Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques

Abstract

1. Introduction

2. Materials and Methods

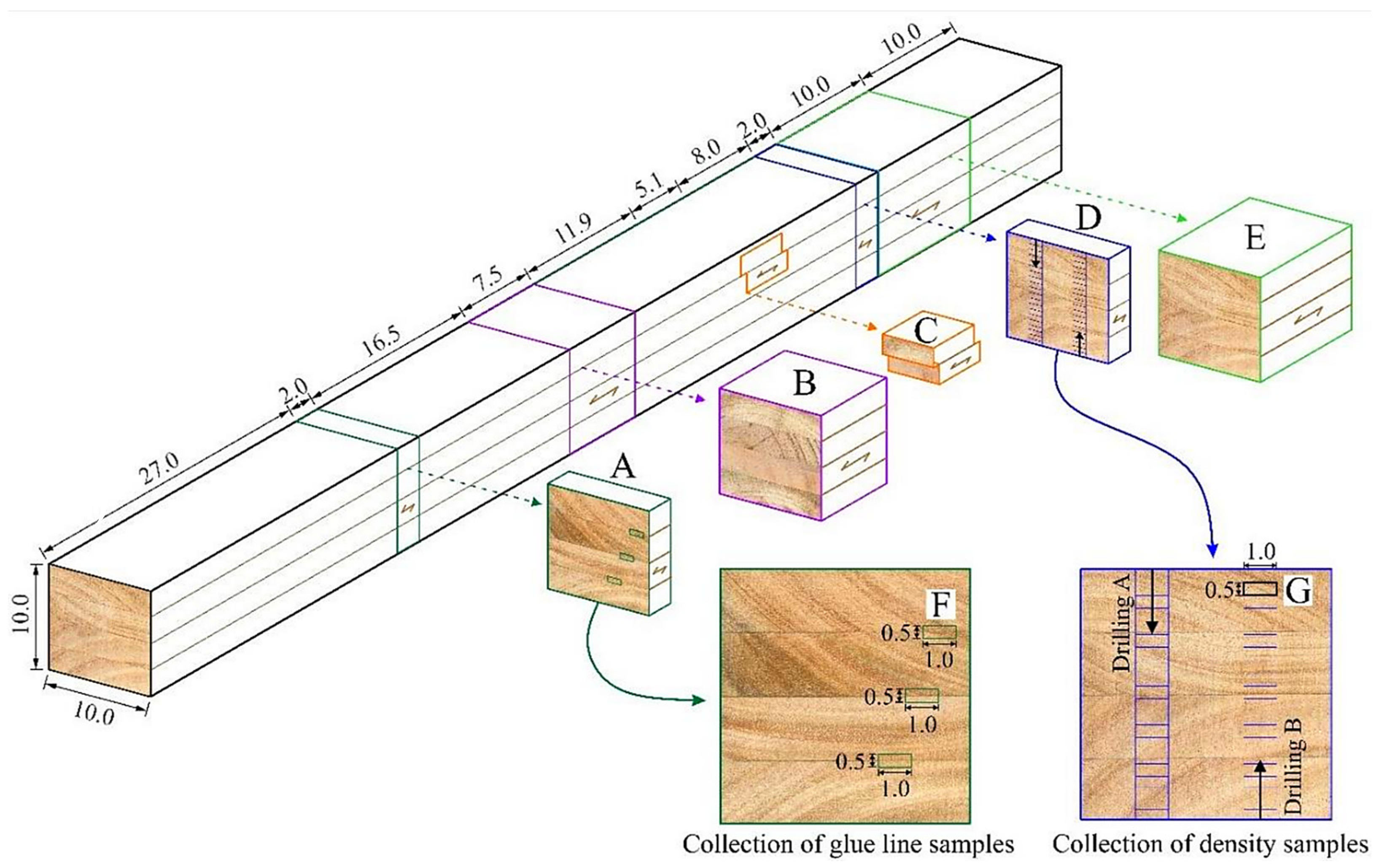

2.1. Materials, Sampling, and Assembly of Glulam Elements

2.2. Delamination Test and Shear and Compressive Strength Test

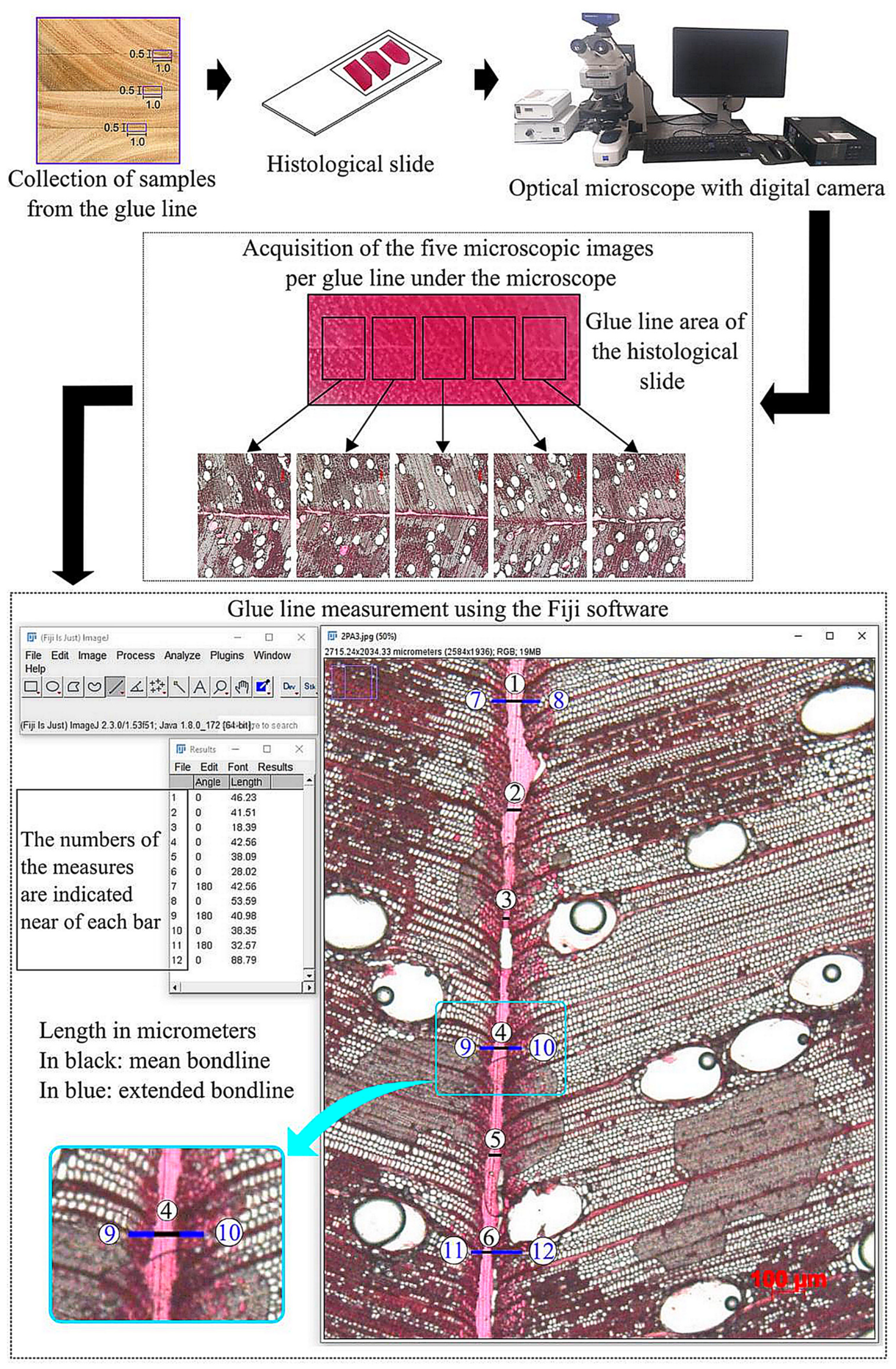

2.3. Glulam Main and Extended Glue Line Thickness

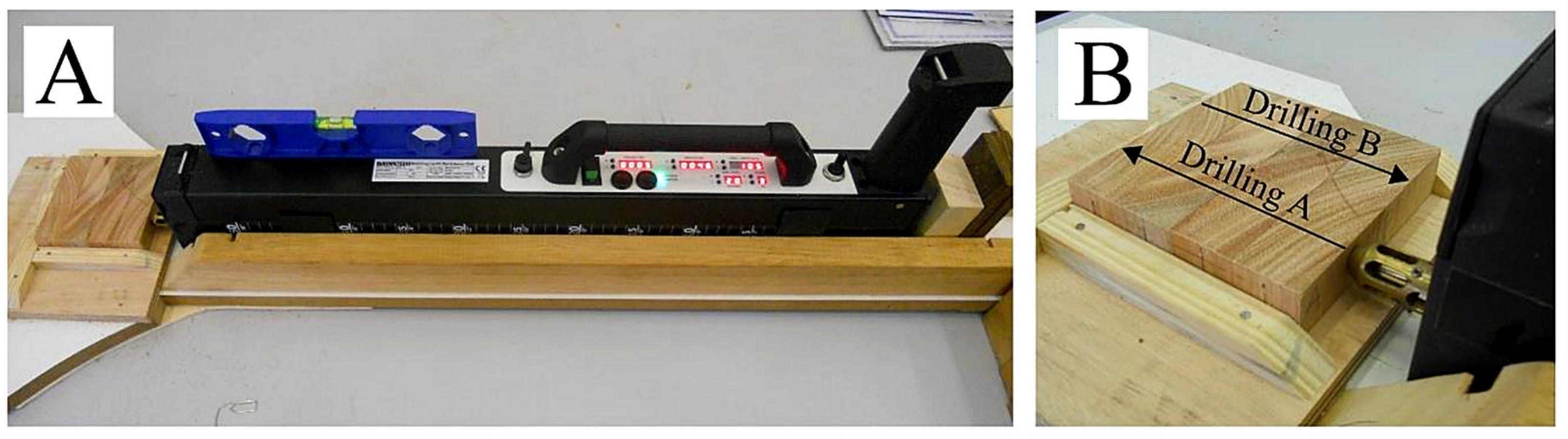

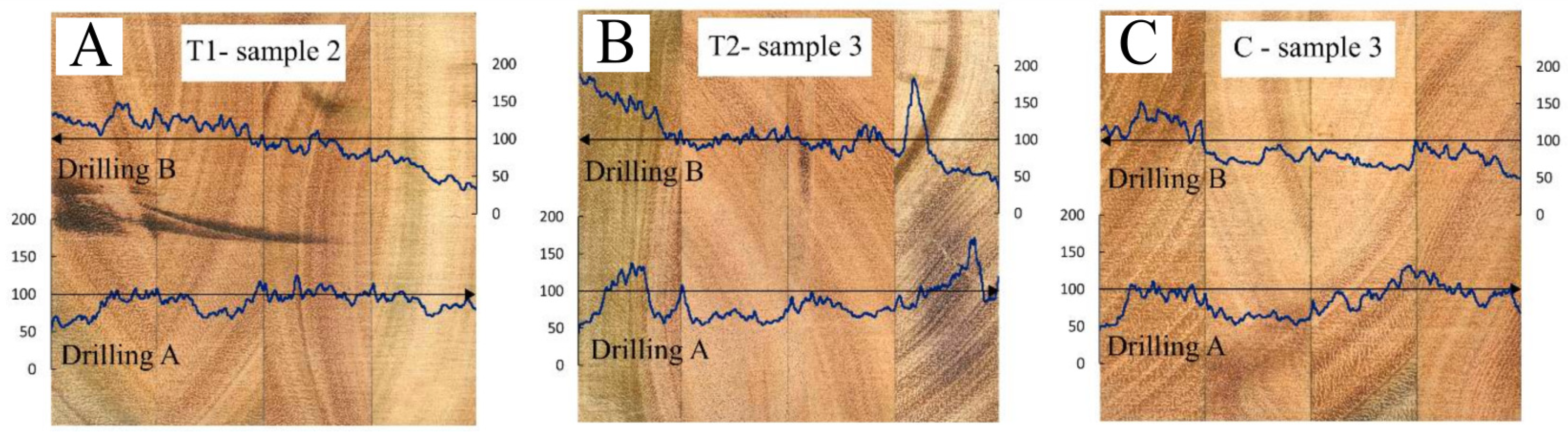

