2. Materials and Methods

Three large Swedish forest owning companies, all of which use an internal planning hierarchy, participated in this study (Holmen, SCA and Sveaskog). Email messages were sent to one person in each company, inviting them to participate. These initial contacts graciously gave the authors the e-mail addresses of a selected group of respondents at each company. The members of these groups included forest planning managers (who are responsible for forest planning at the regional level and/or selecting compartments for the medium-term forest plan), forest planners (who are responsible for measuring and delineating compartments and may also decide which compartments will be included in subsequent planning processes), and harvest managers (who are responsible for scheduling harvesting operations, i.e., creating short-term forest plans). The contact person also sent e-mails to the respondents in each company requesting that they participate in the survey.

In total, 318 individuals from the three companies were contacted by e-mail and given personal links to a web-based questionnaire that was set up using the Netigate survey tool. The respondents’ answers were anonymised; no personal information on the respondents was collected, so it was not possible to trace an individual’s responses back to a specific company or region. This was judged as necessary to avoid non-answer as some of the questions being asked might be regarded by the respondents as touching upon internal business policies not to be revealed to outsiders. However, the design of the questionnaire made it possible to distinguish between the responses of forest planners (including forest planning managers) and harvesting managers. The respondents were given four days in September 2012 to complete the survey (Tuesday–Friday). After two days, a reminder email was automatically sent to individuals who had not completed the survey at that point (The survey tool was able to identify respondents who had not yet answered the survey). At the end of the four days, 159 responses had been received, giving a response rate of 50%. Of the respondents, 62% were forest planners and 35% were harvest managers. Six respondents (4%) were neither forest planners nor harvest managers, and their responses were excluded from the analysis. Nine e-mail responses were received from people who were away from work when the survey was conducted. Each company was asked to provide complete e-mail lists, i.e., lists that contained the email addresses of every one of their employees in the relevant positions. Unfortunately, the lists that were received included the addresses of some employees who worked in other positions. We were unable to determine what proportion of the non-respondents fell into this category. It is also possible that some individuals who work as forest planners/harvest managers were omitted from the lists. The emails that provided the link to the survey stated its purpose clearly and were written with the aim of clearly stating who the desired respondents were and encouraging their participation. It is possible that this may have decreased the rate of response from people who do not work as forest managers or harvest managers but were mistakenly contacted. These factors make it difficult to make any statements about the non-respondents with confidence.

The first questions of the survey were designed to determine whether the respondent’s duties were most like those of a harvest manager or a forest planner. Depending on their answers, the respondent was then directed to questions appropriate for their apparent occupation. Both sets of questions had three sections: one on the short-term forest plan, one on the medium-term forest plan, and one on the TB. The survey included open-ended questions, close-ended questions, and ranking questions. Open-ended questions were used when we wanted to obtain a fundamental understanding of the respondents’ opinion and to avoid bias by giving specific answer opportunities. The majority of questions were however closed-ended questions with specific options to choose between and ranking questions. Both type of questions invited the respondents to comment. To avoid confusion when asking about opinions, all ranking questions consisted of statements to which the respondent could choose one of four responses, ranging from “do not agree at all” to “totally agree”. An even-numbered scale was chosen to avoid neutral answers. Most of the questions were formulated in such a way that the answers were comparable between the two groups. Before sending the survey to the actual respondents, the survey was tested by sending it to several recently retired harvest managers and forest planners to check on the content, wording, alternatives provided in the close-ended questions and comprehension of the scale used. Very few participants did not answer the complete list of questions. When calculating the relative response rate for the options the number of answers for each question was used.

Our analysis focused on four major issues: the selection of compartments that enter and exit the TB, the size and composition of the TB, the information within the TB, and the communication within the organization during work relating to the TB. The answers to open-ended questions were grouped according to overarching themes and specific interesting responses are quoted in their entirety and presented to illustrate more general points.

In connection to harvesting, both production and delivery plans are common terms used by harvest managers and planners. In this study it was seen not relevant to distinguish between these plans and for consistency in terminology these plans are both referred to as delivery plans in this paper. However, as the terms are used in the companies, both words have been used in the questionnaire and they both appear in

Table 1 as separate results.

Table 1.

The most important factors to consider when making short-term forest plans as identified by harvest managers, and the factors that planners believe forest managers should consider to be most important when making short-termplans.

Table 1.

The most important factors to consider when making short-term forest plans as identified by harvest managers, and the factors that planners believe forest managers should consider to be most important when making short-termplans.

| | Harvest managers | (%) | | Planners | (%) |

|---|

| 1 | Delivery plan | 63 | 1 | Delivery plan | 66 |

| 2 | Type of machinery | 43 | 2 | TB | 53 |

| 3 | Season | 27 | 3 | Changes at customers/at mills | 24 |

| 4 | Production plan | 24 | 4 | Production plan | 23 |

| 5 | TB | 22 | 5 | Season | 20 |

| … | | | … | | |

| 8 | Changes in the demands of customers and mills | 18 | 8 | Types of machinery available | 13 |

3. Results

3.1. General Introduction

The harvest managers were asked to specify which factors they considered to be most important in the creation of short-term forest plans. The planners were asked to specify which factors they thought should be given the greatest weight by harvest managers when making short-term forest plans (

Table 1). In this case, the respondents were asked to choose from a range of fixed options, one of which was “other”.

Both groups considered the delivery plan to be the most important factor. The planners considered the TB to be the second most important factor, whereas the harvest managers considered it to be only the fifth most important factor.

One harvest manager added the following comment: “the tree species distribution and the average stem diameter in the compartment are the most important factors to consider when trying to provide timber that will satisfy the mills’ demands. After that, one must consider the condition of the roads and the ground at each site in order to estimate when we will be able to deliver the timber to the mills”. A planner added: “In order to get good results in the forest, it is important to ensure that the right machinery and people are available at the right time, to keep track of ditches, and to use harvesting volumes that are realistic in relation to growth and timber sales”.

Harvest managers and planners identified software and GIS programs as the typical way to store TBs. Approximately two third of the harvest managers said the TB was stored in a specific software and one third that it was stored in the software used for most things. The planners gave the opposite relation between these two software versions, approximately one third said a specific software and two third the GIS-software used for most things. This seems not to be totally adapted by all organizations since one harvest manager wrote: “It is stored in the GIS software. However, because the software does not fully support out workflow, we also store the data in binders”.

