Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Aspects

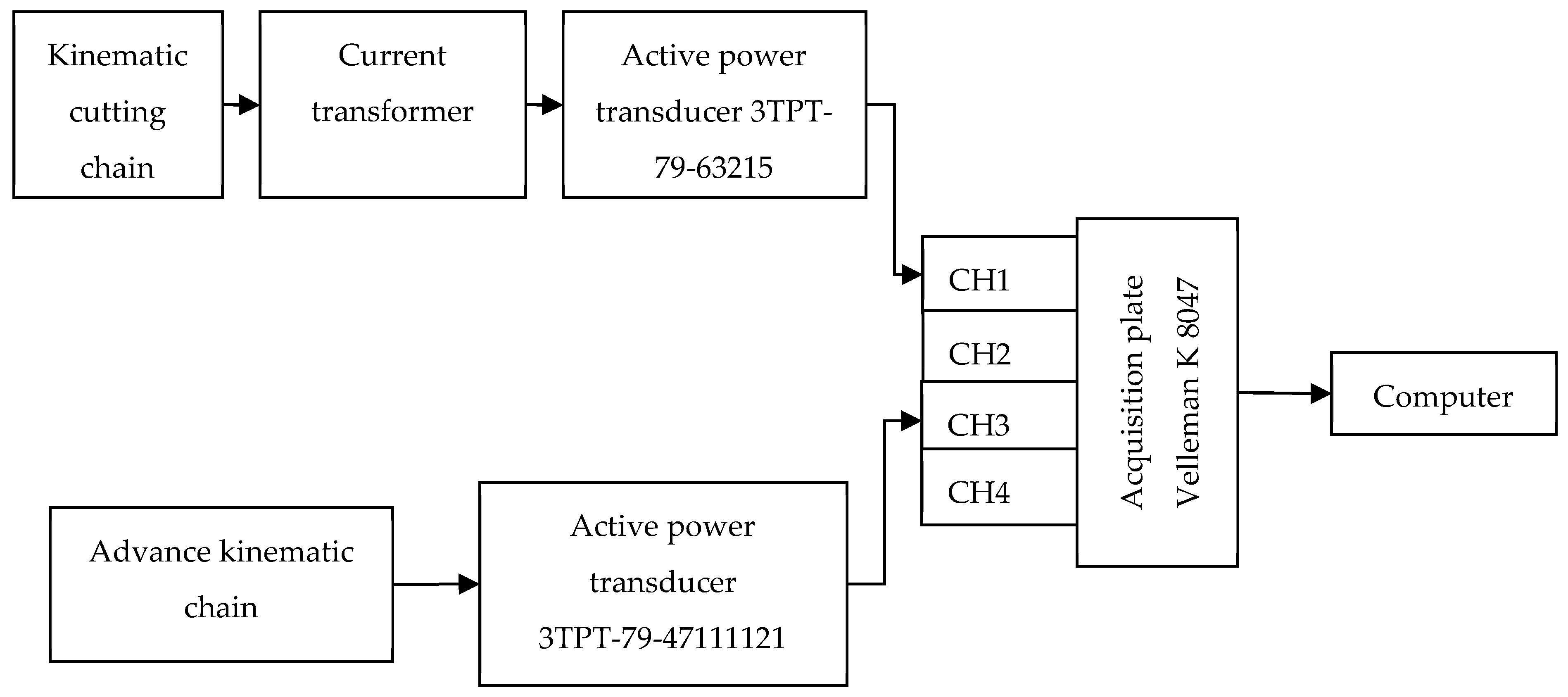

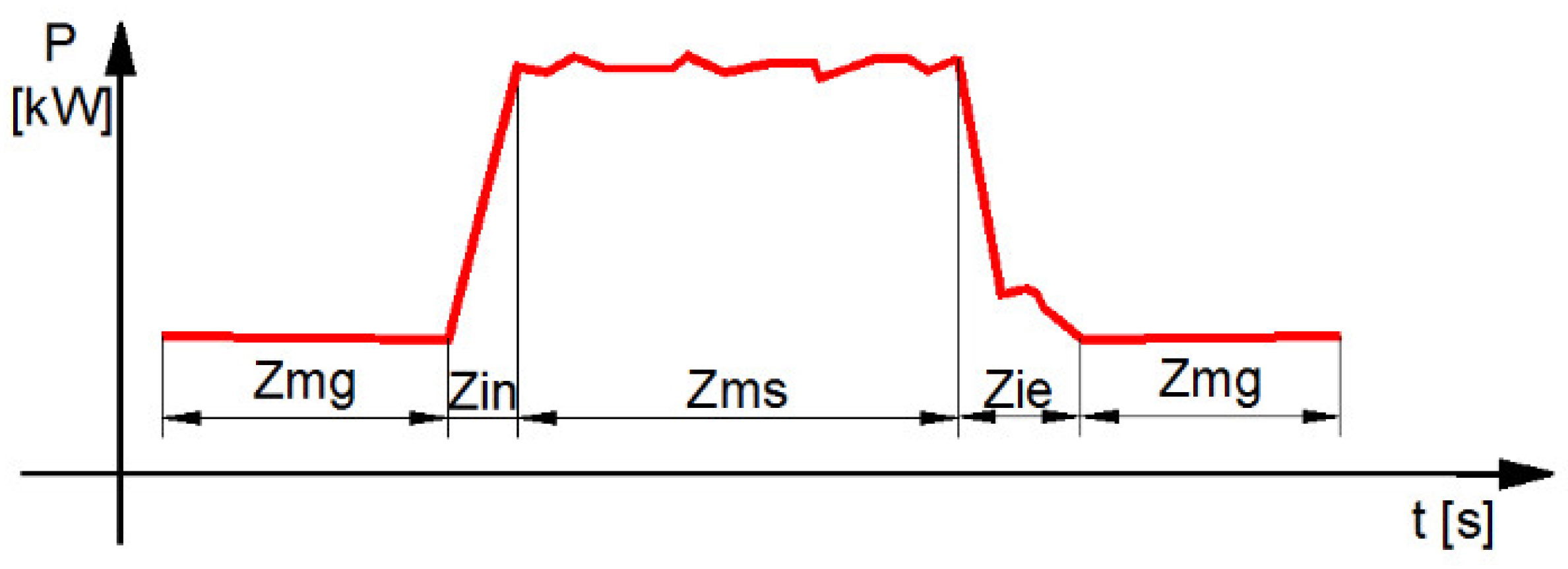

2.2. Measurement Method

2.3. Statistical Analysis

3. Results

3.1. Panel Cutting Parameters for All 10 Working Regimes

- -

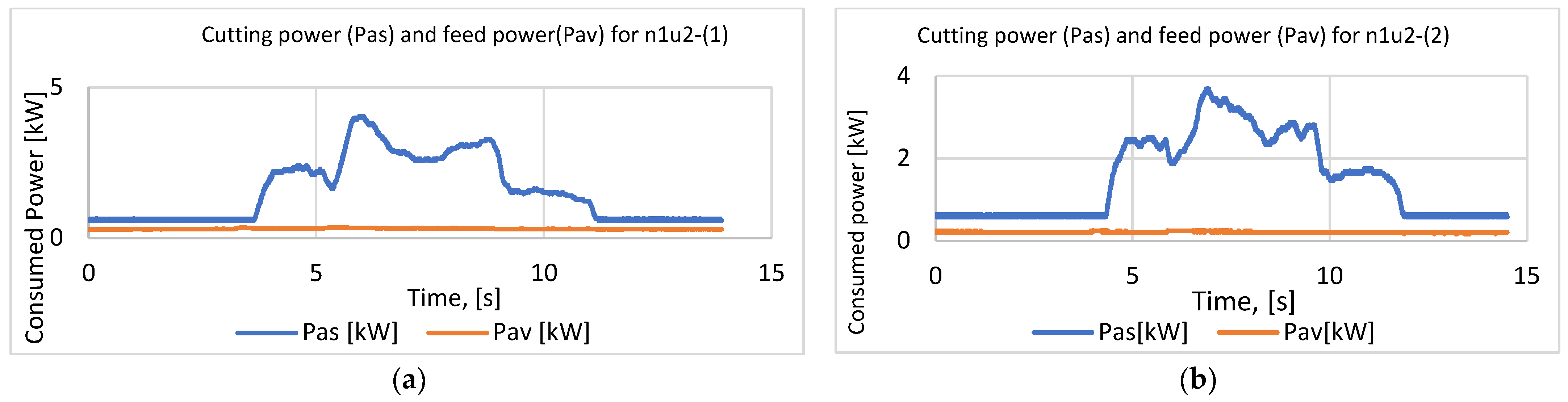

- The advance power at idle represents 96.86% of the forward power at load for the R1 regime and 88.96% for the R2 regime.

- -

- The cutting power at idle represents 25.11% of the cutting power at load for the R1 regime and 27.39% for the R2 regime.

