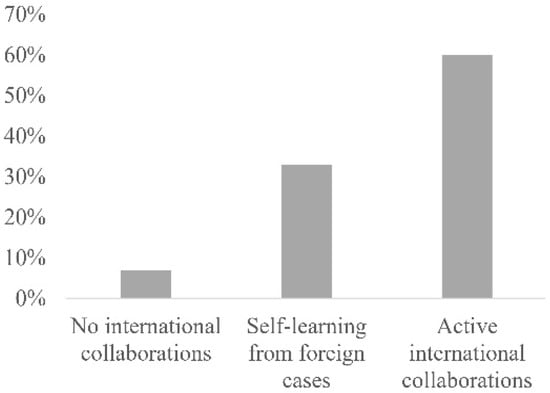

4.1.5. Established Partnerships

The fifth category studies the companies’ collaborations with international I4.0 stakeholders. The interview analysis revealed that 60% of the interviewees had active international collaborations. Furthermore, 33% of the interviewees had no active international partners but were learning I4.0 practices from foreign cases (Figure 6). The rest, 7%, had neither collaborations nor self-learning.

Figure 6.

Established international partnerships among Kazakhstan companies.

The gained analysis in categories 1–4 showed a low level of I4.0 awareness and numerous obstacles toward I4.0 project implementation. These factors inevitably affect the high rate of active international collaborations with I4.0 stakeholders. Moreover, there is a lack of I4.0 solutions providers within the country. Therefore, companies seek ready-made solutions from international experience (Q21). Big companies with sufficient resources enjoy direct international collaborations and participate in employee exchange programs for training. On the country, SMEs usually have fewer resources and limited access to international experience. Therefore, domestic enterprises are becoming self-learners (Q22). They study international I4.0 practices from courses, conferences, articles, etc.

However, the absence of the established process for work with foreign partners harms the project quality (Q23). Domestic companies fear not satisfying the requirements of foreign colleagues because of high demands and standards.

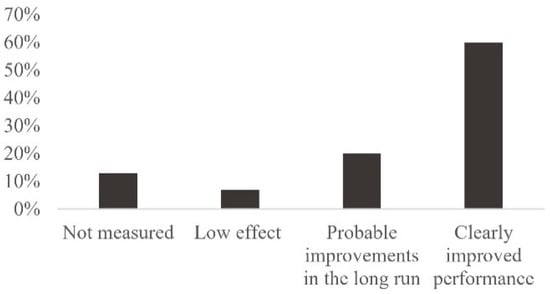

4.1.6. Impact of I4.0

The sixth category investigated the impact of I4.0. All interviewees assessed the average effect of I4.0 tools based on their implemented projects. As a result, a significant percentage of respondents (60%) highlighted an improved business performance (Figure 7). Twenty percent of respondents forecast a high probability of improvements in the long run, but, due to the immaturity of implemented I4.0 projects, it is too early to measure their performance. Thirteen percent of the interviewees indicated that they did not measure the performance at all. Finally, only one company had closed a project because of low returns.

Figure 7.

The impact of Industry 4.0 on companies in Kazakhstan.

The impact of I4.0 tools is mostly positive yet occasionally negligible. Most of the respondents indicated that I4.0 solutions improved their business performance in terms of efficiency, quality control, and strategic management, and, in some cases, already increased the company’s net income (Q24). Moreover, I4.0 projects have a positive impact on society [70]. One of the interviewees stated that the ongoing smart city transformation project in Nur-Sultan helped to increase road safety (Q25). The social impact might become an additional motivation to invest in I4.0 projects for many companies.

Despite the numerous successful projects, sometimes the results of the I4.0 implementation might be insignificant. One interviewee company downgraded the ERP system because of its financial inefficiency. They switched to a simpler ShareFile and 1C: Accounting software. Another respondent completely abandoned the implementation project due to the lack of performance improvements (Q26). Section 4.1.3, critical factors, examined the reasons for the failure of I4.0 projects. Companies must be aware of implementation barriers indicated in Section 4.1.2, I4.0 implementation, and possess resources to overcome them.

Lastly, one of the interviewees stated that the fourth industrial revolution does not inherently bring prosperity. It just creates opportunities to improve the performance of businesses and governments.

Changes happen, and I4.0 catalyzes this opportunity. Companies that take the opportunity will be winners.(Interviewee 2)

4.1.7. Future Perspectives of I4.0

The last category studies the future perspectives of I4.0 development in Kazakhstan. Most of the interviewees stated that changes are inevitable. Companies must understand that the introduction of new technologies is crucial for work in the modern environment. Every company must realize that the digitization process is not a choice but a necessity (Q27).