3.2. The Size and Composition of the TB

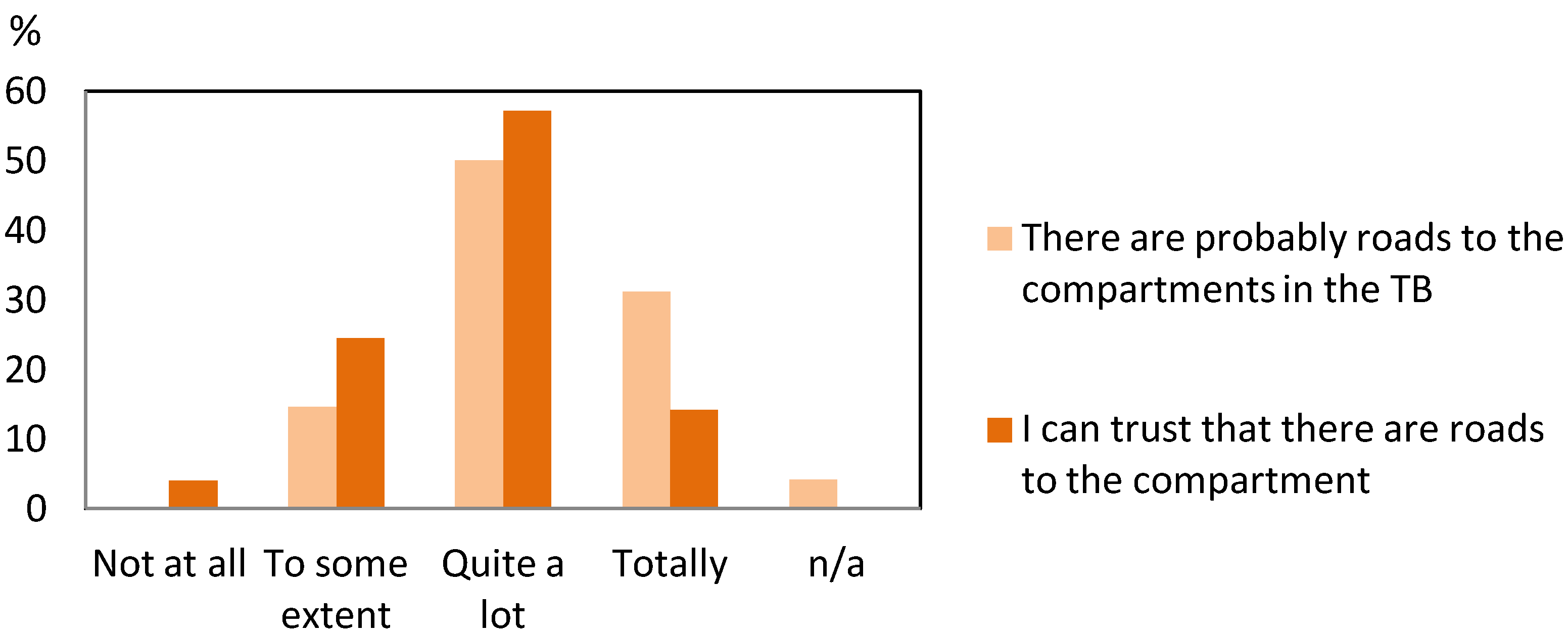

The groups were asked about their perceptions of the size of the TB and how big they would like the TB to be.

Table 2 shows that a considerable share of the harvest managers and planners do not concept the size of the TB in the same way.

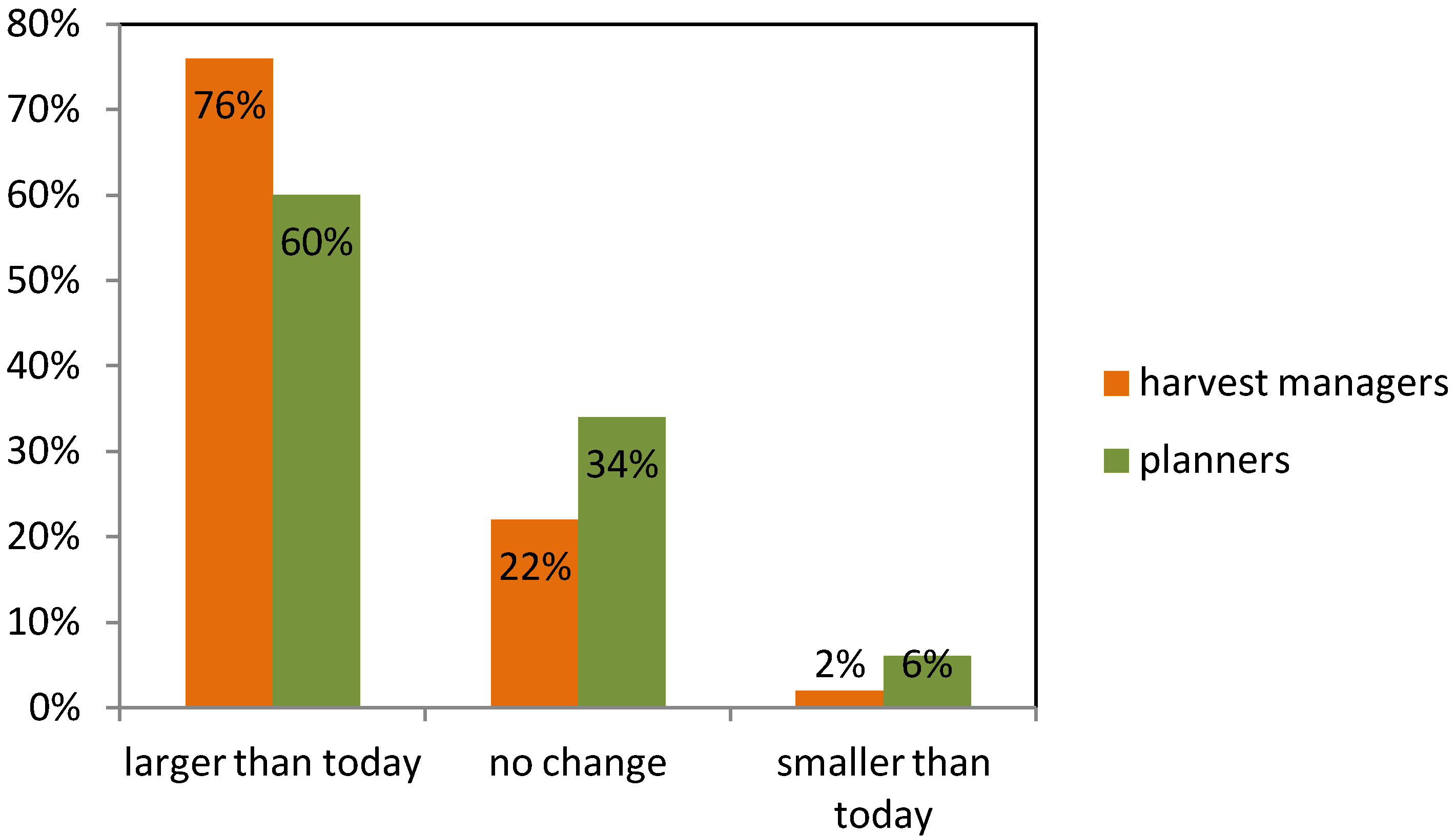

Figure 3 shows the preferred size of the TB compared to the size it is currently believed to have for both groups. It is clear that a majority of both groups would like to have a larger TB.

Table 2.

The perceived size of the tract bank (TB).

Table 2.

The perceived size of the tract bank (TB).

| What is the size of the real TB? |

|---|

| annual cut volume | harvest manager (%) | planners (%) |

|---|

| Smaller than 1,5 | 41 | 21 |

| 1,5 | 43 | 41 |

| Larger than 1,5 | 16 | 32 |

| don’t know | | 6 |

Figure 3.

