A General Rule-Based Framework for Generating Alternatives for Forest Ecosystem Management Decision Support Systems

Abstract

:1. Introduction

2. Materials and Methods

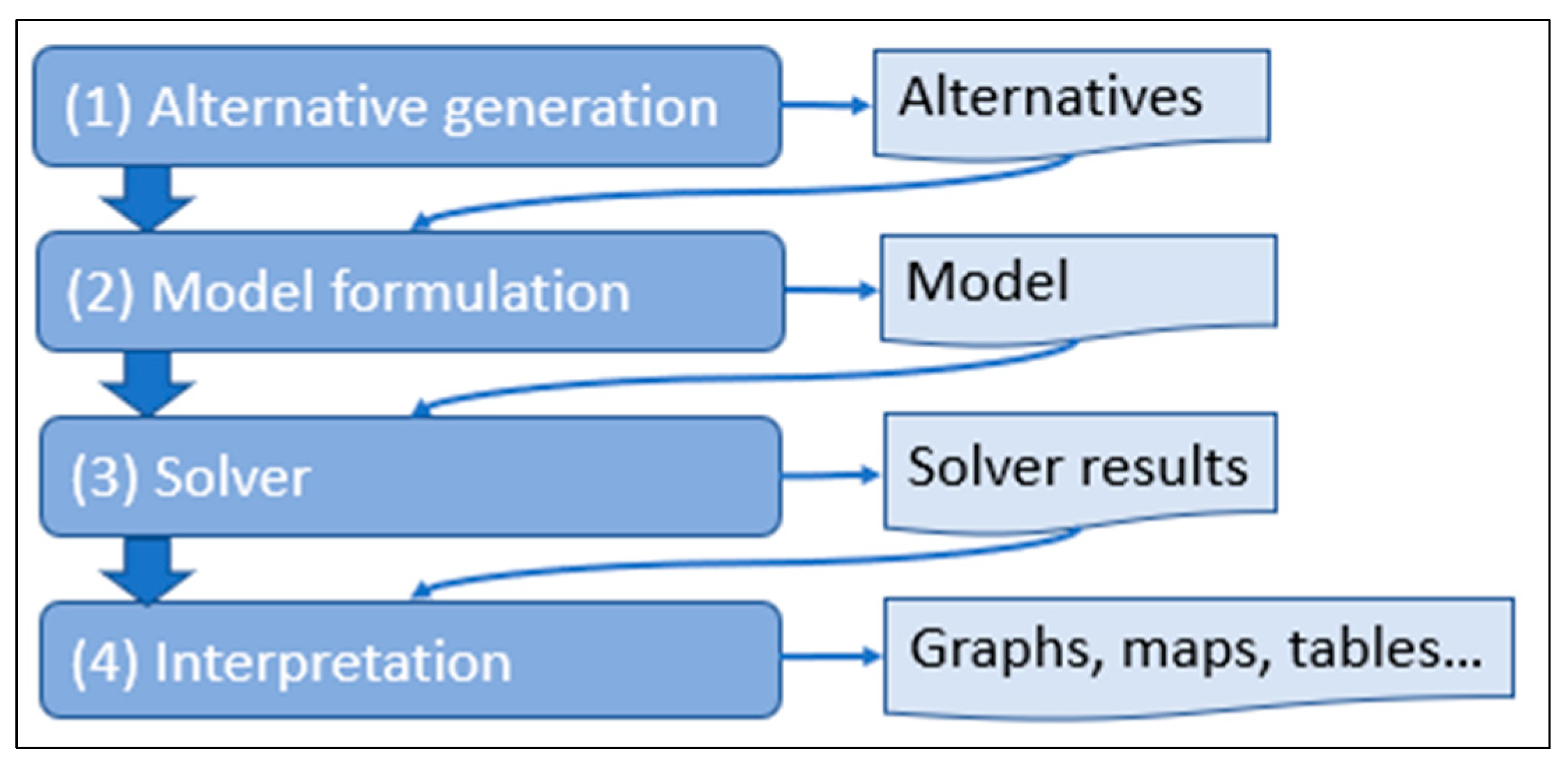

2.1. The Structure of the Management Alternative Generation Process

- The initial state of a management unit i at time (e.g., the time when the last intervention occurred in the management unit or the most recent time with available inventory data) can be described by an initial state vector of n attributes ;

- The state of the forest can be described by aggregating the states of individual management units, and the state of one unit does not depend on the state of other units;

- The initial state of each management unit is a known set of values for ;

- The set of attributes for a management unit at a given time includes all attributes needed as inputs to the equations of motion and any relevant inputs and outputs associated with that management unit at that time.

