Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China

Abstract

1. Introduction

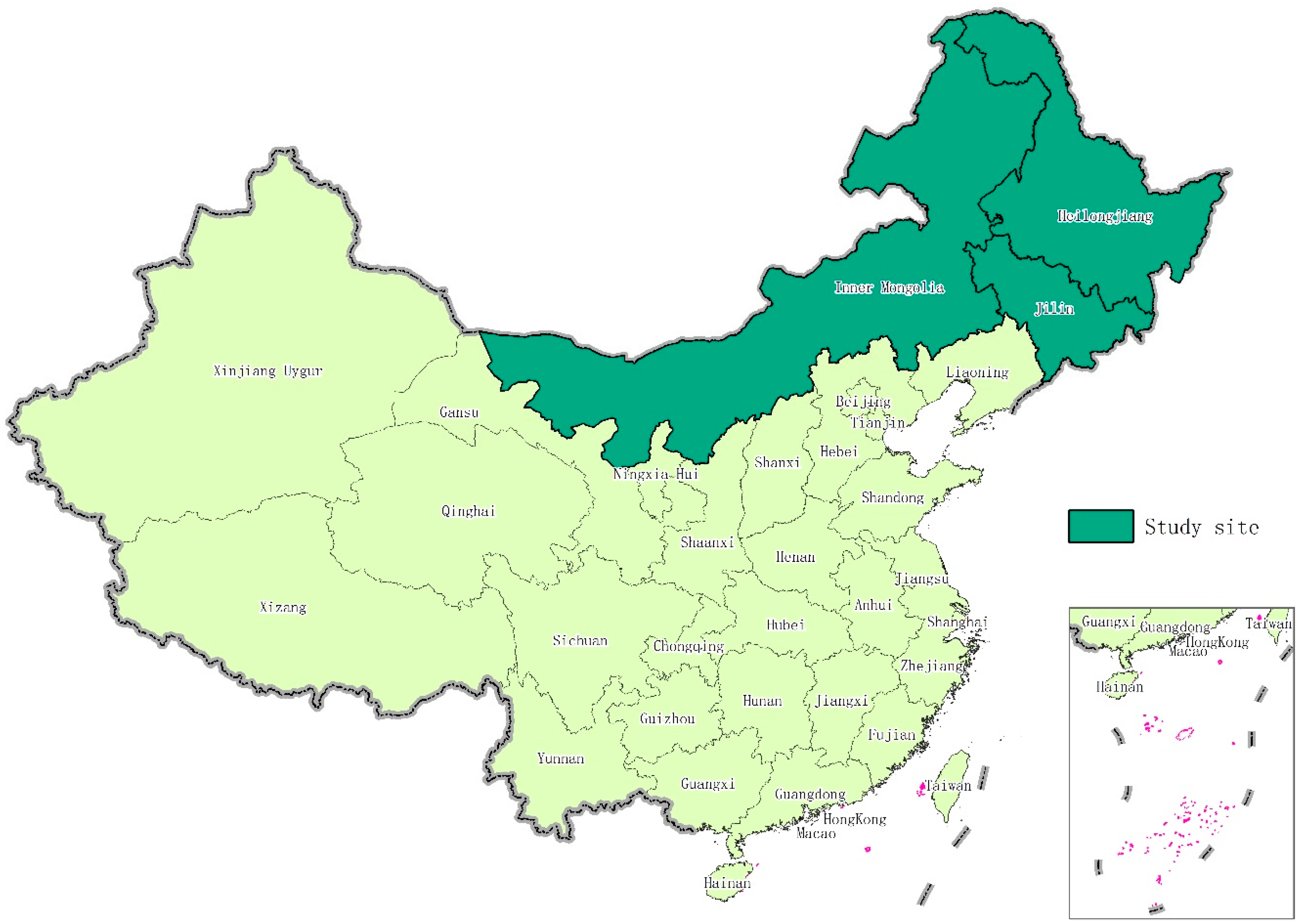

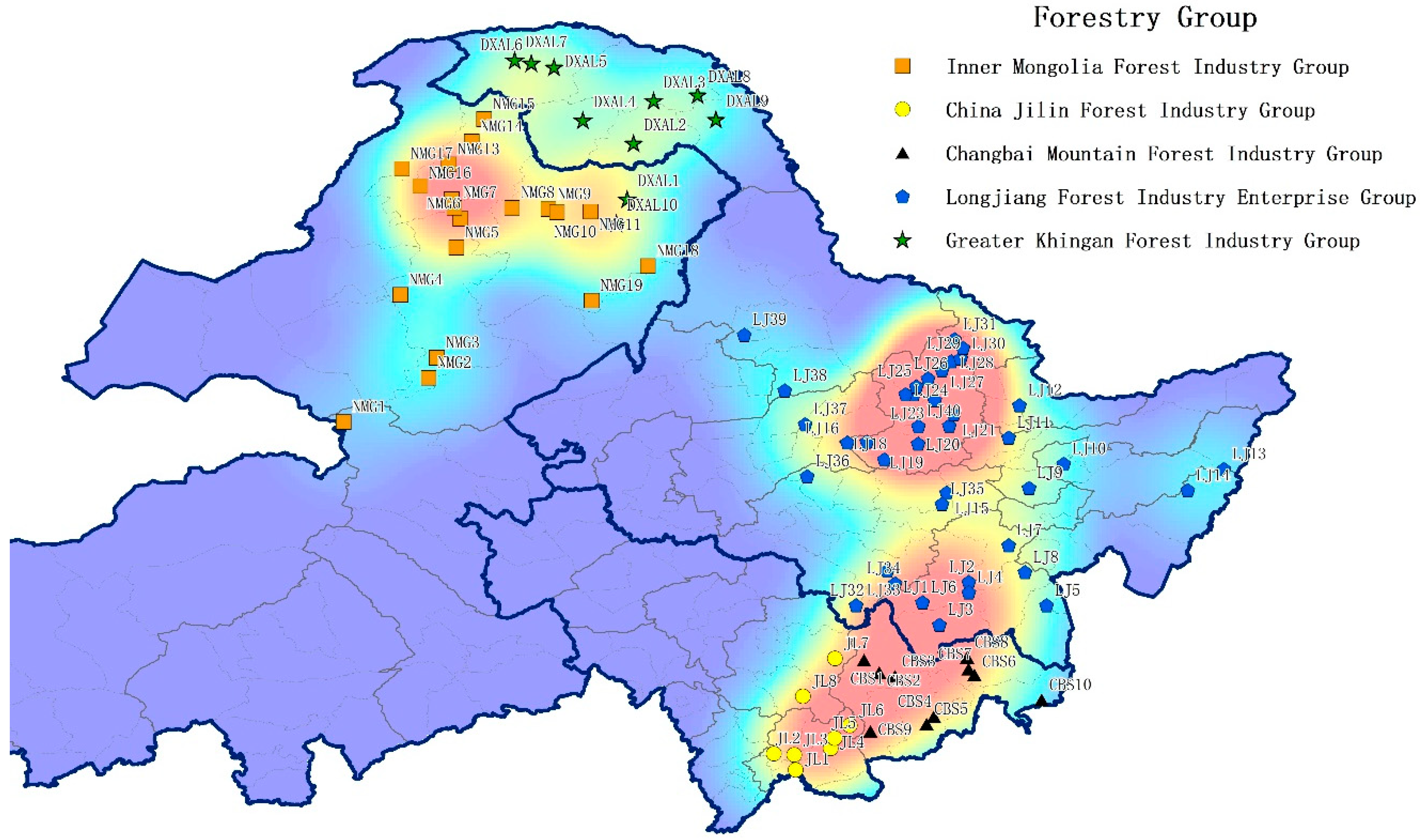

2. State-Owned Forestry Enterprises in Northeast China

3. Literature Review

4. Methodology and Data

4.1. The SBM-DEA Model

4.2. Data Sources and Indicator Selection

5. Results

