Abstract

Sustainability has become a key issue in the forest industry; this research aims to analyze the quantitative techniques and metrics applied to the forest-to-lumber supply chain to achieve sustainable decision-making during the last six years. The methodology used was the PRISMA systematic literature review guide, which provides a complete and updated view of the situation. A total of 724 publications were collected from the Web of Science database. Consequently, 85 papers were selected for analysis and synthesis after applying inclusion criteria. The results show a growing interest in sustainability in the forest-to-lumber supply chain, with a peak of publications in 2019. Mathematical Programming and Simulation models are on top of the quantitative techniques applied. These techniques are applied to the supply chain components, classified according to the raw material’s degree of processing or transformation level in forest entities, sawmills, transportation, and other entities. The concluding remarks highlighted that 19 published works research the social dimension, 43 explore the environmental dimension, and 55 examine the economic dimension. Moreover, in the environmental dimension, there is a concentration on the use of metrics associated with greenhouse gases, and to a lesser extent, they have been concerned with soil and water. Additionally, in the social dimension, they have concentrated mainly on the workers, leaving the local communities around the supply chain in the second place. Our systematic review reports the techniques or quantitative methodologies applied in the forest-to-lumber supply chain and the metrics used to handle the dimensions of sustainability.

Keywords:

sustainability; forest; sawmills; lumber; supply chain; decision making; quantitative techniques; metrics 1. Introduction

The report from the World Commission on Environment and Development has employed the term “sustainability” for over three decades, defining it as the approach to meet present needs without compromising the ability of future generations to meet their demands [1]. Since then, this definition has guided the way toward a better future with opportunities for all [2]. The forest industry is not exempt from this. It plays a crucial role in its supply chain, from forest to lumber, in providing wood products on the current global stage, with a growing recognition of the need for a sustainable timber industry [3]. Sustainability in the forest-to-lumber supply chain refers to a holistic approach that considers integrating economic, social, and environmental aspects at all process stages, from extracting raw materials from the forest to the final delivery of lumber products [4,5].

The planning and decision-making process in the forest-to-lumber supply chain becomes a key factor because the success and efficiency of the supply chain largely depend on how it is planned and decisions made at each stage. Improper planning can affect raw material availability, production efficiency, inventory management, and response to changes in market demand. Furthermore, strategic, tactical, and operational decisions at each link in the chain, from logging to distribution, are interrelated, and coordinated planning improves the synergy between these elements [6,7]. Based on mathematical models, computer systems such as ASICAM, OPTICORT, PLANEX, OPTIMED, and MEDFOR have been developed for essential forestry companies [8]. These systems have been implemented and used for strategic, tactical, and operational decision-making [9,10].

The growing awareness of sustainability in the forest-to-lumber supply chain has forced decision-makers to consider economic aspects and the impact of their decisions on the environment and society [11,12]. However, these complex decisions require decision-makers to use quantitative techniques, such as operational research [13].

The main objective of this paper is to evaluate and classify quantitative techniques applied in the forests-to-lumber supply chain that enables a sustainable decision-making process. Therefore, the procedures are defined as follows: first, analyze the current state of decision-making practices in the component entities of the forest-to-timber supply chain, focusing on sustainability. Secondly, research the various quantitative techniques used for sustainable decision-making in the component entities of the forest-to-timber supply chain. Finally, the challenges associated with implementing these quantitative techniques will be discussed while suggesting possible future research.

In the last six years, several literature reviews have been published that partially address using quantitative methods for sustainable supply chains. Table 1 summarizes the period, scope, number of articles, type of scientific articles reviewed, and characteristics considered.

Table 1.

Comparison between the present systematic literature review and the other reviews identified.

Table 1 shows that only one review analyzes the dimensions of sustainability going up to 2017 and that no review has been done classifying the techniques used by entities involved. In addition to all the review articles that were included, only two ([19,22]) use the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA). Developing a systematic literature review using the PRISMA methodology is necessary as it ensures methodological rigor, transparency, reduction of bias, complete reporting, and compliance with publication standards, making research more credible and valuable to the scientific community [23].

This systematic literature review will focus on the issue of sustainability developed by entities in the forest-to-lumber supply chain. In recent years, the concept of sustainability has attracted increasing attention from researchers and industry, resulting in a significant increase in research efforts focused on assessing and improving sustainability in the forest-to-lumber supply chain [24]. However, little attention has been paid to the reviews of the classification entities of the supply chain. The need arose to classify supply chain entities based on the level of processing or transformation [25] that each entity performs in the forest-to-lumber supply chain.

Ref. [15] identified research gaps and possible lines of research in evaluating and optimizing sustainable forest-to-lumber supply chains. It is suggested that efforts be made to ensure consistency between the sustainability criteria used in assessment and optimization studies and to explore methods such as net present value or internal rate of return to consider economic sustainability. Most studies considered only two dimensions of sustainability, and the bioenergy industry in Europe and North America was the focus of 64.9% of the studies reviewed.

Ref. [16] presented a systematic review of the literature on sustainability and sustainable development. A clear trend towards action-oriented approaches and tools rather than forward-looking ones was identified. It was concluded that sustainability should be treated as a complex and interconnected problem and that long-term and systems-based approaches should be adopted to address sustainability, recognizing it as a concept with permeable, flexible, and adjustable boundaries to different needs and situations.

Ref. [18] proposed a systematic review of tactical logistics planning for the forest bioeconomy. It was found that most of the papers reviewed were decision-support tools based on mathematical models, while only 11 of them were full-fledged decision-support systems. Several challenges in implementing these tools were identified, including needing more data integration and considering social and environmental aspects. Several modeling tools were discussed in tactical logistics planning, including mathematical programming tools, simulation, and geographic information systems (GIS). The three dimensions of sustainability (social, economic, and environmental) that should be considered in tactical logistics planning for the forest bioeconomy were also discussed.

Ref. [21] presented the results of a systematic literature review on production planning and control in the lumber industry, focusing on using “digital twin” models. The results suggested a strong interest in applying innovative models and technologies in the lumber industry to improve production efficiency and profitability.

In their respective scientific review papers, other authors contributed significantly to forest management and the lumber supply chain. Ref. [14] provided a detailed analysis of multiple-use forest management planning, highlighting its strengths, weaknesses, and challenges. Ref. [17] focused on using data analytics to improve lumber and biomass supply chain efficiency. Ref. [19] considering its sustainability dimensions, the impact of Industry 4.0 on the forest supply chain was explored. Ref. [20] provided valuable insights into the complex and highly variable operating environment of roundwood and biomass logistics and the need for innovative solutions to address the challenges and opportunities in this field in Finland and Sweden.

The critical contribution of this work is considering the methodologies or quantitative techniques used in the optimization and decision-making in forest-to-lumber supply chains, as well as taking into account the sustainability dimensions studied and the metrics used from 2018 to 2023. However, this time, it considers issues that have yet to be studied in the published literature reviews, such as the classification by entities involved in developing the forest-to-lumber supply chain (see Table 1).

Other scientific papers addressed various topics ranging from forest to lumber supply chain management. Ref. [26] proposed improvements for lumber companies in North America through product customization and supply chain efficiencies. Ref. [27] highlighted that forest products have a lower environmental impact than alternatives such as concrete and steel. Ref. [28] analyzed competitiveness drivers in sawmills, emphasizing factors like product quality, labor costs, and environmental sustainability. In Asia, Ref. [22] evaluated the timber value chain, identifying 16 indicators and noting environmental and social impacts. Additionally, Ref. [29] suggested a review of industrial ecology application, emphasizing the crucial role of forestry in reducing climate impacts and its significance in the national economy. Integrating these findings, Ref. [30] explored the use of data analytics to enhance forest and biomass supply chain management, Ref. [31] presented an overview of Industry 4.0 application in the forestry sector, Ref. [32] reviewed the use of electronic tools in sustainable forest management, Ref. [33] examined policies and regulations related to wood-based infrastructure in Nepal, while Ref. [34] introduced RFID technology and its application in forest supply chains, highlighting the importance of traceability in forest management.

Through a comprehensive analysis of the available articles, we seek a holistic view of the progress, challenges, and prospects related to sustainability in the forest supply chain. By examining the practices and approaches adopted by each entity, it is expected to identify best practices and lessons learned that can serve as a basis for future decision-making and the design of policies and strategies oriented towards sustainability in the forestry sector.

This paper is structured as follows. Section 2 presents the research methodology used in the present work. Section 3 presents the results based on the content analysis of the included papers with interpretation and discussion. Section 4 presents an analysis of the results. Finally, Section 5 presents the main conclusions with future research directions for future investigation.

2. Research Method

This research includes the development of a systematic literature review. The guidelines described in PRISMA were used in the study to ensure a methodological framework for the review. Until August 2020, approximately 60,000 papers in the academic literature have employed the PRISMA guideline report for conducting systematic reviews, affirming the dependability and appropriateness of the results [23]. The body of literature that has utilized PRISMA serves as evidence of the methodology’s effectiveness in carrying out systematic literature reviews. Four steps are planned: Research questions, search strategy, selection and evaluation process, and finally, analysis and synthesis.

