The Effect of Selected Operation Factors on Cutter Deflection Angles, Instantaneous Speeds, and Accelerations While Cutting Wood with a Petrol Chainsaw

Abstract

1. Introduction

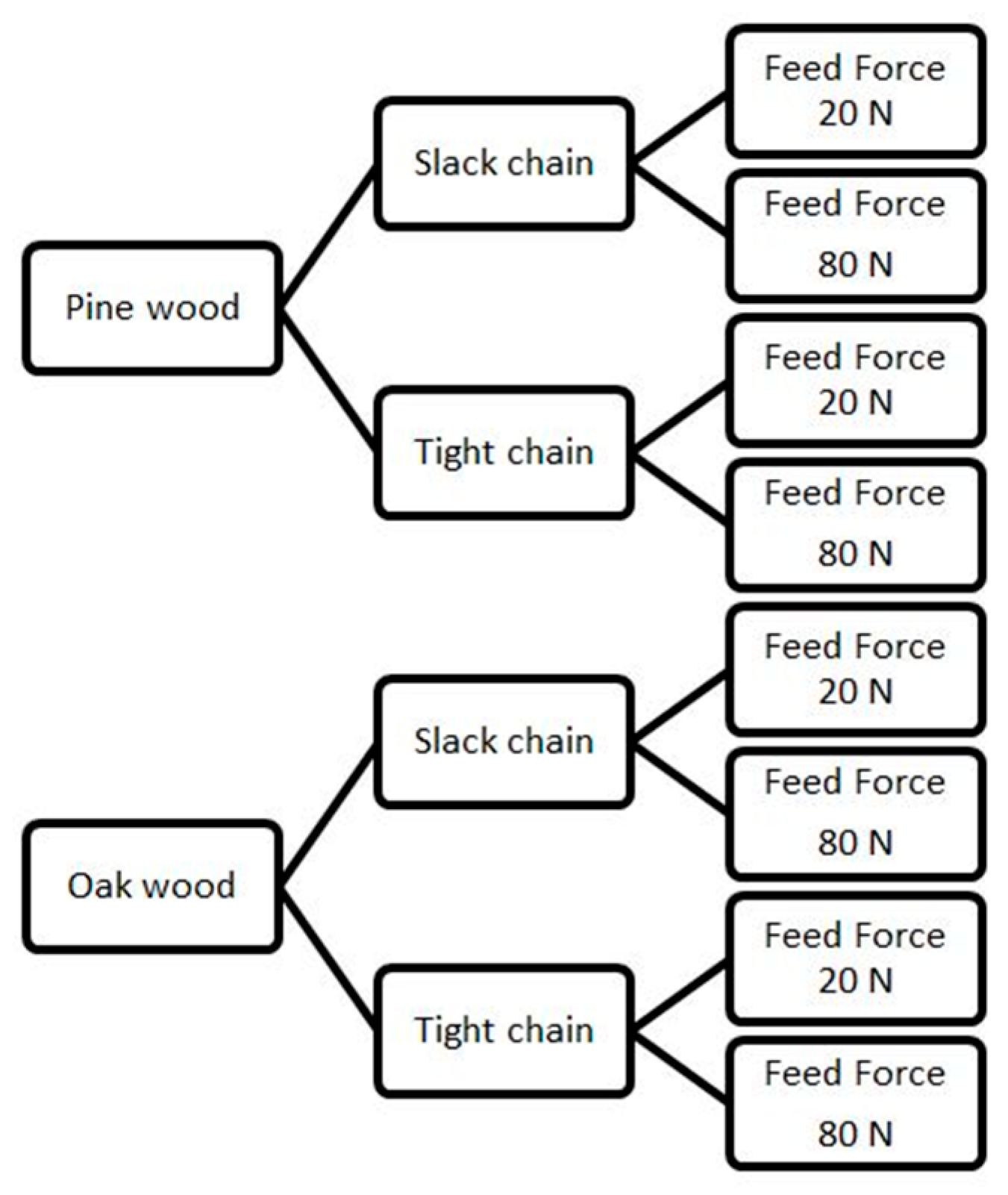

