Performance of Harvesting Residue Treatment Methods in South African Pine Plantations

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

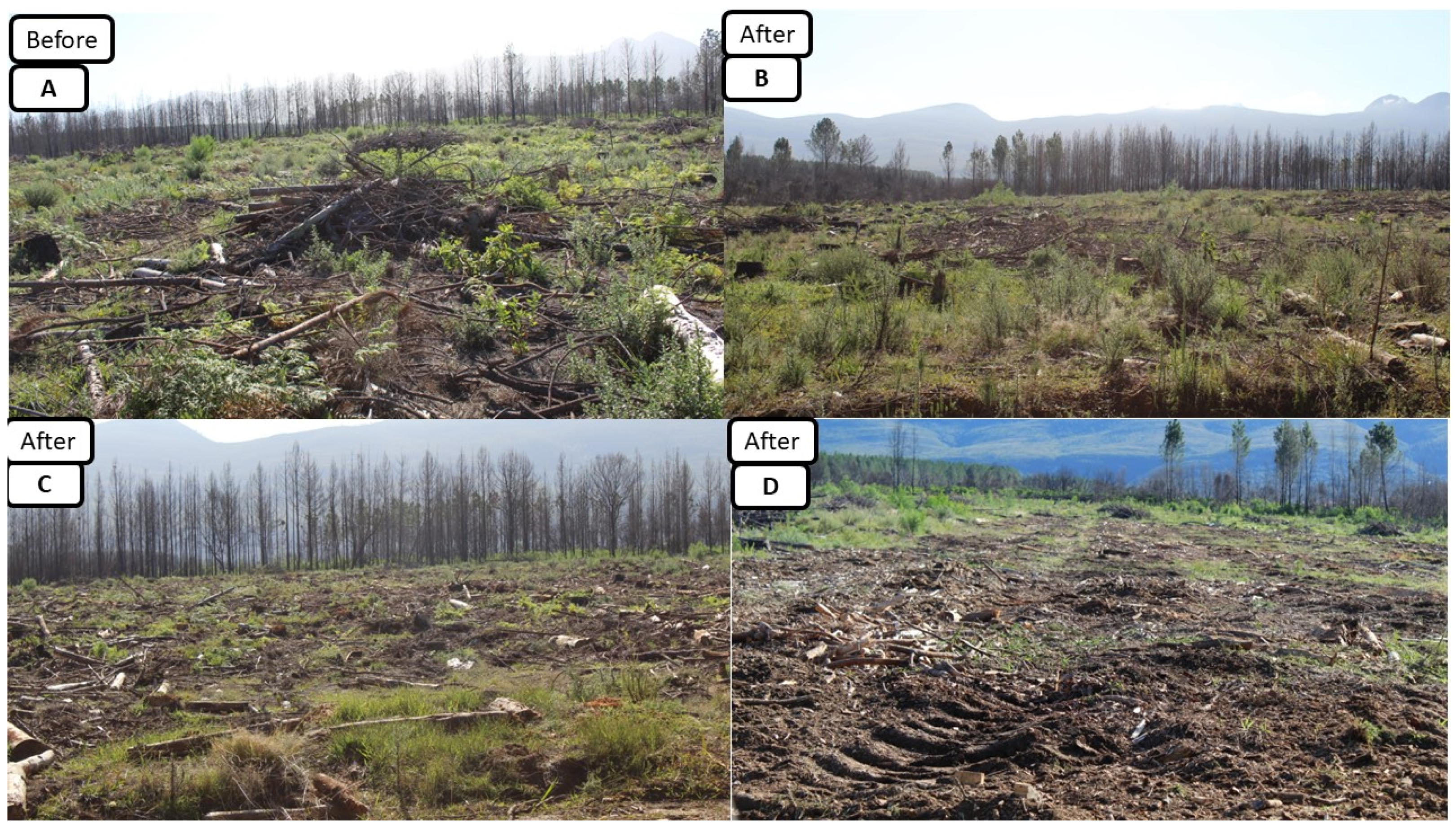

2.2. Experimental Design

2.3. Residue Load Assessment

2.4. Time Consumption Assessment

- Move: Begins when the wheels of the machine start moving and the head is not engaged and stops when the wheels stop and the head is put on the ground to start engaging.