2.2. iGen Description

2.2.1. iGen Elements

State Variables

Set of Intervention Types

Equations of Motion

Rule Base

Network Graph

Relational Database

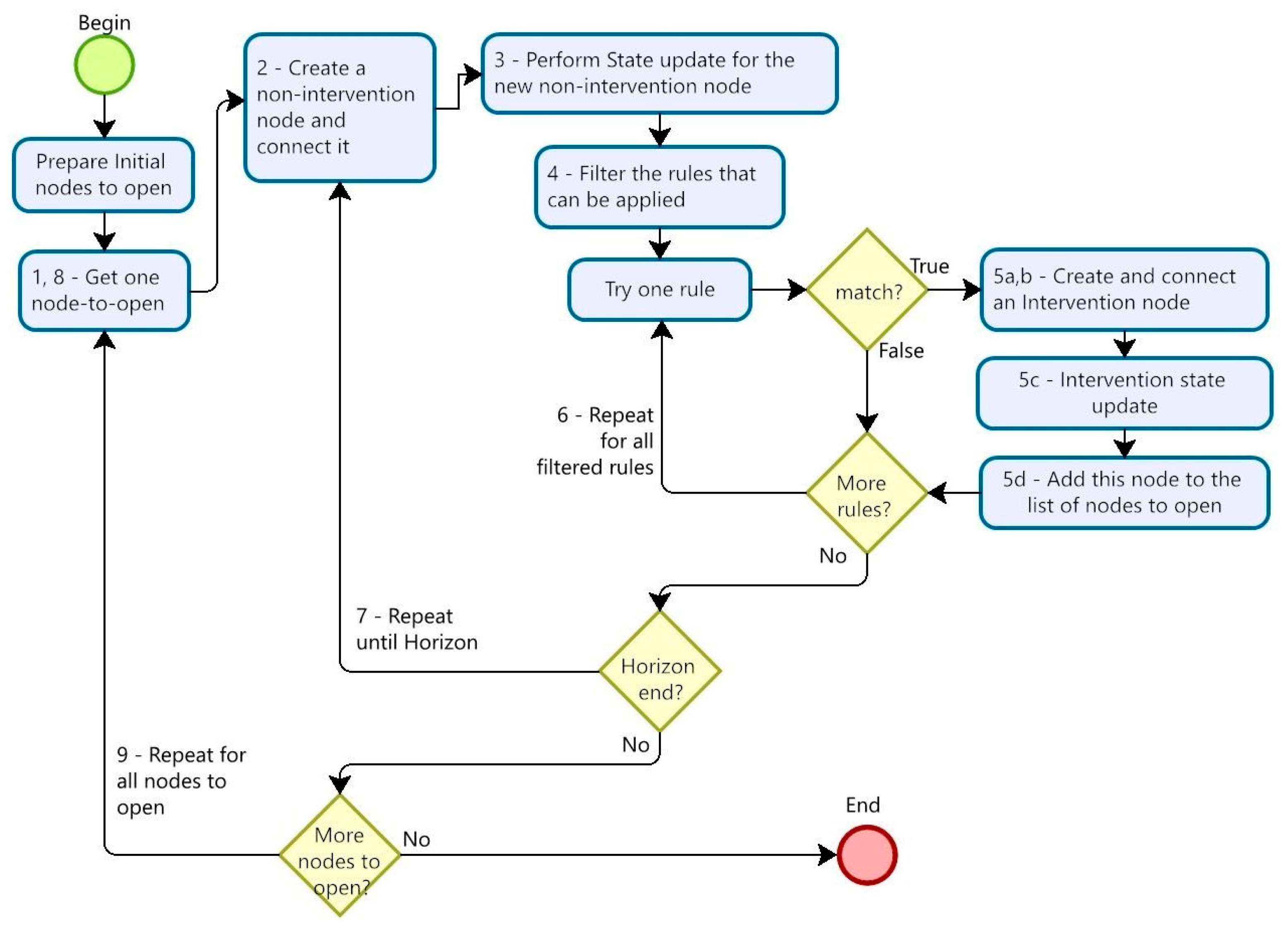

2.2.2. iGen Algorithm: The Inference Engine

- I_Engine gets an intervention node from the “nodes-to-open” list. In our example (Figure 2), an intervention I1 happens in node a:I1.

- I_Engine creates a new non-intervention node in the following period (node #1 in Figure 2) and connects it to the current node being processed (node a:I1 initially).

- I_Engine uses the equations of motion for each variable to update the forest state for the new node.

- I_Engine filters the rules to select only those with I1 as the last intervention.

- For the first rule (Ilast, Inext) = (I1, I2), I_Engine runs the rule Boolean function.

- If it returns True—i.e., if the conditions for applying the intervention are met—I_Engine:

- (a)

- Creates a node with an intervention I2 in the same period,

- (b)

- Connects this node to the previous node,

- (c)

- Evaluates the equation of motion for the intervention I2 for each state variable to determine what happens when I2 occurs, and

- (d)

- Unless the new node occurs at the end of the planning horizon, add this new node to the “node-to-open” list.

- If it returns False, I_Engine does nothing.

