Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana korshinskii (C.K.) Branches

Abstract

:1. Introduction

2. Materials and Methods

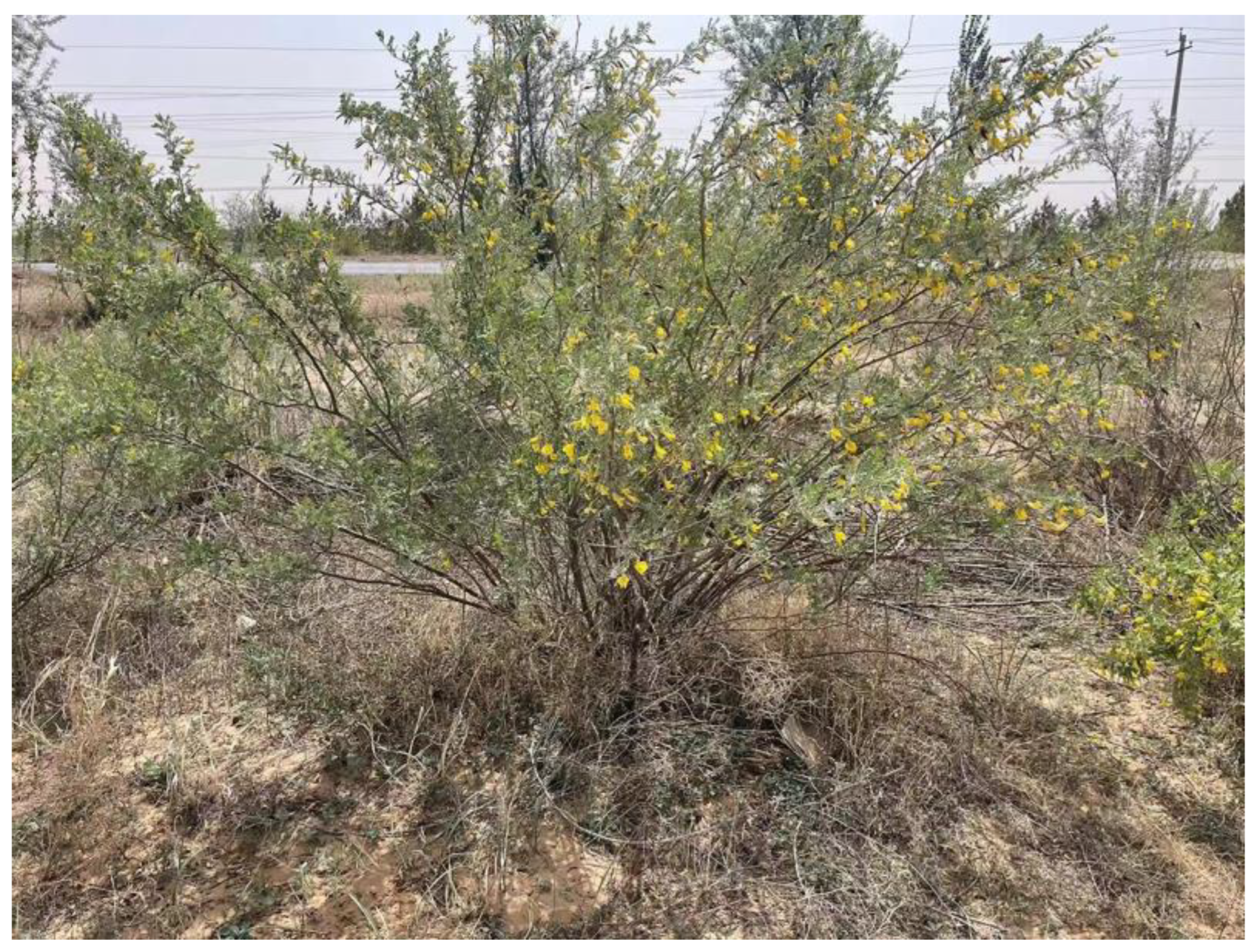

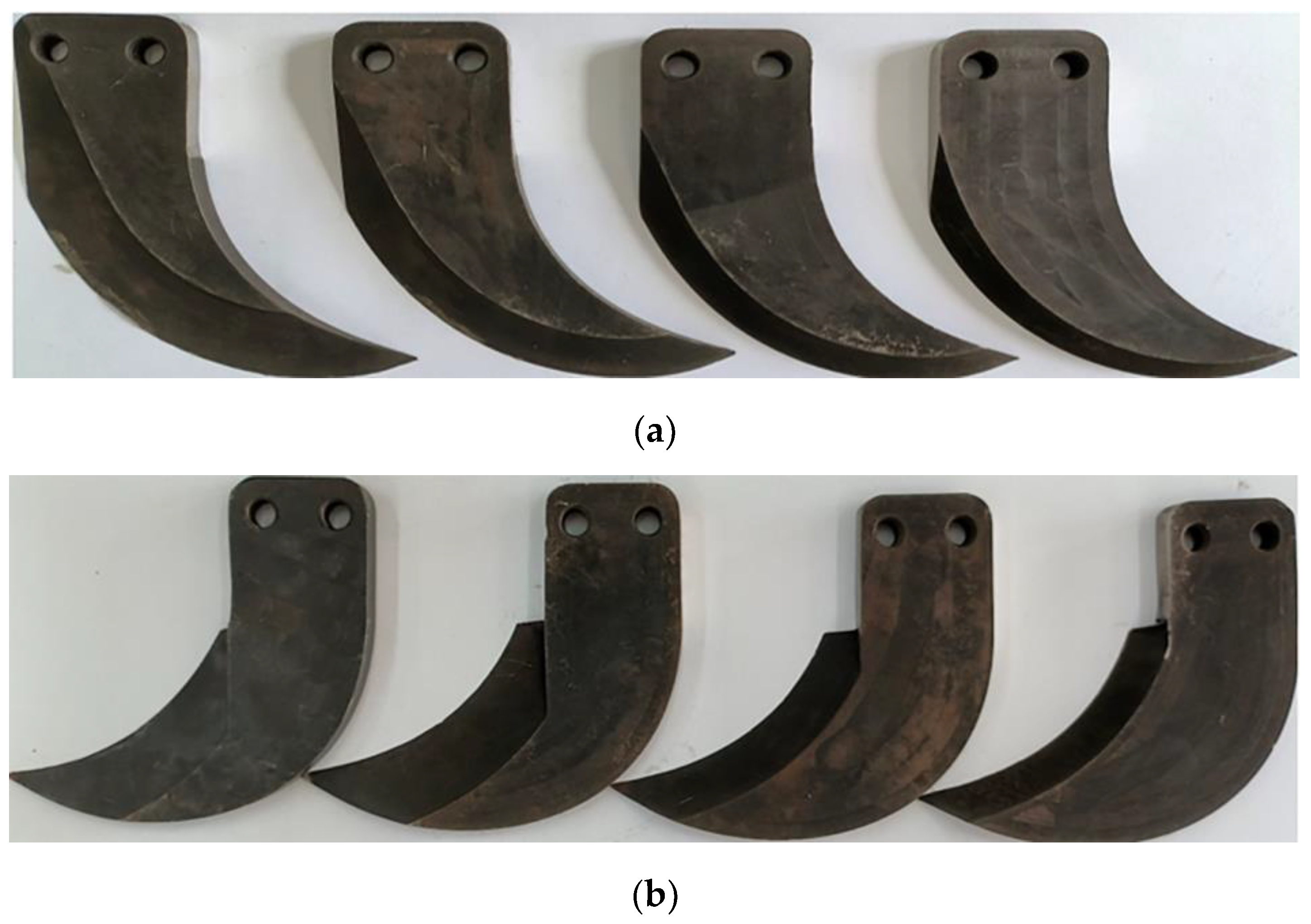

2.1. Test Materials

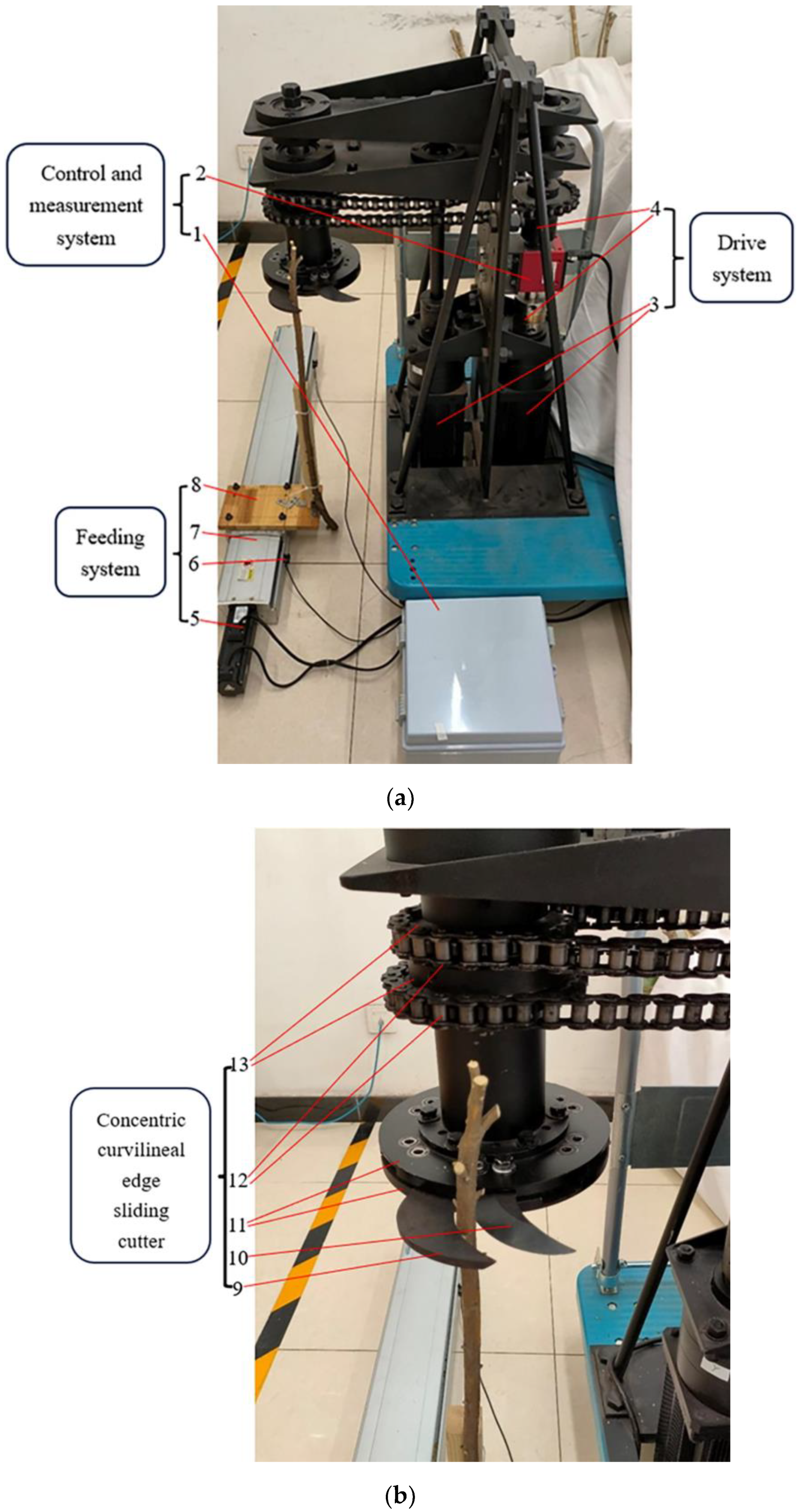

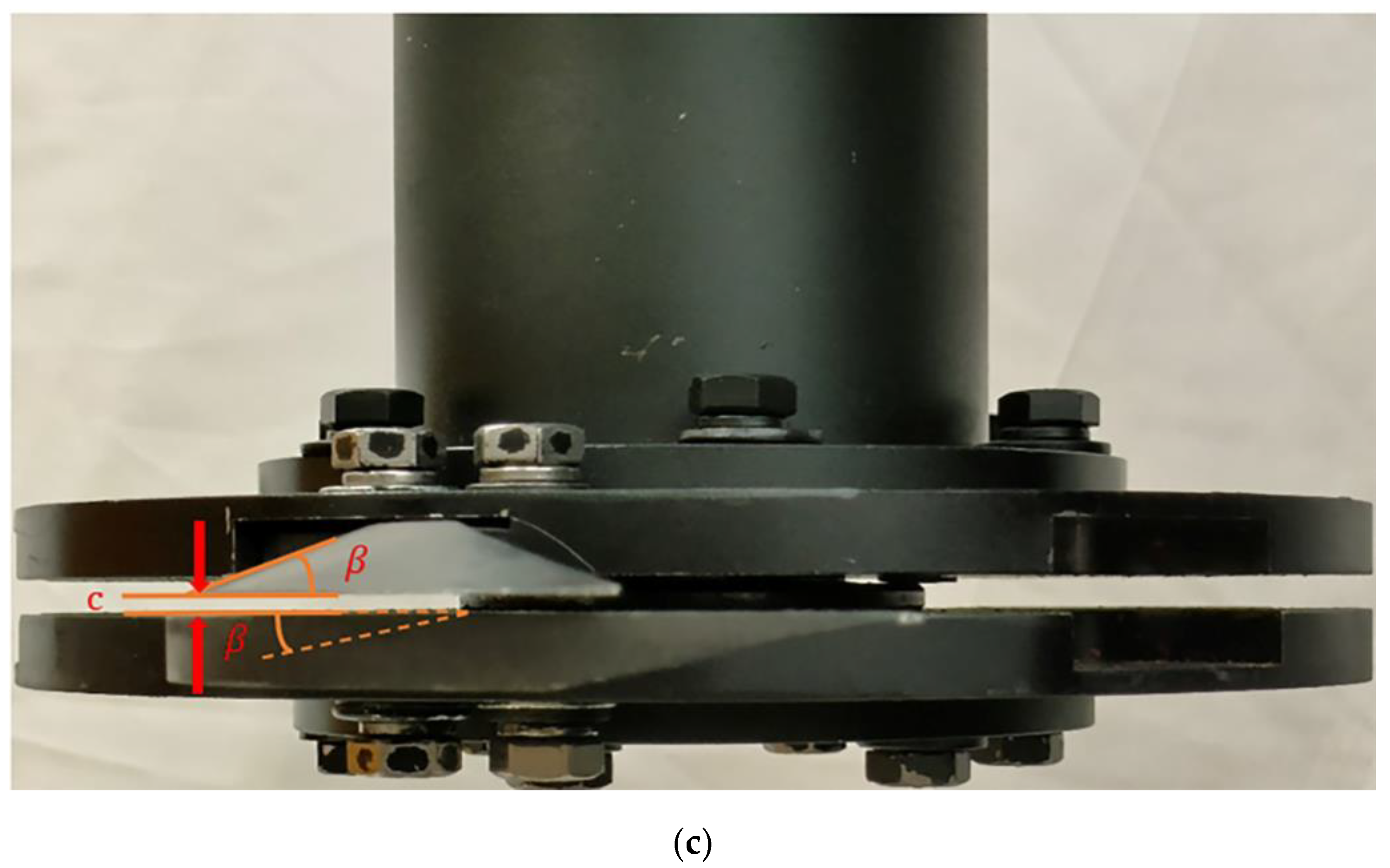

2.2. Cutting Test Bench

2.3. Test Indicators

2.3.1. Peak Torque

2.3.2. Cutting Energy

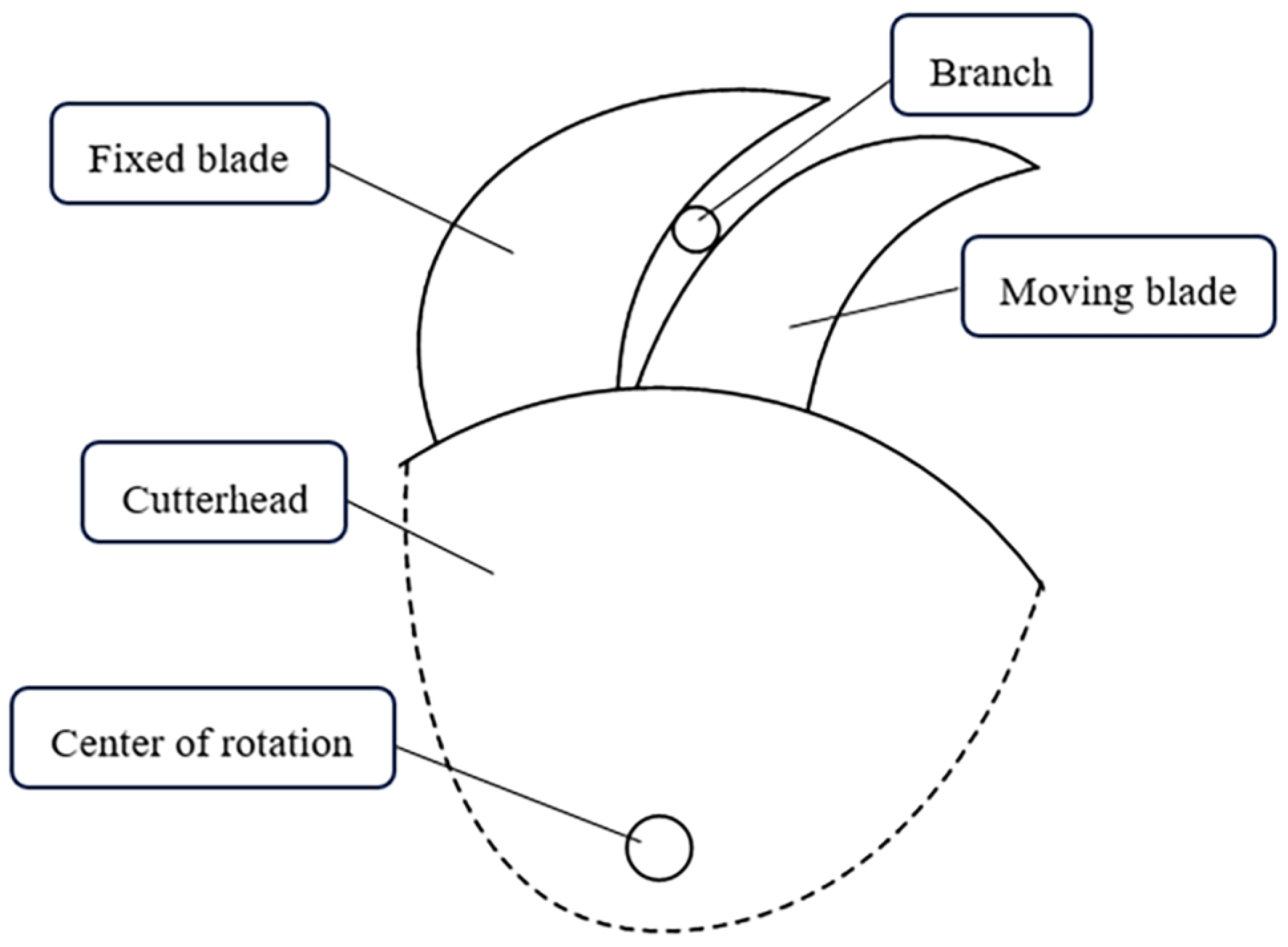