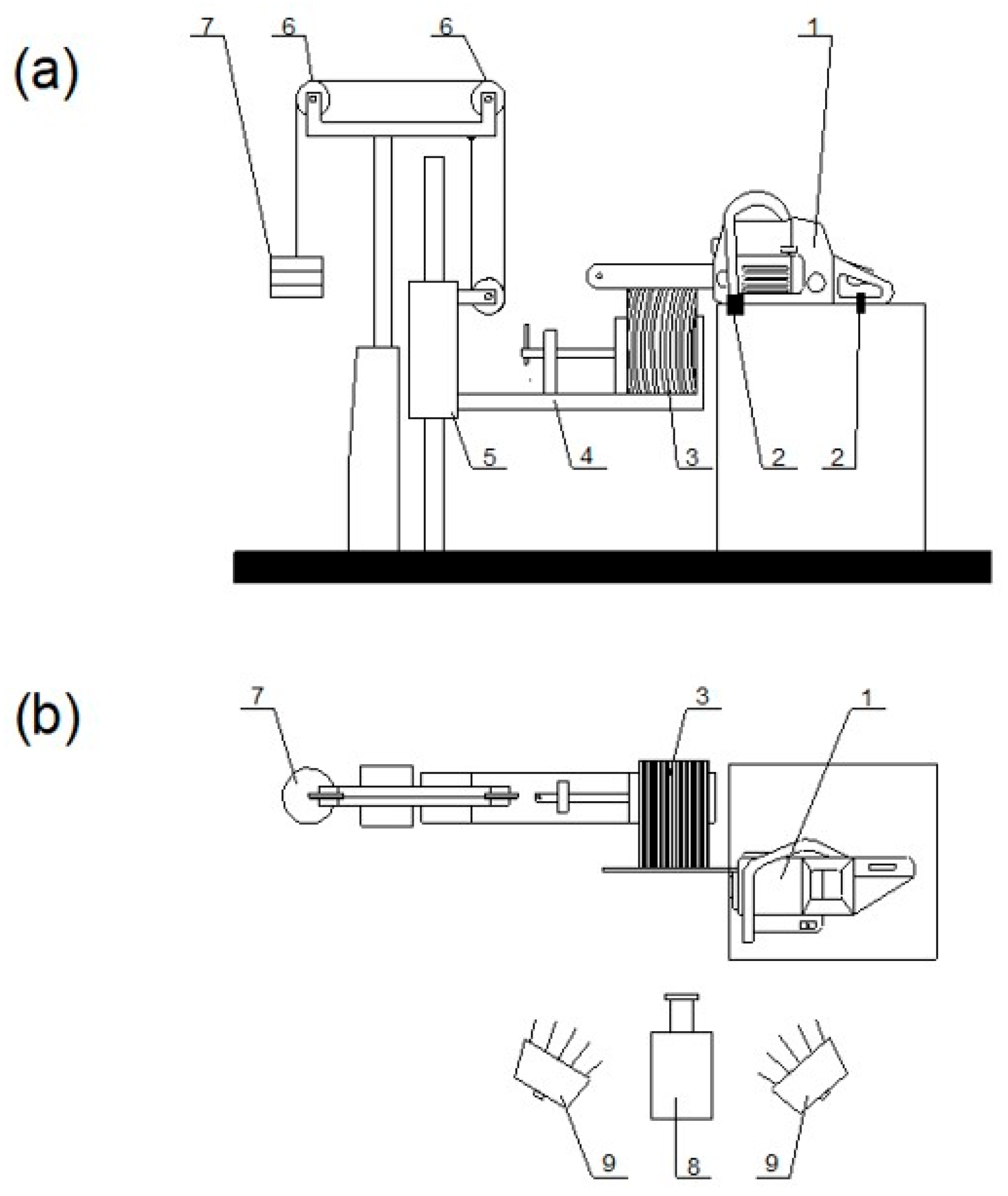

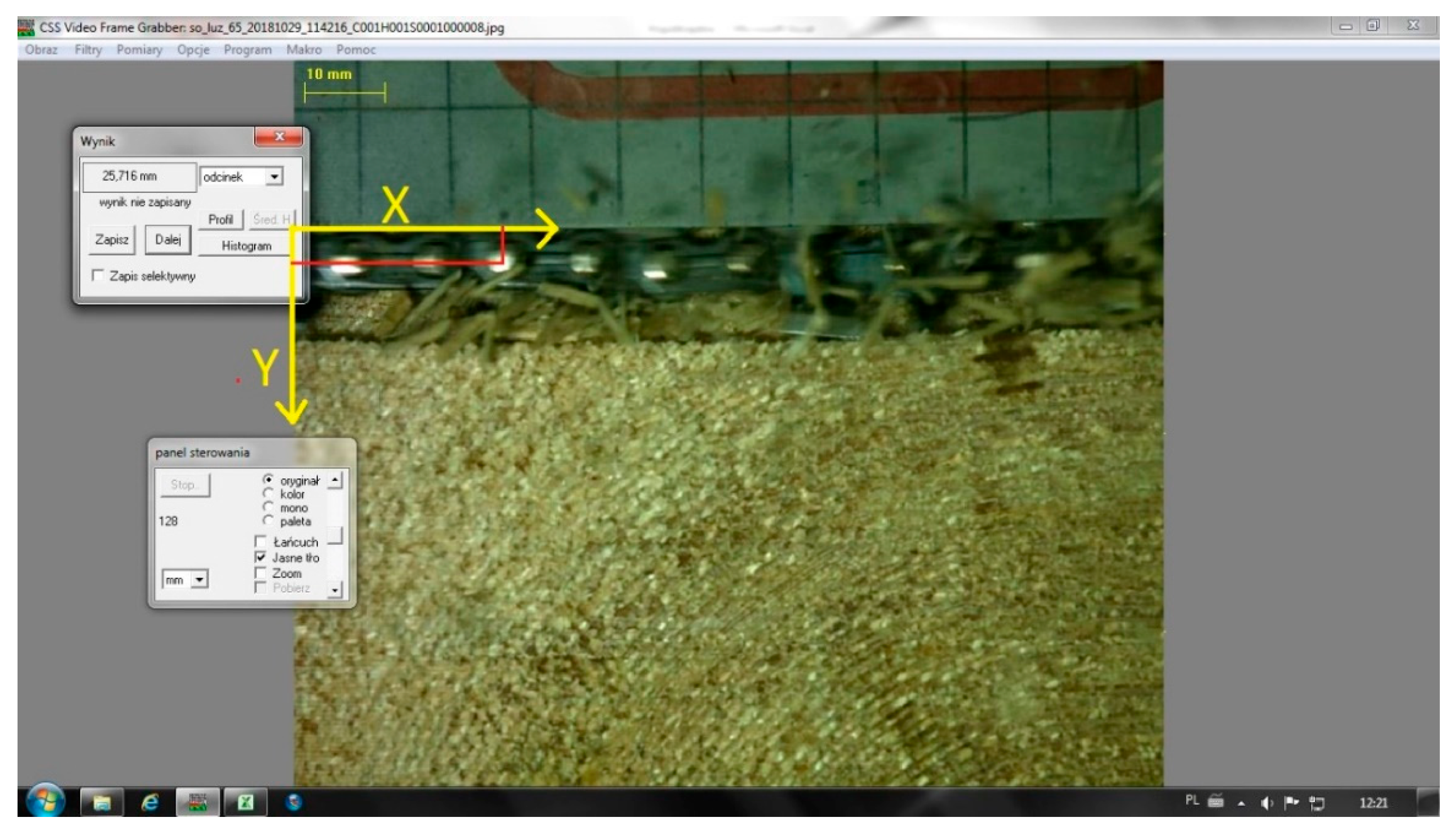

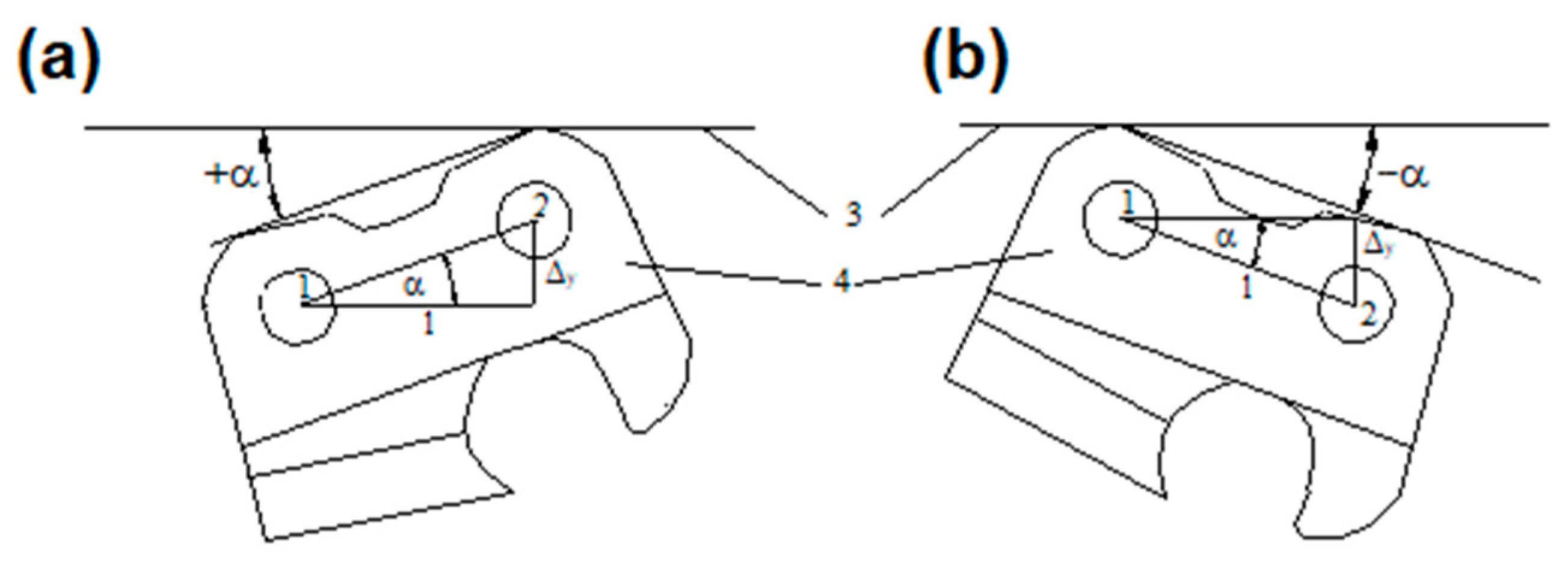

2. Materials and Methods

- —is the difference in Y values between rivet axes [mm],

- l—is the distance between rivet axes [mm] (10 mm for the studied cutters).

- —is the distance of the rear rivet axis (1) from the guide bar raceway [mm],

- —is the distance of the front rivet axis (2) from the guide bar raceway [mm].

