Consumables Usage and Carbon Dioxide Emissions in Logging Operations

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. Analysis of Normal Distributions

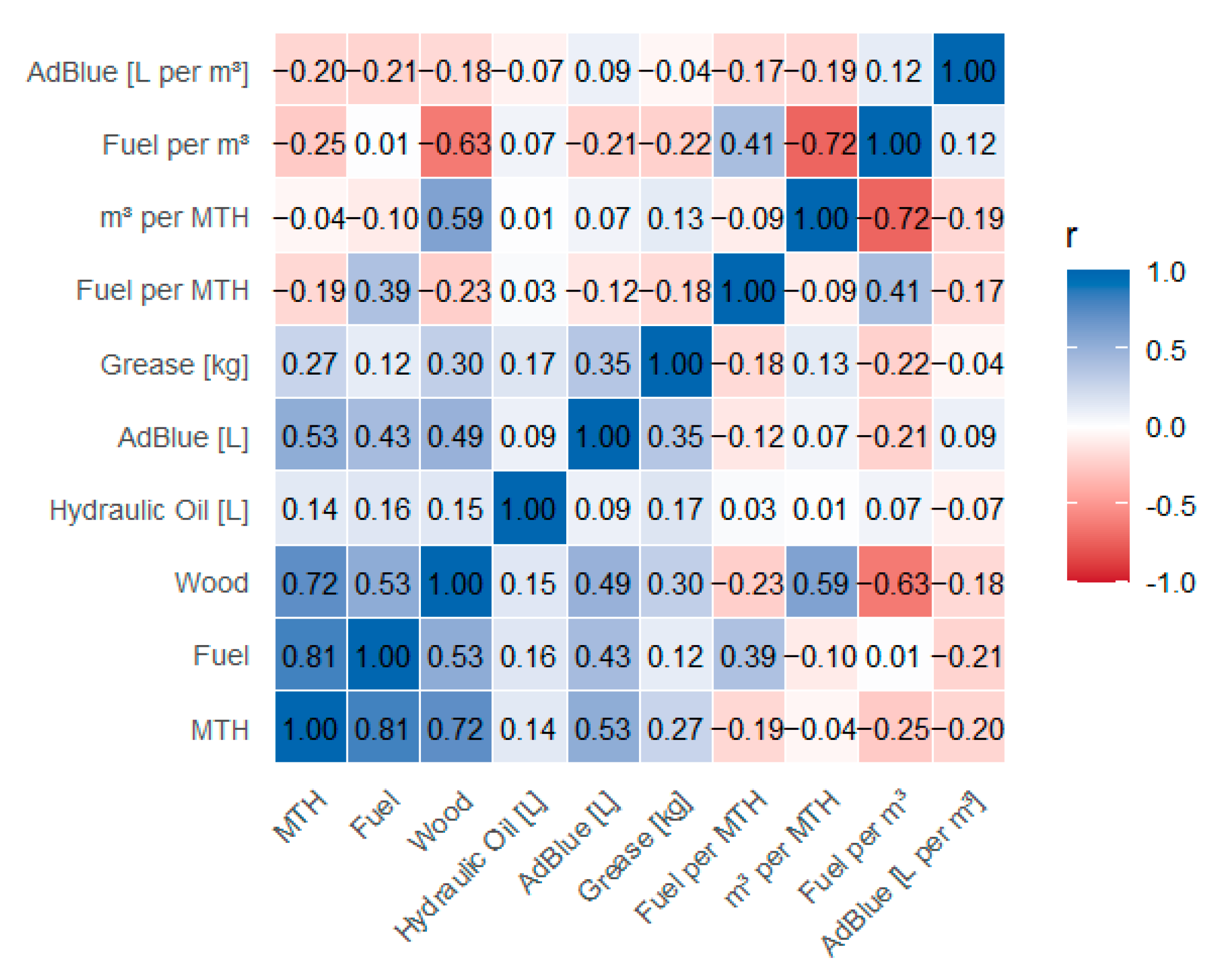

3.2. Correlation Analysis

3.3. Harvester Efficiency Analysis

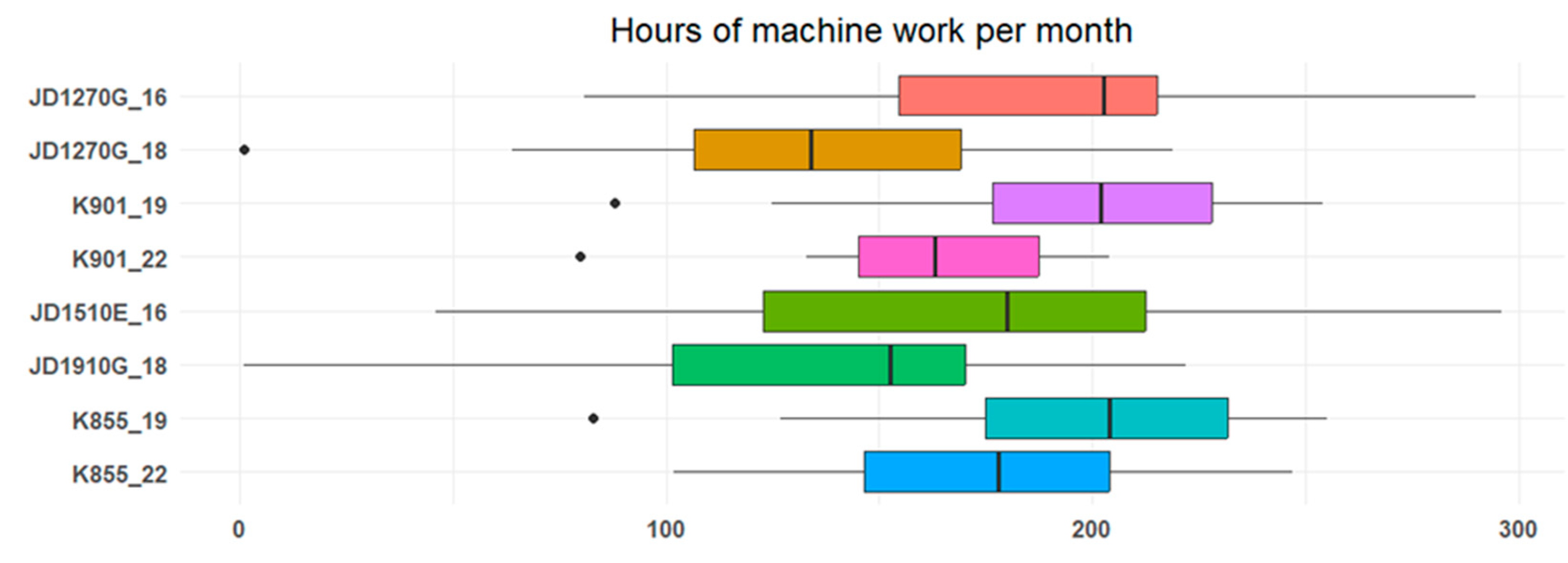

3.3.1. Machine Hours Worked

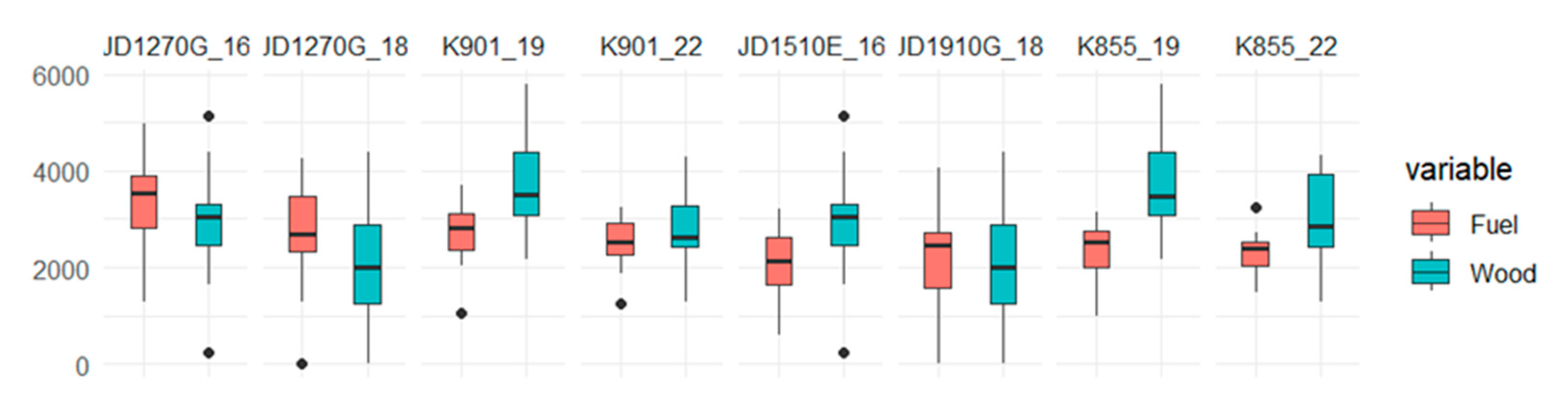

3.3.2. Timber Volume Harvested

3.3.3. Timber Harvesting Efficiency

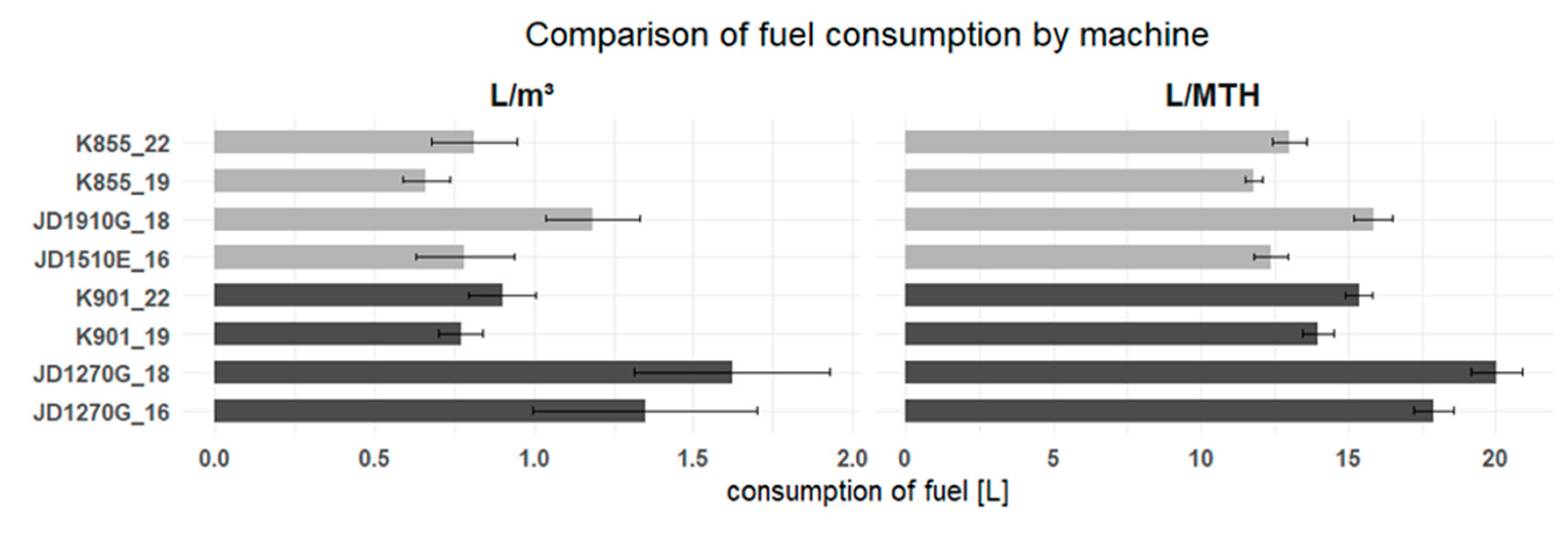

3.3.4. Fuel Consumption per Cubic Meter

3.4. Analysis of Forwarder Performance

3.4.1. Hours Worked

3.4.2. Amount of Transported Wood

3.4.3. Fuel Consumption per Unit Time

3.4.4. Forwarding Efficiency per Unit of Time

Fuel Consumption per Unit of Wood Skidded

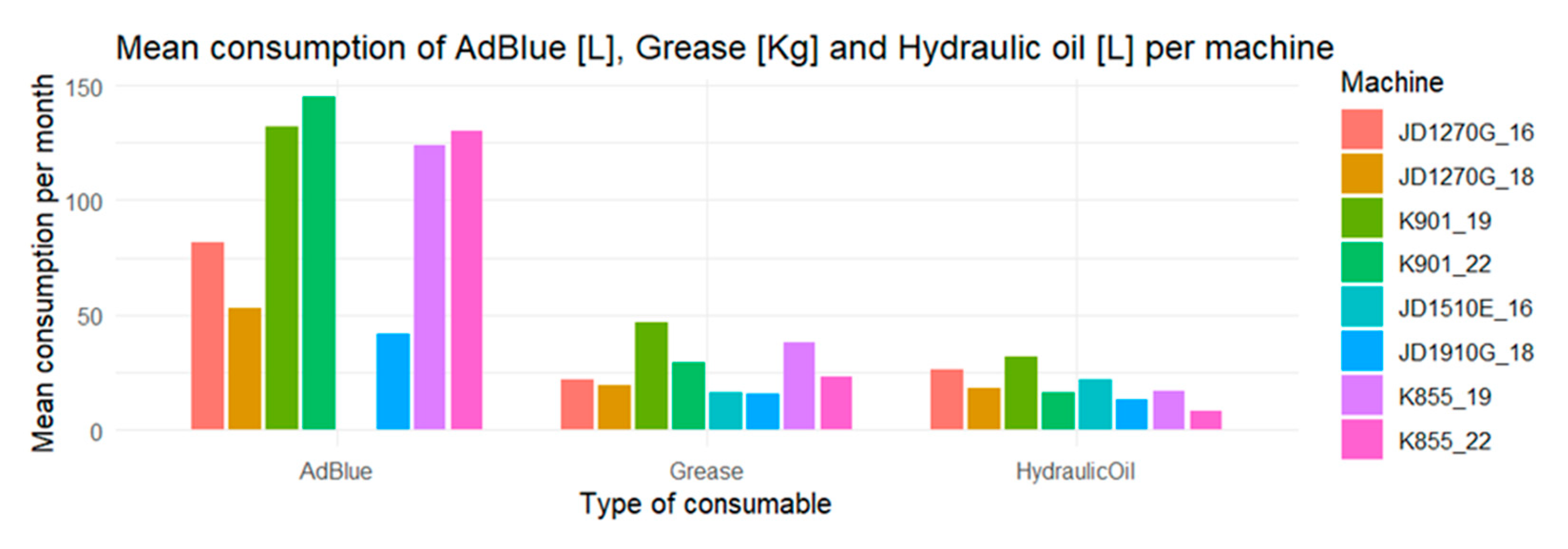