- I_Engine repeats step 5° for each rule in the filtered list of rules.

- I_Engine repeats steps 2° through 6° until the end of the planning horizon.

- I_Engine returns to the nodes-to-open list and picks the next one. In our example, node a:I1 will no longer be in the list, but there will be two others to open: b:I2 and c:I2.

- I_Engine repeats steps from 1° to 8° until the node-to-open list is empty.

- (a)

- generates nodes 1 to 12;

- (b)

- finds a match at node 6, creates node c:I2, connects it to node 5 (the node previous to node 6), and sets c:I2 as a “node-to-open”;

- (c)

- finds a match at node 7, creates node b:I2, connects it to node 6 (the node previous to node 7), and sets b:I2 as a “node-to-open”;

- (d)

- and sets the node a:I1 as “opened”.

3. Examples

3.1. Pennsylvania Example

3.1.1. Problem Description

3.1.2. Set of State Variables

3.1.3. Set of Intervention Types

3.1.4. Initial State

3.1.5. Equation of Motion

3.1.6. Example Rules

3.1.7. Result

3.2. Plantation-Coppice Example

3.2.1. Problem Description

3.2.2. State Variables

3.2.3. Potential Interventions

3.2.4. Initial State

3.2.5. Equation of Motion

3.2.6. Example Rules

3.2.7. Results

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bettinger, P.; Boston, K.; Siry, J.P.; Grebner, D.L. Forest Management and Planning, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9780128094761. [Google Scholar]

- Buongiorno, J.G.J. Decision Methods for Forest Resource Management, 1st ed.; Elsevier Academic Press: Cambridge, MA, USA, 2003; ISBN 978-0121413606. [Google Scholar]

- Borges, J.G.; Nordström, E.M.; Garcia-Gonzalo, J.; Hujala, T.; Trasobares, A. Computer-Based Tools for Supporting Forest Management. The Experience and the Expertise World-Wide, 1st ed.; Department of Forest Resource Management, Swedish University of Agricultural Sciences: Umea, Sweden, 2014. [Google Scholar]

- Rönnqvist, M.; D’Amours, S.; Weintraub, A.; Jofre, A.; Gunn, E.; Haight, R.G.; Martell, D.; Murray, A.T.; Romero, C. Operations Research Challenges in Forestry: 33 Open Problems. Ann. Oper. Res. 2015, 232, 11–40. [Google Scholar] [CrossRef]

- Radke, N.; Yousefpour, R.; von Detten, R.; Reifenberg, S.; Hanewinkel, M. Adopting Robust Decision-Making to Forest Management under Climate Change. Ann. For. Sci. 2017, 74, 43. [Google Scholar] [CrossRef]

- Franca, L.C.D.; Acerbi, F.W.; Silva, C.; Monti, C.A.U.; Ferreira, T.C.; Santana, C.J.D.; Gomide, L.R. Forest Landscape Planning and Management: A State-of-the-Art Review. Trees For. People 2022, 8, 100275. [Google Scholar] [CrossRef]

- Bettinger, P.; Chung, W. The Key Literature of, and Trends in, Forest-Level Management Planning in North America, 1950–2001. Int. For. Rev. 2004, 6, 40–50. [Google Scholar] [CrossRef]

- Hujala, T.; Khadka, C.; Wolfslehner, B.; Vacik, H. Review. Supporting Problem Structuring with Computer-Based Tools in Participatory Forest Planning. For. Syst. 2013, 22, 270–281. [Google Scholar] [CrossRef]

- Pasalodos-Tato, M.; Makinen, A.; Garcia-Gonzalo, J.; Borges, J.G.; Lamas, T.; Eriksson, L.O. Review. Assessing Uncertainty and Risk in Forest Planning and Decision Support Systems: Review of Classical Methods and Introduction of Innovative Approaches. For. Syst. 2013, 22, 282–303. [Google Scholar] [CrossRef]

- Pascual, A.; Giardina, C.P.; Povak, N.A.; Hessburg, P.F.; Asner, G.P. Integrating Ecosystem Services Modeling and Efficiencies in Decision-Support Models Conceptualization for Watershed Management. Ecol. Model. 2022, 466, 109879. [Google Scholar] [CrossRef]

- Borges, J.G.; Falcao, A.O.; Miragaia, C.; Marques, P.; Marques, M. A Decision Support System for Forest Ecosystem Management in Portugal. In Proceedings of the Systems Analysis in Forest Resources, Snowmass Village, CO, USA, 27–30 September 2000; Arthaudf, G.J., Barrett, T.M., Eds.; Springer: Dordrecht, The Netherlands, 2003; Volume 7, pp. 155–163. [Google Scholar]

- Næsset, E. A Spatial Decision Support System for Long-term Forest Management Planning by Means of Linear Programming and a Geographical Information System. Scand. J. For. Res. 1997, 12, 77–88. [Google Scholar] [CrossRef]