- -

- The advance power when running under load represents 33.32% of the cutting power when running empty and 8.36% of the cutting power when running under load for the R1 regime, and 54.89% and 15.03% for the R2 regime, respectively.

- -

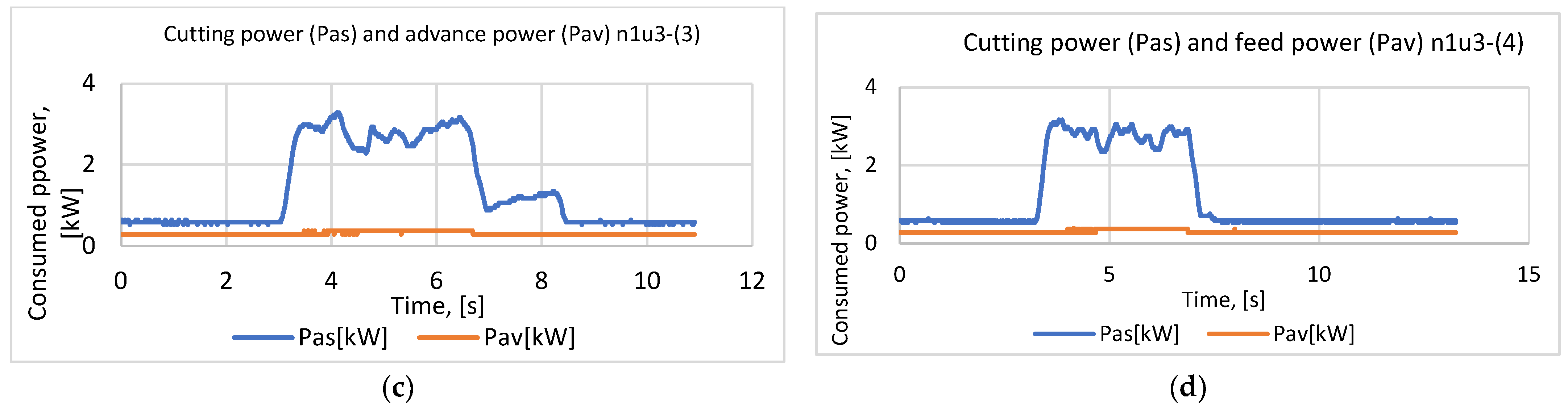

- The advance power at idle represents 75.58% of the forward power at load for the R3 regime and 66.96% for the R4 regime.

- -

- The cutting power at idle represents 20.06% of the cutting power at load for the R3 regime and 14.99% for the R4 regime.

- -

- The advance power when running under load represents 75.85% of the cutting power when running at idle and 15.22% of the cutting power when running under load when the R3 regime is taken in consideration, and 66.88% and 10.03% for the R4 regime, respectively (Figure 4).

| Cutting Code | Regime R3 (n1 = 4216 rot/min; u4 = 7.269 m/min) | ||||||

|---|---|---|---|---|---|---|---|

| Feed Power, [kW] | Cutting Power, [kW] | Mechanical Work, K, [daNm/cm3] | Cutting Force, F, [daN] | Specifical Force, K1, [N/mm2] | |||