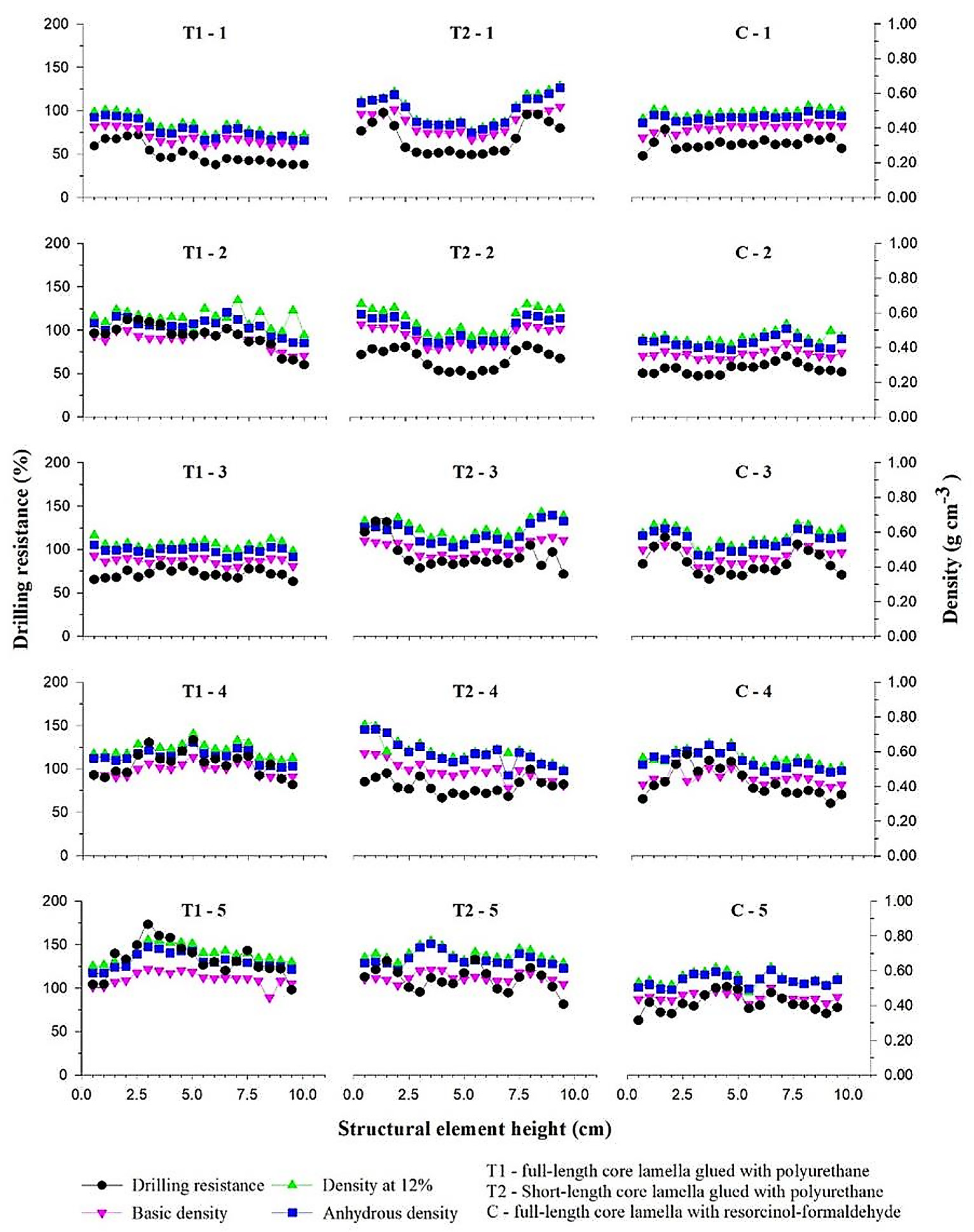

2.4. Resistograph Drilling Resistance and Wood Densities

2.5. Data Analysis

3. Results and Discussion

3.1. Physical-Mechanical Properties of Glulam Elements

| Species (Years) | Ad | Basic Density (g·cm−3) | Spread Rate (g·m−2) | fv0 (MPa) | WF (%) | fc90 (MPa) | Ec90 (MPa) | De (%) | MGL (μm) | EGL (μm) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eucalyptus grandis× urophylla (11y) | PUR | <0.58 | 250 | 7.26 | N/A | 6.70 | N/A | 0.00 | 3.17 | 51.77 | [17,29] |

