Abstract

The mixed emulsion of P(St-MMA-AA) colloidal microspheres doped with black substances in three commercial inks (pen ink, wood color essence, propylene pigment) was coated on the wood surface. The dried colloidal microspheres self-assembled on the wood surface to form a three-dimensional photonic crystal coating. The influence of the coating on the optical properties of the wood surface was analyzed, and the influence of the type, concentration and drying temperature of the black substance on the structural color coating was explored. When three kinds of commercial black ink were mixed with colloidal microsphere emulsion to obtain photonic crystals on the wood surface, the transmitted light and the scattered light outside the photonic band gap were absorbed by black ink, which effectively reduced the light scattering inside the crystal and significantly enhanced the depth of the photonic crystal structure color. This study utilizes both pigment color and structural color, providing an environmentally friendly and novel method for colored coating of wood surfaces.

1. Introduction

Color can be divided into chemical color and structural color [1,2]. Chemical color is mainly derived from the dye or pigment molecules in the chromophore and color groups, these groups on the incident light selective absorption, resulting in color [3,4,5]. Structural color is generated by the optical effects such as reflection, refraction, scattering, diffraction and interference caused by the interaction between the special microstructure of the object surface and the visible light wave. Compared with pigment color, structural color usually has a hue that changes with the observation angle; that is, the iridescent effect and both lightness and saturation are high. Therefore, the coloring effect of structural color cannot be imitated by pigment color.

In special structures that produce structural colors, three-dimensional photonic crystals with long-range ordered structures are constructed by self-assembly of colloidal microspheres exhibiting colorful structural colors [6,7,8]. At present, the raw materials for the preparation of three-dimensional photonic crystals by self-assembly mainly include polystyrene (PSt) and polymethyl methacrylate (PMMA) [9,10,11]. The structural color film has gorgeous color, good stability, high saturation, strong corrosion resistance and never fading. At the same time, it can effectively reduce water and air pollution, and alleviate environmental pressure. The colors of these microspheres are white, which makes the assembled photonic crystals have higher relative reflectivity in the visible light wavelength range; that is, the lightness of the three elements of the structural color is higher. This three-dimensional photonic crystal has been widely used in the study of surface decoration of wood, fiber, textiles and glass [12,13,14,15,16].

In recent years, researchers have tried to apply bionic structural color to the improvement of wood surface color and physical and chemical properties. They mostly adopt colloidal microsphere self-assembly technology to construct photonic crystal bionic structural color film on wood surfaces. However, due to the iridescent effect of photonic crystals, when the angle between the observation line of sight and the incident light becomes larger than 50°, the observed color may show a grayish-white state, which affects the effect of photonic crystals in the field of color and decoration [17]. Moreover, when the structural color generated by this photonic crystal is applied to the decoration of a wood surface, the high lightness decoration effect brought by its high reflectivity is too monotonous and the color lacks a deep sense [18,19]. This limits the application of photonic crystal structure color in the field of wood.

Researchers have used the method of adding black substances to solve this problem in other industrial fields. For example, black material layers like polydopamine (PDA) and polypyrrole are added to the surface of microspheres such as PSt or Silica (SiO2) to form colloidal microspheres with a black shell and white core structure [20,21,22]. Some researchers directly use black materials such as iron oxide (Fe3O4) and PDA to synthesize microspheres, and then use microspheres to self-assemble into photonic crystals [23,24,25]. Or the white microspheres are assembled with carbon materials, cuttlefish juice, dyes and other substances [26], the surface energy of carbon materials such as carbon black, graphene and carbon nanotubes is high and unstable, which is easy to settle in the mixed emulsion, resulting in a significant decrease in the lightness of photonic crystals [27]. Zhang et al. incorporated cuttlefish ink particles into polystyrene (PS) microspheres, enhancing the visibility of amorphous photonic crystal (APS) coatings, resulting in vivid non-iridescent structural colors [26]. Furthermore, by adjusting the ratio of cuttlefish ink particles, the researchers were able to control the hue of the APS coatings, achieving a full spectral range of colors. Therefore, black ink has the potential to overcome the monotonous decorative effect caused by the high reflectivity of the photonic crystal coatings, while still retaining the iridescent effect, without significantly reducing the brightness of the structural color material.

In this study, three commercial black inks (pen ink, wood color essence and propylene pigment) were blended with P(St-MMA-AA) microsphere emulsion and assembled on the surface of wood. The effects of ink type, addition amount and self-assembly temperature on the microstructure, optical properties and structural color of the formed photonic crystal modification layer were analyzed. The results of this study can promote the application of photonic crystal structure color in the field of wood surface decoration.