- vx—is the rivet speed in the X axis [mm·s−1],

- xi—is the X coordinate of the axis of the rivet in image i [mm],

- xi+1—is the X coordinate of the axis of the rivet in image i + 1 [mm],

- t—is the interval between images [s].

- vy—is the rivet speed in the Y axis [mm·s−1],

- yi—is the Y coordinate of the axis of the rivet in image i [mm],

- yi+1—is the Y coordinate of the axis of the rivet in image i + 1 [mm],

- t—is the interval between images [s].

- ax—is the rivet acceleration in the X axis [mm·s−2];

- vxi—is the rivet speed in the X axis [mm·s−1];

- vx(i+1)—is the rivet speed in the X axis after 1/12,000 s [mm·s−1];

- t—is the interval between images [s].

- ay—is the rivet acceleration in the Y axis [mm·s−2];

- vyi—is the rivet speed in the Y axis [mm·s−1];

- vy(i+1)—is the rivet speed in the Y axis after 1/12,000 s [mm·s−1];

- t—is the interval between images [s].

3. Results

4. Discussion

5. Conclusions

- In the process of pine wood cutting at low feed force, the absolute value of the mean cutter deflection angle increased with increasing initial chain tension. That phenomenon was not observed in the case of pine wood cutting at high feed force.

- In the process of pine wood cutting, the absolute value of the mean cutter deflection angle decreased with increasing feed force for both initial chain tension values.

- In the process of oak wood cutting at low feed force, the absolute value of the mean cutter deflection angle increased with increasing initial chain tension, as was the case with pine wood. Similarly, no significant differences in the mean cutter deflection angle were observed at high feed force. Thus, for both wood species, differences in the mean cutter deflection angle occurred only at low feed force.

- In the case of a lower feed force, the absolute values of the mean cutter deflection angles were higher for pine wood compared to oak wood at both chain tension values. No significant differences in that respect were found between the two wood species at a higher feed force.

- The speed and acceleration values recorded for the Y axis were much lower than those for the X axis. Mean cutter speeds in the X axis were 18.94–21.95 m·s−1 as compared to 2.12–2.58 m·s−1 in the Y axis.

- Mean cutter accelerations ranged from 52.54 m·s−2 to 109.39 m·s−2 in the X axis and from 19.83 m·s−2 to 25.18 m·s−2 in the Y axis.

- The rear part of the cutter was characterized by greater speed variation in the X axis.

- In the case of cutting pine wood, no statistically significant differences in cutter speed in the X axis were found between the two chain tensions at a feed force of 20 N, while at a feed force of 80 N the speed recorded for a tight chain was significantly lower than that for a slack chain.

- In the case of cutting oak wood at a feed force of 80 N, statistically significant differences in cutter speed were noted between different chain tensions in the X axis, with the speed for a slack chain being higher.

- There were also statistically significant differences in cutter speed in the X axis when cutting oak wood with a tight chain at different feed forces (a higher speed was achieved at the lower feed force).

- In the case of pine wood processing, no statistically significant differences in cutter speed in the Y axis were found between the various setups. On the other hand, in the case of oak wood, there was a difference between the two feed forces applied with a slack chain, with a higher speed recorded for the feed force of 80 N.

- The greatest accelerations in the X axis were found for cutting pine wood with a slack chain at a feed force of 20 N. At the higher feed force (80 N) accelerations in the X axis significantly decreased by almost 50%.

- When using tight chains, applying a higher feed force did not cause a statistically significant decrease in rivet acceleration in the X axis.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moskalik, T.; Borz, S.; Dvořák, J.; Ferenčík, M.; Glushkov, S.; Muiste, P.; Lazdiņš, A.; Styranivsky, O. Timber Harvesting Methods in Eastern European Countries: A Review. Croat. J. For. Eng. 2017, 38, 231–241. [Google Scholar]

- Karjalainen, T.; Zimmer, B.; Berg, S.; Welling, J.; Schwaiger, H.; Finér, L.; Cortijo, P.; Metsäntutkimuslaitos. Energy, Carbon and Other Material Flows in the Life Cycle Assessment of Forestry and Forest Products. Achievements of the Working Group 1 of the COST Action E9. Joensuu Eur. For. Inst. Discuss. Pap. 2001, 10, 1–67. [Google Scholar]

- Spinelli, R.; Magagnotti, N.; Nati, C. Options for the Mechanized Processing of Hardwood Trees in Mediterranean Forests. Int. J. For. Eng. 2009, 20, 39–44. [Google Scholar] [CrossRef]

- Montorselli, N.B.; Lombardini, C.; Magagnotti, N.; Marchi, E.; Neri, F.; Picchi, G.; Spinelli, R. Relating Safety, Productivity and Company Type for Motor-Manual Logging Operations in the Italian Alps. Accid. Anal. Prev. 2010, 42, 2013–2017. [Google Scholar] [CrossRef]

- Vusić, D.; Šušnjar, M.; Marchi, E.; Spina, R.; Zečić, Ž.; Picchio, R. Skidding Operations in Thinning and Shelterwood Cut of Mixed Stands—Work Productivity, Energy Inputs and Emissions. Ecol. Eng. 2013, 61, 216–223. [Google Scholar] [CrossRef]