| RF | <0.58 | 250 | 7.84 | N/A | 6.39 | N/A | 0.00 | 125.22 | 278.18 | ||

| Eucalyptus spp. (7–10y) | PUR | 0.51 | 300 | 12.68 | 79.58 | 10.61 | 493.0 | N/A | 24.25 | N/A | [42] |

| RF | 0.54 | 300 | 10.40 | 93.50 | 8.68 | 476.75 | N/A | 80.31 | N/A | ||

| Eucalyptus spp. | PUR | 0.67 | 250 | 8.10 | 71.10 | N/A | N/A | N/A | 100.70 | N/A | [14,18] |

| RF | 0.67 | 250 | 6.73 | 29.75 | N/A | N/A | N/A | 41.80 | N/A | ||

| Eucalyptus cloeziana (6–8y) | PUR | 0.62 | 150 | 8.29 | 44.16 | N/A | N/A | 14.91 | 13.41 | 15.79 | [3] |

| RF | 0.62 | 150 | 11.44 | 91.88 | N/A | N/A | 0.00 | 52.13 | 60.23 | ||

| Eucalyptus spp. | RF | N/A | N/A | 7.75 | N/A | N/A | N/A | 13 | N/A | N/A | [2] |

| Eucalyptus spp. | RF | N/A | 300–350 | 3.80 | N/A | N/A | N/A | 38 | N/A | N/A | [1] |

| Eucalyptus grandis (18y) | RF | 0.55 | 250 | 4.72 | 93.04 | N/A | N/A | N/A | 129.0 | N/A | [16] |