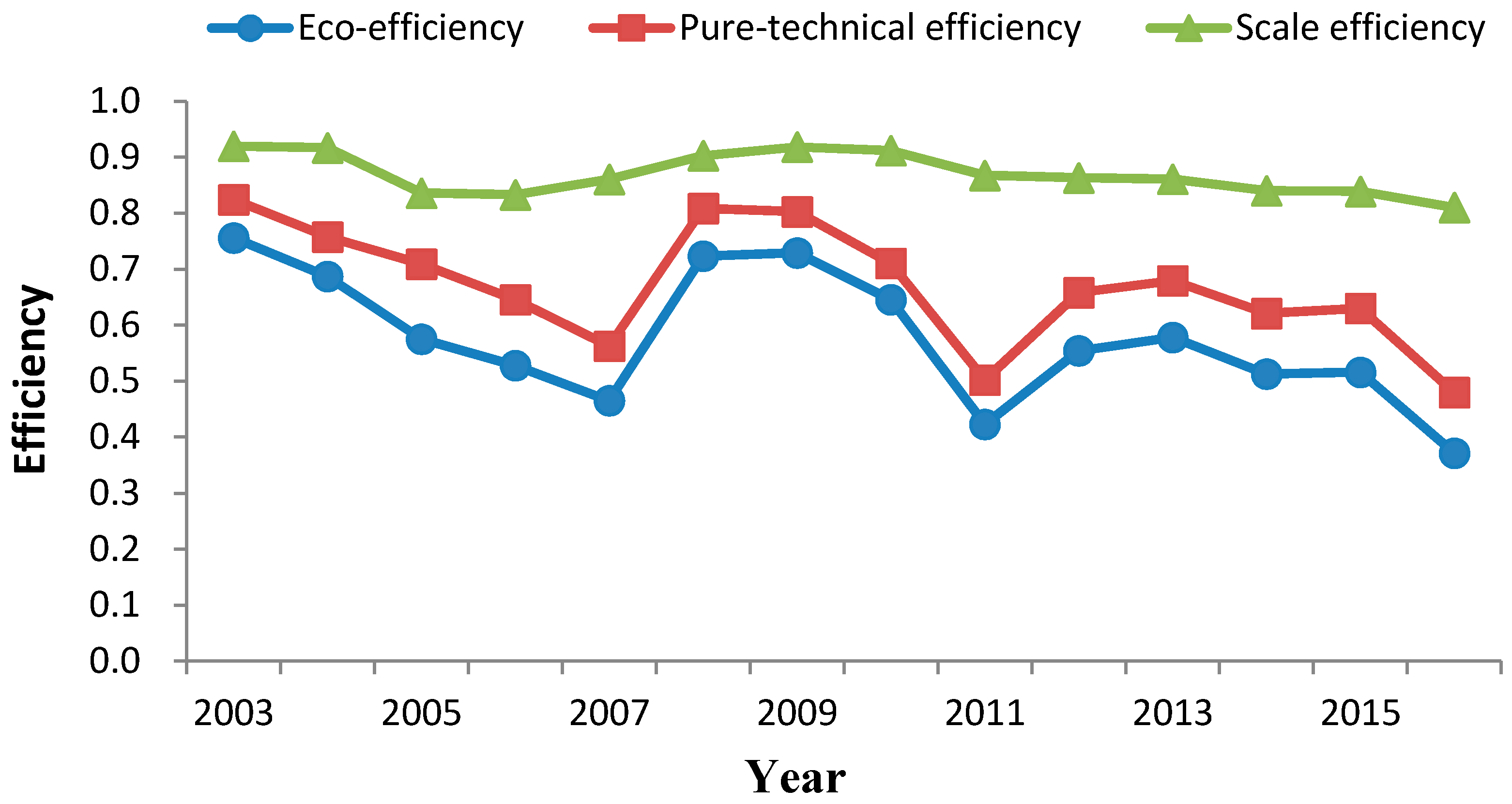

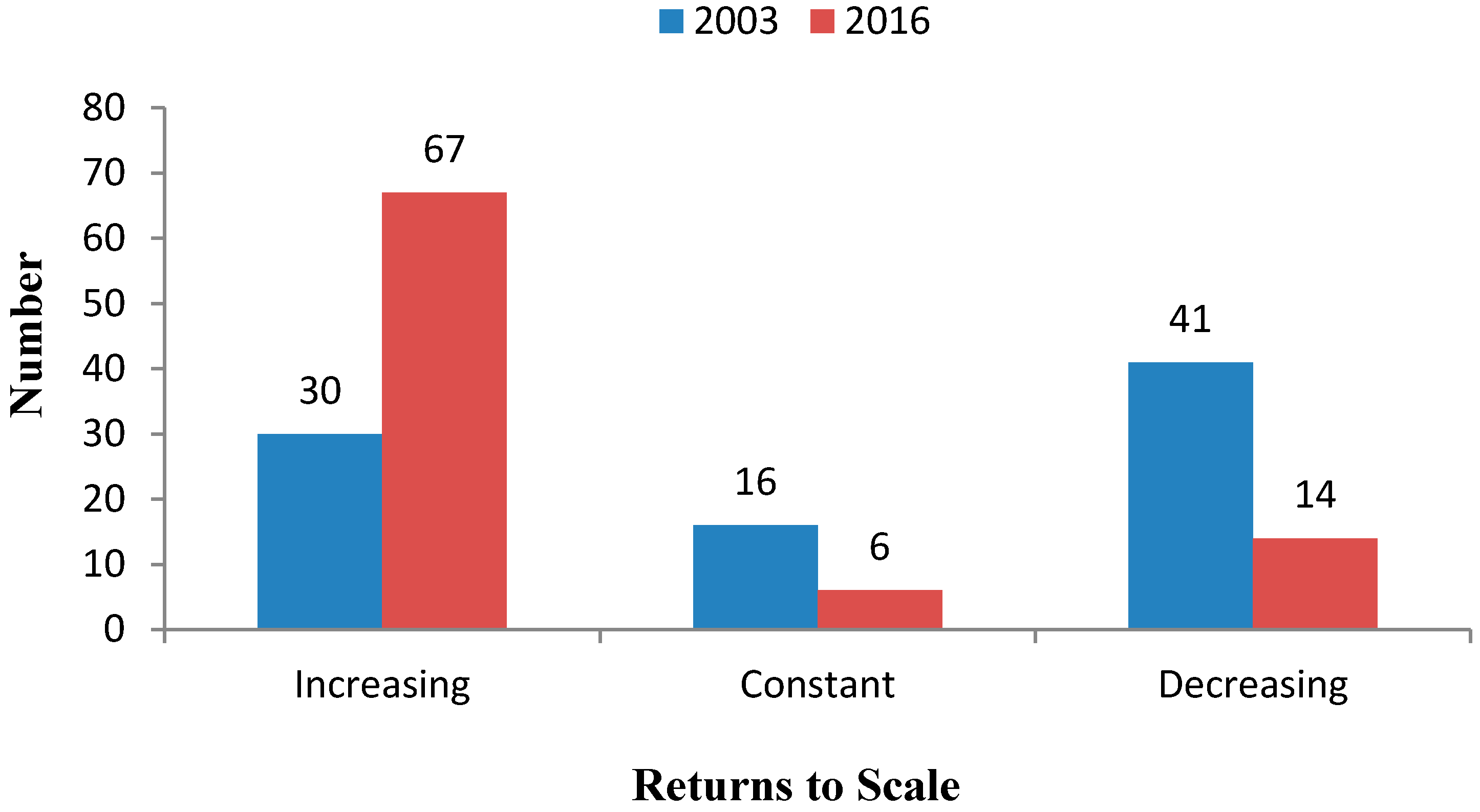

5.1. Analysis of the Eco-Efficiency of SOFEs from the Time Dimension

5.2. Analysis of the Eco-Efficiency of SOFEs from the Spatial Dimension

6. Conclusions and Policy Implications

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SBM-DEA | Data envelopment analysis |

| SDG | Sustainable Development Goal |

| SOFE | State-owned forestry enterprise |

| SOFEs | State-owned forestry enterprises |

| IM | Inner Mongolia Forest Industry Group |

| JL | China Jilin Forest Industry Group |

| CBM | Changbai Mountain Forest Industry Group |

| LJ | Longjiang Forest Enterprise Industry Group |

| GK | Greater Khingan Forest Industry Group |

| NFPP | Natural Forest Protection Project |

Appendix A

| Reference | Target | Method | Indicator | Result |

|---|---|---|---|---|

| [10] | Japan’s forestry industry | Luenberger-DEA | Inputs: forestry machinery, labor, forest roads, forest area and rate of man-made forests Outputs: volume | The average annual growth rate of TFP was 6.4% from 1975 to 2000. |

