Quantity and Quality of Narrow-Leaved Ash (Fraxinus angustifolia Vahl) Wood Forest Products in Relation to Tree Crown Defoliation

Abstract

1. Introduction

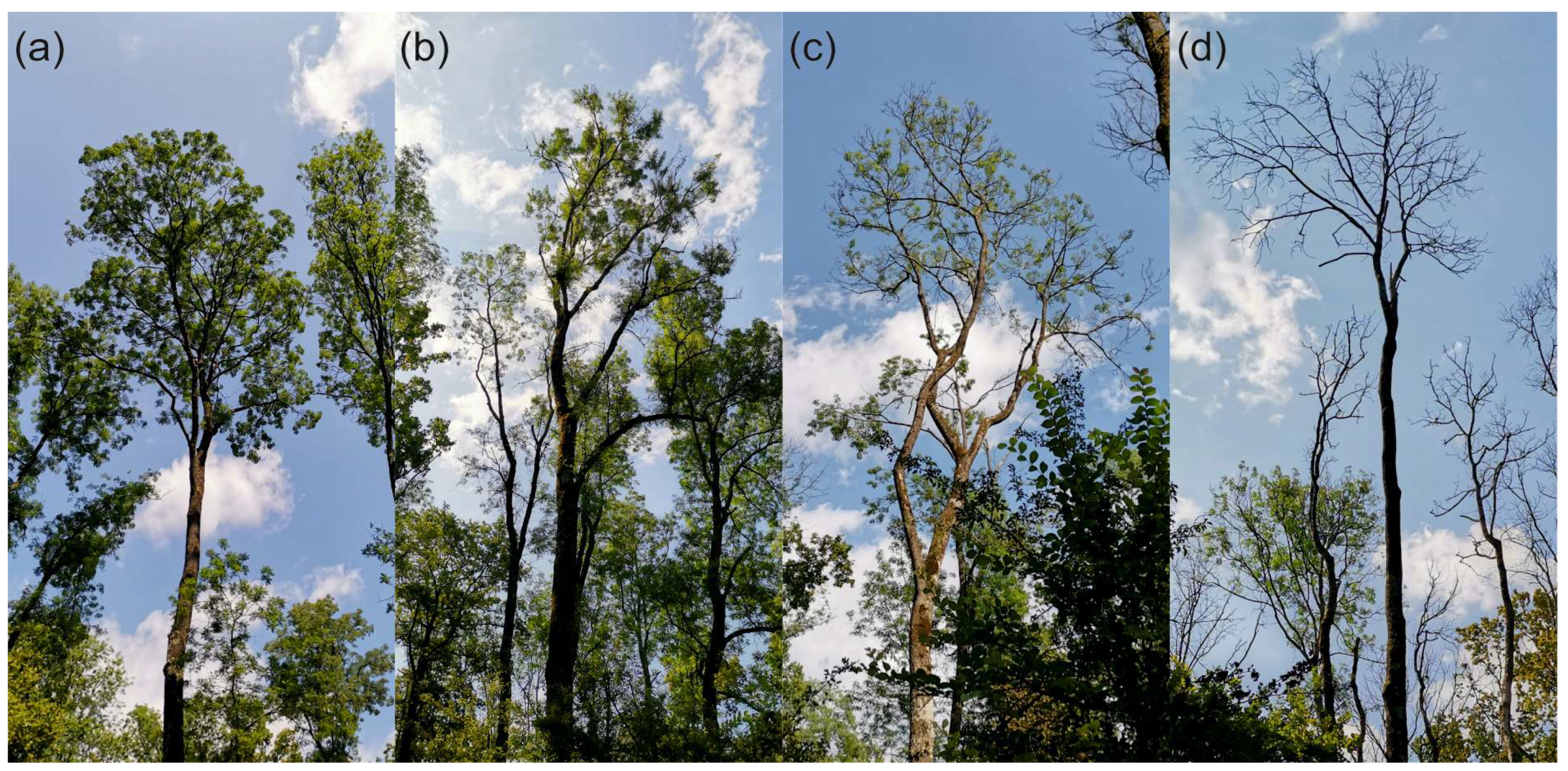

2. Materials and Methods

2.1. Research Sites

2.2. Sample Preparation

2.3. Logs Measurements

2.4. Wood Chips Quality Determination

- WCH–wood chips produced from fuel wood that was produced from H trees;

- WC3A–wood chips produced from fuel wood that was produced from 3A trees;

- WC3B–wood chips produced from fuel wood that was produced from 3B trees;

- WCD–wood chips produced from fuel wood that was produced from D trees.