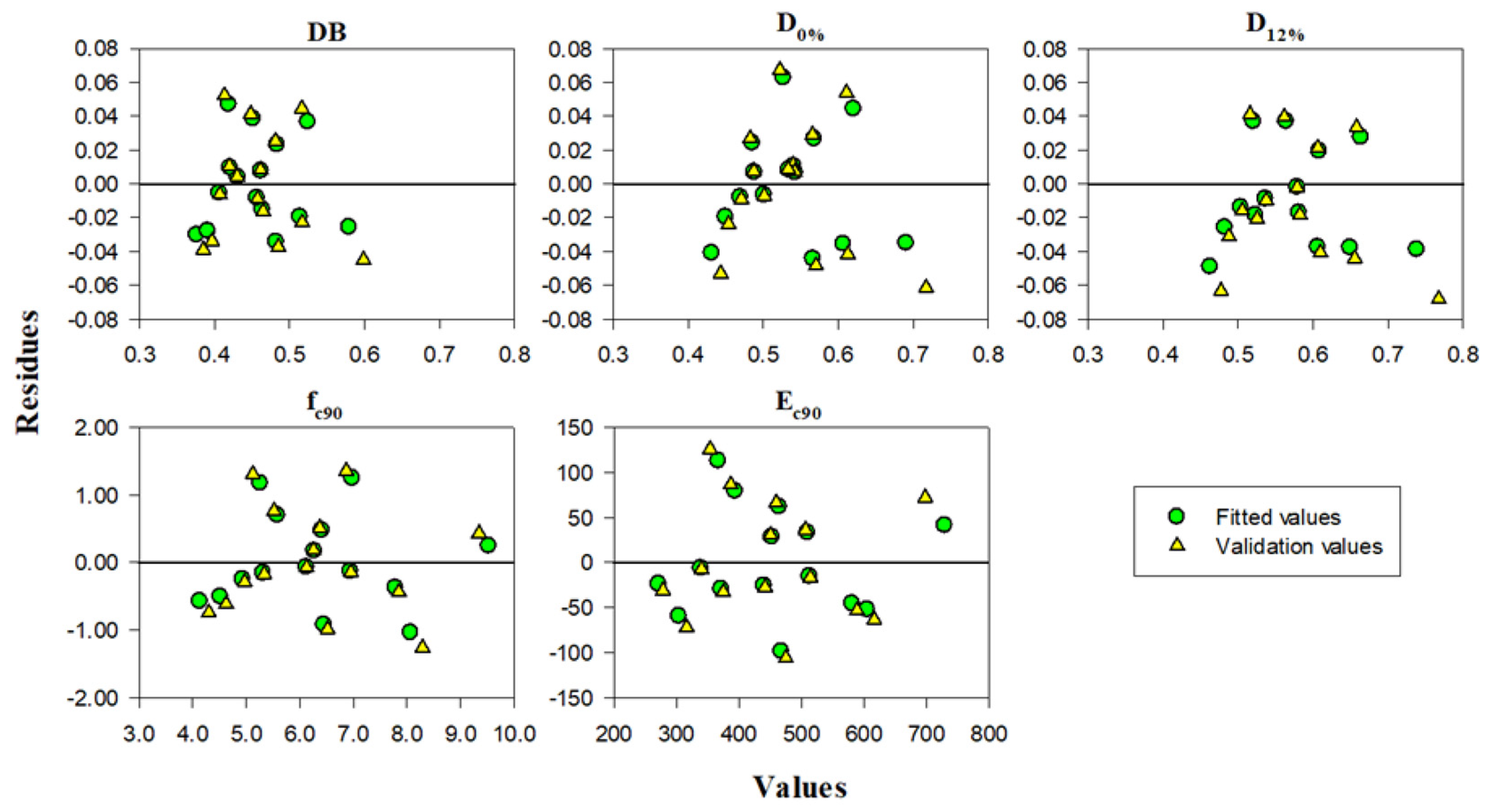

3.2. Estimative of the Physical-Mechanical Properties of Glulam by Drilling Resistance

4. Conclusions

- Treatments T1 and control, consisting of full-length core lamellae, demonstrate effectiveness for external use due to lower delamination (less than 8%) and positive evaluations of their physical and mechanical properties;

- Treatment T2, comprising short-length core lamellae, is not recommended for external use due to delamination exceeding 8%. However, T2 shows promise for internal use because of its potential to reduce production costs using short-length core lamellae and a sustainable adhesive;

- Drilling resistance proves to be a valuable tool for recording functional relationships between physical and mechanical properties in the wood across each lamella of the glulam elements, except MGL;

- Linear regression models based on drilling resistance made it possible to estimate, with desired accuracy (R2adj ≈ 80%), the wood density as well as strength and stiffness in compression perpendicular to the grain;

- The results can be considered indicative; however, an increase in the number of specimens in future research is suggested, and it is expected that the conclusions will corroborate the current ones.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Calil Neto, C.; Christoforo, A.L.; Ribeiro Filho, S.L.M.; Lahr, F.A.R.; Calil Junior, C. Avaliação da resistência ao cisalhamento e à delaminação em madeira laminada colada. Ciência Florest 2014, 24, 989–996. [Google Scholar] [CrossRef]

- de Almeida, D.H.; Cavalheiro, R.S.; de Macêdo, L.B.; Neto, C.C.; Christoforo, A.L.; Junior, C.C.; Lahr, F.A.R. Evaluation of quality in the adhesion of glued laminated timber (Glulam) of paricá and lyptus wood species. Int. J. Mater. Eng. 2014, 4, 114–118. [Google Scholar] [CrossRef]

- Segundinho, P.G.A.; Gonçalves, F.G.; Gava, G.C.; Tinti, V.P.; Alves, S.D.; Regazzi, A.J. Eficiência da colagem de madeira tratada de Eucalyptus cloeziana F. Muell para produção de madeira laminada colada (MLC). Rev. Mater. 2017, 22, e11808. [Google Scholar] [CrossRef]

- Chiniforush, A.A.; Akbarnezhad, A.; Valipour, H.; Malekmohammadi, S. Moisture and temperature induced swelling/shrinkage of softwood and hardwood glulam and LVL: An experimental study. Constr. Build. Mater. 2019, 207, 70–83. [Google Scholar] [CrossRef]

- Aicher, S.; Ahmad, Z.; Hirsch, M. Bondline shear strength and wood failure of European and tropical hardwood glulams. Eur. J. Wood Wood Prod. 2018, 76, 1205–1222. [Google Scholar] [CrossRef]

- Kovryga, A.; Stapel, P.; van de Kuilen, J.W.G. Mechanical properties and their interrelationships for medium-density European hardwoods, focusing on ash and beech. Wood Mater. Sci. Eng. 2020, 15, 289–302. [Google Scholar] [CrossRef]

- Morin-Bernard, A.; Blanchet, P.; Dagenais, C.; Achim, A. Use of northern hardwoods in glued-laminated timber: A study of bondline shear strength and resistance to moisture. Eur. J. Wood Wood Prod. 2020, 78, 891–903. [Google Scholar] [CrossRef]