- Mulch: Begins when the mulching head is put on the ground and the mulcher starts moving and stops when the mulcher picks up the mulching head and starts turning.

- Turn: Begins when the mulcher picks up the head and starts turning and stops when the mulching head is put on the ground and the mulcher starts moving.

2.5. Work Quality Assessment

2.6. Cost Assessment

2.7. Data Analysis

3. Results

3.1. Time Consumption and Costs

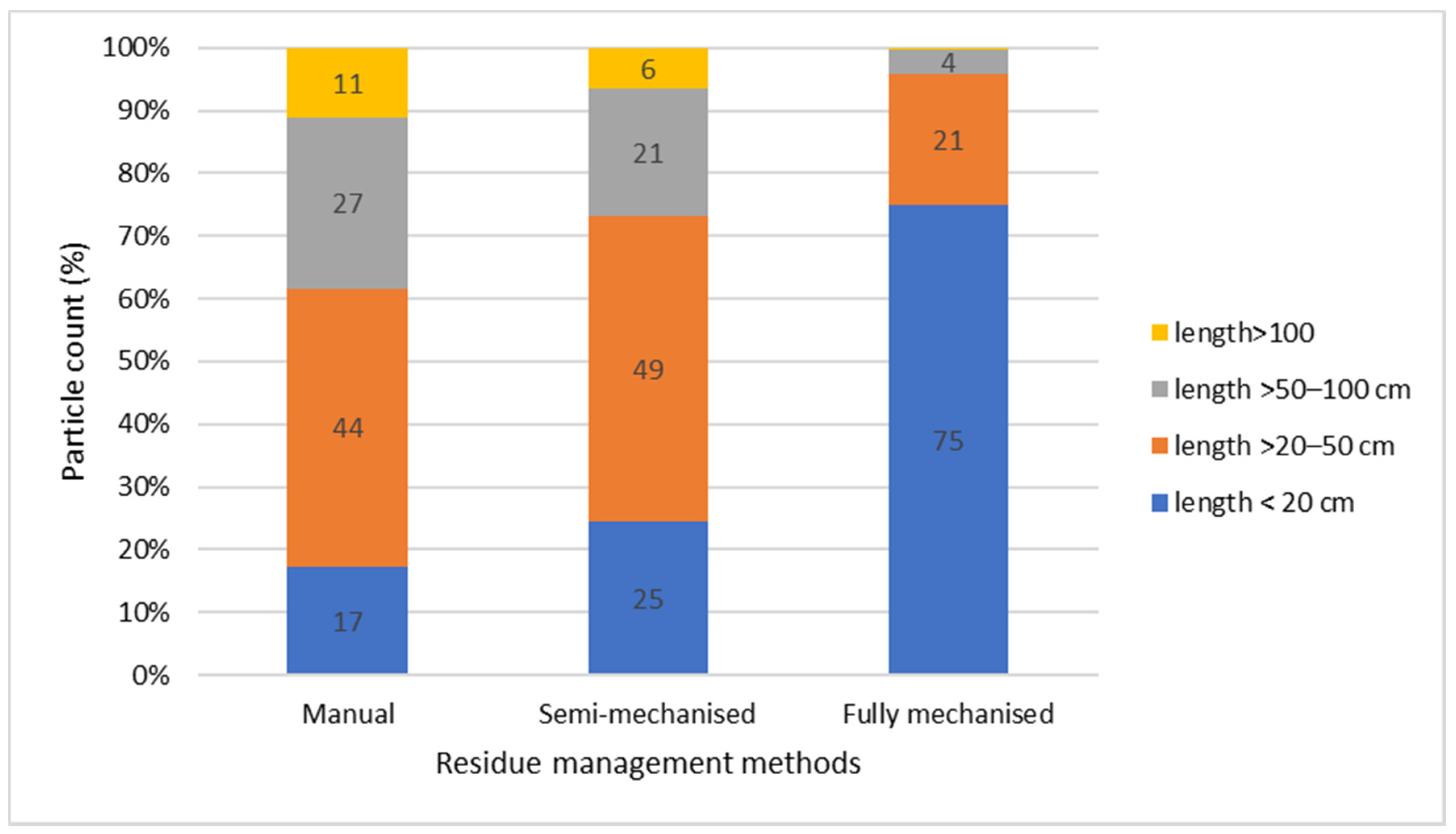

3.2. Work Quality

4. Discussion

4.1. Fully Mechanised Method

4.2. Semi-Mechanised Method

4.3. Manual Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eckert, M.; Gaigher, R.; Pryke, J.S.; Samways, M.J. Short-term arthropod recovery in Eucalyptus plantations after harvesting is not affected by different residue management practices. For. Ecol. Manag. 2023, 537, 120973. [Google Scholar] [CrossRef]

- FAO. Global Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable Economy—Background Paper for The State of the World’s Forests 2022; FAO Forestry Working: Rome, Italy, 2022. [Google Scholar]

- Xu, H.; Latta, G.; Lee, U.; Lewandrowski, J.; Wang, M. Regionalized life cycle greenhouse gas emissions of forest biomass use for electricity generation in the United States. Environ. Sci. Technol. 2021, 55, 14806–14816. [Google Scholar] [CrossRef]

- Franco, C.R.; Page-Dumroese, D.S.; Archuleta, J. Forest management and biochar for continued ecosystem services. J. Soil Water Conserv. 2022, 77, 60A–64A. [Google Scholar] [CrossRef]

- Skovsgaard, J.P.; Johansson, U.; Holmström, E.; Tune, R.M.; Ols, C.; Attocchi, G. Effects of thinning practice, high pruning and slash management on crop tree and stand growth in young even-aged stands of planted silver birch (Betula pendula Roth). Forests 2021, 12, 225. [Google Scholar] [CrossRef]

