Power Compensation Strategy and Experiment of Large Seedling Tree Planter Based on Energy Storage Flywheel

Abstract

1. Introduction

2. Materials and Methods

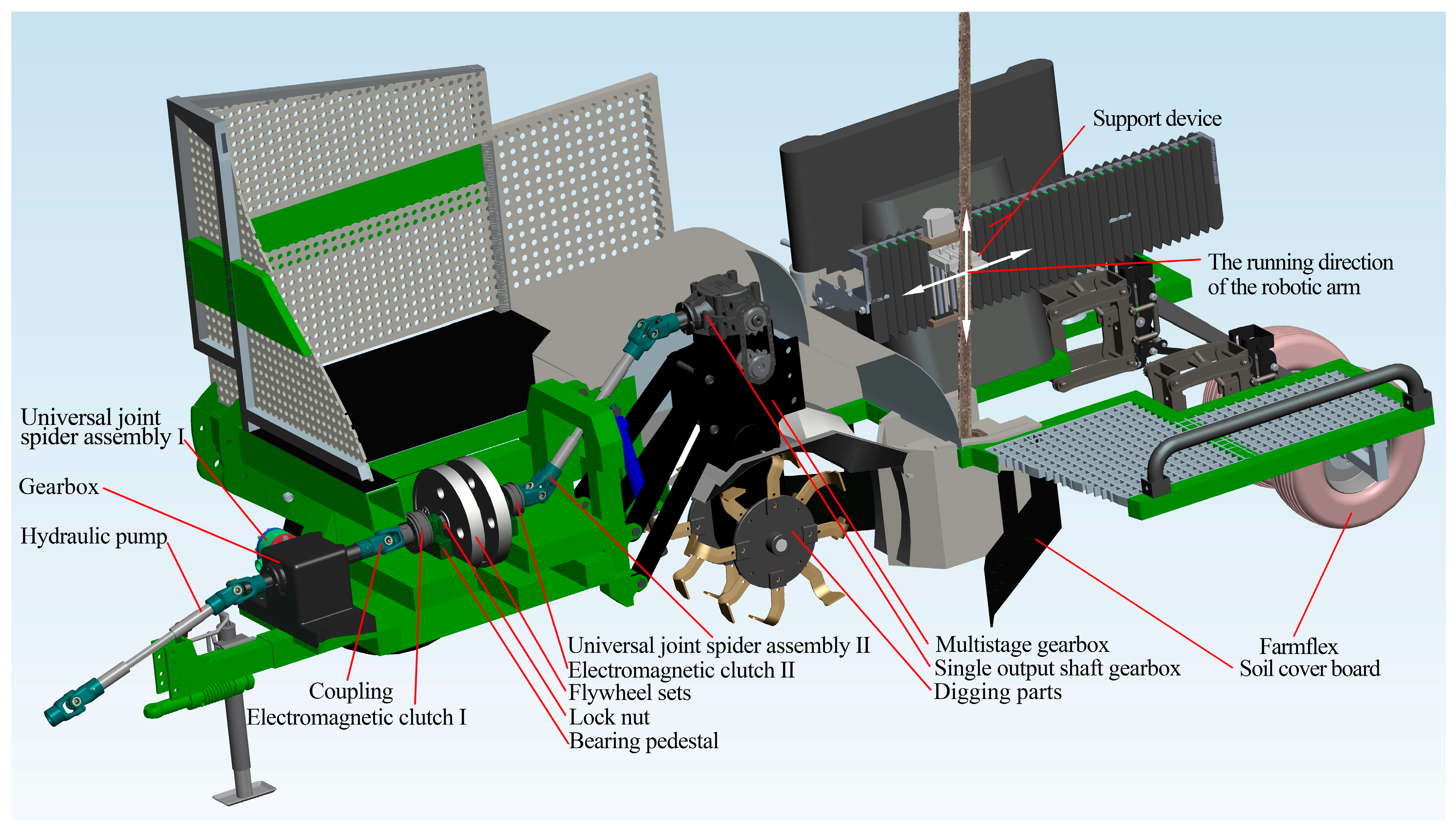

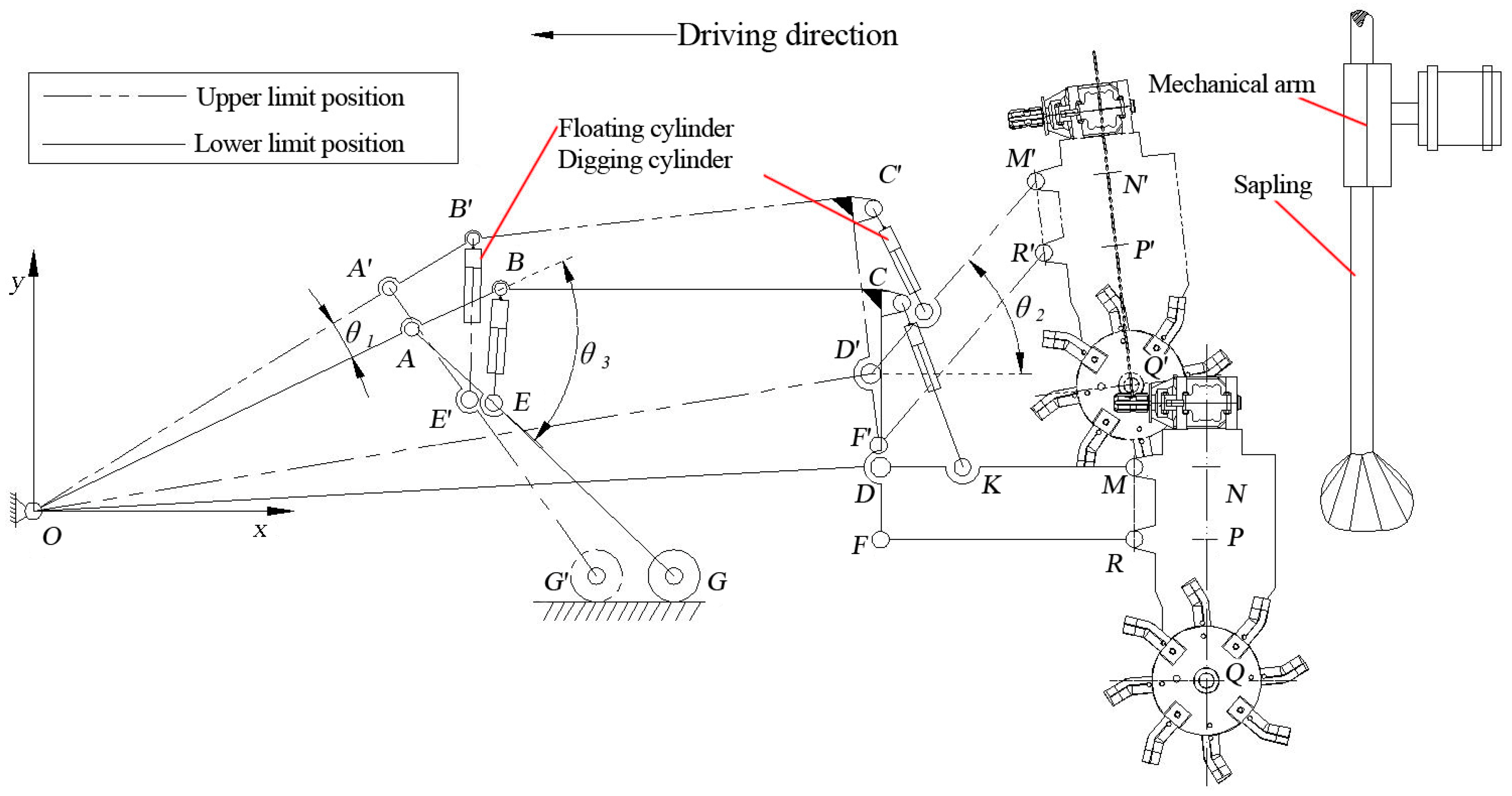

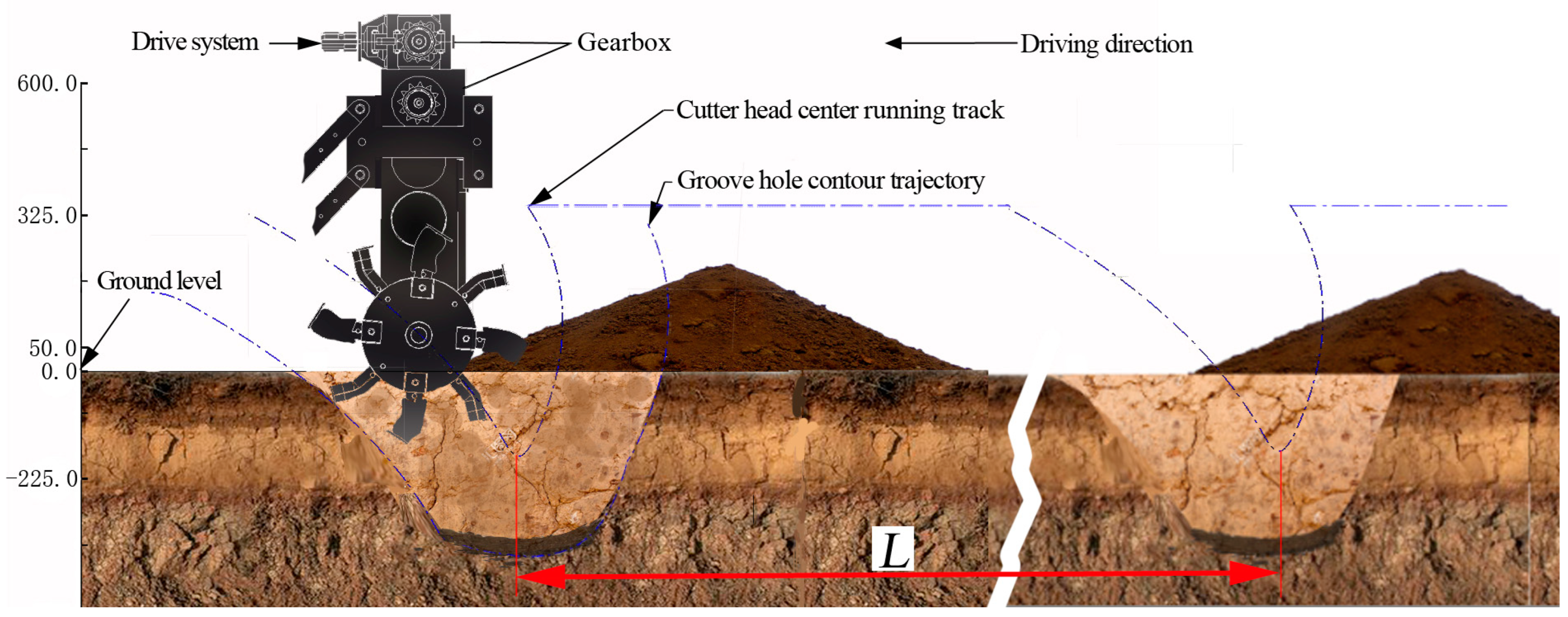

2.1. Description of the Tree Planting Machine

2.2. Consumption Analysis of Soil Cutting Based on Multi-Body Dynamics

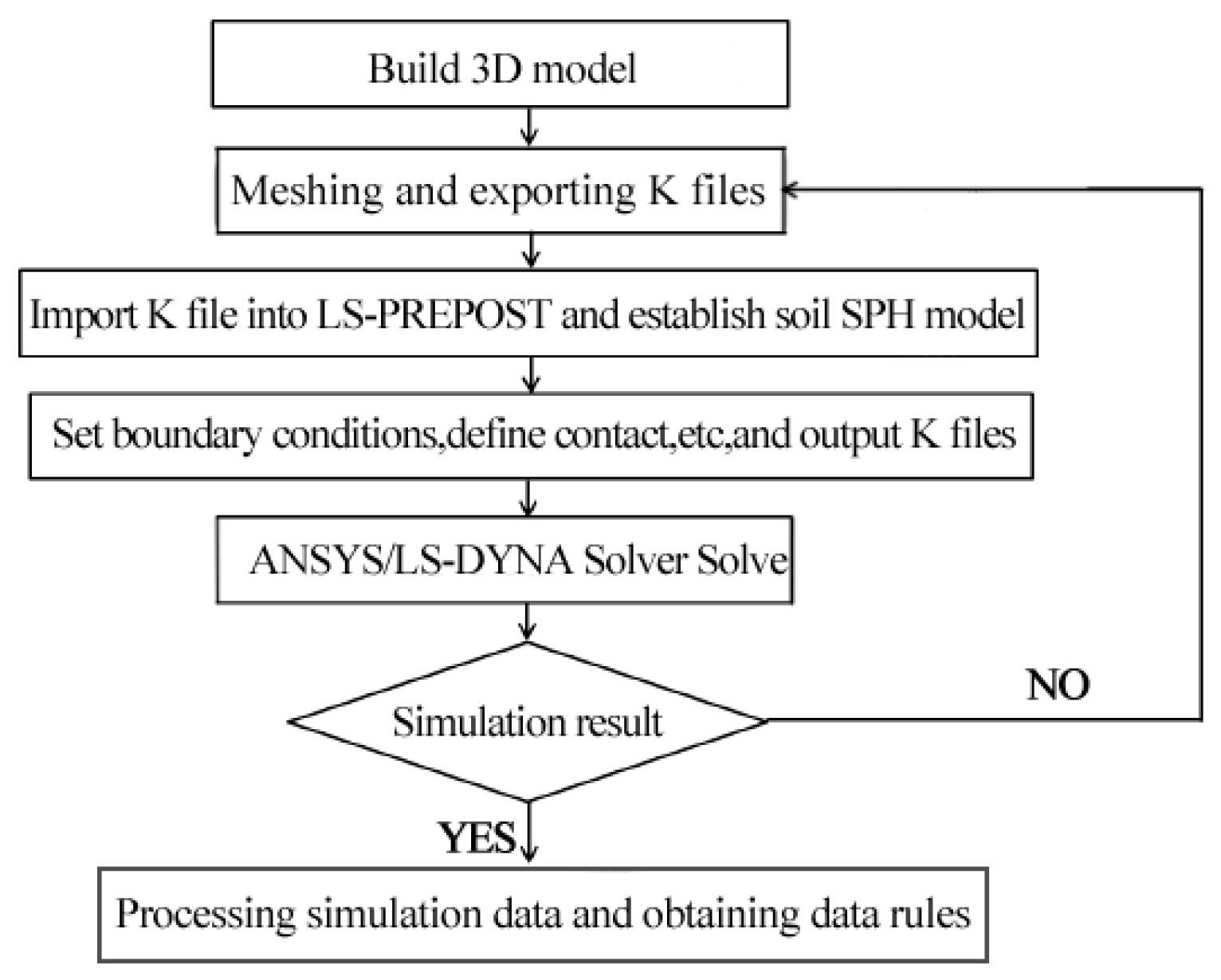

2.2.1. Smooth Particle Hydrodynamics (SPH) Algorithm