- Brockerhoff, E.G.; Jactel, H.; Parrotta, J.A.; Quine, C.P.; Sayer, J. Plantation forests and biodiversity: Oxymoron or opportunity? Biodivers. Conserv. 2008, 17, 925–951. [Google Scholar] [CrossRef]

- Sapucci, G.R.; Negri, R.G.; Massi, K.G.; Alcântara, E.H.D. Eucalyptus plantation benefits to patch size and shape of forested areas in Southeast Atlantic Forest. Rev. Árvore 2022, 46, e4626. [Google Scholar] [CrossRef]

- Dias, F.M.; Lahr, F.A.R. Alternative castor oil-based polyurethane adhesive used in the production of plywood. Mater. Res. 2004, 7, 413–420. [Google Scholar] [CrossRef]

- Azambuja, M.D.A.; Dias, A.A. Use of castor oil-based polyurethane adhesive in the production of glued laminated timber beams. Mater. Res. 2006, 9, 287–291. [Google Scholar] [CrossRef]

- Silva, S.A.M.; Christoforo, A.L.; Ribeiro Filho, S.L.M.; Varanda, L.D.; Lahr, F.A.R. Particleboard manufactured with bicomponent polyurethane resin base on castor oil. Int. J. Compos. Mater. 2013, 2, 115–118. [Google Scholar] [CrossRef][Green Version]

- Chen, Y.-H.; Wu, C.-H.; Chen, Y.-C. Optimized condition for eco-friendly wood composites manufactured from castor oil-based polyurethane. Constr. Build. Mater. 2021, 306, 124789. [Google Scholar] [CrossRef]

- Bianche, J.J.; Teixeira, A.P.M.; Ladeira, J.P.S.; Carneiro, A.d.C.O.; Castro, R.V.O.; Della Lucia, R.M. Cisalhamento na linha de cola de Eucalyptus sp. colado com diferentes adesivos e diferentes gramaturas. Floresta E Ambient. 2017, 24, 1–9. [Google Scholar] [CrossRef]

- Frihart, C.R.; Hunt, C.G. Wood Adhesives: Bond Formation and Performance. In Wood Handbook: Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; pp. 10.1–10.23. [Google Scholar]

- do Sacramento Albino, V.C.; Mori, F.A.; Mendes, L.M. Estudo da interface madeira-adesivo de juntas coladas com resorcinol-formaldeído e madeira de Eucalyptus grandis w. Hill ex Maiden. Sci. For. 2010, 38, 509–516. [Google Scholar]

- de Oliveira, R.G.E.; Gonçalves, F.G.; Segundinho, P.G.d.A.; Oliveira, J.T.d.S.; Paes, J.B.; Chaves, I.L.S.; Brito, A.S. Analysis of glue line and correlations between density and anatomical characteristics of Eucalyptus grandis × Eucalyptus urophylla glulam. Maderas. Cienc. Y Tecnol. 2020, 22, 495–504. [Google Scholar] [CrossRef]

- Bianche, J.J.; Carneiro, A.d.C.O.; Vital, B.R.; de Andrade, B.G.; Gomes, R.M.; Araújo, S.d.O.; de Souza, E.C. Improving the understanding of wood bonding: Behavior of different adhesives on the surface of eucalyptus and pine wood. Int. J. Adhes. Adhes. 2022, 112, 102987. [Google Scholar] [CrossRef]

- Masoumi, A.; Satir, E.; Adhikari, S.; Hindman, D.; Bond, B.; Zink-Sharp, A. Comparison of microscopy and quality control testing to examine the durability of adhesive bondline in cross-laminated timber. J. Build. Eng. 2024, 86, 108958. [Google Scholar] [CrossRef]

- Teder, M.; Wang, X. Nondestructive evaluation of a 75-year-old glulam. In Proceedings of the 18th International Nondestructive Testing and Evaluation of Wood Symposium, Madison, WI, USA, 24–27 September 2013; Ross, R.J., Wang, X., Eds.; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2013; p. 8. [Google Scholar]

- Rinn, F. Intact-decay transitions in profiles of density-calibratable resistance drilling devices using long thin needles. Arboric. J. 2016, 38, 204–217. [Google Scholar] [CrossRef]

- Nowak, T.P.; Jasieńko, J.; Hamrol-Bielecka, K. In situ assessment of structural timber using the resistance drilling method-Evaluation of usefulness. Constr. Build. Mater. 2016, 102, 403–415. [Google Scholar] [CrossRef]

- Oliveira, J.T.d.S.; Wang, X.; Vidaurre, G.B. Assessing specific gravity of young Eucalyptus plantation trees using a resistance drilling technique. Holzforschung 2017, 71, 137–145. [Google Scholar] [CrossRef]

- Sharapov, E.; Brischke, C.; Militz, H. Assessment of preservative-treated wooden poles using drilling-resistance measurements. Forests 2019, 11, 20. [Google Scholar] [CrossRef]

