Evaluating the Degree of Uncertainty of Research Activities in Industry 4.0

Abstract

1. Introduction

- Uncertainty measure: a series of possible states in which results or probabilities are assigned to each possible state or result—this also includes the application of a probability density function to continuous variables.

- Risk: A state of uncertainty in which some possible results have an unwanted effect or a significant loss.

- Risk measurement: a series of measured uncertainties in which some results are possible losses, and the extent of such losses—also including the formulates of loss on continuous variables.

- “novelty”, since the activity must produce new results;

- “originality”, since each activity must be aimed at developing new concepts and ideas;

- “uncertainty of the results”, as at an early stage, it is not possible to define precisely the type of result and the costs in relation to the objectives to be achieved;

- “orderliness”, since the activity must be conducted in a planned and accountable manner, and both the process and the results must be retained;

- “reproducibility”, since the results of the activity must ensure the transferability of knowledge and the reproducibility of the results within other R&D activities.

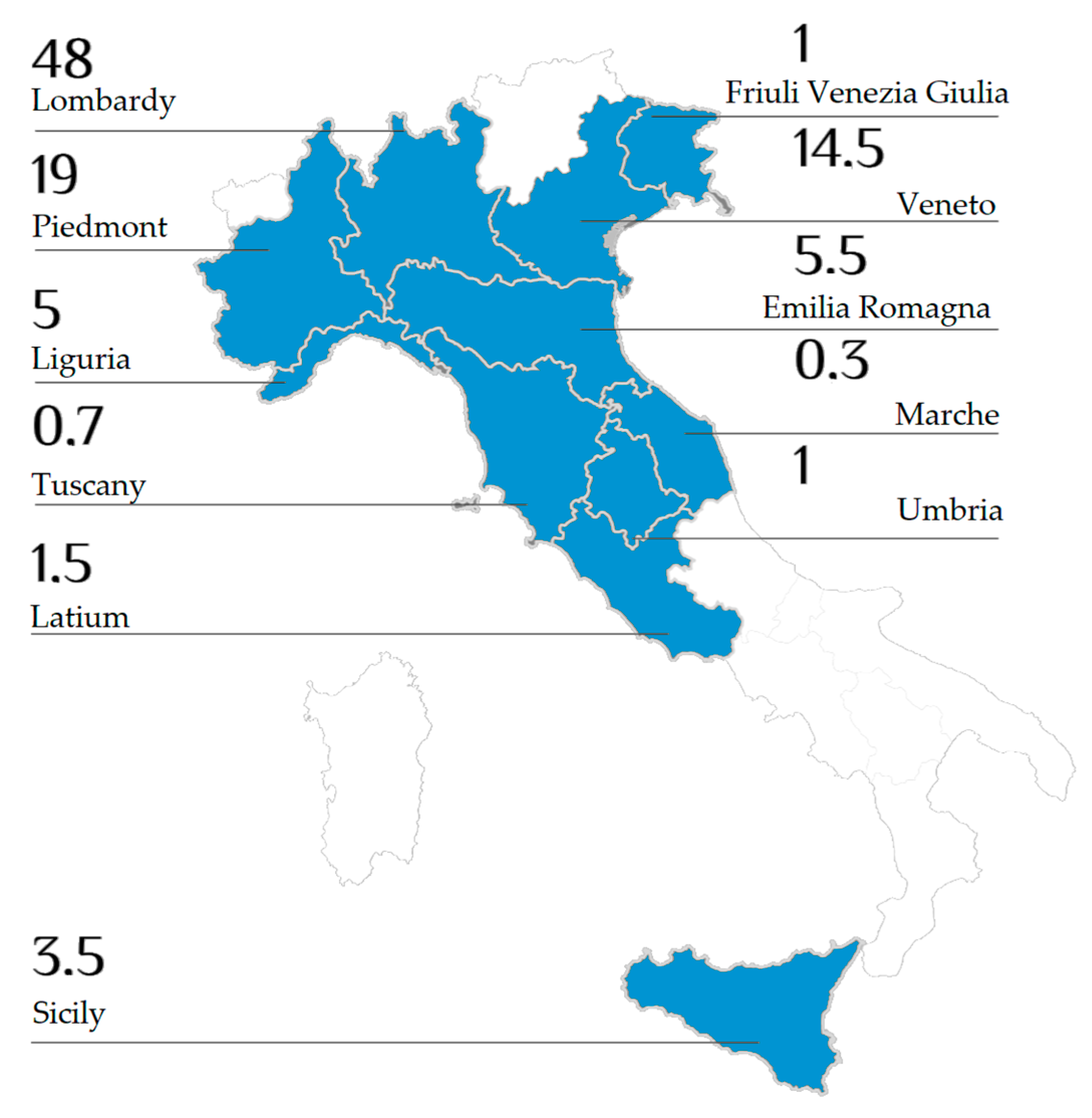

2. Industry 4.0 in Italy

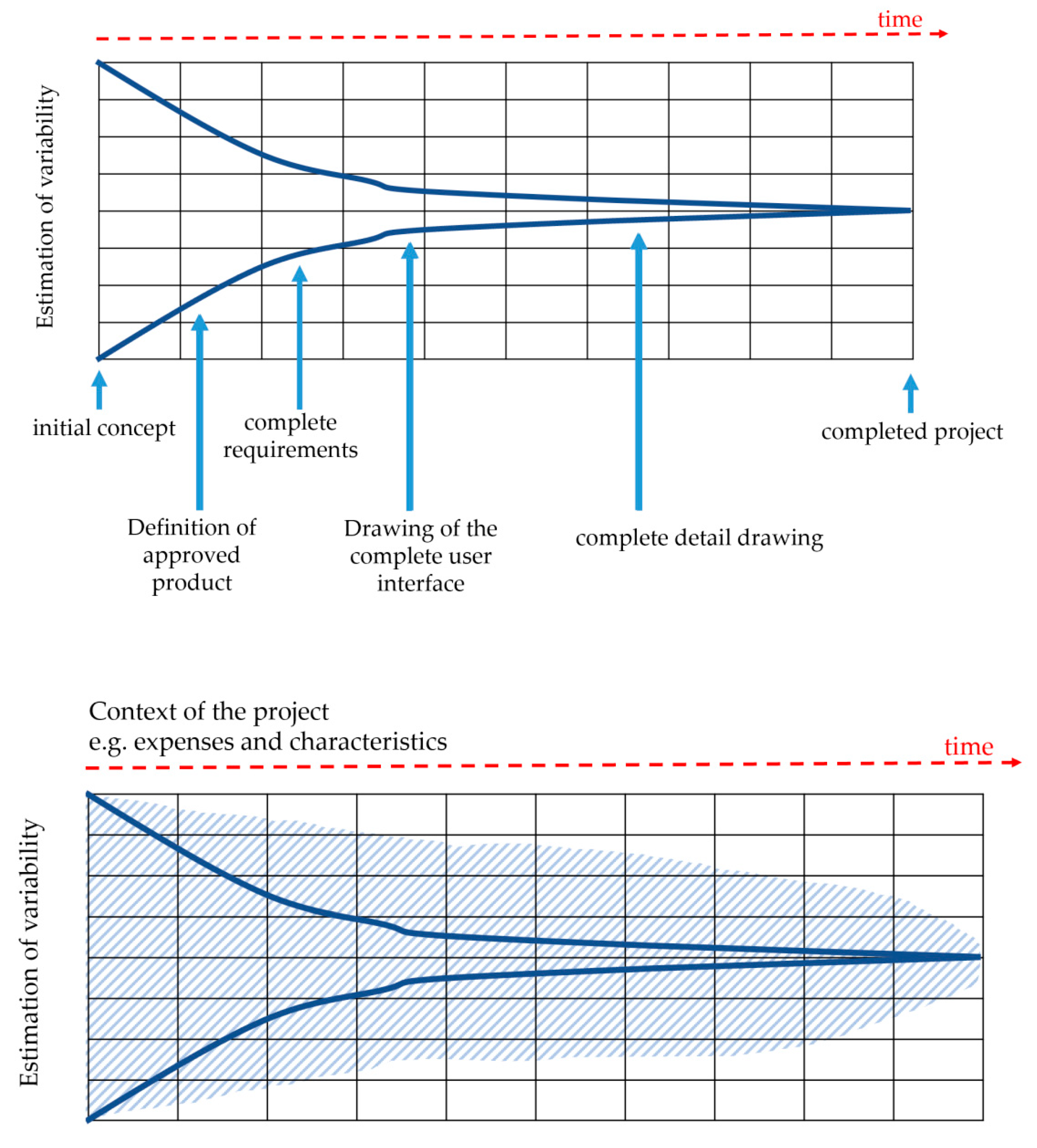

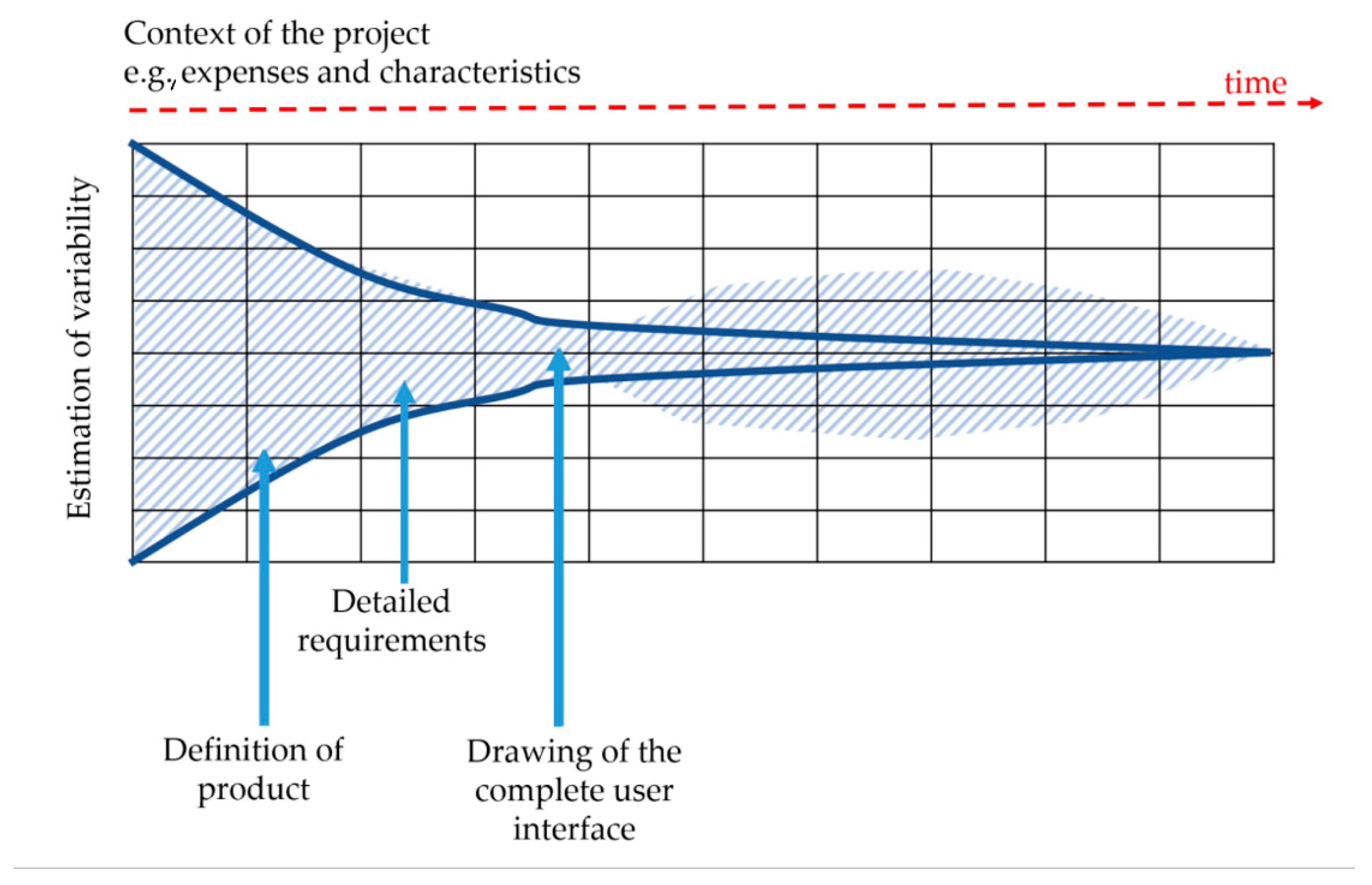

3. Degree of Uncertainty in Industry 4.0

4. Methodology

- Direct survey with the entrepreneur and the internal research team (always being projects of a corporate nature and industrial development);

- A technical analysis of the documentation supporting the project idea.