Desired changes in the size of the TB

Figure 3.

Desired changes in the size of the TB

The open questions allowed both groups to provide further insights into their perception of the TB’s size and composition. Some of their responses are presented in full below. The size of the TB is often given as a measure for how usable it is. The size is often given in units of “years” which is short for “the total volume to be harvested during a year” or the “annual cut volume”. Both harvest managers and planners had comments about the size of the TB. Some of the planners expressed opinions such as: “[The ideal TB size] really depends on the geography and ground conditions within the TB.Areas with better ground conditions could get by with a smaller TB”. Another planner stated that the size of the TB affected the quality of the work that could be achieved: “It is easier to maintain a high quality of operative planning when the TB is sufficiently large” (Operative planning here, is the work done by planners to prepare a compartment for admission into the TB). One planner was unsure of the TB’s true size: “I am not sure how big it really is”. One harvest manager expressed concerns about the size of the TB: “Of course, the TB plays a central role because it is effectively our stock. Obviously, it is not optimal from an overall perspective to have a TB that is too large”.

The respondents also made comments about the composition of the TB in terms of the volume that is actually available for use, not just the size of the TB. One planner said: “How is it the case that the TB has a size of 2 years if there are compartments that have to be replanned many times because the notification of regeneration felling‘expires’ both once and twice? They are not being harvested”. (Notification of regeneration felling concerns the permission to perform aregeneration harvesting operation given by the Swedish Forest Agency. It is usually valid for three years). Another planner wrote: “The contents of the TB must be harmonized with the notifications of regeneration felling. If the TB becomes too large, there is a risk that compartments may be harvested after the notification period has expired (3 years)” and “there is no point in planning for small satellite compartments; they don’t get harvested”. A harvest manager expressed similar opinions: “If you have a larger TB, more compartments will be left unharvested in the TB. Purchased volumes are prioritized. Some compartments are more or less never right for harvesting”.

Some respondents commented on the mixture of different compartments in the TB and their relative quality. The importance of some qualities differs during the year. Some planners expressed strong opinions about the balance of the TB “It is not just the quantity (i.e., the area) of the TB that matters: the quality is more important. You have to have a well balanced bank with compartments that are useful for all seasons and ground conditions” and “It does not need to be very large as long as it has the required qualities”. Another planner said that “size alone does not necessarily mean that it is possible to harvest”. Several harvest managers agreed with these planners: “The TB may provide 3 annual cuts, but what is important is how much you have per season” and “We often have imbalances between the number of compartments within the TB that have acceptable ground conditions and passable roads in each season. In the spring, and also in the fall when it’s wet, there aren’t many compartments that can be harvested, which reduces the scope for planning” and “I have a lot of compartments for the winter and summer, but there is often a lack of harvestable compartments during the spring and fall. I don’t often have problems with the company forests, but there are occasionally troubles with purchased compartments. It can be very hard to find suitable assortments in some cases (e.g. spruce during springtime)”. At least one of the participating organizations uses separate TBs for thinning and final felling, and for their own forests and purchased volumes. These different TBs can differ in the balance and composition of their compartments. One harvest manager noted that “the size of the TB isdifferent for thinning and final felling” and “We have a very low stock of final felling compartments but have far more thinning compartments—approximately two years’ worth”.

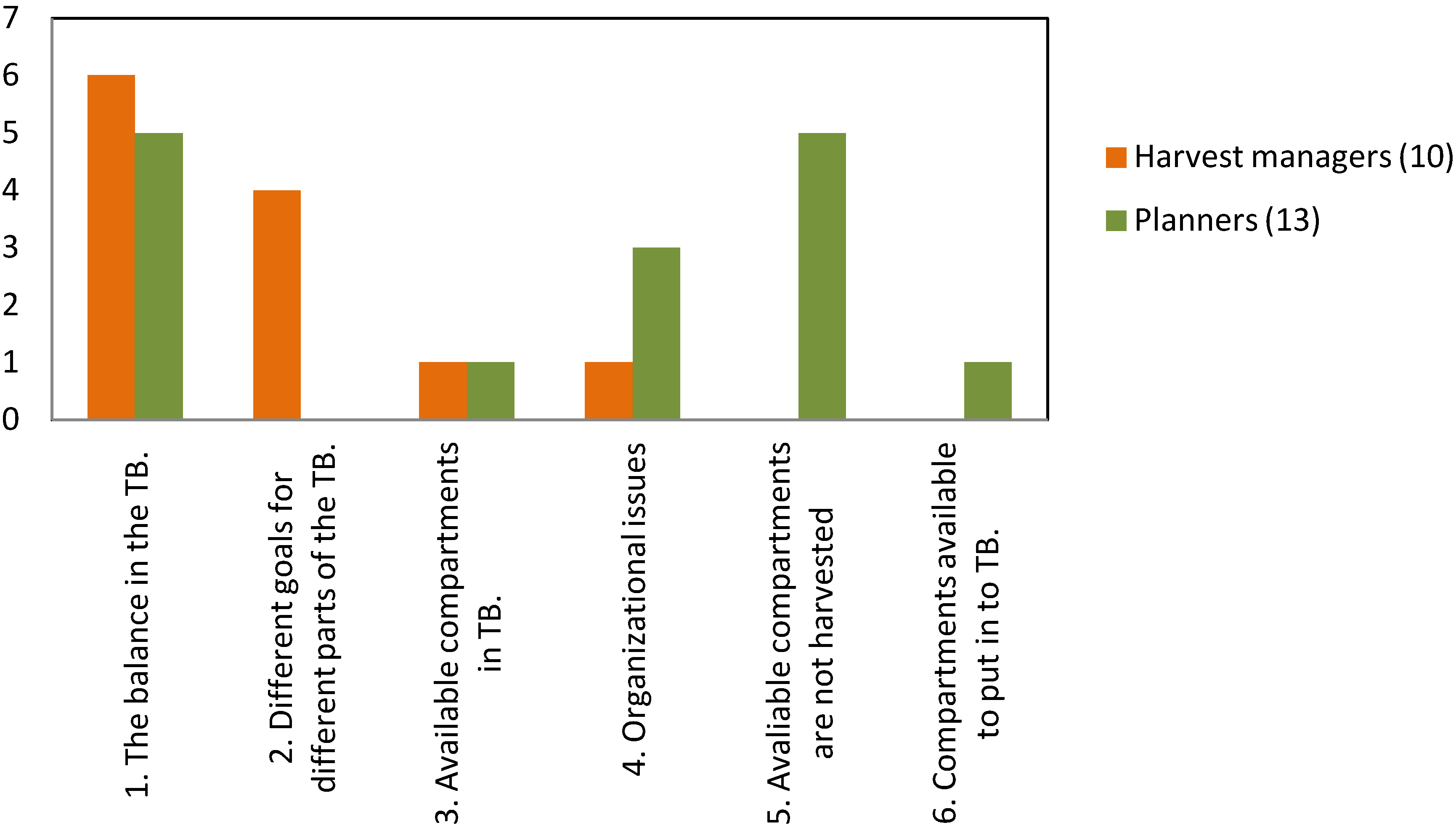

The respondents were given the opportunity to provide open-ended comments about the TB.10 harvest managers and 13 planners did so. Their answers were grouped into six categories based on the factors they mentioned; some were placed in more than one category (