Among interviewed companies, those with existing I4.0 projects already created plans for further I4.0 development. Several respondents emphasized the increasing role of big data (Q28). Many companies plan to integrate the implemented I4.0 technologies. The integration will optimize the existing processes (Q29). Some interviewees noted the exponential growth of complexity of technologies and programs. Thus, the concern regarding people’s abilities to cope with those changes was underlined (Q30).

Concluding this section, I4.0 is becoming more widespread in Kazakhstan. Good I4.0 awareness can foster its successful development all over the country. However, the enhancement of the qualification of employees requires special attention and consideration on a governmental level.

I4.0 technologies have the potential for development, but at least two years are required until people realize this. In general, it will take about five years to develop in Kazakhstan. The potential of Kazakhstan is very high, but it all starts with education. We have great potential, but everything depends on people.(Interviewee 12)

4.2. Comparative Analysis of I4.0 Stakeholders

4.2.1. Comparative Analysis of I4.0 Stakeholders: User Companies vs. Experts

Comparative analysis of interviews with I4.0 user companies and experts (consultants and provider companies) is provided in Table 3. Key differences are highlighted and discussed below.

Table 3.

Comparative analysis: users vs. experts.

The first major difference is in a perception of the cultural factors. In addition, 100% of experts indicated that corporate and employee culture is important for I4.0 transformation, while only 50% of user companies mentioned it.

Moreover, 100% of experts believe that the I4.0 transformation will yield benefits for the company. However, user companies were less optimistic with just 70% of them clearly advocating for the transformation.

4.2.2. Comparative Analysis of I4.0 Stakeholders: Large Enterprises vs. SMEs

Comparative analysis of interviews with large enterprises and SMEs is provided in Table 4. Key differences are highlighted and discussed below.

Table 4.

Comparative analysis: large enterprises vs. SMEs.

Firstly, 27% of SMEs do not have any employees with good awareness of I4.0 concepts. Contrarily, just 7% of large enterprises are experiencing such an issue with human resources.

Secondly, 67% of large enterprises indicated that governmental policies affect their I4.0 transformation. On the other hand, only 22% of small firms noted this. Therefore, governmental influence is not pervasive for small firms. This may imply that the support by governmental digitization programs is known and enjoyed mostly by large enterprises, but not SMEs. Thus, the government should re-evaluate the impact of support programs and then, probably, redesign them.

Thirdly, 44% of SMEs find costs of I4.0 transformation as a barrier. However, only 17% of large enterprises experienced such restrictions.

Fourthly, 100% of large enterprises and just 33% of SMEs have 3+ ongoing or completed I4.0 projects. Thus, the I4.0 implementation level in small firms is much lower.

5. Discussion of Results

Based on the results from the literature review and findings from stakeholders, SWOT analyses were performed. During the literature review, the existence of various state programs such as “Digital Kazakhstan”, and the related big number of projects were identified. As a part of the program, and to increase the digitization level, companies were obliged to implement several tools, which help to optimize resources, increase the transparency of processes, etc. However, due to the lack of knowledge by top management and employees, most of the tools were implemented in order to avoid legal issues, and are not used properly in organizations. Therefore, the efficiency of such programs is questionable; in addition, the urgent need for proper instructions/explanatory work about I4.0, digitalization, its tools, and benefits are required. All of these points combined with primary findings are reflected in the SWOT table. SWOT analysis includes significant implementation factors and accounts for the business environment in Kazakhstan (Table 5).

Table 5.

SWOT analysis of enterprises in Kazakhstan in the I4.0 context.

Making a comparison of the aspects identified for Kazakhstan with other countries, it is clear that most of the issues are related to each other, however, except some specific country-related issues. For example, the authors in [10,39], identified that issues such as high investment costs along with a not clear understanding of the benefits from I4.0 take place in India and, in general, in the construction industry. Moreover, the authors in [39,71] identified issues in lack of integration in horizontal and vertical chains, as well as barriers with disruption of existing jobs, which is also true for Kazakhstan. Another research work by [72] shows that Chinese participants of the survey expect fewer jobs, while participants from Germany in comparison do not have such negative results. In the research by [73], a lack of digital vision was presented as the most affecting barrier, which impacts the rest of the barriers. This research shows issues like lack of strategy and well organization, lack of digital skills, issues with legal frameworks, lack of knowledge about I4.0, etc.

Summarizing the findings presented in the literature review, as well as those identified in the study, recommendations for both the government and businesses are provided, since it is proven that every part of the ecosystem has a significant role in the I4.0 transformation.

