1. Introduction

Forest resources possess abundant biodiversity and are vital to economic development in many countries [

1,

2]. However, the forest area has steadily decreased over the past few decades due to excessive exploitation and utilization of forests [

1]. With increasing emphasis on green, low-carbon economies and sustainable development across nations [

3,

4,

5], there is growing attention on effectively utilizing wood resources, reducing forest destruction, and lowering carbon emissions [

6]. With its renewable and environmentally friendly characteristics, wood finds wide applications in indoor decoration, furniture, construction, and other sectors [

7,

8,

9]. However, wood, especially fast-growing wood, often exhibits the problem of uneven timber color and single timber color [

10,

11]. Therefore, improving the quality and value of ordinary or fast-growing wood with modification methods becomes crucial for optimally using subpar materials. Wood staining is an effective approach to enhance the color and decorative properties of common wood, enabling dye molecules to diffuse, penetrate, and adhere to the wood with impregnation, achieving wood staining. Compared with methods such as bleaching [

12], coating [

13], and heat treatment [

7,

14], wood staining is based on deep coloring [

15], avoiding color sanding while enriching the wood with a diverse and uniform color tone, meeting the aesthetic and functional requirements for wood applications [

16]. However, the wood dyeing process presents several challenges, including excessive use of chemical reagents and additives, difficulties in waste liquid treatment, and low dye fastness. Addressing these issues is of paramount importance. Chinese fir, a typical softwood species, possesses a yellow-white coloration and a lightweight texture, making it suitable for furniture production [

17]. However, the limited range of colors restricts its applications. Scholars have attempted to improve the color of Chinese fir using methods such as coating and modification [

17,

18,

19]. Some researchers have studied the pore size distribution and improved the permeability of the Chinese fir [

20,

21], providing a foundation for the effective contact between modifying agents and Chinese fir. Li et al. [

22] experimented with dyeing Chinese fir and demonstrated satisfactory dye adhesion, but the dye ratio was unsatisfactory. Further research is needed to explore the methods, processes, and dyeing performance of Chinese fir staining.

In recent years, the exploration of wood dyeing techniques has been advancing. Studies have shown that different dyeing methods have varying effects on wood coloring. Nguyen et al. [

15] conducted a comparative analysis of the impact of immersion and vacuum-pressure techniques on the coloration of eucalyptus. The results indicated that the vacuum-pressure method enhanced the penetration of dye into the wood, while the immersion method resulted in some wood damage despite achieving satisfactory coloring. Yu et al. [

23] used acidic dyes under high-pressure conditions to color poplar wood, resulting in a more intense and evenly distributed color. Some researchers also explored the use of supercritical CO

2 for wood dyeing [

24,

25], which increased the accessibility of dyes to wood cell walls but led to a certain degree of loss in wood bending strength and stiffness [

25]. Ultrasound is recognized as an efficient heat and mass transfer technology in the dyeing field and is commonly used as an auxiliary dyeing method. During dyeing, ultrasound can reduce dye molecule aggregation, increase dye solubility in the solution, and promote a more uniform dye dispersion [

26]. Studies have shown that ultrasound can improve dyeing performance. Adeel et al. [

27] used reactive yellow 145 dye to color cotton fabric and found that ultrasound-assisted dyeing resulted in better color intensity and chroma. Furthermore, ultrasound-assisted dyeing significantly reduces dyeing time, dye volume, and energy consumption [

28]. In recent years, ultrasound technology has made significant progress in the field of wood research, particularly in improving wood permeability [

29], wood drying [

30], and extraction [

31] during wood pre-treatment. However, there is still limited research on the application of ultrasound technology for assisted wood staining processes.

Different dyes impart different colors and dyeing performance to wood. Synthetic dyes are widely used in the dyeing field due to their advantages of a wide range of colors, abundant sources, and low cost [

10,

32]. Hu et al. [

33] improved the decorative performance of poplar wood by applying reactive brilliant blue X-BR dye. The dye molecules chemically reacted with the poplar wood, producing a good dyeing effect. Wu et al. [

34] dyed Ayouswood using acid dyes and investigated the effects of temperature, dye concentration, dyeing time, and the mass fraction of the accelerator on wood permeability. After optimizing the process using response surface methodology, the dye uptake reached a maximum of 14.28%. However, the excessive use of synthetic dyes and additives can threaten human health, and improper treatment of dyeing wastewater can harm the natural environment [

35]. With increasing emphasis on the ecological environment and healthy living, researchers have shifted toward using more environmentally friendly natural plant dyes. Naturally sourced plant dyes have the advantages of non-toxicity, biodegradability, and good environmental compatibility, and their colors are often gentle and elegant [

36,

37]. They have found extensive applications in diverse industries, including textiles [

38], wool, hair [

39], food coloring agents, and cosmetic additives [

37].

There have been many attempts to use vegetable dyes in dyeing. Dehnavi et al. [

40] used a two-by-two mixture of three pigments, including pomegranate peel, mullein, and chypre, to dye wool and obtained different shades of color by varying the concentration of the dyes. Ding et al. [

41] used natural dyes, such as the mulberry-orange tree, psyllium, and chestnut in combination with mordant, to dye cotton fibers and obtain colors comparable to those of natural dyes. Benli et al. [

42] used chyme and acorn powder to dye wool fabrics and obtained better color fastness. Mulberry pigment is a kind of natural pigment extracted from the fruit of mulberry. However, research on the natural pigment from mulberry in dyeing is still lacking, especially because research on dyeing wood with the pigment has not been reported. In this study, mulberry natural pigment was used to dye Chinese fir with the aim of improving the color of Chinese fir and reducing the use of chemical dyes. Currently, to improve the dyeing effect of natural dyes, mordants are commonly used for pretreatment to enhance color fastness. However, most of the mordants contain transition metals, which have a certain degree of ecotoxicity. To avoid this problem, an attempt was made to assist the dyeing using ultrasonic technology with the aim of improving the dyeing performance of Chinese fir.

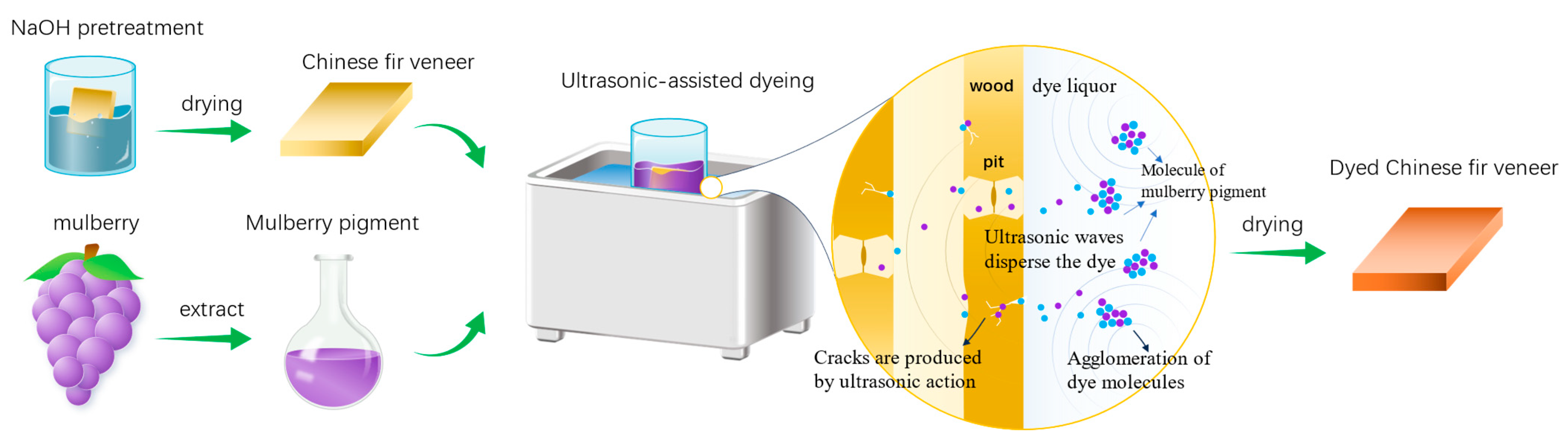

This study investigates the staining effect of mulberry natural pigment on Chinese fir veneer with ultrasound assistance. A single-factor experiment is conducted to explore the influence of ultrasound power, staining temperature, staining time, and dye concentration on the dye uptake and color difference in the veneer. Based on these results, an orthogonal experiment is designed using dye uptake, color difference, and color fastness as indicators. A range analysis is performed to analyze the effects of the four factors on each indicator. Finally, the optimal process conditions for ultrasound-assisted staining of Chinese fir are determined using the fuzzy comprehensive analysis method. Scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), and X-ray diffraction (XRD) are used to observe and evaluate the microstructure, chemical composition, and crystallinity of the stained wood veneer. This study provides a theoretical basis for ultrasonic-assisted wood staining with mulberry natural pigment.