5. Results

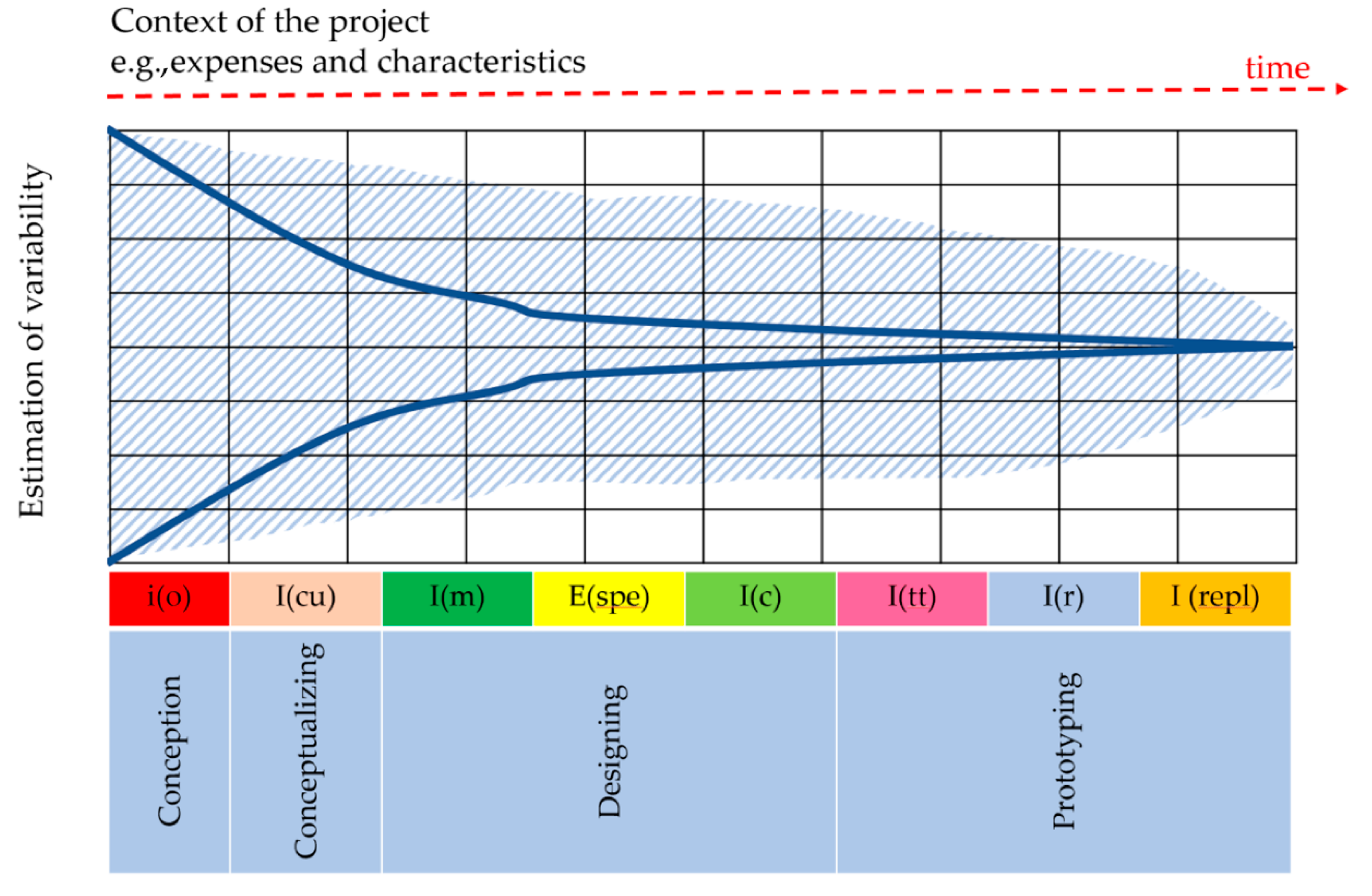

- f(o) = uncertainty related to the objectives;

- f(cu) = uncertainty related to the human and relational components of the firm;

- f (m) = methodological uncertainty;

- f (e spe) = uncertainty related to experimental errors;

- f (c) = cost uncertainty;

- f(tt) = uncertainty related to technology transfer;

- f (r) = uncertainty of result;

- f (replication) = uncertainty in replicability.