| On Empty | On Work | On Empty | On Work | ||||

| n1u4-(1) | 0.335 | 0.438 | 0.582 | 3.125 | 44.718 | 6.292 | 1.119 |

| n1u4-(2) | 0.328 | 0.435 | 0.572 | 2.997 | 42.803 | 6.034 | 1.071 |

| n1u4-(3) | 0.325 | 0.430 | 0.562 | 3.317 | 47.214 | 6.678 | 1.182 |

| n1u4-(4) | 0.327 | 0.431 | 0.599 | 2.902 | 48.865 | 5.843 | 1.140 |

| n1u4-(5) | 0.326 | 0.430 | 0.587 | 2.777 | 46.366 | 5.592 | 1.090 |

| Mean | 0.328 | 0.433 | 0.580 | 3.023 | 45.993 | 6.088 | 1.120 |

| SD | 0.003 | 0.003 | 0.014 | 0.207 | 2.328 | 0.417 | 0.043 |

| V-5% | 0.325 | 0.430 | 0.567 | 2.826 | 43.775 | 5.690 | 1.079 |

| Cutting Code | Regime R4 (n1 = 4216 rot/min; u5 = 10.629 m/min) | ||||||

| n1u5-(1) | 0.270 | 0.419 | 0.608 | 3.781 | 37.187 | 7.614 | 1.364 |

| n1u5-(2) | 0.26 | 0.406 | 0.600 | 3.843 | 38.579 | 7.738 | 1.387 |

| n1u5-(3) | 0.26 | 0.392 | 0.602 | 4.420 | 44.156 | 8.900 | 1.595 |

| n1u5-(4) | 0.26 | 0.380 | 0.577 | 4.408 | 50.048 | 8.876 | 1.588 |

| n1u5-(5) | 0.263 | 0.436 | 0.572 | 4.249 | 40.038 | 8.555 | 1.513 |

| Mean | 0.262 | 0.407 | 0.592 | 4.140 | 42.002 | 8.337 | 1.489 |

| SD | 0.004 | 0.022 | 0.016 | 0.307 | 5.199 | 0.619 | 0.109 |

| V-5% | 0.258 | 0.385 | 0.577 | 3.847 | 37.046 | 7.7465 | 1.385 |

- -

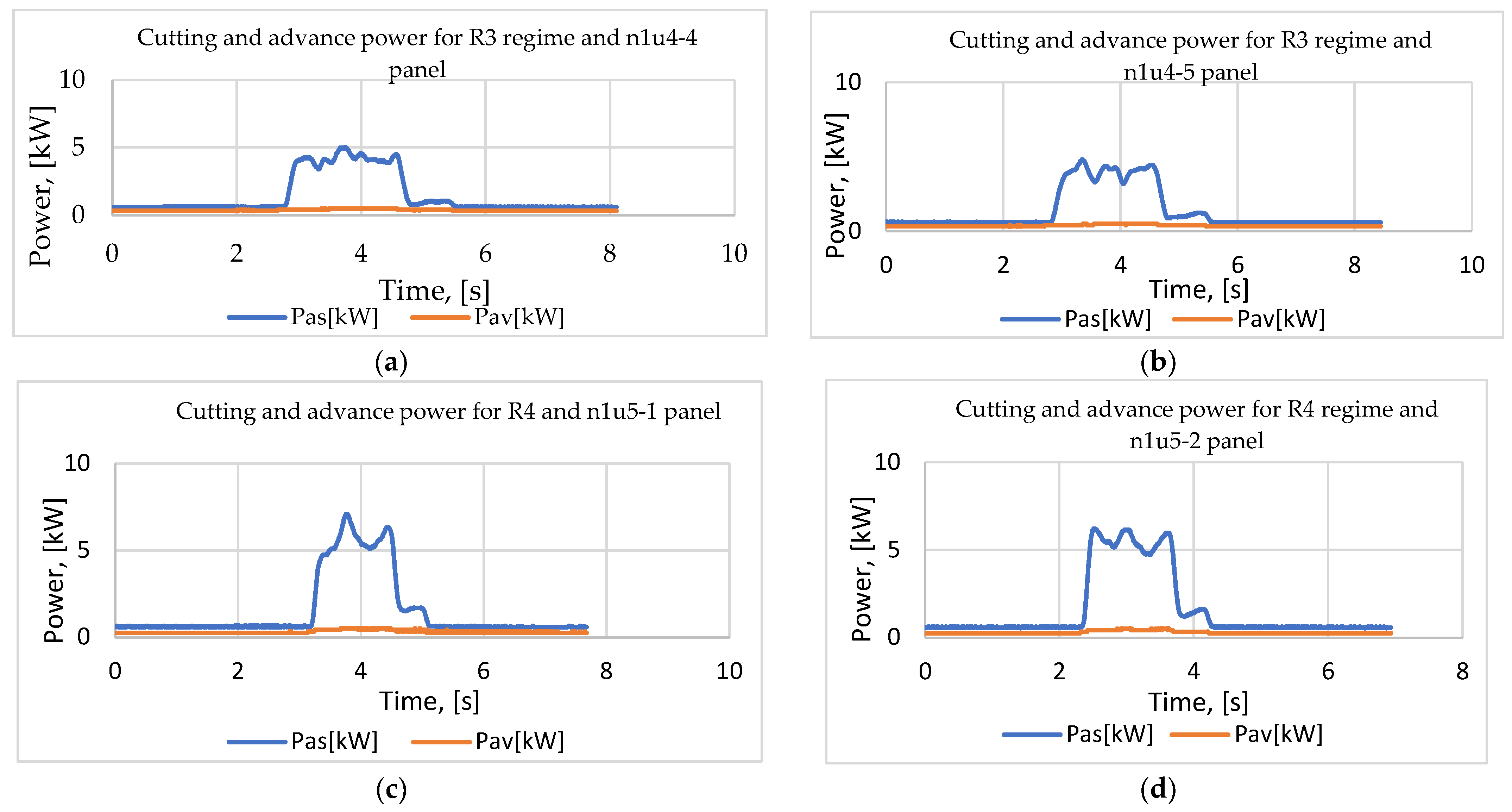

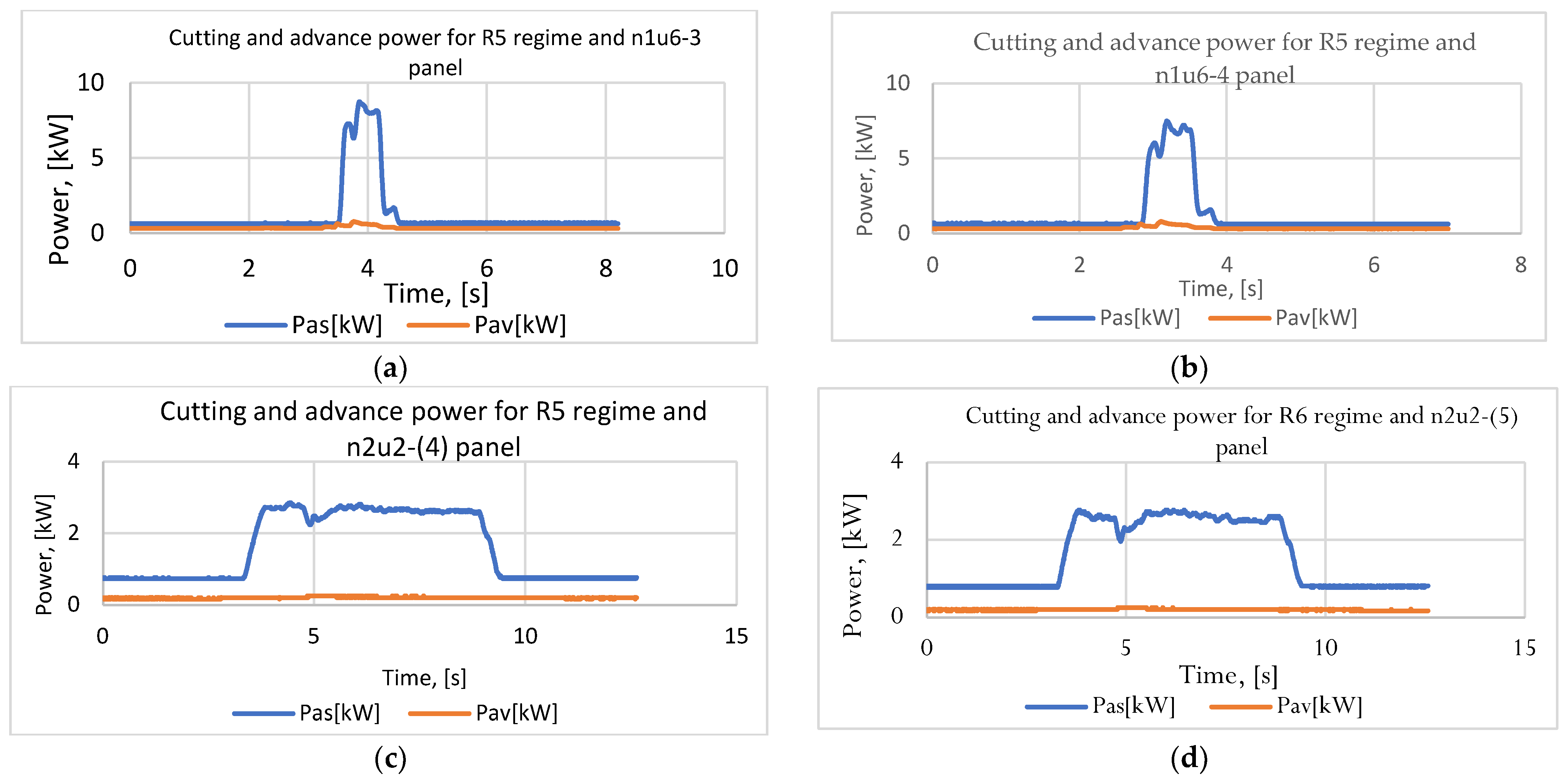

- The forward power at idle represents 62.89% of the forward power at load for the R5 regime and 88.53% for the R6 regime.

- -

- The cutting power at idle represents 14.25% of the cutting power at load for the R5 regime and 35.01 for the R6 regime.

- -

- The feed power when running under load represents 77.20% of the cutting power when running empty, and 11.00% of the cutting power when running under load when the R5 regime is taken in consideration and 30% and 10.50%, respectively, when the R6 regime is taken in consideration (Figure 5).

| Cutting Code | Regime R5 (n1 = 4216 rot/min; u6 = 20.233 m/min) | ||||||

|---|---|---|---|---|---|---|---|

| Feed Power, [kW] | Cutting Power, [kW] | Mechanical Work, K, [daNm/cm3] | Cutting Force, F, [daN] | Specifical Force, K1, [N/mm2] | |||

