Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Design

2.3. Experimental Procedure

2.3.1. Preparation of Nano-SiO2-Modified Urea-formaldehyde Resin

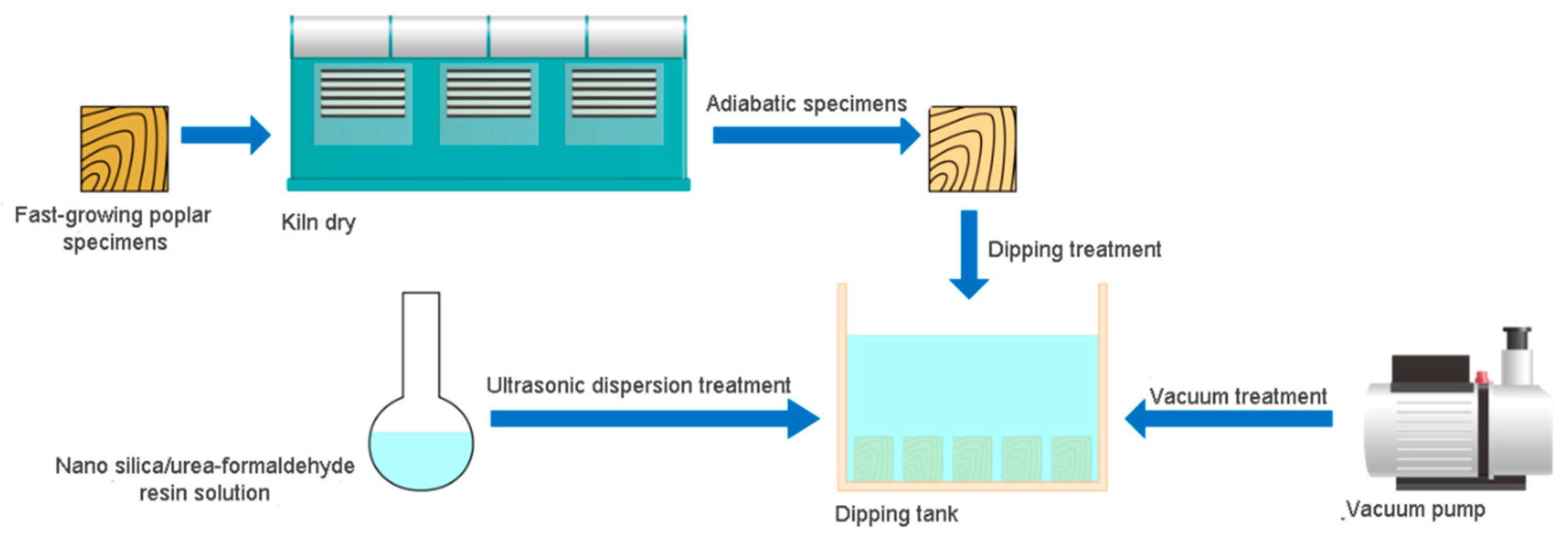

2.3.2. Preparation of Nano-SiO2/UF-Modified Fast-Growing Poplar Wood

2.4. Measurement and Characterization

2.4.1. Statistical Analysis

2.4.2. Hygroscopicity

2.4.3. Wet-Swelling Rate

2.4.4. Dry Shrinkage

2.4.5. Nail-Holding Power

2.4.6. Flexural Strength and Flexural Elastic Modulus

3. Results and Discussion

3.1. Effect of Impregnation Modification on the Physical Properties of Fast-Growing Poplar Wood

3.1.1. Hygroscopicity

3.1.2. Wet-Swelling Rate

3.1.3. Dry Shrinkage

3.2. Effect of Impregnation Modification on the Mechanical Properties of Fast-Growing Poplar Wood

3.2.1. Nail-Holding Power

3.2.2. Flexural Strength and Flexural Elastic Modulus

4. Conclusions

- According to the values of water absorption per unit time of poplar-impregnated treated wood and its simulation curve, the nano-SiO2 content has an effect on water absorption but does not play a decisive role; however, the impregnation treatment with urea-formaldehyde resin solution without the addition of other substances is beneficial in reducing the water absorption of wood, and the impregnation effect is good;

- Nano-SiO2/UF resin impregnation modification treatment can effectively reduce the wet-swelling rate of poplar fast-growing wood and enhance its dimensional stability. Compared with no nano-silica, that is, W = 0%, when the W was 1%, the tangential and volumetric wet-swelling rates of impregnated modified poplar specimens were minimized;

- According to the comparison between poplar-impregnated treated wood and material, the impregnation treatment increased the dry shrinkage of poplar to some extent, which caused the relative weakening of dimensional stability;