| [11] | Chinese forestry industry | Malmquist-DEA | Inputs: capital, labor, forestland Outputs: total output value of forestry industry | The average annual growth rate of TFP was 4.8% from 1995 to 2011. |

| [8] | Chinese forestry industry | SFA | Inputs: labor, capital Outputs: the gross output of the forestry industry and afforestation area | The average technical efficiency changed from 0.3 in 1998 to 0.7 in 2014. |

| [12] | Chinese forestry industry | Malmquist-DEA | Inputs: land, investment, labor Outputs: forest stock volume and gross output value | TFP held up to growth on the whole. |

| [13] | The sawmilling industry of the USA’s Pacific Northwest | SFA | Inputs: saw logs, 8-hour capacity, and labor et al. Outputs: lumber output | TFP growth was strong from 1968 to 2002. |

| [14] | Chinese forestry industry | SFA | Inputs: fixed-asset investment, employee number, and forest area Outputs: forestry output | Technical efficiency in the six Northern provinces declined. |

| [15] | The USA’s sawmill and planing mill industry | The chain-type Fisher index | Inputs: labor, energy, wood, and capital Outputs: lumber | TFP growth increased by 43% from 1947 to 2000. |

| [16] | The sawmill and wood preservation industries of Canada and the USA | The Tornqvist-Theil index | Inputs: worker, capital, and energy et al. Outputs: softwood lumber, hardwood lumber, and wood chips et al. | The TFP of the two countries grew at an average annual compound rate of 1.11% and 0.61% respectively, between 1958 and 2003. |

| [17] | The Canadian sawmilling industry | A translog multilateral index number model | Inputs: capital stock, labour, energy, and raw material et al. Outputs: lumber, shakes and shingles, byproducts | The average annual growth rate of the TFP was 2% from 1961 to 2000. |

| [18] | The pulp and paper industry in Myanmar | Eco-efficiency ratio | Inputs: material consumption, energy consumption, and total waste output et al. Outputs: net sales | Eco-efficiency decreased between 2002 and 2004, but increased in 2005. |

| [19] | The pulp and paper industry in OECD countries | Malmquist-DEA | Inputs: wood pulp capacity, paper and paperboard capacity, number of employees Outputs: wood pulp, paper and paperboard | The TFP growth of the countries therein ranged from 0.9% in Switzerland to 2.4% in Japan. |

| [20] | China’s pulp and paper industry | SBM-DEA | Inputs: water consumption Outputs: wastewater emissions, COD, ammonia nitrogen, and total industrial output value | The industry’s productivity was dominated by high growth efficiency between 2010 and 2013. |

| [2] | Chinese forestry industry | DEA and Malmquist | Inputs: land, labor, investment and energy Outputs: wastewater discharge, chemical oxygen demand of wastewater, and SO2 emission et al. | Eco-efficiency averaged 0.912, compared with the average ecological TFP index of 1.307 from 2004 to 2013. |

| [3] | 15 Chinese provincial forestry industries | DEA | Inputs: energy, timber, industrial wastewater discharge et al. Outputs: production value | The secondary forestry industry’s eco-efficiency was not high, but rising from 2004–2013. |

| [21] | The regional Canadian pulp and paper industries | An input distance function | Inputs: energy, virgin fiber, and non-wood materials et al. Outputs: pulp and paper output, two water pollutant outputs (BOD and TSS) | During 1970–1993, annual average technical efficiency was 0.86 and the average annual TFP growth rate was −0.26%. |

| Reference | Target | Method | Indicator | Result |

|---|---|---|---|---|

| [22] | 50 SOFEs in Northeast China | DEA | Inputs: labour, fixed capital and floating capital Outputs: output value | TFP was reduced by 5% between 1992 and 2001. |