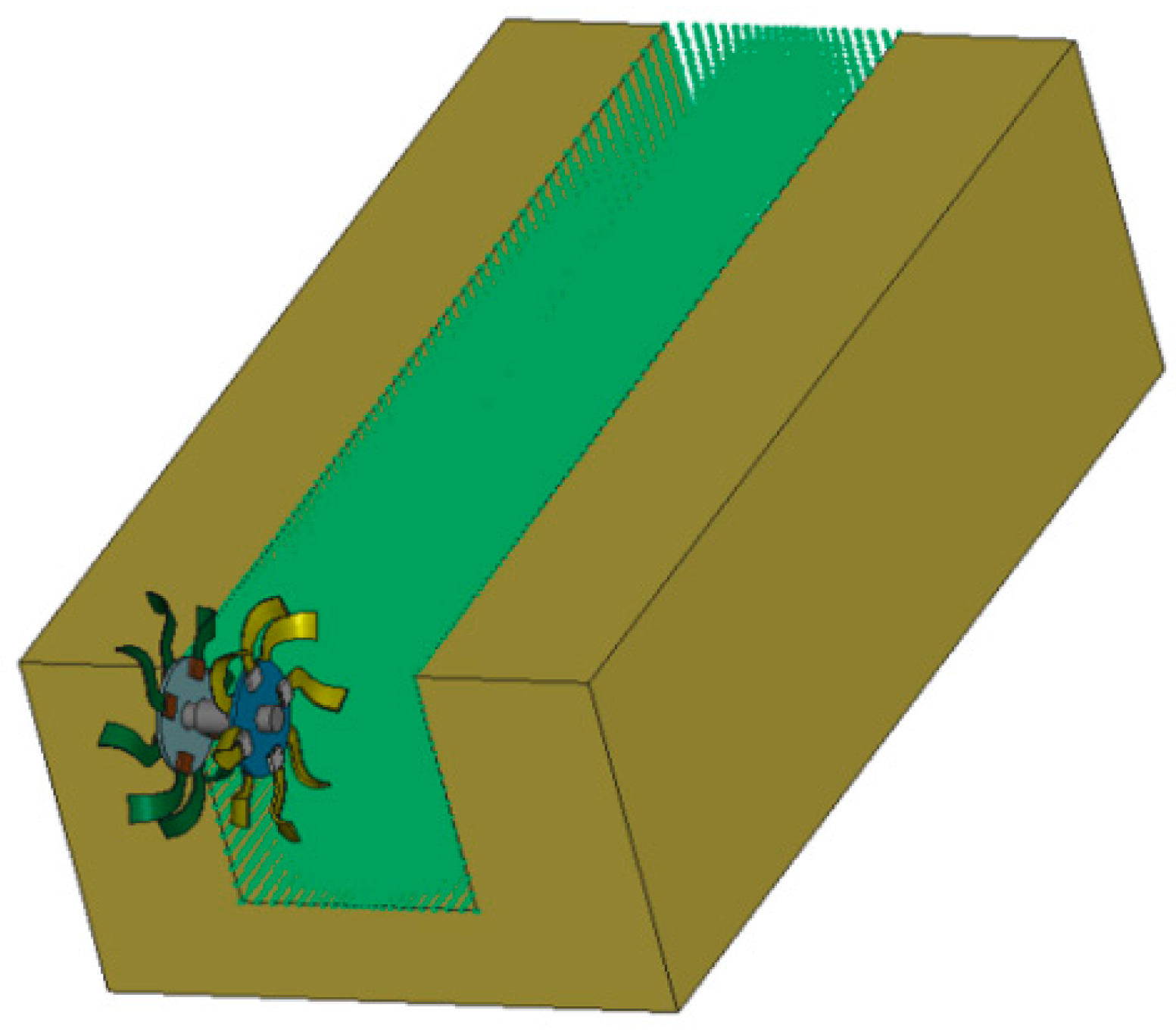

2.2.2. Establishment of the Cutterhead—Soil Simulation Model

2.2.3. Boundary Conditions and Loads

3. Results and Discussion

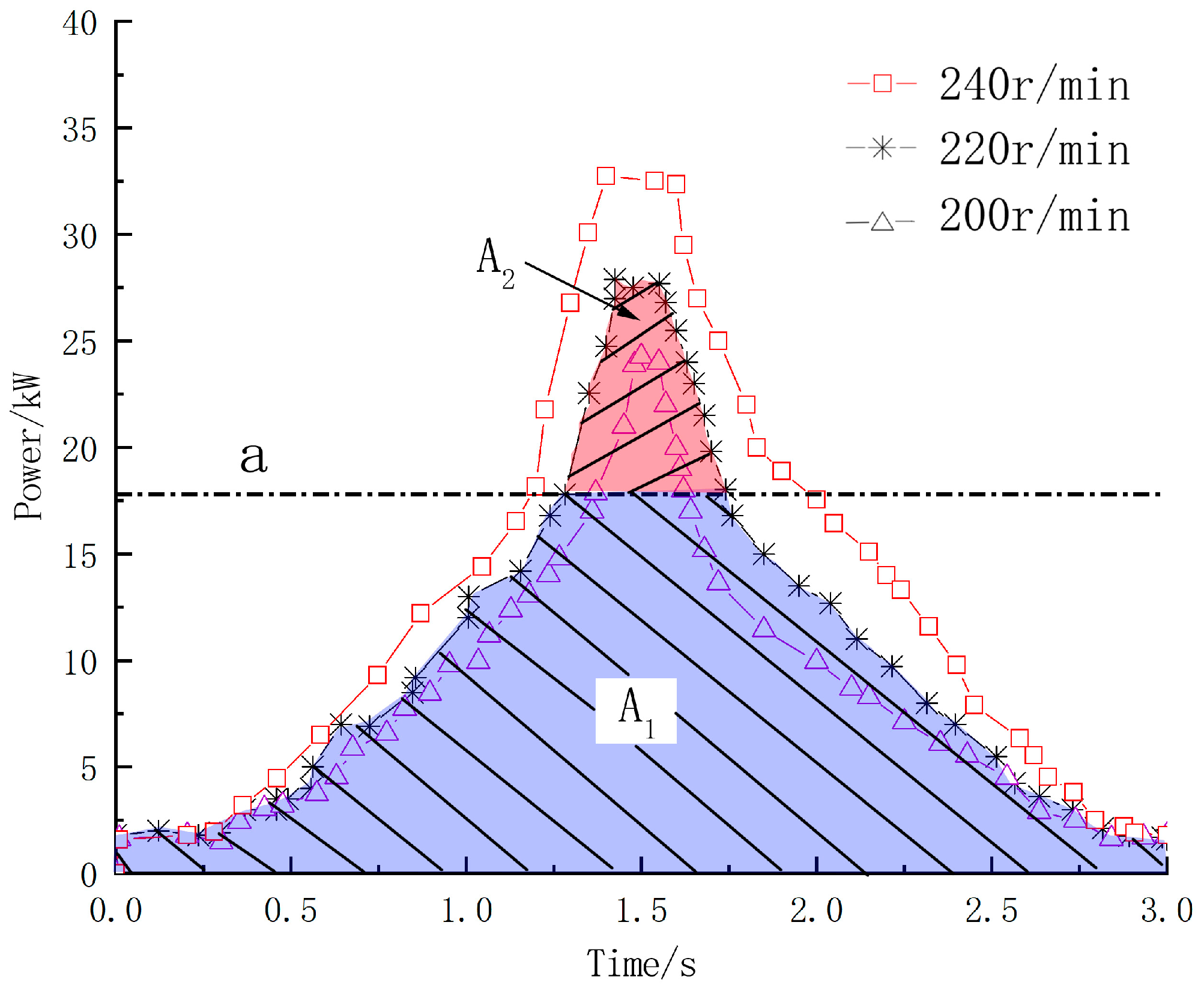

3.1. Simulation Results and Analysis

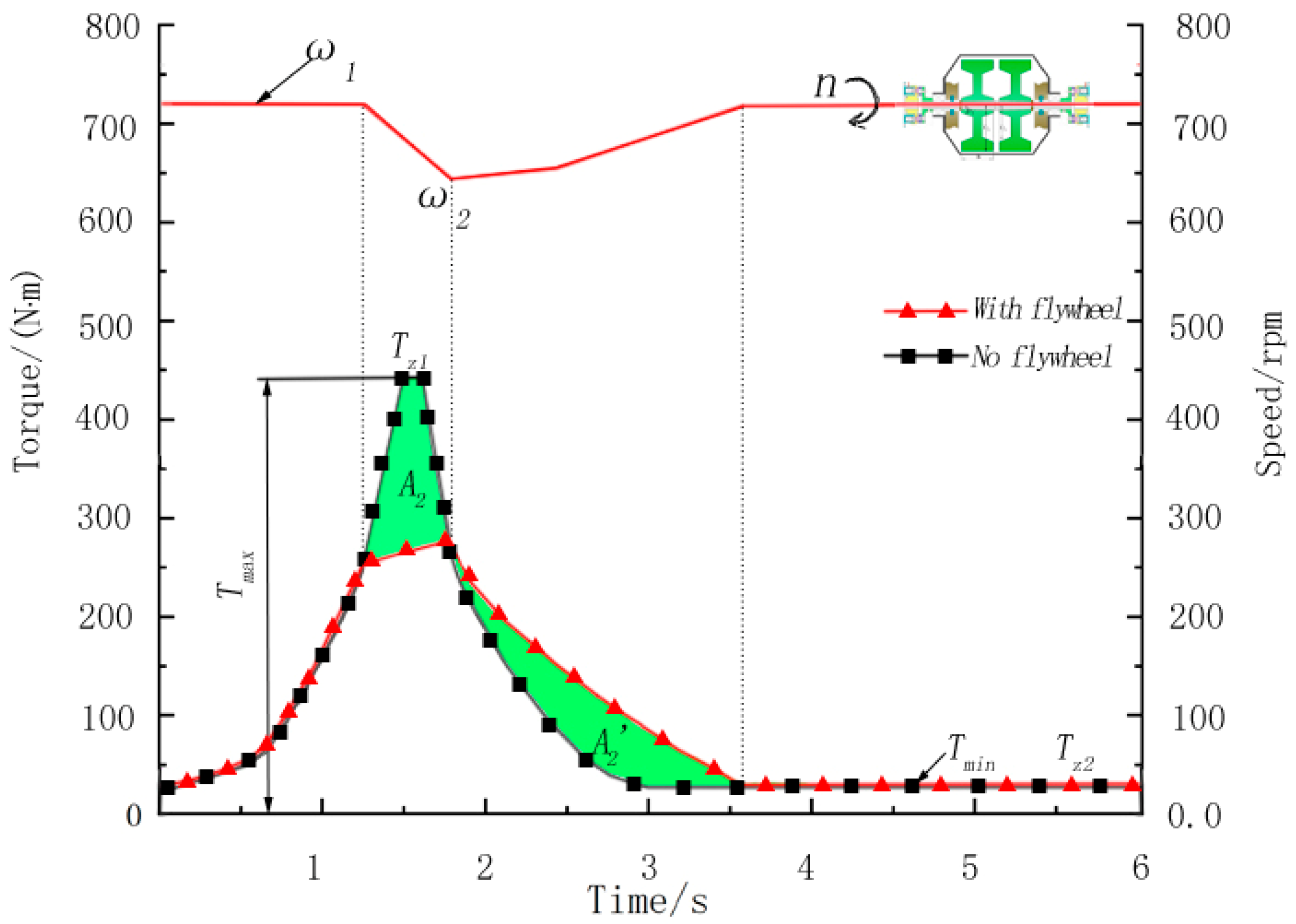

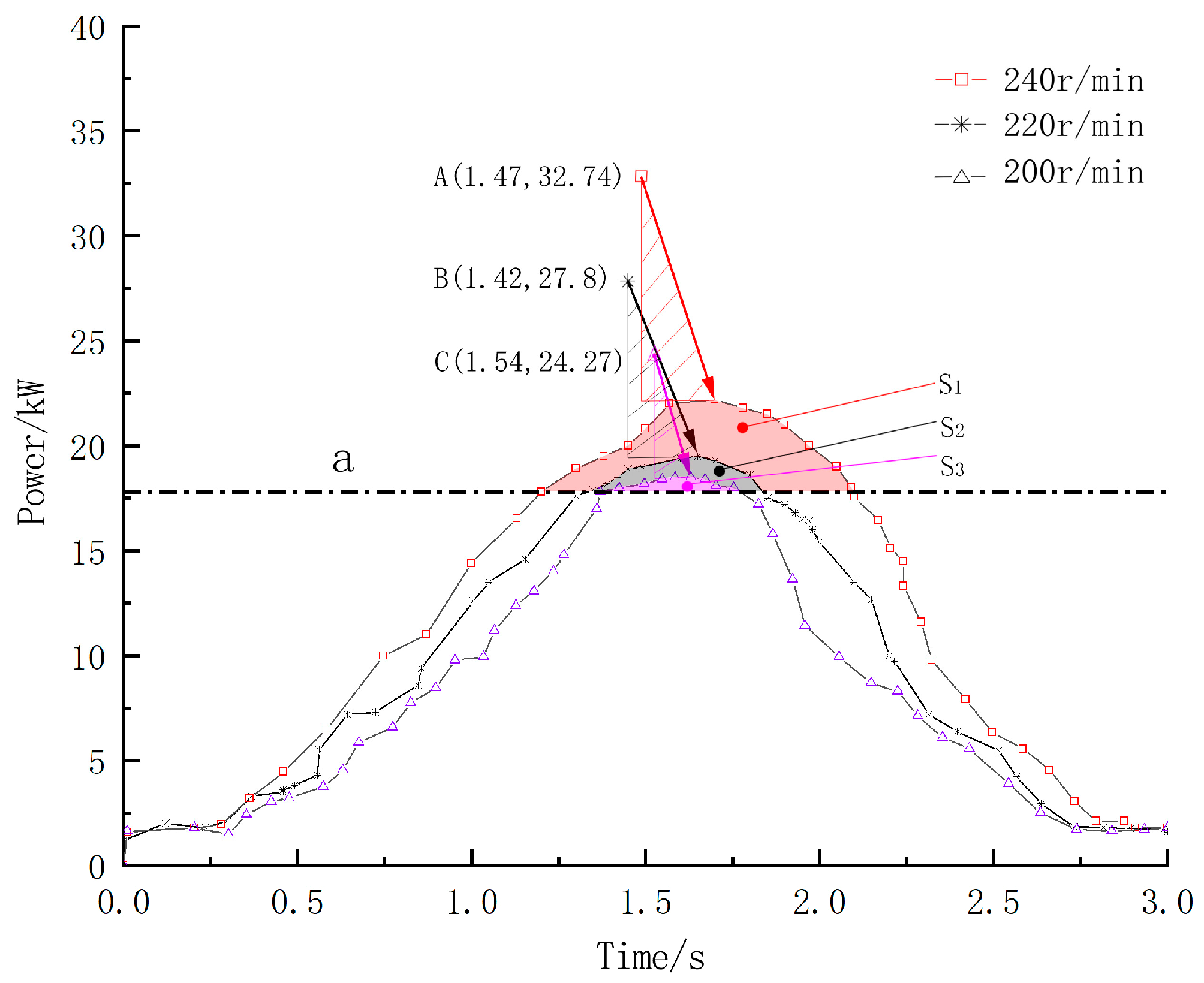

3.2. Flywheel Power Compensation Strategy and Flat Torque Analysis

3.2.1. Power Compensation Scheme Based on Simulation Results

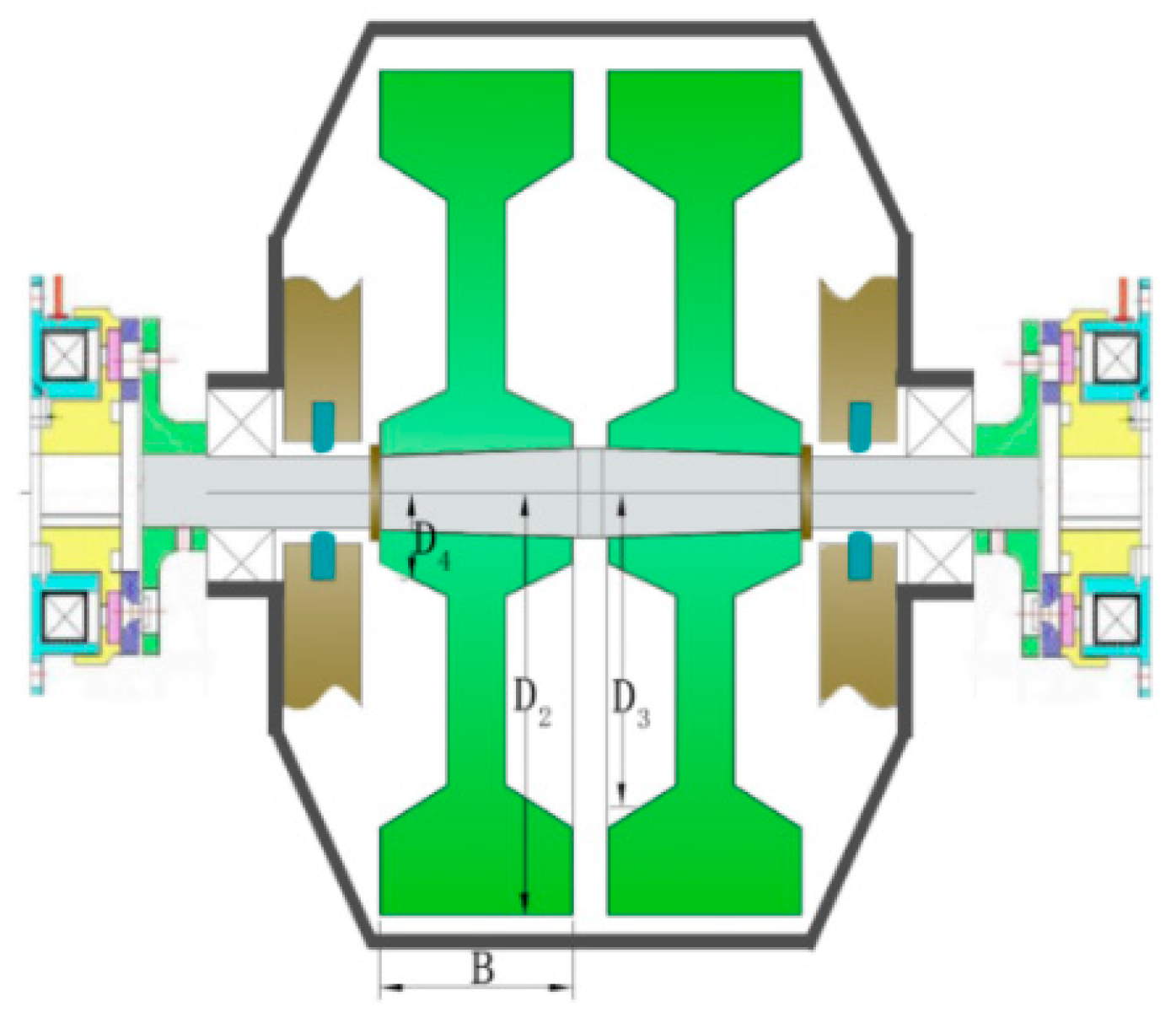

