Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Sample

2.2. Heart Rate Measurement

2.3. Sub-Activities

- Maintenance—This activity started the operator’s working day and included, for example, checking the hydraulic and engine oil levels, checking the air filter, checking the condition and inflation of the tires, checking and cleaning all tight spaces, checking for defects and cracks on the machine, optical inspection of the hydraulic crane (tightness of hoses, joints, and hydraulic cylinders), replenishment of fuel, etc.

- Driving—This activity included driving on public roads or crossing between workplaces in a particular forest stand.

- Forwarding—This was a part of the production process that included the work operations of clearing, load assembly, forwarding, sorting at the pick-up point, and landfilling of wood.

- Break—The operator used the break time for a snack or lunch, or to inspect the workplace.

2.4. Statistical Data Processing

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Neruda, J.; Ulrich, R.; Kupčák, V.; Slodičák, M.; Zemánek, T. Harvestorové Technologie Lesní Těžby; Mendelova Univerzita v Brně: Brno, Czech Republic, 2013; 165p, ISBN 978-807375-842-4. [Google Scholar]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time Consumption Analysis of the Mechanized Cut-to-length Harvesting System. Silva Fenn. 2006, 40, 335–363. [Google Scholar] [CrossRef]

- Dvořák, J.; Malkowský, Z.; Macků, J. Influence of Human Factor on the Time of Work Stages of Harvesters and Crane-Equipped Forwarders. J. For. Sci. 2008, 54, 24–30. [Google Scholar] [CrossRef]

- Axelsson, S. The Mechanization of Logging Operations in Sweden and its Effect on Occupational Safety and Health. Int. J. For. Eng. 1998, 9, 25–31. [Google Scholar]

- Gerasimov, Y.; Sokolov, A. Ergonomic evaluation and comparison of wood harvesting systems in Northewest Russia. Appl. Ergon. 2014, 45, 318–338. [Google Scholar] [CrossRef]

- Więsik, J. Wood hauling aggregate with self-loading trailer. Principles of creation and effective use. Part 1. Description of wood forwarding process and principles of machine aggregation. Tech. Rol. Ogrod. Leśna 2017, 4, 18–21. [Google Scholar]

- Naskrent, B.; Polowy, K.; Grzywiński, W.; Sobczak, A. Timber extraction in thinned stands using agricultural tractor coupled with a trailer with a hydraulic crane. Sylwan 2019, 163, 121–129. [Google Scholar] [CrossRef]

- Väätäinen, K.; Ala-Fossi, A.; Nuutinen, Y.; Röser, D. The Effect of Single Grip Harvester’s Log Bunching on Forwarder Efficiency. Balt. For. 2006, 12, 64–69. [Google Scholar]

- Tervo, K.; Palmroth, L.; Koivo, H.N. Skill Evaluation of Human Operators in Partly Automated Mobile Working Machines. IEEE Trans. Autom. Sci. Eng. 2010, 7, 133–142. [Google Scholar] [CrossRef]

- Manner, J. What is (not) an operator effect in forest work science? Silva Fenn. 2021, 55, 10542. [Google Scholar] [CrossRef]

- Manner, J.; Nordfjell, T.; Lindroos, O. Effects of the number of assortments and log concentration on time consumption of forwarding. Silva Fenn. 2013, 47, 1030. [Google Scholar] [CrossRef]

- Spinelli, R.; Owende, P.; Ward, S.; Tornero, M. Comparison of short-wood forwarding systems used in Iberia. Silva Fenn. 2004, 38, 85–94. [Google Scholar] [CrossRef]

- Tiernan, D.; Zeleke, G.; Owende, P.M.O.; Kanali, C.L.; Lyons, J.; Ward, S.M. Effect of working conditions on forwarder productivity in cut-to-length timber harvesting on sensitive forest sites in Ireland. Biosyst. Eng. 2004, 87, 167–177. [Google Scholar] [CrossRef]

- Ghaffariyan, M.R.; Sessions, J.; Brown, M. Machine productivity and residual harvesting residues associated with a cut-to-length harvest system in southern Tasmania. South. For. J. For. Sci. 2012, 74, 229–235. [Google Scholar] [CrossRef]