3. Results and Discussion

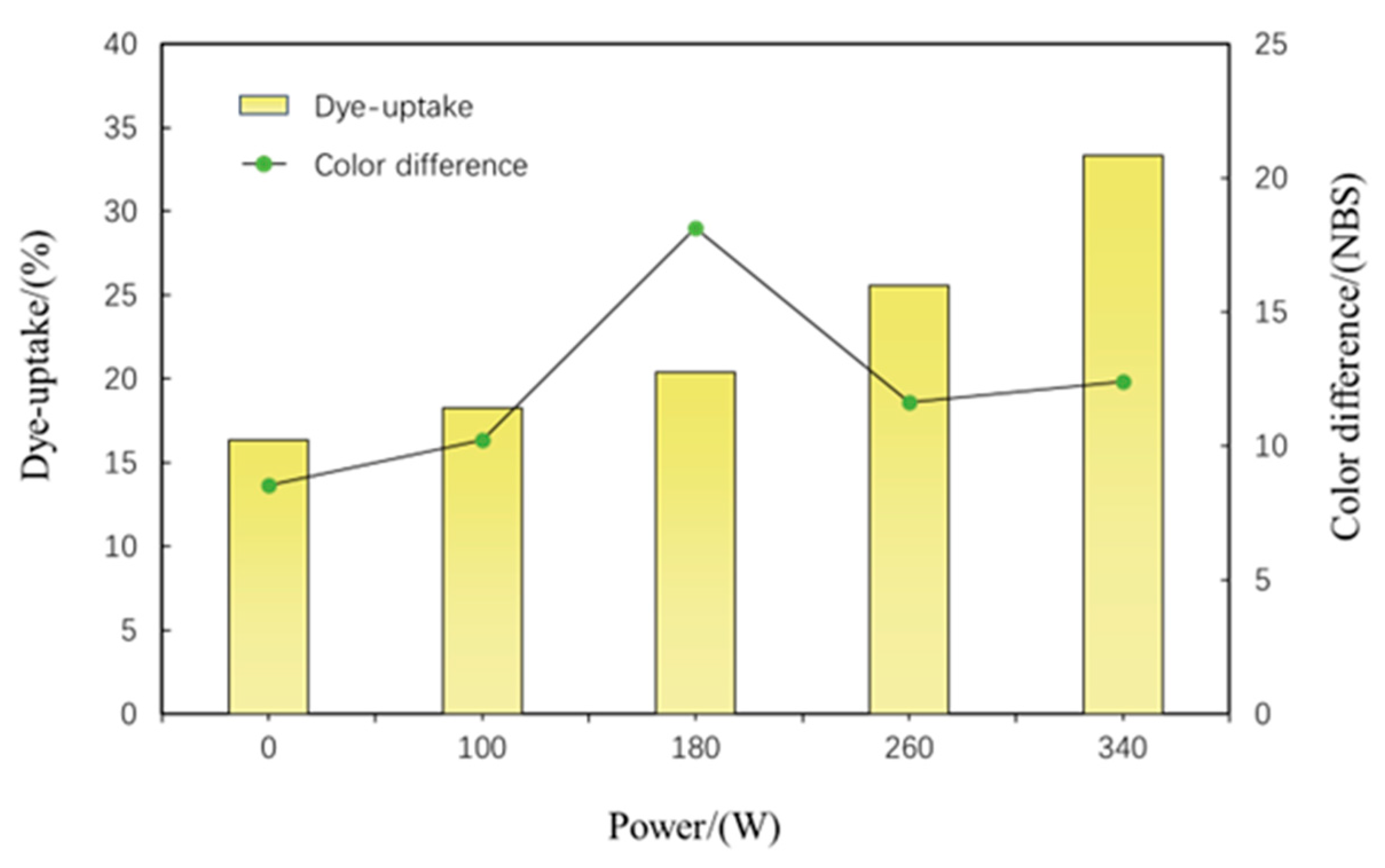

3.1. Effect of Ultrasonic Power on Dye Uptake and Color Difference in Chinese Fir

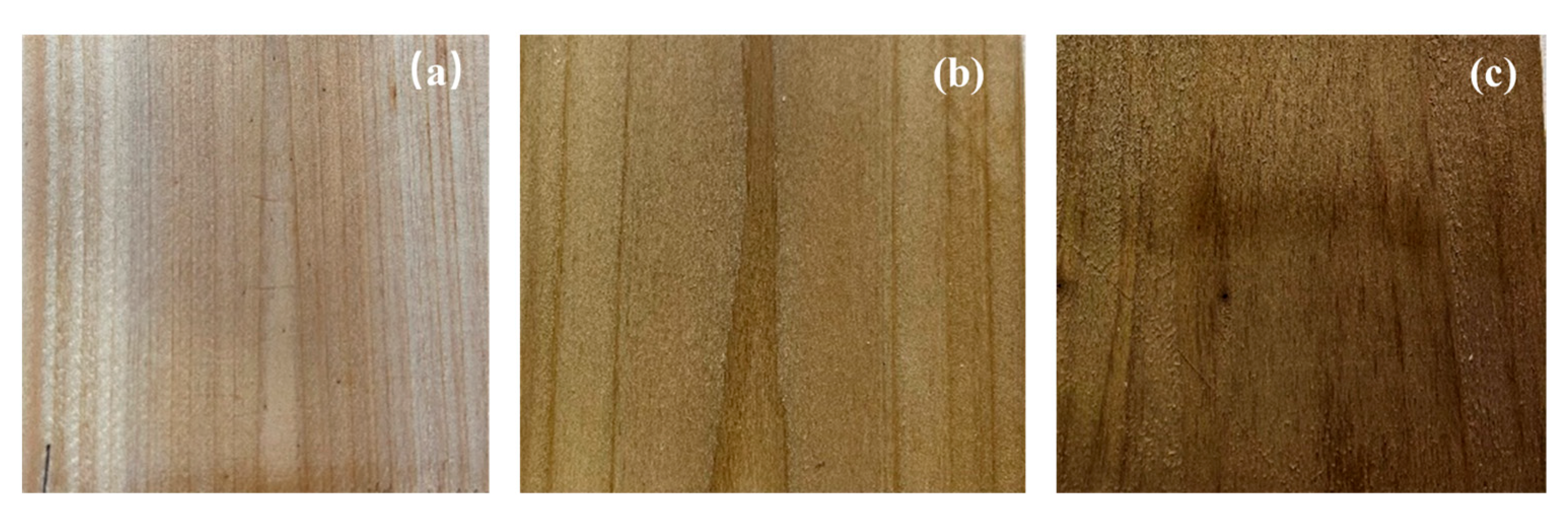

The dyeing time (7 h), dyeing temperature (90 °C), and dye concentration (15%) were kept constant, and different ultrasonic powers (0, 100 W, 180 W, 260 W, 340 W) were used to dye the Chinese fir samples. Physical images of the Chinese fir samples before and after staining are shown in

Figure 2. It can be observed that the color of the Chinese fir samples darkens visually after staining, with the ultrasound-assisted stained samples having the darkest color.

The dye uptake and color difference in the Chinese fir samples assisted with different ultrasound powers are shown in

Figure 3.

Figure 3 shows that the dye uptake rate of wood assisted with ultrasound is higher than that of wood stained with a conventional water bath. Furthermore, as the ultrasound power increases, the dye uptake rate increases. Among them, the maximum dye uptake rate is 33.34% when assisted with 340 W ultrasound power. The enhancement of the dye uptake rate in the Chinese fir samples using ultrasound assistance can be attributed to the cavitation effect formed by ultrasound in the dye solution, which activates the dye molecules and enhances their dissolution [

43], promoting the mass transfer of dye into the interior of the wood. Additionally, ultrasound can disrupt the surface structure of the wood, causing collapses and creating pores, providing more attachment sites for dye molecules [

26]. As the power increases, the color difference in the Chinese fir samples shows an initially increasing and then decreasing trend, with a maximum color difference of 18.127 at a power of 180 W.