| [23] | 135 SOFEs in China | Malmquist-DEA | Inputs: fixed investment fund, number of on-the-job workers, and total costs Outputs: Sales, total output | From 2001–2011, the TFP increased by 19.8%. |

| [24] | Pulp, paper, and board mills in Finland and Sweden | Economic/environmental ratio | Environmental impact: liquid effluents, atmospheric emissions, and solid-waste Outputs: value added | The Swedish mills were more eco-efficient than the Finnish ones from 1993 to 1996. |

| [25] | 32 paper mills along the Huai River in China | DEA | Inputs: labor, capital Outputs: paper products, biochemical oxygen demand | There was a considerable difference in eco-efficiency when undesirable outputs were considered, compared to when they were not. |

| [27] | Four forestry administrations in Heilongjiang province in China | DEA | Inputs: energy consumption, the number of registered workers, and industrial wastewater et al. Outputs: output value | The eco-efficiency of Mudanjiang and Yichun was equal to 1, whereas for Hejiang and Songhuajiang it was less than 1. |

| [28] | Forest companies in Finland | The Delphi method | Inputs: water consumption, energy consumption and, raw material consumption Outputs: sales, air emissions, and water emissions et al. | The economic performance of eco-efficiency should be measured using the ‘value added’ indicator; in environmental performance, however, they preferred using environmental impact or emissions groups. |

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sustainabledevelopment.un.org/content/documents/21252030%20Agenda%20for%20Sustainable%20Development%20web.pdf (accessed on 23 June 2018).

- Chen, K.; Li, X.T.; Piao, H.L. Analysis on forestry eco-efficiency and ecological productivity measure in China. Issues For. Econ. 2016, 36, 115–120. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, Y.M.; Yin, S.H. Empirical analyses on forestry industry eco-efficiency—Based on fifteen provinces. For. Econ. 2016, 28, 36–40. (In Chinese) [Google Scholar] [CrossRef]

- Zheng, S.Q.; Yu, J.H. Evaluation on efficiency of technology innovation in paper industry: Using DEA-Malmquist index. Issues For. Econ. 2012, 32, 329–332. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, L. Strategic adjustment of state-owned forestry industry enterprises. For. Econ. 1998, 4, 29–35. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, X.M.; Gong, P.C.; Bostedt, G.; Xu, J. Impacts of policy measures on the development of state-owned forests in northeast China: theoretical results and empirical evidence. Environ. Dev. Econ. 2013, 19, 74–91. [Google Scholar] [CrossRef]

- State Forestry Administration. China Forestry Statistical Yearbook 2016; Chinese Forestry Press: Beijing, China, 2017; pp. 70–71. ISBN 978-7-5038-9241-7.

- Chen, J.D.; Wu, Y.Y.; Song, M.L.; Zhu, Z. Stochastic frontier analysis of productive efficiency in China’s forestry industry. J. For. Econ. 2017, 28, 87–95. [Google Scholar] [CrossRef]

- Zhang, Y.Q. Costs of plans vs costs of markets: reforms in China’s state-owned forest management. Dev. Policy Rev. 2000, 18, 285–306. [Google Scholar] [CrossRef]

- Managi, S. Productivity measures and effects from subsidies and trade: An empirical analysis for Japan’s forestry. Appl. Econ. 2010, 42, 3871–3883. [Google Scholar] [CrossRef]

- Chen, X.L.; Jiang, X.M. A study on total factor productivity of Chinese forestry. For. Econ. 2014, 36, 75–82. [Google Scholar] [CrossRef]

- Jiang, Y.; Guan, S.Y. Space-time differences and spatial convergence of forestry total factor productivity in China. Issues For. Econ. 2017, 37, 86–91. [Google Scholar] [CrossRef]

- Helvoigt, T.L.; Adams, D.M. A stochastic frontier analysis of technical progress, efficiency change and productivity growth in the Pacific Northwest sawmill industry. For. Policy Econ. 2009, 11, 280–287. [Google Scholar] [CrossRef]

- Xiong, L.C.; Wang, F.T.; Cheng, B.D.; Yu, C. Identifying factors influencing the forestry production efficiency in Northwest China. Resour. Conserv. Recycl. 2018, 130, 12–19. [Google Scholar] [CrossRef]