2. Materials and Methods

2.1. Reagents

Identical to previous studies, P(St-MMA-AA) colloidal microspheres were prepared by emulsion polymerization [17,28]. Styrene, methyl methacrylate and acrylic acid (Shanghai Lingfeng Chemical Reagent Co., Ltd., Shanghai, China) were used as monomers for the synthesis of colloidal spheres. Sodium dodecyl benzene sulfonate (Shanghai Lingfeng Chemical Reagent Co., Ltd., China) was used as emulsifer. The initiator was ammonium persulfate (Nanjing Reagent Co., Ltd., China). Water was used as the dispersant for monomers. The colloidal microspheres prepared by this emulsion polymerization have a shell–core structure and good monodispersity (PDI < 0.08). The solid content of the emulsion measured by the dry weighing method was about 10 wt%. Deionized water was used for the whole experiment. Black pen ink (Shanghai Hero Golden Pen Factory Co., Ltd., Shanghai, China), primarily composed of carbon, wood color essence (Suzhou Sanyuanse Dye Co., Ltd., Shanghai, China) primarily composed of metal complexes, and propylene pigment (Shanghai Industrial Mali Co., Ltd., Shanghai, China) primarily composed of metal complexes, were selected as commercial inks doped with white colloidal microsphere emulsion in this study. Three commercial black inks were used without further purification. The relative humidity of the laboratory was 60% and the temperature was 25 °C.

2.2. Materials

The substrate used in this experiment is Aspen (Populus tremuloides). Aspen is light and soft but has good toughness, mechanical strength and plasticity [29,30]. The growth rate of Aspen is fast, and it has relatively stable growth characteristics. It can obtain large size and uniform texture wood in a short time. It is widely distributed and can represent tree species in different regions and environmental conditions [31]. Therefore, the choice of Aspen as the experimental substrate has certain representativeness. Boards of Aspen were bought from the local market, cut into dimensions of 0.05 m × 0.05 m × 0.01 m, planed by the laboratory and ground with 320 mesh sandpaper to ensure that the wood sample surface smoothness. The air–dry density of the Aspen was determined to be 0.39 g per cubic centimeter. Figure S1 displays the image of the Aspen wood sample.

2.3. Colloidal Microsphere Emulsion Mixed with Commercial Black Ink

Before doping with colloidal microsphere emulsion, the three commercial inks were dried at 150 °C for more than 24 h to remove the evaporable substances such as dispersants until their mass was constant. The remaining residue content of the three commercial inks was measured by weighing, and the mass fraction of non-volatile black substances in the three commercial inks was calculated. The calculation results for each black substance were obtained by averaging the data from three parallel experiments. After testing and calculation, the black substance content of black pen ink, wood color essence and propylene pigment were 9.10 wt%, 22.85 wt% and 35.21 wt%, respectively. Three commercial black inks were diluted with deionized water to a concentration of 0.3 wt% according to the mass fraction and used as stock solutions. The diluted three commercial black ink stock solutions were mixed with colloidal microsphere emulsions with a solid content of 10 wt% in a reagent bottle. The mixing ratios were 1/100, 1/120, 1/150, 1/200 and 1/300 according to the mass ratio of solid substances in the mother liquor to microspheres in the emulsion. The mixed emulsion was dispersed by ultrasonic dispersion for 30 min to make it uniformly dispersed (Shenzhen Jiemeng Cleaning Equipment Co., Ltd., Shenzhen, China).

2.4. Construction of Colloidal Photonic Crystals Doped with Commercial Black Ink by Coating Mixed Emulsion on Wood Surface

In this study, photonic crystals doped with black materials were constructed on the surface of wood by thermal-assisted gravity deposition. A square wire frame with a side length of 0.035 m × 0.035 m was drawn by pencil on the surface of the diameter section of the Aspen with a surface area of 0.05 m × 0.05 m. Figure S2 displays the image of the Aspen wood sample with a wire frame. The amount of mixed emulsion droplets in this area is 0.5 mL. The wood samples coated with hybrid emulsion were placed in a drying oven. Through the evaporation of the dispersant, the microspheres in the emulsion and the commercial ink black material were promoted to assemble together to construct photonic crystals on the wood surface. The drying time was set according to the ambient temperature of the wood sample during the drying process to ensure that the water in the dispersant and microspheres in the emulsion could be completely evaporated.

2.5. Best Addition Amount of the Black Ink and the Best Temperature of the Drying Process

This study examines the influence of different addition amounts of three black inks on the optical properties of photonic crystal coatings formed by a mixed emulsion on Aspen wood surfaces. The analysis and discussion are based on a single-variable experiment design. The aim is to understand how the addition levels of these inks impact the resulting optical characteristics of the photonic crystal coatings. Photonic crystal coatings were constructed on a wood surface by using mixed emulsion containing different mass fractions of pen ink, wood color essence and propylene pigments by thermal-assisted gravity deposition. The self-assembly temperature was 40 °C. The coatings were characterized and analyzed by digital photos and ultraviolet reflection spectra to obtain the best addition amount of the three kinds of black ink. After obtaining the best addition amount of each of the three inks. The optimal drying temperature experiment was carried out with the drying temperature as the only variable. The same method as the best addition amount experiment was used to make the mixed emulsion build a photonic crystal coating on the surface of the Aspen wood. The addition amount of the three inks was based on the results of the optimal addition amount experiment. The temperature in the oven during the drying process was 20 °C, 40 °C, 60 °C, 80 °C and 100 °C. A total of 33 samples were used in all experiments.