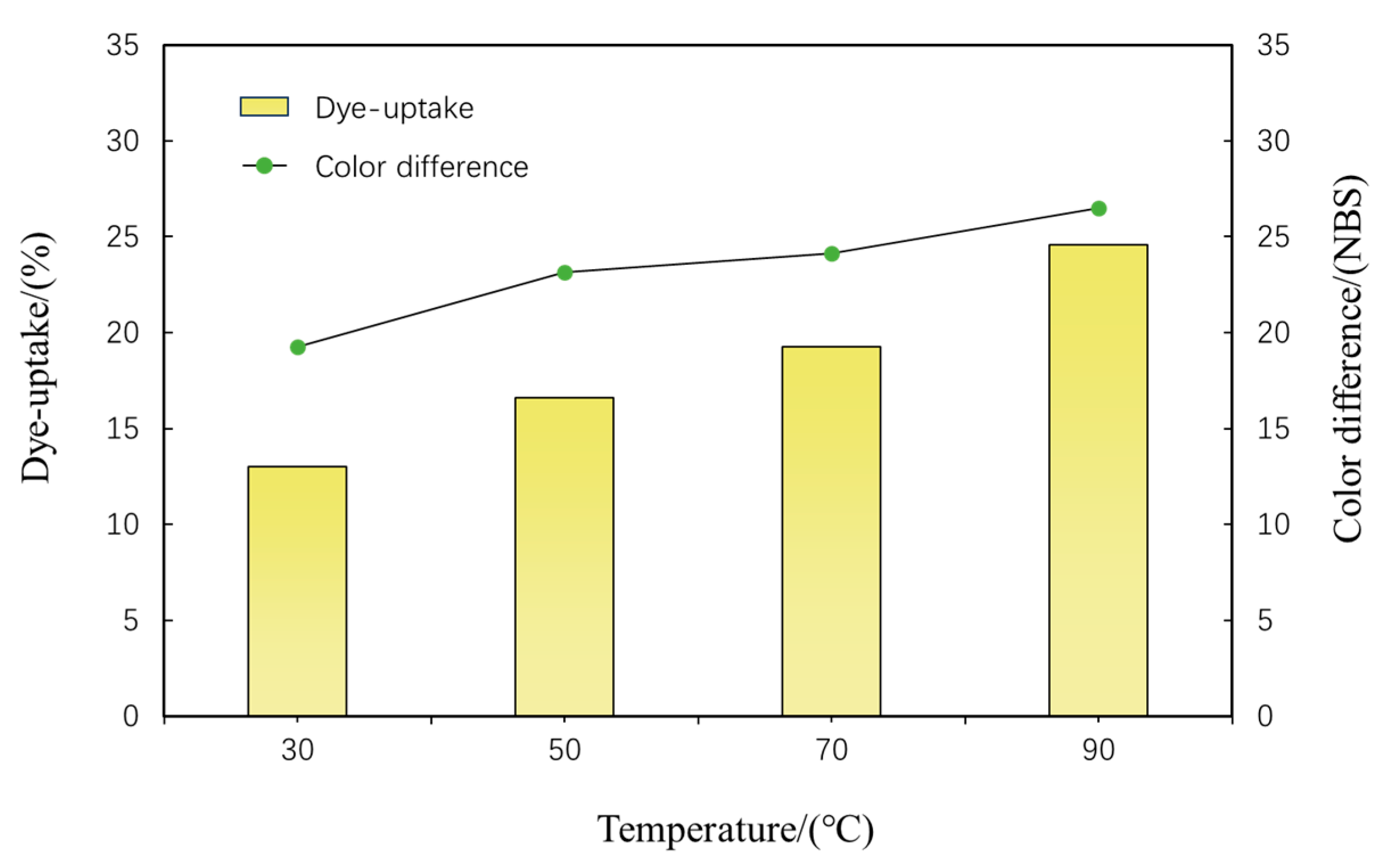

3.2. Effect of Temperature on Dye Uptake and Color Difference in Chinese Fir

The ultrasonic power (340 W), dyeing time (7 h), and dye concentration (15%) were kept constant, and Chinese fir was dyed at different dyeing temperatures (30 °C, 50 °C, 70 °C, 90 °C). The influence of ultrasonic-assisted dyeing temperature on the dye uptake and color difference in the Chinese fir samples is shown in

Figure 4. Based on the information depicted in

Figure 4, the dye uptake rate exhibits a gradual increase as the treatment temperature rises. Under the condition of 90 °C, the ultrasound-assisted staining of the Chinese fir samples achieves the maximum dye uptake rate of 24.58%. As the temperature increases, the thermal motion of dye molecules becomes more intense, which enhances the diffusion of dye in the solution and the wood [

43]. The wood expands in hot water, increasing the gap between wood fibers and facilitating dye diffusion into the wood [

26]. The color difference in the Chinese fir veneer samples increases with the increase in temperature, gradually increasing from 19.25 at 30 °C to a maximum of 26.51 at a temperature of 90 °C.

3.3. Effect of Dyeing Time on Dye Uptake and Color Difference in Chinese Fir

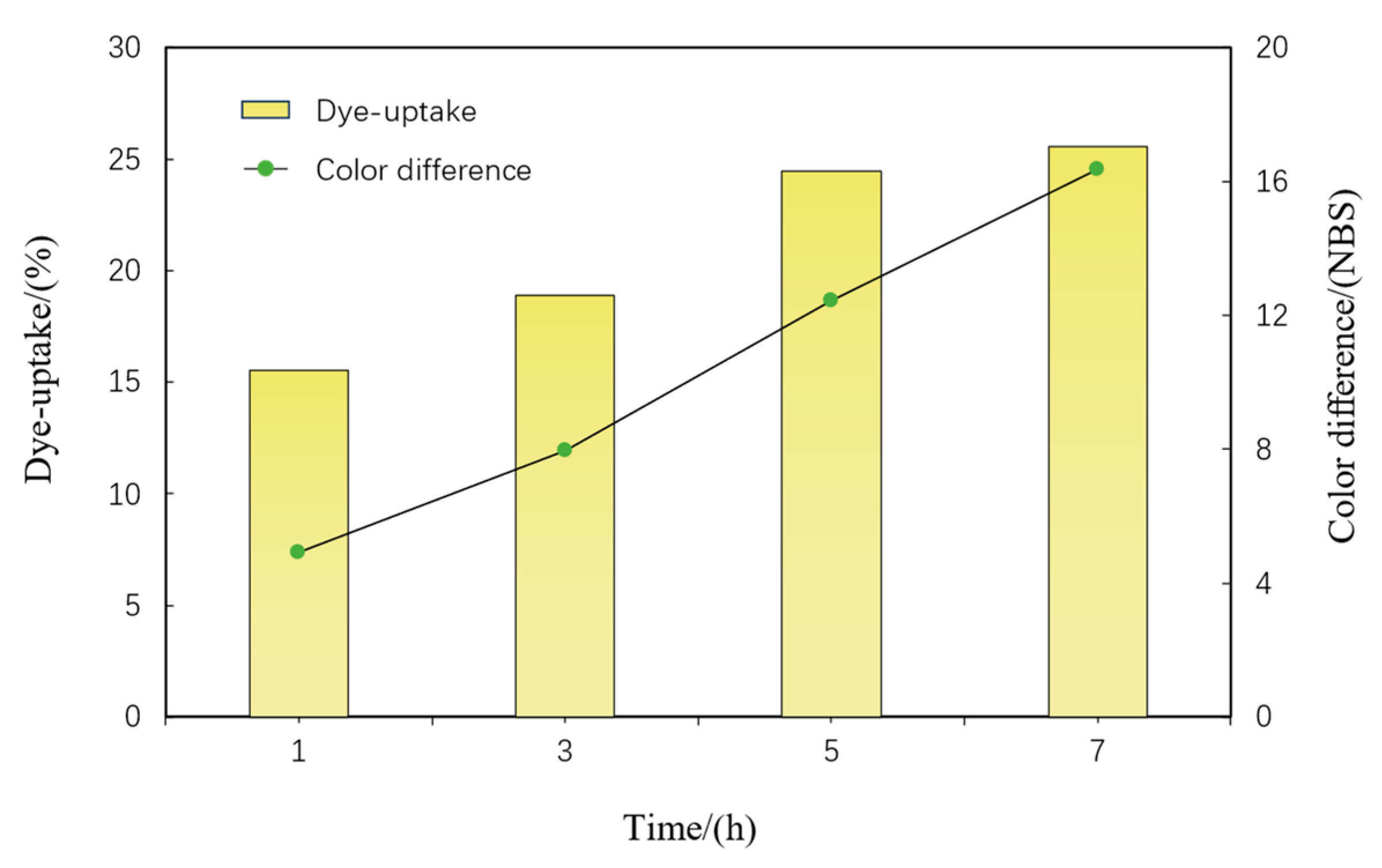

The ultrasonic power (340 W), dyeing temperature (90 °C), and dye concentration (15%) were kept constant, and the Chinese fir samples were dyed at different times (1 h, 3 h, 5 h, 7 h). The influence of ultrasonic-assisted dyeing time on the dye uptake and color difference in the Chinese fir samples is shown in

