Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review

Abstract

1. Introduction and Scope

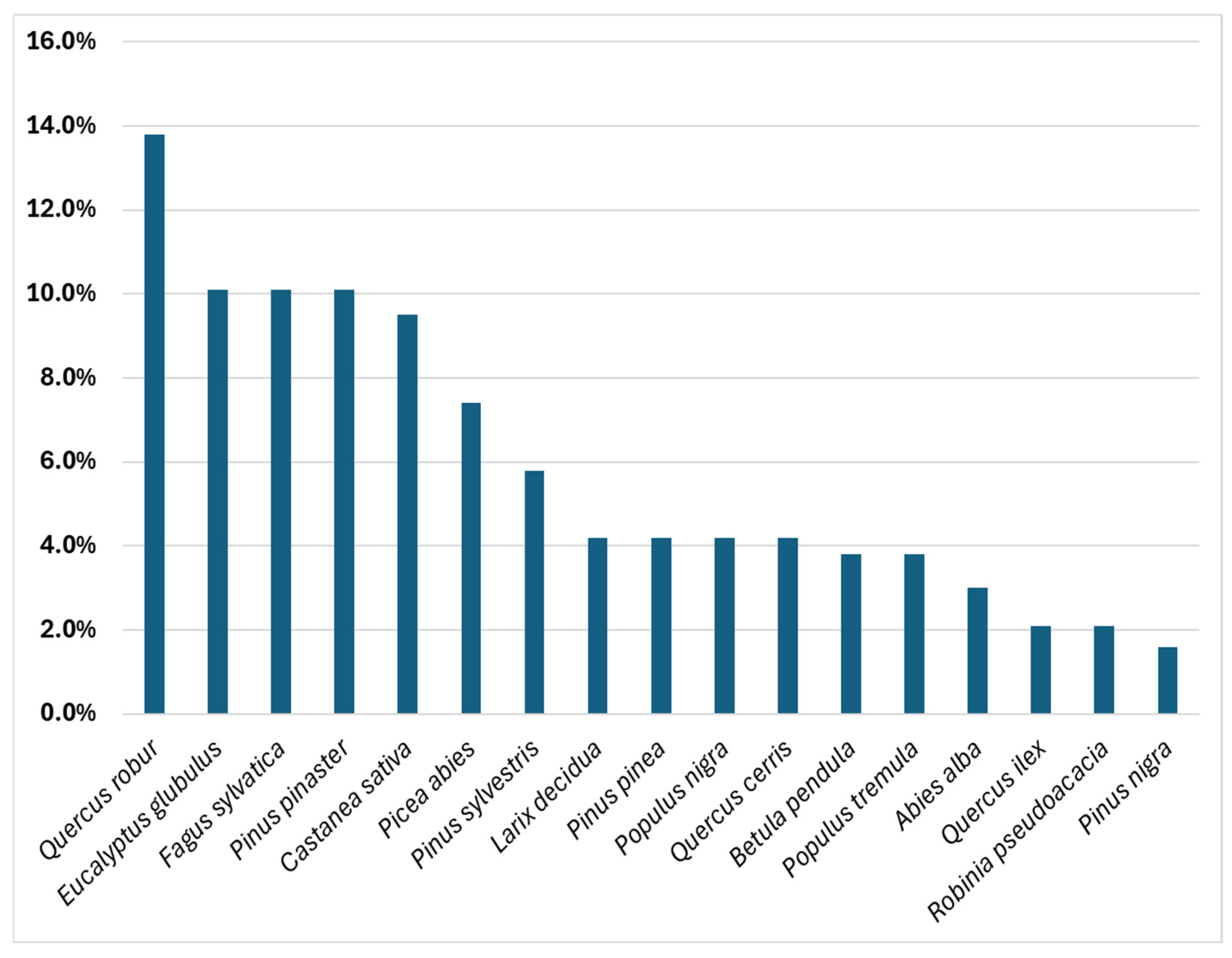

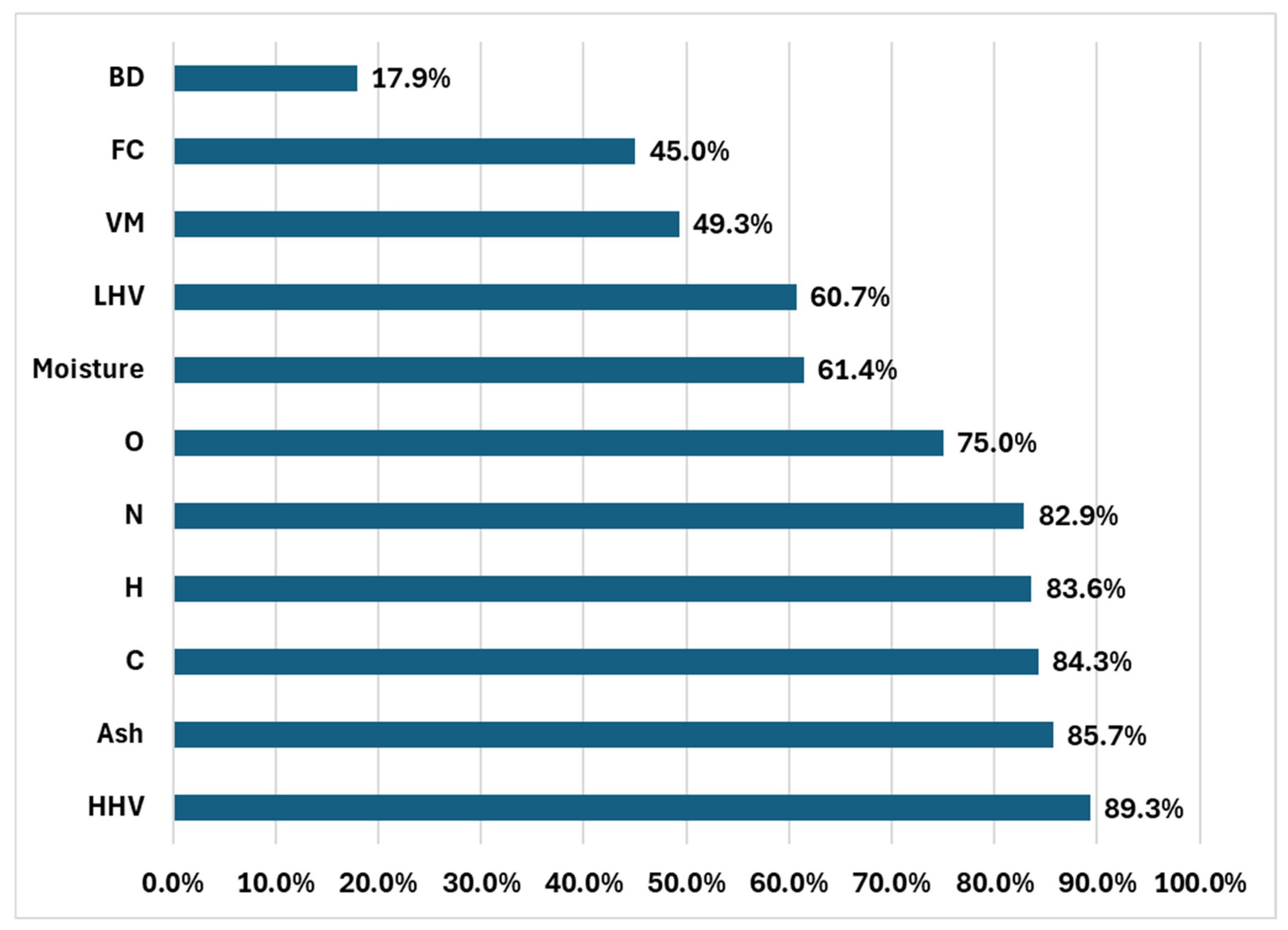

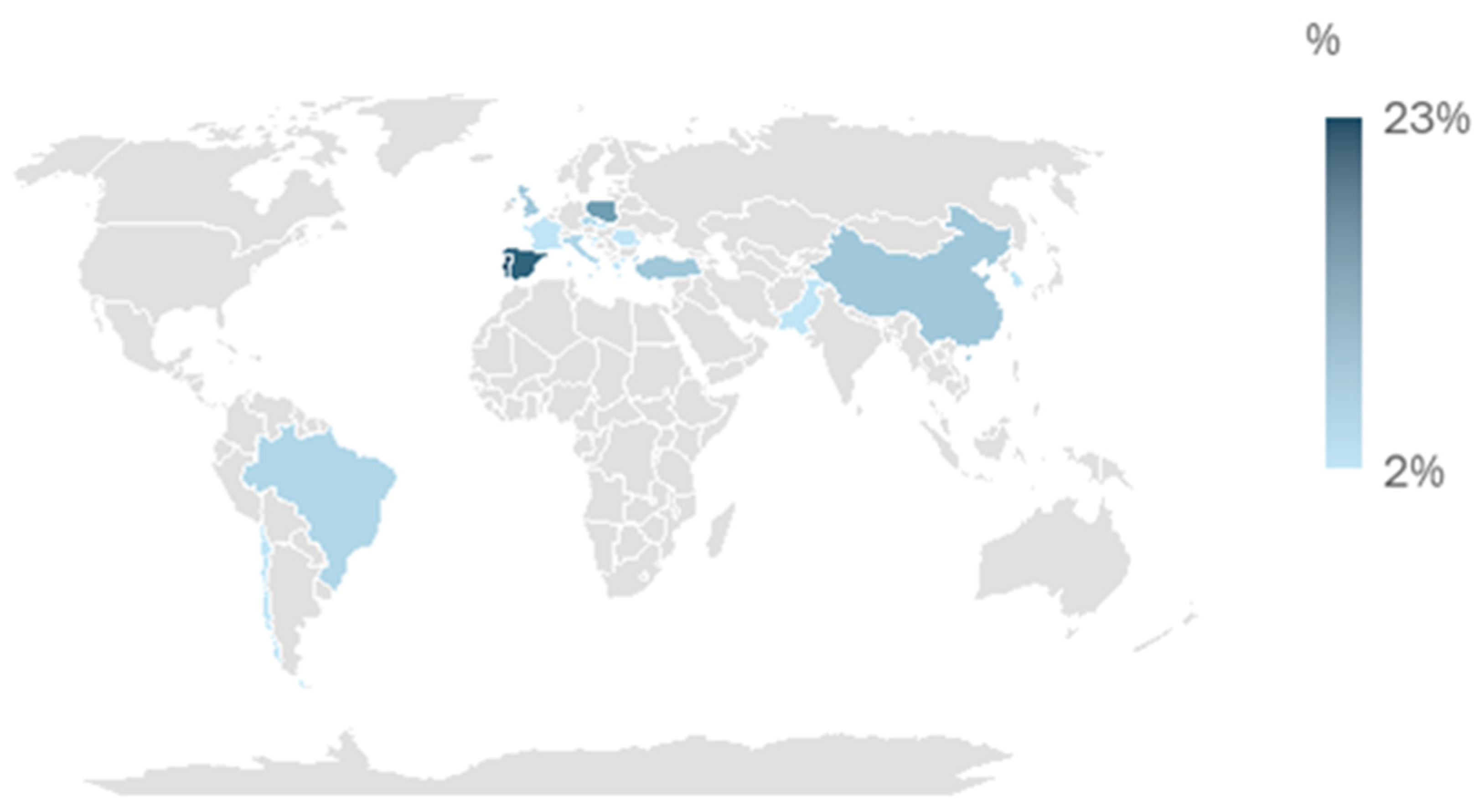

2. Method

3. Physicochemical Properties of Forest Biomass

3.1. Moisture Content

3.2. Ash Content

3.3. Volatile Matter Content

3.4. Fixed Carbon Content

3.5. Elemental Composition

3.6. Bulk Density

3.7. Energy Content

4. Discussion

| Specie | SI | M % | A % | VM % | FC % | C % | O % | H % | N % | HHV MJ kg−1 | LHV MJ kg−1 | BD kg m−3 | Ref |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Betula pendula Roth | M | 34.8 | 0.6 | 80.4 | 18.9 | 53.1 | 40.3 | 6.3 | 0.3 | 19.7 | 11.2 | nd | [59,60] |

| SD | 17.7 | 0.3 | 0.8 | 0.6 | 2.4 | 2.5 | 0.1 | 0.1 | 0.1 | 3.6 | nd | ||

| Castanea sativa Mill. | M | 42.8 | 1.2 | 77.8 | 18.9 | 46.5 | 46.0 | 6.0 | 1.3 | 17.8 | 7.6 | 597.5 | [11,48,61,62,63,64] |