Recommendations to the Government:

- The feasibility of the enterprise support programs should be improved. Interviewees reported that the actual impact from such programs is insignificant. Moreover, the competency of program developers should be raised. The results show that digitalization programs do not reflect the real needs of enterprises. Thus, the actual condition of Kazakhstan enterprises should be well investigated;

- Increase possibilities for the R&D development in the country (grants, competitions, scholarships, etc.) through growth in investments;

- Major investments are required to develop the ICT infrastructure across the country. They can be attained not only by the governmental financing but also by creating a competitive atmosphere;

- Investments or other tools (special credit terms, leasing mechanisms, and others) for renewal/renovation of the factories are needed as well. They will slow down the equipment aging for industries;

- Transparency of processes should be increased to minimize the corruption level, one of the possible solutions to toughen laws on corruption and exceeding authorized duties, close all avenues to shadow business using digitalization tools;

- Creation of the correct “ecosystem” (tax free for the initial few years, identification of the pool of promising areas/businesses, improving their conditions through covering the needs) within the country would allow local companies to reach the global supply chain;

- Official regulations should be updated to keep up with modern technologies. Costly projects with high possibilities to optimize processes and efficiency frequently fail because of legislative issues;

- The communication between the government, industry, and academy should be improved to prepare skilled professionals. The lack of professionals pushes domestic enterprises to seek solutions outside the country. This option is not affordable to most of the companies due to the high cost of international consultants. One of the options possible is to legally oblige related businesses pass training about Industry 4.0, in the universities/educational organizations approved by government;

- The technological culture should be promoted. Currently, some managers are punished for initiatives. Others are too conservative for innovations and resilient to them. The paradigm shift will help to overcome the fear of digitalization and uncertainty and decrease the resistance to change;

- The adoption of international experience should account for cultural differences. Unfortunately, this factor is sometimes ignored.

Recommendations to Businesses:

- Companies need to pay more attention to the proper processes’ establishment. The systematic approach is the basement of any organization. A poorly set system deteriorates the overall effectiveness of the enterprise;

- A culture of self-learning from international experience should be supported. If it does not exist, it should be developed. It is an excellent opportunity for SMEs with low financial possibilities to study from international experience for an affordable price. Moreover, it is great not only to imply that experience to the company’s processes but to train employees;

- Proper formation of the vertical integration within company is a need for the successful implementation of I4.0 projects. Lack of communication leads to misunderstandings, which is a reason for 70% of cases of projects fail, according to interviewee 4;

- A system of change management needs to be introduced. It might include systematic continuous training for employees, since the project is dependent on the capabilities of employees’ success. The explanatory sessions, presenting the need of the organization to apply new tools and other benefits, especially for employees need to be carried. Develop the inter-organizational culture of life-long learning, allowing the workforce to optimize their approach to work by searching for new optimal ways;

- Leaders with a high knowledge of digital transformations are required, especially for large enterprises and governmental entities. This critically important, yet simple suggestion, is missed by governmental entities in most cases;

- The smooth transition to Industry 4.0 can be reached through a prior defined strategy, which will allow avoiding chaos and application of costly and inappropriate technologies. It was indicated that most of the companies in the country tend to learn or make major changes in the strategy in the process of transformation; this approach must be exterminated;

- Digital/Industry 4.0 roadmap should be created to clearly define needed steps, roles of the involved parties, employees, partners, etc. On top of that, a roadmap is required to focus on the critical aspects, and avoid wasting resources. It should be clear for stakeholders that not the strategy, but the roadmap can be adjusted, changed, and modified according to the needs of the enterprise.

Recommendations indeed are not limited to only provided ones, and their further development can be considered.

6. Conclusions

This study investigated the actual opinion and needs of I4.0 stakeholders in Kazakhstan. Moreover, this paper studied most of the aspects of I4.0 transformation from the implementers’ perspective. Key research findings are presented in Table 6.

Table 6.

Key research findings.

In conclusion, the I4.0 revolution is already affecting many countries and industries. Somewhere faster, somewhere slower, all enterprises will come to it. Therefore, organizations should correctly understand the conception of the revolution. If they want to succeed, they should take the lead in the application of transformational projects. The pandemic certainly had some lessons for all enterprises when the application of technologies was the only way to survive. In general, by examining the analysis received during the study and future forecasts of I4.0 development in the country, the positive impact of I4.0 is seen. The number of transformation projects per company is increasing. Many companies plan the further enhancement of existing projects. With such an active elimination of barriers and interaction with international partners, Kazakhstan companies have great potential for the rapid implementation of I4.0.

6.1. Limitations

The first limitation of this study is that the Industry 4.0 concept is newly developing in the country. Since most of the concepts and applications related to I4.0 have been developed in the manufacturing sectors, its development in Kazakhstan, whose economy is generally based on oil and gas production, has only been possible in parallel with the development of the manufacturing sector in recent years.

The second limitation is the lack of trust by Kazakhstan companies. The academy-government-industry triangle is not yet established in Kazakhstan, especially for the manufacturing industry. Local firms remain skeptical about external researchers and have strong privacy concerns. Thus, unwillingness of companies to participate in such studies creates issues when conducting research projects.