Figure 5. Under the same ultrasonic-assisted staining condition, the dye uptake rate increases with the increase in staining time. After 5 h, the increase in the dye uptake rate becomes relatively small, reaching a maximum uptake rate of 25.56% at 7 h. During the staining process, dynamic adsorption and desorption of the dye molecules occurs in the wood occur [

26]. At the beginning of staining, due to the concentration gradient, the dye uptake rate is greater than the desorption rate, resulting in an increase in the uptake rate with time. As time continues to increase, the dye uptake rate decreases as the wood adsorption approaches saturation. In addition, the continuous extraction of hot water increases the concentration of extractives in the wood [

26], slowing down the further uptake of dye molecules. These two factors may contribute to the decrease in dye uptake rate during the 5–7 h period.

The color difference in the Chinese fir samples also gradually increases with the increase in staining time, reaching a maximum of 16.36 at 7 h. Compared with the color difference in the Chinese fir samples after 7 h of conventional staining under atmospheric pressure (8.55) (

Figure 1), the color difference in the samples after 5 h of ultrasound-assisted staining reaches 12.42, indicating that ultrasound-assisted staining can greatly save time and energy.

3.4. Effect of Dye Concentration on Dye Uptake and Color Difference in Chinese Fir

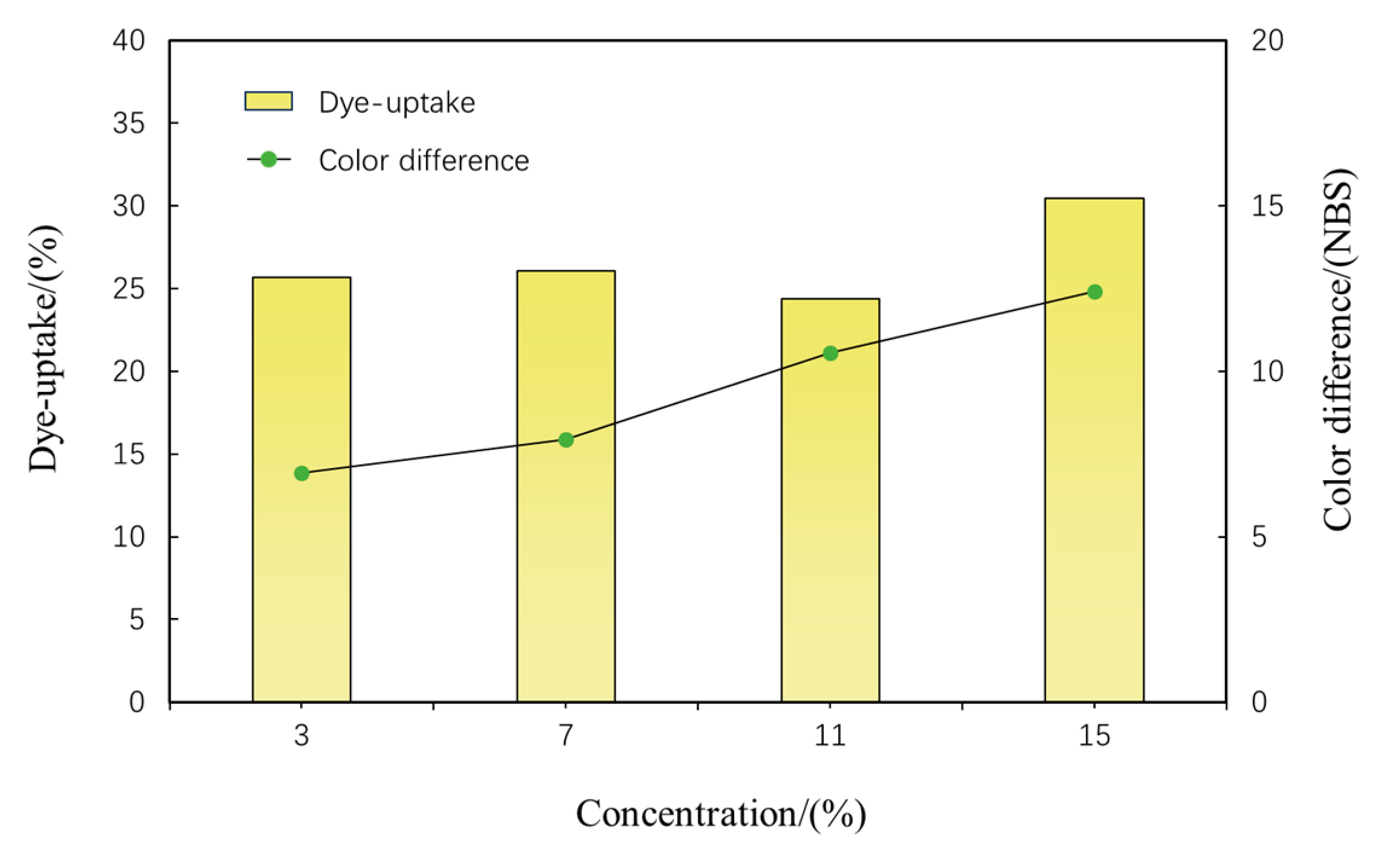

The ultrasonic power (340 W), dyeing time (7 h), and dyeing temperature (90 °C) were kept constant, and the Chinese fir samples were dyed at different dye concentrations (3%, 7%, 11%, 15%).

Figure 6 illustrates the impact of ultrasonic-assisted dye concentration on the dye uptake and color difference in the Chinese fir samples. According to

Figure 6, it can be observed that the dye uptake initially increases and then decreases with the increase in dye concentration. The dye uptake is lowest at 24.35% when the dye concentration is 11%, and it reaches its maximum at 30.44% when the concentration is 15%. This may be attributed to the initial increase in concentration difference between the solution and the wood, which accelerates the diffusion of dye molecules into the wood, thus increasing the dye uptake. As the dye concentration increases, the number of dye molecules per unit volume increases, causing the dye molecules to aggregate and making it difficult for them to diffuse into the wood [

33]. However, as the dye concentration further increases, the concentration difference between the solution and the wood overcomes the hindering effect of dye molecule aggregation, leading to an increase in the dye uptake into the Chinese fir veneer.

The color difference in the Chinese fir samples increases with increasing dye concentration, reaching a maximum of 12.41 when the dye concentration is 15%. It can be seen that a higher dye concentration is not necessarily better, as excessively high concentrations may lead to the accumulation of dye molecules, which is not conducive to an increase in the dyeing rate for Chinese fir. While increasing the dye concentration can improve the dyeing rate and color difference, it also increases dye consumption.