- Santos, D.A.S.; Gonçalves, F.G.; Segundinho, P.G.A.; Almeida, A.T.S.; Brito, L.D.; Chaves, I.L.S. Evaluation of pathological manifestations by non-destructive analysis techniques (NDT) in rural bridges. Contrib. Cienc. Soc. 2023, 16, 22108–22130. [Google Scholar]

- Silva, J.G.M. Aplicação da Resistografia na Estimativa da Densidade e Umidade da Madeira em Árvores Jovens de Eucalipto. Ph.D. Thesis, Universidade Federal do Espírito Santo, Vitória, Brazil, 2019. [Google Scholar]

- ASTM D-245; Standard Practice for Establishing Structural Grades and Related Allowable Properties for Visually Graded Lumber. ASTM (American Society for Testing and Materials): West Conshohocken, PA, USA, 2019; p. 17.

- Plaster, O.B.; Oliveira, J.T.D.S.; Gonçalves, F.G.; Motta, J.P. Comportamento de adesão da madeira de um híbrido clonal de Eucalyptus urophylla× Eucalyptus grandis proveniente de três condições de manejo. Ciência Florest. 2012, 22, 323–330. [Google Scholar] [CrossRef]

- Segundinho, P.G.A.; Oliveira, R.G.E.; Gonçalves, F.G.; Lopes, N.F.; Alves, R.C.; Azevedo, M.S. Evaluation of wood from the hybrid Eucalyptus grandis × Eucalyptus urophylla to be used in glued laminated timber. Matéria 2021, 26, e13030. [Google Scholar] [CrossRef]

- T110; Test Methods for Structural Glued Laminated Timber-Cyclic Delamination Test. AITC (American Institute of Timber Construction): Centennial, CO, USA, 2007; p. 3.

- D-905; Standard Test Method for Strength Properties of Adhesive Bonds in Shear by Compression Loading. ASTM (American Society for Testing and Materials): West Conshohocken, PA, USA, 2021; p. 5.

- D-5266; Standard Practice for Estimating the Percentage of Wood Failure in Adhesive Bonded Joints. ASTM (American Society for Testing and Materials): West Conshohocken, PA, USA, 2020; p. 5.

- D-143-22; Standard Test Methods for Small Clear Specimens of Timber. ASTM (American Society for Testing and Materials): West Conshohocken, PA, USA, 2022; p. 32.

- NBR 7190-3; Parte 3: Métodos de Ensaio Para Corpos de Prova Isentos de Defeitos Para Madeiras de Florestas Nativas. ABNT (Associação Brasileira de Normas Técnicas).: Projeto de estruturas de madeira: Rio de Janeiro, Brazil, 2022.

- Rasband, W.S. (1997–2015) ImageJ. National Institutes of Health, Bethesda, Maryland, USA. 2018. Available online: https://imagej.net/ij/ (accessed on 24 August 2024).

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [PubMed]

- NBR 7190-2; Métodos de Ensaio Para Classificação Visual e Mecânica de Peças Estruturais de Madeira. ABNT (Associação Brasileira de Novas Técnicas): Rio de Janeiro, Brazil, 2022; p. 15.

- Kloppenburg, A.M. Density determination of tropical hardwoods with the Resistograph. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Barbosa, T.L.; Oliveira, J.T.d.S.; Rocha, S.M.G.; Câmara, A.P.; Vidaurre, G.B.; Rosado, A.M.; Leite, F.P. Influence of site in the wood quality of Eucalyptus in plantations in Brazil. South. A J. Sci. 2019, 81, 247–253. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2023; Available online: https://www.R-project.org (accessed on 30 October 2023).

- Rinn, F.; Schweingruber, F.-H.; Schär, E. Resistograph and X-Ray density charts of wood. Comp. Eval. Drill Resist. Profiles X-ray Density Charts Differ. Wood Species. Holzforsch. 1996, 50, 303–311. [Google Scholar] [CrossRef]

- Segundinho, P.G.A.; Silva, A.C.; Gonçalves, F.G.; Regazzi, A.J. Caracterização da madeira laminada colada de Eucalyptus sp. produzida com adesivos resorcinol-fenol-formaldeído e poliuretano. Ciência Da Madeira 2018, 9, 123–133. [Google Scholar] [CrossRef]

- Leggate, W.; Shirmohammadi, M.; McGavin, R.L.; Outhwaite, A.; Knackstedt, M.; Brookhouse, M. Examination of wood adhesive bonds via MicroCT: The influence of pre-gluing surface machining treatments for southern pine, spotted gum, and Darwin stringybark timbers. BioResources 2021, 16, 5058–5082. [Google Scholar] [CrossRef]

- Leggate, W.; McGavin, R.L.; Outhwaite, A.; Gilbert, B.P.; Gunalan, S. Barriers to the Effective Adhesion of High-Density Hardwood Timbers for Glue-Laminated Beams in Australia. Forests 2022, 13, 1038. [Google Scholar] [CrossRef]

- Singh, A.K.; Mehra, D.S.; Niyogi, U.K.; Sabharwal, S.; Swiderska, J.; Czech, Z.; Khandal, R.K. Effect of crosslinkers on adhesion properties of electron beam curable polyurethane pressure sensitive adhesive. Int. J. Adhes. Adhes. 2013, 41, 73–79. [Google Scholar] [CrossRef]

