In-Line Detection of Bed Fluidity in Gas–Solid Fluidized Beds Using Near-Infrared Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

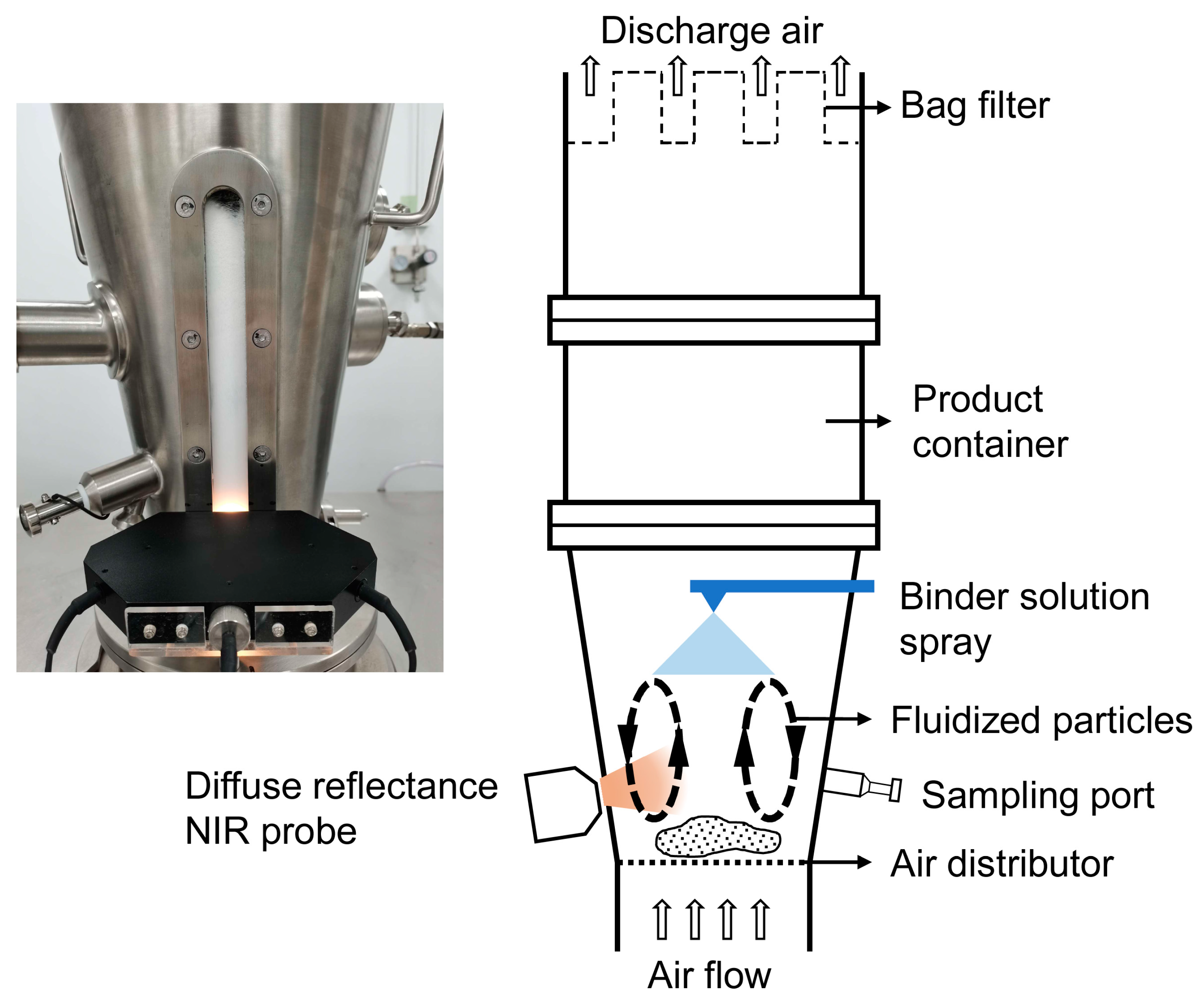

2.2. Experimental Setup

2.3. Experimental Procedure