| SD | 19.4 | 0.9 | 2.5 | 2.0 | 1.1 | 2.2 | 0.6 | 1.0 | 0.6 | 3.2 | 9.6 | ||

| Eucalyptus globulus Labill. | M | 32.0 | 1.2 | 80.2 | 16.2 | 48.2 | 44.2 | 6.7 | 0.8 | 18.6 | 11.5 | 627.0 | [14,48,61,62,64,65,66,67,68,69,70] |

| SD | 23.5 | 0.9 | 6.4 | 1.8 | 2.7 | 3.4 | 1.9 | 0.9 | 1.6 | 5.4 | 4.2 | ||

| Fagus sylvatica L. | M | 33.6 | 1.2 | 81.4 | 17.8 | 48.9 | 41.6 | 7.6 | 1.0 | 19.3 | 12.4 | 750.0 | [61,63,64,71,72,73,74,75,76,77] |

| SD | 23.5 | 0.9 | 6.4 | 1.8 | 2.7 | 3.4 | 1.9 | 0.9 | 1.6 | 5.4 | 4.2 | ||

| Populus nigra L. | M | 52.0 | 2.9 | 77.5 | 19.6 | 48.0 | 46.2 | 4.3 | 0.5 | 18.5 | 17.2 | 285.1 | [48,61,70,78,79] |

| SD | 62.9 | nd | nd | nd | 2.9 | 5.4 | 2.7 | 0.3 | 0.2 | 1.5 | nd | ||

| Populus tremula L. | M | 40.8 | 1.7 | 79.4 | 18.6 | 50.6 | 43.1 | 6.1 | 0.3 | 19.1 | 10.4 | nd | [59,73,74] |

| SD | 21.1 | 1.0 | 0.7 | 0.4 | 1.3 | 1.2 | 0.1 | 0.1 | 0.6 | 4.1 | nd | ||

| Quercus cerris L. | M | 33.6 | 3.0 | 77.8 | 17.0 | 47.9 | 43.8 | 6.2 | 1.4 | 18.9 | nd | 500.0 | [5,76,80] |