- Siitonen, M.; Anola-Pukkila, A.; Haara, A.; Harkonen, K.; Redsven, V.; Salminen, O.; Suokas, A. Mela Handbook, 2nd ed.; The Finish Forest Research Institute: Helsinki, Finland, 2001; Volume 1. [Google Scholar]

- Wikström, P.; Edenius, L.; Elfving, B.; Eriksson, L.O.; Lämås, T.; Sonesson, J.; Öhman, K.; Wallerman, J.; Waller, C.; Klintebäck, F. The Heureka Forestry Decision Support System: An Overview. Math. Comput. For. Nat. Resour. Sci. 2011, 3, 87–95. [Google Scholar]

- Rodriguez, L.C.E.; Stansfield, W.F. ForXGen—A Matrix Generator for Use with ForxCel; School of Forestry: Flagstaff, AZ, USA, 1995. [Google Scholar]

- Laacke, R.J. Building a Decision-Support System for Ecosystem Management—Klems. AI Appl. 1995, 9, 115–127. [Google Scholar]

- Packalen, T.; Marques, A.F.; Rasinmäki, J.; Rosset, C.; Mounir, F.; Rodriguez, L.C.E.; Nobre, S.R. Review. A Brief Overview of Forest Management Decision Support Systems (FMDSS) Listed in the FORSYS Wiki. For. Syst. 2013, 22, 263–269. [Google Scholar] [CrossRef]

- Kaya, A.; Bettinger, P.; Boston, K.; Akbulut, R.; Ucar, Z.; Siry, J.; Merry, K.; Cieszewski, C. Optimisation in Forest Management. Curr. For. Rep. 2016, 2, 1–17. [Google Scholar] [CrossRef]

- Constantino, M.; Martins, I.; Borges, J.G. A New Mixed-Integer Programming Model for Harvest Scheduling Subject to Maximum Area Restrictions. Oper. Res. 2008, 56, 542–551. [Google Scholar] [CrossRef]

- Goycoolea, M.; Murray, A.T.; Barahona, F.; Epstein, R.; Weintraub, A. Harvest Scheduling Subject to Maximum Area Restrictions: Exploring Exact Approaches. Oper. Res. 2005, 53, 490–500. [Google Scholar] [CrossRef]

- Goycoolea, M.; Murray, A.; Vielma, J.P.; Weintraub, A. Evaluating Approaches for Solving the Area Restriction Model in Harvest Scheduling. For. Sci. 2009, 55, 149–165. [Google Scholar]

- Könny, N.; Tóth, S.F. A Cutting Plane Method for Solving Harvest Scheduling Models with Area Restrictions. Eur. J. Oper. Res. 2013, 228, 236–248. [Google Scholar] [CrossRef]

- Vielma, J.P.; Murray, A.T.; Ryan, D.M.; Weintraub, A. Improving Computational Capabilities for Addressing Volume Constraints in Forest Harvest Scheduling Problems. Eur. J. Oper. Res. 2007, 176, 1246–1264. [Google Scholar] [CrossRef]

- Hernandez, M.; Gómez, T.; Molina, J.; León, M.A.; Caballero, R. Efficiency in Forest Management: A Multiobjective Harvest Scheduling Model. J. For. Econ. 2014, 20, 236–251. [Google Scholar] [CrossRef]

- Hof, J.G.; Pickens, J.B.; Barlett, E.T. A Maxmin Approach to Nondeclining Yield Timber Harvest Scheduling Problems. For. Sci. 1986, 32, 653–666. [Google Scholar]

- Martins, I.; Alvelos, F.; Cerveira, A.; Kaspar, J.; Marusak, R. Solving a Harvest Scheduling Optimization Problem with Constraints on Clearcut Area and Clearcut Proximity. Int. Trans. Oper. Res. 2023, 30, 3930–3948. [Google Scholar] [CrossRef]

- Xavier, A.M.D.; Freitas, M.D.C.; Fragoso, R.M.D. Management of Mediterranean Forests—A Compromise Programming Approach Considering Different Stakeholders and Different Objectives. For. Policy Econ. 2015, 57, 38–46. [Google Scholar] [CrossRef]

- Marques, S.; Bushenkov, V.A.; Lotov, A.v.; Marto, M.; Borges, J.G. Bi-Level Participatory Forest Management Planning Supported by Pareto Frontier Visualization. For. Sci. 2020, 66, 490–500. [Google Scholar] [CrossRef]

- Marques, M.; Reynolds, K.M.; Marques, S.; Marto, M.; Paplanus, S.; Borges, J.G. A Participatory and Spatial Multicriteria Decision Approach to Prioritize the Allocation of Ecosystem Services to Management Units. Land 2021, 10, 747. [Google Scholar] [CrossRef]

- Marto, M.; Marques, M.; Borges, J.G.; Tomé, M. Forestry Databases to Simulators and Decision Support Systems; Technical Report No. 01/2015 (Version 2.6); Center for Forestry Studies: Lisbon, Portugal, 2015. [Google Scholar]