3.2.2. Design of Energy Storage Flywheel and Analysis of Torque Fluctuation

3.3. Performance Testing

3.3.1. Test Preparation

3.3.2. Test Results and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Turchetto, F.; Araujo, M.M.; Tabaldi, L.A.; Griebeler, A.M.; Rorato, D.G.; Aimi, S.C.; Berghetti, L.; Gomes, D.R. Can transplantation of forest seedlings be a strategy to enrich seedling production in plant nurseries? For. Ecol. Manag. 2016, 375, 96–104. [Google Scholar] [CrossRef]

- Chen, D.; Hou, J.; Shi, G. Analysis on the current situation of technology of domestic dryland transplanter. J. Chin. Agric. Mech. 2018, 39, 98–102. [Google Scholar] [CrossRef]

- Warguła, Ł.; Lijewski, P.; Kukla, M. Effects of Changing Drive Control Method of Idling Wood Size Reduction Machines on Fuel Consumption and Exhaust Emissions. Croat. J. For. Eng. 2023, 44, 137–151. [Google Scholar] [CrossRef]

- Laitila, J.; Routa, J. Performance of a small and a medium sized professional chippers and the impact of storage time on Scots pine (Pinus sylvestris) stem wood chips characteristics. Silva Fenn. 2015, 49, 1382. [Google Scholar] [CrossRef]