- Ahn, S.; Abt, R.C. Productivity measurement with improved index numbers: Application to the sawmills and planning mills industry of the U.S.: 1947–2000. For. Policy Econ. 2006, 8, 323–335. [Google Scholar] [CrossRef]

- Zhang, D.W.; Nagubadi, R.V. Total factor productivity growth in the sawmill and wood preservation industry in the United States and Canada: A comparative study. For. Sci. 2006, 52, 511–521. [Google Scholar]

- Ghebremichael, A.; Karen, P.W. Effects of tax incentives on long-run capital formation and total factor productivity growth in the Canadian sawmilling industry. For. Policy Econ. 2009, 11, 85–94. [Google Scholar] [CrossRef]

- Thant, M.M.; Charmondusit, K. Eco-efficiency assessment of pulp and paper industry in Myanmar. Clean Technol. Environ. Policy 2010, 12, 427–439. [Google Scholar] [CrossRef]

- Hseu, J.S.; Shang, J.K. Productivity changes of pulp and paper industry in OECD countries, 1991–2000: A non-parametric Malmquist approach. For. Policy Econ. 2005, 7, 411–422. [Google Scholar] [CrossRef]

- Yu, C.; Shi, L.; Wang, Y.; Chang, Y.; Cheng, B. The eco-efficiency of pulp and paper industry in China: An assessment based on slacks-based measure and Malmquist-Luenberger index. J. Clean. Prod. 2016, 127, 511–521. [Google Scholar] [CrossRef]

- Hailu, A. Pollution abatement and productivity performance of regional Canadian pulp and paper industries. J. For. Econ. 2003, 9, 5–25. [Google Scholar] [CrossRef]

- Liu, C.; Yu, F.W. Efficiency analysis of the Northeast national forest enterprise-DEA approach. Rev. Ind. Econ. 2006, 5, 107–121. (In Chinese) [Google Scholar]

- Yang, H.Q.; Yuan, T.; Zhang, X.B.; Li, S. A decade trend of total factor productivity of key state-owned forestry enterprises in China. Forests 2016, 7, 97. [Google Scholar] [CrossRef]

- Helminen, R.R. Developing tangible measures for eco-efficiency: The case of the Finnish and Swedish pulp and paper industry. Bus. Strategy Environ. 2000, 9, 196–2010. [Google Scholar] [CrossRef]

- Hua, Z.S.; Bian, Y.W.; Liang, L. Eco-efficiency analysis of paper mills along the Huai River: An extended DEA approach. Omega 2007, 35, 578–587. [Google Scholar] [CrossRef]

- Koskela, M.; Vehmas, J. Defining eco-efficiency: A case study on the Finnish forest industry. Bus. Strategy Environ. 2012, 21, 546–566. [Google Scholar] [CrossRef]

- Zhang, Y.; Wan, Z.F.; Wen, W. Accounting of the Heilongjiang state-owned forest area eco-efficiency based on DEA. Issues For. Econ. 2014, 34, 281–284. [Google Scholar] [CrossRef]

- Koskela, M. Measuring eco-efficiency in the Finnish forest industry using public data. J Clean. Prod. 2015, 98, 316–327. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhode, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Tone, K. Advances in DEA Theory and Applications: With Extensions to Forecasting Models; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2017; pp. 315–330. ISBN 9781118946701. Available online: https://www.wiley.com/en-gb/Advances+in+DEA+Theory+and+Applications%3A+With+Extensions+to+Forecasting+Models-p-9781118945629 (accessed on 9 May 2018).

