A Hydraulic Online Monitoring System for Forestry Harvesters Based on LabVIEW

Abstract

:1. Introduction

2. Materials and Methods

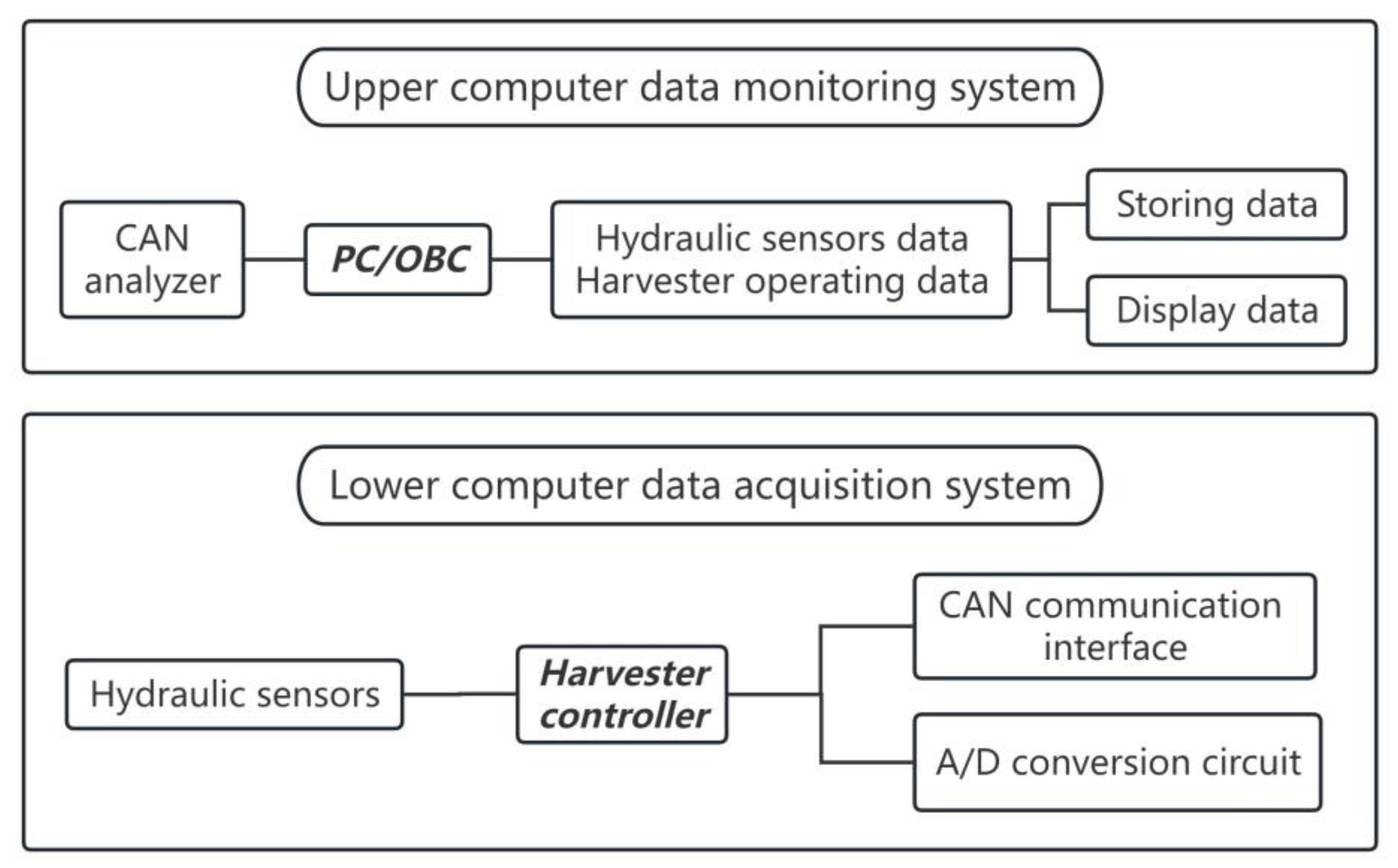