- Acuna, M.A.; Kellogg, L.D. Evaluation of Alternative Cut-to-Length Harvesting Technology for Native Forest Thinning in Australia. Int. J. For. Eng. 2009, 20, 17–25. [Google Scholar] [CrossRef]

- Gingras, J.F.; Favreau, J. Effect of Log Length and Number of Products on the Productivity of Cut-to-Length Harvesting in the Boreal Forest. Advantage 2005, 6, 1–8. [Google Scholar]

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Ghaffarian, M.R.; Stampfer, K.; Sessions, J. Forwarding Productivity in Southern Austria. Croat. J. For. Eng. 2007, 28, 169–175. [Google Scholar]

- Strandgard, M.; Mitchell, R.; Acuna, M. Impact of Slope on Forwarder Load Size and Productivity. In Proceedings of the 48th FORMEC Symposium, Linz, Austria, 1 December 2015; pp. 101–105. [Google Scholar]

- Zimbalatti, G.; Proto, A.R. Productivity of Forwarders in South Italy. In Proceedings of the 44th FORMEC Symposium, Padova, Italy, 11–14 July 2010. [Google Scholar]

- Proto, A.R.; Macri, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. A Case Study on the Productivity of Forwarder Extraction in Small-Scale Southern Italian Forests. Small-Scale For. 2017, 17, 71–87. [Google Scholar] [CrossRef]

- Mola-Yudego, B.; Picchi, G.; Röser, D.; Spinelli, R. Assessing chipper productivity and operator effects in forest biomass operations. Silva Fenn. 2015, 49, 1342. [Google Scholar] [CrossRef]

- Malinen, J.; Taskinen, J.; Tolppa, T. Productivity of cut-to-length harvesting by operators’ age and experience. Croat. J. For. Eng. 2018, 39, 15–22. [Google Scholar]

- Bovenzi, M.; Zadini, A.; Franzinelli, A.; Borgogni, F. Occupational musculoskeletal disorders in the neck and upper limbs of forestry workers exposed to hand-arm vibration. Ergonomics 1991, 34, 547–562. [Google Scholar] [CrossRef]

- Burström, L.; Nilsson, T.; Wahlström, J. Whole-body vibration and the risk of low back pain and sciatica: A systematic review and meta-analysis. Int. Arch. Occup. Environ. Health 2014, 88, 403–418. [Google Scholar] [CrossRef]

- Staněk, L.; Mergl, V. Whole Body Vibrations during Fully Mechanised Logging. Forests 2022, 13, 630. [Google Scholar] [CrossRef]

- Poje, A.; Spinelli, R.; Magagnotti, N.; Mihelic, M. Exposure to noise in wood chipping operations under the conditions of agro-forestry. Int. J. Ind. Ergon. 2015, 50, 151–157. [Google Scholar] [CrossRef]

- Yovi, E.Y.; Yamad, Y. Addressing occupational ergonomics issues in indonesian forestry: Laborers, operators, or equivalent workers. Croat. J. For. Eng. 2019, 40, 351–363. [Google Scholar] [CrossRef]

- Albizu-Urionabarrenetxea, P.M.; Tolosana-Esteban, E.; Roman-Jordan, E. Safety and health in forest harvesting operations. Diagnosis and preventive actions. A review. For. Syst. 2013, 22, 392–400. [Google Scholar] [CrossRef]

- Sedmíková, M.; Löwe, R.; Jankovský, M.; Natov, P.; Linda, R.; Dvořák, J. Estimation of over-and under-bark volume of scots pine timber produced by harvesters. Forests 2020, 11, 626. [Google Scholar] [CrossRef]

- Häggström, C.; Lindroos, O. Human, technology, organization and environment—A human factors perspective on performance in forest harvesting. Int. J. For. Eng. 2016, 27, 67–78. [Google Scholar] [CrossRef]

- Zvěřina, L.; Cibulka, M.; Staněk, L.; Ulrich, R. Analysis of Field View from Tractor and Trailer Units Using the Method of Terrestrial Laser Scanning. Forests 2022, 13, 1383. [Google Scholar] [CrossRef]

- Marzano, F.; Souza, A.; Minette, L. Proposal for an ergonomic conformity index for evaluation of harvesters and forwarders. Rev. Arvore 2017, 41, e410401. [Google Scholar] [CrossRef]