2.4. Cutting Principle

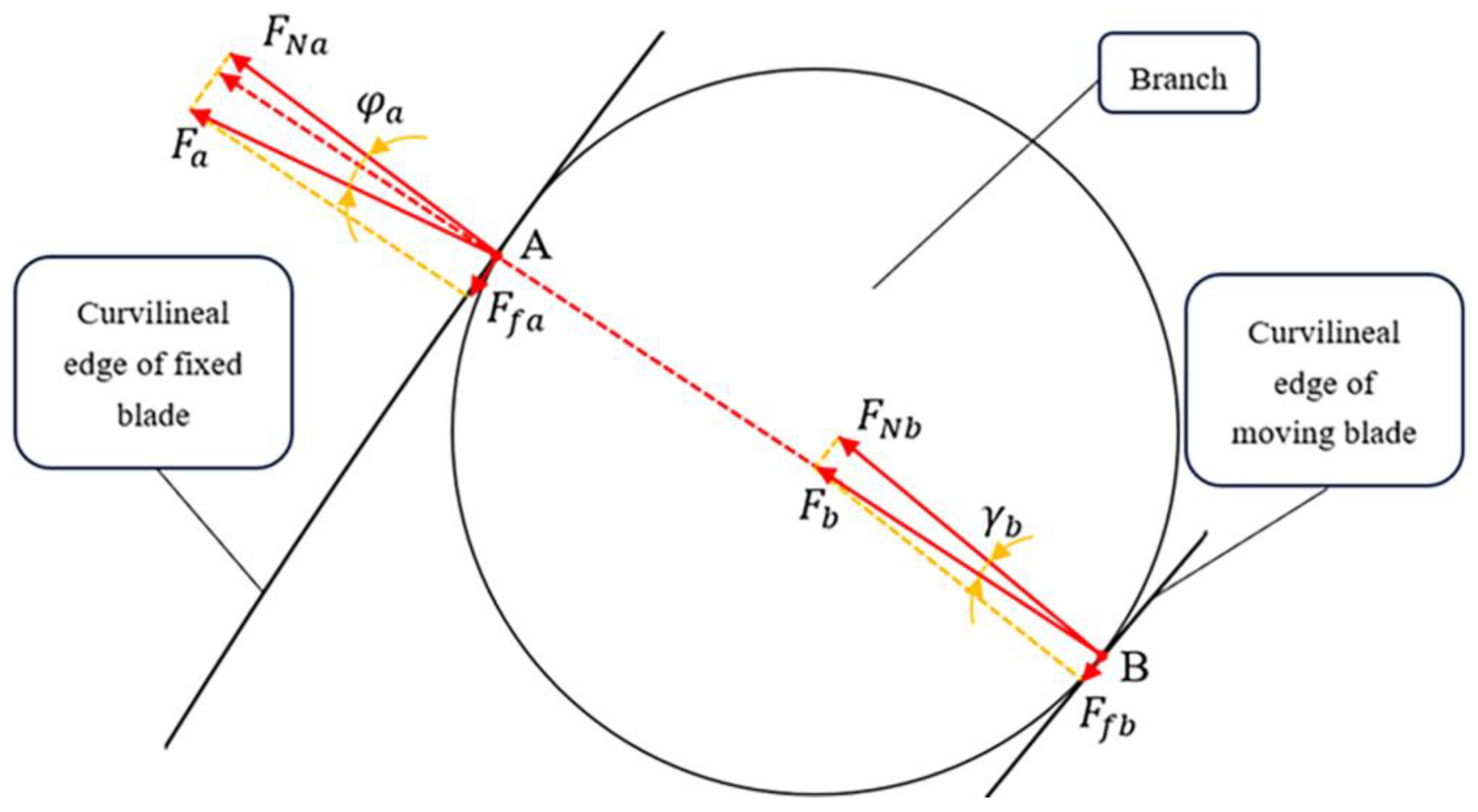

2.4.1. Clamping Stage

2.4.2. Sliding Stage

3. Experimental Design

3.1. Single-Factor Experiment Design

3.2. Multi-Factor Experimental Design

4. Results

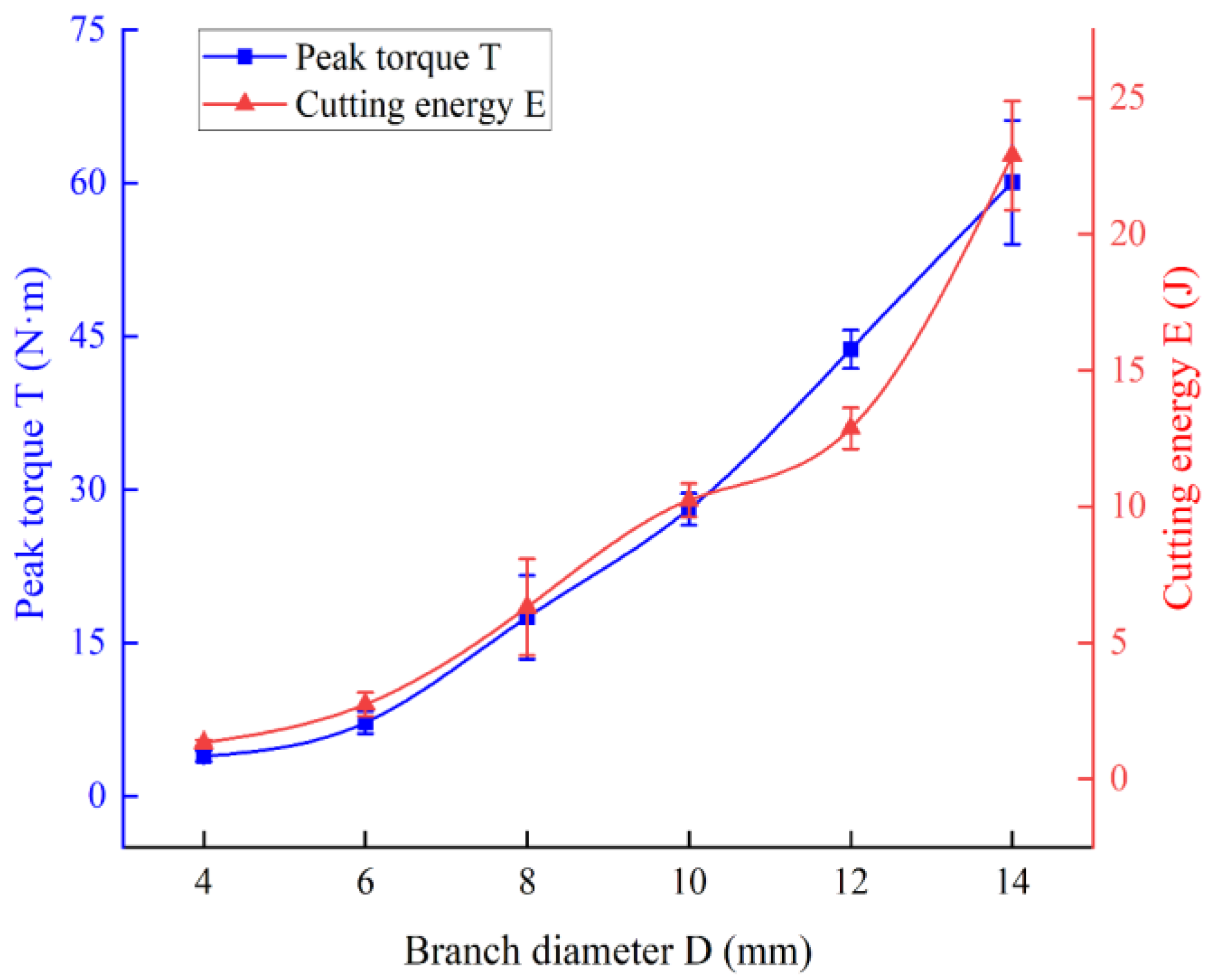

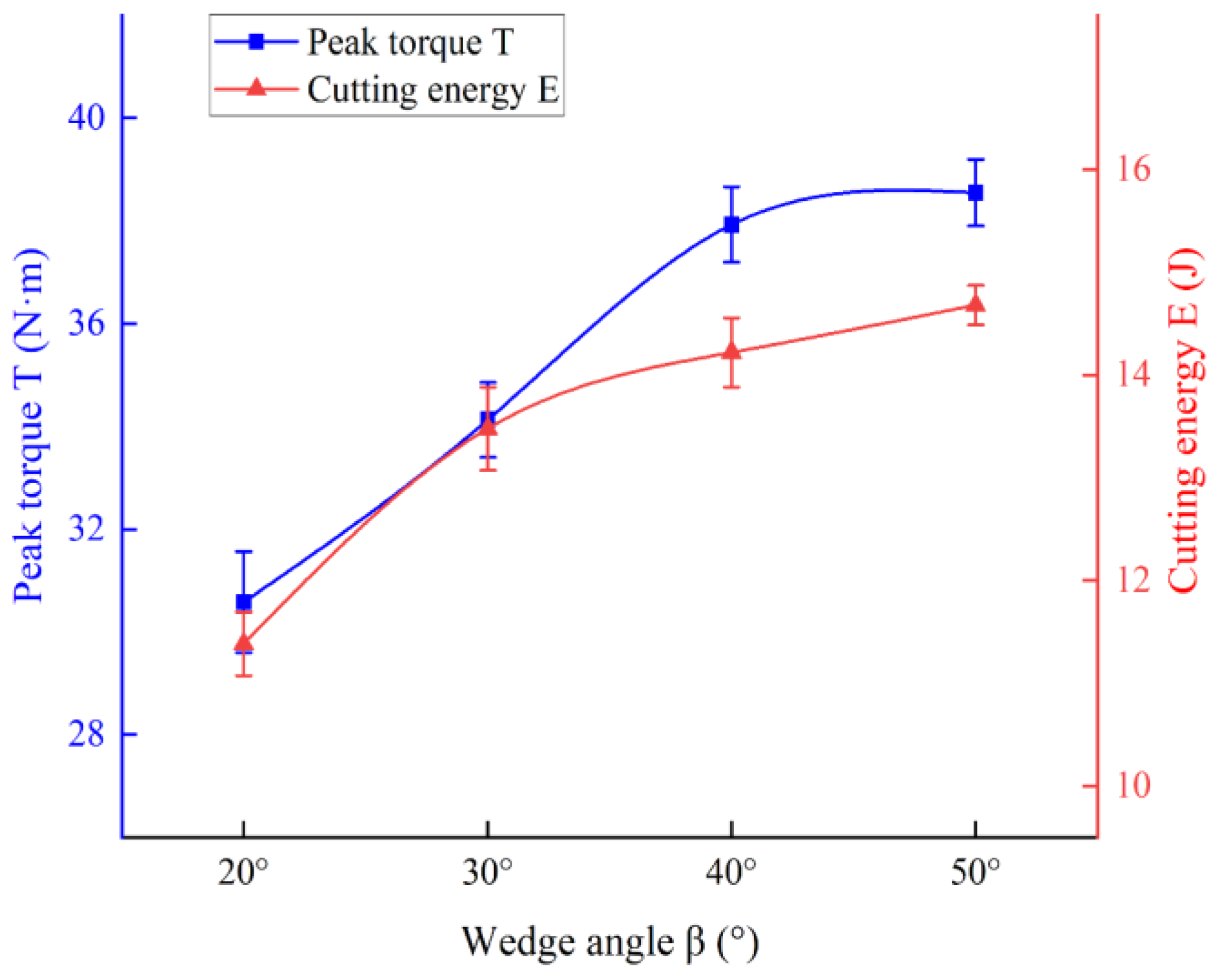

4.1. Single-Factor Test Results

4.2. Multi-Factor Test Results

5. Discussion

5.1. Analysis of Single-Factor Tests

5.1.1. Branch Diameter

5.1.2. Cutting Speed

5.1.3. Wedge Angle