2.6. Characterization

The structural colors of photonic crystals were recorded as digital photographs under white light by a digital camera (D7000, Nikon, Tokyo, Japan). The reflection spectra of photonic crystals and wood samples were obtained by UV-vis spectrometry (U3900, HITACHI, Tokyo, Japan), in which the incident light mode was normal. The Fourier transform infrared spectrum of P(St-MMA-AA) colloidal microspheres and composite emulsion microspheres were characterized by the Fourier transform infrared spectrograph in ATR mode, the number of scans is typically six, the ATR crystal material is diamond (Alpha II, Bruker, Beijing, China).

3. Results and Discussion

3.1. Characterizing Coatings from Varying Addition Levels of Commercial Ink Emulsion Using UV-Visible Reflectance Spectroscopy

In this study, Aspen was selected as the base material. The wood color was light and rice white and a small part was light gray-brown. The property of white color, which does not absorb visible light, determines that the reflectance gradually increases as the wavelength of light increases in the UV–visible reflectance spectra. As a result, the reflectance spectrum of the Aspen wood exhibits a smooth curve. The photonic crystal coating was constructed on the tangential section of the wood. The waveform curve of the pure microspheres showed obvious fluctuations in the range of 612.5–724.5 nm. In the range of visible light, it showed red at a wavelength of 650–780 nm, which was consistent with the red color of the structural color coating self-assembled by the microspheres. The peak at about 400 nm was the reflection peak generated by the response of the P(St-MMA-AA) colloidal microspheres to the light wave.

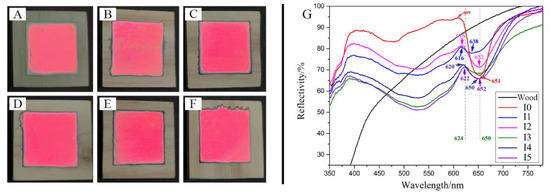

Figure 1A–F shows the structural color of the coatings obtained by the experiment of optimal addition amount with pen ink as an additive. Compared with the pure emulsion coating without pen ink in Figure 1A, there was obvious precipitation of black material around the coating formed by the emulsion adding pen ink after drying. May the non-carbon ink cannot be well mixed with P(St-MMA-AA) emulsion after drying, and more black substances were precipitated from the emulsion at the bottom of the photonic crystal coating. The color observed did have some changes, and the color was different when different concentrations of pen ink black substances were added.

Figure 1.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with pen inks of different concentrations and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with pen inks of different concentrations: (A) 0; (B) 1/300; (C) 1/200; (D) 1/150; (E) 1/120; (F) 1/100; (G) reflection spectra.

Figure 1G shows the UV-Vis reflectance spectra of photonic crystal coatings obtained by the best addition amount experiment with pen ink as an additive. The mass fractions of solid material of pen ink to microspheres in the emulsion were 0, 1/300, 1/200, 1/150, 1/120 and 1/100, respectively (I0-5 in Figure 1G). The reflection spectra of the emulsions showed different degrees of difference. When the pen ink was not added, the peak value of the reflection peak generated by the response of the P(St-MMA-AA) colloidal microspheres to the light wave was located at about 403.5 nm. With the increase in the amount of pen ink added, the reaction peak generated by the microsphere itself was obviously shifted to the left, the waveform curve on the right until the lowest reflectivity was extended, and the peak valley was obviously shifted to the right. May the pen ink will stain the surface of the substrate, and the more biased towards the black, the larger the range of visible light absorption, coupled with the interaction between the colloidal microspheres themselves and the reflected waves of the ordered structure formed by them, the two peaks showed a small range of fluctuations on the Y axis.

At the same time, with the increase in the addition of black substance of pen ink, the double peak which was not obvious at the wavelength of about 600 nm gradually changed into a steep single peak, but the change of the reflectivity of the red light was irregular, showing a trend of increasing first and then decreasing, and the half peak width gradually decreased. May when a small amount of black material was added at the beginning, the surface of the substrate began to absorb visible light after being dyed, which interacted with the light reaction of its coating. As the amount of pen ink increased, more black material penetrates into the wood fiber, so its reflectivity gradually decreased. In conclusion, when the mass fraction of the solid material of the pen ink was 1/100, the waveform curve of the reflection spectrum was the best; that is, it presented the best optical performance.

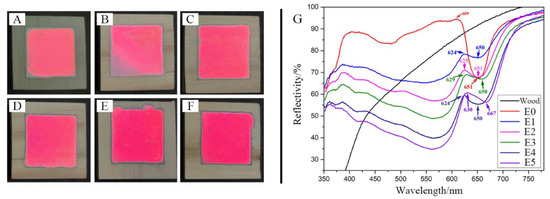

Figure 2A–F shows the structural color of the coatings obtained by the experiment of optimal addition amount with wood color essence as an additive. Compared with the coating of pure emulsion without wood color essence in Figure 2A, the color of the coating that mixed wood color essence changed obviously after drying, and the change increased with the increase in the concentration of wood color essence, and the red saturation and lightness were improved. The edge of the pure emulsion coating was milky white, and the edge of the coating showed blue-gray after adding wood color essence. May the toner used by the manufacturer to blend black wood color essence is a blue-black based dye, which shows its true color after a large amount of dilution of deionized water.