- Arman, Z.; Nikooy, M.; Tsioras, P.A.; Heidari, M.; Majnounian, B. Physiological workload evaluation by means of heart rate monitoring during motor-manual clearcutting operations. Int. J. For. Eng. 2021, 32, 91–102. [Google Scholar] [CrossRef]

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, Exposure to Noise, and Risk of Musculoskeletal Disorders: A Case Study of Motor-Manual Tree Feeling and Processing in Poplar Clear Cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- McCraty, R.; Shaffer, F. Heart rate variability: New Perspectives on Physiological Mechanisms, Assessment of Self-regulatory Capacity, and Health risk. Glob. Adv. Health Med. 2015, 4, 46–61. [Google Scholar] [CrossRef] [PubMed]

- Fiľo, P. Nové Metody v Ergonomii; Mendelova Univerzita v Brně: Brno, Czech Republic, 2013; 104p, ISBN 978-80-7375-870-7. [Google Scholar]

- Garet, M.; Boudet, G.; Montaurier, C.; Vermorel, M.; Coudert, J.; Chamoux, A. Estimating relative physical workload using heart rate monitoring: A validation by whole-body indirect calorimetry. Eur. J. Appl. Physiol. 2005, 94, 46–53. [Google Scholar] [CrossRef]

- Hoover, A.; Singh, A.; Fishel-Brown, S.; Muth, E. Real-time detection of workload changes using heart rate variability. Biomed. Signal Process. Control 2012, 7, 333–341. [Google Scholar] [CrossRef]

- Afshari, D.; Shirali, G. The effect of heat exposure on physical workload and maximum acceptable work duration (MAWD) in a hot and dry climate. Urban Clim. 2019, 27, 142–148. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, W.; Li, F. Association between Resting Heart Rate and Coronary Artery Disease, Stroke, Sudden Death and Noncardiovascular Diseases: A Meta-Analysis. Can. Med. Assoc. J. 2016, 188, 384–392. [Google Scholar] [CrossRef]

- Alugubelli, N.; Abuissa, H.; Roka, A. Wearable Devices for Remote Monitoring of Heart Rate and Heart Rate Variability-What We Know and What Is Coming. Sensors 2022, 22, 8903. [Google Scholar] [CrossRef]

- Yokoyama, K.; Hayashi, E.; Ito, H.; Kawahara, Y. Estimation of Heart Rate Variability from Heartrate Measured with Wristwatch-Type Heartrate Monitor. IEEJ Trans. Electron. Inf. Syst. 2022, 142, 46–54. [Google Scholar] [CrossRef]

- Can, Y.S.; Chalabianloo, N.; Ekiz, D.; Ersoy, C. Continuous Stress Detection Using Wearable Sensors in Real Life: Algorithmic Programming Contest Case Study. Sensors 2019, 19, 1849. [Google Scholar] [CrossRef]

- Quiroz, J.C.; Geangu, E.; Yong, M.H. Emotion Recognition Using Smart Watch Sensor Data: Mixed-Design Study. JMIR Ment. Health 2018, 5, e10153. [Google Scholar] [CrossRef]

- Zhang, Y.; Tsujikawa, M.; Onishi, Y. Sleep/wake classification via remote PPG signals. In Proceedings of the 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Berlin, Germany, 23–27 July 2019; pp. 3226–3230. [Google Scholar]

- Häggström, C. Human Factors in Mechanized Cut-to-Length Forest Operations. Doctoral Thesis, Swedish University of Agricultural Sciences, Umeå, Sweden, 2015. [Google Scholar]

- Zemánek, T.; Fiľo, P. Influence of Intelligent Boom Control in Forwarders on Performance of Operators. Croat. J. For. Eng. 2022, 43, 47–64. [Google Scholar] [CrossRef]

- Støve, M.P.; Haucke, E.; Nymann, M.L.; Sigurdsson, T.; Larsen, B.T. Accuracy of the wearable activity tracker Garmin Forerunner 235 for the assessment of heart rate during rest and activity. J. Sports Sci. 2019, 37, 895–901. [Google Scholar] [CrossRef] [PubMed]