- Clauß, S.; Joscak, M.; Niemz, P. Thermal stability of glued wood joints measured by shear tests. Eur. J. Wood Wood Prod. 2011, 69, 101–111. [Google Scholar] [CrossRef]

- Frihart, C. Wood Adhesion and Adhesives. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2012; pp. 255–320. [Google Scholar]

| Treatments | Description | Adhesive | Repetition |

|---|---|---|---|

| T1 | Elements comprising 105 cm-length core and external lamellae | PUR (bicomponent castor oil-based polyurethane) | 5 |

| T2 | Elements comprising short-length core lamellae (35 to 55 cm) bonded by end joints, and 105 cm-length external lamellae | PUR (bicomponent castor oil-based polyurethane) | 5 |

| Control (T3) | Elements comprising 105 cm-length core and external lamellae | RF (resorcinol-formaldehyde) | 5 |

| Properties | Treatments | |||

|---|---|---|---|---|

| T1 | T2 | Control | ||

| Shear 12% | fv0 (MPa) | 9.06 a (1.78) | 10.08 a (1.16) | 9.86 a (1.84) |

| WF (%) | 81.00 a (29.38) | 94.00 a (7.41) | 96.50 a (2.09) | |

| Compression perpendicular to the grain 12% | fc90 (MPa) | 6.77 a (2.23) | 6.58 a (1.14) | 5.51 a (1.19) |

| Ec90 (MPa) | 513.97 a (186.81) | 457.47 a (81.19) | 390.80 a (113.62) | |

| Basic density (BD) (g·cm−3) | 0.46 a (0.08) | 0.49 a (0.05) | 0.43 a (0.04) | |

| Density at 12% (D12%) (g·cm−3) | 0.56 a (0.11) | 0.60 a (0.07) | 0.56 a (0.09) | |

| Density at 0% (D0%) (g·cm−3) | 0.53 a (0.10) | 0.57 a (0.07) | 0.51 a (0.06) | |

| Main glue line (MGL) (μm) | 33.26 b (14.71) | 39.35 b (13.57) | 79.80 a (17.44) | |

| Extended glue line (EGL) (μm) | 55.83 a (21.60) | 64.67 a (15.49) | 40.43 a (11.17) | |

| Delamination (DL) (%) | 7.92 ab (14.09) | 27.42 a (23.32) | 0.29 b (0.66) | |

| Drilling resistance (DR) (%) | 90.68 a (31.86) | 83.80 a (18.37) | 74.01 a (14.18) | |

| Models | R2aj | RMSE | R2CV | RMSECV |

|---|---|---|---|---|

| BD = 0.255354 * + 0.002437 × DR | 0.79 | 0.0258 | 0.73 | 0.0308 |

| D12% = 0.298655 * + 0.03308 × DR | 0.70 | 0.0437 | 0.64 | 0.0503 |

| D0% = 0.276592 * + 0.003116 × DR | 0.81 | 0.0306 | 0.75 | 0.0371 |

| fc90 = 0.92310 ns + 0.06472 × DR | 0.80 | 0.6572 | 0.76 | 0.7491 |

| Ec90 = 0.89810 ns + 5.4930 × DR | 0.80 | 55.9220 | 0.76 | 64.0361 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, R.F.; Segundinho, P.G.d.A.; da Silva, J.G.M.; Gonçalves, F.G.; Lopes, D.J.V.; Silva, J.P.M.; Lopes, N.F.; Mastela, L.d.C.; Paes, J.B.; de Souza, C.G.F.; et al. Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques. Forests 2024, 15, 1658. https://doi.org/10.3390/f15091658

Oliveira RF, Segundinho PGdA, da Silva JGM, Gonçalves FG, Lopes DJV, Silva JPM, Lopes NF, Mastela LdC, Paes JB, de Souza CGF, et al. Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques. Forests. 2024; 15(9):1658. https://doi.org/10.3390/f15091658

Chicago/Turabian StyleOliveira, Ramon Ferreira, Pedro Gutemberg de Alcântara Segundinho, João Gabriel Missia da Silva, Fabricio Gomes Gonçalves, Dercílio Junior Verly Lopes, Jeferson Pereira Martins Silva, Nayara Franzini Lopes, Leonor da Cunha Mastela, Juarez Benigno Paes, Clara Gaspar Fossi de Souza, and et al. 2024. "Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques" Forests 15, no. 9: 1658. https://doi.org/10.3390/f15091658

APA StyleOliveira, R. F., Segundinho, P. G. d. A., da Silva, J. G. M., Gonçalves, F. G., Lopes, D. J. V., Silva, J. P. M., Lopes, N. F., Mastela, L. d. C., Paes, J. B., de Souza, C. G. F., Lahr, F. A. R., Belumat, M. A. R., Christoforo, A. L., & de Araujo, C. P. (2024). Eucalyptus-Based Glued Laminated Timber: Evaluation and Prediction of Its Properties by Non-Destructive Techniques. Forests, 15(9), 1658. https://doi.org/10.3390/f15091658