2.1. Research Questions

Two research questions were formulated that the review aims to answer to meet the objectives of the paper:

Q1. What quantitative techniques or methodologies are currently used in the forest-to-lumber supply chain to improve sustainable decision-making, and how are they applied at different entities?

Q2. What are the challenges and future research directions?

2.2. Search Strategy

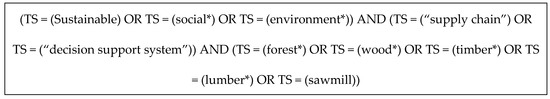

A search strategy was created to collect papers on the research topic. Based on the topic to be investigated and the proposed objectives, a search string is formed using keywords combined with Boolean logic operators (see Figure 1). We used peer-reviewed papers from the Web of Science database for the last six years (2018 until 2023). The Web of Science database is selected because it is recognized for its broad coverage of high-quality peer-reviewed publications in various academic disciplines. This broad coverage ensures that our literature review is built on a solid foundation, covering various relevant and reliable sources.

Figure 1.

Search string used to search related articles.

2.3. Selection and Evaluation Process

Inclusion criteria were established for the selection. Only peer-reviewed papers published in English were included in the search for reliable results because English is the most common language and avoids local bias. For the sample to represent the current state of the art, this review only considered research papers published in the last six years covering the period since 2018 and performing the last search on 31 December 2023. Table 2 presents the inclusion criteria of this systematic review for selecting papers.

Table 2.

Inclusion criteria to select papers in this review.

2.4. Analysis and Synthesis

The data extracted from the included papers were examined and integrated in accordance with the research inquiries. The essential characteristics of the included scientific articles, for example, the distribution of publications by year and the number of articles found in each journal, were extracted and analyzed. The methodologies and quantitative optimization techniques used in the decision support systems considered in each article were analyzed to answer the first question.

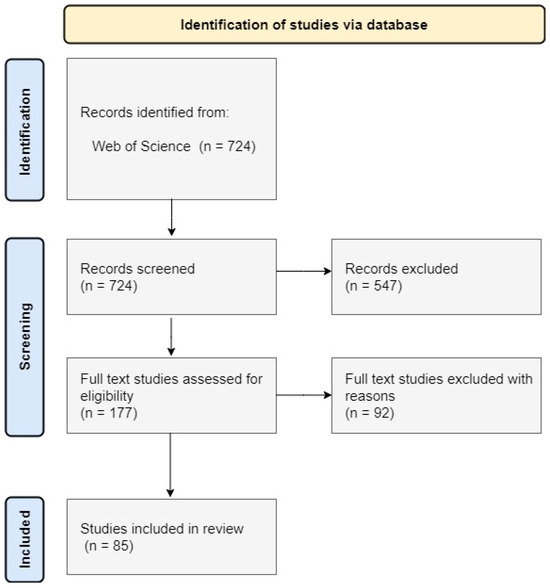

The Web of Science database search retrieved 724 records. Figure 2 shows the flowchart of the PRISMA 2020 statement [23]. As shown in Figure 2, the search was performed, followed by identification, screening, and inclusion. In the screening stage, the inclusion criteria in Table 2 were used to select scientific articles related to the topic. Two steps in the selection were carried out. The first step was to filter the abstracts and keywords of the articles. Following the first screening step, 177 articles remained for the second step. The second step was to assess the eligibility of the full-text articles. Ninety-two articles were excluded for specific reasons. After selecting full-text articles, 85 were selected for data extraction and analysis. Supplementary Materials lists 85 articles included in this systematic review. The list shows the author(s), publication year, article title, and journal of the included papers.

Figure 2.

Diagram outlining the systematic literature review in accordance with the PRISMA 2020 guidelines.

The results and findings of this systematic review of the literature are shown in Section 3. The results are presented based on the selected papers’ content analysis.

3. Results

This section showcases the key outcomes and discoveries of the literature review. It begins with a descriptive analysis of the scientific articles reviewed, providing an overview. Subsequently, a more detailed analysis of each paper is presented, highlighting the individual contributions and their relevance in the research context.

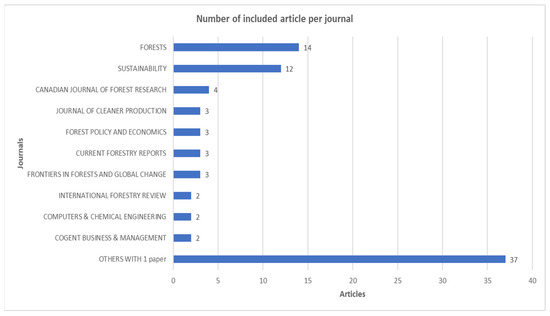

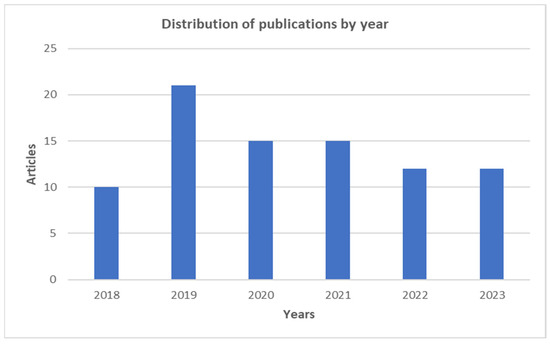

After the selection, the essential characteristics of the included articles were summarized, which provided an overview of the trend of the topic in academia. The 85 scientific articles analyzed in this paper were published in 47 journals. 56% of the scientific articles were published in 10 journals. Figure 3 shows the number of articles found in each journal, highlighting the two leading journals with the highest number of articles included: Forests and Sustainability. These two journals have been highlighted for their frequent publication of research related to the area since 2018. On the other hand, Figure 4 represents the distribution of publications by year, evidencing a maximum of publications in 2019, followed by a steady trend in subsequent years. This constant interest in the topic in academia may be a key factor driving this trend.

Figure 3.

Summary of the selected articles sorted by journal.

Figure 4.

Distribution of publications by years.

Sustainability is generally based on the integrated consideration of three dimensions (economic, environmental, and social) [35]. On the economic side, it seeks to ensure financial viability by optimizing resource allocation and maximizing economic efficiency using metrics such as total supply chain cost, net present value, prices, investment, and profitability. From the environmental perspective, the focus is on minimizing impacts throughout the life cycle of the products, contemplating the reduction of emissions, the conservation of biodiversity, and the responsible utilization of natural resources, using metrics such as carbon footprint, water footprint, ecological footprint, noise levels, and greenhouse gas emissions. Finally, the social dimension seeks to ensure respect for human rights, foster equitable and safe working conditions, and promote local communities’ participation and development through metrics such as job creation, employment stability, social profit, social benefit, and safety [15].

In supply chains, several quantitative techniques play an essential role in the search for balance between economic efficiency, environmental preservation, and social welfare. Among these techniques are linear, integer, and mixed integer programming, which offer powerful tools for optimal resource allocation and operations planning. Multiobjective optimization is used for various goals that may sometimes conflict, while stochastic and robust optimization allow consideration of uncertainty scenarios and data variability. In addition, cost-benefit analysis and life-cycle analysis help to measure the economic, environmental, and social impacts of decisions. Sensitivity analysis adds depth by considering how fluctuations in key factors influence outcomes. Finally, discrete event simulation adds dynamism by modeling different scenarios and understanding their impact over time.

To develop this systematic literature review, we analyzed and divided the forest-to-lumber supply chain into its main component entities (see Figure 5).

Figure 5.

Main component entities of the forest-to-lumber supply chain.

3.1. Forest

The forest is the agent or set of processes for planning, organizing, controlling, and operating the felling or harvesting of trees for commercial or industrial purposes [36].

3.1.1. Forest Entities and Sustainability

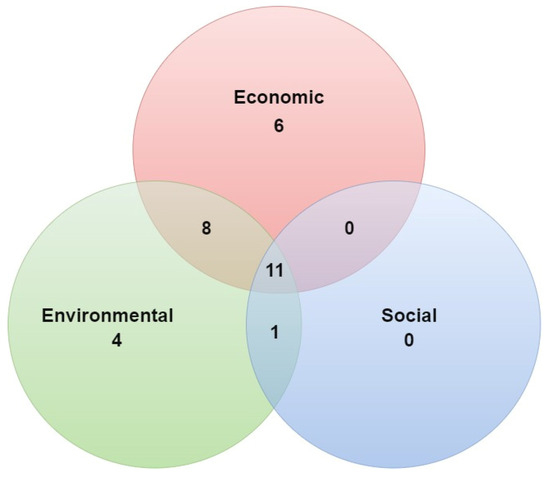

Of the 30 articles analyzed in the Forest entities, the most researched dimension of sustainability is the economic dimension, with 25 articles, followed by the environmental dimension, with 24 articles, and finally, the social dimension, with 12 articles (see Figure 6).