The third limitation is the lack of weighting of discussed factors. This restriction is inherent to the selected methodology. Lengthy semi-structured interviews have their advantage in the richness of information, insights, and flexibility. However, the trade-off is the lack of items weighting. This research is frontier in Kazakhstan, and thus it could not provide interviewees with the list of I4.0 implementation factors to compare. Thus, detailed quantitative analysis was not the aim of this study. Instead, it aimed to assess the current status of I4.0 qualitatively, name existing problems, and suggest possible directions and scopes for future research.

6.2. Future Research

Further research can develop a tool to evaluate company readiness for the I4.0 transformation, its drivers, and bottlenecks. Next, such studies can be used to produce an I4.0 roadmap and draw recommendations for organizations in Kazakhstan. These might consider company-specific characteristics and general Kazakhstan human resource, cultural, governmental, financial, and technical factors of I4.0 implementation.

To create an effective guide, a study weighting the I4.0 implementation factors should be conducted. It may employ a structured interview or survey to identify the most critical items of the SWOT table. The study might use governmental resources to collect data from a larger number of companies.

Since business processes vary from field to field, the I4.0 transformation plan should be adjusted accordingly. Therefore, industry-specific I4.0 stakeholders’ analysis should be performed. Future research might compare the I4.0 status and implementation factors in different domains, such as manufacturing, mining, metallurgy, oil and gas industry, and agriculture.

Furthermore, the I4.0 transformation can be accelerated by designing the I4.0 training courses for managers and employees. A future study might identify the best learning methodologies considering Kazakhstan’s cultural aspects.

Author Contributions

Conceptualization, A.T. (Ali Turkyilmaz), D.D. and E.S.; data curation, Y.L., A.T. (Akmaral Tokbergenova) and D.D.; formal analysis, D.D., A.T. (Akmaral Tokbergenova) and Y.L.; funding acquisition, A.T. (Ali Turkyilmaz) and E.S.; investigation, A.T. (Akmaral Tokbergenova), D.D., A.T. (Ali Turkyilmaz); methodology, Z.P., D.D., A.T. (Akmaral Tokbergenova) and Y.L.; project administration, D.D., A.T. (Ali Turkyilmaz); resources, A.T. (Ali Turkyilmaz) and E.S.; Software, Y.L. and A.T. (Akmaral Tokbergenova); supervision, A.T. (Ali Turkyilmaz) and E.S.; Validation, E.S. and Z.P.; visualization, Y.L.; writing—original draft, D.D., A.T. (Akmaral Tokbergenova) and Y.L.; writing—review and editing, A.T. (Ali Turkyilmaz), E.S. and Z.P. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank Nazarbayev University for funding this research within the project “Industry 4.0 Assessment of SMEs in Kazakhstan” under the Faculty Development Competitive Research Grant Program (FDCRGP), Grant No.: 240919FD3919.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to the privacy concerns of interviewees.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Quotation ID (Q), Quotation, Interviewee ID (I)

Q1, “At the moment, the company uses technologies such as the IoT. When laying the network, we install special sensors. They allow us to determine breakdowns and other technical problems in the operation of cables. In addition, the organization plans to use Big Data processing technologies. The aim is to optimize future large amounts of data.”, I8.

Q2, “The main problem with the implementation of I4.0 is that many entrepreneurs do not understand what benefits they can get from the implementation of certain technologies of I4.0. The second problem is the low level of awareness among top management about I4.0. The third problem is a direct result of the above two problems. It is that companies that do not have sufficient knowledge in I4.0 technologies are trying to implement them, which leads to a fiasco.”, I7.

Q3, “There is no technological culture at all in Kazakhstan.”, I3.

Q4, “There was an attempt to implement the ERP system in the company three years ago. It failed because of the misunderstanding of the ERP system by employees. If a company does not build the processes correctly, no system will work correctly. All employees must understand the principle of the system and the exact order of all procedures for the most harmonious work.”, I7.

Q5, “There was a proposed project in the sphere of biometrics—facial recognition via the deployment of computer vision technologies. However, even though the project can be facilitated and launched in little time, there is a huge room for bureaucracy from the government side. This holds not only for this project but for all projects related to the governmental sector. Thus, the main obstacle here is the high level of bureaucracy that greatly decelerates the development of projects and strategies.”, I10.

Q6, “In Kazakhstan, most of the problems with digitalization are cultural. People may not be convinced, even though the project is objectively good.”, I5.

Q7, “One of the challenges is the fear of new things or fear of uncertainty. The majority of customers still stick to the old technologies and past trends, and there is no willingness to accept the new trends.”, I10.