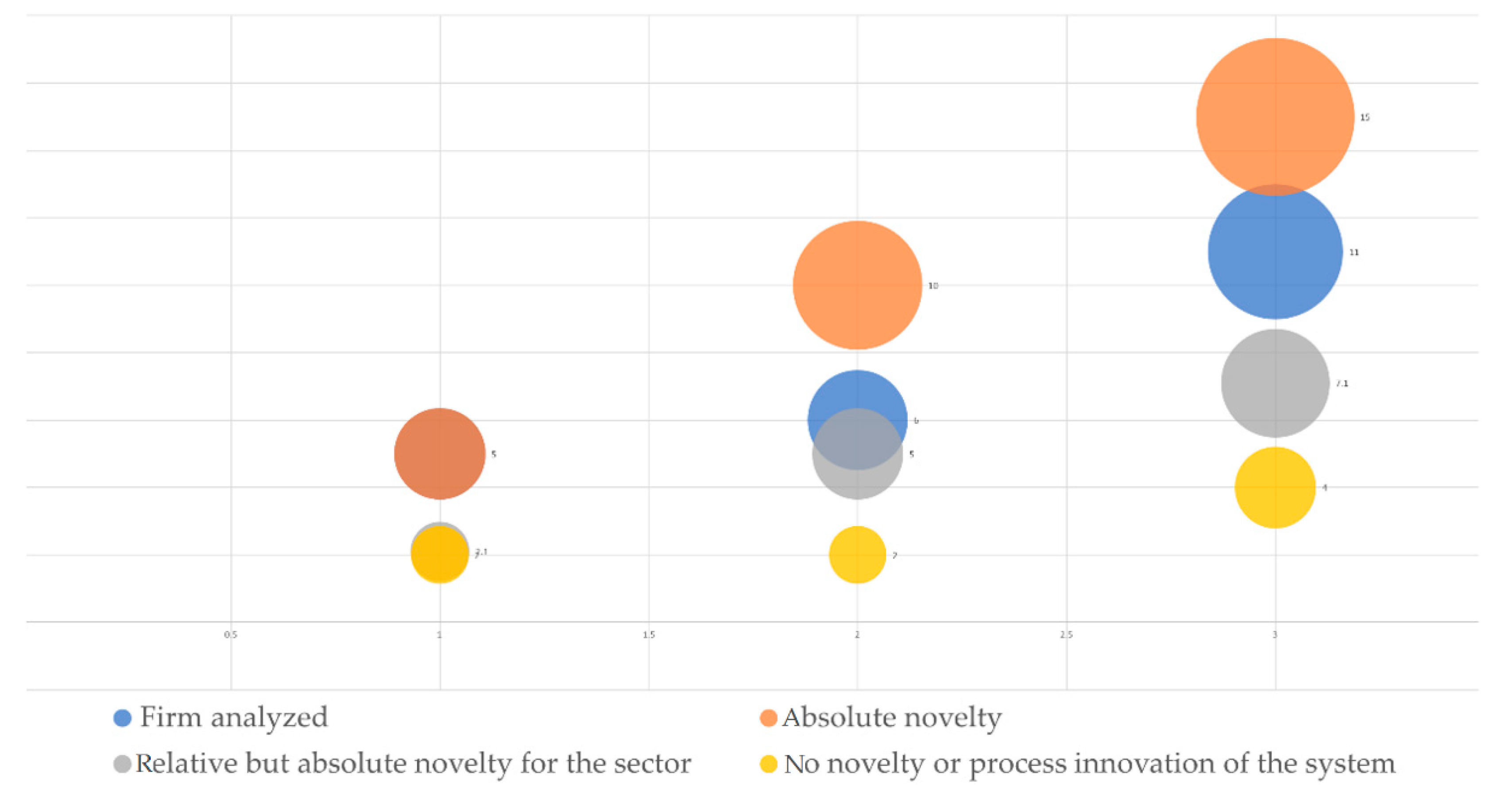

5.1. Method of Analysis of the Degree of Novelty of the Project

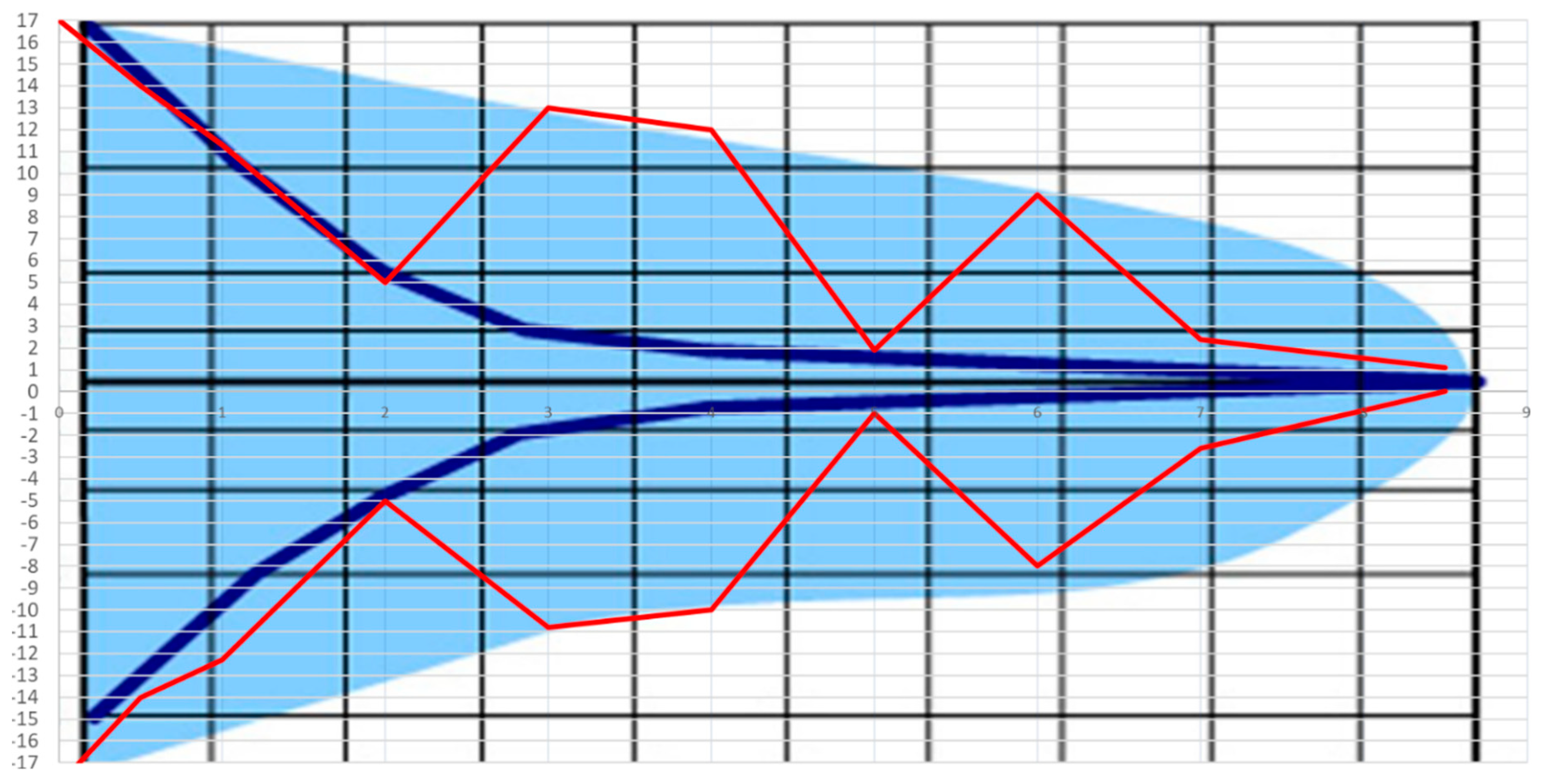

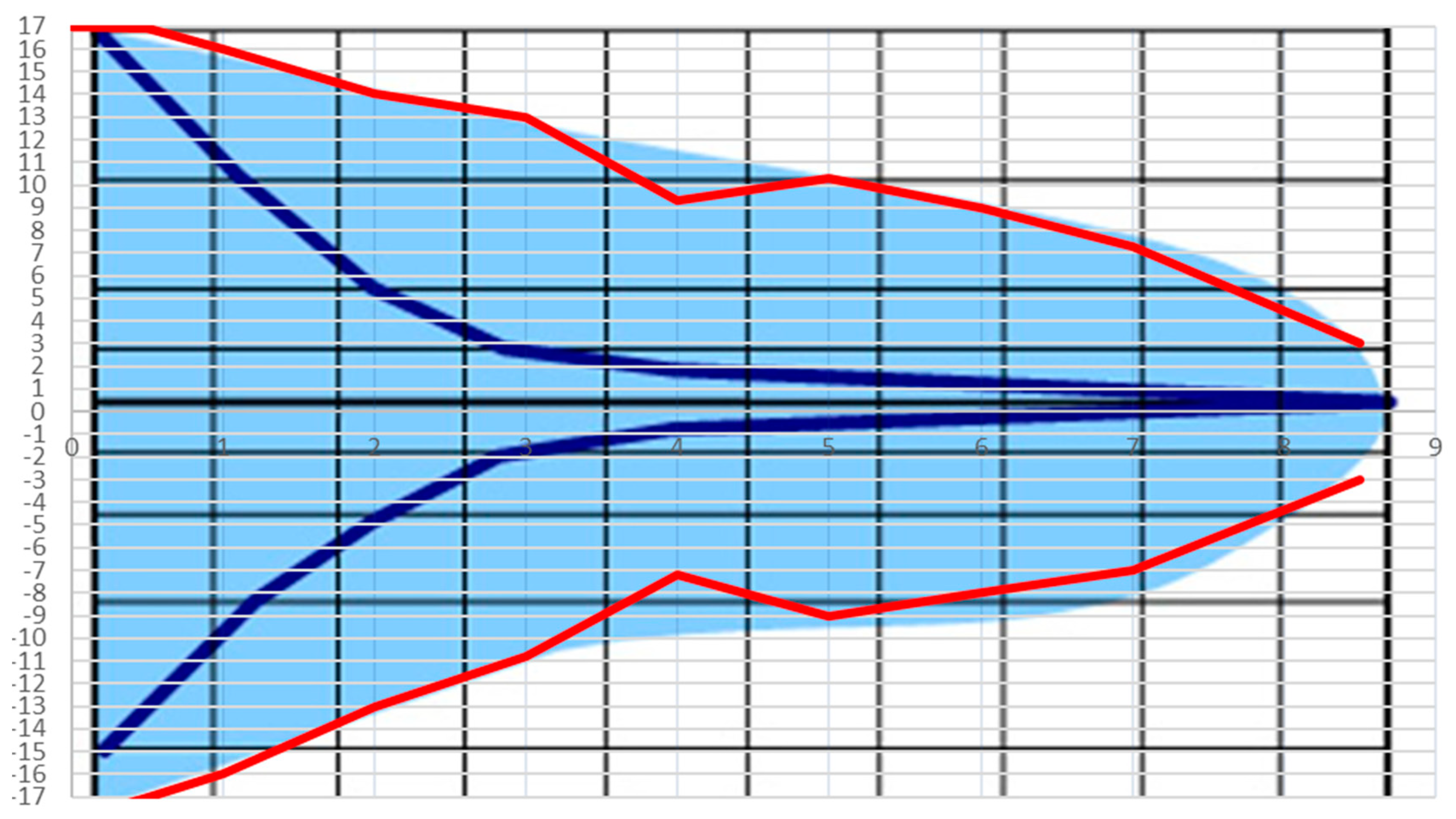

5.2. Measuring the Degree of Uncertainty

- P > 1: Project unrelated to the production model and only known from research reports;

- ES: A firm that produces hydraulic elements that wants to study new filtering technologies, with the help of experiments that do not relate in any way to the world of production or the existing market;

- P < 1: Project directly or indirectly linked to aspects of production;

- ES: A firm that works on orders, a firm that has already the studied technology in production, a firm that already sells the studied or developed technology;

- (C): Factor C determines the scientific consistency with the context; the firm must produce research on elements not already present within the range of know-outs and skills of the sector, territory or firm

- C > 1: Consistent with the scientific and innovation context;

- ES: The technology or process does not present in territorial, corporate or international competences;

- C < 1: Inconsistent;

- ES: New, mature or already widespread technology or process.

5.3. Classification of the Research

5.3.1. D: Definition of the Search

- Process (Proc)

- Product (Prod)

- Method (Met)

- Knowledge (With)

- Model (Mod)

- Business (Bus)

- Technician (tec)

- Organizational (Management)

5.3.2. Novelty

5.3.3. Creative

- Absolute creativity (completely innovative element);

- Relative creativity (new and creative elements for a given scenario or application);

- Comparison creativity (analysis and comparison with respect to comparison, validation or comparison).