| On Empty | On Work | On Empty | On Work | ||||

| n1u6 (1) | 0.333 | 0.543 | 0.646 | 5.388 | 28.191 | 10.849 | 1.917 |

| n1u6 (2) | 0332 | 0.524 | 0.642 | 5.593 | 29.582 | 11.261 | 1.992 |

| n1u6 (3) | 0.318 | 0.503 | 0.654 | 4.840 | 25.471 | 9.7456 | 1.732 |

| n1u6 (4) | 0.316 | 0.497 | 0.647 | 4.148 | 21.714 | 8.352 | 1.491 |

| n1u6 (5) | 0.311 | 0.506 | 0.649 | 5.793 | 30.912 | 11.665 | 2.082 |

| Mean | 0.322 | 0.515 | 0.648 | 5.153 | 27.174 | 10.374 | 1.843 |

| SD | 0.009 | 0.018 | 0.004 | 0.664 | 3.657 | 1.338 | 0.235 |

| V-5% | 0.312 | 0.497 | 0.644 | 4.519 | 23.688 | 9.099 | 1.6195 |

| Cutting Code | Regime R6, (n2 = 6722 rot/min; u2 = 3.705 m/min) | ||||||

| n2u2-(1) | 0.211 | 0.238 | 0.689 | 2.054 | 57.334 | 2.593 | 0.456 |

| n2u2-(2) | 0.200 | 0.222 | 0.737 | 2.103 | 61.584 | 2.655 | 0.467 |

| n2u2-(3) | 0.187 | 0.215 | 0.744 | 2.035 | 58.346 | 2.570 | 0.451 |

| n2u2-(4) | 0.194 | 0.216 | 0.744 | 2.454 | 68.789 | 3.099 | 0.543 |

| n2u2-(5) | 0.190 | 0.214 | 0.795 | 2.402 | 68.045 | 3.033 | 0.531 |

| Mean | 0.196 | 0.221 | 0.742 | 2.209 | 62.820 | 2.790 | 0.490 |

| SD | 0.009 | 0.010 | 0.037 | 0.201 | 5.352 | 0.254 | 0.044 |

| V-5% | 0.187 | 0.211 | 0.706 | 2.017 | 57.7195 | 2.547 | 0.448 |

- -

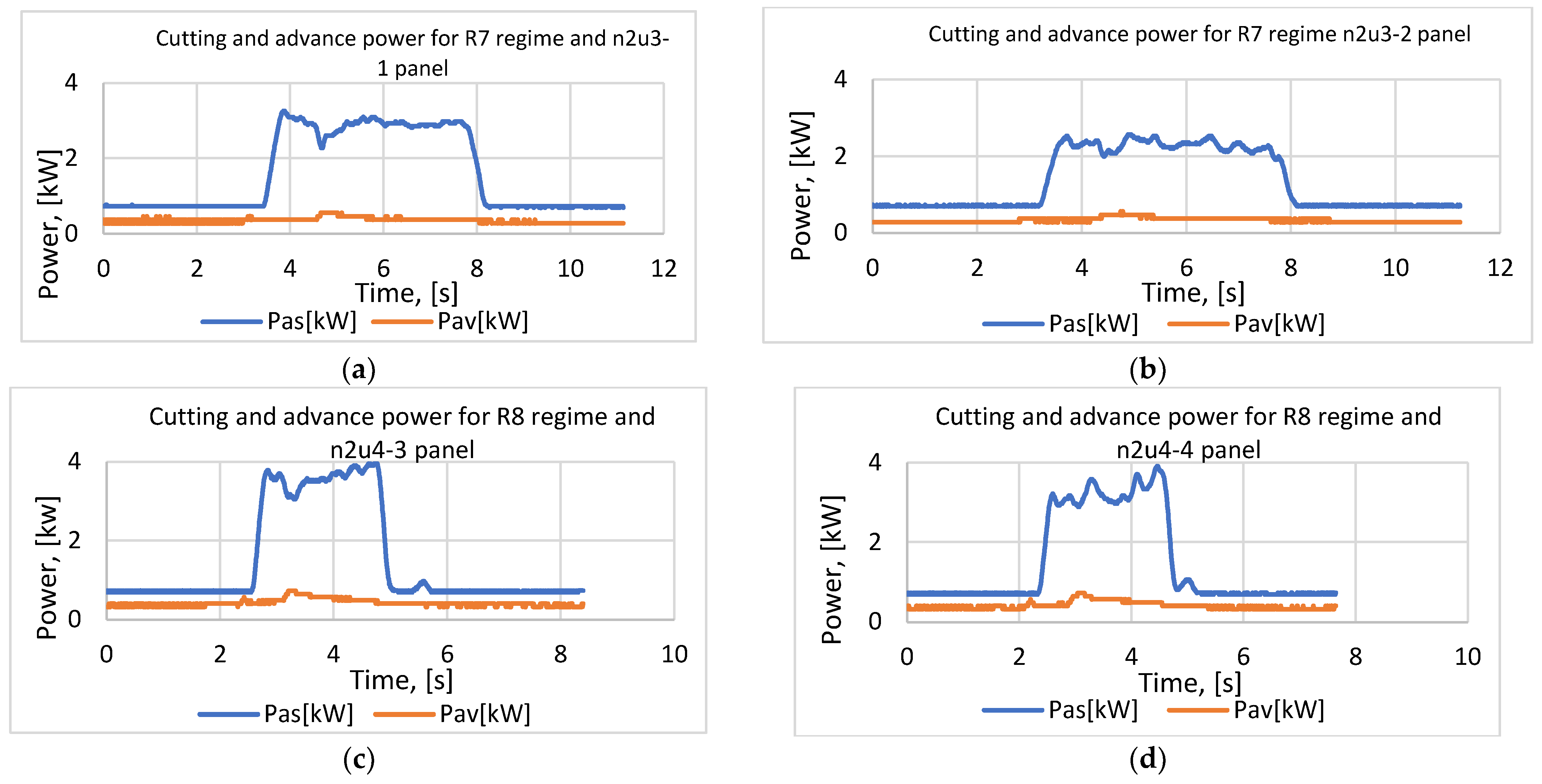

- The forward power at idle represents 76.48% of the forward power at load for the R7 regime and 73.60% for the R8 regime.

- -

- The cutting power at idle represents 31.29% of the cutting power at load for the R7 regime and 27.78 for the R8 regime.

- -

- The advance power when running under load represents 53.48% of the cutting power when idle running and 16.74% of the cutting power when running under load when the R7 regime is taken in consideration, and 68.02 and 18.89%, respectively, for the R8 regime (Figure 6).

| Cutting Code | Regime R7 (n2 = 6722 rot/min; u3 = 4.798 m/min) | ||||||

|---|---|---|---|---|---|---|---|

| Feed Power, [kW] | Cutting Power, [kW] | Mechanical Work, K, [daN·m/cm3] | Cutting Force, F, [daN] | Specifical Force, K1, [N/mm2] | |||

| On Empty | On Work | On Empty | On Work | ||||

| n2u3 (1) | 0.303 | 0.399 | 0.731 | 2.721 | 59.217 | 3.436 | 0.603 |

| n2u3 (2) | 0.290 | 0.376 | 0.703 | 2.125 | 47.295 | 2.683 | 0.470 |

| n2u3 (3) | 0.291 | 0.381 | 0.709 | 2.492 | 55.049 | 3.147 | 0.553 |

| n2u3 (4) | 0.289 | 0.376 | 0.704 | 2.522 | 55.231 | 3.185 | 0.561 |

| n2u3 (5) | 0.287 | 0.384 | 0.708 | 2.371 | 52.213 | 2.995 | 0.528 |

| Mean | 0.292 | 0.383 | 0.711 | 2.446 | 53.801 | 3089 | 0.543 |

| SD | 0.006 | 0.009 | 0.011 | 0.219 | 4.409 | 0.276 | 0.048 |

| V-5% | 0.286 | 0.374 | 0.700 | 2.237 | 49.598 | 2.825 | 0.497 |

| Cutting Code | Regime R8, (n2 = 6722 rot/min; u4 = 7.937 m/min) | ||||||

| n2u4-(1) | 0.404 | 0.513 | 0.706 | 2.831 | 40.733 | 3.576 | 0.632 |

| n2u4-(2) | 0.390 | 0.490 | 0.709 | 3.029 | 43.541 | 3.825 | 0.676 |

| n2u4-(3) | 0.378 | 0.511 | 0.719 | 3.240 | 36.900 | 4.091 | 0.725 |

| n2u4-(4) | 0.360 | 0.487 | 0.711 | 2.686 | 34.672 | 3.392 | 0.600 |

| n2u4-(5) | 0.346 | 0.477 | 0.719 | 2.429 | 35.102 | 3.067 | 0.543 |

| Mean | 0.376 | 0.496 | 0.713 | 2.843 | 38.190 | 3.590 | 0.635 |

| SD | 0.023 | 0.015 | 0.006 | 0.311 | 3.829 | 0.393 | 0.069 |

| V-5% | 0.354 | 0.481 | 0.707 | 2.546 | 34.540 | 3.215 | 0.569 |

- -

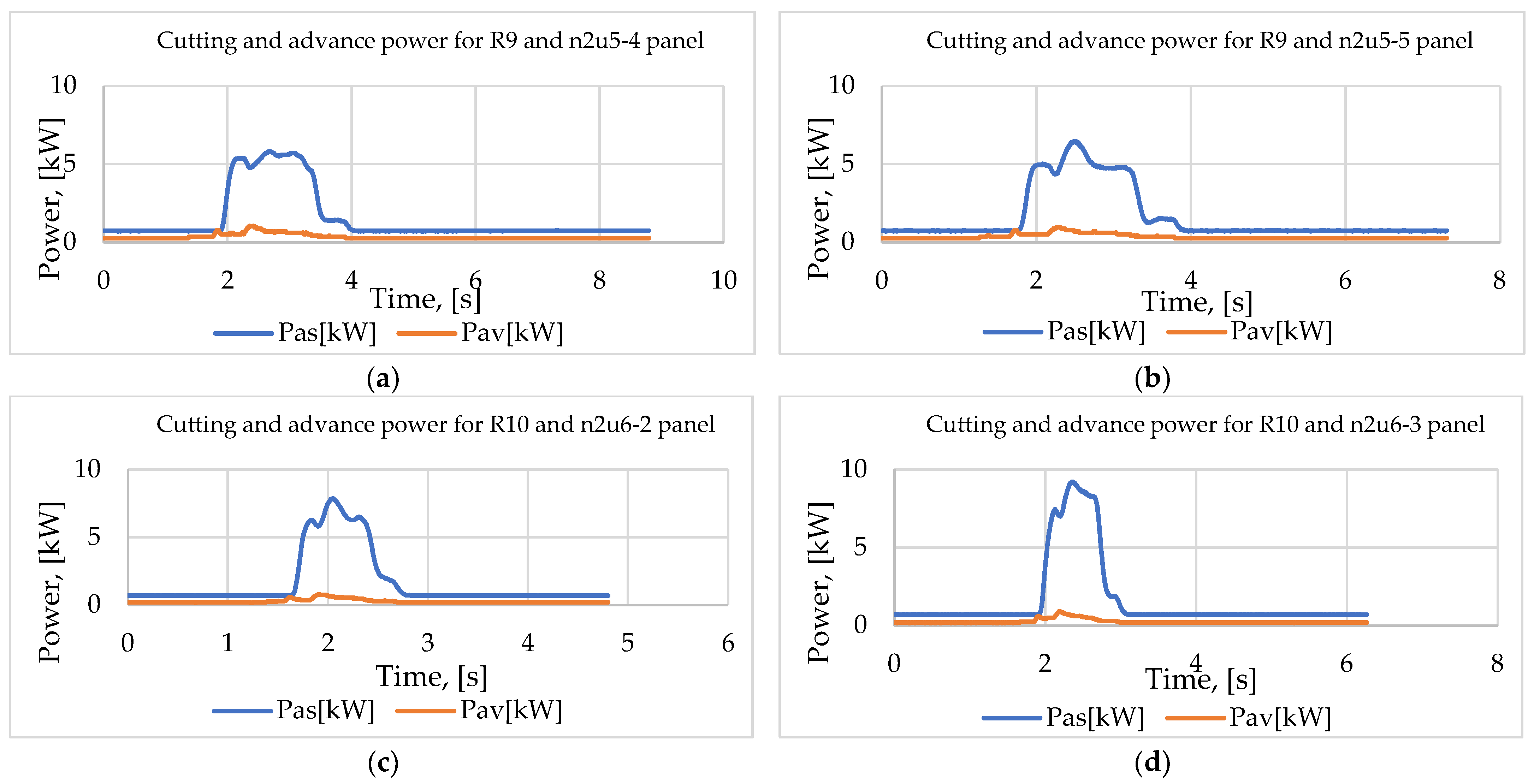

- The advance power when idling represents 51.37% of the advance power when it is running under load for the R9 regime, and 49.86% for the R10 regime.