- Lu, J. Analysis on the development trend of energy conservation and emission reduction of oil drilling diesel engines. China Pet. Chem. Stand. Qual. 2021, 41, 118–119. [Google Scholar] [CrossRef]

- Patel, T.; Chakravorty, A.; Karmakar, S. Software for performance prediction and matching of tractor-implement system. In Proceedings of the 2012 3rd National Conference on Emerging Trends and Applications in Computer Science, Shillong, India, 30–31 March 2012; pp. 262–269. [Google Scholar] [CrossRef]

- Song, D.; Wang, Z.; Zhang, Y. Overview of the development of ecological transplanters. For. Mach. Wood-Work. Equip. 2004, 32, 4–6. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Domeika, R. Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution. Atmosphere 2021, 12, 674. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Špokas, L.; Saldukaitė, L.; Semenišin, M. Impact of Combine Harvester Technological Operations on Global Warming Potential. Appl. Sci. 2021, 11, 8662. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Pupinis, G. Tractor’s engine performance and emission characteristics in the process of ploughing. Energy Convers. Manag. 2013, 75, 498–508. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A.; Khatir, Z.; Jammal, A. Comparative analysis of two hybrid energy storage systems used in a two front wheel driven electric vehicle during extreme start-up and regenerative braking operations. Energy Convers. Manag. 2017, 144, 69–87. [Google Scholar] [CrossRef]

