1. Introduction

Characterizing single particle mechanical properties can be of paramount importance in the design of various manufacturing operations involving pharmaceutical powders or in the excipient selection during the early formulation of new drug products. To name just a few examples:

- -

To have a good chance of reaching the deep acinar airways, the aerodynamic size of the active pharmaceutical ingredient (API) particles in a dry powder for inhalation must lie between

and

[

1,

2]. This range of particle size is typically attained by milling a coarser, brittle starting material in a jet mill, where particle collisions and the consequent fragmentation are responsible for the particle size reduction [

3,

4,

5]. The size reduction of API particles by milling is also frequently used to increase the dissolution, and thus the bio-availability, of poorly soluble drugs by enhancing the specific surface area accessible to the solvent [

6,

7,

8];

- -

The ductility of the API and the excipient particles is very important during powder compaction; it determines the mechanical properties of the compact and thus the overall quality of the oral solid product (tablet) [

9,

10];

- -

Finally, a poor mechanical resistance of the composite particles, such as soft pellets or granulated particles, might lead to alterations in the drug product’s quality during conveying and handling operations [

11].

Establishing a correlation between single particle mechanical properties and the behavior of powder products during manufacturing operations might promote novel effective design methods. Cheap and fast measurements on single particle mechanical properties could be used to exploit new targeted materials and to envisage innovative product solutions, thus significantly reducing the time and material consumption in trials at manufacturing plants.

Process design and control are nowadays increasingly assisted by numerical modelling and simulation [

12,

13,

14]. For the realistic modeling of those processes where particle breakage occurs, both as a desired [

15,

16,

17] or a detrimental effect [

18], a breakage probability distribution for the mother particle and a fragmentation distribution describing the generation of daughter fragments must be properly defined [

19]. Meier et al. demonstrated how the parameters appearing in such functions directly depend on the single particle mechanical properties [

20,

21].