- Verfaillie, H.A.; Bidwell, R. Measuring Eco-Efficiency: A Guide to Reporting Company Performance; World Business Council for Sustainable Development (WBCSD): Geneva, Switzerland, 2000; Available online: http://www.gdrc.org/sustbiz/measuring.pdf (accessed on 23 June 2018).

| Name | Contents |

|---|---|

| The primary industry | Breeding of trees, afforestation and forest management, wood and bamboo lumbering, cultivation and collection of non-wood forest products, etc. |

| The secondary industry | Wood processing, wood-based panel manufacturing, wood furniture manufacturing, paper products manufacturing, etc. |

| The tertiary industry | Forestry production services, forestry tourism services, forestry ecological services |

| Item | Indicator | Unit | Obs. | Mean | Std. Dev. | Min. | Max. |

|---|---|---|---|---|---|---|---|

| Input indicators | land | thousand hm2 | 1218 | 343.966 | 216.489 | 71.316 | 966.110 |

| capital | RMB million | 1218 | 114.395 | 108.792 | 4.894 | 1698.573 | |

| labor | people | 1218 | 4850.885 | 2325.268 | 684.000 | 21,580.000 | |

| Desirable outputs | total output | RMB million | 1218 | 449.787 | 339.734 | 25.670 | 1955.000 |

| sale | RMB million | 1218 | 288.199 | 416.226 | 0.075 | 5622.822 | |

| Undesirable outputs | effluent | t | 1218 | 61,324.235 | 64,608.191 | 0.337 | 364,888.388 |

| exhaust | thousand m3 | 1218 | 57,639.578 | 60,726.218 | 0.317 | 342964.127 | |

| solid-waste | t | 1218 | 11.687 | 12.313 | 0.000 | 69.542 |

| Name | Eco-Efficiency | Pure-Technical Efficiency | Scale Efficiency | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2003 | 2015 | 2016 | 2003–2016 | 2003 | 2015 | 2016 | 2003–2016 | 2003 | 2015 | 2016 | 2003–2016 | |

| IM | 0.711 | 0.309 | 0.039 | 0.467 | 0.805 | 0.501 | 0.157 | 0.595 | 0.896 | 0.685 | 0.656 | 0.807 |

| JL | 0.845 | 0.760 | 0.482 | 0.699 | 0.876 | 0.867 | 0.767 | 0.835 | 0.964 | 0.884 | 0.682 | 0.849 |

| CBM | 0.703 | 0.469 | 0.296 | 0.570 | 0.787 | 0.563 | 0.366 | 0.700 | 0.909 | 0.848 | 0.788 | 0.832 |

| LJ | 0.769 | 0.553 | 0.506 | 0.604 | 0.823 | 0.661 | 0.595 | 0.674 | 0.931 | 0.868 | 0.892 | 0.903 |

| GK | 0.769 | 0.612 | 0.452 | 0.581 | 0.862 | 0.629 | 0.515 | 0.641 | 0.894 | 0.973 | 0.901 | 0.913 |

| Mean | 0.756 | 0.516 | 0.372 | 0.576 | 0.824 | 0.630 | 0.480 | 0.671 | 0.920 | 0.839 | 0.810 | 0.870 |

| CV | 0.231 | 0.539 | 0.781 | 0.281 | 0.213 | 0.456 | 0.716 | 0.263 | 0.112 | 0.260 | 0.291 | 0.143 |

| Range | Grade | 2003 | 2016 | 2003–2016 | |||

|---|---|---|---|---|---|---|---|

| Number | Percent | Number | Percent | Number | Percent | ||

| EE = 1 | DEA Efficient | 16 | 18.39% | 6 | 6.90% | 2 | 2.30% |

| 0.75 ≤ EE < 1 | High Level | 23 | 26.44% | 1 | 1.15% | 11 | 12.64% |

| 0.5≤ EE < 0.75 | Medium Level | 43 | 49.43% | 23 | 26.44% | 45 | 51.72% |

| EE < 0.5 | Low Level | 5 | 5.75% | 57 | 65.52% | 29 | 33.33% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, Y.; Liu, Z.; Ning, Z.; Zhang, H. Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China. Forests 2018, 9, 455. https://doi.org/10.3390/f9080455

Ning Y, Liu Z, Ning Z, Zhang H. Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China. Forests. 2018; 9(8):455. https://doi.org/10.3390/f9080455

Chicago/Turabian StyleNing, Youliang, Zhen Liu, Zekui Ning, and Han Zhang. 2018. "Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China" Forests 9, no. 8: 455. https://doi.org/10.3390/f9080455

APA StyleNing, Y., Liu, Z., Ning, Z., & Zhang, H. (2018). Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China. Forests, 9(8), 455. https://doi.org/10.3390/f9080455