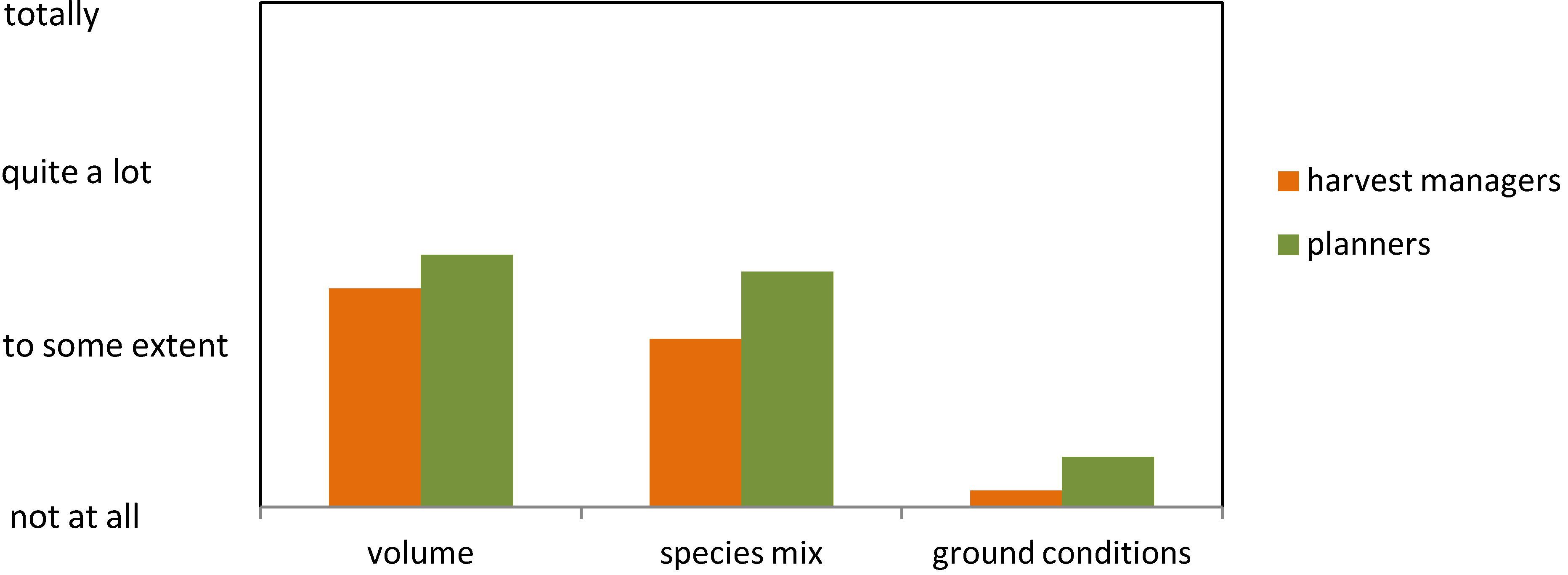

Figure 4). The results show that the view of the TB can differ between the two groups. In general, the harvest managers focused on issues with the compartments within the TB, and the planners primarily focused on which compartments that are in the TB. The planners also mentioned that compartments can remain in the TB for a very long time without being harvested.

Figure 4.

Factors mentioned in open-ended comments about the size of the TB.

Figure 4.

Factors mentioned in open-ended comments about the size of the TB.

3.5. The Selection of Compartments that Enter or Exit the TB

The harvest managers were asked whether they ever select compartments for the short-term forest plan that are not in the TB. The specific statement they were asked to assess was “sometimes I have to schedule compartments in the short-term forest plan that are not in the TB”; 39% (19) of the managers did not agree with this at all, 35% (17) agreed to some extent, 8% (4) agreed quite a lot, 8% (4) agreed totally, and 10% (5) did not respond or said the statement was inapplicable to their work.

The TB is the last stage of the medium-term plan. In the planning system, the medium-term plan is supposed to be the source of the compartments that go into the TB. In order to provide a satisfactory foundation for the establishment of the TB, the medium-term plan must satisfy some essential criteria. One of the planners’ main desires was that the medium-term plan should be presented in a straightforward way, preferably via GIS. When asked about how he/she would like the TB to be laid out, one planner stated that “it should be as exact as possible and should take road systems, ground conditions, tree species and assortments into account. Its details should be checked and updated after the planning seasons and it should be easily viewed in a GIS software package”. Another wrote that “it should be easy to visualize the TB geographically and to see the selected volumes in the GIS software package. It should also be better connected to the national road database”. Some organizations seem to have a method for storing the medium-term plan that is well suited to the planners’ workflow;one wrote that he/she was content with the employer’s current system in which “compartments that have been selected and prioritized are identified in the GIS-software along with their designated year for harvesting”. One planner stated that compartments are sometimes admitted into the TB without having been accounted for in the medium-term plan: “Extra volumes that are taken are never compensated for in other years. These days it is difficult to maintain coordination between purchased volumes and volumes sourced from our own forests because the relative sizes of these volumes are more important than their coordination”.

The planners also wanted the medium-term plan to be balanced in the sense that it should contain compartments with different attributes in the same way that the TB should be balanced so as to mirror the composition of the forests. One planner noted that ideally, the TB would contain “a geographically even and concentrated selection of assortments with an even distribution between thinning and final felling”. Another planner highlighted the importance of the forest planning hierarchy: “The plan must be designed to allow for long-term sustainable forest management in a way that accounts for environmental values, economic factors, and the company’s strategy”.

The planners were also interested in the information within the medium term plan because they use it in their work on the TB. Some of the planners commented on this subject: “The medium-term plan provides helpful support in the planning work [inventory, etc]. It should contain information on the approximate volume in each compartment, as well as data on road and ground conditions and an order of priority”. Another said that “the stand information is more reliable when there is time to go out and visit the sites. This is especially true for the site index; if we are dealing with a spring compartment, it should not be visited during the winter. Unfortunately, this is not always the case at present; a lot of time is wasted because of relocations”. A third planner highlighted a range of factors that should be included in the medium-term plan: “The priority assigned to different compartments. The accessibility of the compartments for both winter and summer harvests. The contents of the compartments. Longer time horizons of accessible compartments after consultations with different stakeholders”. One planner provided an alternative perspective on working with medium-term forest plans: “There is nothing wrong with the plans. Unfortunately, however, the demand from the mills does not always match up with the composition of the forest”.