3.5. Consumption of Other Materials

3.6. CO2 and Other Greenhouse Gas Emissions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bacescu, N.M.; Cadei, A.; Moskalik, T.; Wiśniewski, M.; Talbot, B.; Grigolato, S. Efficiency Assessment of Fully Mechanized Harvesting System through the Use of Fleet Management System. Sustainability 2022, 14, 16751. [Google Scholar] [CrossRef]

- Axelsson, S.-Ă. The Mechanization of Logging Operations in Sweden and Its Effect on Occupational Safety and Health. J. For. Eng. 1998, 9, 25–31. [Google Scholar] [CrossRef]

- Ackerman, S.A.; McDermid, H.; Ackerman, P.; Terblanche, M. The Effectiveness of a Small-Scale Combination Harvester/Forwarder in Industrial Plantation First Thinning Operations. Int. J. For. Eng. 2022, 33, 56–65. [Google Scholar] [CrossRef]

- Stoilov, S.; Proto, A.R.; Oslekov, D.; Angelov, G.; Papandrea, S.F. Forest Operations Using a Combi–Forwarder in Deciduous Forests. Small-Scale For. 2024, 23, 25–40. [Google Scholar] [CrossRef]

- Hnilica, R.; Jankovský, M.; Dado, M. Model Assessment of the Complex Workload of Harvester Operator. Forests 2022, 13, 1196. [Google Scholar] [CrossRef]

- Nordfjell, T.; Björheden, R.; Thor, M.; Wästerlund, I. Changes in Technical Performance, Mechanical Availability and Prices of Machines Used in Forest Operations in Sweden from 1985 to 2010. Scand. J. For. Res. 2010, 25, 382–389. [Google Scholar] [CrossRef]

- Asikainen, A.; Anttila, P.; Verkerk, H.; Díaz-Yáñez, O.; Röser, D. Development of forest machinery and labour in the EU in 2010–2030 Development of Forest Machinery and Labour in the EU in 2010–2030. In Proceedings of the Austro2011/FORMEC’11, 44th International Symposium on Forestry Mechanisation, Graz, Austria, 9–13 October 2011; pp. 9–13. [Google Scholar]

- Aniszewska, M.; Gendek, A.; Kędziora, W.; Moskalik, T.; Nurek, T.; Trzcianowska, M.; Wójcik, R.; Zychowicz, W. Łańcuch Dostaw w Leśnictwie. Stan Obecny i Wyzwania; Inżynieria Rolnicza: Kraków, Poland, 2025. [Google Scholar]

- Lundbäck, M.; Häggström, C.; Nordfjell, T. Worldwide Trends in Methods for Harvesting and Extracting Industrial Roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Hartsch, F.; Dreger, F.A.; Englund, M.; Hoffart, E.; Rinkenauer, G.; Wagner, T.; Jaeger, D. Positive and Negative Work Practices of Forest Machine Operators: Interviews and Literature Analysis. Forests 2022, 13, 2153. [Google Scholar] [CrossRef]