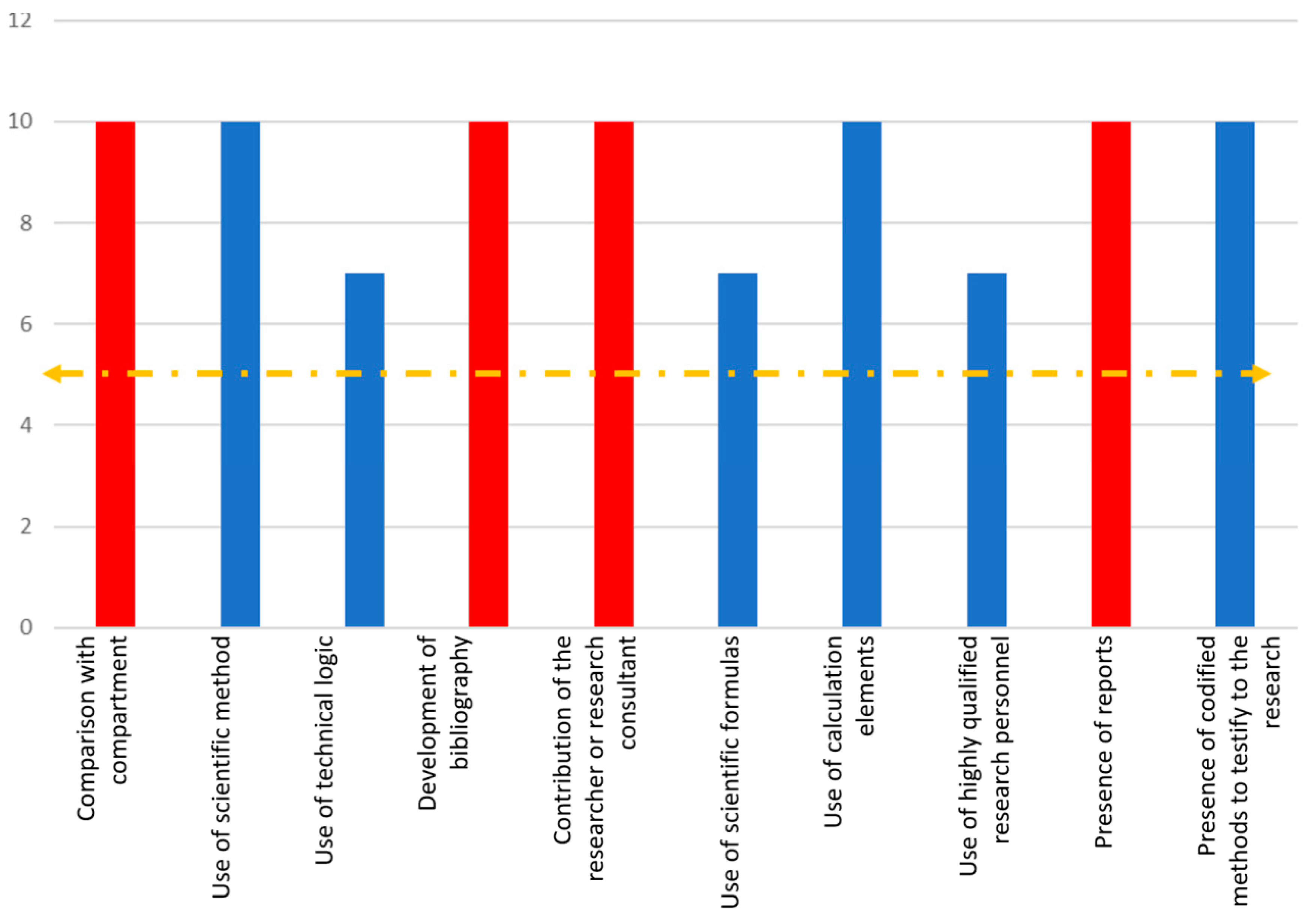

5.3.4. Uncertainty Factor

- (Ir) Uncertainty of the result (not being a mature or normally validated process, the research carried out did not always have a positive result, because it develops, codifies, and carries out new activities and actions both at the firm level and in terms of territory or scenario, and for some research also at the international or global level);

- (ic) Uncertainty of costs. In this case, being unable to delineate the certainty of a result, it was not always possible to respect the budget assigned to the single activity of research.

- (im) Uncertainty of methodology. In this case, the experimental process saw the application of either new methodologies or methods applied in contexts never before studied and tested.

5.3.5. Systematicity

5.3.6. Replicability

- Intra-firm closed (strategic project for the firm that is shared and disclosed only at certain levels);

- Intra-firm open (project disclosed to firm personnel from all sectors);

- Extra-firm market (project disclosed to other firms or customers);

- Extra-firm tc (project disseminated on channels of a technical or sectoral nature);

- Info science (project disseminated at the level of non-reported scientific journals);

- Info top science (project published in whole or in part in peer-reviewed scientific journals).

5.4. Classification of the Research as a Function of the Methods Carried Out and of the Reading of the Results

- F: sic (occupational safety aspects);

- F: gest (event management aspects);

- F: dida (didactic aspects);

- F: sani (aspects of sanitation, hygiene, and management of the drink),

- F: aspects of the pry (elements of privacy);

- DLI: employer/entrepreneur;

- Op: operator;

- UV: visitor user;

- Ter: another firm or another user;

- Didr: teaching operator.

5.5. Systematic Nature of the Research Project

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bollinger, L.; Hope, K.; Utterback, J.M. A review of literature and hypotheses on new technology-based firms. Res. Policy 1983, 12, 1–14. [Google Scholar] [CrossRef]

- Brown, S.L.; Eisenhardt, K.M. Product development: Past research, present findings, and future directions. Acad. Manag. Rev. 1995, 20, 343–378. [Google Scholar] [CrossRef]

- Calantone, R.J.; Cavusgil, S.T.; Zhao, Y. Learning orientation, firm innovation capability, and firm performance. Ind. Mark. Manag. 2002, 31, 515–524. [Google Scholar] [CrossRef]

- Granstrand, O. Towards a theory of the technology-based firm. Res. Policy 1998, 27, 465–489. [Google Scholar] [CrossRef]

- Homburg, C.; Alavi, S.; Rajab, T.; Wieseke, J. The contingent roles of R&D-sales versus R&D-marketing cooperation in new-product development of business-to-business firms. Int. J. Res. Mark. 2017, 34, 212–230. [Google Scholar]

- Salunke, S.; Weerawardena, J.; McColl-Kennedy, J.R. The central role of knowledge integration capability in service innovation-based competitive strategy. Ind. Mark. Manag. 2019, 76, 144–156. [Google Scholar] [CrossRef]

- Sirilli, G. Ricerca e Sviluppo. Il Futuro del Nostro Paese: Numeri, Sfide, Politiche; Il Mulino: Bologna, Italy, 2005. [Google Scholar]

- Wales, W.J. Entrepreneurial orientation: A review and synthesis of promising research directions. Int. Small Bus. J. 2016, 34, 3–15. [Google Scholar] [CrossRef]

- Klomp, L. Measuring output from R&D activities and innovation statistics. In Proceedings of the ISI 53 Conference, Seoul, Korea, 22–29 August 2001. [Google Scholar]