- The nano-SiO2/UF resin impregnation treatment modification can effectively improve the nail grip strength of poplar wood on all sides. The best modification effect of poplar wood was achieved when the urea-formaldehyde resin impregnating solution with W = 1% of nano-SiO2 was added when the grip strength of poplar wood was strongest on the diameter, chord, and end surfaces;

- The flexural strength and flexural modulus of poplar fast-growing wood were improved by impregnation with nano-SiO2/UF resin. The best modification effect of poplar wood was achieved by adding the urea-formaldehyde resin impregnation solution with W = 2% of nano-SiO2, and the bending strength and bending modulus of elasticity of impregnated wood were optimized;

- The addition and content of nano-SiO2 in urea-formaldehyde resin have different effects on different properties of specimens. In general, the urea-formaldehyde resin solution added with nano-silica has an effect on the physical properties of poplar specimens. However, compared with the urea-formaldehyde resin solution without nano-SiO2, that is, W = 0%, the addition of nano-SiO2 can effectively improve the mechanical properties of poplar wood specimens and increase its dimensional stability. The flexural strength and flexural elastic modulus improved with the increase in nano-SiO2 concentration.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, W. Technical conditions for modified wood for furniture national standards interpretation. Furniture 2020, 41, 105–110. [Google Scholar] [CrossRef]

- Liu, M.; Sun, D.; Zhang, Q.; Liu, D. Application of Fast-growing Fir on Office Furniture. Furnit. Inter. Des. 2015, 22, 24–25. [Google Scholar] [CrossRef]

- Mao, Y.; Xu, W. The Present Status and Its Prospect of Modifed Fast-growing Wood for Furniture and Wooden Products. Furnit. Inter. Des. 2019, 26, 13–15. [Google Scholar] [CrossRef]

- Ke, Q.; Yang, S.; Wang, J.; Wang, N.; Zhang, Y. Preliminary study on pivotal technology of furniture design based on modifies fast-growing poplar. China For. Prod. Ind. 2015, 42, 8–10+14. [Google Scholar] [CrossRef]

- Chen, G.; Gao, Z.; Ma, H.; Wang, C. Investigation and characterization on synthesis of Nano-CaCO3 and Composite with Fast-Growing Poplar. J. Northeast For. Univ. 2013, 41, 108–111+139. [Google Scholar] [CrossRef]

- Li, R.; Pei, W.; Tian, Y.; Meng, F. Nano-silica/urea-formaldehyde resin modified fast-growing fir wood surface finishing performance study. For. Mach. Woodwork Equip. 2019, 47, 32–35. [Google Scholar] [CrossRef]

- Liu, M.; Tang, Q.; Fu, Y.; Wei, P. Effect of high-temperature heat treatment on the mechanical processing properties of Sargassum pine wood. J. Northeast For. Univ. 2021, 49, 95–99. [Google Scholar] [CrossRef]

- Lu, Q.; Li, J.; Zeng, X.; Jiang, H.; Li, X.; Liu, Z.; Li, M. Study on densification of oil palm wood and its dimensional stability. Chin. J. Trop. Crops 2019, 20, 2211–2216. [Google Scholar] [CrossRef]

- Hou, R.; Li, X.; Liu, Y.; Liao, R.; Xu, K.; Hu, J.; Wang, C.; Wang, Y.; Cheng, X.; Wang, C. Effect of impregnation enhancement-heat treatment on mechanical properties of plantation poplar. J. Cent. South Univ. For. Technol. 2016, 36, 125–129. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, T. Effect of vacuum impregnation on mechanical properties of fast-growing poplar. J. Northeast For. Univ. 2019, 47, 53–56. [Google Scholar] [CrossRef]

- Wei, X.; Tao, D.; Sheng, X.; Zhang, M. Modification of Poplar Wood Using Polyhexahydrotriazine and Its Effect on Hygroscopicity. J. Wood Chem. Technol. 2018, 38, 214–233. [Google Scholar] [CrossRef]

- Altun, S.; Tokdemir, V. Modification with melamine formaldehyde and melamine-urea formaldehyde resin to improve the physical and mechanical properties of wood. BioResources 2017, 12, 586–596. [Google Scholar] [CrossRef]

- Ying, Q.; Tang, H.; Zhu, M.; Luo, D.; Li, Z. Phenolic resin compostie impregnation to strengthen and modify fast-growing wood. Thermosetting Resin 2021, 36, 48–52+58. [Google Scholar] [CrossRef]

- Chai, Y.; Liu, J.; Sun, B.; Lv, W. Dimensional stability, mechanical properties and combustion performance of poplar wood modified with a mixture of MUF/Boric Acid/Borax. Chian Woodind. 2015, 29, 5–9. [Google Scholar] [CrossRef]