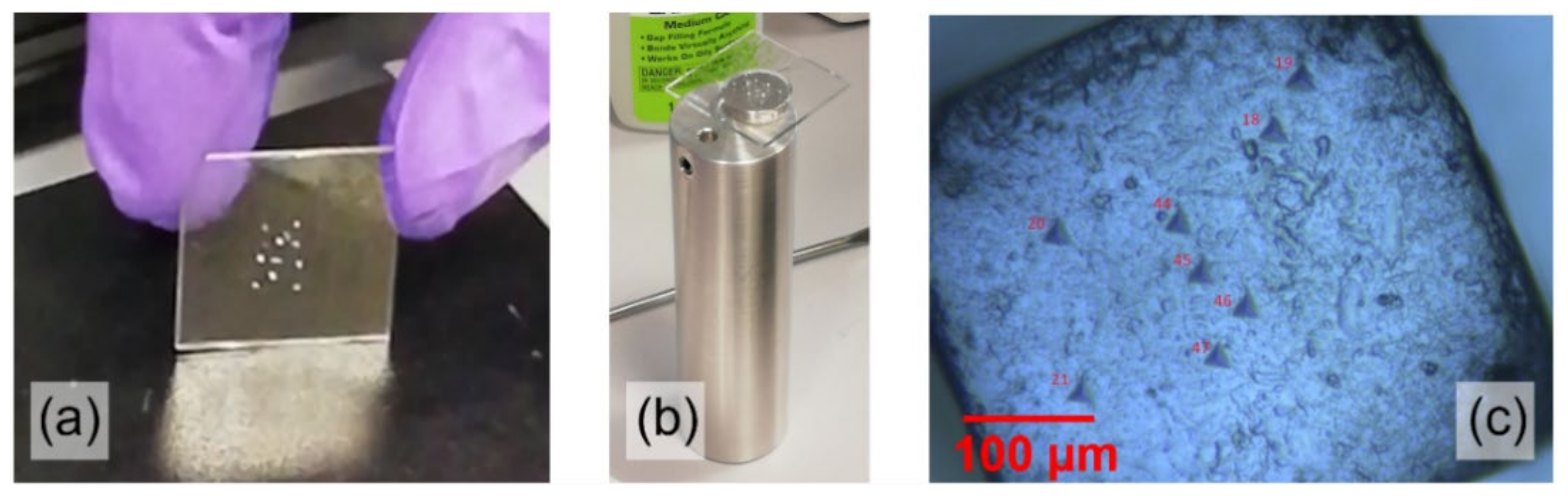

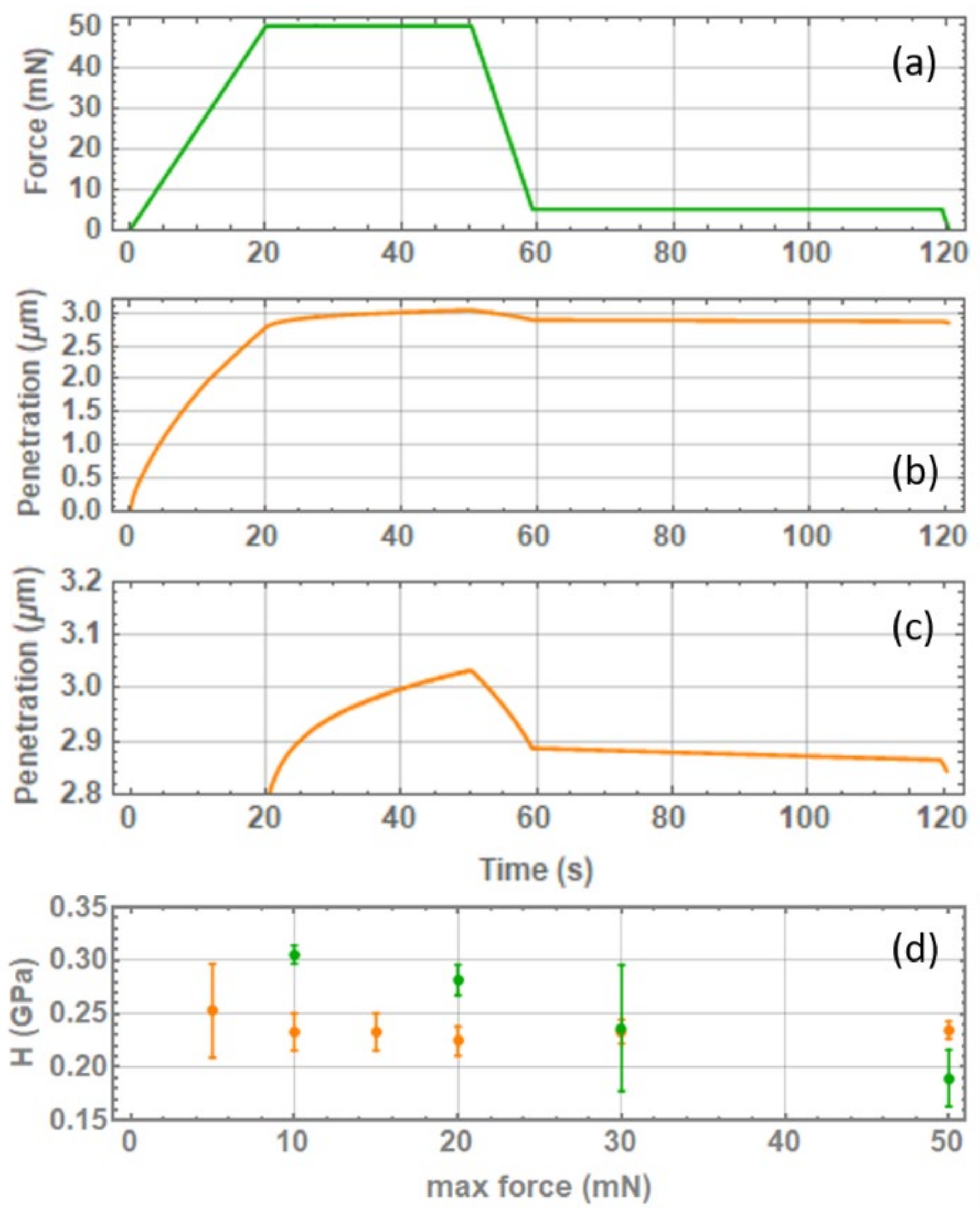

The nano-indentation technique enables the measurement of single particle mechanical properties with practically no consumption of material, e.g., only a few tens of particles are necessary. Such versatility is particularly appreciated when dealing with an API of a new synthesis, whose total amount, in the early development phases, is limited, while the synthesis costs are considerable. A typical nano-indentation test consists of pushing a hard metallic tip on a single powder particle, glued onto a sample holder, with increasing force, while measuring the tip displacement [

22,

23,

24]. The typical indentation profiles acquired on our samples are shown in

Figure 1a. Part of the tip displacement is due to the elastic deformation of the particle surface and part is due to plastic penetration inside it, as illustrated in

Figure 1b. From the recorded curve, it is thus possible to extract information on both the elastic response and the plastic (irreversible) deformation. By imaging the indentation footprint with optical microscopy, atomic force microscopy (AFM), or scanning electron microscopy (SEM), it is possible to measure the length of the generated cracks. Examples are shown in panels (c) and (d) of

Figure 1. Assuming a certain model of deformation and crack propagation beneath the tip, a brittleness index can be defined indicating the nature of the plastic deformation, i.e., whether the material responds in a brittle or a ductile fashion.