Q8, “The 1st basic issue is business mental readiness. I4.0 will not immediately give a result. Thus, companies need to prepare for this fact. The company must have a culture of introducing something new all-time and do not expect that everything will be successful.”, I4.

Q9, “The problem is in people’s culture. Any transformation is based on people, processes, and technology, but the most important part is people. If dwellers are against the idea, they start sabotaging ideas. Then, the system will not work. If a culture does not have a welcome strategy, then it is doomed to fail.”, I5.

Q10, “Everything that we take from other countries needs adaptation: methods, mentality, political, economic, environmental, and human resources.”, I3.

Q11, “Enterprises have no financial opportunities to invest in digitalization.”, I3.

Q12, “Consulting companies ask for a big salary.”, I12.

Q13, “Not many people realize that digital transformation will pay off in the future.”, I11.

Q14, “There are no equipment and powerful computers. Therefore, these systems cannot work. It is also important to pull up the level of communication, the Internet. The Internet should be accessible throughout the KZ.”, I11.

Q15, “Another main problem is the disintegration of technological systems. Several technologies can complement each other. However, the lack of an integrating framework hinders the application of both technologies effectively and efficiently.”, I10.

Q16, “The government agencies and laws should keep pace with the development of technology. Technology often allows, but the legislation still prohibits it. Legislative changes must be liberal. When the law allows the development of Industry, the business responds quickly.”, I5.

Q17, “Government support of SMEs in terms lessening the taxation rate and providing financial leasing is a good thing. However, the important factor here would be to not put the obstacles for the development. Some initiatives are not as helpful as expected. The realities of actual business processes are a bit harsh because of corruption, bureaucracy, lack of competence.”, I1.

Q18, “…one of the most popular and demanded technologies are Big Data. For all Kazakhstan companies, Big Data analysis is becoming critical to optimize operations and improve processes.”, I13.

Q19, “The software programs develop very fast. There is a focus on cloud-based ERP platforms. So, you have your company on your smartphone.”, I2.

Q20, “There are no Kazakhstan specialists who can work on modern equipment. There are no technical schools in Kazakhstan to prepare people.”, I3.

Q21, “Our company uses the experience of a Russian telecommunications company since there are no such technologies in companies of Kazakhstan.”, I8.

Q22, “Yes, we take many courses, study literature, invent a lot of ourselves, read articles, talk with other experts, but we try to implement our ideas.”, I4.

Q23, “One of the problems in Kazakhstan is the problem of working with foreign companies. Some companies cannot work with foreign colleagues, since, in their opinion, foreign companies have too high demands. This problem exists mainly because companies in Kazakhstan do not have an established system of work processes.”, I7.

Q24, “We implemented several technologies, such as financial system, quality management, and CRP. These allowed the company to be more efficient and increased the net income.”, I7.

Q25, “Now the majority of citizens understand that the established project increases the safety on roads.”, I10.

Q26, “The main reason for the project failure was the lack of concrete results or the lack of funding for the project.”, I15.

Q27, “Digitalization is inevitable, somewhere faster, somewhere slower. Gradually, programs and hardware become cheaper, more affordable.”, I4.

Q28, “We have been operating for just four years, but we already emphasize big data. Today we do not have much data, but over decades our new wells will produce it. This data will be recorded every second or even more frequently.”, I13.

Q29, “All technologies will be used in symbiosis with each other. This symbiosis helps to correctly distribute tasks between employees and optimize processes.”, I14.

Q30, “We as individuals are constrained because we use a system that was good in previous revolution, previous stages of development. We cannot cope with changes and it’s creating a problem which means we need a system to bridge this gap exponentially.”, I2.

References

- Carvalho, N.; Chaim, O.; Cazarini, E.; Gerolamo, M. Manufacturing in the Fourth Industrial Revolution: A Positive Prospect in Sustainable Manufacturing. In Proceedings of the Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 21, pp. 671–678. [Google Scholar]

- Matt, D.T.; Rauch, E. SME 4.0: The Role of Small-and Medium-Sized Enterprises in the Digital Transformation. Ind. SMEs 2020, 1, 3–36. [Google Scholar]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Eburdy, R.; Tamayo, S.; Pellerin Polytechnique Montréal, R. Industry 4.0 and the SME: A Technology-Focused Review of the Empirical Literature. In Proceedings of the 7th International Conference on Industrial Engineering and Systems Management IESM, Saarbrücken, Germany, 11–13 October 2017. [Google Scholar]

- Horváth, D.; Szabó, R.Z. Driving Forces and Barriers of Industry 4.0: Do Multinational and Small and Medium-Sized Companies Have Equal Opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.-A.; Yang, S. Others Service Innovation and Smart Analytics for Industry 4.0 and Big Data Environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Nazarbayev, N. The President of Kazakhstan Nursultan Nazarbayev’s Address to the Nation of Kazakhstan. 2018. Available online: https://www.akorda.kz/en/addresses/addresses_of_president/the-president-of-kazakhstan-nursultan-nazarbayevs-address-to-the-nation-of-kazakhstan-january-31-2017 (accessed on 19 May 2021).

