Heating Rate during Thermal Modification in Steam Atmosphere: Influence on the Properties of Maple and Ash Wood

Abstract

1. Introduction

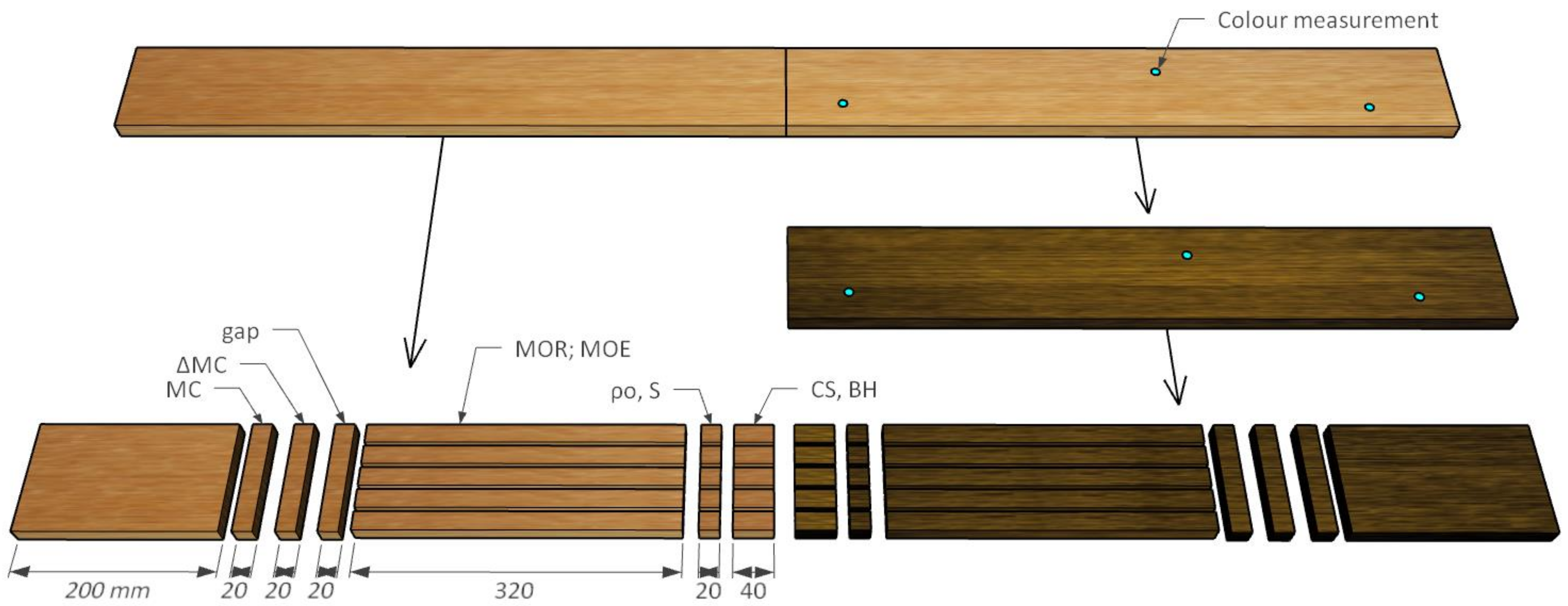

2. Materials and Methods

3. Results and Discussion

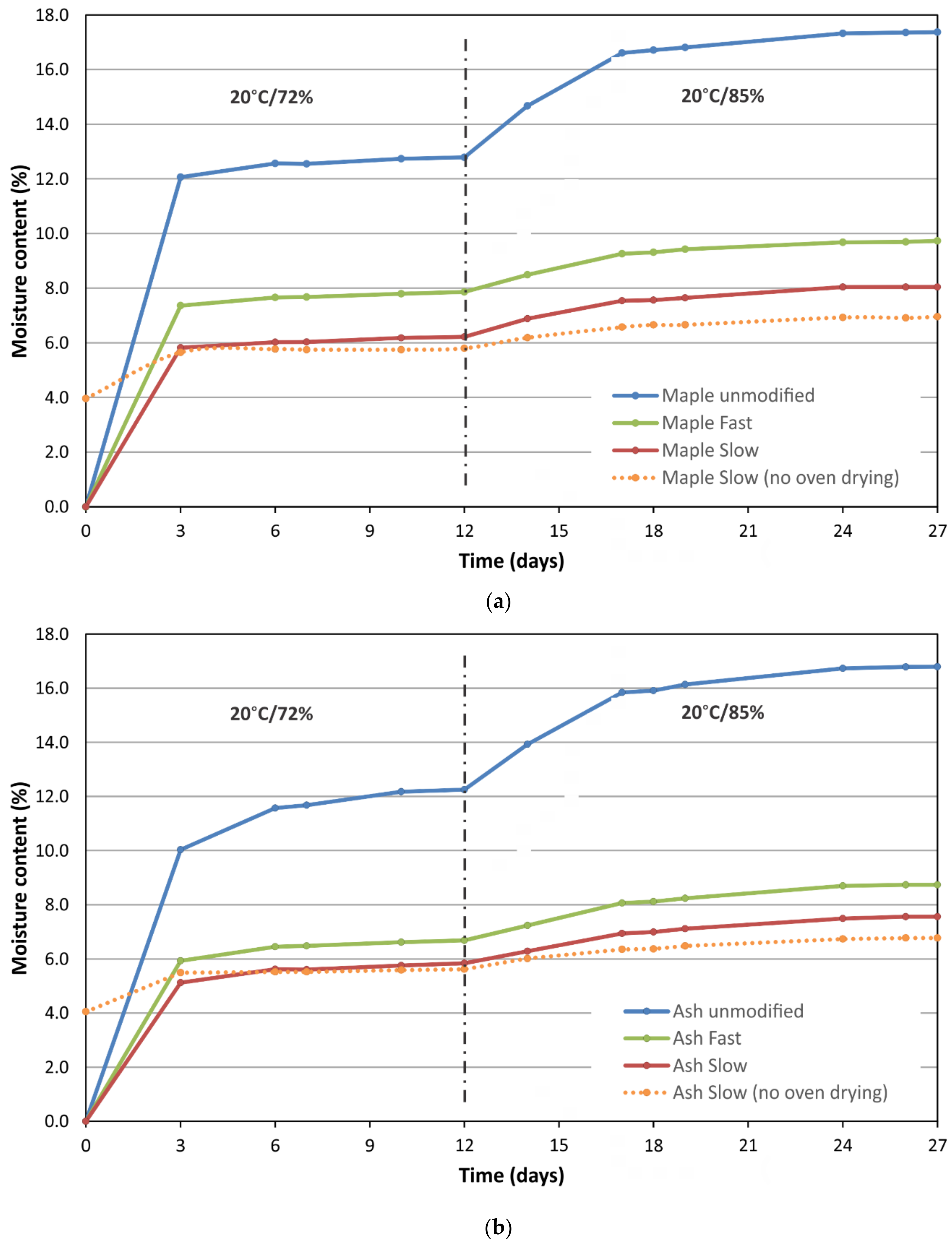

3.1. Hygroscopicity and Dimensional Stability

3.2. Mechanical Properties

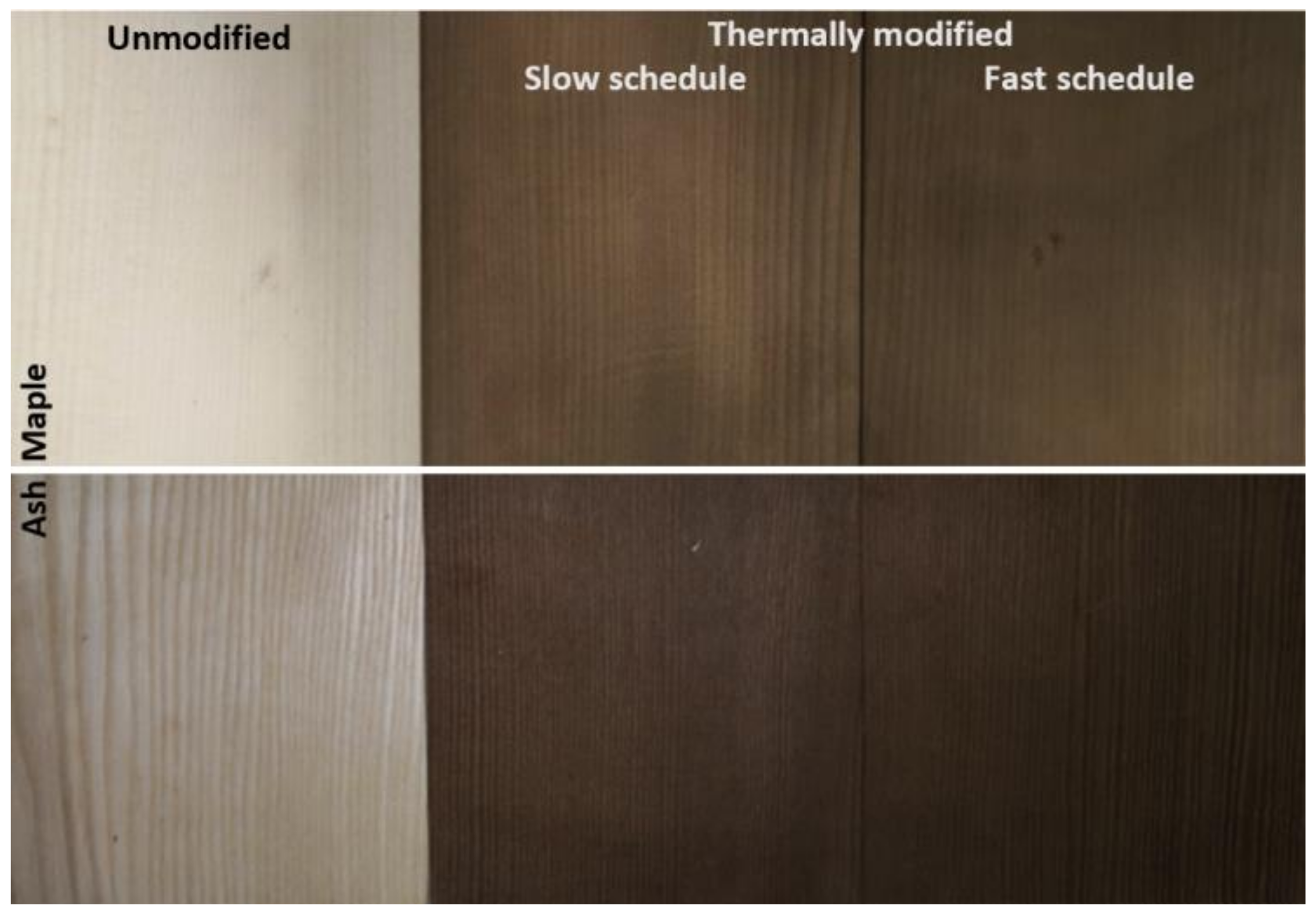

3.3. Colour

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—A