- Potter, M.W.; Kessell, S.R.; Cattelino, P.J. FORPLAN: A FORest Planning LANguage and Simulator. Environ. Manag. 1979, 3, 59–72. [Google Scholar] [CrossRef]

- Eriksson, L.O. Planning under Uncertainty at the Forest Level: A Systems Approach. Scand. J. For. Res. 2006, 21, 111–117. [Google Scholar] [CrossRef]

- Nobre, S.R.; Eriksson, L.O.; Trubins, R. The Use of Decision Support Systems in Forest Management: Analysis of FORSYS Country Reports. Forests 2016, 7, 72. [Google Scholar] [CrossRef]

- Skovsgaard, J.P.; Vanclay, J.K. Forest Site Productivity: A Review of the Evolution of Dendrometric Concepts for Even-Aged Stands. Forestry 2008, 81, 13–31. [Google Scholar] [CrossRef]

- Shifley, S.R.; He, H.S.; Lischke, H.; Wang, W.J.; Jin, W.; Gustafson, E.J.; Thompson, J.R.; Thompson, F.R.; Dijak, W.D.; Yang, J. The Past and Future of Modeling Forest Dynamics: From Growth and Yield Curves to Forest Landscape Models. Landsc. Ecol. 2017, 32, 1307–1325. [Google Scholar] [CrossRef]

- Miles, P.D. Forest Inventory and Analysis Data for FVS Modelers. In Proceedings of the Third Forest Vegetation Simulator Conference, Fort Collins, CO, USA, 13–15 February 2007; Havis, R.N., Crookston, N.L., Eds.; Rocky Mountain Research Station: Fort Collins, CO, USA, 2008; Volume 54, pp. 125–129. [Google Scholar]

- de Oliveira, E.B.; de Oliveira, Y.M.M.; Hafley, W.L. Software to predict Growth and Yield for p.ellioti and p.taeda in southern Brazil. Pesqui. Agropecu. Bras. 1991, 26, 149–151. [Google Scholar]

- Gupta, R.; Sharma, L.K. The Process-Based Forest Growth Model 3-PG for Use in Forest Management: A Review. Ecol. Model. 2019, 397, 55–73. [Google Scholar] [CrossRef]

- Eriksson, L.O.; Bergh, J. A Tool for Long-Term Forest Stand Projections of Swedish Forests. Forests 2022, 13, 816. [Google Scholar] [CrossRef]

- Mcdermott, J. RI: A Rule-Based Configurer of Computer Systems. Artif. Intell. 1982, 19, 39–88. [Google Scholar] [CrossRef]

- Waterman, D.A.; Hayes-Roth, F. Pattern-Directed Inference Systems, 1st ed.; Waterman, D.A., Ed.; Academic Press: New York, NY, USA, 1978; ISBN 978-0-12-737550-2. [Google Scholar]

- Amarel, S.; Brown, J.S.; Buchanan, B.; Hart, P.; Kulikowski, C.; Martin, W.; Pople, H. Reports of Panel on Applications of Artificial Intelligence. In Proceedings of the Fifth International Joint Conference on Artificial Intelligence, Cambridge, MA, USA, 22–25 August 1977; pp. 994–1006. [Google Scholar]

- Duda, R.; Hart, P.E.; Nilsson, N.J.; Sutherland, G.L. Network Representations in Rule-Based Inference Systems 1. In Pattern Directed Inference Systems; Waterman, D.F., Ed.; Academic Press: New York, NY, USA, 1978; ISBN 0127375503. [Google Scholar]

- Grosan, C.; Abraham, A. Rule-Based Expert Systems. In Intelligent Systems; Grosan, C., Abraham, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; pp. 149–185. ISBN 978-3-642-21004-4. [Google Scholar]

- Minutolo, A.; Esposito, M.; De Pietro, G. Optimization of Rule-Based Systems in MHealth Applications. Eng. Appl. Artif. Intell. 2017, 59, 103–121. [Google Scholar] [CrossRef]

- Gustafson, E.J.; Crow, T.R. Forest Management Alternatives in the Hoosier National Forest. J. For. 1994, 92, 28–29. [Google Scholar] [CrossRef]

- McDill, M.E. RxWrite: An Information Management Tool for Minnesota’s Generic Environmental Impact Statement on Timber Harvesting. In Proceedings of the E4-Management Science and Operations Research Session at SAF National Convention, Indianapolis, IN, USA, 7 November 1993. [Google Scholar]

- Williams, S.B.; Roschke, D.J.; Holtfrerich, D.R. Designing Configurable Decision-Support Software—Lessons Learned. AI Appl. 1995, 9, 103–114. [Google Scholar]

- Albert, M. Predicting the selection of elite trees in mixed-species stands—A rule-based algorithm for silvicultural decision support systems. Allg. Forst Jagdztg. 2002, 173, 153–161. [Google Scholar]