Figure 2.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with wood color essences of different concentrations and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with wood color essences of different concentrations: (A) 0; (B) 1/300; (C) 1/200; (D) 1/150; (E) 1/120; (F) 1/100; (G) reflection spectra.

Figure 2G shows the UV-Vis reflectance spectra of photonic crystal coatings obtained by the best addition amount experiment with wood color essence as an additive. The mass fractions of solid material of wood color essence to microspheres in the emulsion were 0, 1/300, 1/200, 1/150, 1/120 and 1/100, respectively (E0-5 in Figure 2G). The reflection spectra of the structural color coating formed by the mixed emulsion were quite different from those of log and pure P(St-MMA-AA) emulsion, and compared with pen ink, the waveform curve of the wood color essence mixed emulsion was clearer. With the increase in the amount of wood color essence, the reflectivity of the P(St-MMA-AA) microsphere’s response to light was lower, and the peak value of the peak was constantly shifted to the left. When the mass fraction was 1/120, it even showed an adjacent double peak, which was consistent with the nature of the black material itself to absorb all visible light.

In the range of red light wavelength, with the increase in the amount of wood color essence, the single peak was more obvious and its half-peak width decreased first and then increased. When the solid mass fraction of wood color essence was 1/120, its half-peak width was the smallest and the reflectivity was the lowest. Although the peak of the highest peak generally moved to the right, it was not completely regular. When the mass fraction of the solid substance of wood color essence was 1/120, the structural color coating formed by self-assembly of mixed P(St-MMA-AA) emulsion at the same temperature had the best optical properties.

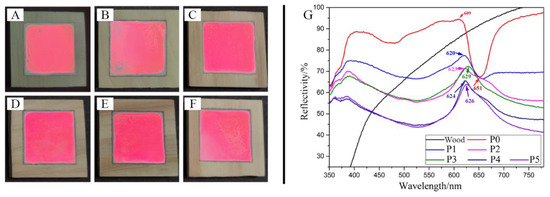

Figure 3A–F shows the structural color of the coatings obtained by the experiment of optimal addition amount with propylene pigment as an additive. Compared with the coating of pure emulsion without propylene pigment in Figure 3A, the color of the coating after adding propylene pigment did not change in an increasing trend with the increase in the concentration of propylene pigment. It could be clearly observed that the difference between the coating of pure P(St-MMA-AA) emulsion and the coating that mixed with 1/300 propylene pigment was the largest, and then the trend became smaller. The color saturation and lightness of the structural color presented by the coating of pure P(St-MMA-AA) emulsion mixed with 1/120 propylene pigment were the highest. Instead, the effect of the coating that mixed with 1/100 propylene pigment was not as good as the coating that mixed with 1/120 propylene pigment. This should be that the effect of black material on the optical properties of photonic crystal coatings began to weaken when the mass fraction of propylene pigment solid material exceeds a certain value of 1/150 to 1/120.

Figure 3.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with propylene pigment of different concentrations and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with propylene pigment of different concentrations: (A) 0; (B) 1/300; (C) 1/200; (D) 1/150; (E) 1/120; (F) 1/100; (G) reflection spectra.

Figure 3G shows the UV-Vis reflectance spectra of photonic crystal coatings obtained by the best addition amount experiment with propylene pigment as an additive. The mass fractions of solid material of wood color essence to microspheres in the emulsion were 0, 1/300, 1/200, 1/150, 1/120 and 1/100, respectively (P0-5 in Figure 3G). Similar to the former two, the reflectivity of P(St-MMA-AA) microspheres decreased after adding propylene pigment, and the concentration corresponding to the lowest reflectivity curve was 1/100, with a peak value of 57%. At the same time, the peak value of the highest peak showed a trend of left shift and showed an adjacent double peak when the mass fraction of propylene pigment was 1/100.

In the red light wavelength region, with the increase in the amount of propylene pigment, the single peak was more obvious than that of the pure emulsion without adding propylene pigment and its half-peak width generally showed a decreasing trend, and the position of the single peak peak did not change greatly. However, the single peak of the coating formed by the pure emulsion mixed with 1/150 propylene pigment was obviously shifted to the right and the half-peak width became larger, which deviated from the general rules. This should be a problem of the sample itself and not discussed in the analysis. When the mass fraction of propylene pigment was 1/120, the single peak width of the curve at half maximum was the smallest, it almost coincides with the curve produced by the coating with the mass fraction of propylene pigment of 1/150 at about 650 nm wavelength, and the reflectivity reaches 65.5% at the peak of 623 nm. In general, when the mass fraction of propylene pigment was 1/120, the optical properties of the structural color coating formed by self-assembly of mixed P(St-MMA-AA) emulsion at the same temperature were the best. The waveform curve of the coatings formed by P(St-MMA-AA) emulsion mixed with propylene pigment did not appear more regular than that mixed with wood color essence, but better than that mixed with pen ink.