Naturally, single particle nano-indentation also has some intrinsic limitations and is generally less controllable and reproducible than its counterpart on tablets and powder compacts [

10,

22,

25]. Powder particles must be tightly glued to a sample holder to be manipulated and placed individually under the indenter. This is only possible if the particles have a size of at least

–

; below such a limit, cohesion forces will dominate over gravity, keeping the powder particles aggregated. Powders with a peculiar crystal habit (e.g., acicular, lamellar) will lie on the sample holder with certain preferential orientations, i.e., certain crystallographic directions might not be accessible to indentation. In other cases, the single crystal shape (e.g., octahedra) might prevent the glued particles from exposing horizontal surfaces, i.e., the planes parallel to the sample holder and perpendicular to the indentation axis; if this alignment condition is not met, the indentation data are meaningless. If the indentation footprint is too small, a local or “microscopic” value of the elasto-plastic properties of the material is probed; thus, a large variability in the measures must be expected due to surface inhomogeneities, local disorder, and defects. Only if the indentation footprint is large enough to average over the microscopic surface disorder and to probe enough “weak spots” of the particle surface will the data variability be substantially reduced, and the results will no longer depend on the indentation depth (meaning also the maximum indentation force and footprint size) [

24].

Several works are present in the literature discussing the application of single particle nano-indentation to active pharmaceutical ingredients and excipients [

26,

27,

28] and its correlation with powder processability [

20,

22,

29,

30,

31]. Shariare et al. [

27] demonstrated the difficulty in correlating directly the brittleness properties of pharmaceutical powders with the calculated interaction energy between crystalline planes within the particles. This difficulty stems from the fact that the material breakage is dominated by defects, dislocations, and pre-existing flaws, which might considerably lower the theoretical energy barrier to initiate slip motion between the molecular planes, as proved by Vegt et al. [

31,

32]. Zuegner et al. [

30] found that the connection between powder milling efficiency and the elastic and plastic properties of single particles is non-trivial. They concluded that particle elasticity impacts the breakage resistance of materials more than particle hardness. However, their picture cannot explain the behavior of materials such as sodium chloride, and without any further measurement, it is not possible to determine whether the plastic deformation of the particles has a ductile or a brittle character. This problem was further addressed by Meier et al. [

20], who showed how the brittleness index remains the most promising parameter to predict the milling behavior of powders. Taylor at al. [

29] found a very nice correlation between the milling efficiency and different single particle mechanical properties, such as the Young modulus, the hardness, and the brittleness index of different pharmaceutical compounds. The single particle nano-indentation data also correlate very well with the powder behavior during the compaction and tableting processes; a summary can be found in the review by Egart et al. [

22].

In this work, we characterize the elastic and plastic responses of different pharmaceutical powders by measuring the Young modulus and hardness via nano-indentation. The estimation of the average length of the generated cracks allows the evaluation of the fracture toughness and brittleness index. Our results are compared with those already present in the literature; the variability and reproducibility of the measurements are also analyzed. Particle comminution is then studied through a tabletop jet mill, and the size reduction effects are discussed for the different materials and process conditions. Finally, the correlation between the single particle mechanical properties and the powder grindability is illustrated and discussed, as is the possibility of building a predictive model for the powder behavior during milling, solely based on the single particle mechanical properties measured via nano-indentation.

3. Results and Discussion

The data on the elastic and plastic behavior acquired for all the samples are summarized in

Table 1; the values present in the literature for the reference compounds are also reported for comparison (sodium chloride [

26,

30], tartaric acid [

20], and lactose [

20,

30]). The hardness of the sodium chloride is to be found in good agreement with the data reported by Duncan-Hewitt et al. [