- Moskalik, T.; Borz, S.A.; Dvořák, J.; Ferencik, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber Harvesting Methods in Eastern European Countries: A Review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Bodył, M. Drwal. Pismo Przedsiębiorców Leśnych; Oficyna Wydawnicza OIKOS: Warsaw, Poland, 2022; Volume 4, p. 2428. [Google Scholar]

- Lijewski, P.; Merkisz, J.; Fuć, P.; Ziółkowski, A.; Rymaniak, Ł.; Kusiak, W. Fuel Consumption and Exhaust Emissions in the Process of Mechanized Timber Extraction and Transport. Eur. J. For. Res. 2017, 136, 153–160. [Google Scholar] [CrossRef]

- Grünberg, J.; Holzleitner, F.; Behringer, M.; Gollob, C.; Kanzian, C.; Katzensteiner, K.; Kühmaier, M. Impacts of a Fully Mechanized Timber Harvesting System on Soil Physical Properties after a Pronounced Dry Period. Soil Tillage Res. 2025, 251, 106551. [Google Scholar] [CrossRef]

- Labelle, E.R.; Lemmer, K.J. Selected Environmental Impacts of Forest Harvesting Operations with Varying Degree of Mechanization. Croat. J. For. Eng. 2019, 40, 239–257. [Google Scholar] [CrossRef]

- Solgi, A.; Najafi, A.; Page-Dumroese, D.S.; Zenner, E.K. Assessment of Topsoil Disturbance Caused by Different Skidding Machine Types beyond the Margins of the Machine Operating Trail. Geoderma 2020, 367, 114238. [Google Scholar] [CrossRef]

- Marra, E.; Laschi, A.; Fabiano, F.; Foderi, C.; Neri, F.; Mastrolonardo, G.; Nordfjell, T.; Marchi, E. Impacts of Wood Extraction on Soil: Assessing Rutting and Soil Compaction Caused by Skidding and Forwarding by Means of Traditional and Innovative Methods. Eur. J. For. Res. 2022, 141, 71–86. [Google Scholar] [CrossRef]

- Staněk, L.; Neruda, J.; Ulrich, R. Changes in the Concentration of CO2 in Forest Soils Resulting from the Traffic of Logging Machines. J. For. Sci. 2025, 71, 250–267. [Google Scholar] [CrossRef]

- Mergl, V.; Zeizinger, L.; Kománek, M. Advancing Sustainability in Forestry Machinery: Electro-Hybrid Drives for Greenhouse Gas Reduction and Enhanced Energy Efficiency. Cent. Eur. For. J. 2024, 70, 41–50. [Google Scholar] [CrossRef]

- European Parliament and Council. 2004. Directive 2004/26/EC of 21 April 2004 Amending Directive 97/68/EC on the Approximation of the Laws of the Member States Relating to Measures Against the Emission of Gaseous and Particulate Pollutants from Internal Combustion Engines to be Installed in Non-Road Mobile Machinery. Official Journal of the European Union, L 146, 30.4.2004, pp. 1–107. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32004L0026 (accessed on 1 July 2025).

- European Parliament and Council. 2009. Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 Amending Directive 98/70/EC as Regards the Specification of Petrol and Diesel Fuels and Introducing a Mechanism to Monitor and Reduce Greenhouse Gas Emissions. Official Journal of the European Union, L 140, 5.6.2009, pp. 88–113. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32009L0030 (accessed on 1 July 2025).

- Weiss, M.; Rodríguez, F.; Muncrief, R.; Delgado, O. 2016. European Stage V Non-Road Emission Standards: Final Regulations. The International Council on Clean Transportation. November 2016. Available online: https://theicct.org/wp-content/uploads/2021/06/EU-Stage-V_policy-update_ICCT_nov2016.pdf (accessed on 1 July 2025).

- Moskalik, T.; Gendek, A. Production of Chips from Logging Residues and Their Quality for Energy: A Review of European Literature. Forests 2019, 10, 262. [Google Scholar] [CrossRef]

- Bright, G. Calculating Costs and Charges for Forest Machinery Use. Forestry 2004, 77, 75–84. [Google Scholar] [CrossRef]

- Dvořák, J.; Jankovský, M.; Chytrý, M.; Nuhlíček, O.; Natov, P.; Kormanek, M.; Löwe, R. Operational Costs of Mid-Performance Forwarders in Czech Forest Bioeconomy. Forests 2021, 12, 435. [Google Scholar] [CrossRef]

- EMEP/EEA. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2016: Technical Guidance to Prepare National Emission Inventories; European Environment Agency: Copenhagen, Denmark, 2016; p. 124. [Google Scholar]

- UK Department for Business, Energy & Industrial Strategy. 2019. 2019 Government GHG Conversion Factors for Company Reporting: Methodology Paper. Version 1.02. London: UK Government. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/904215/2019-ghg-conversion-factors-methodology-v01-02.pdf (accessed on 1 July 2025).