- Cao, S.; Cai, J.; Wu, M.; Zhou, N.; Huang, Z.; Cai, L.; Zhang, Y. Surface properties of poplar wood after heat treatment, resin impregnation, or both modifications. BioResources 2021, 16, 7562–7577. [Google Scholar] [CrossRef]

- Hou, R.; Li, H.; Liu, Y.; Qiao, J.; Hu, J.; Cheng, X.; Li, Y. Study on impregnation technology by using UF resin for fast-grown poplar wood. J. Cent. South Univ. For. Technol. 2015, 35, 122–125. [Google Scholar] [CrossRef]

- Shi, J.; Li, J.; Zhou, W.; Zhang, D. Improvement of wood properties by urea-formaldehyde resin and nano- SiO2. Front. For. China 2007, 2, 104–109. [Google Scholar] [CrossRef]

- Tao, X.; Chen, L.; Xu, W.; Chen, C.; Tang, X. Study on mechanical properties of Nano-TiO2 impregneated modified poplar wood. For. Grassl. Mach. 2019, 30, 21–23+29. [Google Scholar] [CrossRef]

- Shen, D.; Zhou, C. Physical and Mechanical Properties of Poplar Wood Modified with Nanometer Hybrid Materia. J. Northeast For. Univ. 2009, 3, 53–54. [Google Scholar] [CrossRef]

- Lie, G.; Tang, Z.; Lie, G.; Yang, T.; Tang, X. Measure of the optical and electrical properties of semiconductor SiO2 Nano–Crystalline by using photo–acoustic technology. Adv. Mater. Res. 2011, 415, 2156–2159. [Google Scholar] [CrossRef]

- Li, X.; Cao, Z.; Zhang, Z.; Dang, H. Surface–modification in situ of Nano-SiO2 and its structure and tribological properties. Appl. Surf. Sci. 2006, 22, 7856–7861. [Google Scholar] [CrossRef]

- Dmitriev, I.A.; Podkovyrkin, M.I.; Kleshcheva, T.M.; Beloborodova, L.G.; Solov’eva, N.G.; Voronova, N.L. Modified Al2O3–based ceramic. Glass Ceram. 1990, 47, 27–29. [Google Scholar] [CrossRef]

- Mazahery, A.; Ostadshabani, M. Investigation on mechanical properties of nano–Al2O3–reinforced aluminum matrix composites. J. Compos. Mater. 2011, 45, 2579–2586. [Google Scholar] [CrossRef]

- Javed, M.A.; Kekkonen, P.M.; Ahola, S.; Teikko, V.V. Magnetic resonance imaging study of water absorption in thermally modified pine wood. Holzforschung 2015, 69, 899–907. [Google Scholar] [CrossRef]

- Kekkonen, P.M.; Ylisassi, A.; Telkki, V.V. Absorption of Water in Thermally Modified Pine Wood As Studied by Nuclear Magnetic Resonance. J. Phys. Chem. 2014, 118, 2146–2153. [Google Scholar] [CrossRef]

- GB/T 1934.1-2009; Method for Determination of the Water Absorption of Wood. Standard Press: Beijing, China, 2009.

- GB/T 14018-2009; Method of Testing Nail Holding Power of Wood. Standard Press: Beijing, China, 2009.

- Chen, E.; Fei, B.; Guo, W. Review of nail withdrawal strength in wood constrection. For. Grassl. Mach. 2008, 3, 38–43. [Google Scholar] [CrossRef]

- YB/T 5002-2017; Round Nails for General Purpose. Standard Press: Beijing, China, 2017.

- Luo, B.; Yin, Y.; Jiang, X.; Luo, X.; Liu, B.; Guo, Q. Evaluating bending and compressive strength properties of Eucalyptus Grandia × E. urophylla plantation wood with three nondestructive methods. J. Beijing For. Univ. 2008, 6, 137–140. [Google Scholar] [CrossRef]

- Ke, B.; Wang, Y. A study on the determming methos of bendings strength and elasticity. J. Anhui Agric. Univ. 1989, 16, 12. [Google Scholar] [CrossRef]

- Zhang, F.; Li, L.; Zhang, L.; Xu, Z. Study of the determination of the elastic constants and mechanical property parameters of five kinds of wood commonly used in furniture. For. Mach. Woodwork. Equip. 2012, 1, 16–19. [Google Scholar]

- Moradpour, P.; Behnia, M.; Pirayesh, H.; Shirmohammadli, Y. The effect of resin type and strand thickness on applied properties of poplar parallel strand lumber made from underutilized species. Eur. J. Wood Wood Prod. 2019, 77, 811–819. [Google Scholar] [CrossRef]