- Becker, R.M.; Keefe, R.F. Prediction of fuel loading following mastication treatments in forest stands in North Idaho, USA. Sustainability 2020, 12, 7025. [Google Scholar] [CrossRef]

- Jain, T.; Sikkink, P.; Keefe, R.; Byrne, J. To masticate or not: Useful tips for treating forest, woodland, and shrubland vegetation. Gen. Tech. Rep. 2018, 381, 55. [Google Scholar] [CrossRef]

- Ramantswana, M.M.; Brink, M.P.; Little, K.M.; Spinelli, R.; Chirwa, P.W. Current status of technology-use for plantation re-establishment in South Africa. South. For. J. For. Sci. 2020, 82, 313–323. [Google Scholar] [CrossRef]

- Ndlovu, N.; Little, K.M.; Titshall, L.; Rolando, C.A. Site preperation and vegetation management impacts on Pinus patula growth and rotation end productivity in South Africa. Aust. For. 2019, 82, 107–115. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Chang, S.X.; Cui, S.; Jagadamma, S.; Zhang, Q.; Cai, Y. Residue retention promotes soil carbon accumulation in minimum tillage systems: Implications for conservation agriculture. Sci. Total Environ. 2020, 740, 140147. [Google Scholar] [CrossRef] [PubMed]

- Fornwalt, P.J.; Rocca, M.E.; Battaglia, M.A.; Rhoades, C.C.; Ryan, M.G. Mulching fuels treatments promote understory plant communities in three Colorado, USA, coniferous forest types. For. Ecol. Manag. 2017, 385, 214–224. [Google Scholar] [CrossRef]

- Mechergui, T.; Pardos, M.; Jhariya, M.K.; Banerjee, A. Mulching and weed management towards sustainability. Ecol. Intensif. Nat. Resour. Sustain. Agric. 2021, 255–287. [Google Scholar] [CrossRef]

- Hvenegaard, S. Mulching productivity in black spruce fuels: Productivity as a function of treatment intensity. FP Innov. Edmont. AB Can. 2019, 14. Available online: https://library.fpinnovations.ca/media/FOP/TR2019N4.PDF (accessed on 22 July 2023).