review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Altgen, M.; Emmerich, L.; Guigo, N.; Keplinger, T.; Kymäläinen, M.; Thybring, E.E.; Thygesen, L.G. Review of Wood Modification and Wood Functionalization Technologies. Forests 2022, 13, 1004. [Google Scholar] [CrossRef]

- Van Blokland, J.; Olsson, A.; Oscarsson, J.; Daniel, G.; Adamopoulos, S. Crack formation, strain distribution and fracture surfaces around knots in thermally modified timber loaded in static bending. Wood Sci. Technol. 2020, 54, 1001–1028. [Google Scholar] [CrossRef]

- Čermák, P.; Suchomelová, P.; Hess, D. Swelling kinetics of thermally modified wood. Eur. J. Wood Wood Prod. 2021, 79, 1337–1340. [Google Scholar] [CrossRef]

- Allegretti, O.; Cuccui, I.; Terziev, N.; Sorini, L. A model to predict the kinetics of mass loss in wood during thermo-vacuum modification. Holzforschung 2021, 75, 474–479. [Google Scholar] [CrossRef]

- Pétrissans, A.; Younsi, R.; Chaouch, M.; Gérardin, P.; Pétrissans, M. Wood thermodegradation: Experimental analysis and modeling of mass loss kinetics. Maderas. Cienc. Tecnol. 2014, 16, 133–148. [Google Scholar] [CrossRef]