- -

- The cutting power at idle running represents 21.37% of the cutting power when running under load for the R9 regime, and 16.22% for the R10 regime.

- -

- The feed power when running under load represents 72.22% of the cutting power when running idle and 15.43% of the cutting power when running under load for the R9 regime, and 58.42% and 9.47%, respectively, for the R10 regime (Figure 7).

| Cutting Code | Regime R9 (n2 = 6722 rot/min; u5 = 10.962 m/min) | ||||||

|---|---|---|---|---|---|---|---|

| Feed Power, [kW] | Cutting Power, [kW] | Mechanical Work, K, [daNm/cm3] | Cutting Force, F, [daN] | Specifical Force, K1, [N/mm2] | |||

| On Un-Load | On Load | On Empty | On Work | ||||

| n2u5 (1) | 0.277 | 0.526 | 0.729 | 3.238 | 31.123 | 4.089 | 0.724 |

| n2u5 (2) | 0.270 | 0.545 | 0.723 | 3.629 | 35.168 | 4.583 | 0.811 |

| n2u5 (3) | 0.271 | 0.546 | 0.732 | 3.841 | 37.471 | 4.850 | 0.860 |

| n2u5 (4) | 0.271 | 0.517 | 0.735 | 3.637 | 35.641 | 4.592 | 0.814 |

| n2u5 (5) | 0.271 | 0.535 | 0.728 | 3.595 | 34.906 | 4.540 | 0.805 |

| Mean | 0.268 | 0.522 | 0.723 | 3.387 | 32.694 | 4.276 | 0.758 |

| SD | 0.003 | 0.012 | 0.005 | 0.219 | 2.320 | 0.276 | 0.049 |

| V-5% | 0.269 | 0.539 | 0.724 | 3.632 | 35.126 | 4.586 | 0.814 |

| Cutting Code | Regime R10, (n2 = 6722 rot/min; u6 = 20.324 m/min)) | ||||||

| n2u6-(1) | 0.206 | 0.405 | 0.707 | 4.101 | 21.048 | 5.179 | 0.918 |

| n2u6-(2) | 0.206 | 0.421 | 0.693 | 4.375 | 23.257 | 5.524 | 0.978 |

| n2u6-(3) | 0.204 | 0.453 | 0.706 | 5.231 | 27.845 | 6.606 | 1.172 |

| n2u6-(4) | 0.204 | 0.420 | 0.699 | 5.049 | 26.157 | 6.375 | 1.130 |

| n2u6-(5) | 0.200 | 0.412 | 0.694 | 4.913 | 25.661 | 6.204 | 1.099 |

| Mean | 0.204 | 0.422 | 0.700 | 4.734 | 24.794 | 5.978 | 1.059 |

| SD | 0.002 | 0.018 | 0.006 | 0.476 | 2.660 | 0.601 | 0.107 |

| V-5% | 0.202 | 0.405 | 0.694 | 4.280 | 22.258 | 5.405 | 0.957 |

3.2. Synthesis of Results

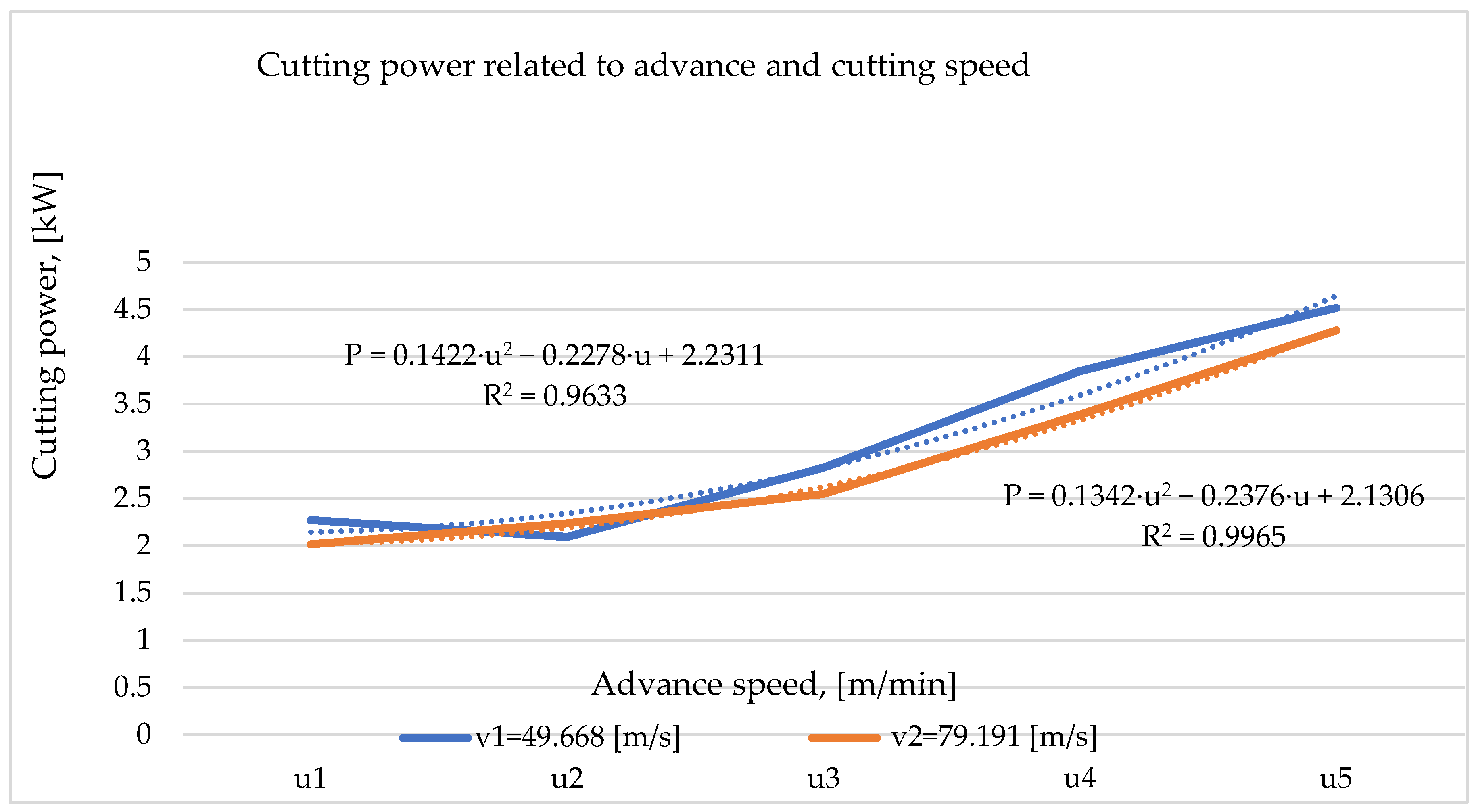

3.3. Results on Cutting Power

3.4. Results on Mechanical Work of Cutting

3.5. Cutting Force

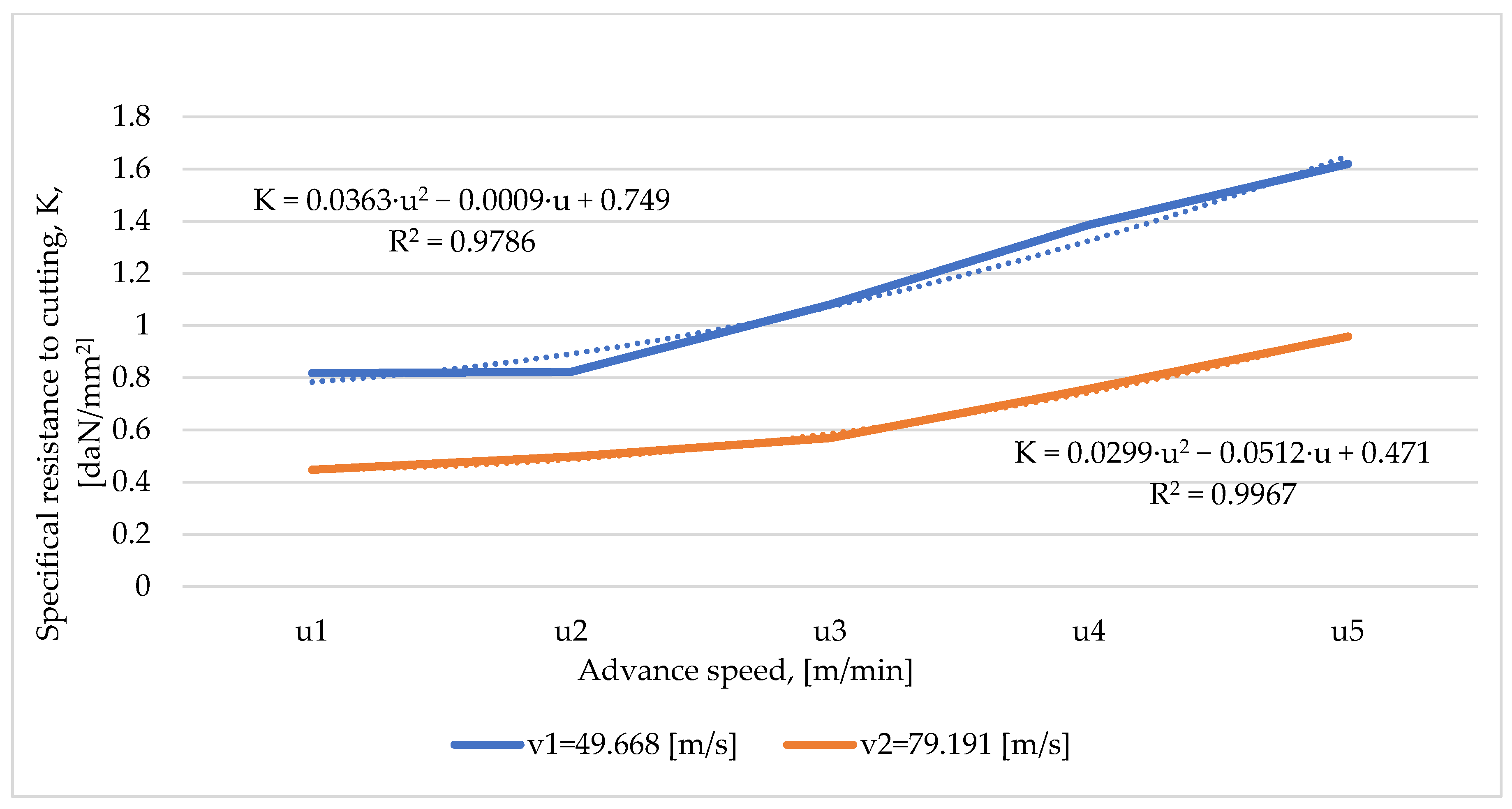

3.6. The Specific Resistance to Cutting

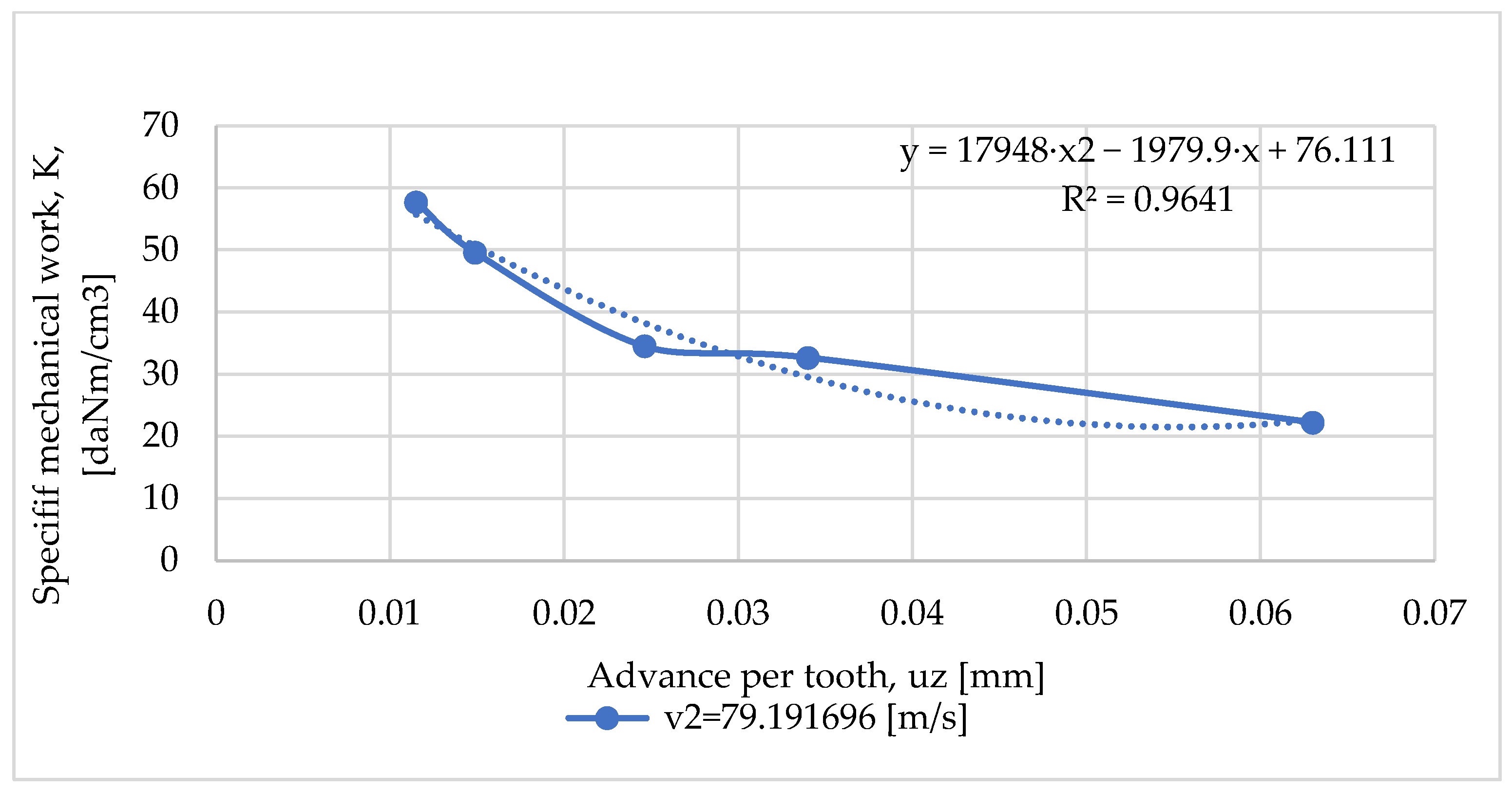

3.7. The Specific Mechanical Work

3.8. Cutting Power, Cutting Force and Specific Cutting Resistance Relating to Advance per Tooth

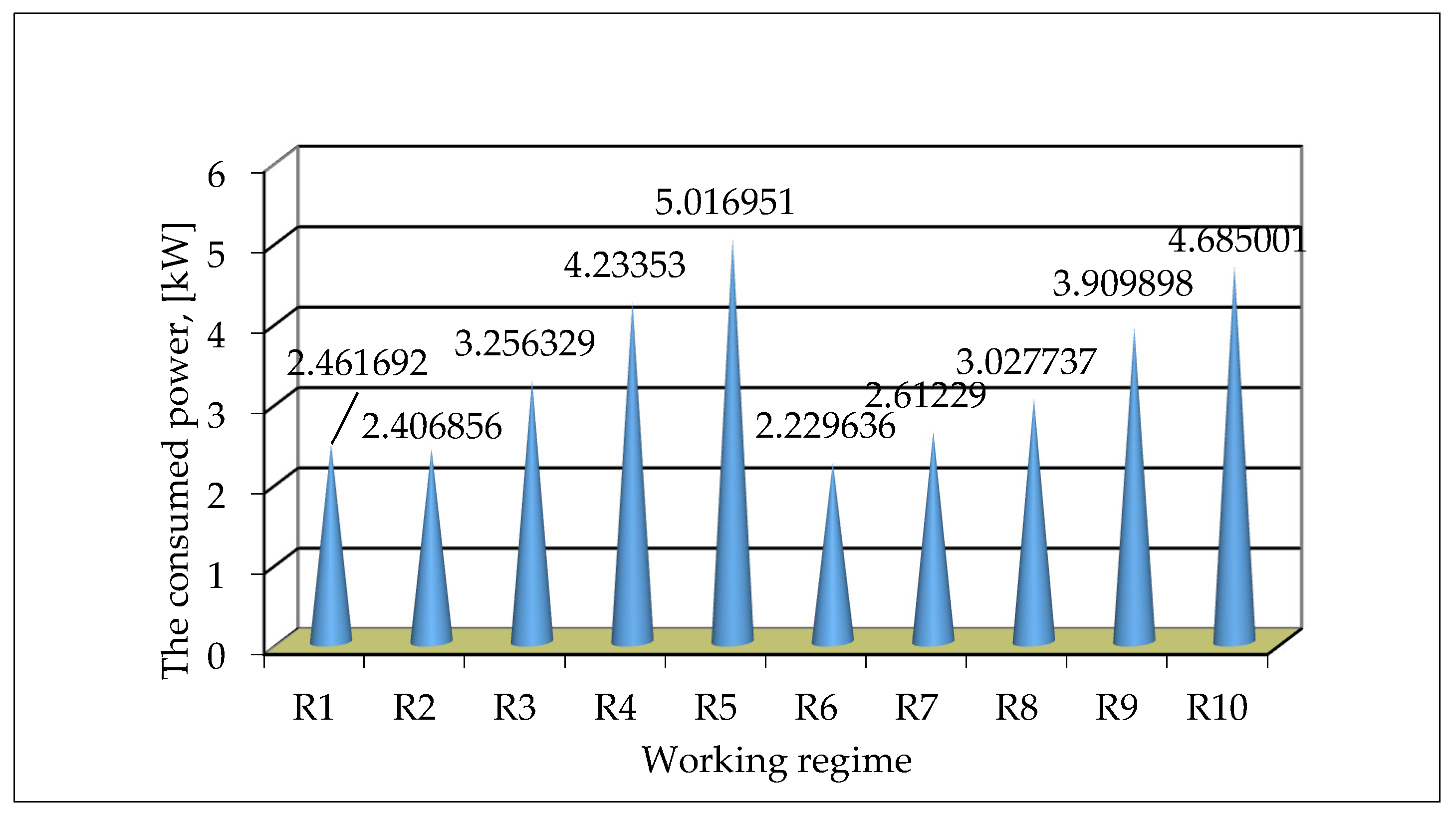

3.9. The Total Power That Was Consumed When the Panels Were Being Cut

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shmulsky, R.; Jones, P.D. Forest Products and Wood Science: An Introduction, 7th ed.; Wiley-Blackwell Publishing: Ames, IA, USA, 2011. [Google Scholar]

- Hakkila, P. Utilization of Residual Forest Biomass; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 1989. [Google Scholar] [CrossRef]

- Swift, M.J.; Healey, I.N.; Hibberd, J.K.J.M.; Sykes, V.; Bampoe, M.E. The decomposition of branch-wood in the canopy and floor of a mixed deciduous woodland. Oecologia 1976, 26, 139–149. [Google Scholar] [CrossRef] [PubMed]