26], while some discrepancy is found for the Young modulus. This material is known to be extremely ductile with a very limited elastic deformation, which makes the unloading curve of the hysteresis loop very steep and thus extremely hard to be correctly fitted for the extrapolation of its derivative by the instrument software. Testing different fitting formula and different numerical methods to determine the fitting coefficients, through an external software, we found that

can increase even by

. This brings the re-crystallized sample value into agreement with the experimental one and slightly enhances the commercial sample value, which remains lower. Though with a little more variability between the different sessions, the hardness of the tartaric acid is also close to the value reported by other authors; the Young modulus is found to be in good agreement except for the commercial session 2, where again we recorded an underestimation. Drops in the

value could be justified by particle gluing issues. If the glue layer is not perfectly stiff, and it undergoes a significant deformation, two terms of Equation (3) must be retained, leading to

; in particular, if the deformation of the glue layer is comparable to the particle one, we obtain

. Both

and

of lactose are in reasonable agreement with the data reported in the literature; a slightly higher variability is visible for

among the different sessions.

For sodium chloride and lactose, it is possible to assess the effect of re-crystallization on the measured mechanical properties. For both materials, the Young modulus and hardness are found to be larger than for the out-of-the-box counterpart. We are thus led to the reasonable conclusion that a small-scale, controlled re-crystallization makes the powder particles harder and more elastic. This finding is in agreement with the results published by de Vegt et al. [

31], showing how an increasing density of pre-existing flaws lowers both

and

. On the other hand, on a large commercial scale, reaching the crystal perfection is far from trivial: in the crystal packing, flaws and defects compromise the hardness. The contained variability among the different measurement sessions for compounds B and C reveals a good reproducibility of the gluing procedure and a weak dependence on the operator. The same is true for sessions 3 to 5 of compound A, all performed on the same batch, while a pronounced difference is visible when compared with tests 1 and 2 performed on two other different batches, even though they are obtained from similar synthesis processes. This finding highlights the importance of characterizing the mechanical properties of every single manufactured batch before setting the milling process specifics and, in any case, it warns about the intrinsic batch-to-batch variability that, for certain molecules of new synthesis, can be significant.

The crack length

c was determined only on a subset of the measurements presented in

Table 1;

,

and

were subsequently calculated. The results are summarized in

Table 2. Sodium chloride particles are extremely ductile and, even applying a high maximum loading

, we never succeeded in inducing cracks around the indentation footprints. This behavior has also been discussed by other authors, with the exception of Duncan-Hewitt et al. [

26], obtaining the values reported in

Table 2. Indeed, their

value is very high compared to all the other materials analyzed here, confirming no attitude to brittle fracture, i.e.,

. For tartaric acid, our

and

values compare nicely with the literature data, while the lactose results are in good agreement with what concerns

and reveal a smaller value for

. As already noted for

and

, compound A shows a considerable batch-to-batch variability; for session 3, only one indentation produced good cracks, and thus, no standard deviation is reported. Moreover, the three sessions on compound B give consistent and reproducible measurements. Compounds B and C appear to be the most brittle; they are thus expected to be easily grindable in milling processes.

The standard deviations associated with all of our measurements are higher than those reported by the other authors for the commercial excipients. This is in part due to our choice of averaging over all the applied loads, including the lowest loads, which typically enhanced the measurement variability. A deep investigation of how the indentation protocol might affect the results variability is certainly necessary. In particular, the impact of the loading and unloading rates, as well as the importance of the dwell time, must be assessed. This point is poorly discussed in the literature, and as it would require a large measurement campaign, focusing on few materials, this is beyond the scope of the present paper.