- Ferrari, S.; Cuccui, I.; Allegretti, O. Thermo-vacuum Modification of some European Softwood and Hardwood Species Treated at Different Conditions. BioResources 2013, 8, 1100–1109. [Google Scholar] [CrossRef]

- Chaouch, M.; Pétrissans, M.; Pétrissans, A.; Gérardin, P. Use of wood elemental composition to predict heat treatment intensity and decay resistance of different softwood and hardwood species. Polym. Degrad. Stab. 2010, 95, 2255–2259. [Google Scholar] [CrossRef]

- Torniainen, P.; Elustondo, D.; Dagbro, O. Industrial Validation of the Relationship between Color Parameters in Thermally Modified Spruce and Pine. BioResources 2016, 11, 1369–1381. [Google Scholar] [CrossRef]

- Perré, P.; Rémond, R.; Turner, I. A comprehensive dual-scale wood torrefaction model: Application to the analysis of thermal run-away in industrial heat treatment processes. Int. J. Heat Mass Transf. 2013, 64, 838–849. [Google Scholar] [CrossRef]

- Welzbacher, C.R.; Brischke, C.; Rapp, A.O. Influence of treatment temperature and duration on selected biological, mechanical, physical and optical properties of thermally modified timber. Wood Mater. Sci. Eng. 2008, 2, 66–76. [Google Scholar] [CrossRef]

- Brischke, C.; Welzbacher, C.R.; Brandt, K.; Rapp, A.O. Quality control of thermally modified timber: Interrelationship between heat treatment intensities and CIE L*a*b* color data on homogenized wood samples. Holzforschung 2007, 61, 19–22. [Google Scholar] [CrossRef]

- Todorović, N.; Popović, Z.; Milić, G.; Popadić, R. Estimation of heat-treated beechwood properties by color change. BioResources 2012, 7, 799–815. [Google Scholar]

- Bächle, H.; Zimmer, B.; Wegener, G. Classification of thermally modified wood by FT-NIR spectroscopy and SIMCA. Wood Sci. Technol. 2012, 46, 1181–1192. [Google Scholar] [CrossRef]

- Todorović, N.; Popović, Z.; Milić, G. Estimation of quality of thermally modified beech wood with red heartwood by FT-NIR spectroscopy. Wood Sci. Technol. 2015, 49, 527–549. [Google Scholar] [CrossRef]

- Funaoka, M.; Kako, T.; Abe, I. Condensation of lignin during heating of wood. Wood Sci. Technol. 1990, 24, 277–288. [Google Scholar] [CrossRef]

- Turner, I.; Rousset, P.; Rémond, R.; Perré, P. An experimental and theoretical investigation of the thermal treatment of wood (Fagus sylvatica L.) in the range 200–260 °C. Int. J. Heat Mass Transf. 2010, 53, 715–725. [Google Scholar] [CrossRef]

- He, Z.; Wang, Z.; Qu, L.; Qian, J.; Yi, S. Modeling and simulation of heat-mass transfer and its application in wood thermal modification. Results Phys. 2019, 13, 102213. [Google Scholar] [CrossRef]

- Candelier, K.; Hannouz, S.; Elaieb, M.; Collet, R.; Dumarçay, S.; Pétrissans, A.; Gérardin, P.; Pétrissans, M. Utilization of temperature kinetics as a method to predict treatment intensity and corresponding treated wood quality: Durability and mechanical properties of thermally modified wood. Maderas Cienc. Tecnol. 2015, 17, 253–262. [Google Scholar] [CrossRef]

- Borrega, M.; Kärenlampi, P.P. Effect of relative humidity on thermal degradation of Norway spruce (Picea abies) wood. J. Wood Sci. 2008, 54, 323–328. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A. Thermally modified timber: Recent developments in Europe and North America. Wood Fiber Sci. 2016, 48, 28–39. [Google Scholar]

- Milić, G.; Glišić, M.; Todorović, N.; Veizović, M. Influence of heating rate during thermal modification on some properties of maple wood. In Proceedings of the Final COST Action FP1407 International Conference “Living with modified wood”, Belgrade, Serbia, 12–13 December 2018; pp. 142–143. [Google Scholar]

- ISO 13061-4:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 4: Determination of Modulus of Elasticity in Static Bending. ISO: Geneva, Switzerland, 2014.