2.5. Data Processing

3. Results

3.1. Gross and Net Volume

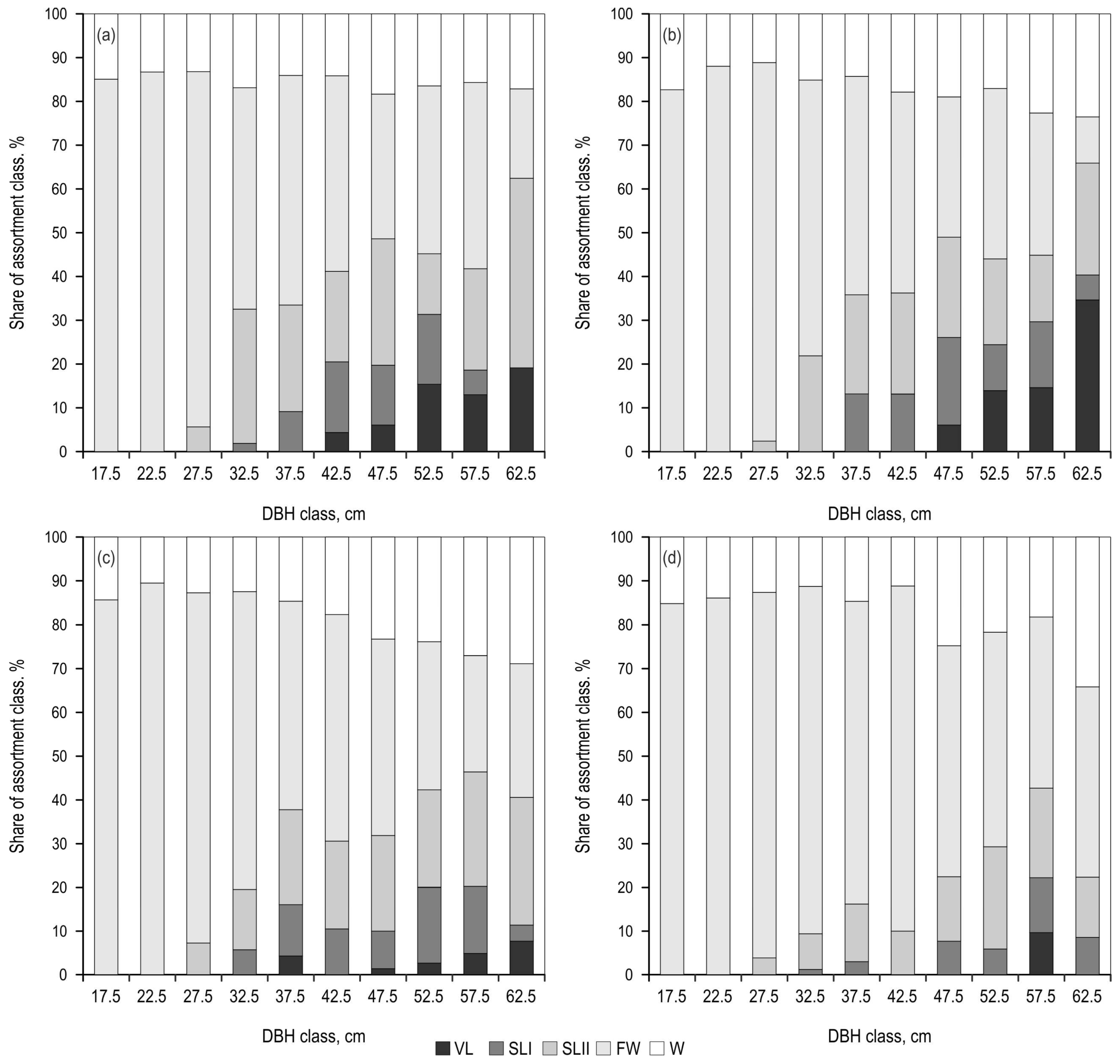

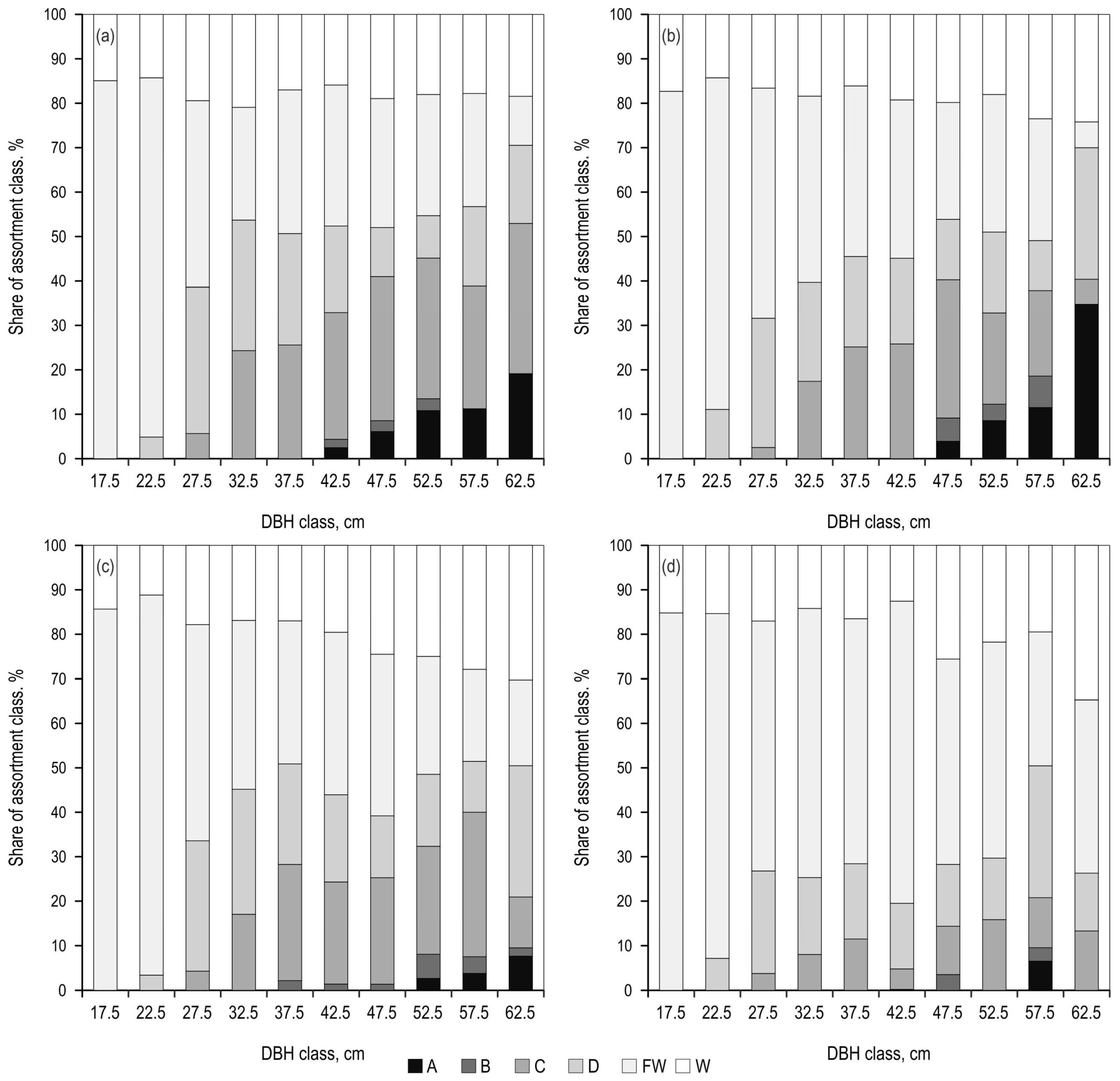

3.2. Assortment Structure and Average Tree Value

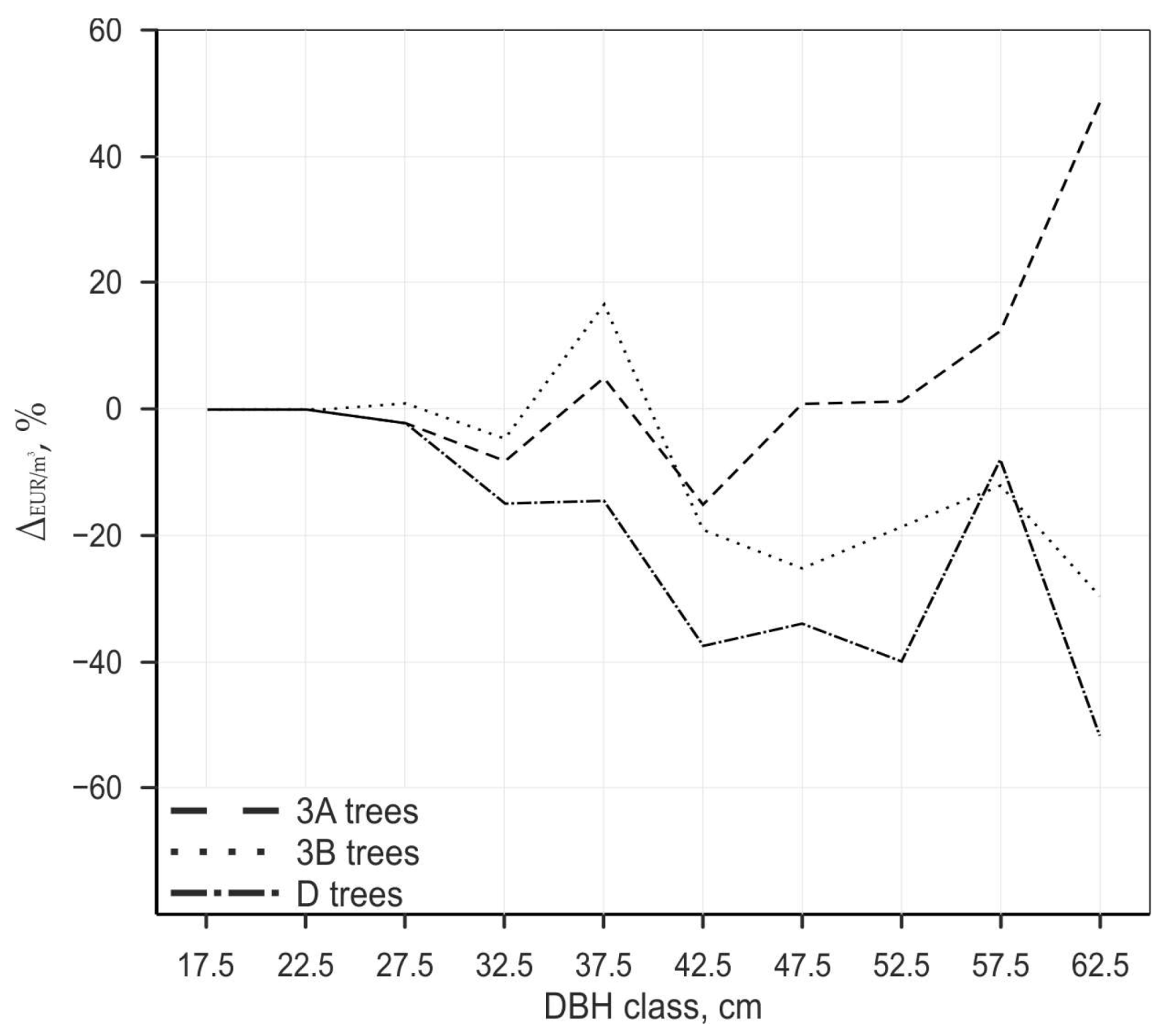

3.2.1. Influence of Tree Crown Defoliation Degree on Actual Average Tree Value

3.2.2. Influence of Site Characteristics on Average Tree Value

3.3. Wood Chips Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Materials and Methods

| Site | Chipper | Mesh Size, mm |

|---|---|---|

| A | Rudnick & Enners, Rudnick & Enners Maschinen- und Anlagenbau GmbH, Alpenrod, Germany | 50 × 50 |

| B | Albach Diamant 2000, Albach Maschinenbau AG, Menning, Germany | 80 × 80 |

| D | Jenz, Jenz GmbH Maschinen- und Fahrzeugbau, Petershagen, Germany | 50 × 50 |

| G | Albach Diamant 2000, Albach Maschinenbau AG, Menning, Germany | 80 × 80 |

| H | Albach Diamant 2000, Albach Maschinenbau AG, Menning, Germany | 80 × 80 |

| Researched Features | Used Standard | Used Equipment |

|---|---|---|

| Moisture content | HRN EN ISO 18134-2–Solid biofuels–Determination of moisture content–Part 2: Total moisture–Simplified method [53] | Heating chambers Binder FD 115 and Binder FD 250, Binder GmbH, Tuttlingen, Germany; Balance Kern 440-49A, KERN & SOHN GmbH, Balingen-Frommern, Germany |

| Sample preparation | HRN EN ISO 14780 Solid biofuels–Sample preparation [43] | Retsch SM 300 cutting mill; Mash size 0.5 mm, Retsch GmbH, Haan, Germany |

| Ash content | HRN EN ISO 18122–Solid biofuels–Determination of ash content [54] | Furnace Nabertherm P330, Nabertherm GmbH, Lilienthal, Germany; Analytical balance Mettler Toledo XA204, Mettler-Toledo AG, Greifensee, Switzerland |