Figure 6.

Distribution of scientific articles according to the dimensions of sustainability addressed in the Forest entities.

3.1.2. Forest Entities: One Sustainability Dimension

In the articles that analyzed the economic dimension of sustainability in the Forest entities (see Table 3), we observed that Ref. [37] proposed a linear programming model to maximize the NPV of timber sales in Ireland’s western peatland forests using Remsoft Woodstock optimization software (version 2017.11.0), which used forest inventory information, growth and yield tables, and timber costs and prices to generate a linear programming matrix that is solved to generate future scenarios of forest landscape condition. The model was updated to include climate change scenarios and dynamic timber prices. In addition, ArcGIS 10.4 software was used to produce a spatial information capability integrated into the Woodstock model. The model for strategic forest management planning allows spatial constraints and management objectives. The article does not present the details of the linear programming model and does not present the extensive results of the model.

Table 3.

Forest entities articles of the forest-to-lumber supply chain, methodology or technique used, and metrics that address sustainability dimensions.

Ref. [38] analyzed the lumber supply chain by evaluating the theoretical and technical potential of the roundwood supply, focusing on three technical constraints: the terrain’s slope, the harvesting intensity, and the mechanization level. The study results provided a detailed evaluation of the lumber supply chain in a forest in Mexico, considering the technical and operational constraints that affect productivity and profitability.

Ref. [39] proposed a profit maximization model (revenue minus the costs of harvesting, felling, transportation, sorting, production, inventory, and yard implementation) applied to a real case in the Mauricie region of Quebec (Canada). The authors showed that implementing a forest logistics center brings $0.52 in profit per cubic meter of wood available for harvest (more than 2,580,411 m3 per year) to the network under study ($1.4 million per year). The research can be extended through a mathematical model for route generation that considers full truck loads.

Ref. [40] approached the problem of salvage harvesting under uncertainty and proposed a multistage mixed-integer stochastic programming model to schedule harvesting at different intensities of spruce budworm outbreaks. The objective was to maximize revenue derived from the value of the wood minus logistic costs while satisfying the demand for wood in the industry.

Ref. [41] three linear programming models were proposed to determine the most cost-effective and sustainable approach to timber harvest planning in Canadian forests. Model A was based on sustained yield principles and maximized the allowable cut by ensuring a uniform flow of harvest volume per period for the entire planning horizon. Model B was an integrated model that maximized net present value (NPV) globally for the supply chain. Model C aimed to sequentially meet the demands of all mills based on the value of the product it generates. In all models, the objective function was expressed to maximize economic profitability regarding harvest volume, net present value, or net revenue per product. A helpful contribution of this research is the flexibility of Model C to respond to market conditions.

Ref. [42] used an agent-based model as a simulation and decision-making tool to support the collective analysis of scenarios and find solutions with supply chain stakeholders. The PARDI method gathered the necessary knowledge about the supply chain and its context. This research could be extended by considering game theory with multiple stakeholders.

In the articles that analyzed the environmental dimension of sustainability in the Forest entities (see Table 3), we observed that Ref. [43] conducted a life cycle assessment of the wood supply chain in Tennessee. They evaluated the environmental impacts of logging and transportation of wood, including greenhouse gas emissions and fossil energy demand. The results indicated that the cutting (selective or clear-cut) and the equipment used to harvest and transport the wood significantly impact greenhouse gas emissions and fossil energy demand. In general, it was found that an increase in cutting intensity, from selective to clear-cut, results in lower emissions per ton of wood harvested, and the environmental impacts associated with the production and maintenance of logging and transport equipment were found to account for only 6%–8% of the total impact. In contrast, the impacts associated with fuel and lubricant use dominate the emissions and energy demand results. This research can be extended using other transport-related factors, such as transport modes and road conditions.

Ref. [44] presented the results of developing and implementing a decision support system for forest management planning called wSADfLOR. Results included the system’s ability to enable stakeholders to analyze trade-offs between ecosystem services and develop participatory and sustainable forest management objectives. In addition, the system included multicriteria scheduling routines that provide proposals for management plans. The application of the system to a forest landscape in Portugal and stakeholders’ involvement in the system’s development was described. The results showed that the system is effective in decision-making and optimizing the selection of ecosystem service packages in forest management. NSGA-III and SPEA2 can extend this research to generate the Pareto frontier.

Ref. [45] used forest simulation models (Kupolis simulator) and decision support tools to model the development and use of Lithuanian forest resources under different scenarios, estimate the total carbon balance in Lithuanian forests, and assess the potential of Lithuanian forests to absorb carbon. They evaluated variables such as standing volume, area-weighted average age, net annual increment of wood volume, volume of wood harvested annually, and total area of forest stands belonging to a specific age class.

Ref. [46] described the development of the FESEDSS decision support system for forest ecological security assessment and governance in China. The system integrated econometric models, mathematical methods, geographic information systems, and a dynamic database to calculate ecological and relative security indices for the forest ecosystem and its three subsystems (forests, wetlands, and deserts) at the national and provincial levels. The results showed an improvement in the ecological security of the forest ecosystem, while the ecological security of wetlands and deserts had decreased.

3.1.3. Forest Entities: Two Sustainability Dimensions

In the scientific papers that analyzed two dimensions of sustainability in the Forest entities (see Table 3), we observed Ref. that [47] used an ethnographic approach based on semi-structured interviews, community meetings, and participant observation to examine the informal supply chain of wood produced in abandoned agricultural fields in the Peruvian Amazon. They succeeded in providing a detailed understanding of the dynamics of the informal wood supply chain in the region. They offered recommendations for improving the situation of farmers and the sustainability of wood production. This study can be extended by considering administrative processes to eliminate informal procedures.

Ref. [48] presented integer linear programming (ILP) models to minimize the distance between harvested trees and planned log landing sites in a sustainable forest management area in the Brazilian Amazon. The models integrated forest structure, economics, adjacency constraints, and wood production parameters. The mathematical models were solved using the branching and bounding algorithm in Lingo software (version 14.0), showing that they have a high potential to improve selective logging activities in the Amazon rainforest and can be integrated into uneven-aged forest management projects. The study also identified possible log landing sites and derived the BDq method to determine the number of trees to harvest by species and diameter class. The results indicated that mathematical models can balance economic and ecological concerns while adhering to sustainable forest management principles. This article can be extended using metaheuristics or decomposition techniques to obtain better computational results.

Ref. [49] introduced a mathematical programming framework that integrates multi-objective optimization (MOO) and mixed-integer linear programming (MILP) to enhance economic and environmental aspects in the forest supply chain, considering Sequential and Integrated scenarios. The economic metric, net revenue (NR), and the environmental metric, net GHG emissions savings (NS), were employed to measure the respective objectives. The model used a set of Pareto optimal solutions, wherein for each solution, one objective cannot be improved without sacrificing the other objective.

Ref. [50] developed two decision support tools (GIFT and SOILCONSWEB-GCI). GIFT is a geospatial decision support tool developed on an open-source geospatial cyberinfrastructure (GCI) platform for forest resource management. The tool was applied to a forest area in southern Italy. It was proposed to approach forest knowledge and management, which requires operational support to private forest owners and decision-makers involved in forest landscape management at different levels. The tool includes LiDAR-derived information combined with expert knowledge of forest resources and the application of regulations, aiming to guide the future evolution of the resource, taking into account the owner’s needs. SOILCONSWEB-GCI is a decision support system for forest management, including a soil protection module in forest management planning. Forest planners and private forest owners can use the tool to obtain information on forest types, dendrometric parameters, and environmental factors that facilitate forest operations. The decision-making tool can benefit from the data obtained from the LIDAR sensors.

Ref. [51] used the Remsoft Woodstock modeling tool to develop a linear programming model for forest management decision support (FMDSS) called ALTERFOR. They presented several results related to sustainable forest management and the provision of forest ecosystem services in the western region of Ireland, including correlations between the amount of clear areas and phosphorus emissions. This research does not present the mathematical model used and could be extended with game theory.

Ref. [52] proposed a stochastic model for annual forest harvest planning that considers the risk of soil compaction generated by heavy machinery used in the forest industry. The model was presented in deterministic and stochastic versions, incorporating uncertainty from different soil compaction risk scenarios. Computational experiments were performed on a case study involving 40 stands and more than 1000 hectares of forest. The results showed that the stochastic approach reduces costs by 15% compared to the deterministic approach for monthly planning and 10% for annual planning. In addition, the Progressive Hedging algorithm was a valuable tool for managing the computational complexity of solving these problems. It was concluded that approaching soil compaction in a plan is vital if soil properties were to be protected, mainly to preserve the edaphic mesofauna that contributes to renewing soil nutrients. Stochastic programming can be used to approach this risk and optimize harvesting plans, considering factors such as soil moisture and productivity.