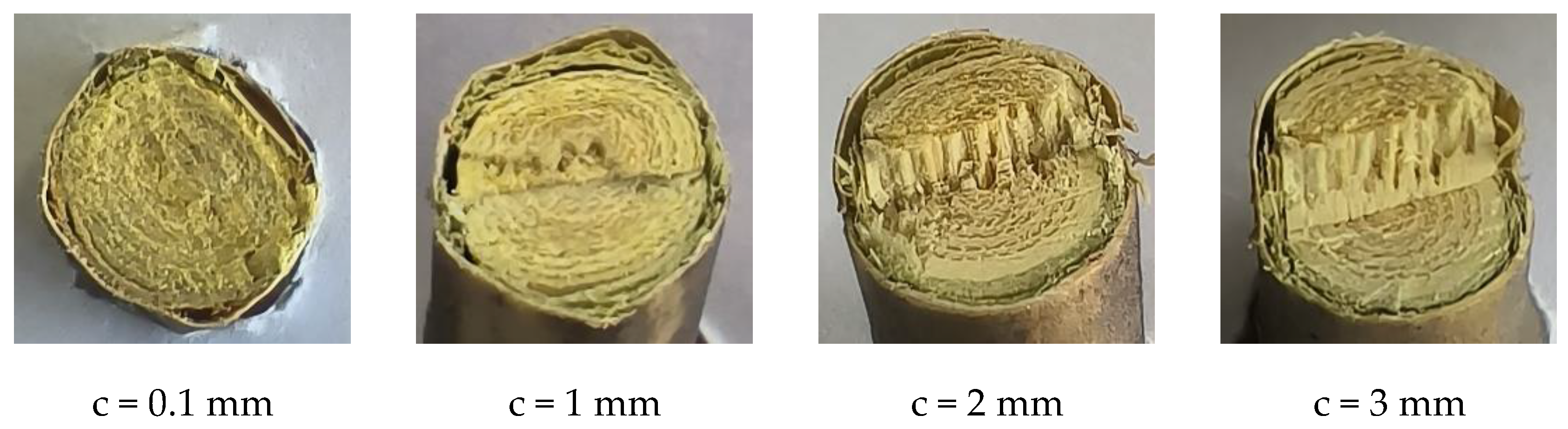

5.1.4. Cutting Clearance

5.1.5. Moisture Content

5.2. Multi-Factor Test Analysis

5.2.1. Variational Analysis (ANOVA)

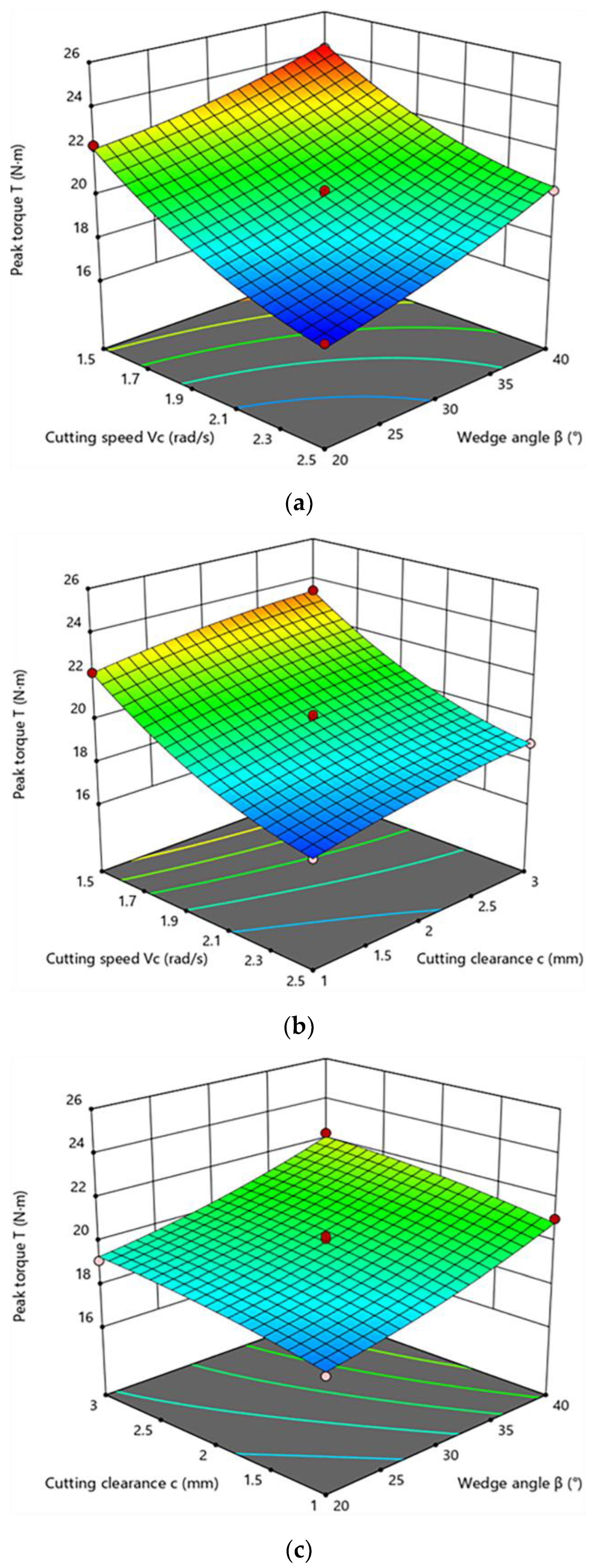

5.2.2. Response Surface Analysis

5.3. Optimization of the Parameters and Experimental Validation

5.4. Comparison of Peak Cutting Force and Cutting Energy

6. Conclusions

- A concentric curvilineal edge sliding cutter is proposed in this paper. Two sets of curvilineal edge blades were mounted on two concentrically nested cutterheads. The clamping stage and sliding stage of the concentric curvilineal edge sliding cutter were studied to explore the cutting mechanism;

- With the concentric curvilineal edge sliding cutter, the peak torque and cutting energy of C.K. branch pruning stubble were tested and studied. Through single-factor and multi-factor experiments, the relationship between branch diameter, cutting speed, wedge angle, cutting clearance, moisture content and peak torque, cutting energy were explored. Test results: (1) Peak torque grows with the increase in branch diameter and wedge angle; it decreases with the growth of cutting speed and moisture content, and with the growth of cutting clearance, it declines first and then rises. (2) Cutting energy increases with increasing branch diameter and wedge angle, it reduces with the increase in moisture content, and as the growth of cutting clearance and cutting speed, first it will reduce and then it will rise. (3) The results of multi-factor tests were consistent with those of single-factor tests. The optimum combination of parameters is the following: cutting speed is 2.16 rad/s, wedge angle is 20, cutting clearance is 1.0 mm. The peak torque for this combination is 17.25 N·m, and the cutting energy is 7.03 J, which are confirmed by the validation tests with discrepancies of 0.87% and 5.004%.