- English, B. Wastes into wood: Composites are a promising new resource. Environ. Health Perspect. 1994, 102, 168–170. [Google Scholar] [CrossRef] [PubMed][Green Version]

- FAO. Wood Handbook. Available online: https://www.fpl.fs.fed.us/documnts/fplgtr/fpl_gtr190.pdf (accessed on 25 April 2022).

- Jahan-Latibari, A.; Roohnia, M. Potential of utilization of the residues from poplar plantation for particleboard production in Iran. J. For. Res. 2010, 21, 503–508. [Google Scholar] [CrossRef]

- Suansa, N.I.; Al-Mefarrej, H.A. Branch wood properties and potential utilization of this variable resource. BioResources 2020, 15, 479–491. [Google Scholar] [CrossRef]

- Olarescu, A.; Lunguleasa, A.; Radulescu, L. Using deciduous branch wood and conifer spindle wood to manufacture panels with transverse structure. BioResources 2022, 17, 6445–6463. [Google Scholar] [CrossRef]

- Olarescu, A.; Lunguleasa, A.; Radulescu, L.; Spirchez, C. Manufacturing and Testing the Panels with a Transverse Texture Obtained from Branches of Norway Spruce (Picea abies L. Karst.). Forests 2023, 14, 665. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, M.; Busse-Wicher, G.; Fereday, T.; Reynolds, D.U.; Shah, G.; Wu, L.; Yuc, P.; Densley-Tingleye, D.; Allwoode, J.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Hassanpoor Tichi, A. Investigation of the use of old railroad ties (Fagus orientalis) and citrus branches (orange tree) in the particleboard industry. BioResources 2021, 16, 6984–6992. [Google Scholar] [CrossRef]

- Wilsson, B.F. Apical control of compression wood action in white pine branches. Wood Sci. Technol. 1986, 20, 111–117. [Google Scholar] [CrossRef]

- Li, X.; Yang, X.; Wu, H.X. Transcriptome profiling of radiata pine branches reveals new insights into reaction wood formation with implications in plant gravitropism. BMC Genom. 2013, 14, 768. [Google Scholar] [CrossRef]

- Hung, L.F.; Tsai, C.C.; Chen, S.J.; Huang, Y.-S.; Kuo-Huang, L.-L. Strain distribution, growth eccentricity, and tension wood distribution in the plagiotropic and orthotropic branches of Koelreuteria henryi Dummer. Trees 2017, 31, 149–164. [Google Scholar] [CrossRef]

- Aiso-Sanada, H.; Ishiguri, F.; Irawati, D.; Wahyudi, I.; Yokota, S. Reaction wood anatomy and lignin distribution in Gnetum gnemon branches. J. Wood Sci. 2018, 64, 872–879. [Google Scholar] [CrossRef]

- Tsai, C.C.; Hung, L.F.; Chien, C.T.; Chen, S.-J.; Huang, Y.-S.; Kuo-Huang, L.-L. Biomechanical features of eccentric cambial growth and reaction wood formation in broadleaf tree branches. Trees 2012, 26, 1585–1595. [Google Scholar] [CrossRef]

- Westing Arthur, H. Formation and function of compression wood in gymnosperms. Bot. Rev. 1965, 31, 381–480. [Google Scholar] [CrossRef]

- Petrovici, V.; Popa, V. Chemistry and Chemical Processing of Wood; Lux Libris Print-House: Brasov, Romania, 1997. [Google Scholar]

