Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Classification of Production Models

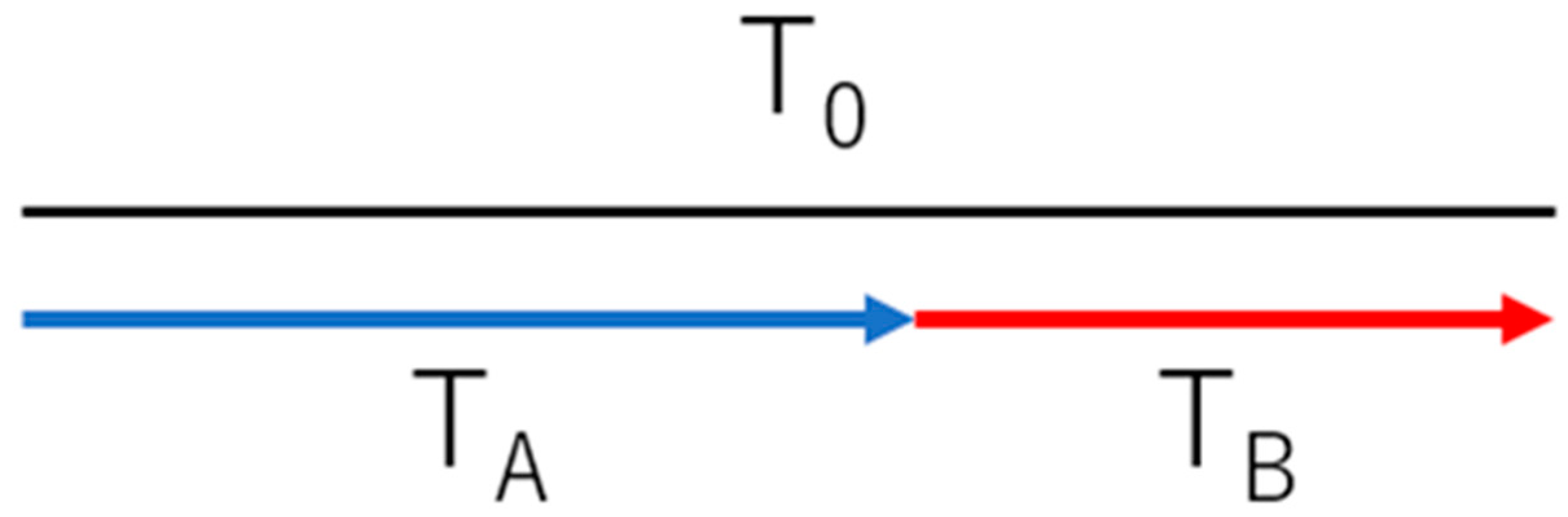

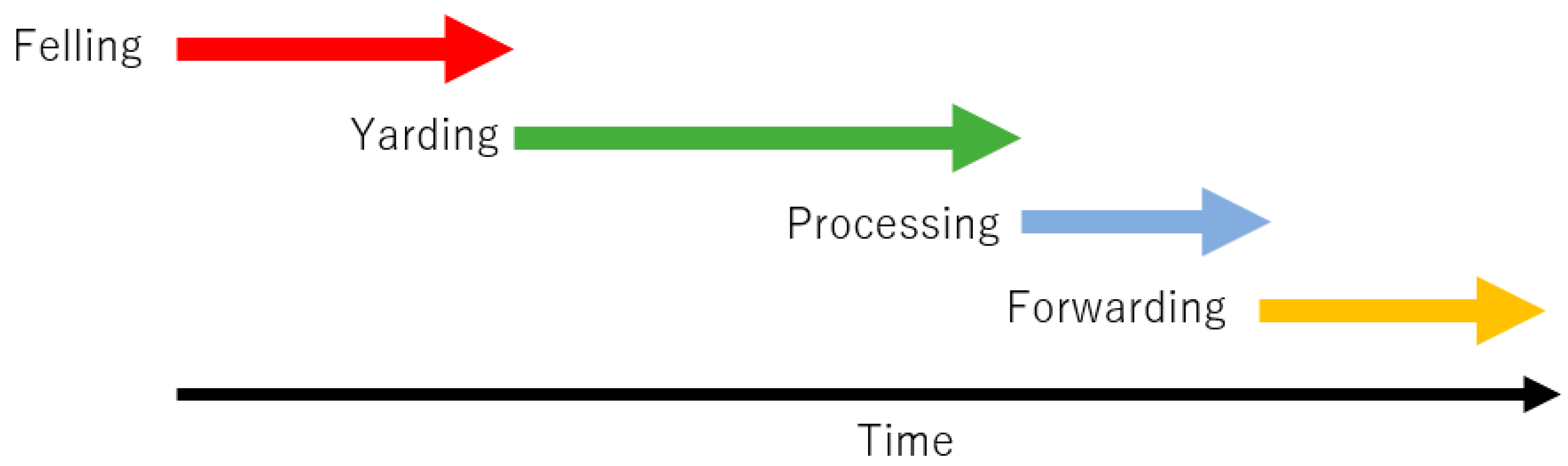

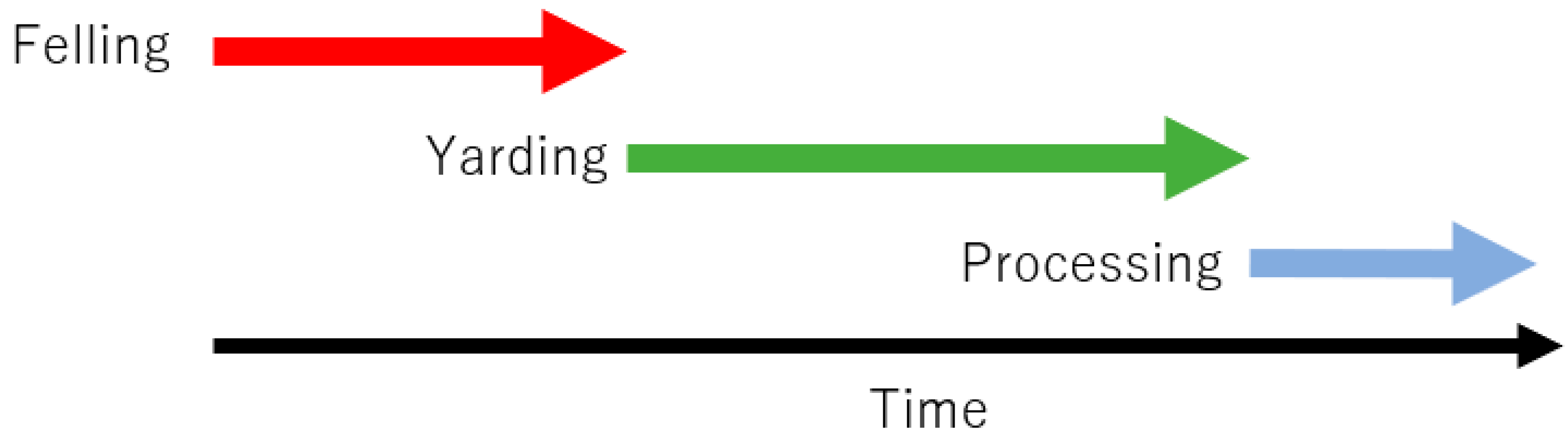

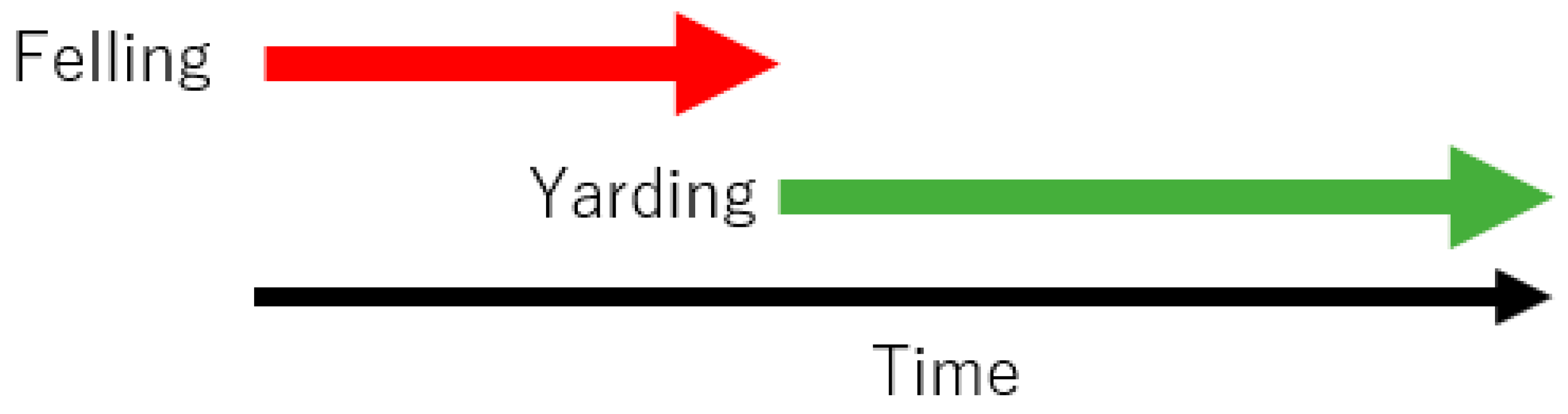

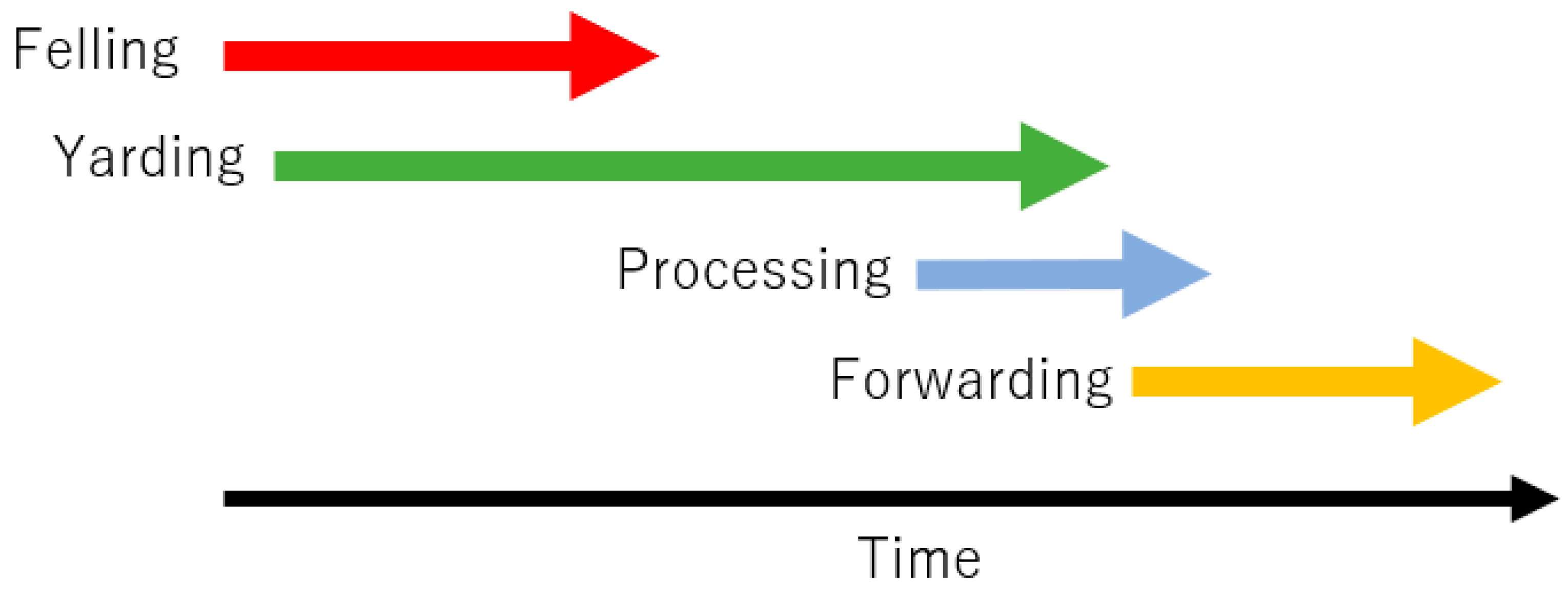

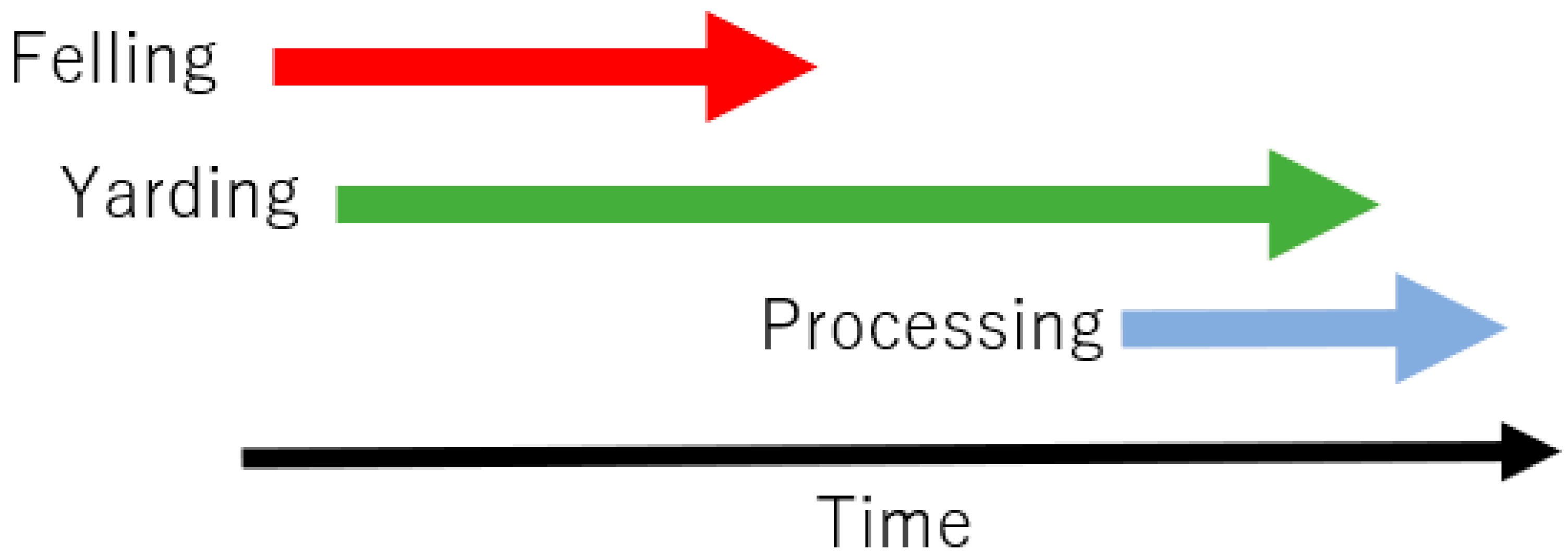

2.1.1. Serial Production System

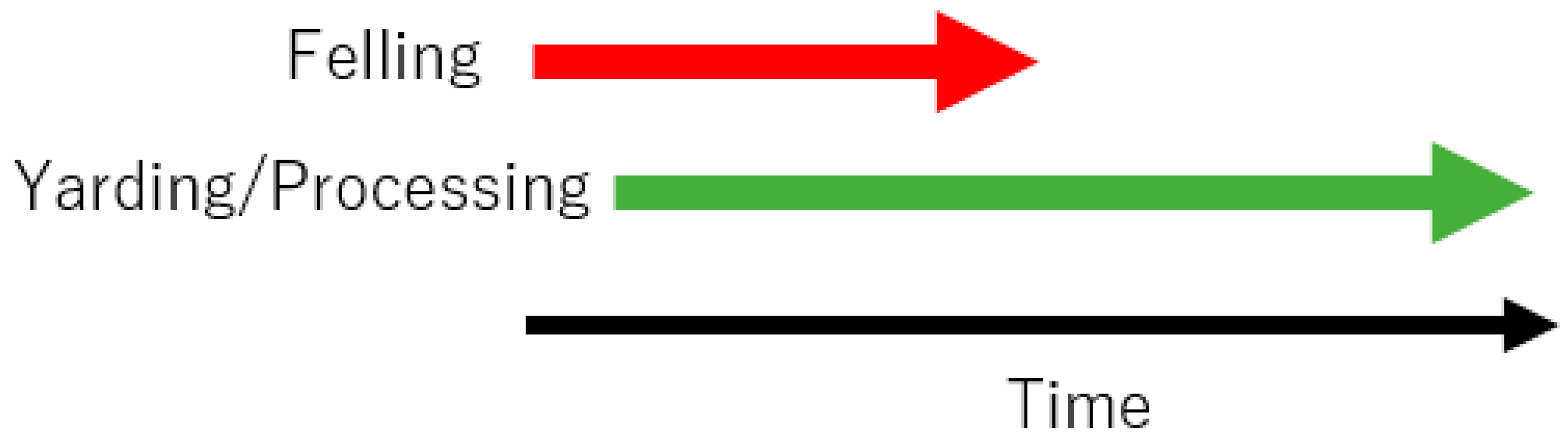

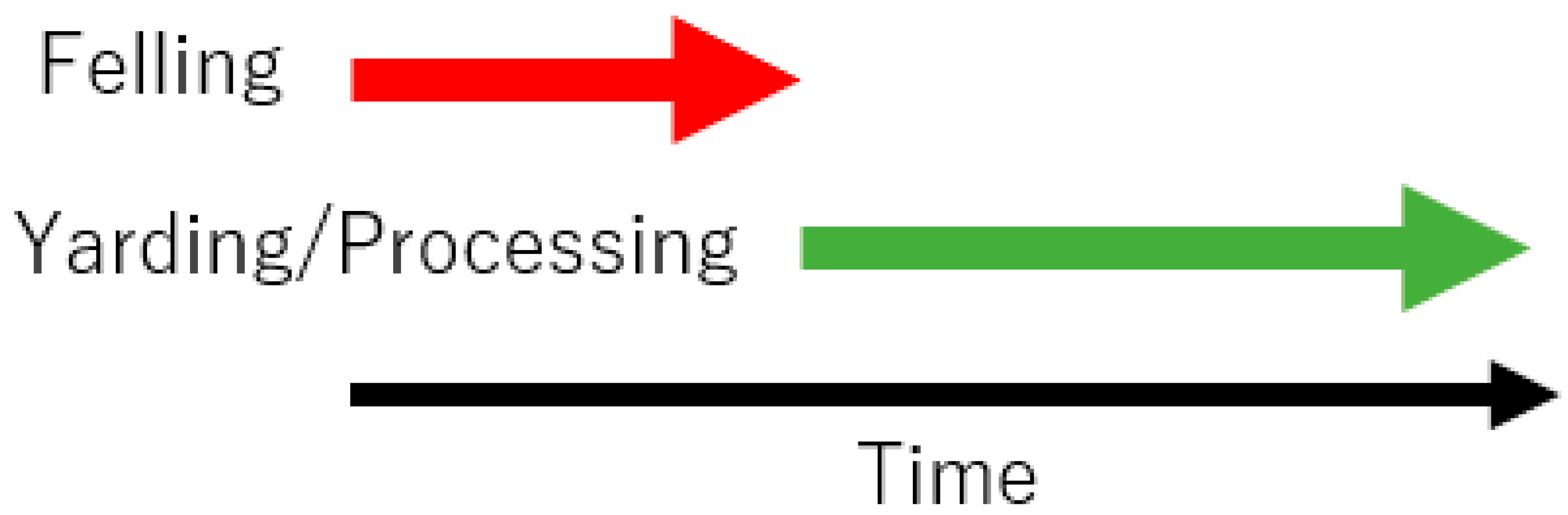

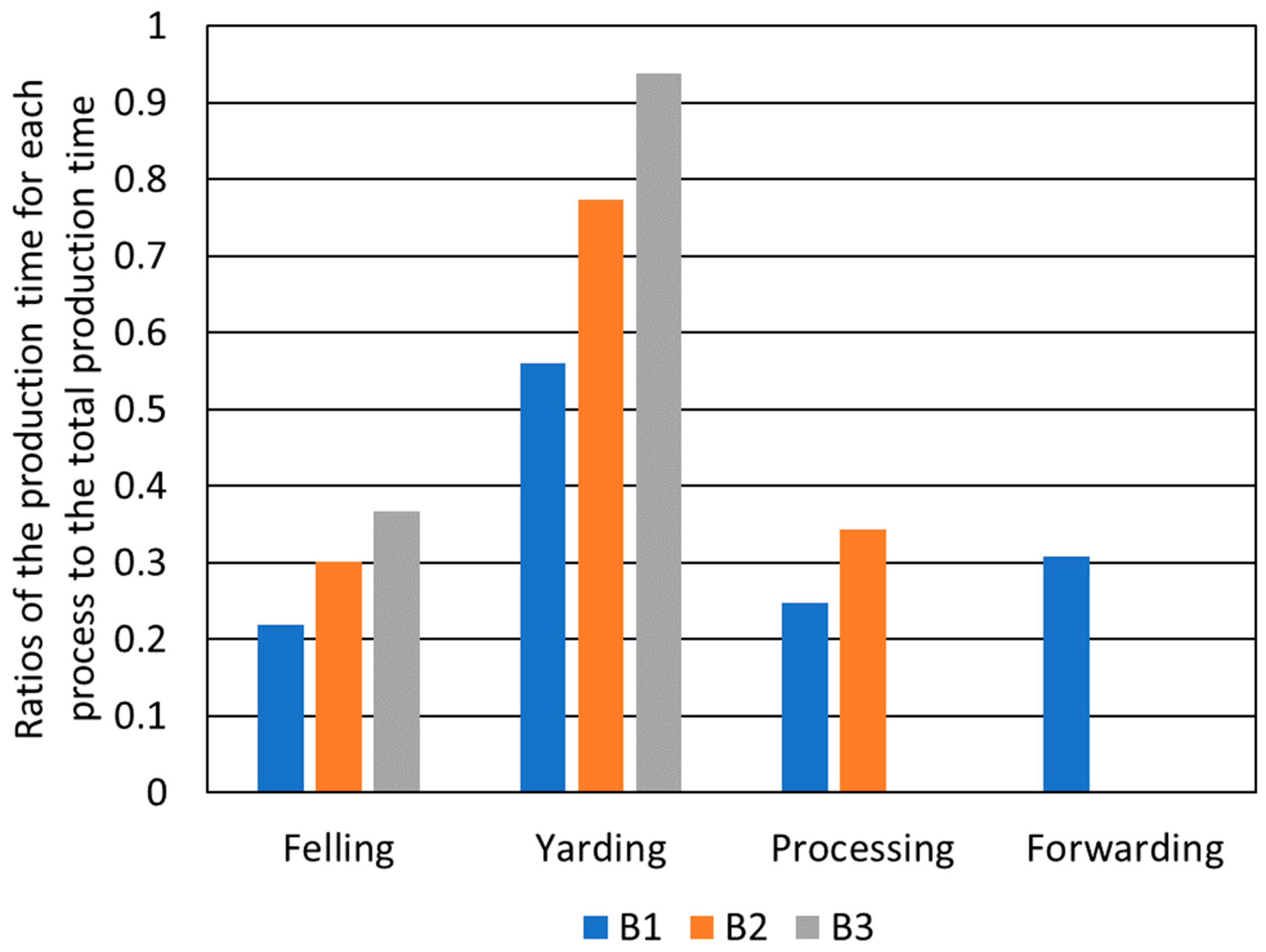