- Reddy, R.K.; Pooni, R.; Zaharieva, D.P.; Senf, B.; Youssef, J.E.; Dassau, E.; Doyle lii, F.J.; Clements, M.A.; Rickels, M.R.; Patton, S.R.; et al. Accuracy of Wrist-Worn Activity Monitors During Common Daily Physical Activities and Types of Structured Exercise: Evaluation Study. JMIR mHealth uHealth 2018, 6, e10338. [Google Scholar] [CrossRef] [PubMed]

- Jones, A.Y.M.; Kam, C.; Lai, K.W.; Lee, H.Y.; Chow, H.T.; Lau, S.F.; Wong, L.M.; He, J. Changes in heart rate and R-wave amplitude with posture. Chin. J. Physiol. 2003, 46, 63–69. [Google Scholar] [PubMed]

- Šipinková, I.; Hahn, G.; Meyer, M.; Tadlánek, M.; Hájek, J. Effect of respiration and posture on heart rate variability. Physiol. Res. 1997, 46, 173–179. [Google Scholar]

- Tynkkynen, M. Assessing Harvester Operators’ Mental Workload Using Continuous ECG Recording Technique. Int. J. Cogn. Ergonomics 2001, 5, 213–219. [Google Scholar] [CrossRef]

- Helander, M. A Guide to Human Factors and Ergonomics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 224–255. ISBN 0-203-68775-2. [Google Scholar]

- Hnilica, R.; Jankovský, M.; Dado, M. Model Assessment of the Complex Workload of Harvester Operator. Forests 2022, 13, 1196. [Google Scholar] [CrossRef]

- Poorabdian, S.; Mirlohi, A.H.; Habibi, E.; Shakerian, M. Association between job strain (high demand-low control) and cardiovascular disease risk factors among petrochemical industry workers. Int. J. Occup. Med. Environ. Health 2013, 26, 555–562. [Google Scholar] [CrossRef]

- Inoue, M.; Fujimura, T.; Morita, H.; Inagaki, J.; Kan, H.; Harada, N. A comparison of heart rate during rest and work in shift workers with different work styles. Ind. Health 2003, 41, 343–347. [Google Scholar] [CrossRef]

- Eriksson, P.; Schiöler, L.; Söderberg, M.; Rosengren, A.; Torén, K. Job strain and resting heart rate: A cross-sectional study in a Swedish random working sample. BMC Public Health 2016, 16, 228. [Google Scholar] [CrossRef] [PubMed]

| Operator/Activity | Mean Value (bpm) | Median (bpm) | Mode (bpm) | Frequency of Mode | Min. (bpm) | Max. (bpm) | Standard Deviation (bpm) |

|---|---|---|---|---|---|---|---|

| Operator 1/Maintenance | 89.0962 | 89.5000 | Multiple | 5.0000 | 68.0000 | 107.0000 | 8.2015 |

| Operator 1/Driving | 80.8250 | 80.0000 | Multiple | 9.0000 | 67.0000 | 102.0000 | 6.3994 |

| Operator 1/Forwarding | 90.6998 | 89.0000 | Multiple | 31.0000 | 74.0000 | 132.0000 | 8.9051 |

| Operator 1/Break | 86.7963 | 84.5000 | 80.0000 | 6.0000 | 74.0000 | 118.0000 | 10.0684 |

| Operator 2/Maintenance | 102.0357 | 100.0000 | 96.0000 | 4.0000 | 78.0000 | 125.0000 | 10.7685 |

| Operator 2/Driving | 85.4296 | 85.0000 | 81.0000 | 13.0000 | 70.0000 | 115.0000 | 7.8201 |

| Operator 2/Forwarding | 84.4548 | 86.0000 | Multiple | 41.0000 | 43.0000 | 113.0000 | 10.3740 |

| Operator 2/Break | 76.5467 | 76.0000 | Multiple | 6.0000 | 64.0000 | 92.0000 | 6.4626 |

| Operator 3/Maintenance | 83.7000 | 82.5000 | Multiple | 2.0000 | 58.0000 | 127.0000 | 15.5078 |

| Operator 3/Driving | 75.9231 | 77.0000 | 80.0000 | 5.0000 | 44.0000 | 112.0000 | 11.8954 |