- Compared with the reciprocating cutting tool under the optimal parameter combination, the peak cutting force is reduced by 78.8%. The concentric curvilineal edge sliding cutter is verified to be more labor-saving with guaranteed cutting section quality and a very similar cutting energy. The concentric curvilineal edge sliding cutter can be used as a cutting tool module to provide rotational and forward momentum to support it in its work. It can provide new cutter and data support for the development of subsequent C.K. branch stubble equipment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Long, Y.; Liang, F.P.; Zhang, J.W.; Xue, M.D.; Zhang, T.B.; Pei, X.W. Identification of drought response genes by digital gene expression (due) analysis in Caragana korshinskii koi. Gene 2022, 725, 144170. [Google Scholar] [CrossRef]

- Gao, Y.; Kang, F.; Kan, J.; Wang, Y.; Tong, S. Analysis and Experiment of Cutting Mechanical Parameters for Caragana korshinskii (C.k.) Branches. Forests 2021, 12, 1359. [Google Scholar] [CrossRef]

- Li, L.; Yu, G. On Mechanism and Equipment of Large scale Shrub Harvester. J. Anhui Agric. Sci. 2009, 37, 1862–1864. [Google Scholar]

- Aydin, I.; Arslan, S. Mechanical properties of cotton shoots for topping. Ind. Crop. Prod. 2018, 112, 396–401. [Google Scholar] [CrossRef]

- Huang, J.; Tian, K.; Shen, C.; Zhang, B.; Liu, H.; Chen, Q.; Li, X.; Ji, A. Design and parameters optimization for cutting-conveying mechanism of ramie combine harvester. Int. J. Agric. Biol. Eng. 2020, 13, 94–103. [Google Scholar] [CrossRef]

- Aponte-Roa, D.A.; Collazo, X.; Goenaga, M.; Espinoza, A.A.; Vazquez, K. Development and Evaluation of a Remote Controlled Electric Lawn Mower. In Proceedings of the 9th IEEE Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 7–9 January 2019; pp. 90–94. [Google Scholar]

- Cacot, M.; Bigot, E.; Cuchet, E. Developing full-mechanized harvesting systems for broadleaved trees: A challenge to face the reduction of the manual workforce and to sustain the supply of hardwood industries. In Proceedings of the 29th Council on Forest Engineering (COFE) Conference Proceedings: Working Globally—Sharing Forest Engineering Challenges and Technologies around the World, Coeur d’Alene, ID, USA, 22 July–2 August 2006. [Google Scholar]

- Dvoracek, O.; Lechowicz, D.; Haas, F.; Frybort, S. Cutting force analysis of oak for the development of a cutting force model. Wood Mater. Sci. Eng. 2022, 17, 51–74. [Google Scholar]

- Svoren, J.; Nascak, L.; Koleda, P.; Barcik, S.; Nemec, M. The circular saw blade body modification by elastic material layer effecting circular saws sound pressure level when idling and cutting. Appl. Acoust. 2021, 179, 108028. [Google Scholar] [CrossRef]

- Nasir, V.; Mohammadpanah, A.; Cool, J. The effect of rotation speed on the power consumption and cutting accuracy of guided circular saw: Experimental measurement and analysis of saw critical and flutter speeds. Wood Mater. Sci. Eng. 2020, 15, 140–146. [Google Scholar] [CrossRef]

- Huan, X.; You, Y.; Wang, D.; Li, S.; Zhu, L.; Liao, Y. Design and Experiment of Rotary Cutter Disc Type Flat Stubble Cutting Device for King Grass Harvester. Nongye JixieXuebao/Trans. Chin. Soc. Agric. Mach. 2022, 53, 112–124. [Google Scholar]

- Koc, A.B.; Liu, B. Ultrasonic cutting of switchgrass and miscanthus stems. Appl. Eng. Agric. 2018, 34, 343–353. [Google Scholar] [CrossRef]

- Pichler, P.; Springer, S.; Leitner, M. Evaluation of wood cutting forces in dry and wet conditions by small-scale chipping tests applying different analysis methods. Wood Mater. Sci. Eng. 2019, 14, 185–190. [Google Scholar] [CrossRef]

- Song, S.Y.; Zhou, H.P.; Xu, L.Y.; Jia, Z.C.; Hu, G.M. Cutting mechanical properties of sisal leaves under rotary impact cutting. Ind. Crop. Prod. 2022, 182, 114856. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, Q.; Guo, Y.; Li, H. Experiment and analysis of cutting mechanical properties of millet stem. Nongye JixieXuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 146–155. [Google Scholar]

- Kang, F.; Tong, S.; Zhang, H.; Li, W.; Chen, Z.; Zheng, Y. Analysis and experiments of reciprocating cutting parameters for apple tree branches. Nongye GongchengXuebao/Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–16. [Google Scholar]

- Gao, Y.Y.; Kang, F.; Kan, J.M.; Wang, Y.T. Multi-objective optimization of cross-section integrity rate and sawing power consumption in sawing Caragana korshinskii Kom. branches. Ind. Crops Prod. 2023, 193, 116244. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Wang, Y.T.; Qu, A.L.; Wang, Y.T.; Kan, J.M.; Kang, F. Study of Sawing Parameters for Caragana korshinskii (C.K.) Branches. Forests 2022, 13, 327. [Google Scholar] [CrossRef]

- GB/T 1299-2014; Alloy Tool Steels. The National Standards of the People’s Republic of China: Bejing, China, 2014. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT1299-2014 (accessed on 25 October 2023).

- Oraby, S.E.; Hayhurst, D.R. Tool life determination based on the measurement of wear and tool force ratio variation. Int. J. Mach. Tool. Manuf. 2004, 44, 1261–1269. [Google Scholar] [CrossRef]

- Li, Z.P.; Zhang, C.; Wang, B.N. Research on design of blueberry picker based on vibration strategy. For. Eng. 2020, 36, 55–61. [Google Scholar]

- Nasir, V.; Cool, J. Cutting power and surface quality in sawing kiln-dried, green, and frozen hem-fir wood. Wood Sci. Technol. 2021, 55, 505–519. [Google Scholar] [CrossRef]

- Wargula, L.; Kukla, M.; Wieczorek, B.; Krawiec, P. Energy consumption of the wood size reduction processes with employment of a low-power machines with various cutting mechanisms. Renew. Energy 2022, 181, 630–639. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, B.; Li, X.W.; Yin, G.D.; Chen, Q.M.; Xia, C.H. Bench cutting tests and analysis for harvesting hemp stalk. Int. J. Agric. Biol. Eng. 2017, 10, 56–67. [Google Scholar]

- Xun, H.Y. Discussion on sliding cutting theory. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 1979, 4, 107–111. [Google Scholar]

- Xiao, X.; Huang, J.J.; Li, M.; Xu, Y.W.; Zhang, H.D. Parameter analysis and experiment of citrus stalk cutting for robot picking. Eng. Agric. 2021, 41, 551–558. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.T.; Yang, Y.; Zhao, H.M.; Yang, C.H.; He, Y.; Wang, K.; Liu, D.; Xu, H.B. Discrete element modelling of citrus fruit stalks and its verification. Biosyst. Eng. 2020, 200, 400–414. [Google Scholar] [CrossRef]

- Che, C.W.; Xiao, S.C.; Ding, A.J.; Peng, X.M.; Su, J.R. The characteristics of radial growth and ecological response of Caragana korshinskii Kom. under different precipitation gradient in the Western Loess Plateau, China. Front. Plant Sci. 2022, 13, 862529. [Google Scholar] [CrossRef]