| Moisture in general analysis sample | HRN EN ISO 18134-3:2015 Solid biofuels–Determination of moisture content–Oven dry method–Part 3: Moisture in general analysis sample [55] | Heating chamber Binder FD 115, Binder GmbH, Tuttlingen, Germany; Analytical balance Mettler toledo XA204, Mettler-Toledo AG, Greifensee, Switzerland |

| Carbon, hydrogen, nitrogen, and sulfur content | HRN EN ISO 16948–Solid biofuels–Determination of total content of carbon, hydrogen, and nitrogen [56] HRN EN ISO 16994–Solid biofuels–Determination of total content of sulfur and chlorine [57] | Elementar Vario Macro Cube CHNS configuration, Elementar Analysensysteme GmbH, Langenselbold, Germany; Analytical balance Mettler toledo XA204. Mettler-Toledo AG, Greifensee, Switzerland; Reference material: wood chips of Scots pine (Pinus sylvestris L), Institut für Bioenergie GmbH, Vienna, Austria |

| Calorific value | HRN EN ISO 18125–Solid biofuels–Determination of calorific value [58] | Calorimeter IKA C1/10; Analytical balance Mettler toledo XA204; IKA pelletized benzoic acid, IKA-Werke GmbH & Co. KG, Staufen, Germany |

| Particle size distribution | HRN EN ISO 17827-1–Solid biofuels–Determination of particle size distribution for uncompressed fuels–Part 1: Oscillating screen method using sieves with apertures of 3.15 mm and above [59] | Horizontal sieve shaker Retsch AS 400; Sieve sizes 3.15, 8.0, 16.0, 31.5, 45.0, and 63.0 mm, Retsch GmbH, Haan, Germany; Balance Kern 440-49A, KERN & SOHN GmbH, Balingen-Frommern, Germany |