Ref. [53] analyzed several results related to the optimization of forest supply chain management. The net revenue (NR) of the forest supply chain was optimized using linear programming (LP) and mixed integer linear programming (MILP) models. The results showed that the MILP model outperforms the LP model regarding net revenue. They then formulated a multiobjective mixed-integer LP model to maximize the net present value and net GHG emission savings from forest salvage utilization. The results showed that the model can provide Pareto optimal solutions that balance economic and environmental objectives. Finally, they developed a multiobjective metaheuristic log-to-log trip (MRRT) method to simultaneously optimize economic and environmental objectives. The results showed that the MRRT method could efficiently produce non-dominated solutions that help decision-makers understand the trade-offs between various objectives.

Ref. [54] proposed a model for environmentally sustainable purchasing in the wood processing industry. Although it presented a sound methodological approach and significant findings, it needs a deeper analysis of companies’ specific barriers and challenges in implementing these policies. In addition, it needs to fully address the role of stakeholders in adopting sustainable procurement. Also missing is a more detailed discussion of the quantitative techniques used to assess the impact of sustainable purchasing on the industry.

Ref. [55] presented a framework for green contract mechanisms in forest supply chain management but needed a deeper analysis of quantitative techniques and sustainability. Although a mathematical model for optimizing forest management contracts was proposed, it must address sustainability sufficiently. In addition, the lack of further validation of the framework’s effectiveness and the absence of more advanced quantitative techniques limit its applicability in promoting sustainable practices.

3.1.4. Forest Entities: Three Sustainability Dimensions

In the scientific article that analyzed the three dimensions of sustainability in the Forest entities (see Table 3), we observed that Ref. [56] discussed the implementation of forest certification in Brazil, Spain, and Portugal and its associated difficulties. The authors used the hierarchical analysis method (AHP) to identify the most challenging principles to comply with in each country. They found that environmental aspects were generally considered the most complicated to comply with, while social aspects were much more challenging to achieve in Brazil, and economic aspects were not considered a significant problem in any of the three countries.

Ref. [57] evaluated the consequences of various forest management options on economic, ecological, and social aspects of sustainable forest management through scenario analysis using a forest decision support system. The study evaluated ten different forest management scenarios for two contrasting municipalities in Sweden based on expert participation through a web-based multicriteria decision analysis (MCDA) framework. The results indicated that current management practices favor economic aspects (wood production). At the same time, several scenarios would be better suited to meet the Swedish forest policy objective of production and consideration of environmental issues.

Ref. [58] presented a multiobjective optimization model for the management of forest ecosystem services. The optimization problem was addressed using a compromise programming (CP) technique, and an optimal solution was sought by applying a metaheuristic approach grounded in genetic algorithms. The model used different metrics to evaluate forest management and quantify ecosystem services, including wood production, carbon storage, recreation, and biodiversity. In addition, different multiobjective assessment approaches were used to combine these metrics and evaluate trade-offs and conflicts between them. The model also used economic valuation techniques to convert biological values of ecosystem services into economic values. Possible future improvements to the model were discussed, such as integrating additional techniques like a fuzzy multiobjective/multicriteria approach, Monte Carlo simulation, sensitivity analysis, or probabilistic approaches.

Ref. [59] analyzed the factors limiting woodland management and the sustainable use of local wood products in southeast England. Despite the abundance of woodland in the region, only 10% of the UK’s wood demand was sourced from locally grown resources. The study identified 38 factors affecting woodland management and underutilization of broadleaved wood resources, grouped into four dimensions: human, financial, structural, and environmental. The wood products and forestry sector in southeast England is complex and multifaceted, with intense human, economic, environmental, and structural drivers driving away the use of local wood resources. Inputs demonstrated new evidence for policymakers to deliver improved sustainable utilization of forest resources in parallel with support for rural communities and economies.

Ref. [60] presented the sustainability monitoring tool (SUMINISTRO) and its application in the sustainability assessment of wood-based bioeconomy networks in central Germany. The article described the development process of the tool, including the identification of wood-based products, the definition of reference systems, the derivation of sustainability targets, the adaptation of indicator sets to monitor sustainability targets, the acquisition of life cycle inventories and impacts associated with the production volumes of individual value chains, and the calibration of assessment functions.

Ref. [61] described the development of a decision support system (DSS) for strategic planning in forestry companies in Switzerland, which incorporated a wide range of biodiversity and ecosystem service indicators and a flexible multicriteria decision analysis. The DSS was applied to three forest enterprises in Switzerland to assess the effect of different management strategies and climate change scenarios on the provision of ecosystem services. The results showed synergies and trade-offs between ecosystem services and the best management strategy varied by company. They also highlighted the importance of considering multiple objectives and stakeholder collaboration in forest management.

Ref. [62] used the ETCAP forest management decision support system to simulate and assess the impacts of forest management interventions on multiple ecosystem services, including wood production, soil protection, water provision, habitat for biodiversity conservation, cultural values, and carbon sequestration. The study developed four forest management scenarios with different afforestation rates, treatment intensities, and rotation periods to analyze forest dynamics and their impact on ecosystem services.

Ref. [63] provided an innovative approach to assessing forest ecosystem services and forest use suitability. However, it needs a detailed analysis of the quantitative techniques used. It could be scaled up to greater integration of quantitative techniques with a holistic approach considering forest sustainability’s social, economic, and environmental dimensions.

Ref. [64] addressed the Heureka forest decision support system, a multifaceted system for sustainable forest management in Sweden. They discussed its applications in forestry education, research, and practice, as well as its design, functionality, and possible future developments. The limitations of empirical growth functions were highlighted, and a case is made for future forest decision support systems that are more inclusive, adaptive, and focused on ecosystem services.

Ref. [65] discussed using the LANDSUPPORT project, an intelligent web-based geospatial decision support system, to address sustainable land management. They included case studies on sustainable practices in agriculture and forestry, demonstrating the system’s ability to provide options for users to make informed decisions. The system integrates diverse data sources and technologies to support the implementation of EU, national, and regional policies in agriculture, forestry, and the environment.

Ref. [66] addressed the illegal wood trade in the Brazilian Amazon, focusing on the valuable species ipê. It used data from logging permits and timber transport records to identify and quantify the risks of illegality in the supply chain. It highlights the lack of traceability and the need for improved governance to ensure the sustainability of forest resources. However, the study could benefit from greater clarity in presenting key findings.

3.2. Transport

The Transport entities cover the management and logistic process of the transport and are the interface with the sawmills. In addition to the timber inventory, the organization and scheduling of transport, route optimization, truck operations (location, navigation, loading, log transport), and quality control and documentation of the execution are necessary steps [36].

3.2.1. Transport Entities and Sustainability

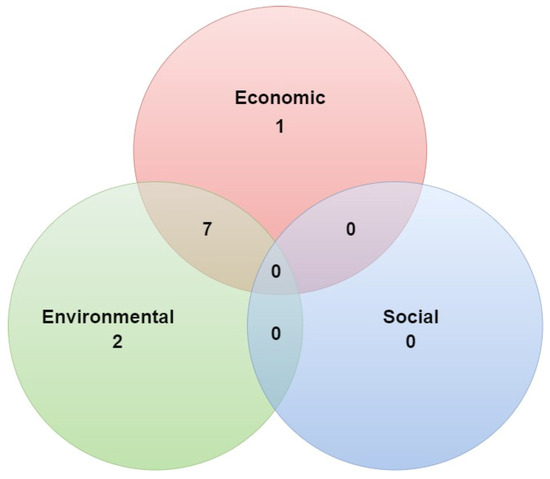

Of the ten articles analyzed in the Transport entities, the most researched dimension of sustainability is the environmental dimension with nine articles, followed by the economic dimension with eight articles (see Figure 7).

Figure 7.

Distribution of scientific articles according to the dimensions of sustainability addressed in the Transport entities.

3.2.2. Transport Entities: One Sustainability Dimension

In the scientific articles that analyzed the economic dimension of sustainability in the Transport entities (see Table 4), we observed that Ref. [67] presented results from an agent-based simulation model that analyzed the influence of various factors on the lead times and costs associated with cable-laying operations. The study used published data from the literature and analyzed scenarios created by varying parameters, including landing storage capacity, timing of information flows, truck availability, and unfavorable weather. The results showed that doubling dock storage capacity can reduce lead time costs by approximately 50%, and pre-ordering trucks also leads to lower costs. The best-case scenario for the number of available trucks depends on the storage capacity at the landing stage and the timing of the information flow, and unfavorable weather always hurts costs.

Table 4.

Transport entities articles of the forest-to-lumber supply chain, methodology or technique used, and metrics that address sustainability dimensions.