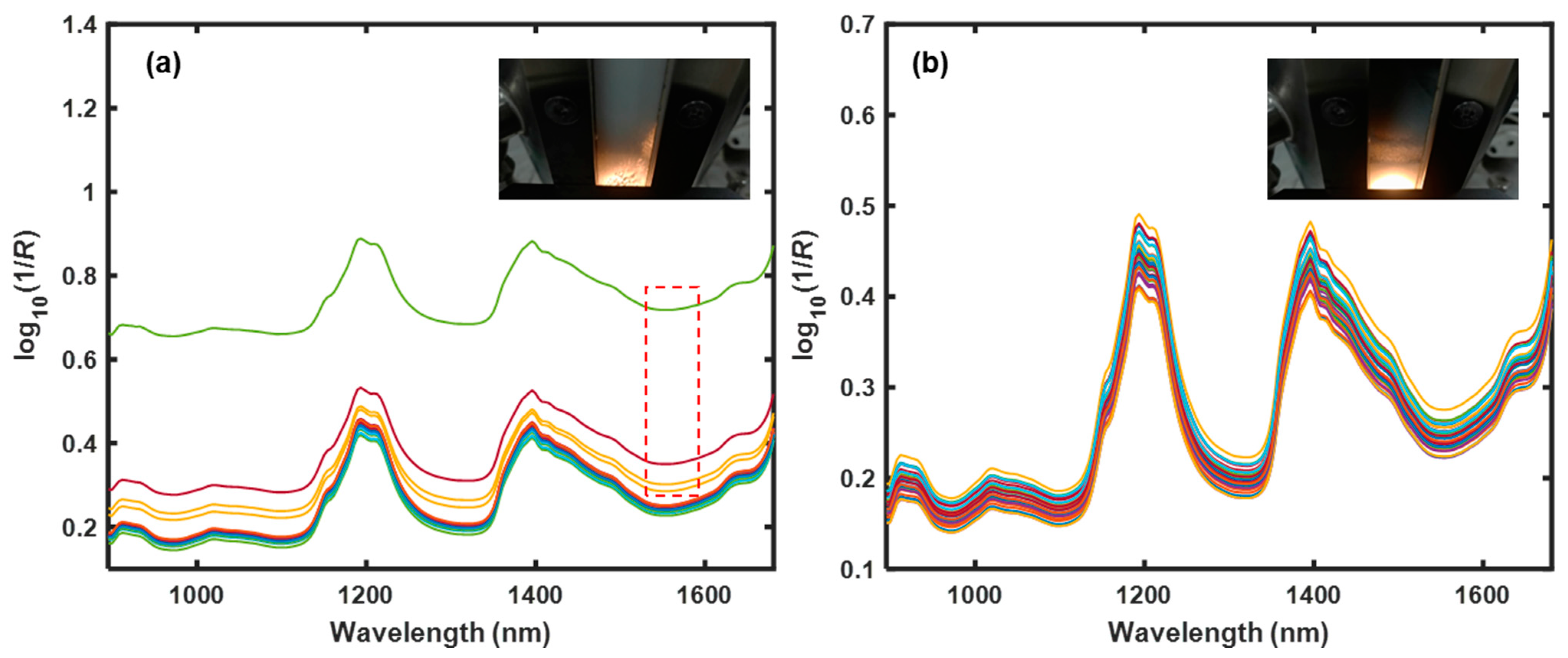

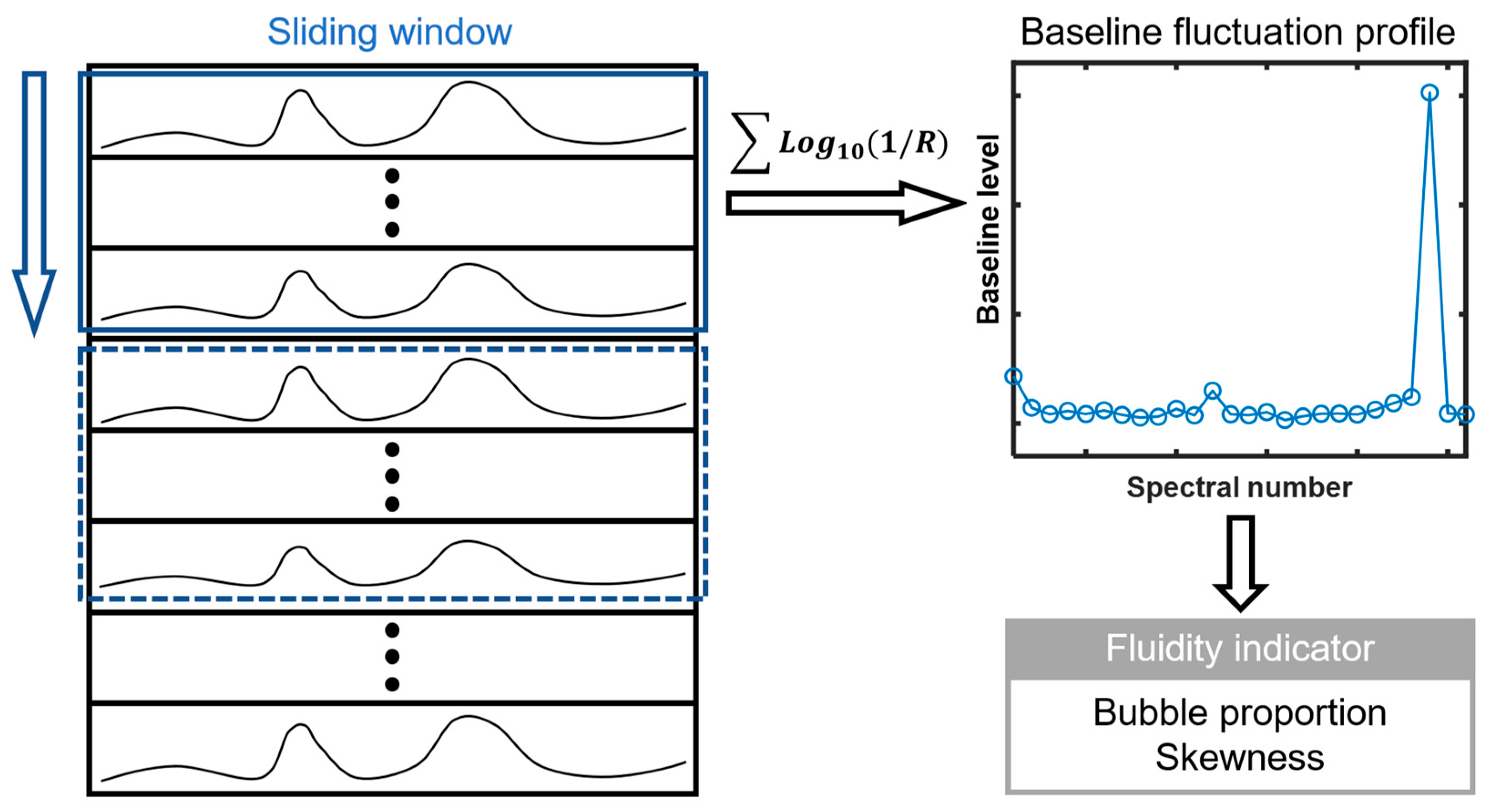

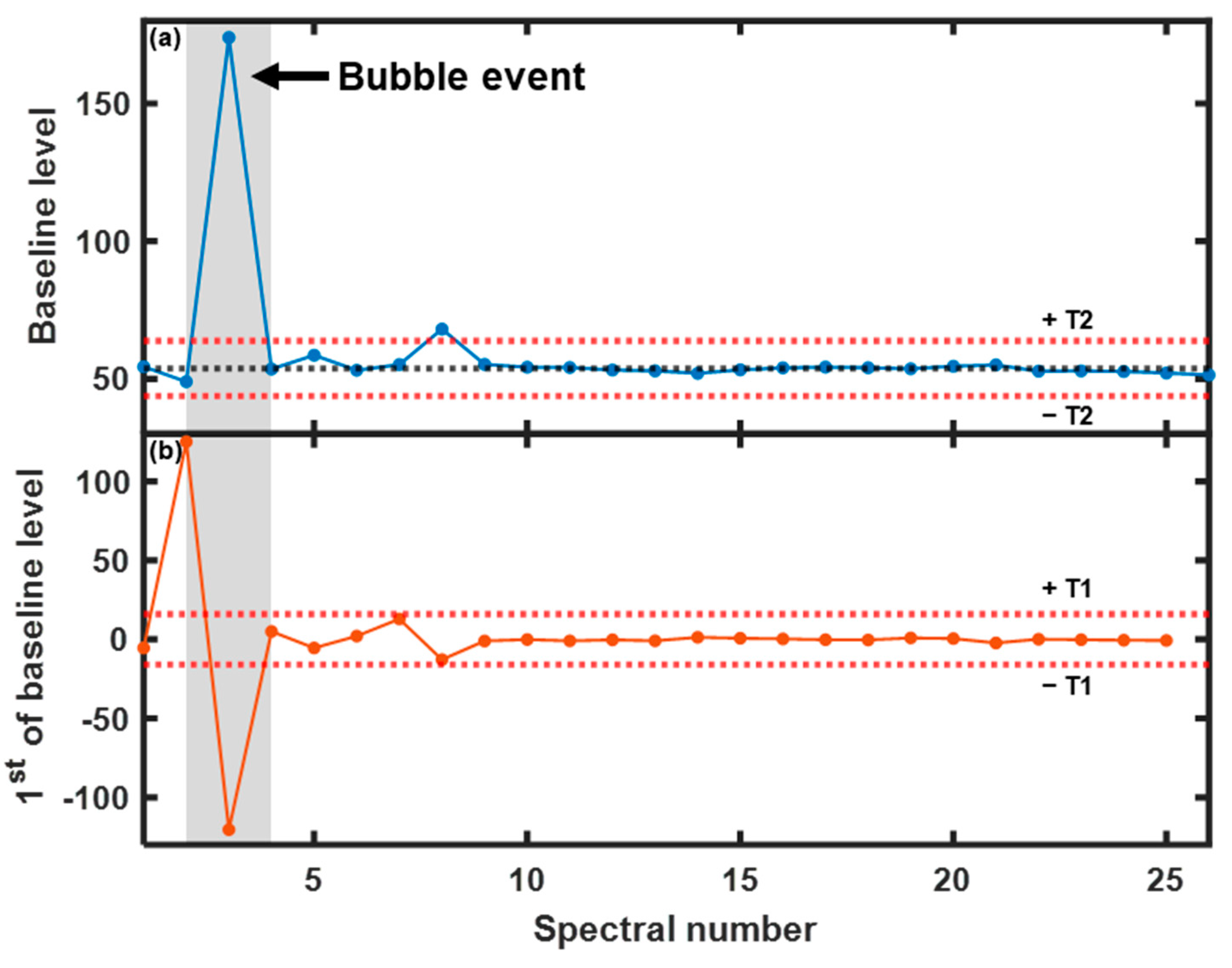

2.4. Signal Processing

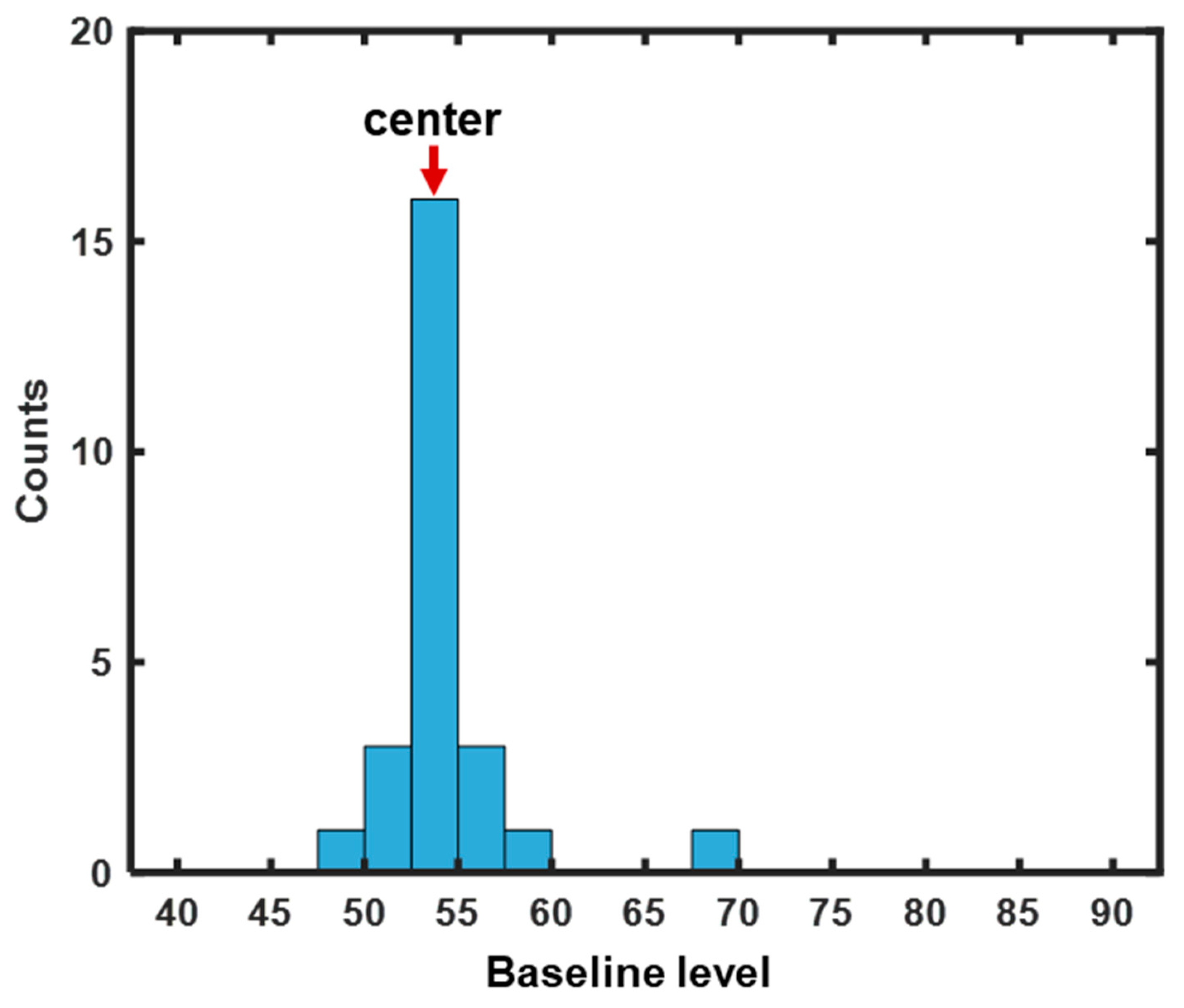

2.4.1. Bubble Proportion