3.2. The Characterization and Analysis of the Coatings Formed by Three Commercial Black Ink Mixed Emulsions at Different Temperatures by UV-Visible Reflectance Spectroscopy

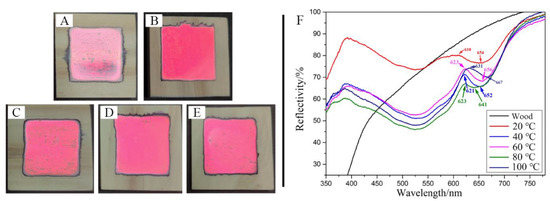

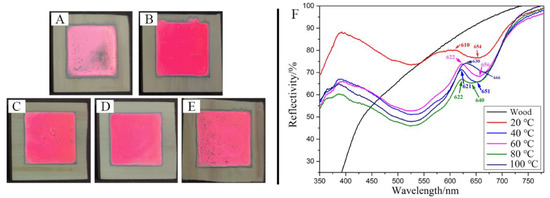

Figure 4A–E shows the structural color of the coatings obtained by the experiment of optimal drying temperature with pen ink as an additive. The mass fraction of pen ink is 1/100. Figure 4F is the reflection spectrum of the coatings obtained by the experiment of optimal drying temperature with pen ink as an additive. In addition to the reflection spectrum curve of the mixed emulsion at 20 °C, the reflection spectrum curves of the structural color coating self-assembled by microspheres at other temperatures were similar.

Figure 4.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/100 pen ink at different temperatures and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/100 pen ink at different temperatures: (A) 20 °C; (B) 40 °C; (C) 60 °C; (D) 80 °C; (E) 100 °C; (F) reflection spectra.

At 20 °C, the peak shape of the reflection curve generated by the coating was steeper than that at other higher temperatures, and the reflectivity was close to 90%, which was much higher than other curves. As the temperature increased, the peak gradually shifted to the left and presented an irregular hill-like peak shape. This should be due to the slow self-assembly process of P(St-MMA-AA) microspheres at 20 °C, and the black material in the pen ink is mostly precipitated inside the substrate. With the increase in temperature, the self-assembly process of the microspheres was accelerated under the thermal effect, the black material could stay on the surface of the substrate and absorb more visible light.

In the red light wavelength region, with the increase in temperature, the peak showed a trend of shifting to the right, and the half-peak width of the single peak decreased first and then increased. When the temperature is 40 °C, the half-peak width was the smallest and the slope of the curve was the largest. In conclusion, combined with the analysis results in the previous section, when the mass fraction of pen ink was 1/100 and the self-assembly temperature was 40 °C, the coating obtained by P(St-MMA-AA) microspheres had the best optical properties.

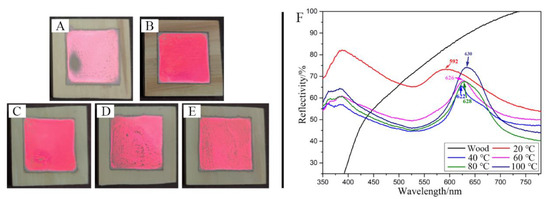

Figure 5A–E shows the structural color of the coatings obtained by the experiment of optimal drying temperature with wood color essence as an additive. The mass fraction of wood color essence is 1/120. Figure 5F is the reflection spectrum of the coatings obtained by the experiment of optimal drying temperature with wood color essence as an additive. Except for the reflection spectrum curves of the mixed emulsion at 20 °C and 100 °C, the reflection spectrum curves of the structural color coating at other temperatures were similar.

Figure 5.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/120 wood color essence at different temperatures and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/120 wood color essence at different temperatures: (A) 20 °C; (B) 40 °C; (C) 60 °C; (D) 80 °C; (E) 100 °C; (F) reflection spectra.

At 20 °C, the waveform curve generated by the P(St-MMA-AA) microsphere itself showed a sharp small double-peak trend, and the reflectivity was close to 85%, which was much higher than other curves. The author believes that in the wavelength range of 350 nm–550 nm, the change of temperature had little effect on the mixed emulsion of wood color essence. In the range of red light wavelength, the reflectivity was higher than other temperatures when the temperature was 20 °C and 100 °C. Even at 100 °C, the peak value was as high as 66.9%, and obviously shifted to the right; also, the half-peak width increased too obviously. This should be that when the temperature was too high or too low, the black material in the wood color can not be dried with the P(St-MMA-AA) microspheres together. The microspheres first floated on the surface of the liquid and were completely in the upper layer of the black material during self-assembly [32]. Under the temperature conditions of 40 °C, 60 °C, and 80 °C, with the increase in temperature, the position of the highest peak was almost unchanged, and the half peak width of the single peak showed a decreasing trend. When the temperature was 40 °C, the half peak width was the smallest and the reflectivity was the lowest. In conclusion, when the mass fraction of wood color essence was 1/120 and the self-assembly temperature was 40 °C, the optical properties of the coating formed by the mixed emulsion of wood color essence were the best.