- Lu, C.; Xie, D.F.; Zhao, X.M.; Qu, X. The Role of Alternative Fuel Buses in the Transition Period of Public Transport Electrification in Europe: A Lifecycle Perspective. Int. J. Sustain. Transp. 2023, 17, 626–638. [Google Scholar] [CrossRef]

- Lajunen, A.; Lipman, T. Lifecycle Cost Assessment and Carbon Dioxide Emissions of Diesel, Natural Gas, Hybrid Electric, Fuel Cell Hybrid and Electric Transit Buses. Energy 2016, 106, 329–342. [Google Scholar] [CrossRef]

- Liu, H.; Ma, J.; Tong, L.; Ma, G.; Zheng, Z.; Yao, M. Investigation on the Potential of High Efficiency for Internal Combustion Engines. Energies 2018, 11, 513. [Google Scholar] [CrossRef]

- Dumböck, O.; Schutting, E.; Eichlseder, H.; Hübner, W. Increasing the Efficiency of the Internal Combustion Engine through Extended Expansion. MTZ Worldw. 2018, 79, 74–79. [Google Scholar] [CrossRef]

- Kováč, J. Perspective Chapter: Analysis of the Operational Reliability of Forest Equipment [Internet]. In Failure Analysis-Structural Health Monitoring of Structure and Infrastructure Components; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R. Work Productivity Assessment of Small Forwarders in Forest Operations: An International Review. Silva Balc. 2022, 23, 55–68. [Google Scholar] [CrossRef]

- Proto, A.R.; Macrì, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. Factors Affecting Forwarder Productivity. Eur. J. For. Res. 2018, 137, 143–151. [Google Scholar] [CrossRef]

- Cambi, M.; Certini, G.; Neri, F.; Marchi, E. The Impact of Heavy Traffic on Forest Soils: A Review. For. Ecol. Manage. 2015, 338, 124–138. [Google Scholar] [CrossRef]

- Yoshimura, T.; Suzuki, Y.; Sato, N. Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain. Forests 2023, 14, 1430. [Google Scholar] [CrossRef]

- Klaes, B.; Struck, J.; Schneider, R.; Schüler, G. Middle-Term Effects after Timber Harvesting with Heavy Machinery on a Fine-Textured Forest Soil. Eur. J. For. Res. 2016, 135, 1083–1095. [Google Scholar] [CrossRef]

- Varol, T.; Ozel, H.B.; Ertugrul, M.; Emir, T.; Tunay, M.; Cetin, M.; Sevik, H. Prediction of Soil-Bearing Capacity on Forest Roads by Statistical Approaches. Environ. Monit. Assess. 2021, 193, 527. [Google Scholar] [CrossRef]

- Ovaskainen, H.; Uusitalo, J.; Väätäinen, K. Characteristics and Significance of a Harvester Operators’ Working Technique in Thinnings. Int. J. For. Eng. 2004, 15, 67–77. [Google Scholar] [CrossRef]

- Ovaskainen, H. Timber Harvester Operators’ Working Technique in First Thinning and the Importance of Cognitive Abilities on Work Productivity; Dissertationes Forestales, University of Helsinki: Helskinki, Finland, 2009; Volume 2009, ISBN 9789516512467. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Labe, E.R. The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croat. J. For. Eng. 2020, 41, 177–190. [Google Scholar] [CrossRef]

- Melander, L.; Ritala, R. Separating the Impact of Work Environment and Machine Operation on Harvester Performance. Eur. J. For. Res. 2020, 139, 1029–1043. [Google Scholar] [CrossRef]

- Gerasimov, Y.; Senkin, V.; Väätäinen, K. Productivity of Single-Grip Harvesters in Clear-Cutting Operations in the Northern European Part of Russia. Eur. J. For. Res. 2012, 131, 647–654. [Google Scholar] [CrossRef]

- Jiroušek, R.; Klvač, R.; Skoupý, A. Productivity and Costs of the Mechanised Cut-to-Length Wood Harvesting System in Clear-Felling Operations. J. For. Sci. 2007, 53, 476–482. [Google Scholar] [CrossRef]