Some comments revealed a lack of faith in the harvest estimates contained in the long-term forest plans, and thus in the output of the subsequent elements of the planning system: “We start from the long term harvest estimates for both final felling and thinning. I think that these are too optimistic for the long term cuttings”. Another noted that “it does not matter what your plan looks like if it is changing all the time, and the main reason for making it in the first place didn’t have anything to do with how the forest growths and looks. That is, plans are often made based on how somebody wants the forest to look in order to meet some financial goal or timber production objective rather than reality”. A third said that “it is hard to fill out the medium-term plan because there are too few available compartments compared to the long-term estimates,” and “planning small compartments is pointless—they don’t get harvested”. One harvest manager also identified a problem in the way plans are drawn up: “theproblem has been that we plan to reach our own goals. The qualitydecreases when the goals are so high that we have to take short cuts to reach them”.

4. Discussion

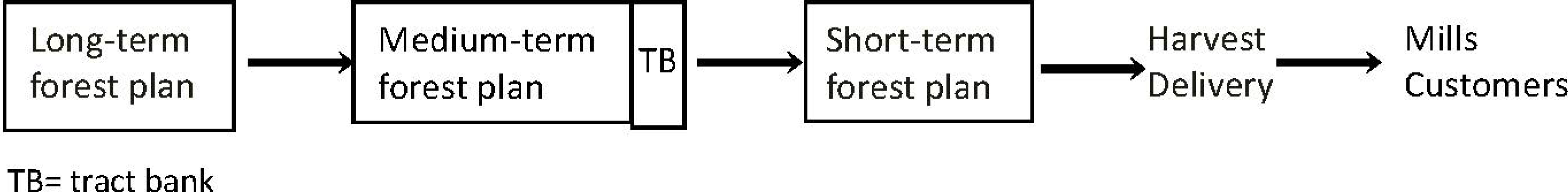

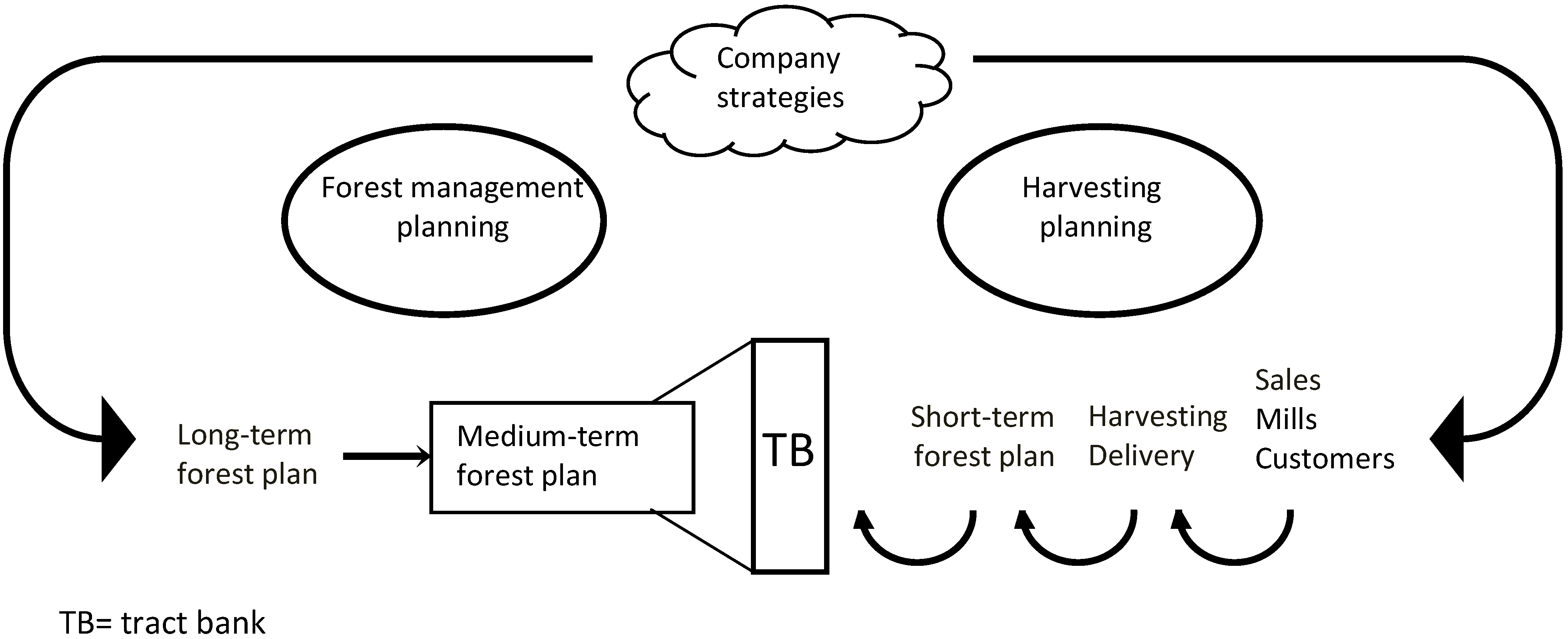

This study revealed that, although planners have a good understanding for the work of the harvest managers and vice versa, the planners’ view on work with the TB is based on the hierarchical forest planning system as depicted in

Figure 1 and that the harvest managers’ view is based on the sales strategy. It appears also that the sales strategy dominates the work with the TB, a majority of the planners and harvest managers maintain contact to ensure that the content of the TB matches delivery plans and a majority of harvest managers state that they have scheduled compartments that were not in the TB. This diversion of the intended forest planning strategy may in itself be justified, but should be regulated by the company’s management. The study also showed that the companies’ employees have doubts about the correctness of data and that these doubts may influence their way of working with the TB. This may affect the strategy pattern that unfolds and therefore the companies’ performances.

Our analysis focused on four basic issues: the size and composition of the TB, the information within the TB, the communication within the organization during work relating to the TB and finally the selection of compartments that enter and exit the TB. These issues were chosen because they show how the company’s knowledge of the forest is managed during the realization of its long- and short-term strategies.

The harvest managers and planners perceived the TB in different ways. Together with the selected quotations, the results shown in

Table 2 describe a situation in which the harvest managers and planners have different understandings of the size and composition of the TB. The TB contains compartments that the harvest managers consider to be unmanageable and which effectively reduce its size from their perspective. Such compartments are not taken into account by the harvest managers, which may be why 76% of the harvest managers want the TB to be larger than it is at present.In addition, the harvest managers use the TB to draw up schedules for their employees and entrepreneurs, and also need to be able to quickly respond to changes in customer demand. These factors may influence their desire for a larger TB that would provide a broader range of options for scheduling. According to

Figure 3, 60% of the planners also want a larger TB. However, their responses also indicate that they are more concerned than the harvest managers about the potential adverse consequences of making the TB too large. If the TB is excessively big, there is a risk that some compartments may never be harvested. The results obtained do not show why the planners would like the TB to be larger than it is at present, and our data cannot be used to make valid comparisons between the two groups’ perceptions of the current TBs or between the TB sizes that they would prefer.

The quoted statements relating to the size of the TB suggest that its absolute size is less important than its composition and balance. The respondents point out that the most important factor is that the TB should contain compartments that can be harvested in different seasons. This supports the conclusion that the balance between the properties of the compartments within the TB and the ground conditions within the compartments scheduled for immediate harvesting are more important than its absolute size.