- Lynn, G.S.; Akgün, A.E. Innovation strategies under uncertainty: A contingency approach for new product development. Eng. Manag. J. 1998, 10, 11–18. [Google Scholar] [CrossRef]

- Thanos, C. Research data reusability: Conceptual foundations, barriers and enabling technologies. Publications 2017, 5, 2. [Google Scholar] [CrossRef]

- Kline, S.J.; Rosenberg, N. Studies on Science and The Innovation Process: Selected Works of Nathan Rosenberg; World Scientific Publishing Co Pte Ltd.: Washington, DC, USA, 2010; An overview of innovation; pp. 173–203. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Uusitalo, L.; Lehikoinen, A.; Helle, I.; Myrberg, K. An overview of methods to evaluate uncertainty of deterministic models in decision support. Environ. Model. Softw. 2015, 63, 24–31. [Google Scholar] [CrossRef]

- White, G.H. Basics of estimating measurement uncertainty. Clin. Biochem. Rev. 2008, 29, S53. [Google Scholar] [PubMed]

- Caloffi, A.; Bellandi, M. Enterprise and innovation policy in Italy: An overview of the recent facts. Rev. d’écon. Ind. 2017, 2, 129–141. [Google Scholar]

- Muscio, A.; Ciffolilli, A. What drives the capacity to integrate Industry 4.0 technologies? Evidence from European R&D projects. Econ. Innov. New Technol. 2019, 1–15. [Google Scholar] [CrossRef]

- Pervaiz, K.; Zairi, M. Benchmarking for brand innovation. Eur. J. Innov. Manag. 1999, 2, 36–48. [Google Scholar]

- Read, A. Determinants of successful organizational innovation: A review of current research. J. Manag. Prac. 2000, 3, 95–119. [Google Scholar]

- Baker, S.R.; Bloom, N.; Davis, S.J. Measuring economic policy uncertainty. Q. J. Econ. 2016, 131, 1593–1636. [Google Scholar] [CrossRef]

- Kerssens-van Drongelen, I.; Nixon, B.; Pearson, A. Performance measurement in industrial R&D. Int. J. Manag. Rev. 2000, 2, 111–143. [Google Scholar]

- Mohanty, R.P.; Agarwal, R.; Choudhury, A.K.; Tiwari, M.K. A fuzzy ANP-based approach to R&D project selection: A case study. Int. J. Prod. Res. 2005, 43, 5199–5216. [Google Scholar]

- Pich, M.T.; Loch, C.H.; Meyer, A.D. On uncertainty, ambiguity, and complexity in project management. Manag. Sci. 2002, 48, 1008–1023. [Google Scholar] [CrossRef]

- Skeffington, R.A. Quantifying uncertainty in critical loads:(A) literature review. Water Air Soil Pollut. 2006, 169, 3–24. [Google Scholar] [CrossRef]

- Gao, J.; Gao, X. A new stock model for credibilistic option pricing. J. Uncertain Syst. 2008, 2, 243–247. [Google Scholar]

- Li, X.; Liu, B. Hybrid logic and uncertain logic. J. Uncertain Syst. 2009, 3, 83–94. [Google Scholar]

- Li, X.; Liu, B. Maximum entropy principle for fuzzy variables. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2007, 15, 43–52. [Google Scholar] [CrossRef]

- Liu, B. Fuzzy process, hybrid process and uncertain process. J. Uncertain Syst. 2008, 2, 3–16. [Google Scholar]

- Peng, J. A general stock model for fuzzy markets. J. Uncertain Syst. 2008, 2, 248–254. [Google Scholar]

- Refsgaard, J.C.; Van der Sluijs, J.P.; Højberg, A.L.; Vanrolleghem, P.A. Uncertainty in the environmental modelling process-a framework and guidance. Environ. Model. Softw. 2007, 22, 1543–1556. [Google Scholar] [CrossRef]

- Colyvan, M. Is probability the only coherent approach to uncertainty? Risk Anal. Int. J. 2008, 28, 645–652. [Google Scholar] [CrossRef]

- Nilsen, T.; Aven, T. Models and model uncertainty in the context of risk analysis. Reliab. Eng. Syst. Saf. 2003, 79, 309–317. [Google Scholar] [CrossRef]

- Walker, W.E.; Harremoës, P.; Rotmans, J.; Van Der Sluijs, J.P.; Van Asselt, M.B.; Janssen, P.; Krayer von Krauss, M.P. Defining uncertainty: A conceptual basis for uncertainty management in model-based decision support. Integr. Assess. 2003, 4, 5–17. [Google Scholar] [CrossRef]

- OCSE Frascati Manual 2015. Guidelines for Collecting and Reporting Data on Research and Experimental Development, The Measurement of Scientific, Technological and Innovation Activities; OECD Publishing: Paris, France, 2015. [Google Scholar] [CrossRef]

- Robbins, C. Linking Frascati-based R&D spending to the System of National Accounts: An application to US data. In Proceedings of the Group on Measurement of Non-Financial Assets, Canberra, Australia, 29 March–1 April 2005. [Google Scholar]

- Esposti, R.; Pierani, P. Building the knowledge stock: Lags, depreciation, and uncertainty in R&D investment and link with productivity growth. J. Product. Anal. 2003, 19, 33–58. [Google Scholar]

- Dari-Mattiacci, G.; Deffains, B. Uncertainty of law and the legal process. JITE 2007, 163, 627–656. [Google Scholar] [CrossRef]

- Klinke, A.; Renn, O. Systemic risks as challenge for policy making in risk governance. Forum Qual. Soz. Forum Qual. Soc. Res. 2006, 7. [Google Scholar]

- Nishizawa, M.; Renn, O. Responding public demand for assurance of genetically modified crops: Case from Japan. J. Risk Res. 2006, 9, 41–56. [Google Scholar] [CrossRef]

- Weiss, C. Communicating uncertainty in intelligence and other professions. Int. J. Intell. Count. Intell. 2008, 21, 57–85. [Google Scholar] [CrossRef]

- Wolpert, D.M.; Ghahramani, Z. Computational principles of movement neuroscience. Nat. Neurosci. 2000, 3, 1212. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A scenario-based approach to learning for the future of production. Procedia CiRp 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Rossini, M.; Costa, F.; Tortorella, G.L.; Portioli-Staudacher, A. The interrelation between Industry 4.0 and lean production: An empirical study on European manufacturers. Int. J. Adv. Manuf. Technol. 2019, 102, 3963–3976. [Google Scholar] [CrossRef]

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. agriculture in a future development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Zambon, I.; Egidi, G.; Rinaldi, F.; Cividino, S. Applied Research Towards Industry 4.0: Opportunities for SMEs. Processes 2019. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly system design in the Industry 4.0 era: A general framework. IFAC-Pap. OnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Ciffolilli, A.; Muscio, A. Industry 4.0: National and regional comparative advantages in key enabling technologies. Eur. Plan. Stud. 2018, 26, 2323–2343. [Google Scholar] [CrossRef]

- Galati, F.; Bigliardi, B. Industry 4.0: Emerging themes and future research avenues using a text mining approach. Comput. Ind. 2019, 109, 100–113. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in management studies: A systematic literature review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Lezzi, M.; Lazoi, M.; Corallo, A. Cybersecurity for Industry 4.0 in the current literature: A reference framework. Comput. Ind. 2018, 103, 97–110. [Google Scholar] [CrossRef]

- Lucchese, M.; Nascia, L.; Pianta, M. Industrial policy and technology in Italy. Econ. Politica Ind. 2016, 43, 233–260. [Google Scholar] [CrossRef]