- Stansfield, S.A. ANGY: A Rule-Based Expert System for Automatic Segmentation of Coronary Vessels from Digital Subtracted Angiograms. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 188–199. [Google Scholar] [CrossRef]

- Michael, D.J.; Nelson, A.C. HANDX: A Model-Based System for Automatic Segmentation of Bones from Digital Hand Radiographs. IEEE Trans. Med. Imaging 1989, 8, 64–69. [Google Scholar] [CrossRef] [PubMed]

- Phan, P.; Ouellet, J.; Mezghani, N.; de Guise, J.A.; Labelle, H. A Rule-Based Algorithm Can Output Valid Surgical Strategies in the Treatment of AIS. Eur. Spine J. 2015, 24, 1370–1381. [Google Scholar] [CrossRef]

- Savadjiev, P.; Chong, J.; Dohan, A.; Vakalopoulou, M.; Reinhold, C.; Paragios, N.; Gallix, B. Demystification of AI-Driven Medical Image Interpretation: Past, Present and Future. Eur. Radiol. 2019, 29, 1616–1624. [Google Scholar] [CrossRef]

- Al Fryan, L.H.; Shomo, M.I.; Alazzam, M.B.; Rahman, M.A. Processing Decision Tree Data Using Internet of Things (IoT) and Artificial Intelligence Technologies with Special Reference to Medical Application. BioMed Res. Int. 2022, 2022, 8626234. [Google Scholar] [CrossRef] [PubMed]

- Hooda, R.; Joshi, V.; Shah, M. A Comprehensive Review of Approaches to Detect Fatigue Using Machine Learning Techniques. Chronic. Dis. Transl. Med. 2022, 8, 26–35. [Google Scholar] [CrossRef] [PubMed]

- Matsuyama, T. Expert Systems for Image Processing: Knowledge-Based Composition of Image Analysis Processes. Comput. Vis. Graph. Image Process. 1989, 48, 22–49. [Google Scholar] [CrossRef]

- Abdullah, U.; Shaheen, M.; Ujager, F.S. Implementing Rule-Based Healthcare Edits. Ksii Trans. Internet Inf. Syst. 2022, 16, 116–132. [Google Scholar] [CrossRef]

- Beccali, M.; Bonomolo, M.; Martorana, F.; Catrini, P.; Buscemi, A. Electrical Hybrid Heat Pumps Assisted by Natural Gas Boilers: A Review. Appl. Energy 2022, 322, 119466. [Google Scholar] [CrossRef]

- Pean, T.Q.; Salom, J.; Costa-Castello, R. Review of Control Strategies for Improving the Energy Flexibility Provided by Heat Pump Systems in Buildings. J. Process Control 2019, 74, 35–49. [Google Scholar] [CrossRef]

- Igder, M.A.; Liang, X.D.; Mitolo, M. Service Restoration Through Microgrid Formation in Distribution Networks: A Review. IEEE Access 2022, 10, 46618–46632. [Google Scholar] [CrossRef]

- Pizarro, P.N.; Hitschfeld, N.; Sipiran, I.; Saavedra, J.M. Automatic Floor Plan Analysis and Recognition. Autom. Constr. 2022, 140, 104348. [Google Scholar] [CrossRef]

- Wu, C.S.; Liu, Y.C. Rule-Based Control of Weld Bead Width in Pulsed Gas Tungsten Are Welding (GTAW). Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 1996, 210, 93–98. [Google Scholar] [CrossRef]

- Fu, Y.Y.; Neill, Z.O.; Wen, J.; Pertzborn, A.T.; Bushby, S. Utilizing Commercial Heating, Ventilating, and Air Conditioning Systems to Provide Grid Services: A Review. Appl. Energy 2022, 307, 118133. [Google Scholar] [CrossRef]

- Yousefli, A.; Heydari, M.; Norouzi, R. A Data-Driven Stochastic Decision Support System to Investment Portfolio Problem under Uncertainty. Soft Comput. 2022, 26, 5283–5296. [Google Scholar] [CrossRef]

- Yang, L.H.; Liu, J.; Ye, F.F.; Wang, Y.M.; Nugent, C.; Wang, H.; Martinez, L. Highly Explainable Cumulative Belief Rule-Based System with Effective Rule-Base Modeling and Inference Scheme. Knowl. Based Syst. 2022, 240, 107805. [Google Scholar] [CrossRef]

- Van Rossum, G.; Drake, F.L. Python 3 Reference Manual; CreateSpace: Scotts Valey, CA, USA, 2009; Volume 1, ISBN 1441412697. [Google Scholar]

- Avaiga Taipy. Available online: https://docs.taipy.io/en/latest/ (accessed on 20 August 2023).

- The Pandas Development Team. pandas-dev/pandas: Pandas (1.5.3). Zenodo. 2020. Available online: https://zenodo.org/record/8239932 (accessed on 20 August 2023).