2.1.2. Parallel Production System

2.2. Combined Machine Productivity

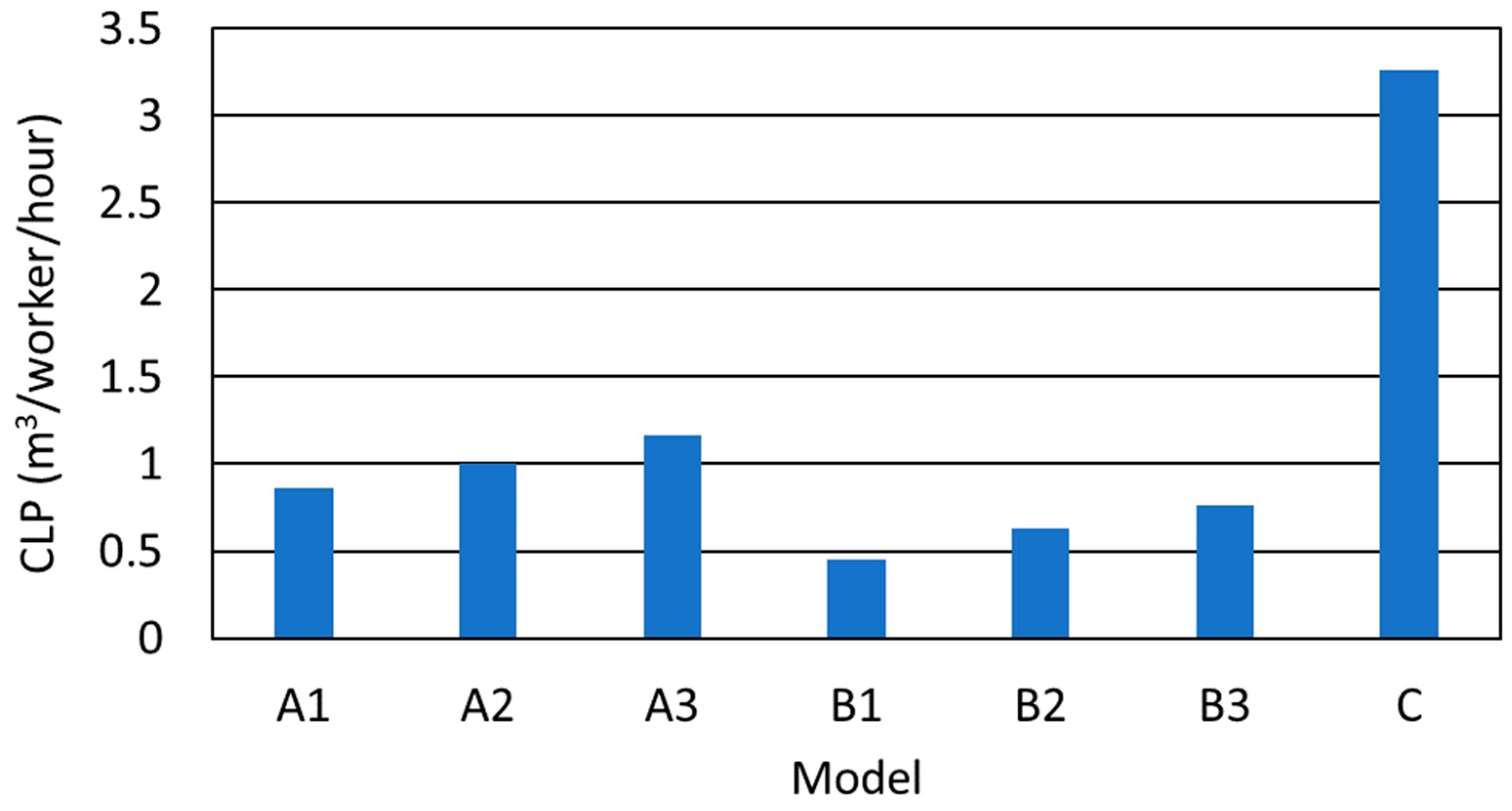

2.3. Combined labor Productivity

2.4. Productivity Assessment

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liski, E.; Jounela, P.; Korpunen, H.; Sosa, A.; Lindroos, O.; Jylhä, P. Modeling the productivity of mechanized CTL harvesting with statistical machine learning methods. Int. J. For. Eng. 2020, 31, 253–262. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Visser, R. Productivity models for cable yarding in Alpine forests. Eur. J. For. Eng. 2015, 1, 9–14. Available online: https://dergipark.org.tr/en/pub/ejfe/issue/5186/70454 (accessed on 10 February 2023).

- Varch, T.; Erber, G.; Spinelli, R.; Magagnotti, N.; Stampfer, K. Productivity, fuel consumption and cost in whole tree cable yarding: Conventional diesel carriage versus electrical energy-recuperating carriage. Int. J. For. Eng. 2021, 32, 20–30. [Google Scholar] [CrossRef]

- Böhm, S.; Kanzian, C. A review on cable yarding operation performance and its assessment. Int. J. For. Eng. 2022, 34, 229–253. [Google Scholar] [CrossRef]

- Cavalli, R. Prospects of research on cable logging in forest engineering community. Croat. J. For. Eng. 2012, 33, 339–356. Available online: https://hrcak.srce.hr/en/116850 (accessed on 7 February 2023).

- Ghaffariyan, M.R.; Stampfer, K.; Sessions, J. Production equations for tower yarders in Austria. Int. J. For. Eng. 2009, 20, 17–21. [Google Scholar] [CrossRef]

- Stampfer, K.; Visser, R.; Kanzian, C. Cable corridor installation times for European yarders. Int. J. For. Eng. 2006, 17, 71–77. [Google Scholar] [CrossRef]

- Heinimann, H.R.; Stampfer, K.; Loschek, J.; Caminada, L. Perspectives on Central European cable yarding systems. In Proceedings of the International Mountain Logging 11th Pacific Northwest Skyline Symposium, Seattle, WA, USA, 10–12 December 2001; Available online: https://depts.washington.edu/sky2001/proceedings/papers/Heinimann.pdf (accessed on 10 February 2023).