- ISO 13061-3:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 3: Determination of Ultimate Strength in Static Bending. ISO: Geneva, Switzerland, 2014.

- ISO 13061-17:2019; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 17: Determination of Ultimate Stress in Compression Parallel to Grain. ISO: Geneva, Switzerland, 2019.

- EN 1534:2020; Wood Flooring and Parquet. Determination of Resistance to Indentation. Test Method. European Committee for Standardization: Brussels, Belgium, 2020.

- Rautkari, L.; Hill, C.A.S. Effect of initial moisture content on the anti-swelling efficiency of thermally modified Scots pine sapwood treated in a high-pressure reactor under saturated steam. Holzforschung 2014, 68, 323–326. [Google Scholar] [CrossRef]

- Altgen, M.; Hofmann, T.; Militz, H. Wood moisture content during the thermal modification process affects the improvement in hygroscopicity of Scots pine sapwood. Wood Sci. Technol. 2016, 50, 1181–1195. [Google Scholar] [CrossRef]

- Cai, C.; Zhou, F. Sorption Characteristic of Thermally Modified Wood at Varying Relative Humidity. Forests 2022, 13, 1687. [Google Scholar] [CrossRef]

- García-Iruela, A.; Esteban, L.G.; García Fernández, F.; de Palacios, P.; Rodriguez-Navarro, A.B.; Martín-Sampedro, R.; Eugenio, M.E. Changes in cell wall components and hygroscopic properties of Pinus radiata caused by heat treatment. Eur. J. Wood Wood Prod. 2021, 79, 851–861. [Google Scholar] [CrossRef]

- Majano-Majano, A.; Hughes, M.; Fernandez-Cabo, J.L. The fracture toughness and properties of thermally modified beech and ash at different moisture contents. Wood Sci. Technol. 2012, 46, 5–21. [Google Scholar] [CrossRef]

- Zhou, Q.; Tu, D.; Liao, L.; Guo, Q. Variation of equilibrium moisture content of heat-treated couratari oblongifolia, Fraxinus excelsior, and Quercus rubra wood. BioResources 2013, 8, 182–188. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Ramsay, J.; Keating, B.; Laine, K.; Rautkari, L.; Hughes, M.; Constant, B. The water vapour sorption properties of thermally modified and densified wood. J. Mater. Sci. 2012, 47, 3191–3197. [Google Scholar] [CrossRef]

- Sargent, R. Evaluating Dimensional Stability in Modified Wood: An Experimental Comparison of Test Methods. Forests 2022, 13, 613. [Google Scholar] [CrossRef]

- Čermák, P.; Rautkari, L.; Horáček, P.; Saake, B.; Rademacher, P.; Sablík, P. Dimensional stability. BioResources 2015, 10, 3242–3253. [Google Scholar]

- Bak, M.; Németh, R. Changes in swelling properties and moisture uptake rate of oil-heat-treated poplar (Populus × euramericana cv. pannónia) wood. BioResources 2012, 7, 5128–5137. [Google Scholar] [CrossRef]

- Altgen, M.; Willems, W.; Hosseinpourpia, R.; Rautkari, L. Hydroxyl accessibility and dimensional changes of Scots pine sapwood affected by alterations in the cell wall ultrastructure during heat-treatment. Polym. Degrad. Stab. 2018, 152, 244–252. [Google Scholar] [CrossRef]

- Výbohová, E.; Kučerová, V.; Andor, T.; Balážová, Ž.; Veľková, V. The Effect of Heat Treatment on the Chemical Composition of Ash Wood. BioResources 2018, 13, 8394–8408. [Google Scholar] [CrossRef]

- Windeisen, E.; Bächle, H.; Zimmer, B.; Wegener, G. Relations between chemical changes and mechanical properties of thermally treated wood. Holzforschung 2009, 63, 773–778. [Google Scholar] [CrossRef]

- Candelier, K.; Hannouz, S.; Thévenon, M.F.; Guibal, D.; Gérardin, P.; Pétrissans, M.; Collet, R. Resistance of thermally modified ash (Fraxinus excelsior L.) wood under steam pressure against rot fungi, soil-inhabiting micro-organisms and termites. Eur. J. Wood Wood Prod. 2017, 75, 249–262. [Google Scholar] [CrossRef]