- Lindroos, O.; Burström, L. Accident Rates and Types among Self-Employed Private Forest Owners. Accid. Anal. Prev. 2010, 42, 1729–1735. [Google Scholar] [CrossRef]

- Ashby, R.J.P.; Tim, A.; Bentley, L., Jr. Human Factors Testing in the Forest Industry. In Handbook of Human Factors Testing and Evaluation; CRC Press: Boca Raton, FL, USA, 2001; ISBN 978-1-00-300081-5. [Google Scholar]

- Melemez, K.; Tunay, M. Determining physical workload of chainsaw operators working in forest harvesting. Technology 2010, 13, 237–243. [Google Scholar]

- Eroglu, H.; Yilmaz, R.; Kayacan, Y. A Study on Determining the Physical Workload of the Forest Harvesting and Nursery-Afforestation Workers. Anthropologist 2015, 21, 168–181. [Google Scholar] [CrossRef]

- Poje, A.; Potočnik, I.; Košir, B.; Krč, J. Cutting Patterns as a Predictor of the Odds of Accident among Professional Fellers. Saf. Sci. 2016, 89, 158–166. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Tsioras, P.; Stampfer, K. Wood Density Impact on Hand-Arm Vibration. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2012, 33, 303–312. [Google Scholar]

- Fonseca, A.; Aghazadeh, F.; de Hoop, C.; Ikuma, L.; Al-Qaisi, S. Effect of Noise Emitted by Forestry Equipment on Workers’ Hearing Capacity. Int. J. Ind. Ergon. 2015, 46, 105–112. [Google Scholar] [CrossRef]

- Marenče, J.; Mihelič, M.; Poje, A. Influence of Chain Filing, Tree Species and Chain Type on Cross Cutting Efficiency and Health Risk. Forests 2017, 8, 464. [Google Scholar] [CrossRef]

- Dado, M.; Kučera, M.; Salva, J.; Hnilica, R.; Hýrošová, T. Influence of Saw Chain Type and Wood Species on the Mass Concentration of Airborne Wood Dust during Cross-Cutting. Forests 2022, 13, 2009. [Google Scholar] [CrossRef]

- Nordfjell, T.; Björheden, R.; Thor, M.; Wästerlund, I. Changes in Technical Performance, Mechanical Availability and Prices of Machines Used in Forest Operations in Sweden from 1985 to 2010. Scand. J. For. Res. 2010, 25, 382–389. [Google Scholar] [CrossRef]

- Maciak, A.; Kubuśka, M.; Moskalik, T. Instantaneous Cutting Force Variability in Chainsaws. Forests 2018, 9, 660. [Google Scholar] [CrossRef]

- Górski, J. Wood Cutting by Means of Electric Chain Saw; Treatises and Monographs; Wydawnictwo SGGW: Warsaw, Poland, 2001; Volume 241, ISBN 83-7244-205-3. [Google Scholar]

- Maciak, A. Treatises and Monographs. The Impact of Structural and Operational Factors on the Process and Performance of Wood Cutting Wit Use of Petrol Chain Saw; Publications of Warsaw University of Life Sciences—SGGW: Warsaw, Poland, 2013; Volume 410, ISBN 978-83-7583-421-5. [Google Scholar]

- Kiepuszewski, B.; Legutko, S.; Wieczorkowski, K. Metal Cutting; Wydawnictwo Politechniki Poznańskiej: Poznań, Poland, 1980. [Google Scholar]

- Górski, J. An attempt to theoretical description of the process of sawing wood with a chainsaw. Przegląd Tech. Rol. I Leśnej 1995, 6, 13–15. [Google Scholar]

- Maciak, A. Influence of Construction Parameters of Chain Saw Cutters on Wood Cutting Efficiency; Warsaw University of Life Sciences—SGGW: Warsaw, Poland, 2001. [Google Scholar]

- Andrew, O.; John, P. Velocity, Depth-of-Cut, and Physical Property Effects on Saw Chain Cutting. BioResources 2015, 10, 7273–7291. [Google Scholar] [CrossRef]

- To, T.; Doi, O.; Yokoyama, M. Cutting Behaviors of Saw Chain (Part 1); Kitami Institute of Technology Repository, Kitami Institute of Technology: Kitami, Japan, 1967. [Google Scholar]

- Maciak, A.; Kubuśka, M.; Młodzińska, E. Impact of Saw Chain Cutters Type on Cutting Efficiency and Fuel Consumption in Timber Cutting. Ann. Wars. Univ. Life Sci.—SGGW Agric. 2017, 69, 71–77. [Google Scholar] [CrossRef]

- Wątroba, J. Supporting Statistical Analysis of Empirical Research Results in the Statistica Program Teaching Materials StatSoft Polska; StatSoft: Kraków, Poland, 2009. [Google Scholar]

- Botwin, M.; Ciesielczuk, P.; Sztyber, J. Trial applications of high-speed video recording for studying some machines used in forestry. Zesz. Probl. Postępów Nauk Rol. 1973, 148, 45–54. [Google Scholar]