| SD | 15.5 | 1.9 | 4.9 | 1.3 | 1.2 | 3.2 | 0.4 | 1.3 | 1.1 | nd | nd | ||

| Quercus ilex L. | M | 8.9 | 2.0 | 80.8 | 11.3 | 46.5 | 44.9 | 5.8 | 0.4 | 18.4 | 17.1 | 890.0 | [65,81,82] |

| SD | nd | 1.9 | 2.7 | nd | 2.4 | 5.1 | 0.1 | 0.2 | 0.9 | 0.1 | nd | ||

| Quercus robur L. | M | 40.9 | 2.0 | 78.7 | 16.3 | 47.2 | 44.2 | 7.1 | 1.2 | 18.3 | 9.0 | 621.0 | [48,59,61,62,63,64,73,83,84,85] |

| SD | 19.1 | 2.7 | 1.8 | 7.6 | 3.7 | 3.8 | 2.1 | 0.9 | 0.6 | 4.4 | 27.0 | ||

| Robinia pseudoacacia L. | M | 42.6 | 0.8 | 86.2 | 12.8 | 46.3 | 46.2 | 6.1 | 0.1 | 18.4 | 14.9 | 285.5 | [74,79,86] |

| SD | nd | 0.7 | nd | nd | nd | nd | nd | nd | 0.9 | 2.6 | nd | ||

| Abies alba Mill. | M | 8.6 | 4.1 | 74.0 | 18.2 | 49.2 | 44.0 | 5.7 | 0.4 | 18.6 | 17.4 | 510.0 | [49,87,88,89] |

| SD | 5.8 | 5.0 | 8.9 | 10.8 | 1.8 | 2.2 | 1.0 | 0.2 | 1.1 | nd | nd | ||

| Larix decidua Mill. | M | 33.6 | 0.9 | 61.9 | 23.0 | 50.9 | 42.6 | 5.8 | 0.3 | 19.5 | 10.2 | 732.0 | [49,59,83,90] |