- Spinelli, R.; Cacot, E.; Mihelic, M.; Nestorovski, L.; Mederski, P.; Tolosana, E. Techniques and Productivity of Coppice Harvesting Operations in Europe: A Meta-Analysis of Available Data. Ann. For. Sci. 2016, 73, 1125–1139. [Google Scholar] [CrossRef]

- Kärhä, K.; Eliasson, L.; Kühmaier, M.; Spinelli, R. Fuel Consumption and CO2 Emissions in Fully Mechanized Cut-to-Length (CTL) Harvesting Operations of Industrial Roundwood: A Review. Curr. For. Rep. 2024, 10, 255–272. [Google Scholar] [CrossRef]

- Haavikko, H.; Kärhä, K.; Poikela, A.; Korvenranta, M.; Palander, T. Fuel Consumption, Greenhouse Gas Emissions, and Energy Efficiency of Wood-Harvesting Operations: A Case Study of Stora Enso in Finland. Croat. J. For. Eng. 2022, 43, 79–97. [Google Scholar] [CrossRef]

- Spinelli, R.; de Arruda Moura, A.C. Decreasing the Fuel Consumption and CO 2 Emissions of Excavator-Based Harvesters with a Machine Control System. Forests 2019, 10, 43. [Google Scholar] [CrossRef]

- Prinz, R.; Spinelli, R.; Magagnotti, N.; Routa, J.; Asikainen, A. Modifying the Settings of CTL Timber Harvesting Machines to Reduce Fuel Consumption and CO2 Emissions. J. Clean. Prod. 2018, 197, 208–217. [Google Scholar] [CrossRef]

- Athanassiadis, D. Energy Consumption and Exhaust Emissions in Mechanized Timber Harvesting Operations in Sweden. Sci. Total Environ. 2000, 255, 135–143. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Picchi, G. Deploying Mechanized Cut-to-Length Technology in Italy: Fleet Size, Annual Usage, and Costs. Int. J. For. Eng. 2010, 21, 23–31. [Google Scholar] [CrossRef]

- Šušnjar, M.; Pandur, Z.; Bačić, M.; Halilović, V.; Nevečerel, H.; Lepoglavec, K.; Kopseak, H. Analysis of Skidder Fuel Consumption by Work Operations During Timber Extraction in Thinning of Even-Aged Forest on Mountainous Terrain: A Case Study. Sustainability 2024, 16, 11240. [Google Scholar] [CrossRef]

- Schweier, J.; Magagnotti, N.; Labelle, E.R.; Athanassiadis, D. Sustainability Impact Assessment of Forest Operations: A Review. Curr. For. Rep. 2019, 5, 101–113. [Google Scholar] [CrossRef]

- Engel, A.M.; Wegener, J.; Lange, M. Greenhouse Gas Emissions of Two Mechanised Wood Harvesting Methods in Comparison with the Use of Draft Horses for Logging. Eur. J. For. Res. 2012, 131, 1139–1149. [Google Scholar] [CrossRef]

- Eriksson, M.; Lindroos, O. Productivity of Harvesters and Forwarders in CTL Operations in Northern Sweden Based on Large Follow-up Datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Tourlonias, P.; Koltsakis, G. Model-Based Comparative Study of Euro 6 Diesel Aftertreatment Concepts, Focusing on Fuel Consumption. Int. J. Engine Res. 2011, 12, 238–251. [Google Scholar] [CrossRef]

- Zhu, N.; Song, H.; Qian, F.; Xu, X. Influence of Exhaust Pipe Structure on Urea-Related Deposits in Diesel Engine SCR System. Processes 2023, 11, 1199. [Google Scholar] [CrossRef]

- Martinovic, F.; Castoldi, L.; Deorsola, F.A. Aftertreatment Technologies for Diesel Engines: An Overview of the Combined Systems. Catalysts 2021, 11, 653. [Google Scholar] [CrossRef]

- Skřivánek, A.; Sedlák, P.; Polcar, A.; Dostál, P. Monitoring of Basic Parameters for Selective Catalytic Reduction System Used in an Agricultural Tractor. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 62, 225–230. [Google Scholar] [CrossRef]

- Athanassiadis, D.; Lidestav, D.G.; Wästerlund, I. Fuel, Hydraulic Oil and Lubricant Consumption in Swedish Mechanized Harvesting Operations, 1996. Int. J. For. Eng. 1999, 10, 59–66. [Google Scholar]