- Stempski, W.; Grodecki, J. The influence of the sharpening angle of cutting links on cutting efficiency and durability of chain saws. Poznańskie Tow. Przyj. L Nauk. Pr. Kom. Nauk Rol. I Leśnych 1998, 86, 73–82. [Google Scholar]

- Więsik, J. Energy of cutting of wood with a chainsaw. Rocz. Nauk Rol. 1990, t. 78-C-1, 144–156. [Google Scholar]

| Initial Chain Tension | Feed Force [N] | Mean Deflection Angle [°] | Min [°] | Max [°] | Standard Deviation [°] |

|---|---|---|---|---|---|

| Oak wood | |||||

| Slack | 20 | 0.23 | −4.69 | 4.66 | 1.87 |

| 80 | −0.41 | −5.34 | 3.99 | 1.78 | |

| Tight | 20 | −0.55 | −5.99 | 3.91 | 1.98 |

| 80 | 0.01 | −6.68 | 5.33 | 2.41 | |

| Pine wood | |||||

| Slack | 20 | 0.78 | −3.91 | 5.88 | 1.86 |

| 80 | −0.15 | −4.81 | 4.32 | 1.87 | |

| Tight | 20 | −1.19 | −9.10 | 3.91 | 3.24 |

| 80 | −0.20 | −3.92 | 3.91 | 1.53 | |

| Initial Chain Tension | Feed Force [N] | Mean Deflection Angle [°] | Min [°] | Max [°] | Standard Deviation [°] |

|---|---|---|---|---|---|

| Oak wood | |||||

| Slack | 20 | 1.52 | 0.00 | 4.69 | 1.11 |

| 80 | 1.42 | 0.00 | 5.34 | 1.13 | |

| Tight | 20 | 1.59 | 0.00 | 5.99 | 1.29 |

| 80 | 1.88 | 0.00 | 6.68 | 1.49 | |

| Pine wood | |||||

| Slack | 20 | 1.55 | 0.00 | 5.88 | 1.29 |

| 80 | 1.43 | 0.00 | 4.81 | 1.21 | |

| Tight | 20 | 2.55 | 0.00 | 9.10 | 2.32 |

| 80 | 1.18 | 0.00 | 3.92 | 0.99 | |

| Initial Chain Tension | Feed Force [N] | Speed vx Rivet 1 [m·s−1] | Speed vx Rivet 2 [m·s−1] | Probability Value p for Differences Between Rivet Speeds | Standard Deviation vx Rivet 1 [m·s−1] | Standard Deviation vx Rivet 2 [m·s−1] |

|---|---|---|---|---|---|---|

| Oak wood | ||||||

| Slack | 20 | 20.42 | 19.58 | 0.272 | 7.61 | 3.84 |

| 80 | 20.86 | 20.1 | 0.359 | 8.63 | 4.62 | |

| Tight | 20 | 20.57 | 20.3 | 0.603 | 4.57 | 3.53 |

| 80 | 19.46 | 19.04 | 0.447 | 4.4 | 4.02 | |

| Pine wood | ||||||

| Slack | 20 | 21.54 | 21.56 | 0.973 | 5.60 | 4.14 |

| 80 | 20.08 | 20.03 | 0.912 | 4.39 | 2.91 | |

| Tight | 20 | 22 | 21.90 | 0.870 | 4.75 | 2.85 |

| 80 | 18.87 | 19.02 | 0.775 | 4.49 | 3.64 | |

| Initial Chain Tension | Feed Force [N] | Mean Speed vx [m·s−1 ] | Min [m·s−1] | Max [m·s−1] | Standard Deviation [m·s−1] |

|---|---|---|---|---|---|

| Oak wood | |||||

| Slack | 20 | 19.99 | 5.13 | 88.58 | 6.02 |

| 80 | 20.47 | 3.17 | 91.5 | 6.90 | |

| Tight | 20 | 20.43 | 1.1 | 33.67 | 4.08 |

| 80 | 19.25 | 0.46 | 37.05 | 4.21 | |

| Pine wood | |||||

| Slack | 20 | 21.55 | 5.67 | 35.25 | 4.91 |

| 80 | 20.05 | 9.09 | 35.24 | 3.71 | |

| Tight | 20 | 21.95 | 1.14 | 51.6 | 3.88 |

| 80 | 18.94 | 5.68 | 40.92 | 4.08 | |

| Oak, Slack Chain, 20 N | Oak, Slack Chain, 80 N | Oak, Tight Chain, 20 N | Oak, Tight Chain, 80 N | Pine, Slack Chain, 20 N | Pine, Slack Chain, 80 N | Pine, Tight Chain, 20 N | Pine, Tight Chain, 80 N | |

|---|---|---|---|---|---|---|---|---|

| Oak, slack chain, 20 N | 1 | 0.398 | 0.356 | 0.119 | 0.006 | 0.896 | 0.000 | 0.029 |

| Oak, slack chain, 80 N | 0.398 | 1 | 0.939 | 0.019 | 0.081 | 0.413 | 0.008 | 0.003 |

| Oak, tight chain, 20 N | 0.356 | 0.939 | 1 | 0.002 | 0.015 | 0.302 | 0.000 | 0.000 |