| SD | 22.9 | 0.5 | 24.6 | 1.3 | 4.5 | 5.5 | 1.2 | 0.1 | 1.5 | 3.7 | 73.5 | ||

| Picea abies L. | M | 26.6 | 0.9 | 74.6 | 23.0 | 52.7 | 38.3 | 6.1 | 0.4 | 20.1 | 13.4 | nd | [49,59,73,75,76,91,92] |

| SD | 20.6 | 0.7 | 7.5 | 4.3 | 3.9 | 4.0 | 0.2 | 0.3 | 0.7 | 4.5 | nd | ||

| Pinus nigra Arnold. | M | 9 | 0.35 | 58.1 | 32.8 | 50.5 | 43.3 | 5.72 | 0.38 | 19.58 | 17.77 | nd | [49,76] |

| SD | nd | 0.4 | nd | nd | 0.64 | nd | 0.8 | 0.2 | 1.2 | nd | nd | ||

| Pinus pinaster Aiton | M | 36.9 | 0.6 | 78.4 | 18.6 | 49.3 | 43.1 | 6.2 | 1.0 | 18.5 | 12.2 | 498.7 | [11,14,49,61,62,64,65,70,76,93,94] |

| SD | 26.4 | 0.3 | 10.4 | 7.9 | 3.0 | 3.3 | 0.5 | 1.0 | 5.2 | 6.1 | 31.5 | ||

| Pinus pinea L. | M | 8.9 | 0.4 | 76.2 | 22.0 | 48.1 | 46.4 | 5.1 | 0.2 | 19.1 | 18.6 | 474 | [48,49,65,70] |

| SD | nd | 0.1 | 9.6 | 5.0 | 5.6 | 6.1 | 0.9 | 0.1 | 0.6 | 0.7 | nd | ||

| Pinus sylvestris L. | M | 28.5 | 0.8 | 76.2 | 20.7 | 54.5 | 37.4 | 6.3 | 0.6 | 20.4 | 13.9 | nd | [49,59,71,73,95,96] |

| SD | 22.4 | 0.7 | 7.0 | 5.6 | 3.3 | 3.5 | 0.3 | 0.8 | 1.9 | 5.9 | nd |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, P.; Nkem, J.; Calvin, K.; Campbell, D.; Cherubini, F.; Grassi, G.; Korotkov, V.; Hoang, A.L.; Lwasa, S.; McElwee, P.; et al. Interlinkages Between Desertification, Land Degradation, Food Security and Greenhouse Gas Fluxes: Synergies, Trade-Offs and Integrated Response Options; Cambridge University Press: Cambridge, UK, 2022; ISBN 9781009157988. [Google Scholar]

- Prasad, B.R.; Padhi, R.K.; Ghosh, G. A Review on Key Pretreatment Approaches for Lignocellulosic Biomass to Produce Biofuel and Value-Added Products. Int. J. Environ. Sci. Technol. 2023, 20, 6929–6944. [Google Scholar] [CrossRef]

- Banerjee, N. Biomass to Energy—An Analysis of Current Technologies, Prospects, and Challenges. Bioenergy Res. 2023, 16, 683–716. [Google Scholar] [CrossRef]

- Putro, J.N.; Soetaredjo, F.E.; Lin, S.Y.; Ju, Y.H.; Ismadji, S. Pretreatment and Conversion of Lignocellulose Biomass into Valuable Chemicals. RSC Adv. 2016, 6, 46834–46852. [Google Scholar] [CrossRef]

- Jerzak, W.; Acha, E.; Li, B. Comprehensive Review of Biomass Pyrolysis: Conventional and Advanced Technologies, Reactor Designs, Product Compositions and Yields, and Techno-Economic Analysis. Energies 2024, 17, 5082. [Google Scholar] [CrossRef]

- Wang, H.M.; Yang, W.; Sipponen, M.H.; Dai, L. Editorial: Lignocellulosic Biomass-Based Materials: Design, Fabrication, and Applications. Front. Bioeng. Biotechnol. 2023, 11, 1188168. [Google Scholar] [CrossRef] [PubMed]

- European Union. Directive 2009/28/EC of the European Parliament and of the Council o parliament and of the council of 23 April 2009. Off. J. Eur. Union 2009, 16–62. [Google Scholar]

- Selivanov, E.; Cudlín, P.; Horáček, P. Carbon Neutrality of Forest Biomass for Bioenergy: A Scoping Review. iForest 2023, 16, 70–77. [Google Scholar] [CrossRef]

- European Commission Directive (EU). 2023/2413 of the European Parliament and of the Council of 18 October 2023 Amending Directive (EU) 2018/2001, Regulation (EU) 2018/1999 and Directive 98/70/EC as Regards the Promotion of Energy from Renewable Sources. Off. J. Eur. Union 2023, 2413, 1–77. [Google Scholar]

- Commission, E. Directives Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance). Off. J. Eur. Union 2018, 82–209. [Google Scholar]

- Álvarez-Álvarez, P.; Pizarro, C.; Barrio-Anta, M.; Cámara-Obregón, A.; María Bueno, J.L.; Álvarez, A.; Gutiérrez, I.; Burslem, D.F.R.P. Evaluation of Tree Species for Biomass Energy Production in Northwest Spain. Forests 2018, 9, 160. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R.; Miles, T.R. Combustion Properties of Biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Biomass Combustion Systems: A Review on the Physical and Chemical Properties of the Ashes. Renew. Sustain. Energy Rev. 2016, 53, 235–242. [Google Scholar] [CrossRef]

- Viana, H.; Rodrigues, A.; Lopes, D.M.M.; Godina, R.; Nunes, L.J.R.; Matias, J.C.O. Pinus Pinaster and Eucalyptus Globulus Energetic Properties and Ash Characterization. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe, EEEIC/I and CPS Europe 2018, Palermo, Italy, 12–15 June 2018. [Google Scholar] [CrossRef]