3.5. Effects of Dyeing Factors on Dye Uptake and Color Difference

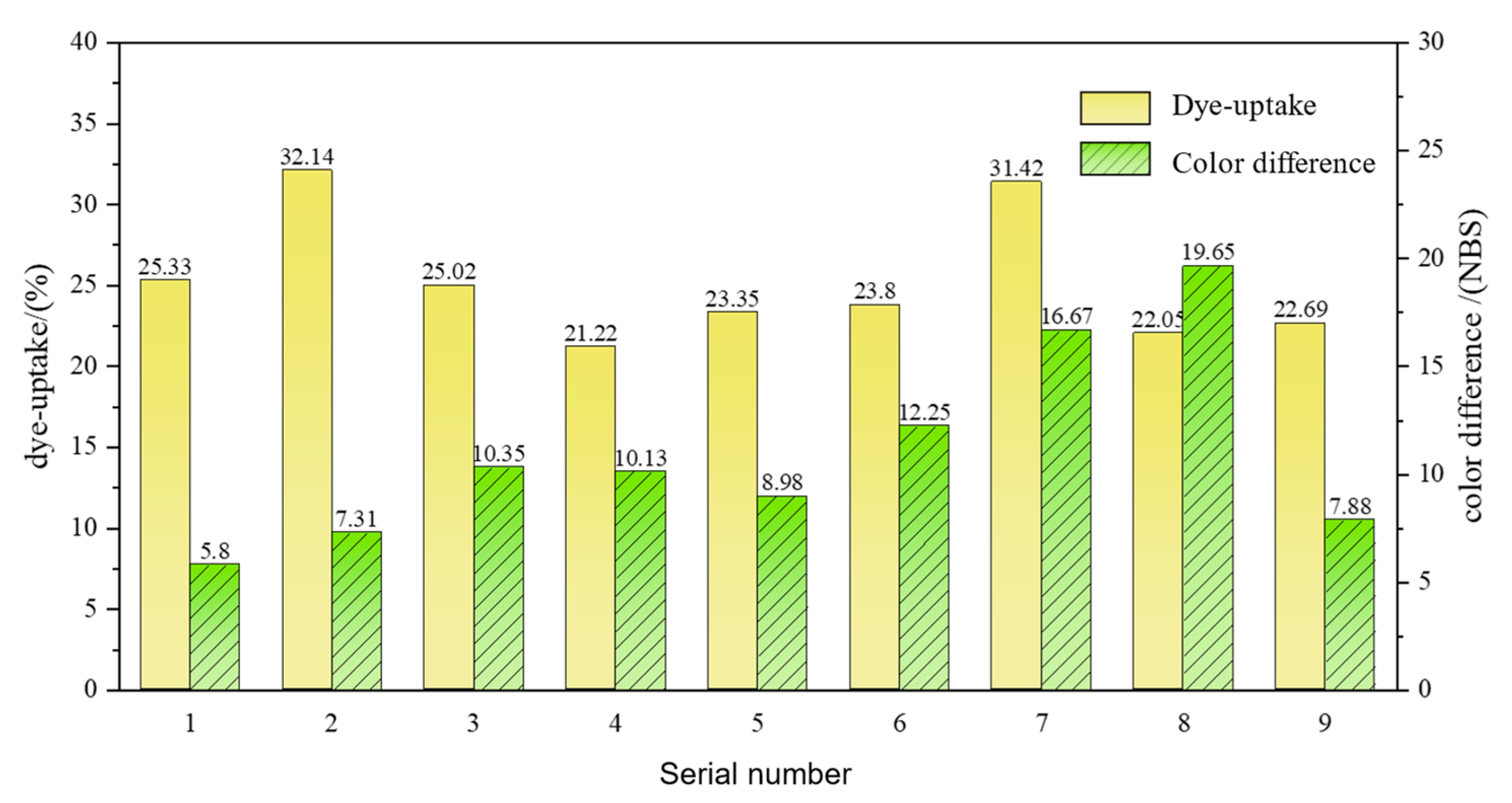

Based on the single-factor experiments, ultrasound power, temperature, time, and dye concentration were selected as four factors for further experiments. Orthogonal experiments were conducted with dye uptake and color difference as indicators to optimize the process for ultrasound-assisted mulberry dyeing of Chinese fir. The experimental results of dye uptake and color difference in the Chinese fir samples after ultrasound-assisted dyeing are shown in

Figure 7.

To further analyze the influence of each factor on the dyeing rate and color difference in the Chinese fir samples, a range analysis was performed on the orthogonal experimental results, as listed in

Table 3. The indices calculated in the range analysis of dye uptake indicate that the dye uptake into the Chinese fir samples is most influenced by ultrasonic power (R = 6.25) and least affected by temperature (R = 2.47). The impact of various factors on the dye uptake with ultrasonic-assisted dyeing is as follows: ultrasonic power (A) > time (C) > dye concentration (D) > temperature (B). A higher dye uptake indicates a better dyeing effect. Therefore, the optimal combination of factors that affect the dye uptake into the Chinese fir samples is A3B3C2D2, i.e., an ultrasonic power of 340 W, temperature of 90 °C, a time of 5 h, and a dye concentration of 10%.

The range analysis of color difference indices reveals that the color difference on Chinese fir is most influenced by dye concentration (R = 7.37) and least by ultrasonic power (R = 3.01). The impact of various factors on the color difference in the Chinese fir samples with ultrasonic-assisted dyeing is as follows: dye concentration (D) > time (C) > temperature (B) > ultrasonic power (A). A larger color difference indicates a better dyeing effect. Therefore, the optimal dyeing process for the Chinese fir samples is A3B3C3D3, i.e., an ultrasonic power of 340 W, temperature of 90 °C, time of 7 h, and dye concentration of 15%.

3.6. Effects of Dyeing Factors on Color Fastness

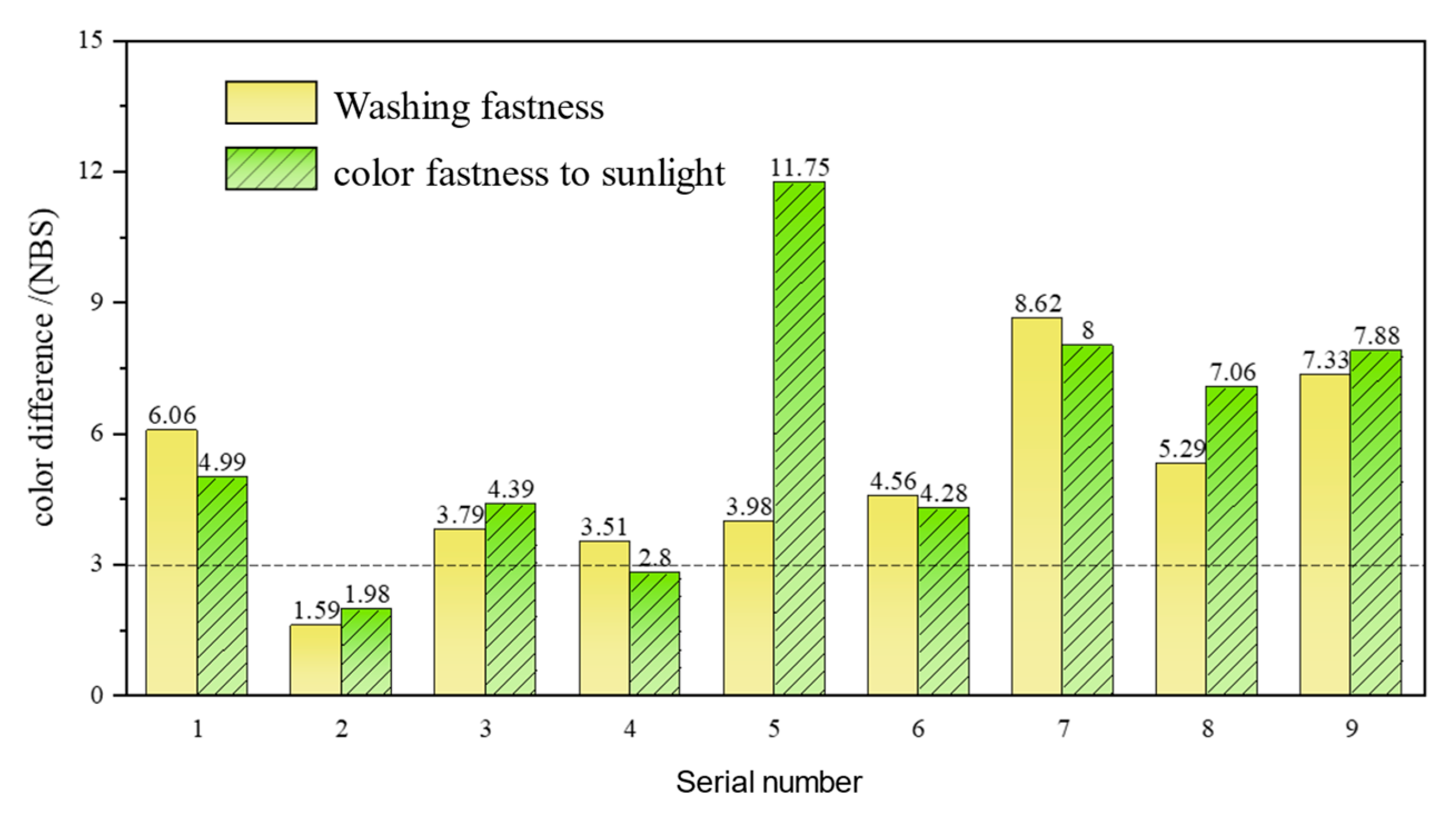

Water washing and sun exposure experiments were conducted on the dyed Chinese fir samples. Based on Formula (5), the color difference in the Chinese fir samples after water washing and sun exposure was calculated, as shown in

Figure 8. The color difference was used as a measurement to assess the color fastness the samples, with a smaller color difference indicating better color fastness. Except for experiment 2 for water washing color fastness and experiments 2 and 4 for sun exposure color fastness, where the color differences were less than 3, the orthogonal experimental results showed that the color differences in the Chinese fir samples in other experiments were greater than 3. This indicates that in color fastness experiments, the overall color difference in the samples was more significant, and human visual perception could detect the color changes [

38]. This suggests that the color fastness performance of Chinese fir dyed with mulberry dye is somewhat lacking and requires further improvement.