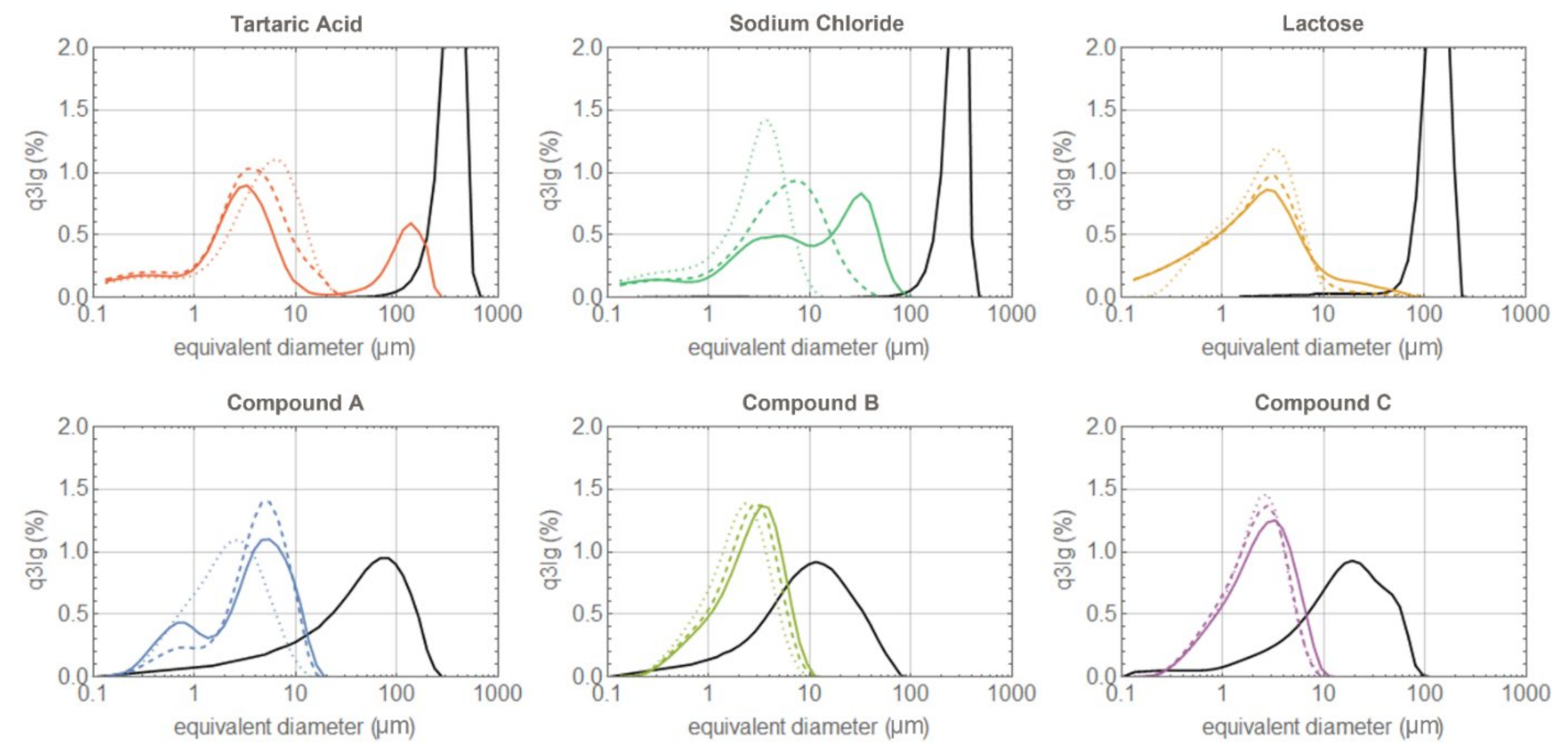

Both the synthesized compounds and the commercial excipients (in their out-of-the-box form) were milled at the same powder feed rates and grinding pressures. The PSD of the processed material was acquired immediately after milling; the results are summarized in

Figure 4. Compound C is indeed the most easily grindable; at 3 barg, its PSD is already close to the limiting distribution with a

dv90 well below 10 μm. Further increases in the grinding pressure only slightly sharpen it, without any significant left shift. The same applies for compound B, with only a minor shift observed with the increasing pressure. Compound A is harder to mill; at low pressure, the collisions are not especially effective in reducing the particle diameter, which results in high particle residence time, i.e., a large hold-up mass accumulates in the mill chamber, reducing even further both the nitrogen and the particle velocity [

41]. At small collision velocities, chipping and abrasion mechanisms are known to begin, generating small size fragments which could lead to the observed bi-modal size distribution [

42,

43,

44]. Another possible scenario justifying a bi-modal distribution at low grinding pressure is an intermittent grinding regime [

41]. If the product is difficult to grind, then, as the particles accumulate in the milling chamber, the large hold-up mass slows down the fluid and its centrifugal force until most of the particles are able to reach the classifier and escape the mill, even though still large in size, giving rise to the rightmost peak. When the mill is almost empty, the fluid accelerates, promoting high energy collisions which are very effective in size reduction and preventing the escape of large particles by restoring a stronger centrifugal force. In this way, only small size particles escape the mill, giving rise to the leftmost peak; this optimal milling condition is gradually lost as the milling chamber refills again. Only at 6 barg are the collisions effective in provoking brittle fracture. This restores a mono-modal PSD slightly left-shifted. Unfortunately, the milling equipment does not allow for a further increase in pressure to verify whether such a distribution is already the limiting one. Something similar happens for lactose, but here, it is clear the limiting distribution is already reached at 4.5 barg. Sodium chloride also displays a bi-modal distribution at low pressure, which disappears with increasing pressure as the PSD shifts to the left and sharpens. The mill is clearly also working in an intermittent regime for tartaric acid, and during its periodic emptying, the particles exit with almost the same size they entered it with. Increasing the grinding pressure causes the intermittent regime to disappear, but the main peak shifts to the right. This can be due to two phenomena: with higher collision speed, chipping and abrasion mechanisms are suppressed and brittle fracture produces only larger fragments; alternatively, a regime where milling efficiency decreases with increasing grinding pressure is known to occur at high feed rates [