- Racero-Galaraga, D.; Rhenals-Julio, J.D.; Sofan-German, S.; Mendoza, J.M.; Bula-Silvera, A. Proximate Analysis in Biomass: Standards, Applications and Key Characteristics. Results Chem. 2024, 12, 101886. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Cai, J.; He, Y.; Yu, X.; Banks, S.W.; Yang, Y.; Zhang, X.; Yu, Y.; Liu, R.; Bridgwater, A.V. Review of Physicochemical Properties and Analytical Characterization of Lignocellulosic Biomass. Renew. Sustain. Energy Rev. 2017, 76, 309–322. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Pan, X.; Zalesny, R.S. Pretreatment of Woody Biomass for Biofuel Production: Energy Efficiency, Technologies, and Recalcitrance. Appl. Microbiol. Biotechnol. 2010, 87, 847–857. [Google Scholar] [CrossRef]

- Smołka-Danielowska, D.; Jabłońska, M. Chemical and Mineral Composition of Ashes from Wood Biomass Combustion in Domestic Wood-Fired Furnaces. Int. J. Environ. Sci. Technol. 2022, 19, 5359–5372. [Google Scholar] [CrossRef]

- Wang, L.; Dibdiakova, J. Characterization of Ashes from Different Wood Parts of Norway Spruce Tree. Chem. Eng. Trans. 2014, 37, 37–42. [Google Scholar] [CrossRef]

- Bianchini, L.; Costa, P.; Dell’omo, P.P.; Colantoni, A.; Cecchini, M.; Monarca, D. An Industrial Scale, Mechanical Process for Improving Pellet Quality and Biogas Production from Hazelnut and Olive Pruning. Energies 2021, 14, 1600. [Google Scholar] [CrossRef]

- Lee, J.S.; Lau, A.K. Clarifying the Uses of Heating Values; University of British Columbia. CHBE 486; University of British Columbia: Vancouver, BC, Canada, 2017. [Google Scholar] [CrossRef]

- Kalivodová, M.; Baláš, M.; Milčák, P.; Lisá, H.; Lisý, M.; Lachman, J.; Kracík, P.; Križan, P.; Vejražka, K. The determination of higher heating value by calculation based on elemental analysis. Paliva 2022, 14, 8–20. [Google Scholar] [CrossRef]

- Akbari, M. Development of Techno-Economic Model for Assessment of Bio-Hubs in Canada Final Report; IEA Bioenergy: Paris, France, 2022. [Google Scholar]

- Klašnja, B.; Orlović, S.; Galić, Z. Comparison of Different Wood Species as Raw Materials for Bioenergy. South-East Eur. For. 2013, 4, 81–88. [Google Scholar] [CrossRef]

- Asaad, S.M.; Inayat, A.; Rocha-Meneses, L.; Jamil, F.; Ghenai, C.; Shanableh, A. Prospective of Response Surface Methodology as an Optimization Tool for Biomass Gasification Process. Energies 2022, 16, 40. [Google Scholar] [CrossRef]

- Feng, Y.; Xiao, B.; Goerner, K.; Naidu, R. Influence of Particle Size and Temperature on Gasification Performance. Adv. Mater. Res. 2011, 281, 78–83. [Google Scholar] [CrossRef]

- FAO. Ministerial Conference on the Protection of Forests in Europe—FOREST EUROPE. State of Forests; FAO: Rome, Italy, 2020. [Google Scholar]

- Karunanithy, C.; Muthukumarappan, K.; Donepudi, A. Moisture Sorption Characteristics of Corn Stover and Big Bluestem. J. Renew. Energy 2013, 2013, 939504. [Google Scholar] [CrossRef]

- UNI EN ISO 18134-1:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2015. Available online: https://store.uni.com/en/uni-en-iso-18134-1-2015 (accessed on 13 February 2025).

- UNI EN ISO 18122:2016; Solid Biofuels—Determination of Ash Content. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2016. Available online: https://store.uni.com/en/uni-en-iso-18122-2016 (accessed on 13 February 2025).

- Silva, J.P.; Teixeira, S.; Teixeira, J.C. Characterization of the Physicochemical and Thermal Properties of Different Forest Residues. Biomass Bioenergy 2023, 175, 106870. [Google Scholar] [CrossRef]

- Bukar, A.A.; Ben Oumarou, M.; Tela, B.M.; Eljummah, A.M. Assessment of Biomass Gasification: A Review of Basic Design Considerations. Am. J. Energy Res. 2019, 7, 1–14. [Google Scholar] [CrossRef]

- Fantini, M. Biomass Availability, Potential and Characteristics. Lect. Notes Energy 2017, 57, 21–54. [Google Scholar] [CrossRef]

- Riley, J.T.; Marsh, M. Measurement and Importance of Volatile Matter in Coals and Biofuels. J. Test. Eval. 2022, 50, 490–504. [Google Scholar] [CrossRef]

- da Silva, D.A.; Eloy, E.; Caron, B.O.; Trugilho, P.F. Elemental Chemical Composition of Forest Biomass at Different Ages for Energy Purposes. Floresta e Ambiente 2019, 26, e20160201. [Google Scholar] [CrossRef]

- Malico, I. Forest Biomass as an Energy Resource. In Green Energy and Technology; Springer: Cham, Switzerland, 2024; pp. 171–207. [Google Scholar] [CrossRef]

- ISO 18123:2023; Solid Biofuels—Determination of Volatile Matter. ISO: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/83192.html (accessed on 13 February 2025).