- Lopes, A.R.; Prats, S.A.; Silva, F.C.; Keizer, J.J. Effects of ploughing and mulching on soil and organic matter losses after a wildfire in Central Portugal. Cuad. Investig. Geográfica/Geogr. Res. Lett. 2020, 46, 303–318. [Google Scholar] [CrossRef]

- Abrantes, J.R.; Prats, S.A.; Keizer, J.J.; de Lima, J.L. Effectiveness of the application of rice straw mulching strips in reducing runoff and soil loss: Laboratory soil flume experiments under simulated rainfall. Soil Tillage Res. 2018, 180, 238–249. [Google Scholar] [CrossRef]

- Bergman, R. Drying and control of moisture content and dimensional changes. In Wood Handbook—Wood as an Engineering Material; Chapter 13 in FPL-GTR; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; Volume 282, p. 543. Available online: https://www.researchgate.net/publication/285852322 (accessed on 22 July 2023).

- Resbank. Key Statistics. Available online: https://www.resbank.co.za/en/home/what-we-do/statistics/key-statistics (accessed on 15 July 2022).

- Department of employment and labour. The National Minimum Wage, a Tool to Close the Wage Gap and to Overcome Poverty, Online Publication. Available online: https://www.labour.gov.za/DocumentCenter/Publications/Basic%20Conditions%20of%20Employment/National%20Minimum%20Wage%20-%20Wage%20increase%202023%20flyer.pdf (accessed on 5 June 2023).

- Piqué, M.; Domènech, R. Effectiveness of mechanical thinning and prescribed burning on fire behavior in Pinus nigra forests in NE Spain. Sci. Total Environ. 2018, 618, 1539–1546. [Google Scholar] [CrossRef]

- Mahadeo, L. Understanding the System and Supply Chain Effects of Two Residue Management Treatments in Pine and Eucalyptus Plantations; Stellenbosch University: Stellenbosch, South Africa, 2022. [Google Scholar]

- DeLasaux, M.J.; Hartsough, B.R.; Spinelli, R.; Magagnotti, N. Small parcel fuel reduction with a low-investment, high-mobility operation. West. J. Appl. For. 2009, 24, 205–213. [Google Scholar] [CrossRef][Green Version]

- Coulter, E.D.; Coulter, K.; Mason, T. Dry Forest mechanized fuels treatment trials project. In Proceedings of the 25th Annual Council on Forest Engineering Meeting, Auburn, AL, USA, 16–20 June 2002. [Google Scholar]

- Halbrook, J.; Han, H.-S.; Graham, R.T.; Jain, T.B.; Denner, R. Mastication: A fuel reduction and site preperation alternative. In Proceedings of the 2006 Council on Forest Engineering (COFE) Meeting, Coeur d’Alene, ID, USA, 24–28 September 2006. [Google Scholar]

- Vitorelo, B.; Han, H.-S.; Varner, J. Masticators for fuel reduction treatment: Equipment options, effectiveness, costs, and environmental impacts. In Proceedings of the 2006 Council on Forest Engineering (COFE) Meeting, Lake Tahoe, CA, USA, 15 June 2009. [Google Scholar]

- Belleau, A.; Brais, S.; Paré, D. Soil nutrient dynamics after harvesting and slash treatments in boreal aspen stands. Soil Sci. Soc. Am. J. 2006, 70, 1189–1199. [Google Scholar] [CrossRef]

- Frame, C. Reducing Fuels through Mulching Treatments: What Are the Ecological Effects? Fire Sci. Brief. August 2011. Available online: http://digitalcommons.unl.edu/jfspbriefs/127 (accessed on 5 June 2023).

- Battaglia, M.A.; Rocca, M.E.; Rhoades, C.C.; Ryan, M.G. Surface fuel loadings within mulching treatments in Colorado coniferous forests. For. Ecol. Manag. 2010, 260, 1557–1566. [Google Scholar] [CrossRef]

- Nati, C.; Boschiero, M.; Picchi, G.; Mastrolonardo, G.; Kelderer, M.; Zerbe, S. Energy performance of a new biomass harvester for recovery of orchard wood wastes as alternative to mulching. Renew. Energy 2018, 124, 121–128. [Google Scholar] [CrossRef]