Figure 6A–E shows the structural color of the coatings obtained by the experiment of optimal drying temperature with propylene pigment as an additive. The mass fraction of propylene pigment is 1/120. Figure 6F is the reflection spectrum of the coatings obtained by the experiment of optimal drying temperature with propylene pigment as an additive. Except for the reflection spectrum curve of the mixed emulsion at 20 °C, the reflection spectrum curve of the structural color coatings self-assembled by the microspheres at other temperatures were roughly similar. When the wavelength of visible light was greater than 675 nm, the curve reflectivity that added pen ink and wood color essence rose sharply, but this group of curves continue to slowly decline until almost unchanged.

Figure 6.

Photographs of the structural color of the coatings that self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/120 propylene pigment at different temperatures and reflection spectra of structural color coatings self-assembled from P(St-MMA-AA) colloidal microspheres mixed with 1/120 propylene pigment at different temperatures: (A) 20 °C; (B) 40 °C; (C) 60 °C; (D) 80 °C; (E) 100 °C; (F) reflection spectra.

Within the waveform range generated by the light response of the microsphere itself, the reflectivity gradually decreased as the temperature increased. In the range of red light wavelength, the reflectivity of the waveform curve at 40 °C was higher than that at other temperatures, reaching 74.1% at a single peak of 633.5 nm, and the peak shifted to the right; also, the half-peak width increased significantly. Under the condition of 60 °C, 80 °C and 100 °C, with the increase in temperature, the position of the highest peak changed little, and the half peak width of the single peak decreased gradually. In conclusion, the same as the former two, when the mass fraction of propylene pigment is 1/120 and the self-assembly temperature is 40 °C, the coating formed by the mixed emulsion of propylene pigment had the best optical properties.

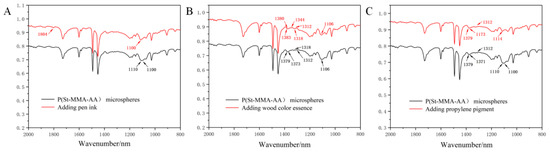

3.3. The Characterization and Analysis of Three Commercial Black Ink Mixed Emulsions by FTIR Infrared Spectroscopy

In order to further clarify the functional groups contained in various colloidal microspheres formed by the emulsion after adding different kinds of black substances, P(St-MMA-AA) colloidal microspheres and composite emulsion microspheres were characterized by FTIR, and their changes were analyzed.

As shown in Figure 7A, the curve of pure P(St-MMA-AA) colloidal microspheres has two unobvious double peaks at 1100 cm−1 and 1110 cm−1. The peak at 1100 cm−1 represented the characteristic peak of a secondary alcohol, the peak at 1110 cm−1 changed from a shoulder peak to a single peak after adding pen ink. The change of the characteristic peak here was due to the stretching vibration of the -C-O-C- ether chain. A clear peak at 1804 cm−1 was also produced, which made the FTIR spectrum of P(St-MMA-AA) microspheres after adding pen ink different from that of pure microspheres. As shown in Figure 7B, the curve of P(St-MMA-AA) colloidal microspheres after mixed wood color essence had an obvious single peak at 1383 cm−1, which was the characteristic peak of the methyl group, two methyl groups sharing one carbon, which was divided into two halves at 1380 cm−1. Compared with the curve of pure microspheres, the curve changed from a shoulder peak at 1379 cm−1 and 1373 cm−1 to a single peak at 1383 cm−1 after adding wood color essence, and the absorption peak at 1344 cm−1 corresponded to the symmetric deformation vibration of -CH3. At the same time, the absorption peaks at 1318 cm−1, 1312 cm−1 and 1106 cm−1 became less obvious than before. As shown in Figure 7C, after adding propylene pigment, compared with the curve of pure microspheres, the curve changed from a shoulder peak at 1371 cm−1 to an obvious single peak at 1373 cm−1, the change of the characteristic peak here is due to the symmetric deformation vibration of -CH3. At the same time, the shoulder peak of the curve of pure microspheres at 1110 cm−1 and 1100 cm−1 changed to a single peak at 1114.6 cm−1. The characteristic peaks at 1379 cm−1 and 1312 cm−1 were not obvious after adding propylene pigments. The addition of the three commercial black inks did not produce any chemical reaction with the original material, and the change they brought in terms of physical effect was very little. However, the physical change that the wood color essence brought was more obvious than the other two, which was consistent with the previous analysis.

Figure 7.

Infrared contrast of pure P(St-MMA-AA) colloidal microspheres and composite emulsion microspheres mixed with three commercial black inks: (A) adding pen ink; (B) adding wood color essence; (C) adding propylene pigment.