- Todorović, N.; Popović, Z.; Milić, G.; Veizović, M.; Popadić, R. Quality evaluation of heat-treated sessile oak (Quercus petraea L.) wood by colour and FT-NIR spectroscopy. Wood Mater. Sci. Eng. 2020, 17, 202–209. [Google Scholar] [CrossRef]

- Gonzalez, J.J.; Bond, B.; Quesada, H. Variability in the Mechanical Properties of Commercially Available Thermally Modified Hardwood Lumber. BioResources 2021, 16, 6083–6099. [Google Scholar] [CrossRef]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Roszyk, E.; Stachowska, E.; Majka, J.; Mania, P.; Broda, M. Moisture-dependent strength properties of thermally-modified Fraxinus excelsior wood in compression. Materials 2020, 13, 1647. [Google Scholar] [CrossRef]

- Hannouz, S.; Collet, R.; Butaud, J.-C.; Bléron, L.; Candelier, K.; Mechanical, K.C. Mechanical characterization of heat-treated ash wood in relation with structural timber standards. Open Access Sci. J. Field Wood Eng. 2015, 11, 13. [Google Scholar]

- Majka, J.; Roszyk, E. Swelling restraint of thermally modified ash wood perpendicular to the grain. Eur. J. Wood Wood Prod. 2018, 76, 1129–1136. [Google Scholar] [CrossRef]

- Straže, A.; Fajdiga, G.; Pervan, S.; Gorišek, Ž. Hygro-mechanical behavior of thermally treated beech subjected to compression loads. Constr. Build. Mater. 2016, 113, 28–33. [Google Scholar] [CrossRef]

- Widmann, R.; Fernandez-Cabo, J.L.; Steiger, R. Mechanical properties of thermally modified beech timber for structural purposes. Eur. J. Wood Wood Prod. 2012, 70, 775–784. [Google Scholar] [CrossRef]

- Kozakiewicz, P.; Laskowska, A.; Drożdżek, M.; Zawadzki, J. Influence of Thermal Modification in Nitrogen Atmosphere on Physical and Technological Properties of European Wood Species with Different Structural Features. Coatings 2022, 12, 1663. [Google Scholar] [CrossRef]

- Zhan, T.; Zhu, J.; Liu, Z.; Li, T.; Peng, H.; Jiang, J.; Lyu, J. Meta-analysis of chromatic properties of heat-treated wood. Eur. J. Wood Wood Prod. 2022, 80, 851–858. [Google Scholar] [CrossRef]

- Chen, Y.; Fan, Y.; Gao, J.; Li, H. Coloring characteristics of in situ lignin during heat treatment. Wood Sci. Technol. 2012, 46, 33–40. [Google Scholar] [CrossRef]

- Salca, E.A.; Kobori, H.; Inagaki, T.; Kojima, Y.; Suzuki, S. Effect of heat treatment on colour changes of black alder and beech veneers. J. Wood Sci. 2016, 62, 297–304. [Google Scholar] [CrossRef]