- Mathanker, S.K.; Grift, T.E.; Hansen, A.C. Effect of blade oblique angle and cutting speed on cutting energy for energycane stems. Biosyst. Eng. 2015, 133, 64–70. [Google Scholar] [CrossRef]

- Wu, B.; Wang, D.; Wang, G.; Fu, Z.; Kang, C. Optimization and experiments of cut-condition device working parameter on mower conditioner. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 76–83. [Google Scholar]

| Level | Branch Diameter D (mm) | (rad/s) | (°) | (mm) | Moisture Content W (%) |

|---|---|---|---|---|---|

| 1 | 4 | 1.5 | 20 | 0.1 | 13.2 |

| 2 | 6 | 2.0 | 30 | 1 | 16.3 |

| 3 | 8 | 2.5 | 40 | 2 | 19.6 |

| 4 | 10 | 3.0 | 50 | 3 | 23.5 |

| 5 | 12 | ||||

| 6 | 14 |

| Level | (rad/s) | (°) | (mm) |

|---|---|---|---|

| −1 | 1.5 | 20 | 1 |

| 0 | 2 | 30 | 2 |

| 1 | 2.5 | 40 | 3 |

| Level | (rad/s) | (°) | (mm) | Peak Torque T (N·m) | Cutting Energy E (J) |

|---|---|---|---|---|---|

| 1 | 1 | 0 | 1 | 18.90 | 8.50 |

| 2 | 0 | −1 | −1 | 17.83 | 6.98 |

| 3 | 0 | −1 | 1 | 19.12 | 7.54 |

| 4 | 1 | 0 | −1 | 17.56 | 8.00 |

| 5 | −1 | 0 | 1 | 23.42 | 8.18 |

| 6 | −1 | −1 | 0 | 22.30 | 6.54 |

| 7 | −1 | 0 | −1 | 22.20 | 7.18 |

| 8 | 1 | 1 | 0 | 20.24 | 8.68 |

| 9 | 0 | 0 | 0 | 19.97 | 8.06 |

| 10 | −1 | 1 | 0 | 24.23 | 7.78 |

| 11 | 0 | 0 | 0 | 19.74 | 8.07 |

| 12 | 0 | 0 | 0 | 20.26 | 8.09 |

| 13 | 0 | 0 | 0 | 19.86 | 8.00 |

| 14 | 1 | −1 | 0 | 17.25 | 7.24 |

| 15 | 0 | 0 | 0 | 20.14 | 7.87 |

| 16 | 0 | 1 | 1 | 22.30 | 8.80 |

| 17 | 0 | 1 | −1 | 21.06 | 8.16 |

| Variance Source | Sum of Squares | Degree of Freedom | Mean Square | F Values | p Values |

|---|---|---|---|---|---|

| Model | 63.73 | 9 | 7.08 | 109.04 | <0.0001 |

| 41.4 | 1 | 41.40 | 637.64 | <0.0001 ** | |

| 16.05 | 1 | 16.05 | 247.11 | <0.0001 ** | |

| 3.24 | 1 | 3.24 | 49.87 | 0.0002 ** | |

| 0.2809 | 1 | 0.2809 | 4.33 | 0.0761 | |

| 0.0036 | 1 | 0.0036 | 0.0554 | 0.8206 | |

| 0.0006 | 1 | 0.0006 | 0.0096 | 0.9246 | |

| ² | 2.22 | 1 | 2.22 | 34.25 | 0.0006 ** |

| 0.3402 | 1 | 0.3402 | 5.24 | 0.0559 | |

| 0.1697 | 1 | 0.1697 | 2.61 | 0.1500 | |

| Residual | 0.4545 | 7 | 0.00649 | ||

| Lack of Fit | 0.2794 | 3 | 0.00931 | 2.13 | 0.2395 |

| Pure Error | 0.1751 | 4 | 0.0438 | ||

| Cor Total | 64.18 | 16 |

| Variance Source | Sum of Squares | Degree of Freedom | Mean Square | F Values | p Values |

|---|---|---|---|---|---|

| Model | 5.73 | 9 | 0.6366 | 58.04 | <0.0001 |

| 0.9385 | 1 | 0.9385 | 85.56 | <0.0001 ** | |

| 3.28 | 1 | 3.28 | 298.74 | <0.0001 ** | |

| 0.9112 | 1 | 0.9112 | 83.08 | <0.0001 ** | |

| 0.0100 | 1 | 0.0100 | 0.9117 | 0.3715 | |

| 0.0625 | 1 | 0.0625 | 5.70 | 0.0484 | |

| 0.0016 | 1 | 0.0016 | 0.1459 | 0.7138 | |

| 0.1387 | 1 | 0.1387 | 12.65 | 0.0093 ** | |

| 0.3219 | 1 | 0.3164 | 29.35 | 0.0010 ** | |

| 0.0695 | 1 | 0.0695 | 6.34 | 0.0399 * | |

| Residual | 0.0768 | 7 | 0.0110 | ||

| Lack of Fit | 0.0449 | 3 | 0.0150 | 1.88 | 0.2743 |

| Pure Error | 0.0319 | 4 | 0.0080 | ||

| Cor Total | 5.81 | 16 |

| Test Serial Number | Peak Torque T (N·m) | Cutting Energy E (J) |

|---|---|---|

| 1 | 17.5 | 6.72 |

| 2 | 17.2 | 6.54 |

| 3 | 16.8 | 6.31 |

| 4 | 18.2 | 7.21 |

| 5 | 17.3 | 6.62 |

| Average value | 17.4 | 6.68 |

| Relative errors | 0.87% | 5.004% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Guo, S.; Zhi, Z.; Kan, J. Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana korshinskii (C.K.) Branches. Forests 2023, 14, 2379. https://doi.org/10.3390/f14122379

Luo H, Guo S, Zhi Z, Kan J. Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana korshinskii (C.K.) Branches. Forests. 2023; 14(12):2379. https://doi.org/10.3390/f14122379

Chicago/Turabian StyleLuo, Haifeng, Shaojun Guo, Zhenkun Zhi, and Jiangming Kan. 2023. "Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana korshinskii (C.K.) Branches" Forests 14, no. 12: 2379. https://doi.org/10.3390/f14122379

APA StyleLuo, H., Guo, S., Zhi, Z., & Kan, J. (2023). Sliding Cutting and Cutting Parameters of Concentric Curvilineal Edge Sliding Cutter for Caragana korshinskii (C.K.) Branches. Forests, 14(12), 2379. https://doi.org/10.3390/f14122379