These results raise questions regarding the extent to which harvest managers and planners are aware of the TB’s contents. Almost all of the respondents said that the TB is stored on computers, in a format that is read using specific software packages or with the GIS software used within the company. Some of the respondents said that their company also maintains a paper version of the TB or a version in Microsoft Excel. The way in which the TB is accessed and searched affects employees’ understanding of its contents and size, and therefore influences the way they use it. Alavi and Leidner (2001) point out that the source of competitive advantage is the application of knowledge rather than knowledge by itself. Importantly, the provision of suitable technology that supports the application of knowledge can influence the way in which it is used. The fact that both harvest managers and planners express a desire for a larger TB could be interpreted as a way of safeguarding their operations against unforeseen changes. The adoption of technology that would allow workers to rapidly search the TB and obtain an overview of its contents could enable more efficient management of its compartments. Around two thirds of the harvest managers reported that the TB was only accessible using a specific software package, while one third reported that it is maintained in the company’s GIS program. The opposite trend was reported by the planners. This could indicate that even in cases where the two groups use the same software to examine the TB, they have a different understanding of the programs used to access it and therefore analyze and explore the TB in different ways.

The quotations show that some or all of the organizations have separate TBs for their own forests and for purchased volumes. These different TBs seem to have different problems, with different levels of severity. In addition, the value of the different TBs is variable. The use of multiple TBs introduces a new dimension to the implementation of strategies within the organization. Purchased volumes, i.e., trees located on land owned by organizations outside the company, must also be planned and these two sources of products must be balanced according to the company’s goals. Each of these TBs must contain an appropriate mixture of compartments or otherwise complement one-another’s contents.

A majority of the harvest managers did not rely exclusively on the data in the TB, and a relatively large proportion of the planners were willing to tolerate deficiencies in the reliability of the data that they entered into the TB. Both groups had at least some tolerance for errors in the data. While some level of inaccuracy in the TB data may be acceptable within the industry, it may be useful to consider how a tacit acknowledgement that the TB data may be unreliable would affect its use by planners and harvest managers. It is possible that one response to unreliable data would be to seek more resources in reserve, in this case by requesting a larger TB. The choices within an organization are affected by its employees’ understanding of each other’s quality decisions. When the people who collect data are not the same as those who use it,

i.e., the decision makers, the quality of the data tends to suffer unless there is an awareness that it must be of high quality. If this awareness is lacking, workers within the organization often make decisions that might be optimal for their individual unit but is disadvantageous for the organization as a whole [

14,

15,

16]. In other words there is a risk that the acceptance of errors may limit the company’s ability to establish a competitive advantage. Both groups agreed that erroneous information relating to ground conditions in a compartment is less acceptable than errors regarding its mixture of tree species or the volume available for harvesting.

A comparison of two different statements about errors in the TB data on the volume and species mix with compartments suggests that the harvest managers do not appreciate the planners’ desire to ensure that the TB contains accurate information about the compartments. Except from the reasons that Storey

et al. [

16] give in their study, discussed in the previous paragraph, this may also be due to a lack of communication and trust between the two groups. However, it could also be due to a mismatch in how information is presented in the TB, or to organizational culture. The software might not be suitable to put in collectable data or to show needed data. This has not been part of the study and we can only speculate if this might be the case at some of the organizations.

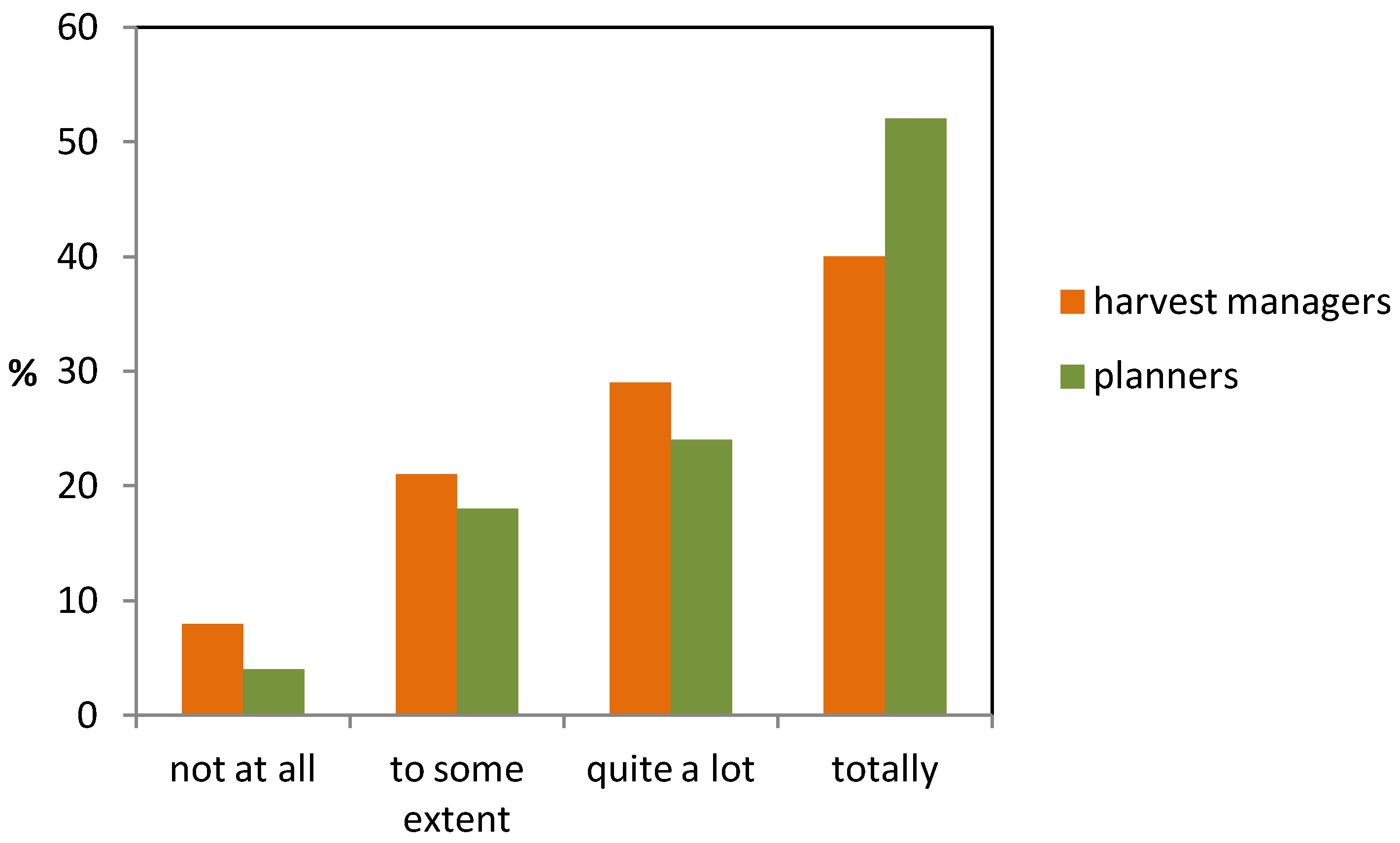

Table 3 showed that there is a high level of communication between the planners and the harvest managers regarding the contents of the TB. Harvest managers want to influence the content of the TB, while planners are keen to satisfy the harvest managers’ demands. However, planners believe that the content of the TB should be determined by the forest plan rather than delivery plans more strongly than do harvest managers.Planners also assume that the TB is an important factor in the way the harvest managers organize the harvesting operations (

Table 1). In contrast, the harvest managers regard the TB as a resource that is used to ensure that their delivery quotas are fulfilled and that if the compartments within the TB are insufficient for this purpose, it is acceptable to schedule compartments that are not in the TB for harvesting. In other words, harvest managers prioritize delivery plans over forest plans.