- Guney, M.S.; Tepe, Y. Classification and assessment of energy storage systems. Renew. Sustain. Energy Rev. 2017, 75, 1187–1197. [Google Scholar] [CrossRef]

- Liu, F.; Li, J.; Li, Y. Research and application demonstration of magnetic levitation energy storage flywheel technology. Shanghai Energy Conserv. 2017, 338, 80–84. [Google Scholar] [CrossRef]

- Dai, X.; Wei, K.P.; Zhang, X. Fifty year review of flywheel energy storage technology research. Energy Storage Sci. Technol. 2018, 7, 765–782. [Google Scholar] [CrossRef]

- Hannan, M.A.; Azidin, F.; Mohamed, A. Hybrid electric vehicles and their challenges: A review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Wang, H.; Wei, Q.; Du, J. Development trend of energy conservation and emission reduction of oil drilling diesel engines. Plant Maint. Eng. 2017, 407, 142–144. [Google Scholar] [CrossRef]

- Kang, J.; Li, S.; Yang, X. Virtual simulation and power test of disc type ditcher based on multi-body dynamics. Trans. Chin. Soc. Agric. Mach. 2017, 48, 57–63. [Google Scholar] [CrossRef]

- Chen, L.; Liang, X.; Cao, C. Virtual simulation and power test of straw counters-field based on multi-body dynamics. Trans. Chin. Soc. Agric. Mach. 2016, 47, 106–111. [Google Scholar] [CrossRef]

- Guo, X.; Tang, L.; Zeng, X. Numerical simulation of soil cutting based on ansys/ls-dyna rotary tillage tool. Sichuan Agric. Mach. 2016, 209, 42–43. [Google Scholar] [CrossRef]

- Cao, Z.; Cui, J.; Zhan, X. Simulation and experimental study of soil cutting process by subsoiler based on SPH method. J. Agric. Mech. Res. 2019, 41, 28–34+41. [Google Scholar] [CrossRef]

- Lu, C.; He, J.; Li, H. Simulation of soil cutting process by plane blade based on SPH method. Trans. Chin. Soc. Agric. Mach. 2014, 45, 134–139. [Google Scholar] [CrossRef]

- Cavoretto, R.; De Rossi, A. A meshless interpolation algorithm using a cell-based searching procedure. Comput. Math. Appl. 2014, 67, 1024–1038. [Google Scholar] [CrossRef]

- Korzani, M.G.; Galindo-Torres, S.; Scheuermann, A.; Williams, D. Smoothed Particle Hydrodynamics for investigating hydraulic and mechanical behaviour of an embankment under action of flooding and overburden loads. Comput. Geotech. 2017, 94, 31–45. [Google Scholar] [CrossRef]

- Stevens, D.; Power, H.; Morvan, H. An order-N complexity meshless algorithm for transport-type PDEs, based on local Hermitian interpolation. Eng. Anal. Bound. Elem. 2009, 33, 425–441. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Diameter of cutterhead/mm | 420 | Maximum drilling hole width/mm | 350 |

| Rotational speed of cutterhead/rpm | 200–240 | Minimum drilling hole length/mm | 450 |

| Maximum drilling hole depth/mm | 350 | Minimum throwing soil distance/mm | 500 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Elastic modulus/MPa | 1.97 × 105 (65 Mn) | Rate of water content/% | 16 |

| Cutterhead density/(g/cm3) | 7.85 | Soil angle of repose/° | 40.5 |

| Poisson’s ratio | 0.282 | Shear modulus/MPa | 1.56 |

| Cutterhead diameter/(mm) | 420 | Cohesion/MPa | 0.02 |

| Blade working length/(mm) | 125 | Bulk modulus/MPa | 29 |

| Soil density/(g/cm3) | 1.73 | Internal friction angle/(°) | 35.5 |

| Specific gravity | 2.62 | Soil poisson’s ratio | 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, B.; Liu, J.; Yang, C.; Qu, W.; Ding, P. Power Compensation Strategy and Experiment of Large Seedling Tree Planter Based on Energy Storage Flywheel. Forests 2023, 14, 1039. https://doi.org/10.3390/f14051039

Zhu B, Liu J, Yang C, Qu W, Ding P. Power Compensation Strategy and Experiment of Large Seedling Tree Planter Based on Energy Storage Flywheel. Forests. 2023; 14(5):1039. https://doi.org/10.3390/f14051039

Chicago/Turabian StyleZhu, Binhai, Jiuqing Liu, Chunmei Yang, Wen Qu, and Peng Ding. 2023. "Power Compensation Strategy and Experiment of Large Seedling Tree Planter Based on Energy Storage Flywheel" Forests 14, no. 5: 1039. https://doi.org/10.3390/f14051039

APA StyleZhu, B., Liu, J., Yang, C., Qu, W., & Ding, P. (2023). Power Compensation Strategy and Experiment of Large Seedling Tree Planter Based on Energy Storage Flywheel. Forests, 14(5), 1039. https://doi.org/10.3390/f14051039