| Oak, tight chain, 80 N | 0.119 | 0.018 | 0.002 | 1 | 0.000 | 0.031 | 0.000 | 0.426 |

| Pine, slack chain, 20 N | 0.006 | 0.081 | 0.015 | 0.000 | 1 | 0.000 | 0.405227 | 0.000 |

| Pine, slack chain, 80 N | 0.896 | 0.413 | 0.302 | 0.031 | 0.000 | 1 | 0.000 | 0.003 |

| Pine, tight chain, 20 N | 0.000 | 0.008 | 0.000 | 0.000 | 0.405 | 0.000 | 1 | 0.000 |

| Pine, tight chain, 80 N | 0.029 | 0.004 | 0.000 | 0.426 | 0.000 | 0.003 | 0.000 | 1 |

| Initial Chain Tension | Feed Force [N] | Speed vy Rivet 1 [m·s−1] | Speed vy Rivet 2 [m·s−1] | Probability Value p for Differences Between Rivet Speeds | Standard deviation vx Rivet 1 [m·s−1] | Standard Deviation vx Rivet 2 [m·s−1] |

|---|---|---|---|---|---|---|

| Oak wood | ||||||

| Slack | 20 | 2.36 | 2.01 | 0.139 | 2.04 | 1.69 |

| 80 | 2.32 | 2.85 | 0.043 | 1.97 | 2.36 | |

| Tight | 20 | 2.62 | 2.11 | 0.048 | 1.93 | 1.93 |

| 80 | 2.62 | 2.79 | 0.559 | 2.08 | 2.25 | |

| Pine wood | ||||||

| Slack | 20 | 2.37 | 2.59 | 0.493 | 2.25 | 2.30 |

| 80 | 1.99 | 2.24 | 0.330 | 1.81 | 1.88 | |

| Tight | 20 | 2.65 | 2.25 | 0.165 | 2.16 | 1.88 |

| 80 | 2.50 | 2.29 | 0.437 | 2.04 | 2.18 | |

| Initial Chain Tension | Feed Force [N] | Mean Speed vy [m·s−1] | Min [m·s−1] | Max [m·s−1] | Standard Deviation [m·s−1] |

|---|---|---|---|---|---|

| Oak wood | |||||

| Slack | 20 | 2.18 | 0.00 | 9.76 | 1.88 |

| 80 | 2.58 | 0.00 | 11.04 | 2.19 | |

| Tight | 20 | 2.35 | 0.00 | 8.36 | 1.94 |

| 80 | 2.70 | 0.00 | 9.77 | 2.17 | |

| Pine wood | |||||

| Slack | 20 | 2.48 | 0.00 | 10.91 | 2.28 |

| 80 | 2.12 | 0.00 | 10.92 | 1.85 | |

| Tight | 20 | 2.44 | 0.00 | 9.55 | 2.03 |

| 80 | 2.40 | 0.00 | 9.57 | 2.11 | |

| Oak, Slack Chain, 20 N | Oak, Slack Chain, 80 N | Oak, Tight Chain, 20 N | Oak, Tight Chain, 80 N | Pine, Slack Chain, 20 N | Pine, Slack Chain, 80 N | Pine, Tight Chain, 20 N | Pine, Tight Chain, 80 N | |

|---|---|---|---|---|---|---|---|---|

| Oak, slack chain, 20 N | 1 | 0.024 | 0.329 | 0.004 | 0.127 | 0.693 | 0.153 | 0.238 |

| Oak, slack chain, 80 N | 0.024 | 1 | 0.216 | 0.538 | 0.624 | 0.011 | 0.487 | 0.330 |

| Oak, tight chain, 20 N | 0.329 | 0.216 | 1 | 0.070 | 0.532 | 0.187 | 0.629 | 0.818 |

| Oak, tight chain, 80 N | 0.004 | 0.538 | 0.070 | 1 | 0.307 | 0.002 | 0.209 | 0.126 |

| Pine, slack chain, 20 N | 0.127 | 0.624 | 0.532 | 0.307 | 1 | 0.072 | 0.871 | 0.691 |

| Pine, slack chain, 80 N | 0.693 | 0.011 | 0.187 | 0.002 | 0.072 | 1 | 0.082 | 0.135 |

| Pine, tight chain, 20 N | 0.153 | 0.487 | 0.629 | 0.209 | 0.871 | 0.082 | 1 | 0.806 |

| Pine, tight chain, 80 N | 0.238 | 0.330 | 0.818 | 0.126 | 0.691 | 0.135 | 0.806 | 1 |

| Initial Chain Tension | Feed Force [N] | Acceleration ax Rivet 1 [m·s−2] | Acceleration ax Rivet 2 [m·s−2] | Probability Value p for Differences Between Accelerations | Standard Deviation vx Rivet 1 [m·s−2] | Standard Deviation vx Rivet 2 [m·s−2] |