- Plotly Technologies Inc. Collaborative Data Science. Available online: https://plot.ly (accessed on 20 August 2023).

- Griffin, N.L.; Lewis, F.D. A Rule-Based Inference Engine Which Is Optimal and VLSI Implementable. In Proceedings of the IEEE International Workshop on Tools for Artificial Intelligence, Fairfax, VA, USA, 23–25 October 1989; pp. 246–251. [Google Scholar]

- Bickle, A. Fundamentals of Graph Theory, 1st ed.; American Mathematical Society: Providence, RI, USA, 2020; Volume 1, ISBN 9781470453428. [Google Scholar]

- Gilabert, H.; Manning, P.J.; McDill, M.E.; Sterner, S. Sawtimber Yield Tables for Pennsylvania Forest Management Planning. North. J. Appl. For. 2010, 27, 140–150. [Google Scholar] [CrossRef]

- Leslie, A.D.; Mencuccini, M.; Perks, M.P.; Wilson, E.R. A Review of the Suitability of Eucalypts for Short Rotation Forestry for energy in the UK. New For. 2020, 51, 1–19. [Google Scholar] [CrossRef]

- Hakamada, R.E.; Moreira, G.G.; Fernandes, P.G.; Martins, S.D.S. Legacy of Harvesting Methods on Coppice-Rotation Eucalyptus at Experimental and Operational Scales. Trees For. People 2022, 9, 100293. [Google Scholar] [CrossRef]

- Amancio, M.R.; Pereira, F.B.; Zanon Paludeto, J.G.; Vergani, A.R.; Bison, O.; Bandeira Peres, F.S.; Tambarussi, E.V. Genetic Control of Coppice Regrowth in Eucalyptus spp. Silvae Genet. 2020, 69, 6–12. [Google Scholar] [CrossRef]

- Gunn, E.A. Models for Strategic Forest Management. In Handbook of Operations Research in Natural Resources; Weintraub, A., Romero, C., Bjorndal, T., Epstein, R., Eds.; Springer: New York, NY, USA, 2007; Volume I, pp. 317–341. [Google Scholar]

- Johnson, K.N.; Scheurman, H.L. Tequiniques for Precribing Optimal Timber Harvest and Investment under Different Objectives—Discussion and Synthesis. For. Sci. 1977, 23 (Suppl. S1), a0001–z0001. [Google Scholar] [CrossRef]

- D’Amours, S.; Ronnqvist, M.; Weintraub, A. Using Operational Research for Supply Chain Planning in the Forest Products Industry. INFOR Inf. Syst. Oper. Res. 2008, 46, 265–281. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Biomass Logistics: A Review of Important Features, Optimization Modeling and the New Trends. Renew. Sustain. Energy Rev. 2018, 94, 587–599. [Google Scholar] [CrossRef]

- Gomez, T.; Hernandez, M.; Molina, J.; Leon, M.A.; Aldana, E.; Caballero, R. A Multiobjective Model for Forest Planning with Adjacency Constraints. Ann. Oper. Res. 2011, 190, 75–92. [Google Scholar] [CrossRef]

- Kaneko, S.; Kim, H.B.; Yoshioka, T.; Nitami, T. Developing a Model for Managing Sustainable Regional Forest Biomass Resources: System Dynamics-Based Optimization. Biomass Bioenergy 2023, 174, 106819. [Google Scholar] [CrossRef]

- Marques, A.F.; de Sousa, J.P.; Ronnqvist, M.; Jafe, R. Combining Optimization and Simulation Tools for Short-Term Planning of Forest Operations. Scand. J. For. Res. 2014, 29, 166–177. [Google Scholar] [CrossRef]

| iGen Elements | Input or Output | Tables Where the Elements Are Stored |

|---|---|---|

| Set of state variables | Input | Variable |

| Set of Intervention types | Input | InterventionType |

| Equations of motion for non-Intervention nodes | Input | Variable |

| Equations of motion for intervention nodes | Input | RuleCondtion |

| Rule base | Input | Rule and RuleCondtion |

| Initial nodes | Input | Nodes |

| Graph | Output | Nodes |

| General Parameters | Input | Parameter |

| Mgm Unit * | Site | Area (acre) | Period | Inter-Vention ** | Age (Years) | Species Composition | Treatment Req ** | Standing Volume (BF/ac ***) | Removed Volume | Remaining Volume |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 100 | -6 | OR | 8 | 1 | SWC | 0 | 0 | 0 |

| 2 | 1 | 90 | -5 | OR | 7 | 2 | OR | 0 | 0 | 0 |

| 3 | 2 | 120 | 0 | SWC | 70 | 1 | OR | 6311 | 2525 | 3787 |

| Rule Var | Rule Expression |

|---|---|

| Conditional Part | |

| Age, Site | ((:Age >= 60) and (:Site == 1)) or ((:Age >= 70) and (:Site == 2)) |