- Rabi Prasad, B.; Suman, P.; Ghosh, G.; Padhi, R.K. Physicochemical Characterisation of Lignocellulosic Biomass for the Identification of Potential Candidacy towards Alternative Renewable Energy. In Proceedings of the 2023 International Conference on Power, Instrumentation, Energy and Control, PIECON, Aligarh, India, 10–12 February 2023. [Google Scholar] [CrossRef]

- UNI EN ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2015. Available online: https://store.uni.com/en/uni-en-iso-16948-2015 (accessed on 14 February 2025).

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Lee, J.S.; Sokhansanj, S.; Lau, A.K.; Lim, C.J. Physical Properties of Wood Pellets Exposed to Liquid Water. Biomass Bioenergy 2020, 142, 105748. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical Characterisation and Chemical Composition of Densified Biomass Fuels with Regard to Their Combustion Behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Yu, Q.; Wang, Y.; Van Le, Q.; Yang, H.; Hosseinzadeh-Bandbafha, H.; Yang, Y.; Sonne, C.; Tabatabaei, M.; Lam, S.S.; Peng, W. An Overview on the Conversion of Forest Biomass into Bioenergy. Front. Energy Res. 2021, 9, 684234. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Igathinathane, C.; Archer, D.; McCulloch, R. Energy-Based Break-Even Transportation Distance of Biomass Feedstocks. Front. Energy Res. 2024, 12, 1347581. [Google Scholar] [CrossRef]

- UNI EN ISO 17828:2016; Solid Biofuels—Determination of Bulk Density. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2016. Available online: https://store.uni.com/en/uni-en-iso-17828-2016 (accessed on 14 February 2025).

- De Jong, W. Biomass Composition, Properties, and Characterization; Wiley: Hoboken, NJ, USA, 2014; pp. 36–68. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish Biofuels Heating Value Estimation. Part I: Ultimate Analysis Data. Fuel 2014, 117, 1130–1138. [Google Scholar] [CrossRef]

- Teixeira, B.M.M.; Oliveira, M.; da Silva Borges, A.D. Coniferous Biomass for Energy Valorization: A Thermo-Chemical Properties Analysis. Sustainability 2024, 16, 7622. [Google Scholar] [CrossRef]

- Senelwa, K.; Sims, R.E.H. Fuel Characteristics of Short Rotation Forest Biomass. Biomass Bioenergy 1999, 17, 127–140. [Google Scholar] [CrossRef]

- UNI EN ISO 18125:2018; Solid Biofuels—Determination of Calorific Value. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2018. Available online: https://store.uni.com/en/uni-en-iso-18125-2018 (accessed on 14 February 2025).

- Channiwala, S.A.; Parikh, P.P. A Unified Correlation for Estimating HHV of Solid, Liquid and Gaseous Fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Methodology for Thermal Efficiency and Energy Input Calculations and Analysis of Biomass Cogeneration Unit Characteristics; U.S. Environmental Protection Agency: Washington, DC, USA, 2007.

- UNI EN ISO 17225-2:2021; Solid Biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2021. Available online: https://store.uni.com/uni-en-iso-17225-2-2021 (accessed on 12 February 2025).

- UNI EN ISO 17225-3:2021; Solid Biofuels—Fuel Specifications and Classes—Part 3: Graded Wood Briquettes. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2021. Available online: https://store.uni.com/uni-en-iso-17225-3-2021 (accessed on 12 February 2025).

- UNI EN ISO 17225-5:2014; Solid Biofuels—Fuel Specifications and Classes—Part 5: Graded Firewood. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2014. Available online: https://store.uni.com/uni-en-iso-17225-5-2014 (accessed on 12 February 2025).

- Stolarski, M.J.; Dudziec, P.; Olba-Zięty, E.; Stachowicz, P.; Krzyżaniak, M. Forest Dendromass as Energy Feedstock: Diversity of Properties and Composition Depending on Systematic Genus and Organ. Energies 2022, 15, 1442. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Wojciechowska, N.; Seliwiak, M.; Dobrzański, T.K. Properties of Forest Tree Branches as an Energy Feedstock in North-Eastern Poland. Energies 2024, 17, 1975. [Google Scholar] [CrossRef]

- Lachowicz, H.; Sajdak, M.; Paschalis-Jakubowicz, P.; Cichy, W.; Wojtan, R.; Witczak, M. The Influence of Location, Tree Age and Forest Habitat Type on Basic Fuel Properties of the Wood of the Silver Birch (Betula pendula Roth.) in Poland. Bioenergy Res. 2018, 11, 638–651. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating Values of Wood Pellets from Different Species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Núñez-Regueira, L.; Rodriguez Añón, J.A.; Castifieiras, J.P. Calorific Values and Flammability of Forest Species in Galicia. Coastal and Hillside Zones. Bioresour. Technol. 1996, 57, 283–289. [Google Scholar] [CrossRef]

- Núñez-Regueira, L.; Rodríguez Añón, J.A.; Proupín Castiñeiras, J.P. Calorific Values and Flammability of Forest Species in Galicia. Continental High Mountainous and Humid Atlantic Zones. Bioresour. Technol. 1997, 61, 111–119. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J.; Moreira, N. Proximate Analysis, Backwards Stepwise Regression between Gross Calorific Value, Ultimate and Chemical Analysis of Wood. Bioresour. Technol. 2010, 101, 3808–3815. [Google Scholar] [CrossRef]

- Charvet, F.; Silva, F.; Ruivo, L.; Tarelho, L.; Matos, A.; da Silva, J.F.; Neves, D. Pyrolysis Characteristics of Undervalued Wood Varieties in the Portuguese Charcoal Sector. Energies 2021, 14, 2537. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; Carneiro, A.d.C.; Pereira, H. Potential of Eucalyptus Globulus Industrial Bark as a Biorefinery Feedstock: Chemical and Fuel Characterization. Ind. Crops Prod. 2018, 123, 262–270. [Google Scholar] [CrossRef]