|---|---|---|---|---|---|---|

| Oak wood | ||||||

| Slack | 20 | 82.68 | 61.27 | 0.109 | 135.78 | 69.13 |

| 80 | 102.82 | 65.19 | 0.0048 | 142.80 | 66.90 | |

| Tight | 20 | 72.12 | 53.38 | 0.022 | 60.55 | 61.91 |

| 80 | 71.556 | 61.86 | 0.259 | 68.08 | 63.96 | |

| Pine wood | ||||||

| Slack | 20 | 118.02 | 100.75 | 0.246 | 102.07 | 104.49 |

| 80 | 59.48 | 45.59 | 0.065 | 56.83 | 39.48 | |

| Tight | 20 | 83.14 | 67.12 | 0.213 | 106.63 | 73.39 |

| 80 | 68.93 | 63.04 | 0.487 | 64.05 | 63.66 | |

| Initial Chain Tension | Feed Force [N] | ay Rivet 1 [m·s−2] | ay Rivet 2 [m·s−2] | Probability Value p for Differences Between Accelerations | Standard Deviation vx Rivet 1 [m·s−2] | Standard Deviation vx Rivet 2 [m·s−2] |

|---|---|---|---|---|---|---|

| Oak wood | ||||||

| Slack | 20 | 20.11 | 18.31 | 0.444 | 18.07 | 19.92 |

| 80 | 23.94 | 30.37 | 0.012 | 20.29 | 22.65 | |

| Tight | 20 | 24.50 | 21.87 | 0.306 | 19.37 | 19.33 |

| 80 | 23.33 | 24.19 | 0.779 | 21.66 | 25.02 | |

| Pine wood | ||||||

| Slack | 20 | 24.65 | 25.72 | 0.733 | 23.34 | 20.05 |

| 80 | 20.13 | 19.54 | 0.806 | 18.64 | 17.47 | |

| Tight | 20 | 23.27 | 23.59 | 0.905 | 19.46 | 19.73 |

| 80 | 21.43 | 23.56 | 0.442 | 17.82 | 23.53 | |

| Initial Chain Tension | Feed Force [N] | Mean Acceleration [m·s−2] | Min [m·s−2] | Max [m·s−2] | Standard Deviation [m·s−2] |

|---|---|---|---|---|---|

| Acceleration in the X axis | |||||

| Slack | 20 | 109.39 | 0.00 | 358.44 | 103.38 |

| 80 | 52.54 | 0.00 | 259.20 | 49.31 | |

| Tight | 20 | 75.13 | 0.00 | 619.20 | 91.65 |

| 80 | 65.99 | 0.00 | 313.80 | 63.78 | |

| Acceleration in the Y axis | |||||

| Slack | 20 | 25.18 | 0.00 | 112.20 | 21.71 |

| 80 | 19.83 | 0.00 | 98.21 | 18.03 | |

| Tight | 20 | 23.43 | 0.00 | 98.19 | 19.54 |

| 80 | 22.49 | 0.00 | 99.30 | 20.85 | |

| Slack Chain, 20 N | Slack Chain, 80 N | Tight Chain, 20 N | Tight Chain, 80 N | |

|---|---|---|---|---|

| Slack chain, 20 N | 1 | 0.000 | 0.000 | 0.000 |

| Slack chain, 80 N | 0.000 | 1 | 0.001 | 0.013 |

| Tight chain, 20 N | 0.000 | 0.001 | 1 | 0.226 |

| Tight chain, 80 N | 0.000 | 0.012 | 0.226 | 1 |

| Slack Chain, 20 N | Slack Chain, 80 N | Tight Chain, 20 N | Tight Chain, 80 N | |

|---|---|---|---|---|

| Slack chain, 20 N | 1 | 0.006 | 0.397 | 0.196 |

| Slack chain, 80 N | 0.006 | 1 | 0.050 | 0.148 |

| Tight chain, 20 N | 0.397 | 0.050 | 1 | 0.631 |

| Tight chain, 80 N | 0.196 | 0.148 | 0.631 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maciak, A.; Kubuśka-Orłowska, M. The Effect of Selected Operation Factors on Cutter Deflection Angles, Instantaneous Speeds, and Accelerations While Cutting Wood with a Petrol Chainsaw. Forests 2025, 16, 859. https://doi.org/10.3390/f16050859

Maciak A, Kubuśka-Orłowska M. The Effect of Selected Operation Factors on Cutter Deflection Angles, Instantaneous Speeds, and Accelerations While Cutting Wood with a Petrol Chainsaw. Forests. 2025; 16(5):859. https://doi.org/10.3390/f16050859

Chicago/Turabian StyleMaciak, Adam, and Magda Kubuśka-Orłowska. 2025. "The Effect of Selected Operation Factors on Cutter Deflection Angles, Instantaneous Speeds, and Accelerations While Cutting Wood with a Petrol Chainsaw" Forests 16, no. 5: 859. https://doi.org/10.3390/f16050859

APA StyleMaciak, A., & Kubuśka-Orłowska, M. (2025). The Effect of Selected Operation Factors on Cutter Deflection Angles, Instantaneous Speeds, and Accelerations While Cutting Wood with a Petrol Chainsaw. Forests, 16(5), 859. https://doi.org/10.3390/f16050859