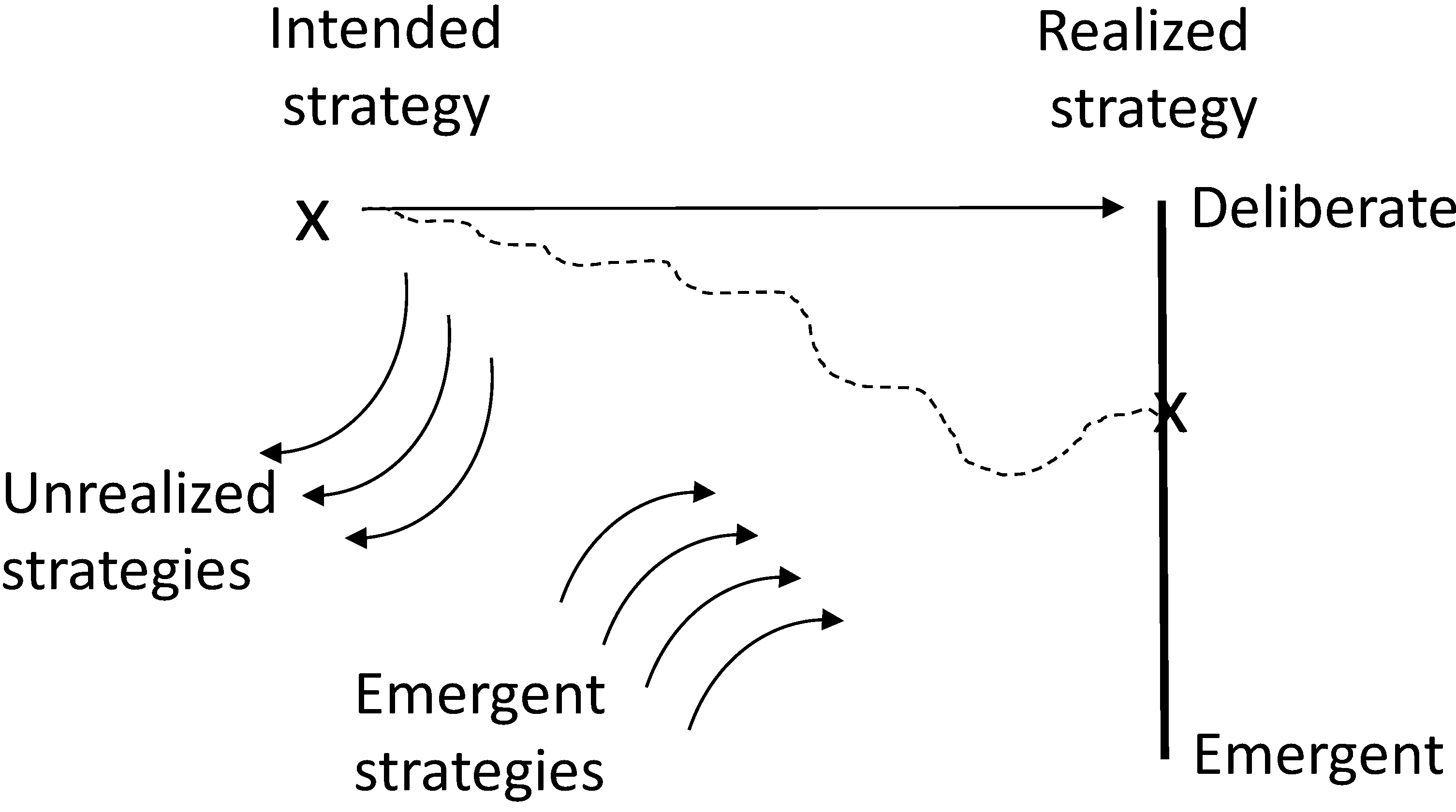

If the contents of the TB are chosen based on the demands of the deliveries rather than on the medium-term plan, then there is a break in the forest planning system and the harvest estimates made at long-term planning stage are ignored. According to the theory of the umbrella strategy, the realized strategy evolves when the environment changes [

11], and therefore this break in the forest planning system cannot be seen as a sub-optimal decision by definition. But if the strategy is changed in a way that goes beyond the boundaries established by the company’s management, there is a risk that the forest resources will be used in an uncontrolled fashion. While it may be possible to correct for this unplanned use when the next set of harvest estimates is made, there is also a risk that such impromptu changes will result in the over-exploitation of scarce compartments, creating a lack of certain attributes that may be hard to compensate for. There is a risk of an imbalance between supply and demand. It is therefore imperative for the company’s management to specify whether the forest management plan or the harvesting plan should be given priority, and for all parties to be aware of how actions taken with respect to one plan will affect the other. If the forest plan is followed strictly, the scope for adjusting the delivery plan to match customer demand will be limited, while strict adherence to the delivery plan may affect the mixture of forest compartments and the ability to deliver products in the future.

The results obtained are not sufficient to determine how often organizations circumvent the established forest planning hierarchy. It is also not clear whether harvest managers only schedule the harvesting of compartments that are not in the TB in order to meet unexpected spikes in customer demand, or whether this behavior is implicitly accounted for within the medium-term plan. In addition to circumventing the company’s forest planning hierarchy, the harvesting of compartments that are not in the TB jeopardizes the sustainability of the forest’s productivity and means that the company may not be in control of its forests’ economic output. To increase the likelihood that the company’s operations will be conducted in a way that is compatible with both the forest plan and the delivery plan, both plans must be well understood at the local level. Several of the respondents to our survey said that the harvest estimates and the associated long-term plans cannot be trusted, and that the estimates are based on stands that cannot be found in the forests. This indicates that the harvest estimates are not considered valid at the local level,

i.e., that knowledge is lost both during the gathering of input data for the harvest estimates and during the implementation of the plans. If the forest plans are not accepted and seen as legitimate, the “willingness” of employees to take decisions that contravene them is increased, even if their directives nominally require that they adhere to the forest plans [

17].

The results obtained indicate that one part of the forest planning hierarchy, the TB, actually works quite well in many parts of the larger forest companies in Sweden, but in other parts the forest hierarchy is not strictly followed. The harvest estimates are economic optimizations that are created to maximize the company’s income in both the long and the short term; if the inputs used to create them are unreliable or the resulting plans are not followed, the company’s financial performance may be reduced.