In the scientific articles that analyzed the environmental dimension of sustainability in the Transport entities (see Table 4), we observed that Ref. [68] presented the results of a study that applied an experimental and data-driven approach to optimizing wood procurement and transportation logistics in the forest industry in Finland. Dynamic linear programming (DLP) model was used to solve the wood supply chain (WSC) problem, and sensitivity and scenario analyses were applied to assess the quality of the model. The results showed that the optimized model of wood procurement and transportation logistics in the Northern Finland region achieved a 4.9% reduction in total wood procurement and transportation costs compared to the initial experiment. However, long-distance transportation costs increased by 23.3%. Ref. [69] the results of a life cycle assessment (LCA) of the wood production chain in Austria were presented using the EN ISO 14040 and 14044 standards [77,78] and the Ecoinvent 3.4 database. The LCA considered various environmental impacts, such as greenhouse gas emissions, biodiversity, water, soil, and air. The results showed that the older the stands to be cared for, the higher the GHG emissions per 1 m3 of wood produced. Road transport of wood had the most significant impact on climate change, and It was crucial to explore environmentally sustainable solutions from both a technical and organizational perspective.

3.2.3. Transport Entities: Two Sustainability Dimensions

In the scientific articles that analyzed two dimensions of sustainability in the Transport entities (see Table 4), we observed that Ref. [70] created a simulation model based on discrete-event techniques to assess multimodal strategies to enhance the sustainability and resilience of the wood supply chain. The model was based on a real case study in Austria and included modules for forests, truck transport, terminals, rail transport, and industry. The model was designed to provide decision support to supply chain managers and included a graphical user interface with animation and critical performance indicators. The results showed the advantage of a combination of unimodal and multimodal transportation in the wood supply chain, as it proved to be resilient and outperforms other proven supply chain strategies by avoiding bottlenecks and poorly synchronized trucks and reducing CO2 emissions.

Ref. [71] used GIS (Geographic Information System) analyses to evaluate the effects of road maintenance policies in Oregon on log truck route selection and cost trade-offs between the user and the agency. The data’s classification, quantification, and analysis were subdivided into seven steps. These steps included quantifying the study area, including forestland and a complete transportation network, and analyzing forest accessibility, transportation cost, energy consumed, and greenhouse gas emissions for each road maintenance scenario.

Ref. [72] they analyzed the potential use of high-capacity haul trucks (HCT) to transport roundwood in Sweden. They used data from actual roundwood transports in 2016 and digitization of the Swedish road network to identify supporting networks and corridors that support the flow. The study then applied a calibrated route finder (CRF) to route relevant transports directly from the landing to the receiver and through the corridor, collecting information on the distance traveled and analyzing transport fuel consumption and potential CO2 savings.

Ref. [73] developed and implemented a decision support system (DSS) called BestWay to optimize primary logging routes in forestry operations. The system used a mixed integer programming model to determine supply points and a solution method based on Lagrangian relaxation to minimize total haul distance and reduce the negative impact on soil and water. The system used LiDAR data and models, network arcs and costs, and extraction routes for loaded and unloaded transports. The DSS was tested in two case studies in Sweden and effectively generated optimized extraction routes with different priority settings.

Ref. [74] proposed the use of data-driven decision support systems to optimize wood procurement and transportation logistics in the forest industry in Finland, specifically in the northern region, where wood production capacity is low and transportation costs are high. They designed a dynamic linear programming (DLP) model with an objective function that minimizes total wood procurement and transportation costs and considers the economic and environmental costs of CO2 emissions. The model also considered multimodal transport capacity, including road and rail transport, and the capacity of rail terminals.

Ref. [75] a supply chain optimization approach was presented for northern Spain’s roundwood and Eucalyptus globulus biomass. They used the MCPLAN tool in linear programming modeling to evaluate the impact of drying and feedstock losses on costs and greenhouse gas emissions in the supply chain, obtaining a 6.5% reduction in supply chain costs, 14.9% less trucks to destination points, and 18.1% less fuel consumption and greenhouse gas emissions.

Ref. [76] focused on the influence of procurement time and quality on transportation strategies in the lumber supply chain. They used a discrete event simulation model to track the development of lumber quality. Results showed that strategies incorporating quality forecasts outperform traditional strategies and suggest the importance of acquisition time thresholds in lumber management.

3.3. Sawmill

The sawmill entities contain activities to transform roundwood into sawn timber and other derived products. The sawmill process includes debarking, sawing, drying, planning, shaping, and packaging. Each stage has its equipment, techniques, and quality standards. The sawmilling process aims to obtain the maximum yield and value from the forest raw material [36].

3.3.1. Sawmill Entities and Sustainability

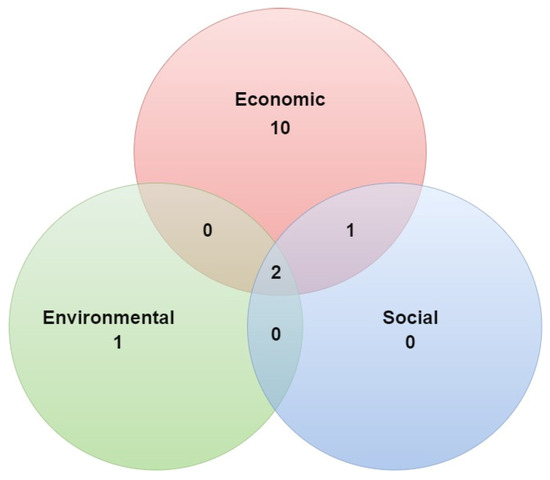

Of the 14 scientific articles analyzed in the Sawmill entities, the most researched dimension of sustainability is the economic dimension with 13 articles, followed by the environmental dimension with three articles and the social dimension with three articles (see Figure 8).

Figure 8.

Distribution of scientific articles according to the dimensions of sustainability addressed in the Sawmill entities.

3.3.2. Sawmill Entities: One Sustainability Dimension

In the scientific articles that analyzed the economic dimension of sustainability in the Sawmill entities (see Table 5), we observed that Ref. [79] analyzed a demand management process that integrated sales and operations planning (S&OP) and order promising in a stock manufacturing environment. They used a simulation approach to compare two configurations of the integrated demand management process and generate Kriging metamodels to analyze the nonlinear relationships between environmental factors and performance measures for Canadian softwood lumber companies. The analysis revealed the potential to improve the performance of the demand management process by knowing the needs of high-priority customers before handling low-priority orders and using the concept of nested reserve limits.

Table 5.

Sawmill entities articles of forest-to-lumber supply chain, methodology or technique used, and metrics that address sustainability dimensions.

Ref. [80] determined the impact on profits due to the decision to change the manufacturing system and explored the relationships between lean-agile-hybrid manufacturing systems and decision-making outcomes. Mixed linear programming (MIP), discrete event simulation (DES), and value stream mapping (VSM) techniques were used to model the manufacturing environment in the forest industry. The results showed that lean, agile, and hybrid manufacturing systems have different benefits and trade-offs depending on the demand for wood. In addition, it was found that the introduction of lean-agile-hybrid manufacturing systems can improve the performance of the forestry supply chain.

Ref. [81] presented a linear programming model to find the minimum cost of the supply network that meets a specific demand of two product markets per year. The model considered several parameters characterizing five entities: forestry departments, sawmills, LBWF, beech furniture lumber buyer, and beech plywood market.

Ref. [82] used a mathematical formulation that includes an S&OP network model in the Canadian softwood lumber industry and an order-promising model that used nested reserve limits. The proposed mixed-integer linear programming (MILP) model considers heterogeneous customers, divergent product structures, and multiple sourcing locations in a multi-period context. The objective function of the model was to maximize profits and improve the level of service offered to high-priority customers.

Ref. [83] proposed a simulation model to evaluate different coordination mechanisms in sawmills in a dynamic context and adapt to long-term objectives. The objective was to improve coordination in the softwood lumber industry to increase sales, improve customer service, and reduce inventory costs.

Ref. [84] analyzed the wood flow in the Czech Republic using the cascade principle of biomass use. They used the reverse input method to analyze the wood flow due to the need for valid and reliable input data from official statistics.

Ref. [85] presented a material flow analysis model of the maritime pine wood supply chain in the Landes de Gascogne region in France from 2013 to 2019. The quantitative model used the wood fiber equivalent unit as a reference and used visualization tools such as Sankey diagrams to represent material flows. The model’s objective was to support decision-making and improve forest design to promote the efficient and circular use of resources.

Ref. [86] developed a binomial negative regression model to analyze the relationship between geographic factors and raw material supply at wood sawmills in Peninsula Malaysia. The model was applied to three types of sawmills: primary, secondary, and tertiary. The model results indicated that the location of log storage and transportation affects the location of primary wood sawmills. In contrast, the location of raw material supply affects the location of primary and secondary sawmills. The model also provided estimates of the regression coefficients for each independent variable and their impact on the sawmill location. This study can be extended using machine learning techniques to make regression analyses and predictions.