- Zhao, X.; Guo, P.; Zhang, Z.; Wang, X.; Peng, H.; Wang, M. Wood density and fiber dimensions of root, stem, and branch wood of Populus ussuriensis Kom. Trees. BioResources 2018, 13, 7026–7036. [Google Scholar] [CrossRef]

- Chaffey, N.J. Wood Formation in Trees. Cell Land Molecular Biology Techniques; CRC Press: Boca Raton, FL, USA, 2019; 384p. [Google Scholar]

- Vurdu, H.; Bensend, D.W. Proportions and Types of Cells in Stems, Branches, and Roots of European Black Alder (Alnus glutinosa L. Gaertn.). J. Wood Sci. 1980, 13, 36–40. [Google Scholar]

- Salem, M.Z.M.; Zayed, M.Z.; Ali, H.M.; Abd El-Kareem, M.S.M. Chemical composition, antioxidant and antibacterial activities of extracts from Schinus molle wood branch growing in Egypt. J. Wood. Sci. 2016, 62, 548–561. [Google Scholar] [CrossRef]

- Pulido-Rodríguez, E.; López-Camacho, R.; Tórres, J. Traits and trade-offs of wood anatomy between trunks and branches in tropical dry forest species. Trees 2020, 34, 497–505. [Google Scholar] [CrossRef]

- ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. International Organization for Standardization: Geneva, Switzerland, 2014.

- EN 325; Wood-Based Panels—Determination of Dimensions of Test Pieces. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- ISO 13061-4; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 4: Determination of Modulus of Elasticity in Static Bending. International Organization for Standardization: Geneva, Switzerland, 2014.

- Gonçalves, R.; Garcia, G.H.L.; Brazolin, S.; Bertoldo, C.; Ruy, M. Methodology for the characterization of elastic constants of wood from tree branches. BioResources 2019, 14, 8439–8454. [Google Scholar] [CrossRef]

- Luan, S.; Yang, R. Predetermination stem wood quality with the branch wood index of Korean pine. J. N. For. Univ. 1992, 3, 54–61. [Google Scholar] [CrossRef]

- Schweingruber, F.H. Trees and Wood in Dendrochronology; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 2009; p. 402. [Google Scholar]

- Schweingruber, F.H.; Börner, A.; Schulze, E. Atlas of Stem Anatomy in Herbs, Shrubs and Trees; Springer: Berlin/Heidelberg, Germany, 2011; Volume 1, p. 495. [Google Scholar]

- Kucera, L.J.; Philipson, W.R. Growth eccentricity and reaction anatomy in branch wood of Drimys winteri and five native New Zealand trees. N. Z. J. Bot. 1977, 15, 517–524. [Google Scholar] [CrossRef]

- Burgert, I.; Jungnikl, K. Adaptive Growth of Gymnosperm Branches- Ultrastructural and Micromechanical Examinations. J. Plant Growth Regul. 2004, 23, 76–82. [Google Scholar] [CrossRef]

- Brezet, H.; van Hemel, C. Ecodesign—A Promising Approach to Sustainable Production and Consumption; United Nations Environment Program: Paris, France, 1997. [Google Scholar]

- Bras, B. Incorporating Environmental Issues in Product Design and Realization. Ind. Environ. 1997, 20, 7–13. [Google Scholar]