2.4.2. Skewness

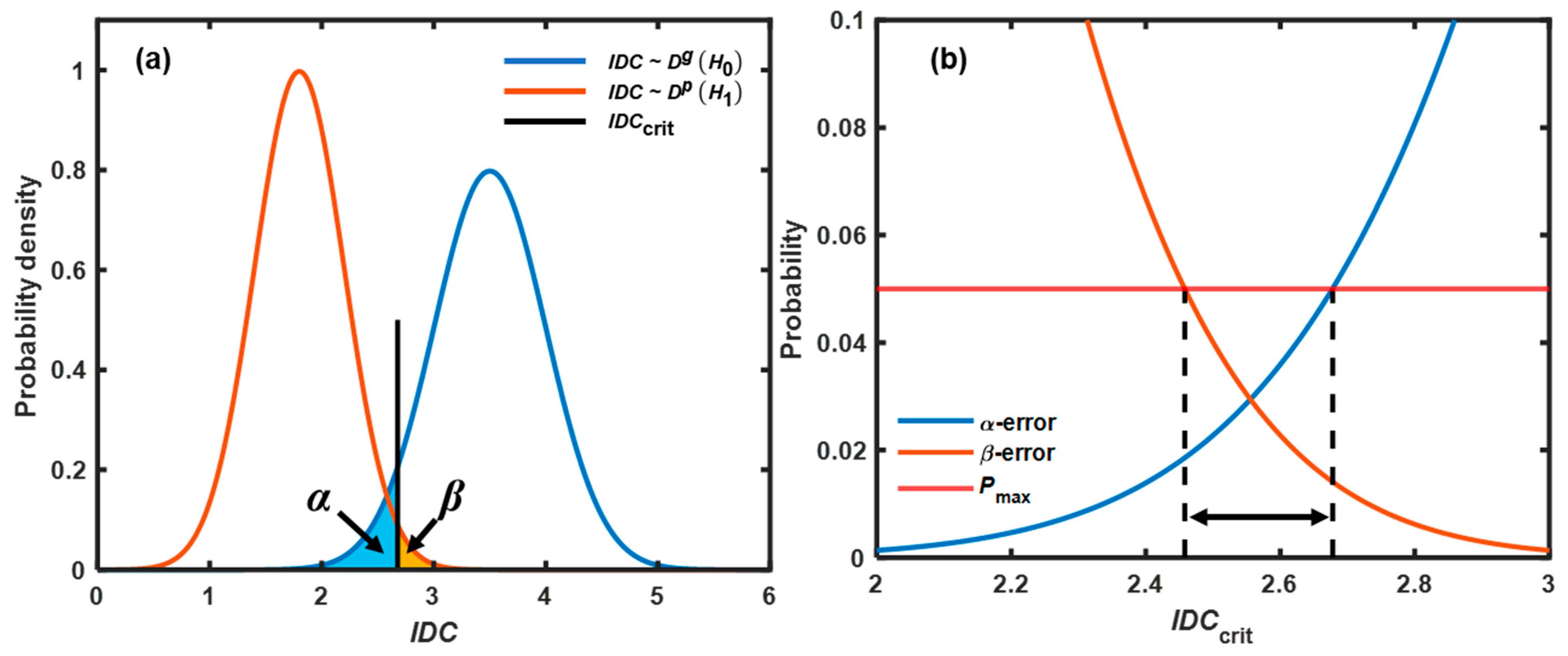

2.5. Methodology of Fluidity Evaluation

3. Results and Discussion

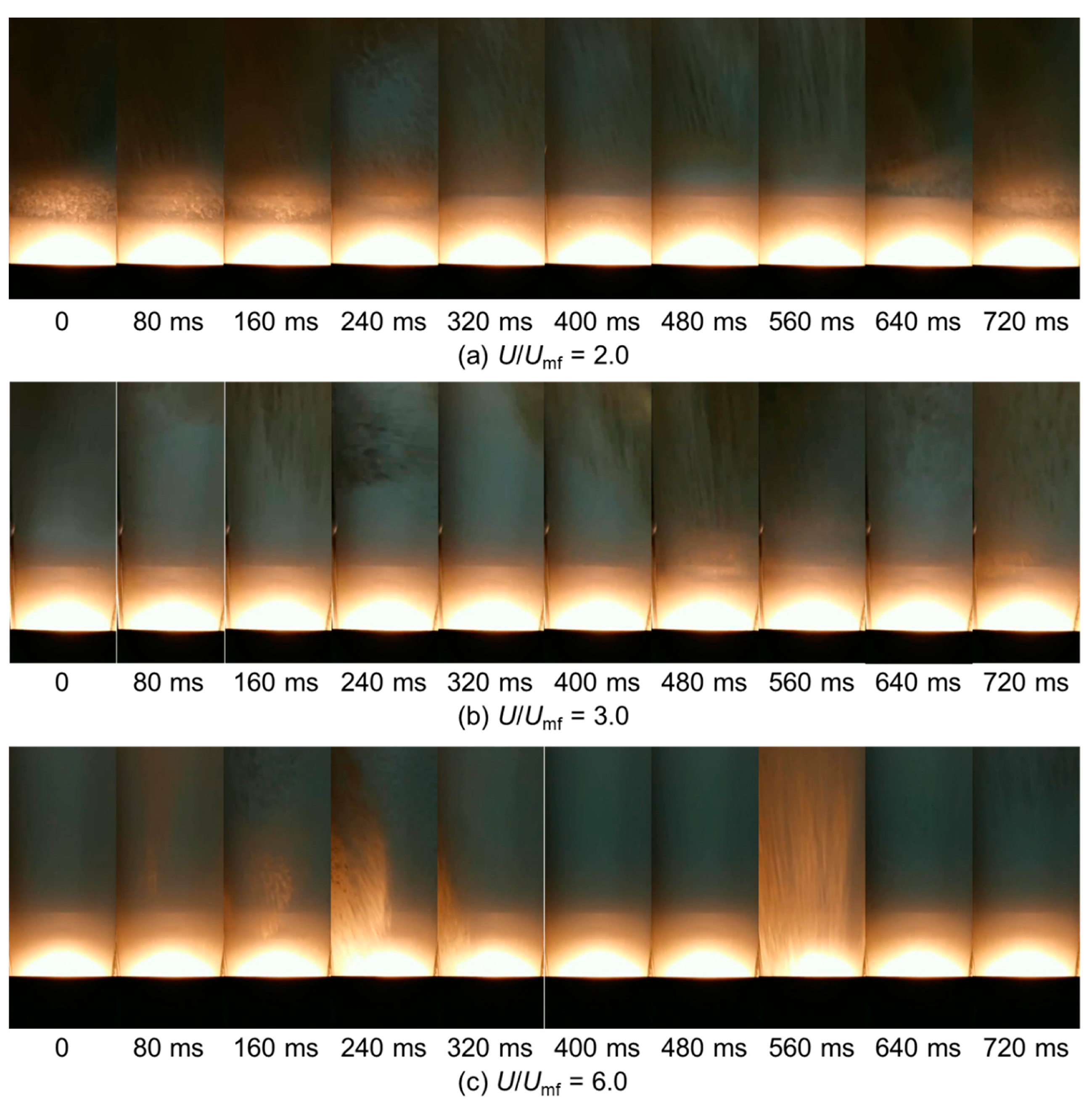

3.1. Fluidity Characterization by Visual Observation