A range analysis of the results was conducted, and the analysis results are shown in

Table 4. The range analysis of various indicators for water washing colorfastness shows that the concentration of the dye solution has the greatest influence on the colorfastness of the Chinese fir samples after water washing (R = 3.20). In contrast, ultrasonic power has the smallest influence (R = 0.11). The factors affecting the colorfastness of the Chinese fir samples after water washing with ultrasonic assistance are as follows: dye solution concentration (D) > temperature (B) > time (C) > ultrasonic power (A). The smaller the color difference after water washing, the better the colorfastness. The optimal dyeing process for water washing colorfastness of the Chinese fir samples is obtained as follows: A3B3C1D2, where the ultrasonic power is 340 W, the temperature is 90 °C, the time is 3 h, and the dye solution concentration is 10%.

From the results of the range analysis of various indicators for sun exposure colorfastness, it can be observed that the concentration of the dye solution has the greatest influence on the colorfastness of the Chinese fir samples after sun exposure (R = 3.82). In contrast, ultrasonic power has the smallest influence (R = 3.04). The factors affecting the colorfastness of Chinese fir after sun exposure with ultrasonic assistance are as follows: dye solution concentration (D) > time (C) > ultrasonic power (A) > temperature (B). The smaller the color difference after sun exposure, the better the colorfastness. The optimal dyeing process for sun exposure colorfastness of the Chinese fir samples is obtained as follows: A3B3C1D1, where the ultrasonic power is 340 W, the temperature is 90 °C, the time is 3 h, and the dye solution concentration is 5%.

3.7. Ultrasonic-Assisted Dyeing Process Optimization

Since the optimal process parameters under each indicator are different, the optimal dyeing process for the Chinese fir samples was further evaluated using the fuzzy comprehensive analysis method. According to Formulas (6)–(8), the evaluation matrices RA, RB, RC, and RD were obtained for the four factors: ultrasonic power, dyeing temperature, dyeing time, and dye solution concentration. Using the entropy weight method, the weights for the four indicators were determined as follows: dye uptake rate of 0.3679, total color difference of 0.3037, water washing colorfastness of 0.1781, and sun exposure colorfastness of 0.1503. Subsequently, the indicators were combined and subjected to normalization, resulting in the derivation of BA, BB, BC, and BD.

According to the comprehensive evaluation results, the ultrasound power level was selected at the third level (340 W); the dyeing temperature was at the third level (90 °C); the dyeing time was at the second level (5 h); and the dye concentration was at the second level (10%). Using the fuzzy comprehensive evaluation of the four indicators, including dye uptake rate, color difference, washing color fastness, and sunlight color fastness, the optimal process for ultrasound-assisted mulberry pigment dyeing of the Chinese fir samples was determined as A3B3C2D2, namely, an ultrasound power of 340 W, dyeing temperature of 90 °C, dyeing time of 5 h, and dye concentration of 10%.

3.8. Microstructure Characterization

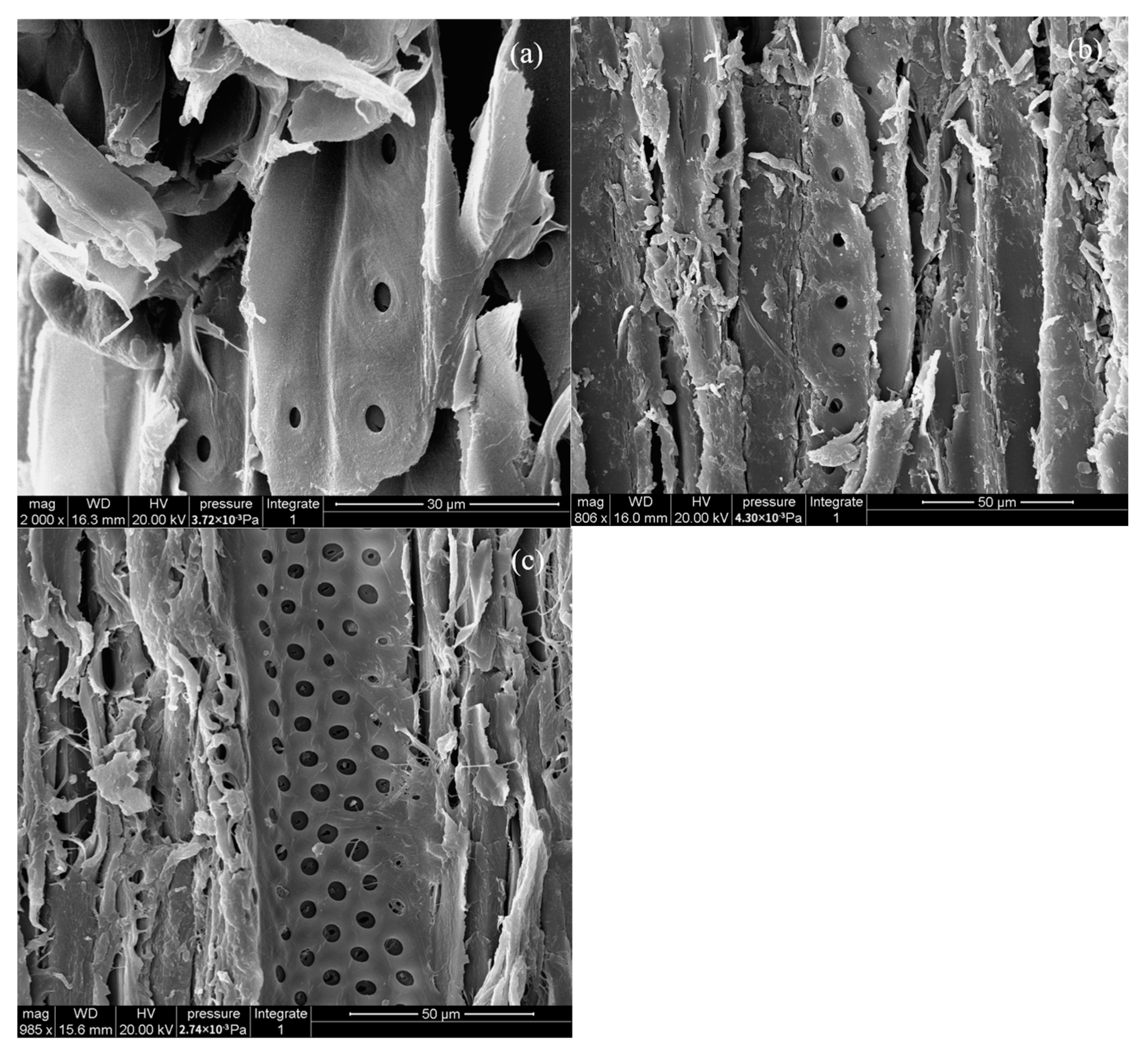

After NaOH pretreatment, the dyed and undyed Chinese fir were subjected to microscopic observation. As shown in

Figure 9, the cell wall surface of the undyed Chinese fir samples appears relatively smooth, and there are many voids within the wood (

Figure 9a). After dyeing in a water bath (

Figure 9b), the number of surface cracks on the wood increases, and a small amount of dye molecules adhere to the surface and cracks. After ultrasound-assisted dyeing (

Figure 9c), the cracks in the wood become larger, the surface becomes rougher, and many dye molecules adhere to the wood surface and pits openings, with some dye molecules penetrating the cracks and voids of the wood. It can be seen that ultrasound-assisted dyeing can improve the permeability of the wood, allowing dye molecules to penetrate deeper into the interior of the wood. At the same time, the ultrasonic cavitation and thermal effect cause the water in the wood to absorb a lot of energy in a short time and vaporize rapidly, increasing the internal pressure of the wood. The high vapor pressure destroys the weak parts of the pit membrane and the tylosis in the vessel, increasing the liquid flow channels, and the high pressure causes more cracks on the surface of the cell wall [

43], providing more attachment sites for dye molecules.