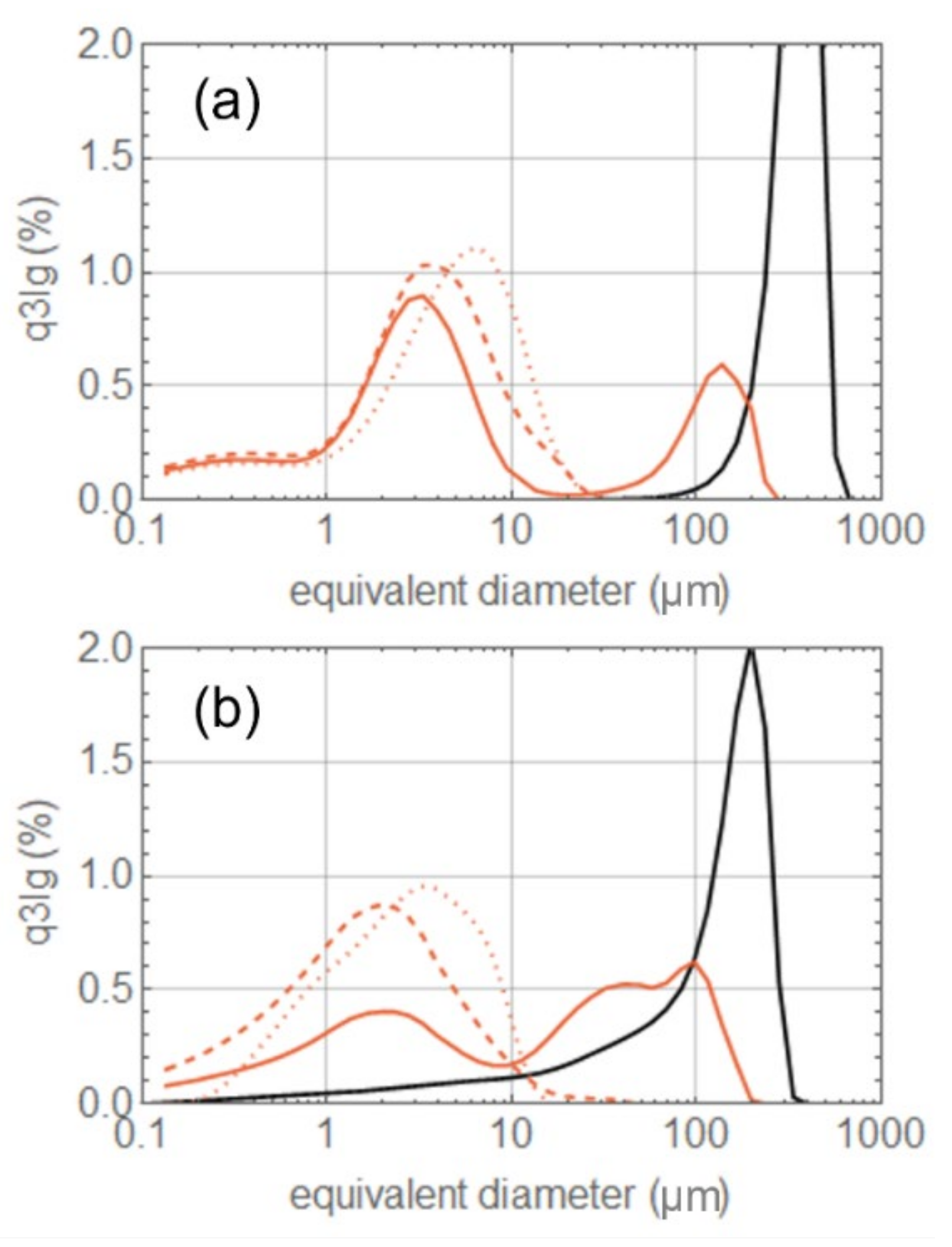

41]. The milling pressure should be increased even more to see the PSD peak shifting back to the left. One might argue that the increasing difficulty in grinding certain materials (sodium chloride and tartaric acid in particular) is due to the larger particle size of the feed rather than to a less brittle attitude. To demonstrate that this is not a correct interpretation, we sieved the tartaric acid material, removing the coarser fraction from the feed. The difference between the original feed and the sieved one can be appreciated by comparing panels (a) and (b) of

Figure 5. Probably due to the fracture of some weak large particles, the new feed shows a left tail enhancing the content of particles with a diameter between

and

; the overall feed PSD closely resembles the lactose one. However, the milled PSD and the powder behavior, with increasing grinding pressure, remain identical to the coarser feed.