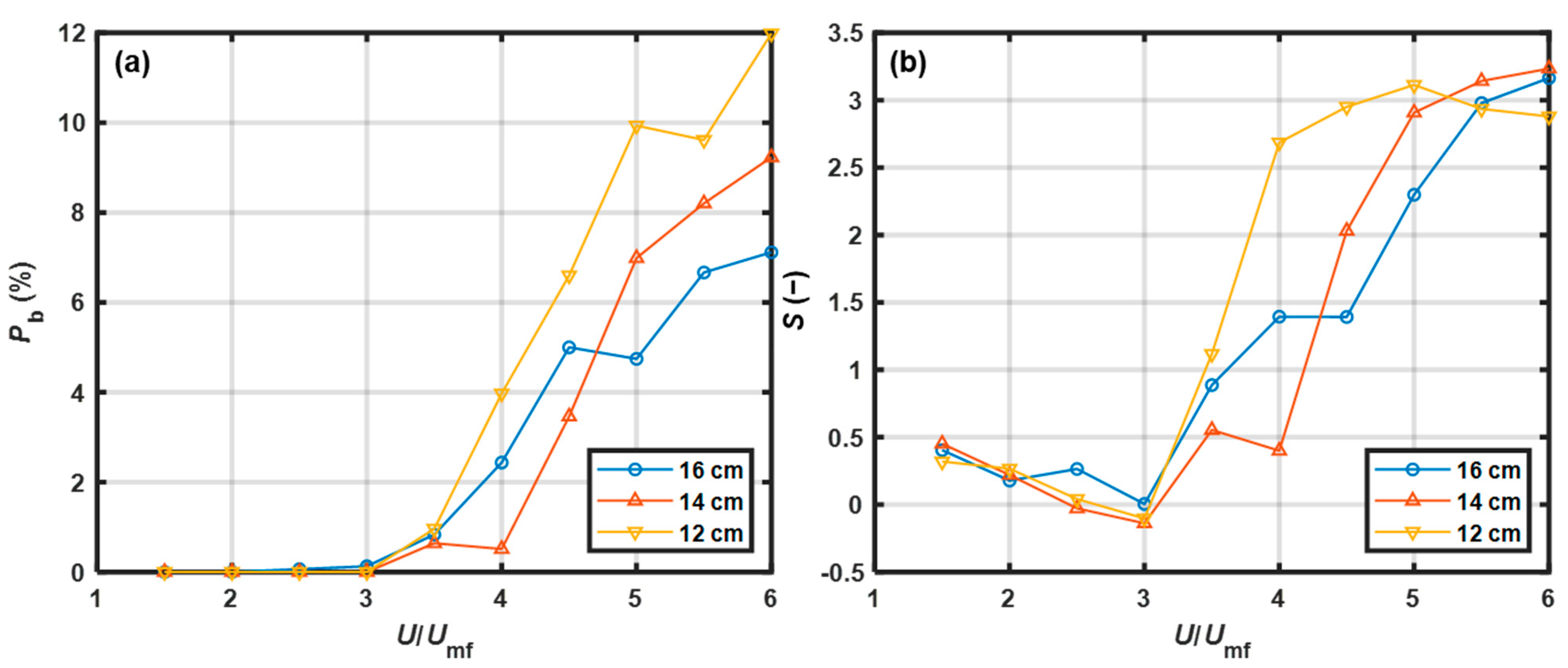

3.2. Effect of Operating Conditions on the Fluidity Indicators

3.2.1. Effect of Static Bed Height

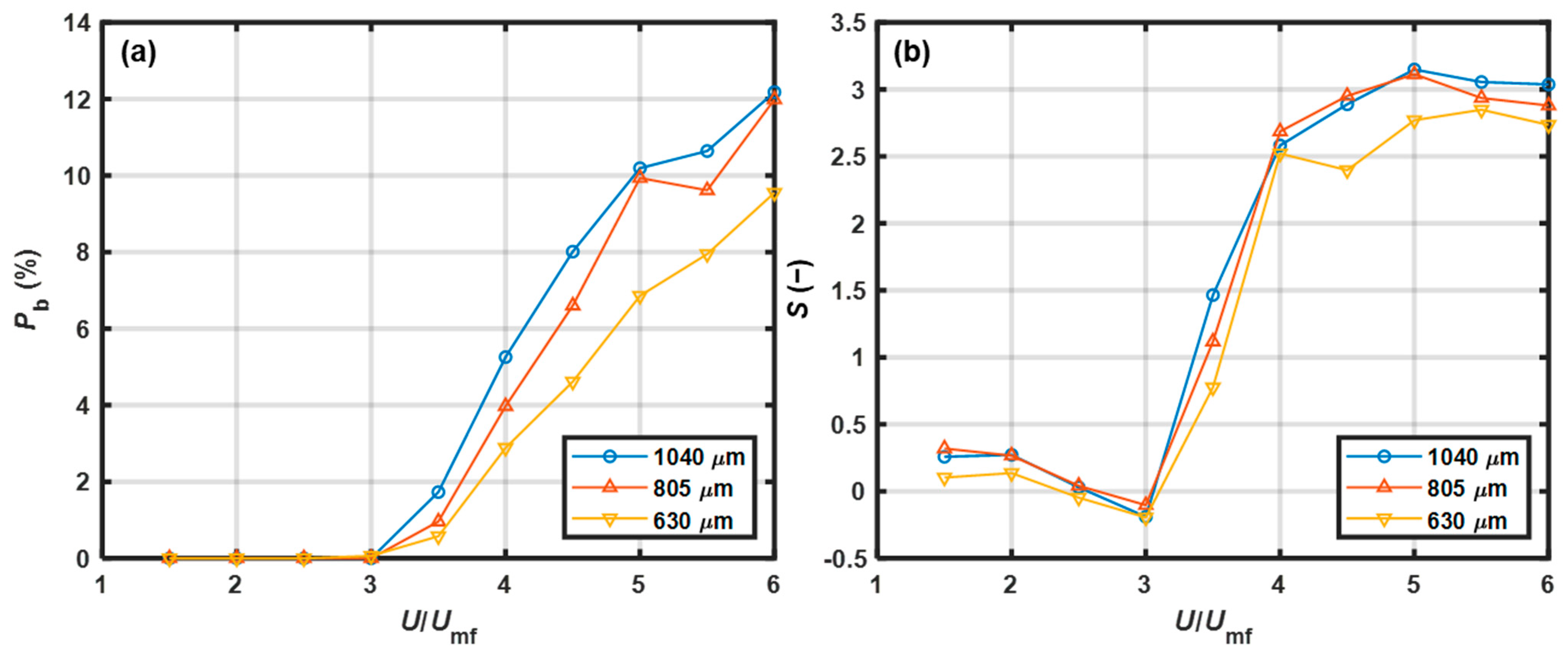

3.2.2. Effect of Particle Size

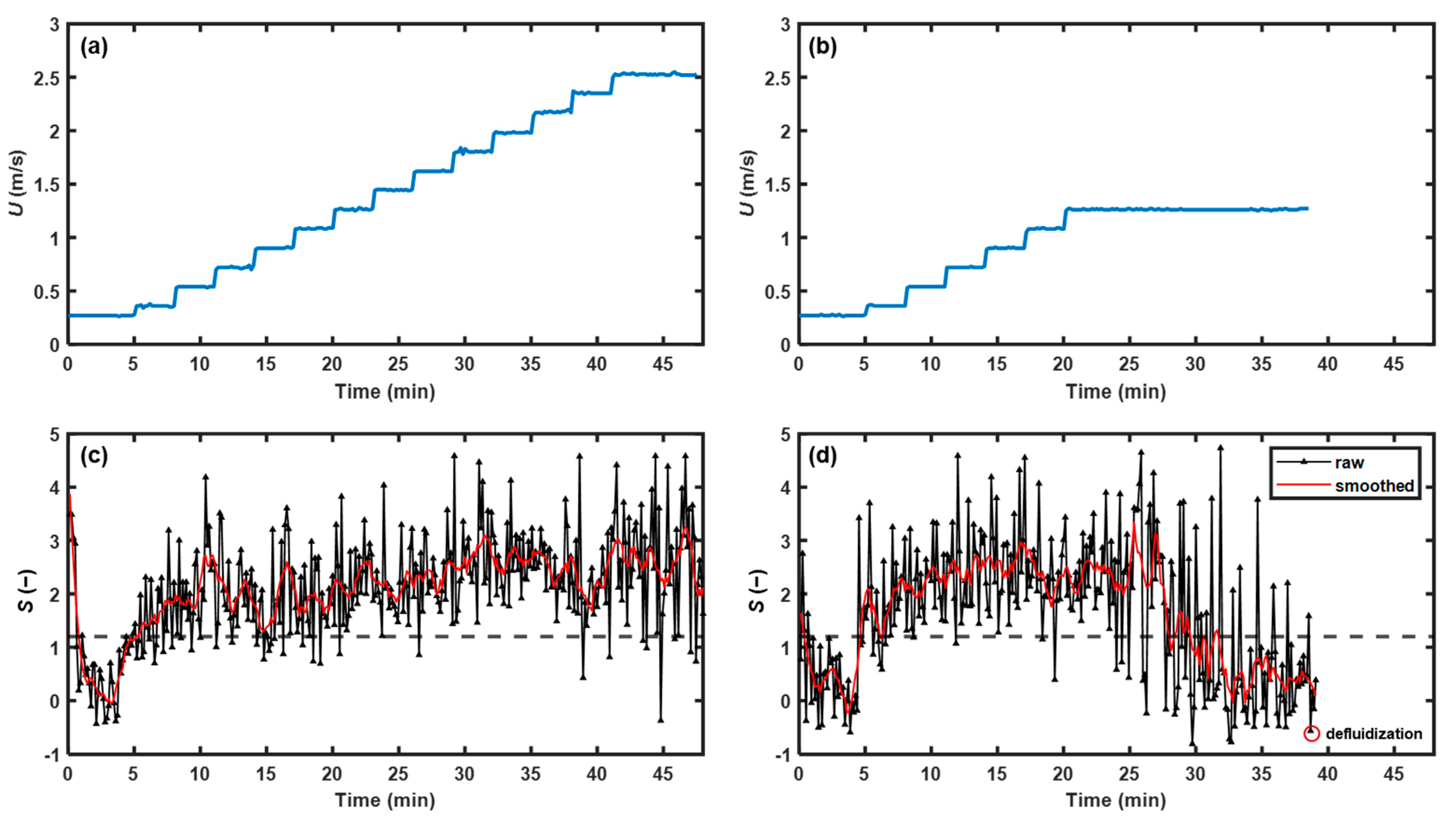