- Government of the Republic of Kazakhstan State Programme ‘Digital Kazakhstan’. Available online: https://digitalkz.kz/wp-content/uploads/2020/03/%D0%93%D0%9F%20%D0%A6%D0%9A%20%D0%BD%D0%B0%20%D0%B0%D0%BD%D0%B3%D0%BB%2003,06,2020.pdf (accessed on 19 May 2021).

- Daribay, A.; Serikova, A.; Ukaegbu, I.A. Industry 4.0: Kazakhstani Industrialization Needs a Global Perspective. Procedia Comput. Sci. 2019, 151, 903–908. [Google Scholar] [CrossRef]

- Madsen, D.Ø. The Emergence and Rise of Industry 4.0 Viewed through the Lens of Management Fashion Theory. Adm. Sci. 2019, 9, 71. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Schuir, J.; Teuteberg, F. The Emperor’s New Clothes or an Enduring IT Fashion? Analyzing the Lifecycle of Industry 4.0 through the Lens of Management Fashion Theory. Sustainability 2020, 12, 8828. [Google Scholar] [CrossRef]

- Dikhanbayeva, D.; Shaikholla, S.; Suleiman, Z.; Turkyilmaz, A. Assessment of Industry 4.0 Maturity Models by Design Principles. Sustainability 2020, 12, 9927. [Google Scholar] [CrossRef]

- Bongomin, O.; Yemane, A.; Kembabazi, B.; Malanda, C.; Chikonkolo Mwewa, M.; Mpofu, N.; Tigalana, D. Industry 4.0 Disruption and Its Neologisms in Major Industrial Sectors: A State of the Art. J. Eng. 2020, 2020, 1–45. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Muhuri, P.K.; Shukla, A.K.; Abraham, A. Industry 4.0: A Bibliometric Analysis and Detailed Overview. Eng. Appl. Artif. Intell. 2019, 78, 218–235. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring Industry 4.0 Technologies to Enable Circular Economy Practices in a Manufacturing Context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Yang, F.; Gu, S. Industry 4.0, a Revolution That Requires Technology and National Strategies. Complex Intell. Syst. 2021, 1–15. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.O.; Chan, F.T.S. The Link between Industry 4.0 and Lean Manufacturing: Mapping Current Research and Establishing a Research Agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The Impact of Industry 4.0 Implementation on Supply Chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Türkeș, M.C.; Oncioiu, I.; Aslam, H.D.; Marin-Pantelescu, A.; Topor, D.I.; Căpușneanu, S. Drivers and Barriers in Using Industry 4.0: A Perspective of SMEs in Romania. Processes 2019, 7, 153. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune Favors the Prepared: How SMEs Approach Business Model Innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Rezqianita, B.L.; Ardi, R. Drivers and Barriers of Industry 4.0 Adoption in Indonesian Manufacturing Industry. In Proceedings of the 3rd Asia Pacific Conference on Research in Industrial and Systems Engineering 2020, Depok, Indonesia, 16–17 June 2020; pp. 123–128. [Google Scholar]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Bahrin, M.A.K.; Othman, M.F.; Azli, N.H.N.; Talib, M.F. Industry 4.0: A Review on Industrial Automation and Robotic. Jurnal Teknologi 2016, 78, 6–13. [Google Scholar]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–a Glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Haddud, A.; DeSouza, A.; Khare, A.; Lee, H. Examining Potential Benefits and Challenges Associated with the Internet of Things Integration in Supply Chains. J. Manuf. Technol. Manag. 2017, 28, 1055–1085. [Google Scholar] [CrossRef]

- Gonzalez, A.G.C.; Alves, M.V.S.; Viana, G.S.; Carvalho, L.K.; Basilio, J.C. Supervisory Control-Based Navigation Architecture: A New Framework for Autonomous Robots in Industry 4.0 Environments. IEEE Trans. Ind. Inform. 2017, 14, 1732–1743. [Google Scholar] [CrossRef]

- Shehadeh, M.A.; Schroeder, S.; Richert, A.; Jeschke, S. Hybrid Teams of Industry 4.0: A Work Place Considering Robots as Key Players. In Proceedings of the 2017 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Banff, Alberta, 5–8 October 2017; pp. 1208–1213. [Google Scholar]

- Rodič, B. Industry 4.0 and the New Simulation Modelling Paradigm. Organizacija 2017, 50, 193–207. [Google Scholar] [CrossRef]