- Halilović, V.; Gurda, S.; Sokolović, D.; Musić, J.; Bajrić, M.; Ganić, E. Fuel and Lubricants Consumption in the Phase of Harvesting and Processing Wood in Public Enterprise Forest Offices Vareš Section 37. Rad. Šumarskog Fak. Univ. Sarajev. 2012, 42, 31–43. [Google Scholar] [CrossRef]

| Machine ID | JD1270G_16 | JD1270G_18 | K901_19 | K901_22 |

|---|---|---|---|---|

| Manufacturer | John Deere | John Deere | Komatsu | Komatsu |

| Model | 1270G | 1270G | 901 | 901 |

| Year of production | 2016 | 2018 | 2019 | 2022 |

| Volume of engine | 9.0 L | 9.0 L | 6.6 L | 6.6 L |

| Rated power | 200 kW | 200 kW | 170 kW | 170 kW |

| Engine torque | 1445 Nm/1300–1400 rpm | 1445 Nm/1300–1400 rpm | 950 Nm/1500 rpm | 950 Nm/1500 rpm |

| Tractive force | 210 kN | 210 kN | 184 kN | 184 kN |

| Weight | 23,400 kg | 23,400 kg | 20,210 kg | 20,210 kg |

| Crane | CH7: 10 m | CH7: 10 m | 200H: 10 m | 200H: 10 m |

| Head/grapple | H480C | H480C | C93 | C93 |

| Gross lifting torque | 197 kNm | 197 kNm | 198 kNm | 198 kNm |

| Machine ID | JD1510E_16 | JD1910G_18 | K855_21 | K855_22 |

|---|---|---|---|---|

| Manufacturer | John Deere | John Deere | Komatsu | Komatsu |

| Model | 1510E | 1910G | 855 | 855 |

| Year of production | 2016 | 2018 | 2021 | 2022 |

| Volume of engine | 9.0 L | 6.8 L | 6.6 L | 6.6 L |

| Rated power | 205 kW | 200 kW | 170 kW | 170 kW |

| Engine torque | 978 Nm/1200–1500 rpm | 1315 Nm/1400 rpm | 950 Nm/1500 rpm | 950 Nm/1500 rpm |

| Tractive force | 185 kN | 230 kN | 187 kN | 187 kN |

| Nominal load capacity | 15,000 kg | 19,000 kg | 14,000 kg | 14,000 kg |

| Weight | 16,330 kg | 19,500 kg | 16,500 kg | 16,500 kg |

| Crane | CF7S: 10 m | CF7S: 10 m | 145F: 10 m | 145F: 10 m |

| Head/grapple | HSP 028 | HSP 050 | G28 | G28 |

| Gross lifting torque | 197 kNm | 210 kNm | 145 kNm | 145 kNm |

| Machine | Fuel Consumption per 1 m3 | kWh Generated | CO2 [kg] | CO [g] | HC [g] | NOx [g] | PM [g] |

|---|---|---|---|---|---|---|---|

| JD1270G_16 | 1.35 | 5.37 | 3.62 | 74.85 | 2.74 | 983.03 | 0.27 |

| JD1270G_18 | 1.62 | 6.46 | 4.35 | 89.98 | 4.88 | 84.84 | 0.64 |

| K901_19 | 0.77 | 3.07 | 2.07 | 42.80 | 2.32 | 4.89 | 0.18 |

| K901_22 | 0.90 | 3.59 | 2.42 | 50.06 | 2.72 | 5.72 | 0.21 |

| JD1510E_16 | 0.79 | 3.12 | 2.10 | 43.52 | N/D | N/D | 2.49 |

| JD1910G_18 | 1.19 | 4.72 | 3.18 | 65.70 | 3.57 | 61.94 | 0.47 |

| K855_19 | 0.67 | 2.65 | 1.78 | 36.87 | 2.00 | 4.21 | 0.16 |

| K855_22 | 0.81 | 3.24 | 2.18 | 45.13 | 2.45 | 5.16 | 0.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pszenny, D.; Moskalik, T. Consumables Usage and Carbon Dioxide Emissions in Logging Operations. Forests 2025, 16, 1197. https://doi.org/10.3390/f16071197

Pszenny D, Moskalik T. Consumables Usage and Carbon Dioxide Emissions in Logging Operations. Forests. 2025; 16(7):1197. https://doi.org/10.3390/f16071197

Chicago/Turabian StylePszenny, Dariusz, and Tadeusz Moskalik. 2025. "Consumables Usage and Carbon Dioxide Emissions in Logging Operations" Forests 16, no. 7: 1197. https://doi.org/10.3390/f16071197

APA StylePszenny, D., & Moskalik, T. (2025). Consumables Usage and Carbon Dioxide Emissions in Logging Operations. Forests, 16(7), 1197. https://doi.org/10.3390/f16071197