3.3. Establishment and Validation of the Fluidity Evaluation Method

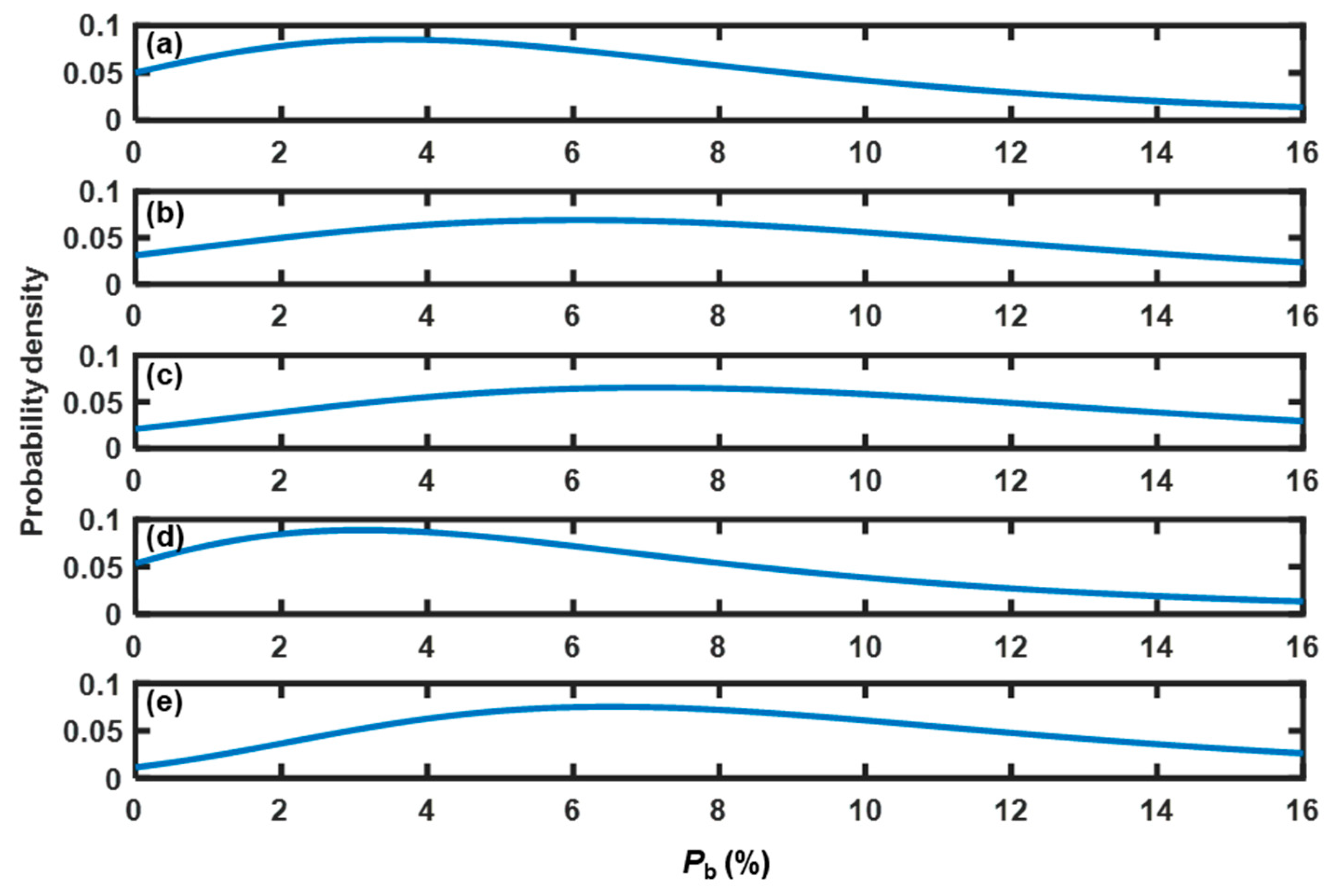

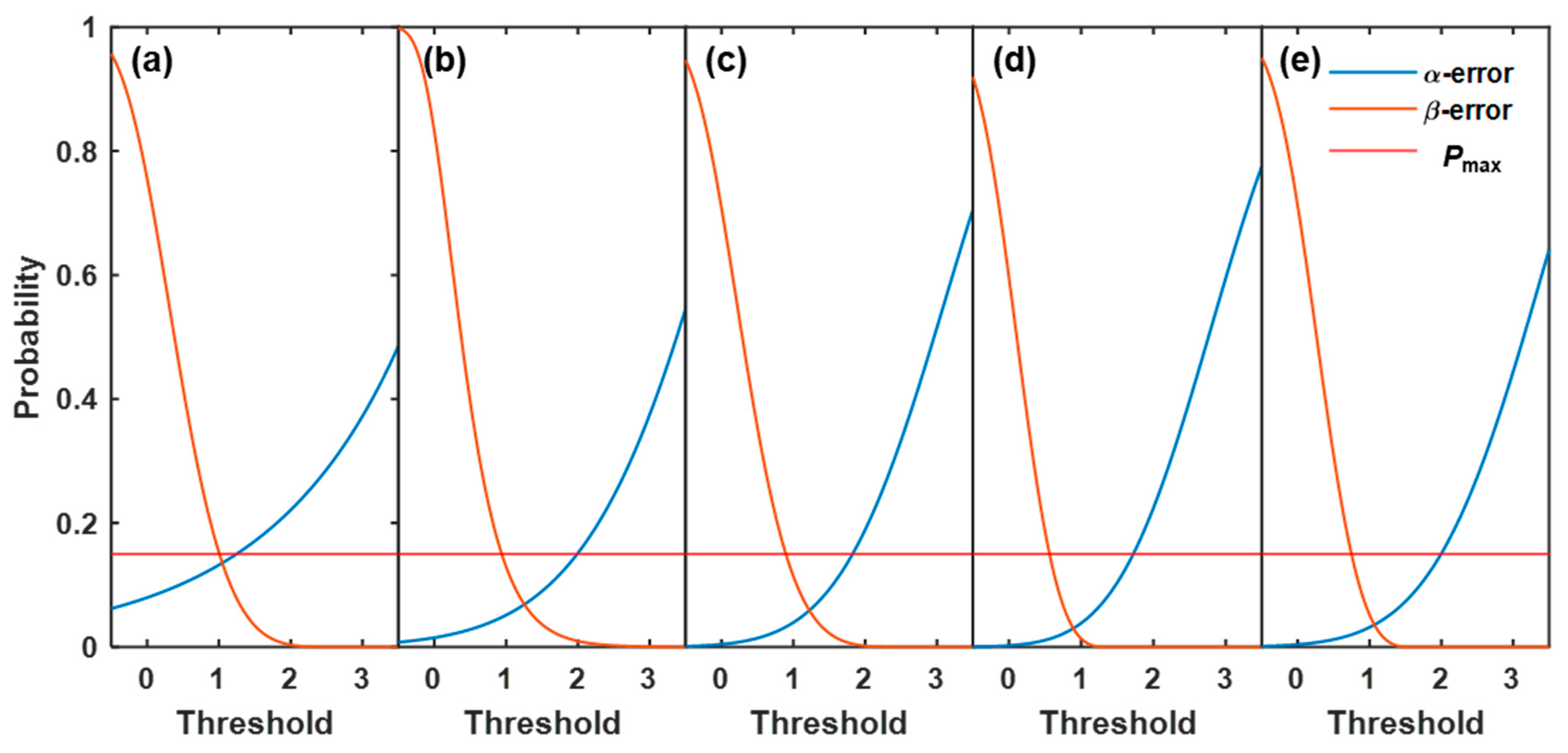

3.3.1. Bubble Proportion

3.3.2. Skewness

3.3.3. Method Validation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McLaughlin, L.J.; Rhodes, M.J. Prediction of fluidized bed behaviour in the presence of liquid bridges. Powder Technol. 2001, 114, 213–223. [Google Scholar] [CrossRef]