Reducing the effect of the hold-up and accessing higher grinding pressures, to also reach the limit PSD for hard materials, could both be achieved using a larger mill. However, working with a larger grinding chamber implies the use of bigger powder samples, requiring tens of grams instead of a few grams per trial, and such an amount of powder is generally not available in the early stages of new drug synthesis.

In setting the milling process parameter for a new material, we are primarily interested in:

- (i)

Understanding whether the particle size can be reduced below a certain value;

- (ii)

How high the grinding pressure must be raised to achieve the desired PSD. As this depends also on the powder feed rate, we should consider the specific milling energy; however, all the presented results were collected at the same feed rate; thus, the specific milling energy varies with pressure only;

- (iii)

How strong the PSD of the milled material depends on our choice of milling pressure;

- (iv)

Estimating the smallest particle size attainable, as this determines the span of our PSD.

To investigate point (i), the

of the milled samples was plotted against their brittleness index for different grinding pressures; see

Figure 6a. Given the impossibility of generating cracks on sodium chloride, we used the

value from Duncan-Hewitt et al. [

26]; for compound B, we averaged

over the data from the different sessions; for compound A, where a large batch-to-batch variability is present, we used only the

value measured directly on the milled batch. With the exception of tartaric acid, whose strongly bi-modal distribution makes the

of little use, there is indeed a correlation. The three barg data appear more scattered as the low-pressure PSD retains memory of the starting material one; at 6 barg, most of the materials reach the limiting distribution and the differences in

become narrow. By fitting the data, it is possible to estimate a dependence of

on the measured brittleness index

; for the 3 and 6 barg data, we get, respectively:

whose predictivity is of course valid only for a certain milling pressure and our specific mill geometry. More general expressions with an explicit dependence on pressure could be defined collecting data on many more materials and at different pressures; they could be used to answer to point (ii), i.e., to predict the

of a new material just by estimating its

via nano-indentation. Looking at panel (a) of

Figure 6, it is also clear how the difference in

between 3 and 6 barg becomes narrower as

increases. Very brittle materials should in fact already reach their limiting distribution at very low pressures, while harder materials lose memory of their starting material PSD only at very high pressure. Thus, similarly to what the other authors have done, we propose the definition of an index representing the ease of milling a powder, a form of grindability index, as

)/

. Considering that this index is estimated by comparing the PSD of two milled samples rather than by referring to the starting material PSD, this index is by construction suitable to answer to point (iii). The grindability index

, as a function of

, is plotted in panel (b) of

Figure 6. Again, with the exception of tartaric acid, all the points lie on the following fitting curve in Equation (10).

which again has a predictivity limited to a certain pressure range and bound to our specific milling equipment. Why tartaric acid does not follow the general trends highlighted here for the other materials remains unclear. According to its

value, it should be a medium brittleness material; however, its behavior in the mill suggests an extreme difficulty in size reduction, with the accumulation of a large hold-up mass. Its large Young modulus, associated with large feed particles, might completely change the particle dynamics inside the mill: random frequent elastic rebound significantly lowers the average particle-particle and particle-wall velocity, reducing the comminution efficiency by brittle fracture. However, these mechanisms should also be at work for sodium chloride; it also has a similarly large

and even less attitude to brittle fracture, and still, it is found to be more easily grindable than tartaric acid.