4. Conclusions

In this study, the P(St-MMA-AA) emulsion prepared by emulsion polymerization was doped with three different kinds of commercial black inks (pen ink, wood color essence and propylene pigment), and the effects of commercial black ink type, concentration and drying temperature on the structural color coating were explored. The results show that temperature is the main factor to promote the formation of photonic crystals at the gas–liquid interface. At 40 °C, the structural color coating on the wood surface has the best optical properties. The beneficial effects of three commercial black inks on the optical properties of structural color coatings on the wood surface were ranked as follows: wood color essence, propylene pigment and pen ink. When the solid mass fraction of pen ink is 1/100, the solid mass fraction of wood color essence and propylene pigment is 1/120, the optical properties of the structural color coating on the wood surface are the best, and the effect of wood color essence is particularly prominent.

When three kinds of commercial black ink were doped into P(St-MMA-AA) colloidal microsphere emulsion and blended with the wood surface to obtain photonic crystals, the transmitted light and the scattered light outside the photonic band gap were absorbed by commercial black ink, which could effectively reduce the light scattering inside the crystal. This method utilizes both pigmentary color and structural color, and the formed wood surface decoration layer exhibits a bright and deep color and iridescent effect. The lightness and saturation of the structural color coating are greatly improved without affecting the order of the coating microstructure, which significantly enhances the deepness of the photonic crystal structure color. The combination of commodity black ink and photonic crystal is used to modify the surface of the wood, which opens up more application prospects for structural color in the wood color coating and enriches the wood color coating scheme.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/f14081549/s1, Figure S1: The image of the Aspen wood sample; Figure S2: The image of the Aspen wood sample with a wire frame.

Author Contributions

Conceptualization, Y.S., Y.L., J.H. and Y.Z.; methodology, Y.S., Y.L., J.H. and Y.Z.; data curation, Y.S.; writing—original draft preparation, Y.S. and Y.L.; writing—review and editing, Y.S., Y.L. and J.H.; visualization, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the postdoctoral research project of Zhejiang Province (271235, Zhejiang Province Human Resources and Social Security Department), Qing Lan Project (Jiangsu Education Department), the Youth Program of Science and Technology Innovation Fund of Nanjing Forestry University (grant numbers CX2019016, Nanjing Forestry University) and the Scientific Research Foundation of Nanjing Forestry University (grant numbers GXL 2018022, Nanjing Forestry University).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kinoshita, S.; Yoshioka, S.; Miyazaki, J. Physics of structural colors. Rep. Prog. Phys. 2008, 71, 076401. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, Q.; Yuan, W.; Zhou, N.; Zhang, K. The mechanism and its application of amorphous photonic crystals with structural color. Mater. Rev. 2017, 1, 43–56. [Google Scholar] [CrossRef]

- Perkins, W.S. A review of textile dyeing processes. Text. Chem. Color. 1993, 23, 23. [Google Scholar] [CrossRef]

- Kinoshita, S.; Yoshioka, S. Structural colors in nature: The role of regularity and irregularity in the structure. ChemPhysChem 2005, 6, 1442–1459. [Google Scholar] [CrossRef]

- Griffiths, J. Speciality dyes-new trends in modern dye chemistry. Color Technol. 1988, 104, 416–424. [Google Scholar] [CrossRef]

- Pan, L.; Xu, H.; Sun, Y.; Zhao, J.; Li, Y. Preparation of three-dimensional photonic crystals of zirconia by electrodeposition in a colloidal crystals template. Crystals 2016, 6, 76. [Google Scholar] [CrossRef]

- Parchine, M.; McGrath, J.; Bardosova, M.; Pemble, M.E. Large area 2D and 3D colloidal photonic crystals fabricated by a roll-to-roll Langmuir-Blodgett method. Langmuir 2016, 32, 5862–5869. [Google Scholar] [CrossRef]

- Gao, W.; Rigout, M.; Owens, H. Self-assembly of silica colloidal crystal thin films with tuneable structural colours over a wide visible spectrum. Appl. Surf. Sci. 2016, 380, 12–15. [Google Scholar] [CrossRef]

- Gao, W.; Muriel, R.; Huw, O. Optical properties of cotton and nylon fabrics coated with silica photonic crystals. Opt. Mater. Express 2017, 7, 341–353. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, X.; Zhang, L.; Cao, M.; Lin, Y.; Zhang, J. Rapid fabrication of angle-independent structurally colored films with a superhydrophobic property. Dye. Pigment. 2016, 130, 202–208. [Google Scholar] [CrossRef]

- Míguez, H.; Meseguer, F.; López, C.; Mifsud, A.; Moya, J.S.; Vázquez, L. Evidence of FCC crystallization of SiO2 nanospheres. Langmuir 1997, 13, 6009–6011. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, Y.; Liu, G.; Li, Y.; Fan, Q.; Shao, J. Fabrication of high-quality silica photonic crystals on polyester fabrics by gravitational sedimentation self-assembly. Color. Technol. 2015, 131, 413–423. [Google Scholar] [CrossRef]

- Jeong, U.; Xia, Y. Synthesis and crystallization of monodisperse spherical colloids of amorphous selenium. Adv. Mater. 2005, 17, 102–106. [Google Scholar] [CrossRef]