Appendix B. Results

| Site | Parameter | b* | SE of b* | b | SE of b | t | p | M R2 |

|---|---|---|---|---|---|---|---|---|

| A | Intercept | −1.11771 | 0.112834 | −9.90584 | <0.000001 | 0.9306 | ||

| DBH | 0.941654 | 0.046882 | 0.06427 | 0.003200 | 20.08576 | <0.000001 | ||

| TH | 0.027957 | 0.046882 | 0.00396 | 0.006645 | 0.59634 | 0.552351 | ||

| B | Intercept | −4.21849 | 0.380217 | −11.0950 | <0.000001 | 0.8916 | ||

| DBH | 0.773889 | 0.048749 | 0.09745 | 0.006139 | 15.8750 | <0.000001 | ||

| TH | 0.221630 | 0.048749 | 0.07248 | 0.015942 | 4.5464 | 0.000017 | ||

| C | Intercept | −1.08947 | 0.133049 | −8.18848 | <0.000001 | 0.9510 | ||

| DBH | 0.942445 | 0.063988 | 0.06527 | 0.004432 | 14.72857 | <0.000001 | ||

| TH | 0.039507 | 0.063988 | 0.00515 | 0.008349 | 0.61742 | 0.540741 | ||

| D | Intercept | −0.927716 | 0.105213 | −8.81750 | <0.000001 | 0.9098 | ||

| DBH | 0.815066 | 0.073065 | 0.047843 | 0.004289 | 11.15530 | <0.000001 | ||

| TH | 0.163976 | 0.073065 | 0.015157 | 0.006754 | 2.24424 | 0.029185 | ||

| E | Intercept | −4.69149 | 0.680992 | −6.88920 | <0.000001 | 0.8681 | ||

| DBH | 0.909280 | 0.061634 | 0.14921 | 0.010114 | 14.75278 | <0.000001 | ||

| TH | 0.051102 | 0.061634 | 0.01773 | 0.021384 | 0.82912 | 0.411725 | ||

| F | Intercept | −8.19991 | 1.879386 | −4.36308 | 0.000557 | 0.7942 | ||

| DBH | 0.833225 | 0.120220 | 0.18446 | 0.026614 | 6.93084 | 0.000005 | ||

| TH | 0.179858 | 0.120220 | 0.06597 | 0.044098 | 1.49608 | 0.155376 |

| Site | Parameter | b* | SE of b* | b | SE of b | t | p | M R2 |

|---|---|---|---|---|---|---|---|---|

| A | Intercept | −0.967335 | 0.094949 | −10.1879 | <0.000001 | 0.9353 | ||

| DBH | 0.942301 | 0.045269 | 0.056044 | 0.002692 | 20.8156 | <0.000001 | ||

| TH | 0.030106 | 0.045269 | 0.003719 | 0.005592 | 0.6650 | 0.507616 | ||

| B | Intercept | −3.17431 | 0.342634 | −9.26445 | <0.000001 | 0.8687 | ||

| DBH | 0.787294 | 0.053650 | 0.08118 | 0.005532 | 14.67471 | <0.000001 | ||

| TH | 0.190231 | 0.053650 | 0.05094 | 0.014366 | 3.54580 | 0.000618 | ||

| C | Intercept | −0.863627 | 0.096154 | −8.98168 | <0.000001 | 0.9574 | ||

| DBH | 0.904408 | 0.059646 | 0.048564 | 0.003203 | 15.16283 | <0.000001 | ||

| TH | 0.088483 | 0.059646 | 0.008951 | 0.006034 | 1.48346 | 0.146420 | ||

| D | Intercept | −0.810662 | 0.082790 | −9.79181 | <0.000001 | 0.9152 | ||

| DBH | 0.759500 | 0.070837 | 0.036184 | 0.003375 | 10.72177 | <0.000001 | ||

| TH | 0.229873 | 0.070837 | 0.017245 | 0.005314 | 3.24508 | 0.002076 | ||

| E | Intercept | −3.14835 | 0.751614 | −4.18878 | 0.000141 | 0.7200 | ||

| DBH | 0.828958 | 0.089794 | 0.10305 | 0.011163 | 9.23177 | <0.000001 | ||

| TH | 0.044647 | 0.089794 | 0.01173 | 0.023601 | 0.49722 | 0.621630 | ||

| F | Intercept | −5.28652 | 1.072518 | −4.92908 | 0.000182 | 0.8490 | ||

| DBH | 0.866585 | 0.102974 | 0.12782 | 0.015188 | 8.41557 | <0.000001 | ||

| TH | 0.173661 | 0.102974 | 0.04244 | 0.025166 | 1.68645 | 0.112390 |

| TCDD | Parameter | b* | SE of b* | b | SE of b | t | p | M R2 |

|---|---|---|---|---|---|---|---|---|

| H | Intercept | −1.44904 | 0.398053 | −3.64033 | 0.000531 | 0.9108 | ||

| DBH | 0.078852 | 0.10485 | 0.008036 | 13.04742 | 0.000000 | 0.078852 | ||

| TH | 0.078852 | −0.02275 | 0.021119 | −1.07715 | 0.285277 | 0.078852 | ||

| 3A | Intercept | −2.00402 | 0.314772 | −6.36658 | <0.000001 | 0.9180 | ||

| DBH | 0.975856 | 0.062314 | 0.10898 | 0.006959 | 15.66019 | <0.000001 | ||

| TH | −0.021145 | 0.062314 | −0.00565 | 0.016653 | −0.33933 | 0.735351 | ||

| 3B | Intercept | −2.28382 | 0.409504 | −5.57704 | <0.000001 | 0.8947 | ||

| DBH | 0.944596 | 0.069652 | 0.11298 | 0.008331 | 13.56169 | <0.000001 | ||

| TH | 0.001436 | 0.069652 | 0.00047 | 0.022564 | 0.02061 | 0.983593 | ||

| D | Intercept | −1.68696 | 0.292228 | −5.77277 | <0.000001 | 0.9002 | ||

| DBH | 0.970022 | 0.063809 | 0.09734 | 0.006403 | 15.20196 | <0.000001 | ||

| TH | −0.024847 | 0.063809 | −0.00643 | 0.016505 | −0.38939 | 0.697878 |

| TCDD | Parameter | b* | SE of b* | b | SE of b | t | p | M R2 |

|---|---|---|---|---|---|---|---|---|

| H | Intercept | −1.20084 | 0.315718 | −3.80352 | 0.000311 | 0.9184 | ||

| DBH | 1.031663 | 0.075389 | 0.08722 | 0.006374 | 13.68455 | <0.000001 | ||

| TH | −0.083594 | 0.075389 | −0.01857 | 0.016750 | −1.10883 | 0.271467 | ||

| 3A | Intercept | −1.52589 | 0.243495 | −6.26661 | <0.000001 | 0.9193 | ||

| DBH | 0.970561 | 0.061826 | 0.08451 | 0.005383 | 15.69831 | <0.000001 | ||

| TH | −0.014007 | 0.061826 | −0.00292 | 0.012882 | −0.22655 | 0.821416 | ||

| 3B | Intercept | −1.90391 | 0.281147 | −6.77194 | <0.000001 | 0.9038 | ||

| DBH | 0.863746 | 0.066560 | 0.07423 | 0.005720 | 12.97703 | <0.000001 | ||

| TH | 0.096283 | 0.066560 | 0.02241 | 0.015492 | 1.44657 | 0.150940 | ||

| D | Intercept | −1.31135 | 0.218090 | −6.01287 | <0.000001 | 0.9016 | ||

| DBH | 0.935370 | 0.063360 | 0.07055 | 0.004779 | 14.76289 | <0.000001 | ||

| TH | 0.016449 | 0.063360 | 0.00320 | 0.012317 | 0.25961 | 0.795739 |

| Effect | SS | DF | MS | F | p |

|---|---|---|---|---|---|

| Intercept | 904,304.6 | 1 | 904,304.6 | 3170.515 | <0.000001 |

| DBH | 118,848.6 | 9 | 13,205.4 | 46.298 | <0.000001 |

| TCDD | 20,258.7 | 3 | 6752.9 | 23.676 | <0.000001 |

| DBH × TCDD | 26,849.4 | 27 | 994.4 | 3.486 | <0.000001 |

| Error | 88,704.4 | 311 | 285.2 |

| TCDD | DBH | Mean, €/m3 | a | b | c | d | e | f | g | h | i | j | k |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H | 17.5 | 35.57 | **** | ||||||||||