Ref. [87] used generalized binomial negative regression models to account for overdispersion in the count data and to model the spatial correlation of primary and secondary forest product manufacturers in North Carolina and the factors that explain their location and clustering in the forest industry. Geographic information system tools were used to identify the significant FPM hot spots in North Carolina, and the factors influencing the location of primary and secondary forest product mills in the state were analyzed.

Ref. [88] presented a robust two-level facility location model and an integer program formulation of the two-level model to design a reverse logistics network for wood waste, which involves collecting and transporting wood to designated processing facilities. They also presented local search and tabu search methods for solving more significant instances of the problem. This study can be extended with the latest results obtained by other authors solving the UFL with Bender decomposition for large-scale instances.

In the scientific article that analyzed the environmental dimension of sustainability in the Sawmill entities (see Table 5), we observed that Ref. [89] used a qualitative research approach based on semi-structured in-depth interviews to explore the user needs of “digital twins” in the Norwegian timber industry to support industrial symbiosis networks, which sought to establish ecological networks between industries with geographic proximity to reduce waste disposal and improve production efficiency.

3.3.3. Sawmill Entities: Two Sustainability Dimensions

In the scientific article that analyzed two dimensions of sustainability in the Sawmill entities (see Table 5), we observed that Ref. [90] presented a mixed integer linear programming (MILP) model with multiobjective formulation for the optimal design of a forest supply chain incorporated economic and social sustainability dimensions. The ε-constraint method was applied to solve the model and to generate a set of Pareto optimal solutions showing the trade-offs among multiple criteria. The case study in the northeastern region of Argentina was used to compare the solutions obtained using different social indicators. It demonstrated the potential of the forestry sector in Argentina, which presents opportunities in areas characterized by low levels of economic activity and significant poverty problems.

3.3.4. Sawmill Entities: Three Sustainability Dimensions

In the scientific articles that analyzed the three dimensions of sustainability in the Sawmill entities (see Table 5), we observed that Ref. [91] the use of GIS modeling as a tool to investigate forest volume estimation and inventory assessment was described, as well as logistic analysis to identify minimum transportation costs as a function of the minimum cost distance matrix. Additionally, GIS integration with the Analytical Hierarchy Process (AHP) was utilized to assess the relative importance of economic, environmental, and social criteria influencing site selection. AHP analysis, a specific technique for estimating factor weighting, was employed. The methodology comprised constructing constraint and suitability models to explore potential areas for available Forest Industrial Complex (FIC) land. Suitable FIC locations were pinpointed using the suitability model based on specific primary and secondary criteria. Ultimately, potential FIC locations were subjected to network analysis simulation to optimize the minimization of total transportation costs between candidate FIC locations and forest resources.

Ref. [92] presented a multiobjective mixed nonlinear programming (MINLP) model considering economic, environmental, and social objectives to develop optimal forest management plans; the epsilon constraint function (ε-constraint) method was used to solve the multiobjective problem. NSGA-III and SPEA2 can extend this research to generate the Pareto frontier. Additionally, different relaxations can be tested to solve the MINLP.

3.4. Other Entities

Other entities comprise companies that transform primary products of wood into final consumer goods or semi-finished products, such as furniture, rolling mill industry, parquet industry, and panels industry.

3.4.1. Other Entities and Sustainability

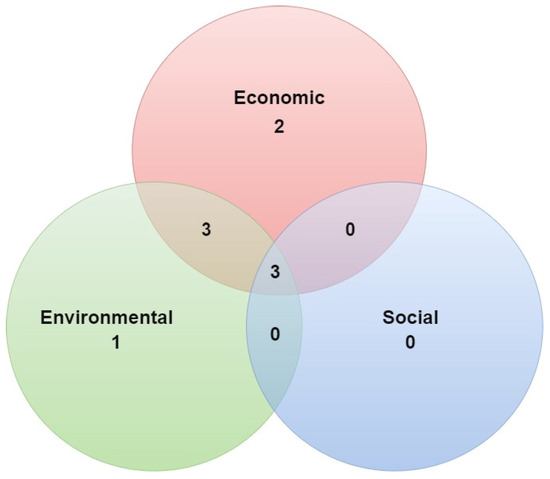

Of the nine scientific articles analyzed in the Other entities, the most researched dimension of sustainability is the economic dimension with eight articles, followed by the environmental dimension with seven articles and the social dimension with three articles (see Figure 9).

Figure 9.

Distribution of scientific articles according to the dimensions of sustainability addressed in the other entities.

3.4.2. Other Entities: One Sustainability Dimension

In the scientific articles that analyzed one dimension of sustainability in other entities (see Table 6), we observed that Ref. [93] proposed a mixed integer linear programming model to find an optimal design for the flow of the supply network while satisfying a specific demand of products per year. The model considered several parameters and decision variables to describe the material flows between entities and within sawmills and production facilities. The study highlighted the importance of inventory management, the impact of raw material augmentation on the supply network, and the potential for cost reduction in the procurement part of the supply chain. The article discussed the optimal location of glulam beechwood production plants in Austria, considering the demand from Italy and Germany.

Table 6.

Other entities’ articles on forest-to-lumber supply chain, methodology or technique used, and metrics that address sustainability dimensions.

Ref. [94] focused on developing a pallet supply chain management simulation model using system dynamics methodology and multi-criteria decision-making techniques. Mathematical optimization models still need to be addressed, which could have provided a better quantitative and analytical approach for decision-making in supply chain management.

Ref. [95] evaluated the environmental sustainability of briquette production from forest and sawmill residues for energy production in the Pacific Northwest region of the United States. A cradle-to-grave life cycle analysis (LCA) was used to compare the environmental impacts of briquette production with firewood and propane production. The study found that briquette production from forest residues is advantageous in the impact categories of smog, acidification, and eutrophication, with considerable environmental benefits from avoided emissions from pile burning.

3.4.3. Other Entities: Two Sustainability Dimensions

In the scientific articles that analyzed two dimensions of sustainability in other entities (see Table 6), we observed that Ref. [96] presented a case study of a wood parquet company in Spain and quantified its organizational environmental footprint using a multi-regional input-output analysis. The study calculated 14 environmental impacts and identified the predominant sectors and regions responsible for these impacts. The highest impact category was ozone depletion, and the dominant sector responsible for this impact was the chemical industry in Spain and China. The study concluded that organizational environmental footprint assessment can be carried out using this well-structured and robust method, allowing the tracking of environmental burdens across a company’s supply chain on a global scale and providing information for environmental strategy adoption.

Ref. [97] focused on optimizing the production of five wood-based products, considering both economic and environmental aspects. They developed a multiobjective linear programming model to minimize costs and greenhouse gas emissions in the cascading utilization of wood. The constraint-ε method was used to solve the model and obtain Pareto optimal solutions. In addition, a life cycle assessment was performed to estimate the environmental impacts of the optimal solutions.

Ref. [98] presented a new mathematical linear programming model with binary variables for inventory management in a wood products supply chain that considers environmental pollution. The proposed model aimed to minimize the costs of the closed supply chain while considering environmental effects. The model included the design of a wood products supply chain, customizing the genetic solution approach, and determining the wood products flow. This study can be improved by using different operators in the genetic algorithm to improve the computational results obtained and by using a compact mathematical formulation.

3.4.4. Other Entities: Three Sustainability Dimensions

In the scientific articles that analyzed the three dimensions of sustainability in other entities (see Table 6), we observed that Ref. [99] presented a supply chain planning and design model using an objective function that included three dimensions of sustainability: economic, environmental, and social. The model was solved using the mixed integer linear programming (MILP) method and the genetic algorithm (GA). The model was applied to four different scenarios to examine the results of multiobjective calculations in a closed, sustainable supply chain. The results showed that most of the value of the economic objective function is due to the cost of raw materials, while most of the value of the social objective function was due to the number of jobs created by the construction entities.

Ref. [100] presented critical success factors (CSFs) for sustainable supply chain management (SSCM) in the Bangladeshi timber industry. The authors used a combination of methods, including success factor impact matrix (SFIM), interpretive structural modeling (ISM), and Matrice d’Impacts Croisés-Multiplication Appliquée à un Classement (MICMAC) analysis, to identify and prioritize CSFs. The study found that the most critical CSFs for SSCM in the Bangladesh wood industry were (1) recycling and waste management, (2) compliance with environmental regulations, (3) green procurement, (4) employee training and awareness, and (5) sustainable product design. This study can be extended by Fuzzy analysis to mitigate the bias of expert arguments.

Ref. [101] addressed the feasibility of a sustainable local supply chain in Sardinia to produce Cross-Laminated Timber (CLT) panels from local wood. Although they highlighted obstacles and proposed measures to foster the chain’s viability, they did not mention using mathematical optimization models for location decision-making. Models could strengthen the analysis and provide a more comprehensive supply chain efficiency and profitability perspective.