- Bartels, M.; Lin, W.; Nijenhuis, J.; Kapteijn, F.; van Ommen, J.R. Agglomeration in fluidized beds at high temperatures: Mechanisms, detection and prevention. Prog. Energy Combust. Sci. 2008, 34, 633–666. [Google Scholar] [CrossRef]

- Scala, F. Particle agglomeration during fluidized bed combustion: Mechanisms, early detection and possible countermeasures. Fuel Process. Technol. 2018, 171, 31–38. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, H.; Zhu, M.; Hu, X.; Yuan, H.; Jiang, S.; Han, L. Effects of liquid content and surface tension on fluidization characteristics in a liquid-containing gas-solid fluidized bed: A CFD-DEM study. Chem. Eng. Process. Process Intensif. 2020, 153, 107928. [Google Scholar] [CrossRef]

- Boyce, C.M.; Penn, A.; Pruessmann, K.P.; Muller, C.R. Magnetic Resonance Imaging of Gas Solid Fluidization with Liquid Bridging. AIChE J. 2018, 64, 2958–2971. [Google Scholar] [CrossRef]

- Schouten, J.C.; van den Bleek, C.M. Monitoring the quality of fluidization using the short-term predictability of pressure fluctuations. AIChE J. 1998, 44, 48–60. [Google Scholar] [CrossRef]

- Briens, C.; McDougall, S.; Chan, E. On-line detection of bed fluidity in a fluidized bed coker. Powder Technol. 2003, 138, 160–168. [Google Scholar] [CrossRef]

- van Ommen, J.R.; de Korte, R.J.; van den Bleek, C.M. Rapid detection of defluidization using the standard deviation of pressure fluctuations. Chem. Eng. Process. 2004, 43, 1329–1335. [Google Scholar] [CrossRef]

- Scala, F.; Chirone, R. Characterization and early detection of bed agglomeration during the fluidized bed combustion of olive husk. Energy Fuels 2006, 20, 120–132. [Google Scholar] [CrossRef]

- Nijenhuis, J.; Korbee, R.; Lensselink, J.; Kiel, J.H.A.; van Ommen, J.R. A method for agglomeration detection and control in full-scale biomass fired fluidized beds. Chem. Eng. Sci. 2007, 62, 644–654. [Google Scholar] [CrossRef]

- Shabanian, J.; Sauriol, P.; Chaouki, J. A simple and robust approach for early detection of defluidization. Chem. Eng. J. 2017, 313, 144–156. [Google Scholar] [CrossRef]

- Briens, C.L.; Briens, L.A.; Barthel, E.; Le Blevec, J.M.; Tedoldi, A.; Margaritis, A. Detection of local fluidization characteristics using the V statistic. Powder Technol. 1999, 102, 95–103. [Google Scholar] [CrossRef]

- Wang, J.; Cao, Y.; Jiang, X.; Yang, Y. Agglomeration Detection by Acoustic Emission (AE) Sensors in Fluidized Beds. Ind. Eng. Chem. Res. 2009, 48, 3466–3473. [Google Scholar] [CrossRef]

- Azizpour, H.; Hadadi-Sisakht, B.; Norouzi, H.R.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N. Detecting Sudden Changes in Fluidization by Wall Vibration. Part. Sci. Technol. 2014, 32, 412–417. [Google Scholar] [CrossRef]

- Alamolhoda, F.; Shamiri, A.; Hussain, M.A.; Sotudeh-Gharebagh, R.; Mostoufi, N. Early detection of agglomeration in a polyethylene fluidized bed at high temperature and pressure by vibration signature analysis. Chem. Eng. Res. Des. 2015, 104, 156–163. [Google Scholar] [CrossRef]

- Alamolhoda, F.; Shamiri, A.; Hussain, M.A.; Zarghami, R.; Sotudeh-Gharebagh, R.; Mostoufi, N. Detection of Agglomeration by Analysis of Vibration Signatures in a Pilot-Scale Fluidized Bed Reactor of Propylene Polymerization. Int. J. Chem. React. Eng. 2019, 17, 20180036. [Google Scholar] [CrossRef]

- ZirGachian, M.A.; Berruti, F.; Briens, C.; McMillan, J. In-site characterization of bed fluidity in a large gas-solid fluidized bed via electric conductance method. Powder Technol. 2015, 286, 697–705. [Google Scholar] [CrossRef]

- Guo, L.; Wang, Z.; Zhong, S.P.; Bao, Q.P.; Guo, Z.C. Fluidization state monitoring using electric current during fluidized bed reduction of iron ore. Powder Technol. 2019, 343, 683–692. [Google Scholar] [CrossRef]

- Wang, T.; Wang, S.; Shen, Y. Particle-scale study of gas-solid flows in a bubbling fluidised bed: Effect of drag force and collision models. Powder Technol. 2021, 384, 353–367. [Google Scholar] [CrossRef]

- Taofeeq, H.; Al-Dahhan, M. The impact of vertical internals array on the key hydrodynamic parameters in a gas-solid fluidized bed using an advance optical fiber probe. Adv. Powder Technol. 2018, 29, 2548–2567. [Google Scholar] [CrossRef]

- Golshan, S.; Patience, G.S.; Zarghami, R.; Chaouki, J.; Blais, B. Experimental methods in chemical engineering: Optical fibre probes in multiphase systems. Can. J. Chem. Eng. 2022, 100, 2762–2777. [Google Scholar] [CrossRef]

- Chung, H. Applications of Near-Infrared Spectroscopy in Refineries and Important Issues to Address. Appl. Spectrosc. Rev. 2007, 42, 251–285. [Google Scholar] [CrossRef]

- Cen, H.; He, Y. Theory and application of near infrared reflectance spectroscopy in determination of food quality. Trends Food Sci. Technol. 2007, 18, 72–83. [Google Scholar] [CrossRef]

- Razuc, M.; Grafia, A.; Gallo, L.; Ramírez-Rigo, M.V.; Romañach, R.J. Near-infrared spectroscopic applications in pharmaceutical particle technology. Drug Dev. Ind. Pharm. 2019, 45, 1565–1589. [Google Scholar] [CrossRef]

- Dahm, D.J.; Dahm, K.D. Representative Layer Theory for Diffuse Reflectance. Appl. Spectrosc. 1999, 53, 647–654. [Google Scholar] [CrossRef]

- Peinado, A.; Hammond, J.; Scott, A. Development, validation and transfer of a Near Infrared method to determine in-line the end point of a fluidised drying process for commercial production batches of an approved oral solid dose pharmaceutical product. J. Pharm. Biomed. Anal. 2011, 54, 13–20. [Google Scholar] [CrossRef]