| Operator 3/Forwarding | 69.0158 | 69.0000 | 74.0000 | 32.0000 | 42.0000 | 119.0000 | 10.7280 |

| Operator 3/Break | 71.0092 | 70.0000 | Multiple | 8.0000 | 50.0000 | 95.0000 | 9.3189 |

| Operator 4/Maintenance | 109.0488 | 112.0000 | 106.0000 | 4.0000 | 69.0000 | 122.0000 | 11.1981 |

| Operator 4/Driving | 91.1786 | 99.5000 | 103.0000 | 4.0000 | 53.0000 | 129.0000 | 21.6519 |

| Operator 4/Forwarding | 79.5497 | 78.0000 | 74.0000 | 26.0000 | 42.0000 | 125.0000 | 13.4346 |

| Operator 4/Break | 71.3636 | 71.0000 | Multiple | 1.0000 | 57.0000 | 99.0000 | 12.3148 |

| Operator 5/Maintenance | 90.6667 | 93.0000 | Multiple | 3.0000 | 61.0000 | 108.0000 | 11.5059 |

| Operator 5/Driving | 79.8702 | 78.0000 | 77.0000 | 16.0000 | 54.0000 | 103.0000 | 7.4796 |

| Operator 5/Forwarding | 84.3120 | 83.0000 | 83.0000 | 56.0000 | 51.0000 | 132.0000 | 10.6976 |

| Operator 5/Break | 77.3125 | 76.5000 | Multiple | 2.0000 | 62.0000 | 95.0000 | 7.7522 |

| Operator 6/Maintenance | 84.2609 | 79.0000 | Multiple | 2.0000 | 58.0000 | 115.0000 | 15.5599 |

| Operator 6/Driving | 82.3882 | 82.0000 | 83.0000 | 8.0000 | 60.0000 | 103.0000 | 7.4739 |

| Operator 6/Forwarding | 79.5571 | 78.0000 | 78.0000 | 34.0000 | 56.0000 | 126.0000 | 10.0631 |

| Operator 6/Break | 73.7368 | 75.0000 | Multiple | 2.0000 | 49.0000 | 107.0000 | 12.1236 |

| Operator 7/Maintenance | 97.9804 | 98.0000 | Multiple | 5.0000 | 78.0000 | 114.0000 | 8.6844 |

| Operator 7/Driving | 82.8605 | 84.5000 | 89.0000 | 7.0000 | 54.0000 | 109.0000 | 11.5516 |

| Operator 7/Forwarding | 83.8573 | 83.0000 | 83.0000 | 45.0000 | 57.0000 | 123.0000 | 9.4690 |

| Operator 7/Break | 70.4490 | 70.0000 | 68.0000 | 4.0000 | 45.0000 | 104.0000 | 12.5051 |