| 3A | 17.5 | 35.57 | **** | ||||||||||

| 3B | 17.5 | 35.57 | **** | ||||||||||

| D | 17.5 | 35.57 | **** | ||||||||||

| H | 22.5 | 35.57 | **** | ||||||||||

| 3A | 22.5 | 35.57 | **** | ||||||||||

| 3B | 22.5 | 35.57 | **** | ||||||||||

| D | 22.5 | 35.57 | **** | ||||||||||

| 3A | 27.5 | 36.21 | **** | **** | |||||||||

| D | 27.5 | 36.46 | **** | **** | |||||||||

| H | 27.5 | 37.02 | **** | **** | **** | ||||||||

| 3B | 27.5 | 37.39 | **** | **** | **** | ||||||||

| D | 42.5 | 38.53 | **** | **** | **** | ||||||||

| D | 32.5 | 38.91 | **** | **** | **** | ||||||||

| D | 37.5 | 41.61 | **** | **** | **** | **** | |||||||

| 3A | 32.5 | 41.98 | **** | **** | **** | **** | |||||||

| 3B | 32.5 | 43.56 | **** | **** | **** | **** | **** | ||||||

| H | 32.5 | 45.70 | **** | **** | **** | **** | **** | **** | |||||

| D | 47.5 | 46.97 | **** | **** | **** | **** | **** | **** | |||||

| H | 37.5 | 48.63 | **** | **** | **** | **** | **** | **** | **** | ||||

| 3B | 42.5 | 49.75 | **** | **** | **** | **** | **** | **** | |||||

| 3A | 37.5 | 51.05 | **** | **** | **** | **** | **** | **** | **** | **** | |||

| D | 52.5 | 52.10 | **** | **** | **** | **** | **** | **** | **** | **** | |||

| 3A | 42.5 | 52.27 | **** | **** | **** | **** | **** | **** | **** | **** | |||

| 3B | 47.5 | 53.22 | **** | **** | **** | **** | **** | **** | **** | **** | **** | ||

| 3B | 37.5 | 56.76 | **** | **** | **** | **** | **** | **** | **** | **** | **** | ||

| D | 62.5 | 59.76 | **** | **** | **** | **** | **** | **** | **** | **** | **** | **** | |

| H | 42.5 | 61.55 | **** | **** | **** | **** | **** | **** | **** | **** | **** | ||

| 3B | 52.5 | 70.61 | **** | **** | **** | **** | **** | **** | |||||

| H | 47.5 | 71.05 | **** | **** | **** | **** | **** | **** | **** | **** | **** | ||

| 3A | 47.5 | 71.69 | **** | **** | **** | **** | **** | **** | **** | **** | |||

| 3B | 57.5 | 81.16 | **** | **** | **** | **** | |||||||

| D | 57.5 | 84.85 | **** | **** | **** | **** | **** | **** | |||||

| H | 52.5 | 86.62 | **** | **** | **** | **** | **** | ||||||

| 3B | 62.5 | 86.92 | **** | **** | **** | **** | **** | ||||||

| 3A | 52.5 | 87.71 | **** | **** | |||||||||

| H | 57.5 | 92.16 | **** | **** | **** | ||||||||

| 3A | 57.5 | 103.49 | **** | ||||||||||

| H | 62.5 | 123.38 | **** | **** | **** | **** | **** | **** | **** | **** | **** | **** | **** |

| 3A | 62.5 | 183.25 | **** |

| Effect | SS | DF | MS | F | p |

|---|---|---|---|---|---|

| Intercept | 199,421.1 | 1 | 199,421.1 | 2041.504 | <0.000001 |

| Stand age | 493.5 | 1 | 493.5 | 5.052 | 0.027062 |

| TCDD | 2939.8 | 3 | 979.9 | 10.032 | 0.000009 |

| Stand age × TCDD | 398.9 | 3 | 133.0 | 1.361 | 0.259824 |

| Error | 8693.8 | 89 | 97.7 |

| Effect | SS | DF | MS | F | p |

|---|---|---|---|---|---|

| Intercept | 90,715.92 | 1 | 90,715.92 | 1417.659 | <0.000001 |

| Ash share | 1277.58 | 1 | 1277.58 | 19.965 | 0.000055 |

| TCDD | 486.68 | 1 | 486.68 | 7.606 | 0.008442 |

| Ash share × TCDD | 34.57 | 1 | 34.57 | 0.540 | 0.466217 |

| Error | 2815.56 | 44 | 63.99 |

| Effect | SS | DF | MS | F | p |

|---|---|---|---|---|---|

| Intercept | 140,398.4 | 1 | 140,398.4 | 577.4725 | <0.000001 |

| Phytocenosis | 517.8 | 1 | 517.8 | 2.1298 | 0.152078 |

| TCDD | 2570.5 | 2 | 1285.2 | 5.2863 | 0.009067 |

| Phytocenosis × TCDD | 340.7 | 2 | 170.4 | 0.7007 | 0.502069 |

| Error | 9968.2 | 41 | 243.1 |

| Variable | SS Effect | DF Effect | MS Effect | SS Error | DF Error | MS Error | F | p |

|---|---|---|---|---|---|---|---|---|

| Mar | 54.75357 | 3 | 18.25119 | 230.961 | 53 | 4.35776 | 4.188207 | 0.009843 |

| Adr | 0.06012 | 3 | 0.02004 | 2.242 | 53 | 0.04229 | 0.473847 | 0.701809 |

| d50 | 26.16842 | 3 | 8.72281 | 2055.200 | 53 | 38.77736 | 0.224946 | 0.878636 |

| C | 0.12634 | 3 | 0.04211 | 8.526 | 53 | 0.16087 | 0.261777 | 0.852608 |

| H | 0.75702 | 3 | 0.25234 | 16.275 | 53 | 0.30707 | 0.821763 | 0.487680 |

| N | 0.00323 | 3 | 0.00108 | 0.077 | 53 | 0.00146 | 0.738929 | 0.533538 |

| S | 0.00000 | 3 | 0.00000 | 0.011 | 53 | 0.00020 | 0.006187 | 0.999322 |

| O | 0.93401 | 3 | 0.31134 | 13.122 | 53 | 0.24759 | 1.257451 | 0.298391 |

| Qp, net, d | 0.03557 | 3 | 0.01186 | 1.081 | 53 | 0.02039 | 0.581513 | 0.629740 |

References

- Merganič, J.; Merganičová, K.; Marušák, R.; Tipmann, L.; Šálek, L.; Dragoun, L.; Stolariková, R. Relation between forest stand diversity and anticipated log quality in managed Central European forests. Int. J. Biodivers. Sci. Ecosyst. Serv. Manag. 2016, 12, 128–138. [Google Scholar] [CrossRef]

- Höwler, K.; Vor, T.; Seidel, D.; Annighöfer, P.; Ammer, C. Analyzing effects of intra- and interspecific competition on timber quality attributes of Fagus sylvatica L.—From quality assessments on standing trees to sawn boards. Eur. J. Forest Res. 2019, 138, 327–343. [Google Scholar] [CrossRef]

- van Leeuwen, M.; Hilker, T.; Coops, N.C.; Frazer, G.; Wulder, M.A.; Newnham, G.J.; Culvenor, D.S. Assessment of standing wood and fiber quality using ground and airborne laser scanning: A review. For. Ecol. Manag. 2011, 261, 1467–1478. [Google Scholar] [CrossRef]

- Marenče, J.; Šega, B.; Gornik Bučar, D. Monitoring the Quality and Quantity of Beechwood from Tree of Sawmill Product. Croat. J. For. Eng. 2020, 41, 119–128. [Google Scholar] [CrossRef]

- Pacia, A.; Borowik, P.; Hsiang, T.; Marozau, A.; Matić, S.; Oszako, T. Ash Dieback in Forests and Rural Areas—History and Predictions. Forests 2023, 14, 2151. [Google Scholar] [CrossRef]

- Ministry of Agriculture. Available online: https://poljoprivreda.gov.hr/istaknute-teme/sume-112/sumarstvo/sumskogospodarska-osnova-2016-2025/250 (accessed on 22 October 2024).

- George, J.P.; Sanders, T.G.M.; Timmermann, V.; Potočić, N.; Lang, M. European-wide forest monitoring substantiate the neccessity for a joint conservation strategy to rescue European ash species (Fraxinus spp.). Sci. Rep. 2022, 12, 4764. [Google Scholar] [CrossRef]

- Timmermann, V.; Børja, I.; Hietala, A.M.; Kirisits, T.; Solheim, H. Ash dieback: Pathogen spread and diurnal patterns of ascospore dispersal, with special emphasis on Norway. EPPO Bull. 2011, 41, 14–20. [Google Scholar] [CrossRef]

- Diminić, D. Nova bolest jasena (Fraxinus spp.) u Hrvatskoj. In Proceedings of the Proizvodnja Hrane i Šumarstvo—Temelj Razvoja Istočne Hrvatske, Osijek, Croatia, 14–15 June 2013. [Google Scholar]

- Kowalski, T. Chalara fraxinea sp. nov. associated with dieback of ash (Fraxinus excelsior) in Poland. For. Pathol. 2006, 36, 264–270. [Google Scholar] [CrossRef]

- Baral, H.O.; Queloz, V.; Hosoya, T. Hymenoscyphus fraxineus, the correct scientific name for the fungus causing ash dieback in Europe. IMA Fungus 2014, 5, 79–80. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M. Advancements in Wood Quality Assessment: Standing Tree Visual Evaluation—A Review. Forests 2024, 15, 943. [Google Scholar] [CrossRef]