- Holzfeind, T.; Kanzian, C.; Gronalt, M. Challenging agent-based simulation for forest operations to optimize the European cable yarding and transport supply chain. Int. J. For. Eng. 2021, 32, 77–90. [Google Scholar] [CrossRef]

- Hara, Y.; Sakagoshi, H. Survey and analysis of exploitation thinning in Shimane Prefecture. Bull. Shimane Pref. Mount. Reg. Res. Ctr. 2007, 3, 21–26. Available online: https://www.pref.shimane.lg.jp/admin/region/kikan/chusankan/syoseki/research/No3_kenkyuhoukoku.data/kenkyuhoukokudai3gou04.pdf (accessed on 9 February 2023). (In Japanese with English Summary).

- Yoshimura, T.; Noba, T. Productivity analysis of thinning operations using a swing yarder on steep slopes in western Japan. In Proceedings of the IUFRO Unit 3.06 International Conference Forest Operations in Mountainous Conditions, Honne, Norway, 2–5 June 2013. [Google Scholar]

- Nakazawa, M.; Yoshida, C.; Sasaki, T.; Taki, S.; Uemura, T.; Ito, T.; Yamaguchi, H.; Mozuna, M.; Usui, K.; Inomata, Y.; et al. Productivity of logging large diameter logs and long logs during final cutting in a mountain forest in Japan. Int. J. For. Eng. 2019, 30, 203–209. [Google Scholar] [CrossRef]

- Kameyama, S.; Suzuki, R.; Yoshioka, T.; Inoue, K. Productivity and economic balance in the plantation forest behind thinning: A case study of Mishima city, Shizuoka. J. Jpn. For. Eng. Soc. 2017, 32, 137–142. (In Japanese) [Google Scholar] [CrossRef]

- Forestry Agency. Annual report on forest and forestry in Japan (Fiscal Year 2021); Forestry Agency: Tokyo, Japan, 2022; p. 207. Available online: https://www.rinya.maff.go.jp/j/kikaku/hakusyo/r3hakusyo/attach/pdf/zenbun-34.pdf (accessed on 9 February 2023). (In Japanese)

- Picchio, R.; Venanzi, R.; Di Marzio, N.; Tocci, D.; Tavankar, F. A comparative analysis of two cable yarder technologies performing thinning operations on a 33 year old pine plantation: A potential source of wood for energy. Energies 2020, 13, 5376. [Google Scholar] [CrossRef]

- Heinimann, H. Operational Productivity Studies in Forestry Based on Statistical Models—A Tutorial; Inst. Terrestrial Ecosystems Forest Engineering: Zurich, Switzerland, 2021; p. 56. [Google Scholar] [CrossRef]

- Talbot, B.; Stampfer, K.; Visser, R. Machine function integration and its effect on the performance of a timber yarding and processing operation. Biosyst. Eng. 2015, 135, 10–20. [Google Scholar] [CrossRef]

- Heinimann, H.R.; Visser, R.; Stampfer, K. Harvester-cable yarder system evaluation on slopes: A Central European study in thinning operations. In Proceedings of the Harvesting Logistics: From Woods to Markets, Portland, OR, USA, 20–23 July 1998; Available online: https://cofe.org/wp-content/uploads/2013/08/COFE_1998.pdf (accessed on 10 February 2023).

- Stampfer, K. (1999) Influence of terrain conditions and thinning regimes on productivity of a track-based steep slope harvester. In Proceedings of the International Mountain Logging 10th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 28 March–1 April 1999. [Google Scholar]

- Stampfer, K.; Steinmüller, T. A new approach to derive a productivity model for the harvester “Valmet 911 Snake”. In Proceedings of the International Mountain Logging 11th Pacific Northwest Skyline Symposium, Seattle, WA, USA, 10–12 December 2001; Available online: https://depts.washington.edu/sky2001/proceedings/papers/Stampfer.pdf (accessed on 10 February 2023).

- Bogo, A.; Cavalli, R. Productivity of a Tracked Excavator-Based Processor in the North-Eastern Italian Alps. Austro 2003: High Tech Forest Operations for Mountainous Terrain 2003. Available online: https://www.formec.org/images/proceedings/2003/45_bogo_cavalli.pdf (accessed on 7 February 2023).

- Affenzeller, G.; Stampfer, K. Comparison of integrated with conventional harvester-forwarder-concepts in thinning operations. In Proceedings of the International Mountain Logging 13th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 1–6 April 2007; Available online: https://www.iufro.org/download/file/4702/4504/30000-mountain-logging-symp07_p_pdf/ (accessed on 10 February 2023).

- Rottensteiner, C.; Affenzeller, G.; Stampfer, K. Evaluation of the feller-buncher Moipu 400E for energy wood harvesting. Croat. J. For. Eng. 2008, 29, 117–128. Available online: https://hrcak.srce.hr/en/32188 (accessed on 10 February 2023).

- Erber, G.; Holzleitner, F.; Kastner, M.; Stampfer, K. Effect of multi-tree handling and tree-size on harvester performance in small-diameter hardwood thinnings. Silva Fenn. 2016, 50, 1428. [Google Scholar] [CrossRef] [Green Version]

- Huber, C.; Kroisleitner, H.; Stampfer, K. Performance of a mobile star screen to improve woodchip quality of forest residues. Forests 2017, 8, 171. [Google Scholar] [CrossRef] [Green Version]

- Holzfeind, T.; Stampfer, K.; Holzleitner, F. Productivity, setup time and costs of a winch-assisted forwarder. J. For. Res. 2018, 23, 196–203. [Google Scholar] [CrossRef]

- Cadei, A.; Mologni, O.; Roser, D.; Cavalli, R.; Grigolato, S. Forwarder productivity in salvage logging operations in difficult terrain. Forests 2020, 11, 341. [Google Scholar] [CrossRef] [Green Version]

- Papandrea, S.F.; Stoilov, S.; Angelov, G.; Panicharova, T.; Mederski, P.S.; Proto, A.R. Modeling productivity and estimating costs of processor tower yarder in shelterwood cutting of pine stand. Forests 2023, 14, 195. [Google Scholar] [CrossRef]