According to Mintzberg and Waters [

11], realized strategies generally exist at some point along a continuum between perfectly deliberate and perfectly emergent. The realized strategy for harvesting in Swedish forest-owning companies seems to deviate quite substantially from the intended strategy due to the harvesting of compartments that are not in the TB and the fact that harvest managers have some influence on the selection of TB compartments. On the other hand, the realized delivery strategies in these companies can also deviate significantly from the original intent. This is largely driven by factors relating to the company’s operating environment, such as changing customer demands, and unpredictable weather.

In general, cooperation and communication between different units in an organization are regarded as positive things and should be promoted. However, if such communication leads to an undesired emergence of strategies that might compromise the firm’s sustained competitive advantage, then the value of the communication must be questioned. According to the forest planning system, all compartments going in to the TB are supposed to be chosen based on the medium-term forest plan. However, only 40% of the harvest managers and 52% of the planners totally agree with the statement that the TB selection depends only on the forest plans and not on the delivery plan. From the perspective of the forest planning system, this is an alarming sign and may indicate that the system is not working properly. On the other hand, the results do not tell us whether the managers of the companies had issued directives prioritizing their short term goals over the objective of the long term goals. 62% of the planners in charge of the input to the TB had some level of contact with the harvesting side of the organization when selecting TB compartments. Given the design of the forest planning system, this number is surprisingly large. The responses to our questionnaire did not specify whether these discussions focused exclusively on compartments that were included in the medium-term forest plan, but other results in the study indicate that the compartments chosen are not always those that are contained within the forest planning hierarchy. This is also indicated by the level of agreement with the statement that “sometimes I have to schedule compartments that are not in the TB”, which only 39% of the harvest managers did not agree with at all. 51% of the harvest managers said that they have been scheduling compartments from outside the TB into the short-term forest plan (10% did not provide a relevant response). This is remarkable in some respects, since the implementation of the forestry planning strategy is in the choice of compartment to harvest. If a compartment is selected that is not included in the forest plans, the forest planning system has been set aside, and short term goals have been prioritized over long term goals. Some level of disagreement regarding which compartments should be put in the TB is to be expected, since forest companies have two units with interest in the process that have different goals and may be making their decisions based on different information [

12]. The relative priority assigned to these goals should be specified by the company’s management, and they should make their decision clearly known within the organization. If the management does not make a decision or communicates its goals poorly, then there will inevitably be deviations at the local level since staff will adopt ad hoc solutions to problems as they occur. It is important to note however that this process can be a useful and integrated element of the company strategy, especially in cases where there is significant variation in the operating environment at the local level.

Three competing companies participated in this study, and the responses from each company’s employees were not separated in the analysis. It is therefore not possible to determine whether the forest planning and delivery strategies were implemented perfectly in the design of the TB in one of the companies, or whether the observed level of confusion is found in all Swedish forest owning companies. As such, the conclusions of this study may not apply to all of the participating companies. However, a general conclusion can be drawn: the establishment of clear directives on how the TB should be created and handled could increase the ability of the studied companies to implement their chosen strategies and thereby maximize their short- and long-term profits, establishing a sustainable competitive advantage.

The analysis of this study has mainly focused on the forest planning system. Further analysis from a strategic management point of view may give further insight in how the long—and short term strategies are realized in the work with the TB and may also give more concrete guidelines on how to handle the risks for unwanted emergent strategies that were identified in this study.

Because the questionnaire results were fully anonymised, it is not possible to determine whether the responses were distributed evenly over all three companies or whether all three companies are represented in both groups. However, since this is a study of how the forest planning is carried out in Sweden today, every respondent primarily represented themselves; their employer is of comparatively little importance. Our objective was not to evaluate a specific company or organization. In addition, all three companies are large and have a geographically dispersed workforce. As such, there may be differences in organizational culture both between and within the studied companies. The study did not aim to investigate how any specific organization manages its TB; instead, the objective was to determine how Swedish TBs are perceived by the people that actually work with them.

There is a risk that due to the short answering period, one or more units within the studied organizations would have been unable to respond to the questionnaire due to a large meeting or training exercise. However, none of the initial contacts within the companies indicated that any such event was happening during the time period in question.

When a compartment is harvested, several assortments are produced. The number of assortments will be greater than the number of tree species within the compartment. As a consequence, when one customer wants a larger delivery at one point in time, the increased harvesting will be accompanied by an increase in the output of various other products. This factor was not considered during this study.

There are reasons to believe that in the different organizations and also in different units of the organizations the words are used in different ways. The concepts of delivery and production plan can have different meanings for different respondents. This means that these words cannot be separated in this study. The demands from mills and customers can be discussed anyway mainly using the word “delivery plan” for all these plans, and only separating the words when needed due to the questionnaire.

Many of the respondents were concerned about the balance of compartments in the TB. This concern seemed to be at least partly motivated by the variation in ground conditions at different sites during different seasons. The time of the year and the prevailing weather conditions when the questionnaire was administered may have influenced the responses we received; it is possible that the results obtained regarding the preferred TB size might have been different if the study had been conducted at a different point in the year.

All of the respondents in this study were speaking for themselves rather than for their employer or the unit in which they worked. It would be interesting to investigate how the TB is perceived within specific subdivisions of a company. Interesting questions that could be examined in such a study include the following: do different individuals working with the same TB have the same opinions about it? What are the company’s strategies for the work these people do? How is the balance between long and short term goals communicated in the organization?

In organizations where the planning process works properly and the TB is used as intended, what is the reason for this? How does this affect the company’s deliveries and sales?

How are the contents of the TB shown in the software that is used to record and maintain it? The extent to which it is accessible and searchable should affect the way it is used by harvest managers and planners and increase their ability to use it effectively.

The sudden changes that are made to the short-term forest plan in response to changes in the operating environment are of particular interest: do they present a problem? How does the organization know when they start creating problems? In addition to these questions, such changes may indicate problems with the planning system—are these followed up on? The lack of adherence to the original plans is one thing, but such changes raise questions regarding the system as a whole; notably, is it really well suited to the forest planning process? If the planning of compartments from outside the medium term plan is performed even outside real emergencies, then the behavior is more deeply rooted within the organization. Is this behavior consistent with the strategy adopted by the company’s management? If it is, then their strategy is not just a pattern but also a plan. However, if this behavior is not consistent with their strategy, its consequences are of interest.

From the analysis it can be concluded that the traditional view of the hierarchical forest planning system limiting the harvesting and delivery of wood products to the customers as depicted in

Figure 1 is not reflecting the actual planning process in the companies. The results showed that the deliberate strategy as expressed by the forest planning system was adjusted and evolved in an emergent strategy as the harvesting operations needed to meet the delivery plans based on the requirements of the customers. As such strategy patterns were created which might be better or worse than the original deliberate strategy. What is important according to the umbrella strategy [

11] is that the employees working with the TB have competence, guidelines and an organizational culture that ensure that the strategy pattern is not jeopardizing the resources of the company as the results identified such risks in today’s practice. An alternative way to depict the forest planning system and its interaction with the harvesting planning system is given in

Figure 8 as a visualization of todays practice and a reminder for the need of management’s guidelines.

Figure 8.

The forest planning process revised.

Figure 8.

The forest planning process revised.