4. Analysis

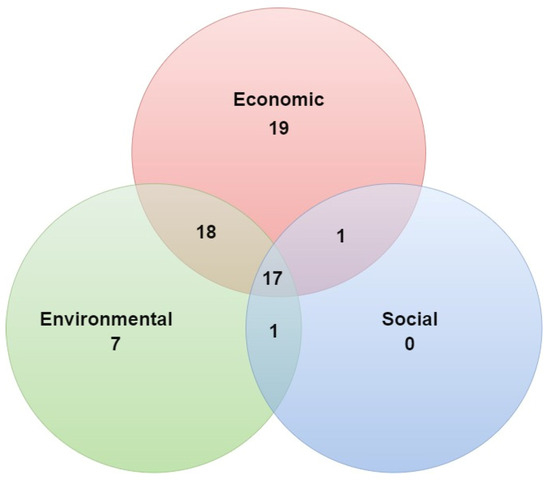

An analysis of how well addressed the dimensions of sustainability are in the articles selected for this systematic review shows that the economic dimension is the most researched, while the social dimension is the least addressed (see Figure 10).

Figure 10.

Distribution of scientific articles according to the dimensions of sustainability addressed in the entities that compound the forest-to-lumber supply chain.

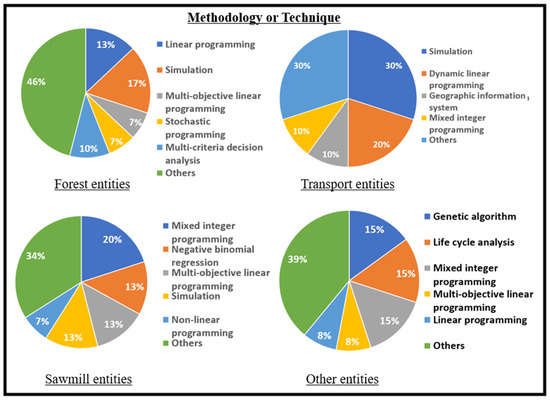

In analyzing the methodologies and techniques used, predictive analytical methods, such as simulation, predominated, and prescriptive analytical methods, such as linear programming and combinatorial optimization (see Figure 11). These methods allow researchers and professional decision-makers to model and optimize the supply chain to improve efficiency and sustainability.

Figure 11.

Main quantitative techniques used in forest-to-lumber supply chain entities.

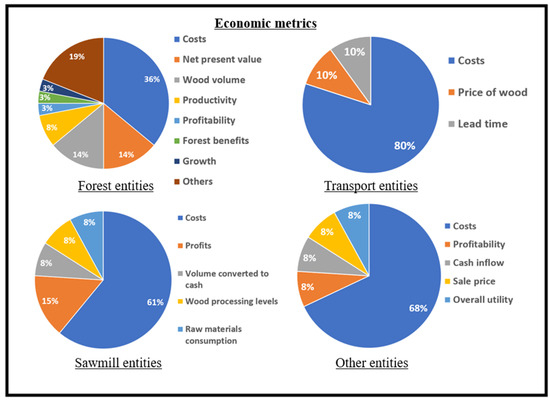

However, an increased consciousness when considering sustainability in decision-making in the forest-to-lumber supply chain, the classical analysis with a mainly economic approach, represented by indicators such as Cost, Net Present Value (NPV), and Profit, continues to predominate (see Figure 12). Even in studies focusing on sustainability, there is a tendency towards the primacy of economic considerations.

Figure 12.

Main economic metrics used in forest-to-lumber supply chain entities.

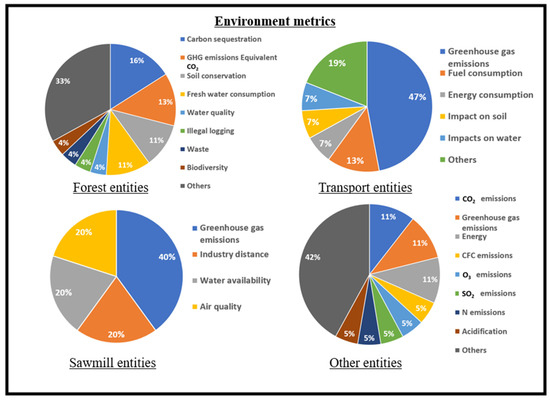

The classic analysis in the environmental dimension focuses mainly on the assessment of greenhouse gas emissions, represented by carbon dioxide equivalent (CO2) through Life Cycle Analysis (LCA) (see Figure 13). In addition, the existence of the concept of “carbon sequestration” in the forestry area is highlighted, suggesting that the capacity of forests to capture and store carbon is recognized, thus contributing to climate change mitigation and highlighting the importance of considering not only emissions but also the capacity of forest ecosystems to act as carbon sinks in sustainability analyses in the forest-to-lumber supply chain [102].

Figure 13.

Main environmental metrics used in forest-to-lumber supply chain entities.

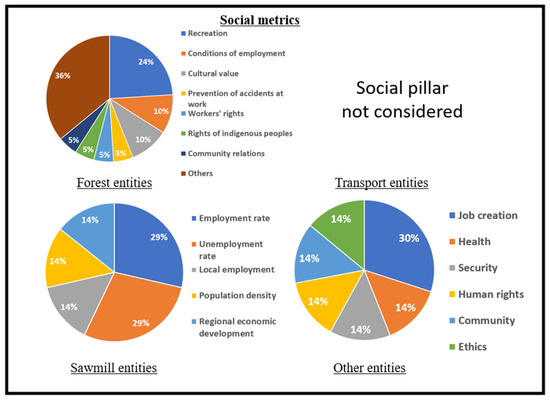

The study and analysis of the social dimension in the context of the forest-to-lumber supply chain is scarce and, in many cases, focuses mainly on aspects related to employment. In addition, it should be noted that in entities such as transportation, this analysis needs to be considered (see Figure 14).

Figure 14.

Main social metrics used in forest-to-lumber supply chain entities.

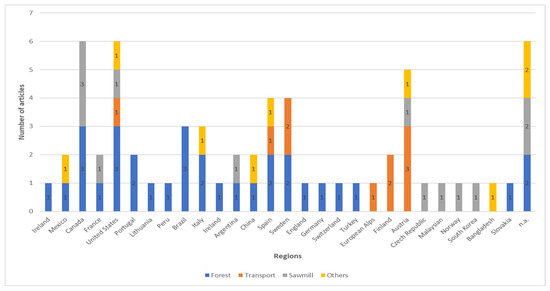

Figure 15 shows the regions and entities used as case studies. Studies related to Forest entities are the most used, followed by Sawmill studies. The least considered are Transport entities. The United States and Canada are the countries with the most case studies (6 articles each), while by continent, Europe has the most studies (33 articles), followed by North America (14 articles).

Figure 15.

Regions and entities used as case studies in sustainable decision-making in forest-to-lumber supply chains.

5. Conclusions

In conclusion, this systematic literature review has offered insight into the evolving landscape of sustainable decision-making within the forest-to-lumber supply chain. The comprehensive analysis of quantitative techniques and methodologies has provided valuable insights into the current state-of-the-art practices and their implications for sustainability.

The findings underscore the increasing importance of integrating advanced quantitative optimization techniques, such as linear programming, combinatorial optimization, and simulation technologies, into the decision-making processes of the forest-to-lumber supply chain. These techniques offer opportunities for enhancing operational efficiency and play a pivotal role in addressing the sustainability dimensions of the industry.

Furthermore, the review has highlighted that although there is a growing emphasis on sustainability metrics and methodologies, reflecting a paradigm shift towards holistic and environmentally conscious practices within the forestry sector, more is needed for the social dimension. The examined articles explore various dimensions: 19 discuss the social aspect, 43 concentrate on the environmental dimension, and 55 delve into the economic dimension. Identifying crucial areas for future research underscores the need to continue exploring and innovating truly sustainable decision-making frameworks.

There is a clear need to focus more on the social aspects of forest supply chain management, considering perspectives other than employment and looking for metrics not exclusively related to economic aspects. Addressing social conflicts in local contexts is essential as an integral part of sustainable forest resource management.

New lines of research in this area are suggested:

- Include a broader approach that considers the social impact of operations in the forest supply chain and not only focuses on economic or environmental aspects. Identifying and developing metrics that more fully reflect the social impact of forestry activities is required, as well as considering the social conflicts that may arise in local contexts.

- Evaluate the adaptability of Industry 4.0 and data science using sensors for different entities in the forest-to-lumber supply chain.

- Value the contribution of competitiveness and collaboration through a game theory approach of the different entities in the forest-to-lumber supply chain to drive efficiencies, reduce costs, and strengthen the sector’s competitiveness, thus contributing to a more agile and sustainable transportation system.

- Evaluate the integral preventive management of forest fires, water consumption, and nutrient depletion of the soils where planted forests are located.

- Analyze the environmental impacts and social conflicts produced by the forestry supply chain affecting indigenous people in their worldview and natural environment.