- Gominho, J.; Lourenço, A.; Miranda, I.; Pereira, H. Chemical and Fuel Properties of Stumps Biomass from Eucalyptus Globulus Plantations. Ind. Crops Prod. 2012, 39, 12–16. [Google Scholar] [CrossRef]

- Pinto, F.; Gominho, J.; André, R.N.; Gonçalves, D.; Miranda, M.; Varela, F.; Neves, D.; Santos, J.; Lourenço, A.; Pereira, H. Improvement of Gasification Performance of Eucalyptus Globulus Stumps with Torrefaction and Densification Pre-Treatments. Fuel 2017, 206, 289–299. [Google Scholar] [CrossRef]

- Arteaga-Pérez, L.E.; Segura, C.; Espinoza, D.; Radovic, L.R.; Jiménez, R. Torrefaction of Pinus Radiata and Eucalyptus Globulus: A Combined Experimental and Modeling Approach to Process Synthesis. Energy Sustain. Dev. 2015, 29, 13–23. [Google Scholar] [CrossRef]

- Rodrigues, A.; Loureiro, L.; Nunes, L.J.R. Torrefaction of Woody Biomasses from Poplar SRC and Portuguese Roundwood: Properties of Torrefied Products. Biomass Bioenergy 2018, 108, 55–65. [Google Scholar] [CrossRef]

- Sahin, H.T. Proximate, Ultimate and Calorific Analysis of European Beech Tree (Fagus Sylvatica) Components for Fuel. Asian J. Chem. Sci. 2021, 10, 8–14. [Google Scholar] [CrossRef]

- Greenhalf, C.E.; Nowakowski, D.J.; Harms, A.B.; Titiloye, J.O.; Bridgwater, A.V. A Comparative Study of Straw, Perennial Grasses and Hardwoods in Terms of Fast Pyrolysis Products. Fuel 2013, 108, 216–230. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Dudziec, P. Wood Pellet Quality Depending on Dendromass Species. Renew Energy 2022, 199, 498–508. [Google Scholar] [CrossRef]

- Kamperidou, V.; Lykidis, C.; Barmpoutis, P. Utilization of Wood and Bark of Fast-Growing Hardwood Species in Energy Production. J. For. Sci. 2018, 64, 164–170. [Google Scholar] [CrossRef]

- Demirbaş, A.; Demirbaş, A.H. Estimating the Calorific Values of Lignocellulosic Fuels. Energy Explor. Exploit. 2004, 22, 135–143. [Google Scholar] [CrossRef]

- Picchio, R.; Spina, R.; Sirna, A.; Monaco, A.L.; Civitarese, V.; Del Giudice, A.; Suardi, A.; Pari, L. Characterization of Woodchips for Energy from Forestry and Agroforestry Production. Energies 2012, 5, 3803–3816. [Google Scholar] [CrossRef]

- Lieskovský, M.; Jankovský, M.; Trenčiansky, M.; Merganič, J.; Dvořák, J. Ash Content vs. the Economics of Using Wood Chips for Energy: Model Based on Data from Central Europe. Bioresources 2017, 12, 1579–1592. [Google Scholar] [CrossRef]

- Carrier, M.; Loppinet-Serani, A.; Denux, D.; Lasnier, J.M.; Ham-Pichavant, F.; Cansell, F.; Aymonier, C. Thermogravimetric Analysis as a New Method to Determine the Lignocellulosic Composition of Biomass. Biomass Bioenergy 2011, 35, 298–307. [Google Scholar] [CrossRef]

- Civitarese, V.; Faugno, S.; Picchio, R.; Assirelli, A.; Sperandio, G.; Saulino, L.; Crimaldi, M.; Sannino, M. Production of Selected Short-Rotation Wood Crop Species and Quality of Obtained Biomass. Eur. J. For. Res. 2018, 137, 541–552. [Google Scholar] [CrossRef]

- Miranda, M.T.; Arranz, J.I.; Rojas, S.; Montero, I. Energetic Characterization of Densified Residues from Pyrenean Oak Forest. Fuel 2009, 88, 2106–2112. [Google Scholar] [CrossRef]

- Matías, J.; Gonzalez, J.; Matías, J.; Royano, L.; González, J. Solid Biofuels: Pellets and Chips. Fuel Specifications and Use in Extremadura Biomass waleva life project view project mesocex view project solid biofuels: Pellets and chips. fuel specifications and use in extremadura biomass. In Proceedings of the 1st International Congress on Bioenergy, Portalegre, Portugal, 23–25 May 2013. [Google Scholar]

- Gañan, J.; González, J.F.; González-García, C.M.; Cuerda-Correa, E.M.; Macías-García, A. Determination of the Energy Potential of Gases Produced in the Pyrolysis Processes of the Vegetal Carbon Manufacture Industry. Bioresour. Technol. 2006, 97, 711–720. [Google Scholar] [CrossRef] [PubMed]

- Lunguleasa, A.; Spirchez, C.; Olarescu, A.M. Calorific Characteristics of Larch (Larix decidua) and Oak (Quercus robur) Pellets Realized from Native and Torrefied Sawdust. Forests 2022, 13, 361. [Google Scholar] [CrossRef]

- Matin, B.; Brandić, I.; Matin, A.; Ištvanić, J.; Antonović, A. Possibilities of Liquefied Spruce (Picea abies) and Oak (Quercus robur) Biomass as an Environmentally Friendly Additive in Conventional Phenol–Formaldehyde Resin Wood Adhesives. Energies 2024, 17, 4456. [Google Scholar] [CrossRef]