- Magruk, A. Uncertainty in the sphere of the industry 4.0-potential areas to research. Bus. Manag. Educ. 2016, 14, 275–291. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia CIRP 2014, 16, 3–8. [Google Scholar] [CrossRef]

- Ślązak, Ł. Integracjaobrabiarek z systemamiinformatycznymiprzedsiębiorstw w aspekciekon- cepcjiprzemysł 4.0. Mechanik 2015, 3, 246–252. [Google Scholar]

- Jędralska, K.; Czech, A. O naturzeniepewności i jejinterpretacjach. Master Bus. Adm. 2011, 3, 9–18. [Google Scholar]

- Mosterman, P.J.; Zander, J. Industry 4.0 as a cyber-physical system study. Softw. Syst. Modeling 2016, 15, 17–29. [Google Scholar]

- Schumacher, A.; Erol, S.; Sihn, W. A maturity model for assessing Industry 4.0 readiness and maturity of manufacturing enterprises. Procedia Cirp 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Pan, M.; Sikorski, J.; Kastner, C.A.; Akroyd, J.; Mosbach, S.; Lau, R.; Kraft, M. Applying industry 4.0 to the Jurong Island eco-industrial park. Energy Procedia 2015, 75, 1536–1541. [Google Scholar] [CrossRef]

- Sittón, I.; Rodríguez, S. Pattern extraction for the design of predictive models in industry 4.0. In Trends in Cyber-Physical Multi-Agent Systems. The PAAMS Collection-15th International Conference, PAAMS 2017. Advances in Intelligent Systems and Computing. Volume 619; Springer International Publishing: Cham, Switzerland, 2017; pp. 258–261. [Google Scholar]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Wittenberg, C. Human-CPS Interaction-requirements and human-machine interaction methods for the Industry 4.0. IFAC-PapersOnLine 2016, 49, 420–425. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Penas, O.; Plateaux, R.; Patalano, S.; Hammadi, M. Multi-scale approach from mechatronic to Cyber-Physical Systems for the design of manufacturing systems. Comput. Ind. 2017, 86, 52–69. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.; Fraga-Lamas, P.; Suárez-Albela, M.; Vilar-Montesinos, M. A fog computing and cloudlet based augmented reality system for the industry 4.0 shipyard. Sensors 2018, 18, 1798. [Google Scholar] [CrossRef] [PubMed]

- Wawiernia, A. Taksonomianiepewności. Zarządzanie Finans. 2013, 11, 445–454. [Google Scholar]

- Alleman, G.; Coonce, T.; Price, R. Increasing the Probability of Program Success with Continuous Risk Management. Meas. News 2018, 27. [Google Scholar]

- Bartodziej, C.J. The Concept Industry 4.0; Springer Gabler: Wiesbaden, Germany, 2017; pp. 27–50. [Google Scholar]

- Balta-Ozkan, N.; Boteler, B.; Amerighi, O. European smart home market development: Public views on technical and economic aspects across the United Kingdom, Germany and Italy. Energy Res. Soc. Sci. 2014, 3, 65–77. [Google Scholar] [CrossRef]

- Enkel, E.; Gassmann, O.; Chesbrough, H. Open R&D and open innovation: Exploring the phenomenon. R&D Manag. 2009, 39, 311–316. [Google Scholar]

- Talbot, S.; Lefebvre, E.; Lefebvre, L.A. Closed-loop supply chain activities and derived benefits in manufacturing SMEs. J. Manuf. Technol. Manag. 2007, 18, 627–658. [Google Scholar] [CrossRef]

- Schneider, J. Making space for the “nuances of truth”: Communication and uncertainty at an environmental journalist’ workshop. Sci. Commun. 2010, 32, 171–201. [Google Scholar] [CrossRef]

- Janasz, K. Ryzykoiniepewność w gospodarce–wybraneaspektyteoretyczne. Studia Prace Wydziału Nauk Ekonomicznych Zarządzania 2009, 14, 87–98. [Google Scholar]

- Kopp, R. Przemysł 4.0 ijegowpływnaprzemysłkuźniczy. Obróbka Plastyczna Metali. 2014, 25, 75–85. [Google Scholar]

- Stein, V.; Wiedemann, A. Risk governance: Conceptualization, tasks, and research agenda. J. Bus. Econ. 2016, 86, 813–836. [Google Scholar] [CrossRef]

- Szulewski, P. Concepts of industrial automation products for Industry 4.0. Mech. 2016, 7, 574–578. [Google Scholar] [CrossRef]

- Boubaker, K.; Colantoni, A.; Allegrini, E.; Longo, L.; Di Giacinto, S.; Monarca, D.; Cecchini, M. A model for musculoskeletal disorder-related fatigue in upper limb manipulation during industrial vegetables sorting. Int. J. Ind. Ergon. 2014, 44, 601–605. [Google Scholar] [CrossRef]

- Rajabi Hamedani, S.; Villarini, M.; Colantoni, A.; Moretti, M.; Bocci, E. Life Cycle Performance of Hydrogen Production via Agro-Industrial Residue Gasification—A Small Scale Power Plant Study. Energies 2018, 11, 675. [Google Scholar] [CrossRef]

- Lempert, R.; Zmud, J. Recrafting scenario practice to achieve robust long-term decisions. In Delivering Tomorrow, Logistics 2050. A Scenario Study; Deutsche Post AG: Bonn, Germany, 2012; pp. 166–172. [Google Scholar]

- Dewett, T. Linking intrinsic motivation, risk taking, and employee creativity in an R&D environment. R&D Manag. 2007, 37, 197–208. [Google Scholar]

- Kachelmeier, S.J.; Reichert, B.E.; Williamson, M.G. Measuring and motivating quantity, creativity, or both. J. Account. Res. 2008, 46, 341–373. [Google Scholar] [CrossRef]

- Kaufmann, G. What to measure? A new look at the concept of creativity. Scand. J. Educ. Res. 2003, 47, 235–251. [Google Scholar] [CrossRef]

- Zambon, I.; Piergentili, A.; Salvati, L.; Monarca, D.; Matyjas-Łysakowska, P.; Colantoni, A. Applied Research for a Safer Future: Exploring Recent Job Accidents in Agriculture, Italy (2012–2017). Processes 2018, 6, 87. [Google Scholar] [CrossRef]

- Monarca, D.; Cecchini, M.; Guerrieri, M.; Colantoni, A. Conventional and alternative use of biomasses derived by hazelnut cultivation and processing. In Proceedings of the VIIth International Congress on Hazelnut, Viterbo, Italy, 23–27 June 2008. [Google Scholar]

- Zambon, I.; Colantoni, A.; Cecchini, M.; Mosconi, E. Rethinking sustainability within the viticulture realities integrating economy, landscape and energy. Sustainability 2018, 10, 320. [Google Scholar] [CrossRef]