- Schluse, M.; Priggemeyer, M.; Atorf, L.; Rossmann, J. Experimentable Digital Twins—Streamlining Simulation-Based Systems Engineering for Industry 4.0. IEEE Trans. Ind. Inform. 2018, 14, 1722–1731. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A Survey on Technologies, Applications and Open Research Issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Rejeb, A.; Keogh, J.G.; Treiblmaier, H. Leveraging the Internet of Things and Blockchain Technology in Supply Chain Management. Future Internet 2019, 11, 161. [Google Scholar] [CrossRef]

- Corallo, A.; Lazoi, M.; Lezzi, M. Cybersecurity in the Context of Industry 4.0: A Structured Classification of Critical Assets and Business Impacts. Comput. Ind. 2020, 114, 103165. [Google Scholar] [CrossRef]

- Kavallieratos, G.; Katsikas, S.; Gkioulos, V. Cybersecurity and Safety Co-Engineering of Cyberphysical Systems—a Comprehensive Survey. Future Internet 2020, 12, 65. [Google Scholar] [CrossRef]

- Lezzi, M.; Lazoi, M.; Corallo, A. Cybersecurity for Industry 4.0 in the Current Literature: A Reference Framework. Comput. Ind. 2018, 103, 97–110. [Google Scholar] [CrossRef]

- Thames, L.; Schaefer, D. Software-Defined Cloud Manufacturing for Industry 4.0. Procedia CIRP 2016, 52, 12–17. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Masoni, R.; Ferrise, F.; Bordegoni, M.; Gattullo, M.; Uva, A.E.; Fiorentino, M.; Carrabba, E.; Di Donato, M. Supporting Remote Maintenance in Industry 4.0 through Augmented Reality. Procedia Manuf. 2017, 11, 1296–1302. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented Reality in Support of Industry 4.0—Implementation Challenges and Success Factors. Robot. Comput. Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Analysis of the Driving and Dependence Power of Barriers to Adopt Industry 4.0 in Indian Manufacturing Industry. Comput. Ind. 2018, 101, 107–119. [Google Scholar] [CrossRef]

- Agostini, L.; Filippini, R. Organizational and Managerial Challenges in the Path toward Industry 4.0. Eur. J. Innov. Manag. 2019, 22, 406–421. [Google Scholar] [CrossRef]

- Kiesel, M.; Wolpers, M. Educational Challenges for Employees in Project-Based Industry 4.0 Scenarios. In Proceedings of the 15th International Conference on Knowledge Technologies and Data-driven Business, Graz, Austria, 21–23 October 2015; pp. 1–4. [Google Scholar]

- Stentoft, J.; Adsbøll Wickstrøm, K.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control 2020, 1–18. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; de Sousa Jabbour, A.B.L.; Rajak, S. Barriers to the Adoption of Industry 4.0 Technologies in the Manufacturing Sector: An Inter-Country Comparative Perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Orzes, G.; Rauch, E.; Bednar, S.; Poklemba, R. Industry 4.0 Implementation Barriers in Small and Medium Sized Enterprises: A Focus Group Study. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 1348–1352. [Google Scholar]

- Müller, J.M. Assessing the Barriers to Industry 4.0 Implementation from a Workers’ Perspective. IFAC Pap. 2019, 52, 2189–2194. [Google Scholar] [CrossRef]

- Schneider, P. Managerial Challenges of Industry 4.0: An Empirically Backed Research Agenda for a Nascent Field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Masanov, Y. Industry 4.0 in Kazakhstan: State Plans or Reality? Available online: https://informburo.kz/stati/industriya-40-v-kazahstane-gosudarstvennye-plany-ili-realnost.html (accessed on 8 April 2021).

- Abdikarimova, K. About Digitalization of the Industry of Kazakhtan. Sci. Bull. Finance Banks Invest. 2018, 1, 167–174. [Google Scholar]

- Vorobiev, A.E.; Tcharo, H. Digitalization of the Oil Industry of Kazakhstan. Probl. Nat. Resour. Manag. 2018, 1, 66–75. [Google Scholar]

- Baimukhamedov, M.; Baimukhamedova, G.; Aymurzinov, M. Technological Modernization of the Economy of the Country Based on the Implementation of State Program “Digital Kazakhstan”. Agrar. Bull. Urals 2019, 2, 42–45. [Google Scholar] [CrossRef][Green Version]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Nazarbayev, N. Strategy Kazakhstan 2050. Available online: https://kazakhstan2050.com/ (accessed on 27 April 2021).