- Evaluate the social impact generated when mechanizing and automating work in high-volume tasks in the forestry industry.

This study has certain limitations that are important to highlight. First, the review was limited to research written exclusively in English and available in the Web of Science database. This choice may have excluded studies written in other languages or present in different databases that could have provided additional information to our analysis.

The present research provides an essential reference point to guide stakeholders in understanding the state-of-the-art quantitative methodologies and techniques employed in the decision-making of the forest-to-lumber supply chain. In addressing the current state of these methodologies, the study highlights their applicability and the specific benefits they bring to sustainability throughout the forest-to-lumber supply chain. These findings inform the current situation and identify crucial areas that could be fundamental for future research, thus consolidating the importance of quantitative approaches for sustainable decisions. Future research on the forest-to-lumber supply chain could be related to the social pillar of sustainability on transportation aspects.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/f15020297/s1.

Author Contributions

Conceptualization, R.L., F.V. and J.F.M.-R.; methodology, J.W.E. and R.L.; software, J.F.M.-R.; validation, F.V. and J.W.E.; formal analysis, J.F.M.-R.; investigation, J.F.M.-R.; resources, R.L.; data curation, J.F.M.-R.; writing—original draft preparation, J.F.M.-R.; writing—review & editing, R.L., J.W.E. and F.V.; visualization, J.F.M.-R.; supervision, R.L.; project administration, R.L.; funding acquisition, R.L. All authors have read and agreed to the published version of the manuscript.

Funding

We thank the grants from projects UBIOBIO GI 2380142, UBIOBIO 2260222 IF/R, and ANID FONDECYT REGULAR 1230125.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank anonymous referees for their valuable contributions to improving our original version of the paper.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Brundtland, G.H. World Commission on Environment and Development ONU. Our Common Future; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Mebratu, D. Sustainability and Sustainable Development: Historical and Conceptual Review. Environ. Impact Assess. Rev. 1998, 18, 483–560. [Google Scholar] [CrossRef]

- Alcalde-Calonge, A.; Ruiz-Palomino, P.; Sáez-Martínez, F.J. The Circularity of the Business Model and the Performance of Bioeconomy Firms: An Interactionist Business-Environment Model. Cogent Bus. Manag. 2022, 9, 2140745. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and Challenges in Sustainable Supply Chain: An Operations Research Perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three Pillars of Sustainability: In Search of Conceptual Origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Rönnqvist, M. Optimization in Forestry. Math. Program. Ser. B 2003, 97, 267–284. [Google Scholar] [CrossRef]

- Joseph, J.; Borland, H.; Orlitzky, M.; Lindgreen, A. Seeing Versus Doing: How Businesses Manage Tensions in Pursuit of Sustainability. J. Bus. Ethics. 2020, 164, 349–370. [Google Scholar] [CrossRef]

- Epstein, R.; Morales, R.; Serón, J.; Weintraub, A. Use of OR Systems in the Chilean Forest Industries. Interfaces 1999, 29, 7–29. [Google Scholar] [CrossRef]

- D’Amours, S.; Rönnqvist, M.; Weintraub, A. Using Operational Research for Supply Chain Planning in the Forest Products Industry. Inf. Syst. Oper. Res. 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Weintraub, A. Using Mathematical Models in the Management of Forest Industries. In Applied Decision Analysis; Girón, F.J., Ed.; Springer: Dordrecht, The Netherlands, 1998; pp. 85–97. ISBN 978-94-017-0759-6. [Google Scholar]

- Päivinen, R.; Lindner, M.; Rosén, K.; Lexer, M.J. A Concept for Assessing Sustainability Impacts of Forestry-Wood Chains. Eur. J. For. Res. 2012, 131, 7–19. [Google Scholar] [CrossRef]

- Marta, C.; Maurizio, C.; Giacomo, C.; Marco, B.; Alessandro, P. A Social Assessment of Forest Resource Based on Stakeholders’ Perception: An Application in Three Balkans Rural Areas. J. For. Res. 2020, 25, 308–314. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and Optimization of Forest Biomass Supply Chains from Economic, Social and Environmental Perspectives—A Review of Literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Başkent, E.Z. A Review of the Development of the Multiple Use Forest Management Planning Concept. Int. Forest. Rev. 2018, 20, 296–313. [Google Scholar] [CrossRef]

- Santos, A.; Carvalho, A.; Barbosa-Póvoa, A.P.; Marques, A.; Amorim, P. Assessment and Optimization of Sustainable Forest Wood Supply Chains—A Systematic Literature Review. For. Policy Econ. 2019, 105, 112–135. [Google Scholar] [CrossRef]

- Lima, J.M.; Partidario, M.R. Plurality in Sustainability—Multipe Understandings with a Variable Geometry. J. Clean. Prod. 2020, 250, 119474. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Vance, J.; Wang, Y.; Wu, J.; Hartley, D. Data Analytics for Enhancement of Forest and Biomass Supply Chain Management. Curr. For. Rep. 2020, 6, 129–142. [Google Scholar] [CrossRef]

- Mobtaker, A.; Ouhimmou, M.; Audy, J.-F.; Rönnqvist, M. A Review on Decision Support Systems for Tactical Logistics Planning in the Context of Forest Bioeconomy. Renew. Sustain. Energy Rev. 2021, 148, 111250. [Google Scholar] [CrossRef]

- He, Z.; Turner, P. A Systematic Review on Technologies and Industry 4.0 in the Forest Supply Chain: A Framework Identifying Challenges and Opportunities. Logistics 2021, 5, 88. [Google Scholar] [CrossRef]

- Väätäinen, K.; Anttila, P.; Eliasson, L.; Enström, J.; Laitila, J.; Prinz, R.; Routa, J. Roundwood and Biomass Logistics in Finland and Sweden. Croat. J. Eng. 2021, 42, 39–61. [Google Scholar] [CrossRef]

- Chabanet, S.; Bril El-Haouzi, H.; Morin, M.; Gaudreault, J.; Thomas, P. Toward Digital Twins for Sawmill Production Planning and Control: Benefits, Opportunities, and Challenges. Int. J. Prod. Res. 2023, 61, 2190–2213. [Google Scholar] [CrossRef]

- Tham, L.T.; Pretzsch, J.; Darr, D. Asian Timber Value Chains- a Systematic Review and Research Agenda. For. Policy Econ. 2020, 112, 102116. [Google Scholar] [CrossRef]

- Page, M.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.; Brennan, S.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Int. J. Surg. 2021, 88, 105906. [Google Scholar] [CrossRef] [PubMed]

- Goldhahn, C.; Cabane, E.; Chanana, M. Sustainability in Wood Materials Science: An Opinion about Current Material Development Techniques and the End of Lifetime Perspectives. Phil. Trans. R. Soc. A. 2021, 379, 20200339. [Google Scholar] [CrossRef] [PubMed]

- Kenessey, Z. The Primary, Secondary, Tertiary and Quaternary Sectors of the Economy. Rev. Income Wealth 1987, 33, 359–385. [Google Scholar] [CrossRef]

- Nicholls, D.; Bumgardner, M. Challenges and Opportunities for North American Hardwood Manufacturers to Adopt Customization Strategies in an Era of Increased Competition. Forests 2018, 9, 186. [Google Scholar] [CrossRef]

- Sahoo, K.; Bergman, R.; Alanya-Rosenbaum, S.; Gu, H.; Liang, S. Life Cycle Assessment of Forest-Based Products: A Review. Sustainability 2019, 11, 4722. [Google Scholar] [CrossRef]

- Hietala, J.; Hänninen, R.; Kniivilä, M.; Toppinen, A. Strategic Management Towards Competitive Advantage—Patterns of Internationalization in the Finnish and Swedish Sawmill Industries. Curr. For. Rep. 2019, 5, 199–209. [Google Scholar] [CrossRef]

- Zargar, S.; Roy, B.B.; Li, Q.; Gan, J.; Ke, J.; Liu, X.; Tu, Q. The Application of Industrial Ecology Methods to Understand the Environmental and Economic Implications of the Forest Product Industries. Curr. For. Rep. 2022, 8, 346–361. [Google Scholar] [CrossRef]

- Pérez-Rodríguez, F.; Nunes, L.; Azevedo, J. Solving Multi-Objective Problems for Multifunctional and Sustainable Management in Maritime Pine Forest Landscapes. Climate 2018, 6, 81. [Google Scholar] [CrossRef]

- Müller, F.; Jaeger, D.; Hanewinkel, M. Digitization in Wood Supply—A Review on How Industry 4.0 Will Change the Forest Value Chain. Comput. Electron. Agric. 2019, 162, 206–218. [Google Scholar] [CrossRef]

- Picchio, R.; Proto, A.R.; Civitarese, V.; Di Marzio, N.; Latterini, F. Recent Contributions of Some Fields of the Electronics in Development of Forest Operations Technologies. Electronics 2019, 8, 1465. [Google Scholar] [CrossRef]