- Yang, L.; Liu, H.-H. Effect of a Combination of Moderate-Temperature Heat Treatment and Subsequent Wax Impregnation on Wood Hygroscopicity, Dimensional Stability, and Mechanical Properties. Forests 2020, 11, 920. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, X.; Xu, M.; Rodrigue, D. Properties of poplar fiber/pla composites: Comparison on the effect of maleic anhydride and kh550 modification of poplar fiber. Polymers 2020, 12, 729. [Google Scholar] [CrossRef] [PubMed]

| Urea-Formaldehyde Resin Solution Information | Solid Content | Relative Molecular Weight | PH Value | Viscosity | Free Formaldehyde Content |

|---|---|---|---|---|---|

| numerical | 49.1% | 300–500 | 7.0–9.5 | ≥20 mPa·s | 0.19% |

| Water Absorption (%) | y = a + blnx | R2 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 d | 1 d | 2 d | 4 d | 8 d | 13 d | 15 d | |||

| Material | 52 | 97 | 113 | 124 | 141 | 161 | 165 | y = 0.26413ln(x) + 0.91779 | 0.98891 |

| W = 0% | 35 | 65 | 77 | 83 | 87 | 93 | 95 | y = 0.13603ln(x) + 0.60703 | 0.94223 |

| W = 1% | 34 | 63 | 76 | 81 | 86 | 91 | 93 | y = 0.13459ln(x) + 0.59401 | 0.94563 |

| W = 2% | 32 | 63 | 75 | 81 | 86 | 92 | 95 | y = 0.14115ln(x) + 0.59637 | 0.94233 |

| From Full Dryness to Water Absorption Saturation Wet Swelling (%) | From Full Dry to Air Dry Wet-Swelling Rate (%) | |||||

|---|---|---|---|---|---|---|

| Radial | Tangential | Volume | Radial | Tangential | Volume | |

| Material | 5.9 | 7.2 | 14.3 | 1.5 | 1.8 | 3.6 |

| W = 0% | 2.7 | 5.1 | 8.2 | 1.1 | 1.6 | 3.1 |

| W = 1% | 3.1 | 4 | 7.1 | 1.1 | 1.3 | 2.7 |

| W = 2% | 3.4 | 4.2 | 7.5 | 1.2 | 1.2 | 2.7 |

| Full Dry Shrinkage Rate (%) | Air-Drying Shrinkage Rate (%) | Air-Dried Moisture Content | |||||

|---|---|---|---|---|---|---|---|

| Radial | Tangential | Volume | Radial | Tangential | Volume | ||

| Material | 5.4 | 6.4 | 11.8 | 2.9 | 3.7 | 6.4 | 13.27% |

| W = 0% | 5.4 | 8.5 | 13.7 | 2.8 | 5.2 | 8 | 12.81% |

| W = 1% | 5.8 | 7.1 | 12.7 | 3.3 | 4.1 | 7 | 12.86% |

| W = 2% | 5.8 | 6.9 | 12.6 | 3.3 | 4 | 7 | 13.27% |

| The Moisture Content in the Test | Nail-Holding Power (N/mm) | |||

|---|---|---|---|---|

| Radial | Tangential | Transection | ||

| Material | 9.4 | 16.8 | 18.8 | 8.3 |

| W = 0% | 11.3 | 22.5 | 25.9 | 15.1 |

| W = 1% | 11.9 | 28.5 | 31.9 | 18.4 |

| W = 2% | 11.3 | 26.6 | 30.5 | 18.5 |

| ρ (g/cm3) | w (%) | MOR (MPa) | MOE (MPa) | |||

|---|---|---|---|---|---|---|

| w | 12% | w | 12% | |||

| Material | 0.446 | 10.5 | 62.6 | 58.9 | 7142 | 6986 |

| W = 0% | 0.52 | 12.9 | 87.6 | 90.8 | 9134 | 9262 |

| W = 1% | 0.534 | 12.9 | 89.3 | 92.6 | 9544 | 9677 |

| W = 2% | 0.594 | 11.1 | 96.4 | 93.1 | 10,152 | 10,019 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, M.; Zhu, Y.; Mao, W.; Zhou, J.; Xu, W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests 2023, 14, 1440. https://doi.org/10.3390/f14071440

Weng M, Zhu Y, Mao W, Zhou J, Xu W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests. 2023; 14(7):1440. https://doi.org/10.3390/f14071440

Chicago/Turabian StyleWeng, Mengyun, Yetong Zhu, Weiguo Mao, Jichun Zhou, and Wei Xu. 2023. "Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study" Forests 14, no. 7: 1440. https://doi.org/10.3390/f14071440

APA StyleWeng, M., Zhu, Y., Mao, W., Zhou, J., & Xu, W. (2023). Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests, 14(7), 1440. https://doi.org/10.3390/f14071440