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186. [Google Scholar] [CrossRef]

| Project | Analytical Component of Project-Specific Uncertainty | |

|---|---|---|

| Variable | Descriptor | Contextualized Descriptor |

| i (m) | Uncertainty of methodology, also in this case, the experimental process saw the application of either new methodologies or methods applied in contexts never studied and tested | New and innovative method, not widespread in the sector and high in complexity |

| Variable | Descriptor | Contextualized Descriptor |

| I (r) | Uncertainty of results (not being a process already mature or validated, normally the research carried out do not always have a positive result, precisely because they are being developed, code and implement new activities and actions both at business level and in the territory or scenario and for some research also at international or global level) | Result not present in other studies, not guaranteed and with high variability |

| Variable | Descriptor | Contextualized Descriptor |

| i (c) | Uncertainty of costs, also in this case, not possible to delineate a certainty of the result, and it was not always possible to respect the budget assigned to the single activity of research | Uncertain costs, given also the complexity of the research action |

| Variable | Descriptor | Contextualized Descriptor |

| i (cu) | human behavioral uncertainty, occurs in organizational models where the specificity of the behavior of one or more subjects involved in the experimentation may lead to the failure to achieve the experiment | Possible negative impact on experimenters testing, difficulty in the method of relief given the complexity |

| Variable | Descriptor | Contextualized Descriptor |

| i (o) | Uncertainty of objective often in experimentation during the experimental action or study should be recalibrated objectives for the following factors arising from some specifics described below: | Single objective but with very high technical and scientific complexity |

| Non-economic sustainability | ||

| Target not reachable | ||

| Objective not aligned with time requirements | ||

| Objective varied according to some experimental results | ||

| Variable | Descriptor | Contextualized Descriptor |

| E (Spe) | Experimental error comes from the uncertainty of the measurement or from the experimental errors determined statistically. This type of error is calculated based on specific elements of statistical analysis | Experimental error not known at the beginning |

| Variable | Descriptor | Contextualized Descriptor |

| i (tt) | Uncertainty of technique and technology (use of new systems whose performance is unknown). Use of different mature technologies that, when related to each other, generate new functional problems. Prototype system | Absolutely new technology in the application and survey phases |

| Variable | Descriptor | Contextualized Descriptor |

| i (Repl) | Replicability stems from the uncertainty of replicating the results and disseminating the results of experimentation and research | Possibility of replication that may be linked to secret scientific publications |

| Value | Keyword |

|---|---|

| I (o) | |

| Easy to achieve objective | |

| Objective already achieved with other systems in the firm | |

| Objective already achieved with other systems in the firm | |

| Objective related only to production logic | |

| Easy to achieve objective with complexity only related to aspects related to production | |

| Only technical objective with little scientific value | |

| Unique experimental objective without testing and simulation | |

| Objective related to basic research with numerous sources available | |

| This is a complex average objective that can be solved by well-known research projects in the sector that have already been published. | |

| Objective with several sub-actions | |

| Objective completely unrelated to knowledge | |

| Objective does not present in the business logic | |

| Objective does not present in the technical literature | |

| Objective providing for preliminary studies in scientific literature | |

| X | Multiple objectives (general |

| Complex objective does not present in the scientific literature, and it is challenging to investigate at a high level | |

| Objective providing for preliminary studies in scientific literature | |

| Multiple objectives with complex, interlinked sub-actions | |

| I (CU) | |

| Project that impacts on a few subjects | |

| Presence of only technical or mechanical contents | |

| Presence of only basic study and research | |

| Project with relations only at a technical level that have little impact on relational aspects | |

| Superficial relations | |

| Activity with low cognitive effects, iteration network activity | |

| Human environment prevailing in the research theme | |

| Project that impacts on organizational and relational environments | |

| Project that has a significant impact on behavioral relationships | |

| Project that has a significant impact on human relations | |

| Project that impacts on cognitive, methodological, or learning logic and systems | |

| X | Project that impacts on many subjects or complex organizations |

| Project that impacts on social areas and relevant scales | |

| I (m) | |

| Method present in the literature and mature | |

| Multi-coded methods | |

| Methods present in the literature but not mature | |

| More methods of applied disciplinary fields | |

| New and encoded methods | |

| Methods applied for the first time in the sector | |

| X | New methods to be compared with methods in the literature |

| New development of methods | |

| E (SPE) | |

| Presence of certain and calculated statistical and instrumental errors | |

| Presence of either only instrumental or statistical error | |

| Presence of only some parameters and data for the calculation of uncertainty factors | |

| X | Absence of statistical or data processing methods for numerical analyses |

| I (c) | |

| Costs determined with a specific component prevalently linked to third-party shares | |

| Determination of the analytical costs and simulation of the three scenarios | |

| Definition of a specific session of cost analysis in the pre-project phase with determination of the budget | |

| X | Hypothesized or simulated costs |

| Irtt | |

| Mature technology used in a new way | |

| Mature technologies interfaced with each other in an unencoded manner | |

| X | Use of experimental technology and a known component |

| Technology used in a sector other than that of application | |

| Known technology significantly modified to be considered as new | |

| Experimental technology | |

| New and untested technology | |

| I (r) | |

| Known result in other similar firms | |

| Result known to non-similar firms | |

| Result not easily predictable | |

| X | Uncertain or complex results |

| Results linked to several experimental objectives | |

| I (REPL) | |

| Easily replicable result | |

| Result characterized by a complex path with the need for specific actions to be replicated | |

| Result characterized by a complex path with the need for a progressive path to be replicated (e.g., training, procedures, manual, protocols) | |

| X | Result characterized by numerous variables with a specific study for replicability on an intra- and extra-firm scale |

| Source | F(a) | F(b) |

|---|---|---|

| Competitors and similar firms | 1 | 2 |

| Firms in the sector | 1 | 2 |

| Technical literature | 1 | 2 |

| Scientific literature | 1 | 2 |

| Firms that deal with technical and scientific issues but are not in the sector | 1 | 2 |

| Category Type | File | Target | Description |

|---|---|---|---|

| F: sic | A.1 | DLI | Road maps and checklist |

| F: sic | A.2 | OP | Operating procedures |

| F: sic | A.3 | Didr | Operating procedures |

| F: sic | A.4–A.5 | UV | Example of a document and information to be provided |

| F: sic | A.6 | Ter | |

| Category type | File | Target | Description |

| F: Gest | B.1 | DLI | Explication |

| F: Gest | Managing | DLI–op | Software |

| F: Gest | Counting | DLI–op | Software |

| Category type | File | Target | Description |

| F: Sani | C.1 | DLI | Elements of analysis |

| F: Sani | C.2 | DLI–op | Checklist |

| F: Sani | C.3 | DLI–op– Didr | Operator procedures |

| Category type | File | Target | Description |

| F: Dida | D.1 | Didr | Elements of analysis |

| F: Dida | D.2 | Didr–DLI | Checklist |

| F: Dida | D.3 | DLI | Operator procedures |

| F: Dida | D.4 | Didr–DLI | literature materials |

| Category type | File | Target | Description |

| F: pry | E.1 | DLI–Didr | Elements of analysis |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cividino, S.; Egidi, G.; Zambon, I.; Colantoni, A. Evaluating the Degree of Uncertainty of Research Activities in Industry 4.0. Future Internet 2019, 11, 196. https://doi.org/10.3390/fi11090196

Cividino S, Egidi G, Zambon I, Colantoni A. Evaluating the Degree of Uncertainty of Research Activities in Industry 4.0. Future Internet. 2019; 11(9):196. https://doi.org/10.3390/fi11090196

Chicago/Turabian StyleCividino, Sirio, Gianluca Egidi, Ilaria Zambon, and Andrea Colantoni. 2019. "Evaluating the Degree of Uncertainty of Research Activities in Industry 4.0" Future Internet 11, no. 9: 196. https://doi.org/10.3390/fi11090196

APA StyleCividino, S., Egidi, G., Zambon, I., & Colantoni, A. (2019). Evaluating the Degree of Uncertainty of Research Activities in Industry 4.0. Future Internet, 11(9), 196. https://doi.org/10.3390/fi11090196