- Mudryk, K.; Jewiarz, M.; Wróbel, M.; Niemiec, M.; Dyjakon, A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies 2021, 14, 4456. [Google Scholar] [CrossRef]

- Ozyuguran, A.; Akturk, A.; Yaman, S. Optimal Use of Condensed Parameters of Ultimate Analysis to Predict the Calorific Value of Biomass. Fuel 2018, 214, 640–646. [Google Scholar] [CrossRef]

- López-González, D.; Fernandez-Lopez, M.; Valverde, J.L.; Sanchez-Silva, L. Thermogravimetric-Mass Spectrometric Analysis on Combustion of Lignocellulosic Biomass. Bioresour. Technol. 2013, 143, 562–574. [Google Scholar] [CrossRef]

- Khan, S.; Ashraf, M.I.; Umair, M.; Majeed, M.A.; Sakici, O.E.; Goheer, M.A.; Jahandad, S. Quantification and Material Characterization of Accumulated Residues as a Biofuel in Moist Temperate Forests of Pakistan. Pak. J. Bot. 2025, 57, 719–726. [Google Scholar] [CrossRef]

- López, F.A.; Rodríguez, O.; Urien, A.; Lobato, B.; Centeno, T.Á.; Alguacil, F.J. Physico-Chemical Characteristics of the Products Derived from the Thermolysis of Waste Abies alba Mill. Wood. J. Environ. Prot. 2013, 04, 26–30. [Google Scholar] [CrossRef]

- Yang, I.; ho Kim, S.; Han, G.S. Effect of Moisture Content of Sawdust and Length to Diameter Ratio of a Hole in Flat-Die Pelletizer on the Fuel Characteristics of Wood Pellets Produced with Quercus Mongolica, Pinus Densiflora, Pinus Rigida and Larix Kaempferi. J. Korean Wood Sci. Technol. 2017, 45, 382–398. [Google Scholar] [CrossRef]

- Malaťák, J.; Gendek, A.; Aniszewska, M.; Velebil, J. Emissions from Combustion of Renewable Solid Biofuels from Coniferous Tree Cones. Fuel 2020, 276, 118001. [Google Scholar] [CrossRef]

- Neiva, D.M.; Araújo, S.; Gominho, J.; de Cássia Carneiro, A.; Pereira, H. An Integrated Characterization of Picea Abies Industrial Bark Regarding Chemical Composition, Thermal Properties and Polar Extracts Activity. PLoS ONE 2018, 13, e0208270. [Google Scholar] [CrossRef]

- Filipe dos Santos Viana, H.; Rodrigues, A.M.; Godina, R.; Matias, J.C.d.O.; Nunes, L.J.R. Evaluation of the Physical, Chemical and Thermal Properties of Portuguese Maritime Pine Biomass. Sustainability 2018, 10, 2877. [Google Scholar] [CrossRef]

- Reva, V.; Fonseca, L.; Lousada, J.L.; Abrantes, I.; Viegas, D.X. Impact of the Pinewood Nematode, Bursaphelenchus Xylophilus, on Gross Calorific Value and Chemical Composition of Pinus Pinaster Woody Biomass. Eur. J. For. Res. 2012, 131, 1025–1033. [Google Scholar] [CrossRef]

- Xu, L.; Zhou, J.; Ni, J.; Li, Y.; Long, Y.; Huang, R. Investigating the Pyrolysis Kinetics of Pinus Sylvestris Using Thermogravimetric Analysis. BioResources 2020, 15, 5577–5592. [Google Scholar] [CrossRef]

- Chen, R.; Li, Q.; Xu, X.; Zhang, D.; Hao, R. Combustion Characteristics, Kinetics and Thermodynamics of Pinus Sylvestris Pine Needle via Non-Isothermal Thermogravimetry Coupled with Model-Free and Model-Fitting Methods. Case Stud. Therm. Eng. 2020, 22, 100756. [Google Scholar] [CrossRef]

- Picchio, R.; Venanzi, R.; Civitarese, V.; Bonaudo, A.; Latterini, F. Energetic Features of Hardwood Pellet Evaluated by Effect Size Summarisation. Forests 2024, 15, 1259. [Google Scholar] [CrossRef]

| Species | Wood Volume (%) |

|---|---|

| Pinus spp. (Pines) | 29.6 |

| Picea spp. (Spruce) | 23.0 |

| Fagus sylvatica L. (Beech) | 11.9 |

| Quercus spp. (Oaks) | 10.0 |

| Betula spp. (Birch) | 6.6 |

| Abies alba Mill. (Fir) | 3.2 |

| Other broadleaf | 12.8 |

| Other conifers | 2.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bianchini, L.; Colantoni, A.; Venanzi, R.; Cozzolino, L.; Picchio, R. Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review. Forests 2025, 16, 702. https://doi.org/10.3390/f16040702

Bianchini L, Colantoni A, Venanzi R, Cozzolino L, Picchio R. Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review. Forests. 2025; 16(4):702. https://doi.org/10.3390/f16040702

Chicago/Turabian StyleBianchini, Leonardo, Andrea Colantoni, Rachele Venanzi, Luca Cozzolino, and Rodolfo Picchio. 2025. "Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review" Forests 16, no. 4: 702. https://doi.org/10.3390/f16040702

APA StyleBianchini, L., Colantoni, A., Venanzi, R., Cozzolino, L., & Picchio, R. (2025). Physicochemical Properties of Forest Wood Biomass for Bioenergy Application: A Review. Forests, 16(4), 702. https://doi.org/10.3390/f16040702