- Ha, S.T.; Park, O.O.; Im, S.H. Size control of highly monodisperse polystyrene particles by modified dispersion polymerization. Macromol. Res. 2010, 18, 935–943. [Google Scholar] [CrossRef]

- Wang, J.; Wen, Y.; Feng, X.; Song, Y.; Jiang, L. Control over the wettability of colloidal crystal films by assembly temperature. Macromol. Rapid Commun. 2006, 27, 188–192. [Google Scholar] [CrossRef]

- You, B.; Wen, N.; Shi, L.; Wu, L.; Zi, J. Facile fabrication of a three-dimensional colloidal crystal film with large-area and robust mechanical properties. J. Mater. Chem. 2009, 19, 3594–3597. [Google Scholar] [CrossRef]

- Liu, Y. Self-assembly of poly(styrene-methyl methacrylate-acrylic acid) (P(St-MMA-AA)) colloidal microspheres on wood surface by thermal-assisted gravity deposition. Wood Sci. Technol. 2021, 55, 403–417. [Google Scholar] [CrossRef]

- Buchelt, B.; Wagenführ, A. Evaluation of colour differences on wood surfaces. Eur. J. Wood Wood Prod. 2012, 70, 389–391. [Google Scholar] [CrossRef]

- Hauptmann, M.; Hermann, P.; Carsten, M. The potential of color measurements with the CIEDE2000 equation in wood science. Eur. J. Wood Wood Prod. 2012, 70, 415–420. [Google Scholar] [CrossRef]

- Yang, X.; Ge, D.; Wu, G.; Liao, Z.; Yang, S. Production of structural colors with high contrast and wide viewing angles from assemblies of polypyrrole black coated polystyrene nanoparticles. ACS Appl. Mater. Interfaces 2016, 8, 16289–16295. [Google Scholar] [CrossRef]

- Kawamura, A.; Kohri, M.; Morimoto, G.; Nannichi, Y.; Taniguchi, T.; Kishikawa, K. Full-color biomimetic photonic materials with iridescent and non-iridescent structural colors. Sci. Rep. 2016, 6, 33984. [Google Scholar] [CrossRef]

- Yi, B.; Shen, H. Facile fabrication of crack-free photonic crystals with enhanced color contrast and low angle dependence. J. Mater. Chem. C 2017, 5, 8194–8200. [Google Scholar] [CrossRef]

- Ge, J.; Hu, Y.; Biasini, M.; Beyermann, W.P.; Yin, Y. Superparamagnetic magnetite colloidal nanocrystal clusters. Angew. Chem. Int. Ed. 2007, 46, 4342–4345. [Google Scholar] [CrossRef] [PubMed]

- Ju, K.Y.; Lee, Y.; Lee, S.; Park, S.B.; Lee, J.K. Bioinspired polymerization of dopamine to generate melanin-like nanoparticles having an excellent free-radical-scavenging property. Biomacromolecules 2011, 12, 625–632. [Google Scholar] [CrossRef] [PubMed]

- Xiao, M.; Li, Y.; Allen, M.C.; Deheyn, D.D.; Yue, X.; Zhao, J.; Gianneschi, N.C.; Shawkey, M.D.; Dhinojwala, A. Bio-inspired structural colors produced via self-assembly of synthetic melanin nanoparticles. ACS Nano 2015, 9, 5454–5460. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Dong, B.; Chen, A. Using cuttlefish ink as an additive to produce non-iridescent structural colors of high color visibility. Adv. Mater. 2015, 27, 4719–4724. [Google Scholar] [CrossRef]

- Cui, Y.; Wang, F.; Zhu, J.; Wu, W.; Qin, Y.; Zhang, X. Preparation of large-scale and angle-independent structural colors by additive of black polypyrrole. J. Colloid Interface Sci. 2018, 531, 609–617. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, J.; Wu, Z. Fabrication of coatings with structural color on a wood surface. Coatings 2020, 10, 32. [Google Scholar] [CrossRef]

- Borrega, M.; Nevalainen, S.; Heräjärvi, H. Resistance of European and hybrid aspen wood against two brown-rot fungi. Eur. J. Wood Wood Prod. 2009, 67, 177–182. [Google Scholar] [CrossRef]

- Knyazeva, N.V.; Konshin, V.V.; Chemeris, N.A. Synthesis of cellulose esters with aliphatic hydroxy acids from aspen wood. Russ. J. Appl. Chem. 2008, 81, 1087–1089. [Google Scholar] [CrossRef]

- Pakull, B.; Groppe, K.; Mecucci, F. Genetic mapping of linkage group XIX and identification of sex-linked SSR markers in a Populus tremula× Populus tremuloides cross. Can. J. For. Res. 2011, 41, 245–253. [Google Scholar] [CrossRef]

- Rao, A.B.; Shaw, J.; Neophytoub, A.; Morphew, D. Leveraging Hierarchical Self-Assembly Pathways for Realizing Colloidal Photonic Crystals. ACS Nano 2020, 14, 5348–5359. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).