- Borz, S.A.; Bîrda, M.; Ignea, G.H.; Popa, B.; Câmpu, V.R.; Iordache, E.; Derczeni, R.A. Efficiency of a Woody 60 processor attached to a Mounty 4100 tower yarder when processing coniferous timber from thinning operations. Ann. For. Res. 2014, 57, 333–345. [Google Scholar] [CrossRef] [Green Version]

- Aruga, K.; Yamada, T.; Yamamoto, T. Comparative analyses of the cycle time, productivity, and cost between 62- and 107-year-old Japanese cypress clear-cutting operations using a small-scale cable logging system. Small-Scale For. 2019, 18, 279–289. [Google Scholar] [CrossRef]

- Nakahata, C.; Aruga, K.; Saito, M.; Hayashi, U. Productivity and cost of clear-cutting and regeneration operations with small and medium-sized forestry machines in Utsunomiya city, Tochigi Prefecture, Japan. Small-Scale For. 2020, 19, 275–289. [Google Scholar] [CrossRef]

- Oka, M. Selection of harvesting systems. In Management of Mechanization for How to Utilize High-Efficient Forestry Machines to Increase Local Profitability; Zenrinkyo, Ed.; Zenrinkyo: Tokyo, Japan, 2001; pp. 105–123. (In Japanese) [Google Scholar]

- Sessions, J.; Berry, M.; Han, H.-S. Machine rate estimates and equipment utilization—A modified approach. Croat. J. For. Eng. 2021, 42, 437–443. [Google Scholar] [CrossRef]

- Kanzaki, K. Think much of the labor productivity on the logging system with the help of high efficient forestry machines. J. For. Mechanization Soc. 1999, 547, 6–11. (In Japanese) [Google Scholar]

- Sawaguchi, I.; Sasaki, S.; Tsuchiya, Y.; Tatsukawa, S. Labor productivity of line thinning with a mini swing-yarder. Bull. Iwate Univ. For. 2004, 35, 47–57, (In Japanese with English Summary). [Google Scholar]

- Goto, M. Systematic productivity of thinning timber harvesting in Tokushima Prefecture. Appl. For. Sci. 2005, 101–105. (In Japanese) [Google Scholar]

- Nakazawa, M.; Imatomi, Y.; Oka, M.; Tanaka, Y.; Yoshida, C.; Uemura, T.; Yamaguchi, H.; Suzuki, H.; Umeda, S.; Takahashi, M.; et al. Development of thinning system using excavator with long-reach grapple-Productivity and cost of the system. J. Jpn. For. Eng. Soc. 2011, 26, 173–180, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Nakazawa, M.; Yoshida, C.; Sasaki, T.; Uemura, T.; Suzuki, H.; Jinkawa, M.; Kondo, M.; Oya, S.; Toda, K.; Takano, T. Development of a thinning system with a small wheel mounted harvester and forwarder-Productivities of ordinary and line thinning. J. Jpn. For. Eng. Soc. 2013, 28, 187–192, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Oya, S.; Saito, M.; Shirota, T.; Otsuka, D.; Miyazaki, T.; Yanagisawa, N.; Kobayashi, N. The productivity of one continuous clearcutting and reforestation operation with the vehicle logging system on moderate slopes in Nagano Prefecture. J. Jpn. For. Soc. 2016, 98, 233–240, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Katagiri, T. Comparative study of production cost for clear cutting between the vehicle logging system and cable logging system in Okayama Prefecture. J. Jpn. For. Eng. Soc. 2018, 33, 37–45. (In Japanese) [Google Scholar] [CrossRef]

- Yamasaki, S.; Yamasaki, T.; Suzuki, Y.; Mitani, Y.; Morimoto, M.; Nagasawa, Y. A verification study of a spur road improvement project on harvesting operational efficiency and total cost reduction. J. Jpn. For. Eng. Soc. 2018, 33, 25–35, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Hirayama, K.; Nozue, N.; Hakamata, T.; Nakazawa, M.; Sasaki, T.; Yoshida, C. Labor productivity of full tree and tree length logging system using a self-propelled carriage introduced from Europe. J. Jpn. For. Eng. Soc. 2019, 34, 141–144, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Kimura, S.; Sasaki, S.; Hoshikawa, T. Work efficiency at the clear cutting site using daily work reports. Chubu For. Res. 2020, 68, 59–60. (In Japanese) [Google Scholar] [CrossRef]

- Watai, J.; Kondo, K. The labor productivity of a thinning operation system according to forest-road density-Study of an operation system using a swing yarder and processor. Bull. Shizuoka Res. Inst. Agric. For. 2012, 5, 53–58. Available online: https://agriknowledge.affrc.go.jp/RN/2010831114 (accessed on 20 March 2023). (In Japanese with English Summary).

- Katagiri, T. Productivity of the felling-yarding alternate system using a swing-yarder-Combination of the felling-yarding alternate system and bucking, improvement of the felling-yarding alternate system. Bull. Okayama Pref. Tech. Ctr. Agric. For. Fish. Res. Inst. For. For. Prod. 2016, 31, 1–7. Available online: https://agriknowledge.affrc.go.jp/RN/2010921501 (accessed on 20 March 2023). (In Japanese).

- Miyazaki, T.; Imai, M.; Shiraishi, R. Development of forest operation systems using high-efficient forestry machines. Bull. Nagano Pref. For. Res. Ctr. 2011, 25, 1–7. Available online: https://agriknowledge.affrc.go.jp/RN/2010900102 (accessed on 20 March 2023). (In Japanese).