| MC [%] | MC [%] after 12 Months in Room Conditions | |||

|---|---|---|---|---|

| Maple | Ash | Maple | Ash | |

| Unmodified | 7.6 (0.3) * | 5.8 (0.9) * | 8.2 (0.2) | 8.1 (0.2) |

| Slow TM | 4.0 (0.3) | 3.5 b (0.4) | 4.0 (0.3) | 3.9 (0.3) |

| Fast TM | 5.4 (0.5) | 4.1 b (0.3) | 5.3 (0.3) | 4.5 (0.2) |

| MCmod/MCunmod | Maple | Ash | ||

|---|---|---|---|---|

| RH = 72% | RH = 85% | RH = 72% | RH = 85% | |

| Slow TM | 0.45 | 0.40 | 0.45 | 0.40 |

| Fast TM | 0.59 | 0.50 | 0.51 | 0.45 |

| ρ₀ [kg/m3] | Swelling (%) | ||||

|---|---|---|---|---|---|

| Radial | Tang. | Vol. | |||

| Maple | Unmodified | 583 (24) | 4.21 (0.46) | 9.19 (0.80) | 14.21 (0.81) |

| Slow TM | 556 a (28) | 2.39 a (0.20) | 4.63 (0.41) | 7.40 (0.57) | |

| Fast TM | 539 a (39) | 2.63 a (0.58) | 5.71 (0.59) | 8.78 (0.71) | |

| Ash | Unmodified | 679 (24) | 5.72 (0.65) | 13.49 (0.80) | 20.40 (1.32) |

| Slow TM | 631 b (25) | 2.69 (0.37) | 5.10 (0.70) | 8.27 (0.79) | |

| Fast TM | 650 b,* (39) | 3.23 (0.28) | 5.94 (0.53) | 9.56 (0.83) | |

| ASE [%] | Maple | Ash |

|---|---|---|

| Slow TM | 47.9 | 59.3 |

| Fast TM | 38.6 | 53.2 |

| MOE [N/mm2] | MOR (N/mm2) | CS (N/mm2) | BH (N/mm2) | |||

|---|---|---|---|---|---|---|

| Radial | Tangential | |||||

| Maple | Unmodified | 10,993 (1071) | 128.8 (16.5) | 74.4 (5.8) | 29.1 (3.6) | 35.2 (4.0) |

| Slow TM | 10,267 * (1012) | 99.6 (17.5) | 75.2 * (8.1) | 27.5 * (4.1) | 33.8 * (5.7) | |

| Fast TM | 9101 (1272) | 83.8 (19.1) | 66.6 (7.7) | 21.7 (4.2) | 23.0 (5.4) | |

| Ash | Unmodified | 11,040 (1752) | 131.8 (18.7) | 78.6 (9.4) | 34.8 (4.3) | 41.8 (9.3) |

| Slow TM | 11,305 * (1281) | 82.6 b (20.1) | 81.2 *,b (9.4) | 31.7 *,b (4.5) | 31.1 (6.0) | |

| Fast TM | 9514 * (1932) | 91.0 b (27.9) | 79.7 *,b (9.0) | 35.3 *,b (6.0) | 40.6 * (10.5) | |

| L * | a * | b * | ΔE * Un. vs. TM | ΔE * Slow vs. Fast | ||

|---|---|---|---|---|---|---|

| Maple | Unmodified | 74.5 (2.8) | 5.0 (0.8) | 14.5 (0.9) | - | |

| Slow TM | 44.1 a (2.2) | 9.3 (0.3) | 18.7 (1.7) | 31.7 (3.8) | 5.1 | |

| Fast TM | 41.0 a (1.0) | 10.8 (0.4) | 22.4 (0.8) | 34.5 (2.0) | ||

| Ash | Unmodified | 69.5 (3.1) | 6.6 (1.0) | 17.2 (1.6) | - | |

| Slow TM | 39.6 b (1.4) | 8.2 (0.3) | 14.7 (1.2) | 28.9 (3.9) | 4.9 | |

| Fast TM | 36.6 b (1.6) | 10.1 (0.4) | 18.2 * (0.8) | 34.0 (3.4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milić, G.; Todorović, N.; Veizović, M.; Popadić, R. Heating Rate during Thermal Modification in Steam Atmosphere: Influence on the Properties of Maple and Ash Wood. Forests 2023, 14, 189. https://doi.org/10.3390/f14020189

Milić G, Todorović N, Veizović M, Popadić R. Heating Rate during Thermal Modification in Steam Atmosphere: Influence on the Properties of Maple and Ash Wood. Forests. 2023; 14(2):189. https://doi.org/10.3390/f14020189

Chicago/Turabian StyleMilić, Goran, Nebojša Todorović, Marko Veizović, and Ranko Popadić. 2023. "Heating Rate during Thermal Modification in Steam Atmosphere: Influence on the Properties of Maple and Ash Wood" Forests 14, no. 2: 189. https://doi.org/10.3390/f14020189

APA StyleMilić, G., Todorović, N., Veizović, M., & Popadić, R. (2023). Heating Rate during Thermal Modification in Steam Atmosphere: Influence on the Properties of Maple and Ash Wood. Forests, 14(2), 189. https://doi.org/10.3390/f14020189