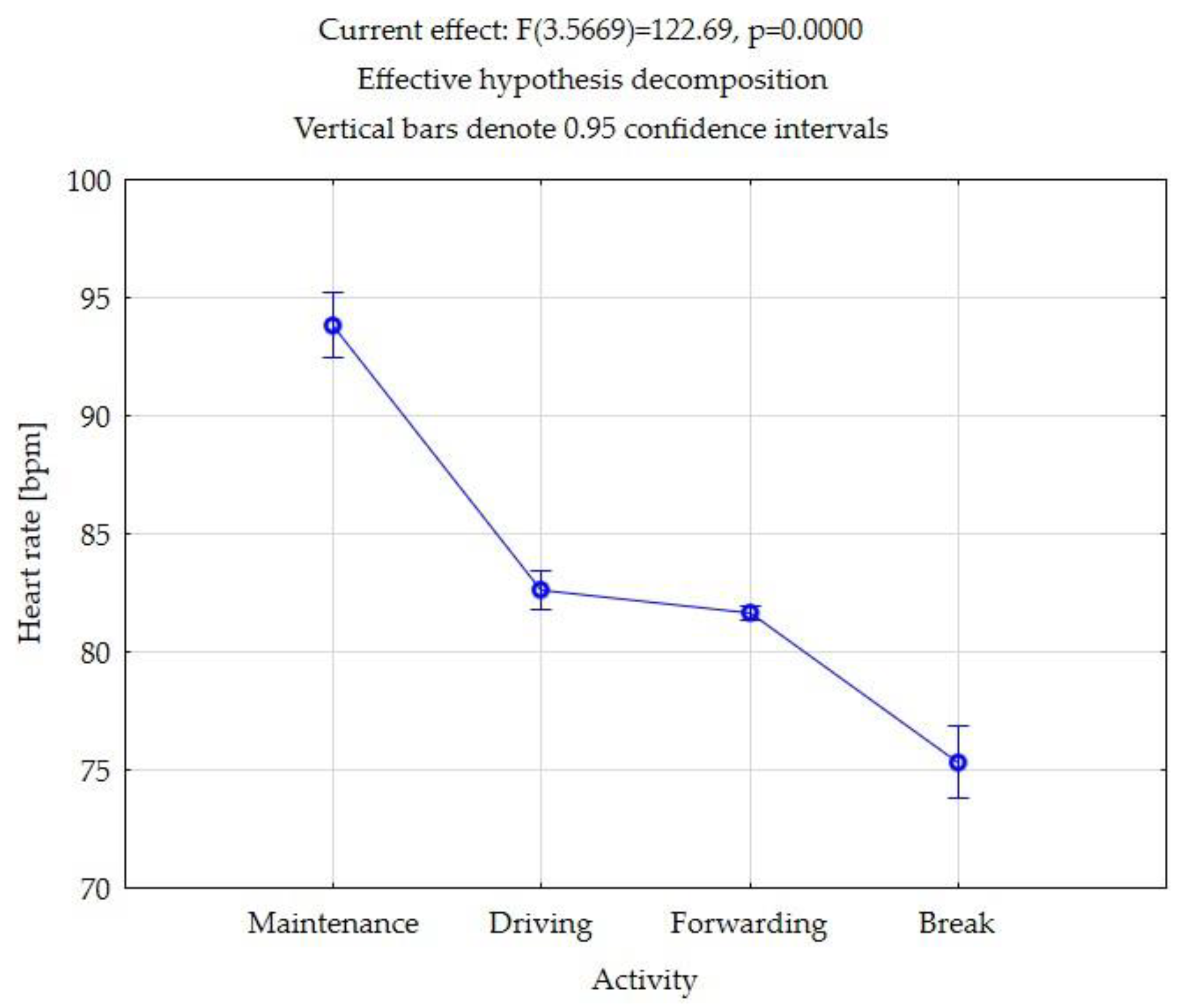

| Effect | Sum of Squares | Degree of Freedom | Mean Square | F Distribution | p-Value |

|---|---|---|---|---|---|

| Intersection | 9,576,663 | 1 | 9,576,663 | 85,555.53 | 0.00 |

| Operator | 32,037 | 6 | 5339 | 47.70 | 0.00 |

| Activity | 41,200 | 3 | 13,733 | 122.69 | 0.00 |

| Operator * Activity | 51,414 | 18 | 2856 | 25.52 | 0.00 |

| Error | 634,560 | 5669 | 112 | - | - |

| Activity | Maintenance | Driving | Forwarding | Break |

|---|---|---|---|---|

| Maintenance | - | 0.000000 | 0.000000 | 0.00 |

| Driving | 0.00 | - | 0.674682 | 0.00 |

| Forwarding | 0.00 | 0.674682 | - | 0.00 |

| Break | 0.00 | 0.000000 | 0.000000 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sláma, D.; Mergl, V.; Pavlíková, E.A. Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities. Forests 2023, 14, 1348. https://doi.org/10.3390/f14071348

Sláma D, Mergl V, Pavlíková EA. Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities. Forests. 2023; 14(7):1348. https://doi.org/10.3390/f14071348

Chicago/Turabian StyleSláma, David, Václav Mergl, and Eva Abramuszkinová Pavlíková. 2023. "Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities" Forests 14, no. 7: 1348. https://doi.org/10.3390/f14071348

APA StyleSláma, D., Mergl, V., & Pavlíková, E. A. (2023). Analysis of the Heart Rate of Operators of Forwarding Machines during Work Activities. Forests, 14(7), 1348. https://doi.org/10.3390/f14071348