- Drew, D.M.; Downes, G.; Seifert, T.; Eckes-Shepard, A.; Achim, A. A Review of Progress and Applications in Wood Quality Modelling. Curr. For. Rep. 2022, 8, 317–332. [Google Scholar] [CrossRef]

- Papanderea, S.F.; Stoilov, S.; Cataldo, M.F.; Nichev, P.; Angelov, G.; Proto, A.R. How Different Distribution of Assortments on Worksites Influences Forwarder Performance in Coniferous Plantations. Croat. J. For. Eng. 2025, 46, 33–45. [Google Scholar] [CrossRef]

- Štefančić, A. The Proportion of Wood Assortments in the up-to-7-cm-Diameter Stemwood Volume of the Pedunculate Oak, Sessile-Flowered Oak and Field Ash—Dry Type. Šumarski List 1997, 121, 479–497. [Google Scholar]

- Jozsa, L.A.; Middleton, G.R. A Discussion of Wood Quality Attributes and Their Practical Implications; Forintek Canada Corp.: Western Laboratory, VA, Canada, 1994; pp. 1–51. [Google Scholar]

- Karaszewski, Z.; Bembenek, M.; Mederski, P.S.; Szczepańska-Alvarez, A.; Byczkowski, R.; Kozłowska, A.; Michnowicz, K.; Przytuła, W.; Giefing, D.F. Identifying Beech Round Wood Quality—Distributions and the Influence of Defects on Grading. Drewno 2013, 56, 39–54. [Google Scholar] [CrossRef]

- Plavšić, M. Istraživanje postotnog odnosa sortimenata kod poljskog jasena. Ann. Pro Exp. For. 1972, 16, 177–196. [Google Scholar]

- Štefančić, A. Udio drvnih sortimenata u volumenu krupnog drva do 7 cm promjera za običnu bukvu u jednodobnim sastojinama. Šumarski List 1998, 122, 329–337. [Google Scholar]

- Musienko, S.; Luk’yanets, V.; Tarnopylska, O.; Kobets, O.; Babenko, V. Merchantability and assortment structure of pine stands affected by root rot in the Volyn Polissya region, Ukraine. Cent. Eur. For. J. 2018, 64, 96–103. [Google Scholar] [CrossRef]

- Pająk, M.; Michalec, K.; Wąsik, R.; Urban, O.; Pietrzykowski, M. Growth and Timber Quality of European Larch Planted in Areas Reclaimed After Coal Mining in Central Poland. Croat. J. For. Eng. 2023, 44, 347–356. [Google Scholar] [CrossRef]

- Parzych, S.; Mandziuk, A. Prices of timber sales in intermediate harvest in Norway spruce stands depending on their age and site index class. Sylwan 2021, 165, 533–541. [Google Scholar] [CrossRef]

- Bojanin, S. Učešće sortimenata i količina gubitaka kod sječe i izrade jelovih stabala u fitocenozi jele sa rebračom (Abieto-Blechnetum). Šumarski List 1960, 84, 21–34. [Google Scholar]

- Petráš, R.; Mecko, J.; Bošeľa, M.; Šebeň, V. Wood quality and value production in mixed fir-spruce-beech stands: Long-term research in the Western Carpathians. Lesn. Cas. For. J. 2016, 62, 98–104. [Google Scholar] [CrossRef][Green Version]

- Prka, M. Features of Assigned Beech Trees According to the Type of Felling in The Felling Areas of Bjelovarska Bilogora and Their Influence on the Assortment Structure. Šumarski List 2006, 130, 319–329. [Google Scholar]

- Prka, M. Defining Assortment Structure of Even-Aged Beech Stands According to Standard HRN EN 1316-1:1999. Šumarski List 2008, 132, 223–238. [Google Scholar]

- Golubović, U. Istraživanje količinskih i vrijednosnih gubitaka u oboljelim sastojinama hrasta lužnjaka. Ann. Pro Exp. For. 1992, 28, 257–278. [Google Scholar]

- Zečić, Ž.; Stankić, I.; Vusić, D.; Bosner, A.; Jakšić, D. Volume Utilization and Value of Timber Assortmets of Dried Silver Fir (Abies alba Mill.) Trees. Šumarski List 2009, 133, 27–37. [Google Scholar]

- Tikvić, I.; Zečić, Ž.; Ugarković, D.; Posarić, D. Damage of Forest Trees and Quality of Timber Assortmets of Pedunculate Oak on Spačva Area. Šumarski List 2009, 133, 237–248. [Google Scholar]

- Paladinić, E.; Štimac, D.; Marjanović, D.; Balenović, I.; Ostrogović, M.Z. Production Aspect of Silver Fir (Abies Alba Mill.) Dieback on Example of a Few Beech-Fir Stands. Šumarski List 2011, 135, 248–260. [Google Scholar]

- Paixo, C.; Krause, C.; Morin, H.; Achim, A. Wood quality of black spruce and balsam fir trees defoliated by spruce budworm: A case study in the boreal forest of Quebec, Canada. For. Ecol. Manag. 2019, 437, 201–210. [Google Scholar] [CrossRef]

- Lemay, A.; Barrette, J.; Krause, C. Balsam Fir (Abies balsamea (L.) Mill.) Wood Quality after Defoliation by Spruce Budworm (Choristoneura fumiferana Clem.) in the Boreal Forest of Quebec, Canada. Forests 2022, 13, 1926. [Google Scholar] [CrossRef]

- Prka, M.; Poršinsky, T. Structure Comparison of Technical Roundwood in Even-Aged Beech Cutblocks by Assortment Tables with Application of Standards HRN (1995) and HRN EN 1316-1:1999. Šumarski List 2009, 133, 15–25. [Google Scholar]

- Malinen, J.; Piira, T.; Kilpeläinen, H.; Wall, T.; Verkasalo, E. Timber Assortment Recovery Models for Southern Finland. Balt. For. 2020, 16, 102–112. [Google Scholar]

- Havreljuk, F.; Achim, A.; Auty, D.; Bédard, S.; Pothier, D. Integrating standing value estimations into tree marking guidelines to meet wood supply objectives. Can. J. For. Res. 2014, 44, 750–759. [Google Scholar] [CrossRef]

- Šašek, M. Iskorištenje pri Sječi i Izradbi i Kakvoćna Struktura Sortimenata Poljskog Jasena (Fraxinus angustifolia Vahl.) u Lipovljanskim Nizinskim Šumama. Master’s Thesis, Faculty of Forestry, University of Zagreb, Zagreb, Croatia, 30 June 2000. [Google Scholar]

- Eichhorn, J.; Roskams, P.; Potočić, N.; Timmermann, V.; Ferretti, M.; Mues, V.; Szepesi, A.; Durrant, D.; Seletković, I.; Schröck, H.W.; et al. Manual on Methods and Criteria for Harmonized Sampling, Assessment, Monitoring and Analysis of the Effects of Air Pollution on Forests; Part IV Visual Assessment of Crown Condition and Damaging Agents, Version 2020-3. 2021, pp. 1–54. Available online: https://www.icp-forests.org/pdf/manual/2020/ICP_Manual_part04_2020_Crown_version_2020-3.pdf (accessed on 12 December 2021).

- HRN D.B4.020 1979; Hrvatske Norme Proizvoda Iskorištavanja Šuma. Trupci za Furnir, Listopadno Drvo. Državni Zavod za Normizaciju i Mjeriteljstvo: Zagreb, Croatia, 1995.