- Shafique, M.; Luo, X. Nanotechnology in Transportation Vehicles: An Overview of Its Applications, Environmental, Health and Safety Concerns. Materials 2019, 12, 2493. [Google Scholar] [CrossRef]

- Hopf, C. Qualitative Interviews: An Overview. In A Companion to Qualitative Research; SAGE Publications: London, UK, 2004; Volume 203. [Google Scholar]

- Castillo-Montoya, M. Preparing for Interview Research: The Interview Protocol Refinement Framework. Qual. Rep. 2016, 21, 811–831. [Google Scholar]

- Karahasanović, A.; Hinkel, U.N.; Sj⊘berg, D.I.K.; Thomas, R. Comparing of Feedback-Collection and Think-Aloud Methods in Program Comprehension Studies. Behav. Inf. Technol. 2009, 28, 139–164. [Google Scholar] [CrossRef]

- The Parliament of the Republic of Kazakhstan Entrepreneurial Code of The Republic of Kazakhstan. Available online: https://adilet.zan.kz/eng/docs/K1500000375 (accessed on 19 May 2021).

- Schmidt, C. The Analysis of Semi-Structured Interviews. Companion Qual. Res. 2004, 253–258. [Google Scholar]

- Golchevskiy, Y.; Yermolenko, A. Knowledge Base as an Integral Attribute of a Modern Company. In Proceedings of the International Conference on Economics, Management and Technologies 2020 (ICEMT 2020), Yalta, Russia, 19–21 May 2020; Atlantis Press: Paris, France, 2020; pp. 548–552. [Google Scholar]

- Mayring, P. Qualitative Content Analysis: Theoretical Foundation, Basic Procedures and Software Solution. Forum Qual. Soc. Res. 2013, 4, 143. [Google Scholar]

- Böhm, A. 5.13 Theoretical Coding: Text Analysis in Grounded Theory. Companion Qual. Res. 2004, 270, 270–275. [Google Scholar]

- “Akorda” Presidential Residence The Head of State Held a Meeting on the Implementation of the “Digital Kazakhstan” State Program. Available online: https://www.akorda.kz/en/events/akorda_news/meetings_and_sittings/the-head-of-state-held-a-meeting-on-the-implementation-of-the-digital-kazakhstan-state-program (accessed on 27 April 2021).

- Brougham, D.; Haar, J. Smart Technology, Artificial Intelligence, Robotics, and Algorithms (STARA): Employees’ Perceptions of Our Future Workplace. J. Manag. Organ. 2018, 24, 239–257. [Google Scholar] [CrossRef]

- Oztekin, A.; Delen, D.; Zaim, H.; Turkyilmaz, A.; Zaim, S. The Influence of Knowledge Management on Financial and Non-Financial Performance. J. Inf. Knowl. Manag. 2015, 14, 1550013. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Dikhanbayeva, D.; Suleiman, Z.; Shaikholla, S.; Shehab, E. Industry 4.0: Challenges and Opportunities for Kazakhstan SMEs. Procedia CIRP 2021, 96, 213–218. [Google Scholar] [CrossRef]

- Čater, T.; Pučko, D. Factors of Effective Strategy Implementation: Empirical Evidence from Slovenian Business Practice. J. East Eur. Manag. Stud. 2010, 15, 207–236. [Google Scholar] [CrossRef]

- Argyngazinov, A. Post-Crisis Business Development in the Republic of Kazakhstan. Economic Systems 2020, 13, 162–167. [Google Scholar] [CrossRef]

- Smagulova, S. Management and Implementation of ICT in Kazakhstan. In Proceedings of the Management 4.0: Governance in the Digital Age, Perm Krai, Russia, 27 November 2019; pp. 82–90. [Google Scholar]

- Kazakhstan Center of Industry and Export “QazIndusry” JSC Recommendations for Solving Problems with the Use of Digital Projects (Solutions) and Improving Work Efficiency. Available online: https://qazindustry.gov.kz/docs/otchety/1597139710.pdf (accessed on 6 April 2021).

- Fonseca, L.M. Industry 4.0 and the Digital Society: Concepts, Dimensions and Envisioned Benefits. In Proceedings of the International Conference on Business Excellence, Bucharest, Romania, 22–23 March 2018; Volume 12, pp. 386–397. [Google Scholar]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards Future Industrial Opportunities and Challenges. In Proceedings of the 2015 12th International conference on fuzzy systems and knowledge discovery (FSKD), Zhangjiajie, China, 15–17 August 2015; pp. 2147–2152. [Google Scholar]

- Beier, G.; Niehoff, S.; Ziems, T.; Xue, B. Sustainability Aspects of a Digitalized Industry–A Comparative Study from China and Germany. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 227–234. [Google Scholar] [CrossRef]

- Saatçioğlu, Ö.Y.; Özispa, N.; Kök, G.T. Scrutinizing the Barriers That Impede Industry 4.0 Projects: A Country-Wide Analysis for Turkey. In Agile Approaches for Successfully Managing and Executing Projects in the Fourth Industrial Revolution; IGI Global: Hershey, PA, USA, 2019; pp. 294–314. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).