- Chamshama, S.; Lupala, Z. Effect of post-harvest Cupressus lusitanica slash management on early growth of Pinus patula at Shume, Lushoto, Tanzania. Tanzan. J. For. Nat. Conserv. 2012, 82, 13–21. [Google Scholar]

- Fernández, C.; Vega, J.A.; Gras, J.M.; Fonturbel, T.; Cuinas, P.; Dambrine, E.; Alonso, M. Soil erosion after Eucalyptus globulus clearcutting: Differences between logging slash disposal treatments. For. Ecol. Manag. 2004, 195, 85–95. [Google Scholar] [CrossRef]

| Specifications | Farm Tractor-Based Mulcher | Purpose-Built Mulcher |

|---|---|---|

| Carrier | ||

| Make and model | SAME Laser 110 | Tigercat M726G |

| Engine power | 74 kW (101 hp) | 275 kW (370 hp) |

| Weight | 8280 kg | 14,880 kg |

| Ground clearance | 450 mm | 635 mm |

| Fuel tank capacity | 320 L | 570 L |

| Cutting head | ||

| Make and model | TMF200 | Tigercat 4061-25 |

| Type | Horizontal shaft | Horizontal shaft |

| Width | 2441 mm | 3000 mm |

| Mulching swath | 2000 mm | 2500 mm |

| Weight | 1255 kg | 4625 kg |

| Machine | Farm Tractor-Based Mulcher | Purpose-Built Mulcher |

|---|---|---|

| Investment (ZAR) | 1,513,750 | 8,384,548.80 |

| Machine life (h) | 10,000 | 20,000 |

| Interest rate (%) | 9 | 9 |

| Residual value (%) | 20 | 20 |

| * Insurance and Licensing (%) | 2 | 2 |

| Fuel cost (ZAR/L) | 21.34 | 21.34 |

| Fuel consumption (L/h) | 7 | 35 |

| Oil cost (% fuel) | 5 | 5 |

| Repair cost value (% dep.) | 100 | 80 |

| Operator | 1 | 1 |

| Overheads (%) | 15 | 15 |

| Operator cost (R/h) | 40 | 77 |

| Treatments | Broadcasting | Farm Tractor-Based Mulcher | Purpose-Built Mulcher |

|---|---|---|---|

| Hectares (ha) | 0.417 | 0.455 | 0.400 |

| No residue piles/plot | 17 | 16 | 16 |

| Residue load ODT/ha | 14 | 12 | 14 |

| % Stem wood | 61 | 64 | 59 |

| Techniques | Farm Tractor-Based Mulcher | Purpose-Built Mulcher |

|---|---|---|

| Mulch h/ha | 3.580 | 1.472 |

| Cost ZAR/ha | 3267 | 4083 |

| Purpose-built only (1st pass vs. 2nd pass) | ||

| Mulch in 1st pass (h/ha) | - | 0.903 |

| Mulch in 2nd pass (h/ha) | - | 0.569 |

| Locations of Sample | Sieve Size | Purpose Built (%) |

|---|---|---|

| Residue piles | >5 cm | 27 |

| Between the residue piles | >5 cm | 31 |

| Residue piles | >40 cm | 12 |

| Between the residue piles | >40 cm | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zitha, H.M.; Ramantswana, M.M.; Spinelli, R. Performance of Harvesting Residue Treatment Methods in South African Pine Plantations. Forests 2023, 14, 1661. https://doi.org/10.3390/f14081661

Zitha HM, Ramantswana MM, Spinelli R. Performance of Harvesting Residue Treatment Methods in South African Pine Plantations. Forests. 2023; 14(8):1661. https://doi.org/10.3390/f14081661

Chicago/Turabian StyleZitha, Henny M., Muedanyi M. Ramantswana, and Raffaele Spinelli. 2023. "Performance of Harvesting Residue Treatment Methods in South African Pine Plantations" Forests 14, no. 8: 1661. https://doi.org/10.3390/f14081661

APA StyleZitha, H. M., Ramantswana, M. M., & Spinelli, R. (2023). Performance of Harvesting Residue Treatment Methods in South African Pine Plantations. Forests, 14(8), 1661. https://doi.org/10.3390/f14081661