- HRN D.B4.028 1979; Hrvatske Norme Proizvoda Iskorištavanja Šuma. Trupci za Rezanje, Listopadno Drvo. Državni Zavod za Normizaciju i Mjeriteljstvo: Zagreb, Croatia, 1995.

- HRN D.B5.023 1979; Hrvatske Norme Proizvoda Iskorištavanja Šuma. Drvo za Ogrjev. Državni Zavod za Normizaciju i Mjeriteljstvo: Zagreb, Croatia, 1995.

- HRN EN 1316-3:1999; Hardwood Round Timber—Qualitative Classification—Part 3: Ash and Maples and Sycamore (EN 1316-3:1997). Croatian Standards Institute: Zagreb, Croatia, 1999.

- HRN EN ISO 18135:2017; Solid Biofuels—Sampling. Croatian Standards Institute: Zagreb, Croatia, 2017.

- HRN EN ISO 14780; Solid Biofuels—Sample Preparation. Croatian Standards Institute: Zagreb, Croatia, 2017.

- Croatian Forests, Ltd. Available online: https://www.hrsume.hr/wp-content/uploads/2023/01/cjenik_glavnih_sumskih_proizvoda_1.1.2023.pdf (accessed on 15 November 2023).

- NN 71/2019. Regulation on Tree Marking, Forest Product Characteristics, Consignment Note and Forest Order. Available online: https://narodne-novine.nn.hr/clanci/sluzbeni/2019_07_71_1506.html (accessed on 5 June 2023).

- Daniš, M.; Neruda, J. Comparison of The Accuracy of Methods for Calculating the Volume of Standing European Beech Trees. Acta Univ. Agric. Silvic. Mendelianae Brun. 2020, 68, 821–830. [Google Scholar] [CrossRef]

- Baynes, J. Derivation of a One Way Single Tree Volume Table for Small-Scale Forestry. In Proceedings of the ACIAR Smallholder Forestry Project—Improving Financial Returns to Smallholder Tree Farmers in the Philippines, Ormoc City, Philippines, 15–17 February 2005. [Google Scholar]

- Zeghichi, K.; Kherchouche, D.; Bentouati, A.; Sghaier, T.; Belkhiri, L. Adjusting roundwood volume tables for the management of Aleppo Pine stands (Pinus halepensis Mill.) in the Beni Imloul forest in Algeria. Bois Forets Tropiques 2023, 357, 29–42. [Google Scholar] [CrossRef]

- Ligot, G.; Dubart, N.; Hapi, M.T.; Bauwens, S.; Doucet, J.L.; Fayolle, A. Revising volume tables to adapt to changes in timber resources in Cameroon. Bois Forets Tropiques 2018, 338, 57–71. [Google Scholar] [CrossRef]

- Donis, J.; Šņepsts, G.; Zeltiņš, P.; Jansons, J.; Zālītis, P.; Jansons, Ā. Sawlog Recovery in Birch, Black Alder, and Aspen Stands of Hemiboreal Forests in Latvia. Forests 2024, 15, 326. [Google Scholar] [CrossRef]

- Popa, I.; Badea, O.; Silaghi, D. Influence of climate on tree health evaluated by defoliation in the ICP level I network (Romania). Iforest Biogeosci. For. 2017, 10, 554–560. [Google Scholar] [CrossRef]

- Dobbertin, M.; Brank, P. Crown defoliation improves tree mortality models. For. Ecol. Manag. 2001, 141, 271–284. [Google Scholar] [CrossRef]

- HRN EN ISO 18134-2:2017; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. Croatian Standards Institute: Zagreb, Croatia, 2017.

- HRN EN ISO 18122:2015; Solid Biofuels—Determination of Ash Content. Croatian Standards Institute: Zagreb, Croatia, 2015.

- HRN EN ISO 18134-2:2015; Solid Biofuels—Determination of Moisture Content—Part 3: Moisture in General Analysis Sample. Croatian Standards Institute: Zagreb, Croatia, 2015.

- HRN EN ISO 16948:2015; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. Croatian Standards Institute: Zagreb, Croatia, 2015.

- HRN EN ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulfur and Chlorine. Croatian Standards Institute: Zagreb, Croatia, 2016.

- HRN EN ISO 18125:2017; Solid Biofuels—Determination of Calorific Value. Croatian Standards Institute: Zagreb, Croatia, 2017.

- HRN EN ISO 17827-1:2016; Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels—Part 1: Oscillating Screen Method Using Sieves with Apertures of 3.15 mm and Above. Croatian Standards Institute: Zagreb, Croatia, 2016.

| Site | Management Unit; Subcompartment | Coordinates | Phytocenosis | Researched Feature | Age | Ash Share, % |

|---|---|---|---|---|---|---|

| A | Radinje; 20c | φ 45°08′35″ N; λ 17°36′05″ E | Genisto elatae-Quercetum roboris Horvat 1938 | Assortment structure and wood chips quality | 65 | 31.05 |

| B | Radinje; 10b | φ 45°08′49″ N; λ 17°34′44″ E | Genisto elatae-Quercetum roboris Horvat 1938 | Assortment structure and wood chips quality | 95 | 48.57 |

| C | Trstenik; 10a | φ 45°12′48″ N; λ 18°29′32″ E | Genisto elatae Quercetum roboris caricetosum remotae Horvat 1938 | Assortment structure | 70 | 79.20 |

| D | Kusare; 6a | φ 45°07′10″ N; λ 18°36′17″ E | Genisto elatae-Quercetum roboris Horvat 1938 | Assortment structure and wood chips quality | 62 | 43.86 |

| E | Česma; 101c, 99a, 99c | φ 45°49′52″ N; λ 16°37′22″ E | Carpino betuli-Quercetum roboris typicum Rauš 1975 | Assortment structure | 116 | 39.50 |

| F | Turopoljski lug; 88a | φ 45°37′58″ N; λ 16°11′43″ E | Carpino betuli-Quercetum roboris fagetosum Rauš 1975 | Assortment structure | 138 | 14.00 |

| G | Radinje; 9c | φ 45°08′46″ N; λ 17°34′15″ E | Genisto elatae-Quercetum roboris Horvat 1938 | Wood chips quality | 107 | 86.31 |

| H | Grede kamare; 13a | φ 45°15′53″ N; λ 16°58′42″ E | Leucojo-Fraxinetum angustifoliae Glavač 1959 | Wood chips quality | 38 | 100.00 |

| Site | A | B | C | D | E | F | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TCDD | H | 3A | 3B | D | H | 3A | 3B | D | 3B | D | H | 3A | 3B | D | 3A | 3B | D | H | 3A | 3B | D |

| DBH, cm | |||||||||||||||||||||

| 17.5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |||||||||||

| 22.5 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |||||||||||

| 27.5 | 4 b | 4 b | 4 b | 4 b | 4 b | 4 b | 4 | 4 | 4 | 5 | |||||||||||

| 32.5 | 5 a, b | 4 a, b | 4 a, b | 4 a, b | 4 a | 4 a | 4a | 4 a | 4 b | 4 b | 3 | 2 | |||||||||

| 37.5 | 4 a, b | 4 a, b | 4 a, b | 4 a, b | 4 a | 4 a | 4a | 4 a | 4 b | 4 b | 2 | ||||||||||