3.9. Fourier Transform Infrared Spectrum Analysis

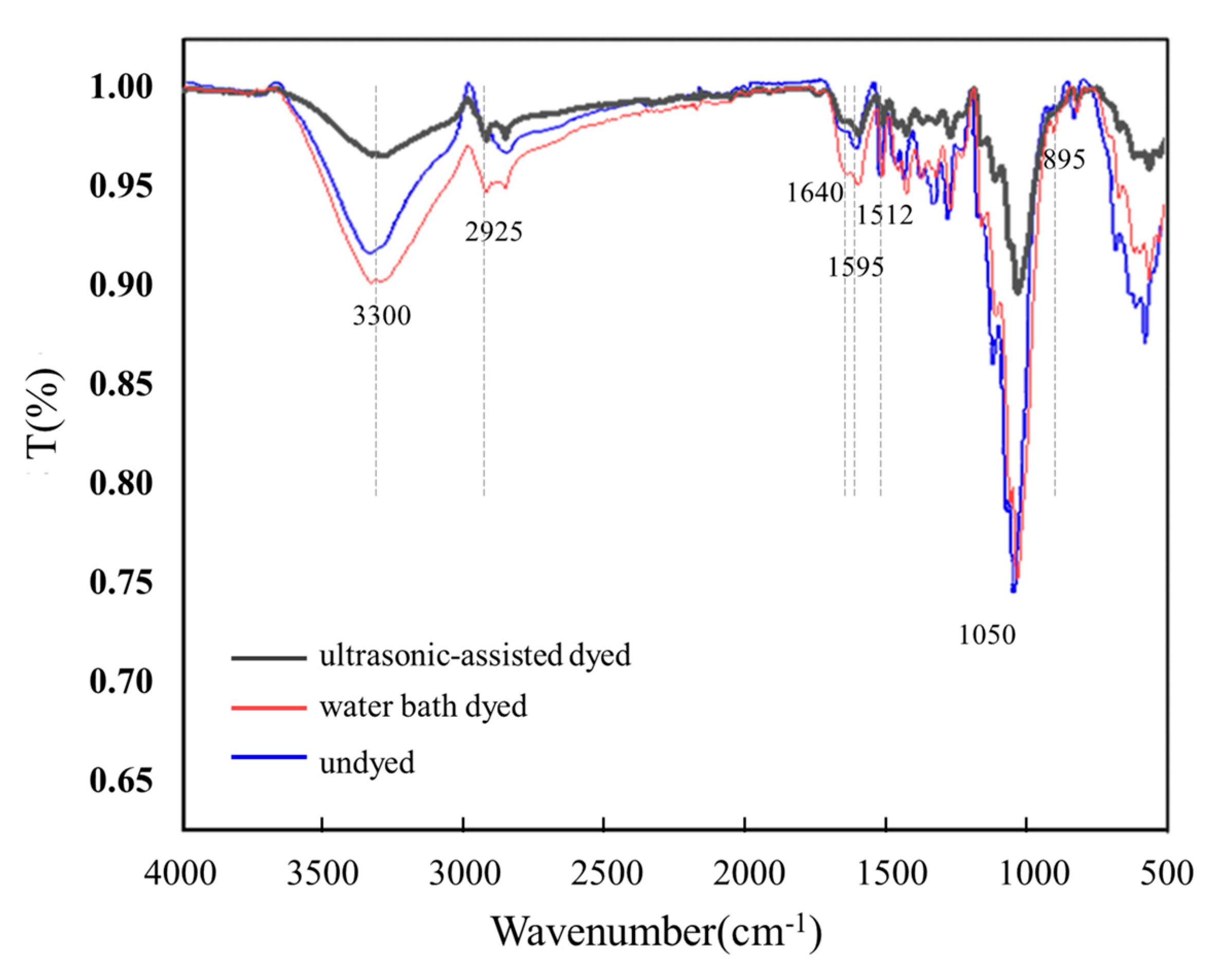

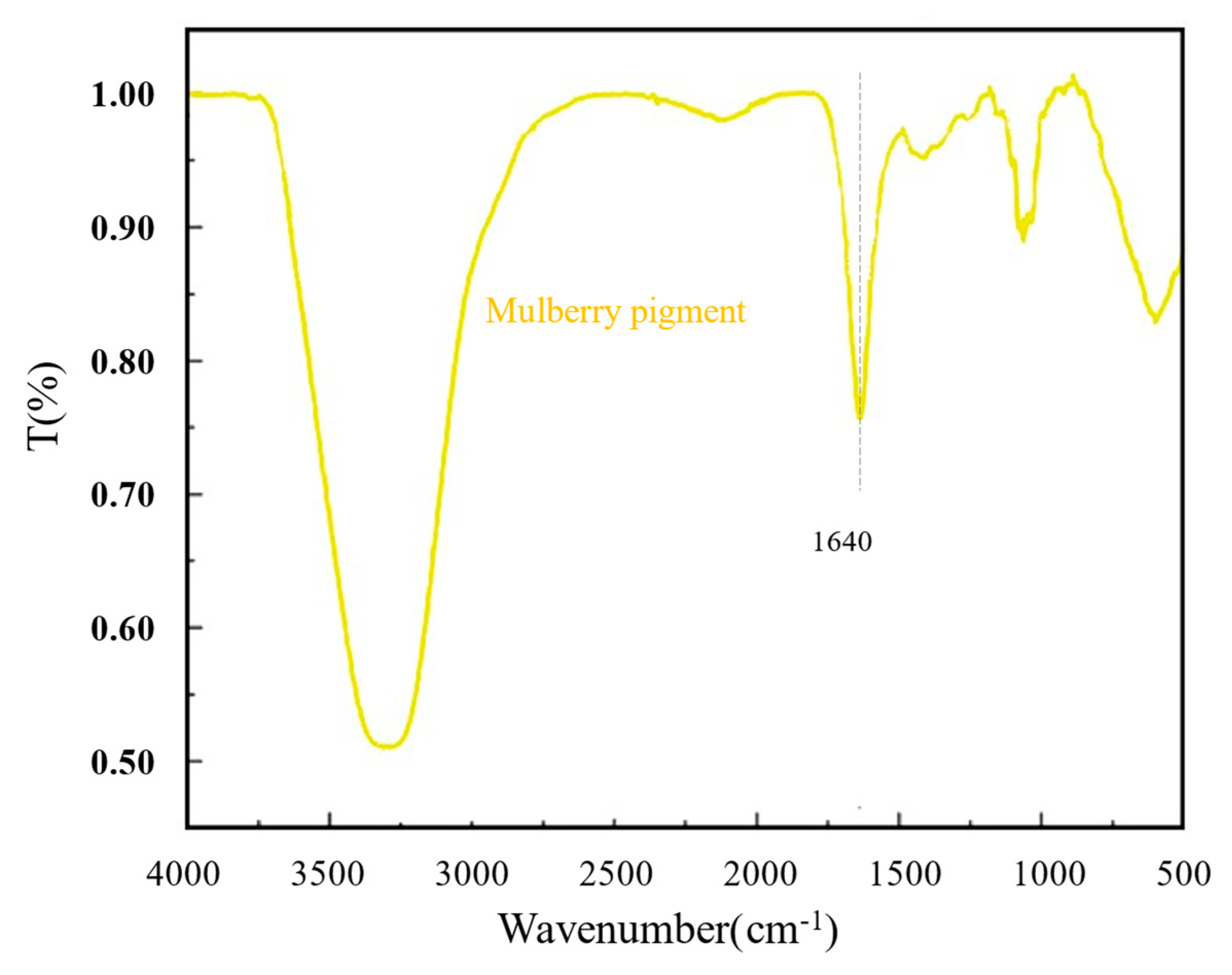

Comparing the Chinese fir samples treated with ultrasound-assisted dyeing to water bath dyeing (

Figure 10), it can be observed that at 3300 cm

−1, there is an absorption peak for cellulose O-H stretching. After water bath dyeing, the absorption peak at this position is enhanced, indicating that water bath dyeing may cause some degradation of the wood, leading to the peeling of hemicellulose and lignin from cellulose and exposing more hydroxyl groups [