- Bogomolov, A.; Mannhardt, J.; Heinzerling, O. Accuracy Improvement of In-line Near-Infrared Spectroscopic Moisture Monitoring in a Fluidized Bed Drying Process. Front. Chem. 2018, 6, 388. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.; Gao, L.; Li, L.; Nei, L.; Wei, Y.; Zhang, K.; Zhang, H.; Yin, W.; Xu, D.; Zang, H. Method development and validation of a near-infrared spectroscopic method for in-line API quantification during fluidized bed granulation. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 274, 121078. [Google Scholar] [CrossRef]

- Otsuka, M.; Koyama, A.; Hattori, Y. Real-time release monitoring for water content and mean particle size of granules in lab-sized fluid-bed granulator by near-infrared spectroscopy. RSC Adv. 2014, 4, 17461–17468. [Google Scholar] [CrossRef]

- Tian, G.; Wei, Y.; Zhao, J.; Li, W.; Qu, H. Application of near-infrared spectroscopy combined with design of experiments for process development of the pulsed spray fluid bed granulation process. Powder Technol. 2018, 339, 521–533. [Google Scholar] [CrossRef]

- Alcalà, M.; Blanco, M.; Bautista, M.; González, J.M. On-line monitoring of a granulation process by NIR spectroscopy. J. Pharm. Sci. 2010, 99, 336–345. [Google Scholar] [CrossRef]

- Ropero, J.; Beach, L.; Alcala, M.; Rentas, R.; Dave, R.N.; Romanach, R.J. Near-infrared Spectroscopy for the In-line Characterization of Powder Voiding Part I: Development of the Methodology. J. Pharm. Innov. 2009, 4, 187–197. [Google Scholar] [CrossRef]

- Schillinger, F.; Maurer, S.; Künstle, M.; Schildhauer, T.J.; Wokaun, A. Hydrodynamic investigations by a local optical measurement technique designed for high-temperature applications—First measurements at a fluidized bed immersed by vertical internals at cold conditions. Powder Technol. 2019, 344, 849–863. [Google Scholar] [CrossRef]

- Fonteyne, M.; Vercruysse, J.; De Leersnyder, F.; Besseling, R.; Gerich, A.; Oostra, W.; Remon, J.P.; Vervaet, C.; De Beer, T. Blend uniformity evaluation during continuous mixing in a twin screw granulator by in-line NIR using a moving F-test. Anal. Chim. Acta 2016, 935, 213–223. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.; Hames, D. Minimum Sample Size Determination for Generalized Extreme Value Distribution. Commun. Stat.Simul. Comput. 2010, 40, 87–98. [Google Scholar] [CrossRef]

- Wormsbecker, M.; Pugsley, T.; Tanfara, H. Interpretation of the hydrodynamic behaviour in a conical fluidized bed dryer. Chem. Eng. Sci. 2009, 64, 1739–1746. [Google Scholar] [CrossRef]

- Jang, K.; Feng, Y.; Li, H. Investigation of Bubble Behavior in Gas-Solid Fluidized Beds with Different Gas Distributors. Chem. Eng. Technol. 2021, 44, 723–731. [Google Scholar] [CrossRef]

- Khodabandehlou, R.; Askaripour, H.; Molaei Dehkordi, A. Numerical investigation of gas bubble behavior in tapered fluidized beds. Particuology 2018, 38, 152–164. [Google Scholar] [CrossRef]

| Experiment Number | dp (μm) | Hb (cm) | Umf (m/s) | U/Umf |

|---|---|---|---|---|

| C1 | 805 | 16 | 0.33 | 1.5, 2.0, 2.5, 3.0, 3.5 4.0, 4.5, 5.0, 5.5, 6.0 |

| C2 | 805 | 14 | 0.32 | |

| C3 | 805 | 12 | 0.30 | |

| C4 | 630 | 12 | 0.26 | |

| C5 | 1040 | 12 | 0.33 |

| Experiment Number | dp (μm) | Hb (cm) | U/Umf |

|---|---|---|---|

| V1 | 805 | 16 | 1.5–6.0 |

| V2 | 805 | 14 | 1.5–6.0 |

| V3 | 805 | 12 | 1.5–6.0 |

| V4 | 630 | 12 | 1.5–6.0 |

| V5 | 1040 | 12 | 1.5–6.0 |

| U/Umf | Experiment C1 | Experiment C2 | Experiment C3 | Experiment C4 | Experiment C5 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Flow Pattern | Fluidity | Flow Pattern | Fluidity | Flow Pattern | Fluidity | Flow Pattern | Fluidity | Flow Pattern | Fluidity | |

| 1.5 | P1 1 | P 2 | P1 | P | P1 | P | P1 | P | P1 | P |

| 2.0 | P1 | P | P1 | P | P1 | P | P1 | P | P1 | P |

| 2.5 | P1 | P | P1 | P | P1 | P | P1 | P | P1 | P |

| 3.0 | P1 | P | P2 | M | P2 | M | P2 | M | P2 | M |

| 3.5 | P2 | M | P2 | M | P2 | M | P2 | M | P2 | M |

| 4.0 | P2 | M | P2 | M | P2 | M | P2 | M | P2 | M |

| 4.5 | P2 | M | P2 | M | P2 | M | P2 | M | P2 | M |

| 5.0 | P2 | M | P2 | M | P3 | G | P3 | G | P3 | G |

| 5.5 | P3 | G | P3 | G | P3 | G | P3 | G | P3 | G |

| 6.0 | P3 | G | P3 | G | P3 | G | P3 | G | P3 | G |

| Indicator | Threshold Value | Error Type | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|---|---|

| Pb | 3.85 | α | 36.7% | 25.5% | 18.3% | 37.9% | 14.9% |

| Skewness | 1.20 | α | 14.7% | 6.5% | 5.7% | 5.9% | 4.5% |

| β | 9.0% | 7.9% | 6.4% | 0.1% | 1.5% |

| Skewness | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| range | 1.01–1.24 | 0.94–1.98 | 0.90–1.82 | 0.55–1.71 | 0.75–1.99 |

| Indicator | Threshold Value | Error Type | V1 | V2 | V3 | V4 | V5 |

|---|---|---|---|---|---|---|---|

| Skewness | 1.20 | α | 12.7% | 9.3% | 3.1% | 8.4% | 4.0% |

| β | 5.3% | 3.6% | 3.1% | 1.8% | 3.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, H.; Teng, K.; Zhao, J.; Zhang, S.; Qu, H. In-Line Detection of Bed Fluidity in Gas–Solid Fluidized Beds Using Near-Infrared Spectroscopy. Pharmaceutics 2023, 15, 2246. https://doi.org/10.3390/pharmaceutics15092246

Fu H, Teng K, Zhao J, Zhang S, Qu H. In-Line Detection of Bed Fluidity in Gas–Solid Fluidized Beds Using Near-Infrared Spectroscopy. Pharmaceutics. 2023; 15(9):2246. https://doi.org/10.3390/pharmaceutics15092246

Chicago/Turabian StyleFu, Hao, Kaixuan Teng, Jie Zhao, Sheng Zhang, and Haibin Qu. 2023. "In-Line Detection of Bed Fluidity in Gas–Solid Fluidized Beds Using Near-Infrared Spectroscopy" Pharmaceutics 15, no. 9: 2246. https://doi.org/10.3390/pharmaceutics15092246

APA StyleFu, H., Teng, K., Zhao, J., Zhang, S., & Qu, H. (2023). In-Line Detection of Bed Fluidity in Gas–Solid Fluidized Beds Using Near-Infrared Spectroscopy. Pharmaceutics, 15(9), 2246. https://doi.org/10.3390/pharmaceutics15092246