| 42.5 | 4 a | 4 a | 4 a | 4 a | 4 a | 4 a | 4a | 4 a | 5 | 1 | |||||||||||

| 47.5 | 2 | 4 | 4 c | 4 c | 4 c | 1 c | 7 c | 4 c | 1 | 2 | 1 | ||||||||||

| 52.5 | 4 | 4 c | 4 c | 4 c | 2 c | 5 c | 4 c | 1 | 1 | 1 | |||||||||||

| 57.5 | 4 | 4 | 3 | 4 | 3 | 5 | 1 | 2 | 2 | 1 | |||||||||||

| 62.5 | 3 | 3 | 1 | 2 | 2 | ||||||||||||||||

| Total | 27 | 24 | 24 | 24 | 24 | 24 | 23 | 24 | 20 | 20 | 15 | 14 | 12 | 13 | 6 | 25 | 14 | 4 | 7 | 6 | 1 |

| Site | N | Mean A | Mean E | MND | MPD | p | SD A | SD E | Difference, % |

|---|---|---|---|---|---|---|---|---|---|

| A | 99 | 0.906 | 0.837 | −0.0606 | 0.1313 | >0.10 | 0.608 | 0.537 | 8.21 |

| B | 95 | 2.465 | 2.040 | −0.0211 | 0.2316 | <0.025 * | 1.065 | 0.841 | 20.82 * |

| C | 40 | 0.824 | 0.805 | −0.1250 | 0.1250 | >0.10 | 0.448 | 0.453 | 2.36 |

| D | 54 | 0.550 | 0.477 | −0.0926 | 0.2963 | <0.025 * | 0.276 | 0.227 | 15.38 * |

| E | 45 | 3.461 | 3.298 | −0.1333 | 0.1778 | >0.10 | 1.066 | 0.943 | 4.93 |

| F | 18 | 4.305 | 2.953 | 0.0000 | 0.555556 | <0.01 * | 1.367 | 0.685 | 45.78 * |

| Site | Mean A | Mean E | t-Value | df | p | SD A | SD E | F–Ratio Variances | p Variances |

|---|---|---|---|---|---|---|---|---|---|

| A | 40.34503 | 43.40048 | −2.39277 | 196 | 0.017666 * | 9.132891 | 8.832978 | 1.069060 | 0.741648 |

| B | 58.97778 | 55.95384 | 1.079147 | 188 | 0.281905 | 24.31241 | 12.44410 | 3.817062 | <0.000001 |

| C | 43.40735 | 40.05651 | 1.834057 | 78 | 0.070459 | 10.58738 | 4.628840 | 5.231581 | 0.000001 |

| D | 37.01006 | 36.98164 | 0.039946 | 106 | 0.968211 | 4.277673 | 3.004811 | 2.026660 | 0.011295 |

| E | 58.15193 | 56.02327 | 0.745544 | 88 | 0.457930 | 17.87081 | 6.890167 | 6.727120 | <0.000001 |

| F | 124.3079 | 69.76236 | 5.005913 | 34 | 0.000017 * | 41.50789 | 18.03862 | 5.294863 | 0.001584 |

| Variable | TCDD | N | Mean | Minimum | Maximum | SD |

|---|---|---|---|---|---|---|

| Mar, % | WCH | 15 | 31.19 a | 27.70 | 33.60 | 1.75 |

| WC3A | 15 | 31.12 a | 28.80 | 33.10 | 1.17 | |

| WC3B | 12 | 30.83 ab | 26.70 | 32.90 | 2.08 | |

| WCD | 15 | 28.85 b | 23.70 | 32.60 | 2.95 | |

| Adr, % | WCH | 15 | 1.43 | 1.13 | 1.85 | 0.22 |

| WC3A | 15 | 1.49 | 1.21 | 1.80 | 0.18 | |

| WC3B | 12 | 1.48 | 1.26 | 1.67 | 0.14 | |

| WCD | 15 | 1.41 | 1.07 | 2.09 | 0.25 | |

| d50, cm | WCH | 15 | 16.40 | 8.00 | 25.00 | 6.13 |

| WC3A | 15 | 17.00 | 8.00 | 24.00 | 6.04 | |

| WC3B | 12 | 18.33 | 8.00 | 24.00 | 5.97 | |

| WCD | 15 | 16.93 | 8.00 | 28.00 | 6.70 | |

| C, % | WCH | 15 | 49.39 | 48.70 | 49.83 | 0.36 |

| WC3A | 15 | 49.51 | 48.80 | 49.95 | 0.38 | |

| WC3B | 12 | 49.44 | 48.80 | 50.02 | 0.44 | |

| WCD | 15 | 49.48 | 48.60 | 50.00 | 0.43 | |

| H, % | WCH | 15 | 5.607 | 5.024 | 6.383 | 0.504 |

| WC3A | 15 | 5.590 | 5.138 | 6.483 | 0.473 | |

| WC3B | 12 | 5.876 | 5.160 | 6.787 | 0.694 | |

| WCD | 15 | 5.584 | 5.030 | 6.336 | 0.554 | |

| N, % | WCH | 15 | 0.157 | 0.090 | 0.260 | 0.043 |

| WC3A | 15 | 0.138 | 0.090 | 0.163 | 0.027 | |

| WC3B | 12 | 0.141 | 0.100 | 0.180 | 0.025 | |

| WCD | 15 | 0.148 | 0.100 | 0.277 | 0.050 | |

| S, % | WCH | 15 | 0.013 | <0.002 UCR | 0.045 | 0.013 |

| WC3A | 15 | 0.013 | <0.002 UCR | 0.038 | 0.013 | |

| WC3B | 12 | 0.014 | <0.002 UCR | 0.046 | 0.018 | |

| WCD | 15 | 0.014 | <0.002 UCR | 0.038 | 0.013 | |

| O, % | WCH | 15 | 43.40 | 42.44 | 44.01 | 0.46 |

| WC3A | 15 | 43.26 | 42.40 | 43.85 | 0.49 | |

| WC3B | 12 | 43.06 | 42.33 | 43.92 | 0.48 | |

| WCD | 15 | 43.36 | 42.27 | 44.00 | 0.55 | |

| Qp, net, d, MJ/kg | WCH | 15 | 18.43 | 18.21 | 18.61 | 0.12 |

| WC3A | 15 | 18.45 | 18.28 | 18.59 | 0.10 | |

| WC3B | 12 | 18.41 | 18.10 | 18.56 | 0.17 | |

| WCD | 15 | 18.48 | 18.20 | 18.75 | 0.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ursić, B.; Zečić, Ž.; Vusić, D. Quantity and Quality of Narrow-Leaved Ash (Fraxinus angustifolia Vahl) Wood Forest Products in Relation to Tree Crown Defoliation. Forests 2025, 16, 147. https://doi.org/10.3390/f16010147

Ursić B, Zečić Ž, Vusić D. Quantity and Quality of Narrow-Leaved Ash (Fraxinus angustifolia Vahl) Wood Forest Products in Relation to Tree Crown Defoliation. Forests. 2025; 16(1):147. https://doi.org/10.3390/f16010147

Chicago/Turabian StyleUrsić, Branko, Željko Zečić, and Dinko Vusić. 2025. "Quantity and Quality of Narrow-Leaved Ash (Fraxinus angustifolia Vahl) Wood Forest Products in Relation to Tree Crown Defoliation" Forests 16, no. 1: 147. https://doi.org/10.3390/f16010147

APA StyleUrsić, B., Zečić, Ž., & Vusić, D. (2025). Quantity and Quality of Narrow-Leaved Ash (Fraxinus angustifolia Vahl) Wood Forest Products in Relation to Tree Crown Defoliation. Forests, 16(1), 147. https://doi.org/10.3390/f16010147