44]. This can also be attributed to the stretching and bending vibrations of the intermolecular hydrogen bonds between mulberry pigment molecules at 3000–3500 cm

−1 (

Figure 11). In contrast, ultrasonic treatment enhances the degree of cellulose hydrolysis, reduces the hydroxyl content, and has a certain destructive effect on the O-H bonds in mulberry pigments. At 2925 cm

−1 and 895 cm

−1, there are vibrations of the cellulose C-H bonds (

Figure 10). At 1050 cm

−1, there is a stretching vibration of the hemicellulose C-O bonds (

Figure 10). It can be observed that both cellulose and hemicellulose in the Chinese fir samples undergo some degradation after ultrasonic staining. During water bath staining, there is an increase in the intensity of the absorption peaks at 1595 cm

−1 and 1512 cm

−1, corresponding to the vibrations of the unsaturated functional groups in lignin (

Figure 10), as well as the stretching and bending vibrations of the conjugated C=C bonds and aromatic ring skeleton of mulberry molecules at 1640 cm

−1 (

Figure 11). However, after ultrasonic-assisted staining, the peak intensities decrease, indicating that ultrasonic treatment may cause degradation of lignin in the wood and disrupt the structure of mulberry molecules. Ultrasonic treatment degrades macromolecular substances such as cellulose into smaller molecules [

26], facilitating the penetration of dye molecules into the wood.

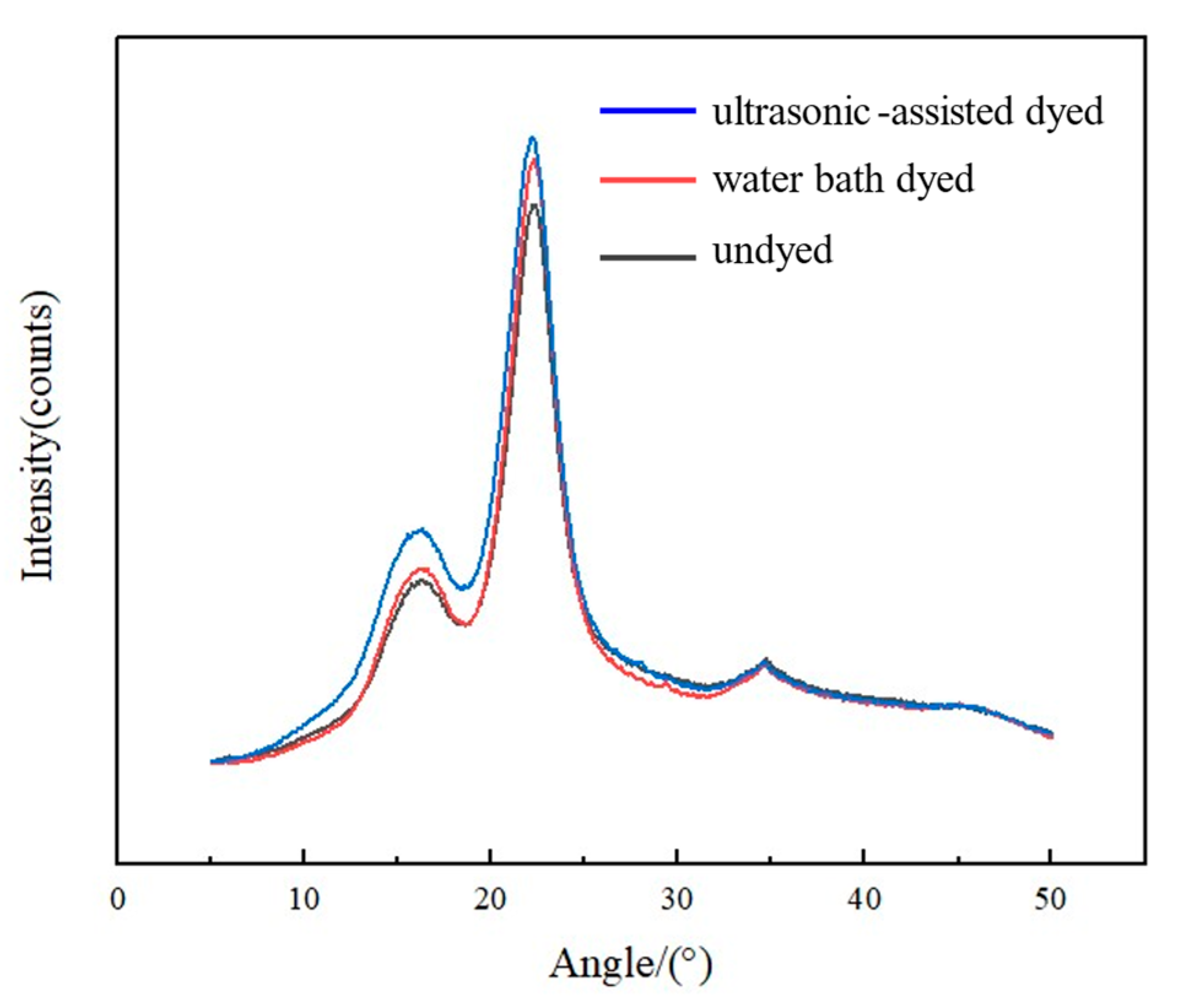

3.10. X-ray Diffraction Analysis

Figure 12 shows the X-ray color spectra of the Chinese fir samples before and after staining. The characteristic peaks of Chinese fir are located at 2θ = 18°, 22°, and 35°, corresponding to the diffraction peaks of the (101), (002), and (040) planes in cellulose. The positions of the wood crystalline diffraction peaks hardly changed, indicating that the staining process did not cause damage to the crystalline structure of the wood. The relative crystallinity of the Chinese fir samples after pretreatment is 69.92% and is 71.98% after water bath staining and 67.67% after ultrasound-assisted staining. The increase in wood crystallinity after water bath staining may be attributed to the entry of water molecules into the non-crystalline region of cellulose, enhancing the hydroxyl activity on the surface of the amorphous region microfibrils and promoting the attraction and orderly arrangement of fibers, thereby increasing the fiber crystallinity. Furthermore, water bath staining has the potential to extract components from the amorphous region [

45] of the wood, thereby playing a role in the observed increase in crystallinity. On the other hand, the crystallinity of the wood decreases after ultrasound treatment, which may be due to the continuous cavitation effect of ultrasound on the fiber surface, inducing fatigue cracks [

26] in the fibers and causing certain damage to the crystalline region. Generally, an increase in crystallinity leads to a decrease in the dye uptake rate [

26], which may explain why the dye uptake rate is higher in ultrasound-assisted staining compared with atmospheric pressure water bath staining.

4. Conclusions

Based on the single-factor results, ultrasound-assisted treatment improves the dye uptake rate and color difference in the mulberry-stained Chinese fir samples compared with conventional water bath staining. The results of the four-factor, three-level orthogonal experiment indicated that ultrasound power has the greatest influence on the dye uptake rate, while dye concentration has the greatest impact on color difference, washing fastness, and lightfastness. Moreover, in the colorfastness assessment, it was generally observed that the color difference in the stained Chinese fir samples exceeds 3, which suggests that there is room for improvement in the colorfastness performance of Chinese fir stained with mulberry pigment. The optimal process for ultrasound-assisted mulberry dyeing of the Chinese fir samples varied for each evaluation index. Using fuzzy comprehensive analysis, the optimal process was determined as an ultrasound power of 340 W, dyeing temperature of 90 °C, dyeing time of 5 h, and dye concentration of 10%.

Scanning electron microscope observations showed that under ultrasound, more dye molecules entered the pits and cavities of the wood, and ultrasound also caused cracks on the wood surface, providing more attachment sites for dye molecules. The infrared analysis showed that ultrasound caused degradation of cellulose, hemicellulose, and lignin in the Chinese fir samples, and the degradation degree was higher compared with water bath dyeing, resulting in the breakdown of large wood molecules into smaller ones and increasing dyeability. Furthermore, combined with the infrared spectroscopic analysis of mulberry pigment, it is possible that ultrasound may have caused structural damage to the mulberry pigment molecules. The X-ray diffraction analysis showed that ultrasound staining reduced the crystallinity of the wood, facilitating the penetration of dye into cellulose molecules. Our study on the ultrasound-assisted mulberry staining of Chinese fir provides a theoretical basis for natural pigment staining of wood and offers a reference for the green and sustainable utilization of forest resources. However, further research is needed to improve the dyeing performance due to the inability to form stable chemical bonds between the natural pigments and wood.