| TreatReq | (:TreatReq == ‘SWC’) |

| Consequent Part | |

| MgmUnit | = :MgmUnit |

| Site | = :Site |

| Area | = :Area |

| AfterInt | = 0 |

| Age | = 5 |

| SpcComposition | = :SpcComposition |

| TreatReq | = ‘SWC’ |

| Yield | = ExtFunctions.PennsylvaniaYield (:Age,[:Site], [:SpcComposition], [9],’stocked’,’SWC’, ‘Standing’) |

| YRemoved | = ExtFunctions.PennsylvaniaYield (:Age,[:Site], [:SpcComposition], [9],’stocked’,’SWC’, ‘Removed’) |

| yRemaining | = ExtFunctions.PennsylvaniaYield (:Age,[:Site], [:SpcComposition], [9],’stocked’,’SWC’, ‘Remaining’) |

| Rule Var | Rule Expression |

|---|---|

| Conditional Part | |

| TreatReq | (:TreatReq == ‘OR’) |

| Consequent Part | |

| MgmUnit | = :MgmUnit |

| Site | = :Site |

| Area | = :Area |

| AfterInt | = 0 |

| Age | = 5 |

| SpcComposition | = :SpcComposition |

| TreatReq | = ‘SWC’ |

| Yield | = ExtFunctions.PennsylvaniaYield (:Age,[:Site],[:SpcComposition], [9],’stocked’,’OR1′, ‘Standing’) |

| YRemoved | = ExtFunctions.PennsylvaniaYield(:Age,[:Site],[:SpcComposition], [9],’stocked’,’OR1′, ‘Removed’) |

| yRemaining | = ExtFunctions.PennsylvaniaYield(:Age,[:Site],[:SpcComposition], [9],’stocked’,’OR1′, ‘Remaining’) |

| NodeId | Previous Node | LiNode | Period | Intervention | Age | After-Int | Yield | Yield Removed | Yield Remaining |

|---|---|---|---|---|---|---|---|---|---|

| 43 | 41 | 2 | 1 | OR | 5 | 0 | 13,432 | 13,432 | |

| 197 | 43 | 43 | 2 | ni | 15 | 1 | 217 | ||

| 198 | 197 | 43 | 3 | ni | 25 | 2 | 1821 | ||

| 199 | 198 | 43 | 4 | ni | 35 | 3 | 4528 | ||

| 200 | 199 | 43 | 5 | ni | 45 | 4 | 7510 | ||

| 201 | 200 | 43 | 6 | ni | 55 | 5 | 10,362 | ||

| 203 | 201 | 43 | 7 | SWC | 65 | 0 | 12,949 | 5180 | 7770 |

| Mgm Unit | Stratum | Area | Period | Last Intervention | Age | Rotation Count | Yield |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 40 | −2 | CCR | 0 | 1 | 0 |

| 2 | 1 | 50 | −4 | CCR | 0 | 1 | 0 |

| 3 | 2 | 54 | −2 | CCR | 0 | 1 | 0 |

| 4 | 1 | 20 | −1 | CCS | 0 | 2 | 0 |

| Node Id | Previous Node | LiNode | Period | Age | Rotation Count | Yield |

|---|---|---|---|---|---|---|

| 214 | 15 | 15 | 5 | 1 | 2 | 60 |

| 215 | 214 | 15 | 6 | 2 | 2 | 100 |

| 216 | 215 | 15 | 7 | 3 | 2 | 140 |

| 217 | 216 | 15 | 8 | 4 | 2 | 190 |

| 218 | 217 | 15 | 9 | 5 | 2 | 210 |

| 219 | 218 | 15 | 10 | 6 | 2 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nobre, S.; McDill, M.; Estraviz Rodriguez, L.C.; Diaz-Balteiro, L. A General Rule-Based Framework for Generating Alternatives for Forest Ecosystem Management Decision Support Systems. Forests 2023, 14, 1717. https://doi.org/10.3390/f14091717

Nobre S, McDill M, Estraviz Rodriguez LC, Diaz-Balteiro L. A General Rule-Based Framework for Generating Alternatives for Forest Ecosystem Management Decision Support Systems. Forests. 2023; 14(9):1717. https://doi.org/10.3390/f14091717

Chicago/Turabian StyleNobre, Silvana, Marc McDill, Luiz Carlos Estraviz Rodriguez, and Luis Diaz-Balteiro. 2023. "A General Rule-Based Framework for Generating Alternatives for Forest Ecosystem Management Decision Support Systems" Forests 14, no. 9: 1717. https://doi.org/10.3390/f14091717

APA StyleNobre, S., McDill, M., Estraviz Rodriguez, L. C., & Diaz-Balteiro, L. (2023). A General Rule-Based Framework for Generating Alternatives for Forest Ecosystem Management Decision Support Systems. Forests, 14(9), 1717. https://doi.org/10.3390/f14091717