- Zeng, Y. Environment-Based Design (EBD): A Methodology for Transdisciplinary Design+. JIDPS 2015, 19, 5–24. [Google Scholar] [CrossRef]

- Nielsen, P. Integration of Environmental Aspects in Product Development: A Stepwise Procedure Based on Quantitative Lifecycle Assessment. J. Clean. Prod. 2002, 10, 247–257. [Google Scholar] [CrossRef]

- Hlásková, L.; Orlowski, K.A.; Kopecký, Z.; Jedinák, M. Sawing processes as a way of determining fracture toughness and shear yield stresses of wood. BioResources 2015, 10, 5381–5394. [Google Scholar] [CrossRef][Green Version]

- Warguła, Ł.; Kukla, M.; Wieczorek, B.; Krawiec, P. Energy Consumption of the Wood Size Reduction Processes with Employment of a Low-power Machines with Various Cutting Mechanisms. Renew. Energy 2022, 181, 630–639. [Google Scholar] [CrossRef]

- Guedes, O.J.T.; da Silva, R.M.; Gherardi Hein, P.R.; Fereira, S.C. Cutting energy required during the mechanical processing of wood species at different drying stages. Maderas Cienc. Tecnol. 2020, 22, 477–482. [Google Scholar] [CrossRef]

- Chuchala, D.; Ochrymiuk, T.; Orlowski, K.; Lackowski, M.; Taube, P. Predicting Cutting Power for Band Sawing Process of Pine and Beech Wood Dried with the Use of Four Different Methods. BioResources 2020, 15, 1844–1860. [Google Scholar] [CrossRef]

- Cristóvão, L.; Ekevad, M.; Grönlund, A. Industrial sawing of Pinus sylvestris L.: Power Consumption. BioResources 2013, 8, 6044–6053. [Google Scholar] [CrossRef]

- ISO 2602; Statistical Interpretation of Test Results—Estimation of the Mean—Confidence Interval Interpretation. International Organization for Standardization: Geneva, Switzerland, 1980.

| Characteristics | Active Power Measured with the Wattmeter, [kW] | Output Signal Value (Acquisition Board) Vu, [V] | The Correlation Factor, fc |

|---|---|---|---|

| u1 | 0.30 | 0.838 | 0.357 |

| u2 | 0.28 | 0.353 | 0.793 |

| u3 | 0.34 | 0.493 | 0.688 |

| u4 | 0.26 | 0.353 | 0.736 |

| u5 | 0.33 | 0.940 | 0.350 |

| v1 | 0.56 | 0.224 | 2.492 |

| v2 | 0.68 | 0.392 | 1.730 |

| Regime | Code of Sample |

|---|---|

| R1 (n1 = 4216 rot/min; u1 = 2.811 m/min) | n1u1-(i) (i = 1,2,3,4,5) |

| R2 (n1 = 4216 rot/min; u2 = 3.981 m/min) | n1u2-(i) (i = 1,2,3,4,5) |

| R3 (n1 = 4216 rot/min; u3 = 7.269 m/min) | n1u3-(i) (i = 1,2,3,4,5) |

| R4 (n1 = 4216 rot/min; u4 = 10.629 m/min) | n1u4-(i) (i = 1,2,3,4,5) |

| R5 (n1 = 4216 rot/min; u5 = 20.233 m/min) | n1u5-(i) (i = 1,2,3,4,5) |

| R6 (n2 = 6722 rot/min; u1 = 3.705 m/min) | n2u1-(i) (i = 1,2,3,4,5) |

| R7 (n2 = 6722 rot/min; u2 = 4.798 m/min) | n2u2-(i) (i = 1,2,3,4,5) |

| R8 (n2 = 6722 rot/min; u3 = 7.937 m/min) | n2u3-(i) (i = 1,2,3,4,5) |

| R9 (n2 = 6722 rot/min; u4 = 10.962 m/min) | n2u4-(i) (i = 1,2,3,4,5) |

| R10 (n2 = 6722 rot/min; u5 = 20.324 m/min) | n2u5-(i) (i = 1,2,3,4,5) |

| Cutting Code | Regime R1 (n1 = 4216 rot/min; u2 = 2.8 m/min) | ||||||

|---|---|---|---|---|---|---|---|

| Feed Power, [kW] | Cutting Power, [kW] | Mechanical Work, K, [daN·m/cm3] | Cutting Force, F, [daN] | Specifical Force, K1, [N/mm2] | |||

| On Empty | On Work | On Empty | On Work | ||||

| n1u2 (1) | 0.300 | 0.325 | 0.614 | 2.321 | 88.413 | 4.673 | 0.834 |

| n1u2 (2) | 0.211 | 0.216 | 0.607 | 2.288 | 87.831 | 4.608 | 0.825 |

| n1u2 (3) | 0.208 | 0.218 | 0.586 | 2.357 | 91.296 | 4.746 | 0.848 |

| n1u2 (4) | 0.209 | 0.212 | 0.588 | 2.342 | 89.996 | 4.715 | 0.843 |

| n1u2 (5) | 0.194 | 0.211 | 0.558 | 2.251 | 84.207 | 4.532 | 0.810 |

| Mean | 0.224 | 0.237 | 0.591 | 2.312 | 88.349 | 4.655 | 0.832 |

| SD | 0.042 | 0.049 | 0.021 | 0.042 | 2.684 | 0.085 | 0.015 |

| V-5% | 0.184 | 0.190 | 0.570 | 2.271 | 85.790 | 4.573 | 0.817 |

| Cutting Code | Regime R2 (n1 = 4216 rot/min; u3 = 3.981 m/min) | ||||||

| n1u3-(1) | 0.28 | 0.313 | 0.577 | 2.138 | 69.695 | 4.305 | 0.840 |

| n1u3-(2) | 0.28 | 0.314 | 0.586 | 2.109 | 68.718 | 4.248 | 0.829 |

| n1u3-(3) | 0.28 | 0.3234 | 0.584 | 2.158 | 70.574 | 4.345 | 0.848 |

| n1u3-(4) | 0.280 | 0.329 | 0.568 | 2.434 | 62.498 | 4.901 | 0.956 |

| n1u3-(5) | 0.279 | 0.329 | 0.591 | 2.506 | 63.949 | 5.046 | 0.983 |

| Mean | 0.279 | 0.322 | 0.581 | 2.269 | 67.087 | 4.569 | 0.891 |

| SD | 0.00007 | 0.007 | 0.008 | 0.186 | 3.623 | 0.374 | 0.072 |

| V-5% | 0.279 | 0.314 | 0.573 | 2.092 | 63.634 | 4.212 | 0.822 |

| Cutting speed, v = 49.668 [m/s] | |||||

| Parameter | Advance per Tooth, uz, [mm/tooth] | ||||

| 0.013 | 0.019 | 0.035 | 0.052 | 0.099 | |

| Cutting power, Pas, [kW] | 2.271 | 2.092 | 2.826 | 3.847 | 4.519 |

| Advance power, Pav, [kW] | 0.190 | 0.314 | 0.430 | 0.385 | 0.497 |

| Cutting force, F, [daN] | 4.573 | 4.212 | 5.690 | 7.746 | 9.099 |

| Specific mechanical strength, K, [N/mm2] | 0.817 | 0.822 | 1.079 | 1.385 | 1.619 |

| Specific mechanical work, K1, [daNm/cm3] | 85.790 | 63.634 | 43.775 | 37.046 | 23.688 |

| Cutting speed, v = 79.191 [m/s] | |||||

| Parameter | Advance per tooth, uz, [mm/tooth] | ||||

| 0.011 | 0.014 | 0.024 | 0.033 | 0.062 | |

| Cutting power, Pas, [kW] | 2.017 | 2.237 | 2.546 | 3.387 | 4.280 |

| Advance power, Pav, [kW] | 0.211 | 0.374 | 0.481 | 0.522 | 0.404 |

| Cutting force, F, [daN] | 2.547 | 2.825 | 3.215 | 4.276 | 5.405 |

| Specific mechanical strength, K, [N/mm2] | 0.448 | 0.497 | 0.569 | 0.758 | 0.957 |

| Specific mechanical work, K1, [daNm/cm3] | 57.719 | 49.598 | 34.540 | 32.694 | 22.258 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olarescu, A.M.; Lunguleasa, A. Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches. Forests 2024, 15, 685. https://doi.org/10.3390/f15040685

Olarescu AM, Lunguleasa A. Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches. Forests. 2024; 15(4):685. https://doi.org/10.3390/f15040685

Chicago/Turabian StyleOlarescu, Alin M., and Aurel Lunguleasa. 2024. "Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches" Forests 15, no. 4: 685. https://doi.org/10.3390/f15040685

APA StyleOlarescu, A. M., & Lunguleasa, A. (2024). Cutting with Circular Saw of Traversal-Structured Panels Obtained from Spruce (Picea abies L.) Branches. Forests, 15(4), 685. https://doi.org/10.3390/f15040685