Panel (c) of

Figure 6 shows the overlay of the PSD for all the samples milled at 6 barg; assuming these distributions closely resemble the limiting ones (which is verified only by compounds B and C and for lactose), one can verify the predictivity of the Hagen model and try to answer point (iv). For compounds A, B, and C, as well as for lactose, the smallest fragment size is around 0.2 μm; for sodium chloride and tartaric acid, longer left tails suggest the presence of much smaller fragments. There is however a spurious numerical effect emerging when combining the measurements of different lenses to generate a unique PSD. Checking the PSD using the R1 lens, we also found for sodium chloride and tartaric acid a minimum fragment size of 0.2 μm. The smallest fragment size attainable by brittle fracture, as predicted by the Hagen theory, is calculated through Equation (7), reported in

Table 2, and plotted in

Figure 6d. The predicted and measured data are in good agreement only for lactose and compound B. The prediction for compound A, tartaric acid, and sodium chloride significantly overestimates the smallest attainable particle size by orders of magnitude; an underestimation occurs for compound C. We must conclude that, for these compounds, either the simple assumptions underlying the Hagen model are not correct or brittle fracture is not the sole size reduction mechanism at play. The inadequacy of the Hagen model has also been reported by other authors showing how single particles can break into fragments much smaller than the calculated

[

37]. Their argument is that the simple models for the estimation of

are based on static stress distributions in the samples and are thus more suitable for quasi-static loading experiments, rather than for high-speed collisions such as those occurring in single impaction testers (or jet-impact testers), as well as in jet mills. Further investigations in this direction would require dedicated work and the use of a particle size analysis tool more suitable for the sub-micron range, i.e., the application of Mie light scattering theory with the wet dispersion laser diffraction method.

4. Conclusions

Once the proper sample preparation procedure had been set up, the indentation analysis proved to be reliable and reproducible. The measurements on commercial excipients were in good agreement with the data available in the literature. However, the single particle handling and gluing, the search for good and flat terraces for indentation, and the measurement of the crack length are all manually executed operations which make nano-indentation a very time-consuming analysis. Another main weakness of the technique is the need for re-crystallization to generate larger particles for those compounds whose selected synthesis path leads to the precipitation of very small crystals. This is not only another time-consuming procedure, but it might significantly alter the mechanical properties of the particles, making them not representative of the larger amount of powder used in the milling trials. The differences in the mechanical properties of re-crystallized and out-of-the-box commercial excipients are evident from our analysis; however, re-crystallization did not prevent us from obtaining a good correlation between and for compounds B and C. This might mean that, for these compounds, the re-crystallization process does not significantly alter the measured mechanical properties. Indeed, the industrial-scale synthesis process of the commercial excipients, and their post-synthesis handling, differs significantly from the lab-scale synthesis of compounds A, B, and C. It is thus reasonable to expect for them a more pronounced impact of re-crystallization. Finally, it must be noted that the nano-indentation technique alone is not able to give any prediction about the possible alterations to the solid-state properties of the milled material as a consequence of the received mechanical stress. This is a very important aspect to consider while designing a milling process, and to date, it is possible to evaluate it only on the milled samples, i.e., on a trial-and-error basis. For all the above-mentioned reasons, we believe nano-indentation remains of great value only in the very early development phases, when new compounds are synthesized in the order of a few grams. With such limited abundance, milling process design cannot be afforded on a trial-and-error basis. However, when the synthesis scale is many tens of grams, a few milling trials (guided by the data collected in the past on other compounds) should allow the setup of a decent milling process in a shorter time compared to the duration of an indentation analysis.

Despite all the limitations of nano-indentation, a correlation exists between the brittleness index and the powder behavior during milling, and it can certainly be exploited to build predictive models. The dependence of the or the grindability index upon deserves further investigation, enriching the statistics with new compounds, especially those with little brittle fracture attitude. Another aspect to better clarify is how strongly the and the grindability index still depend on the particle size of the feed material. The classification mechanism of jet mills should eliminate by design the dependence of the milled product PSD on the starting material one; however, this is true only in an ideal working regime, which might not be met here for small compounds. With a much larger set of milling experiments, it is certainly possible to define a generalized version of Equations (8) and (9), predicting the (as well as other characteristic diameters) as a function of the milling pressure, the feed rate, and the index .

We confirmed the known inadequacy of the ductile–brittle transition models by Hagen and Kendall in predicting the smallest fragment size. We stress that deeper quantitative considerations on this point cannot be made on the basis of the presented data. Working with sub-micron size particles requires, in fact, the use of different particle size characterization methods (wet dispersion, Mie scattering) and the definition of a different set of milling trials, aimed at finding the limiting distribution of the different compounds, raising the pressure above 6 barg when necessary.

If these points are addressed and further investigated, we believe it will be possible to build a predictive model, enabling the estimation of the PSD of a milled product solely based on the mechanical properties measured via nano-indentation. Such a model of course remains valid only for the specific milling equipment used in the investigation; scaling the milling process up on larger mills or porting the process from one mill to another would require the construction of predictive models for each of them.