- Schweier, J.; Ludowicy, C. Comparison of a cable-based and a ground-based system in flat and soil-sensitive area: A case study from southern Baden in Germany. Forests 2020, 11, 611. [Google Scholar] [CrossRef]

- Sakai, H. Seminar on Forestry Production Techniques for Practical Management-Logging, Road Networks and Supply Chain; Zenrinkyo: Tokyo, Japan, 2012; p. 349. (In Japanese) [Google Scholar]

- Schweier, J.; Klein, M.-L.; Kirsten, H.; Jaeger, D.; Brieger, F.; Sauter, U.H. Productivity and cost analysis of tower yarder systems using the Koller 507 and the Valentini 400 in southwest Germany. Int. J. For. Eng. 2020, 31, 172–183. [Google Scholar] [CrossRef]

- Borz, S.A.; Secelean, V.-N.; Iacob, L.-M.; Kaakkurivaara, N. Bucking at landing by a single-grip harvester: Fuel consumption, productivity, cost and recovery rate. Forests 2023, 14, 465. [Google Scholar] [CrossRef]

- Committee for improving productivity in forestry enterprises. In Guide to Productivity Improvement for Establishing a High Productivity Forestry Industry; Forestry Agency: Tokyo, Japan, 2022; p. 108. Available online: https://www.rinya.maff.go.jp/j/gyoumu/gijutu/attach/pdf/torikumi-11.pdf (accessed on 3 July 2023). (In Japanese)

- Ackerman, S.A.; McDermid, H.; Ackerman, P.; Terblanche, M. The effectiveness of a small-scale combination harvester/forwarder in industrial plantation first thinning operations. Int. J. For. Eng. 2022, 33, 56–65. [Google Scholar] [CrossRef]

- Ackerman, P.; Martin, C.; Brewer, J.; Ackerman, S. Effect of slope on productivity and cost of Eucalyptus pulpwood harvesting using single-grip purpose-built and excavator-based harvesters. Int. J. For. Eng. 2018, 29, 74–82. [Google Scholar] [CrossRef]

- Strandgard, M.; Alam, M.; Mitchell, R. Impact of slope on productivity of a self-levelling processor. Croat. J. For. Eng. 2014, 35, 193–200. Available online: https://hrcak.srce.hr/en/clanak/187578 (accessed on 12 February 2023).

- Borz, S.A.; Marcu, M.V.; Cataldo, M.F. Evaluation of an HSM 208F 14tone HVT-R2 forwarder prototype under conditions of steep-terrain low-access forests. Croat. J. For. Eng. 2021, 42, 185–200. [Google Scholar] [CrossRef]

- Berendt, F.; Tolosana, E.; Hoffmann, S.; Alonso, P.; Schweier, J. Harvester productivity in inclined terrain with extended machine operating trail intervals: A German case study comparison of standing and bunched trees. Sustainability 2020, 12, 9168. [Google Scholar] [CrossRef]

- Holzfeind, T.; Visser, R.; Chung, W.; Holzleitner, F.; Erber, G. Development and benefits of winch-assist harvesting. Curr. For. Rep. 2020, 6, 201–209. [Google Scholar] [CrossRef]

- Visser, R.M.; Spinelli, R. Benefits and limitations of winch-assist technology for skidding operations. Forests 2023, 14, 296. [Google Scholar] [CrossRef]

- Wester, F.; Eliasson, L. Productivity in final felling and thinning for a combined harvester-forwarder (harwarder). Int. J. For. Eng. 2003, 14, 45–51. [Google Scholar] [CrossRef]

- Laitila, J.; Asikainen, A. Energy wood logging from early thinnings by harwarder method. Baltic For. 2006, 12, 94–102. Available online: https://balticforestry.lammc.lt/bf/PDF_Articles/2006-12[1]/94_102%20Juha%20Laitila%20&%20Asikainen.pdf (accessed on 22 February 2023).

- Karha, K.; Poikela, A.; Palander, T. Productivity and costs of harwarder systems in industrial roundwood thinnings. Croat. J. For. Eng. 2018, 39, 23–33. Available online: https://hrcak.srce.hr/en/clanak/285567 (accessed on 11 February 2023).

- Jonsson, R.; Rönnqvist, M.; Flisberg, P.; Jönsson, P.; Lindroos, O. Comparison of modeling approaches for evaluation of machine fleets in central Sweden forest operations. Int. J. For. Eng. 2023, 34, 42–53. [Google Scholar] [CrossRef]

- Inoue, M. The present situation and further research of the high productive mechanization system in logging operation. Res. J. Food Agric. 1994, 17, 6–12. Available online: https://agriknowledge.affrc.go.jp/RN/2030520036.pdf (accessed on 10 February 2023). (In Japanese).

- Bjerketvedt, J.; Talbot, B.; Kindernay, D.; Ottaviani Aalmo, G.; Clarke, N. Evaluation of site impact after harvesting in steep terrain with excavator assisted ground based systems. In Proceedings of the IUFRO Unit 3.06 International Conference Forest Operations in Mountainous Conditions, Honne, Norway, 2–5 June 2013. [Google Scholar]

| Type of Operation | Type of Machine | Country/Region | Hourly Processed Volume (m3/h) | Number of Worker(s) |

|---|---|---|---|---|

| Felling | Chainsaw (×2) | Japan | 8.30 (4.15 × 2) | 2 |

| Yarding | Swing yarder | Japan | 3.24 | 2 |

| Processing | Processor | Japan | 7.32 | 1 |

| Forwarding | Forwarder | Japan | 5.89 | 1 |

| Felling | Chainsaw (×2) | Central Europe | 15.00 (7.50 × 2) | 2 |

| Yarding/Processing | PTY | Central Europe | 11.54 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshimura, T.; Suzuki, Y.; Sato, N. Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain. Forests 2023, 14, 1430. https://doi.org/10.3390/f14071430

Yoshimura T, Suzuki Y, Sato N. Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain. Forests. 2023; 14(7):1430. https://doi.org/10.3390/f14071430

Chicago/Turabian StyleYoshimura, Tetsuhiko, Yasushi Suzuki, and Noriko Sato. 2023. "Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain" Forests 14, no. 7: 1430. https://doi.org/10.3390/f14071430

APA StyleYoshimura, T., Suzuki, Y., & Sato, N. (2023). Assessing the Productivity of Forest Harvesting Systems Using a Combination of Forestry Machines in Steep Terrain. Forests, 14(7), 1430. https://doi.org/10.3390/f14071430