2.1. Subsection System Structure and Principle

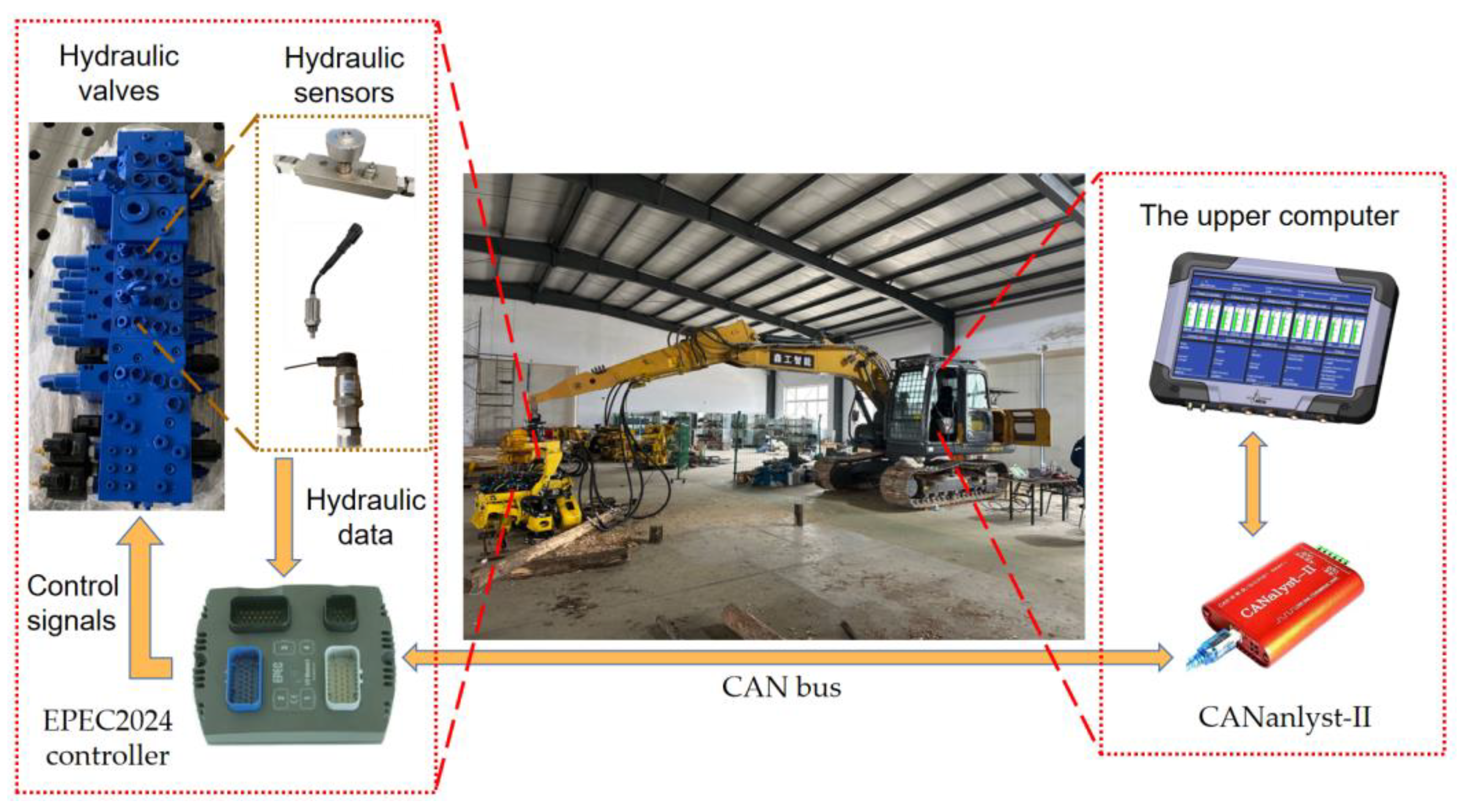

2.2. System Hardware Selection

2.3. System Software Design

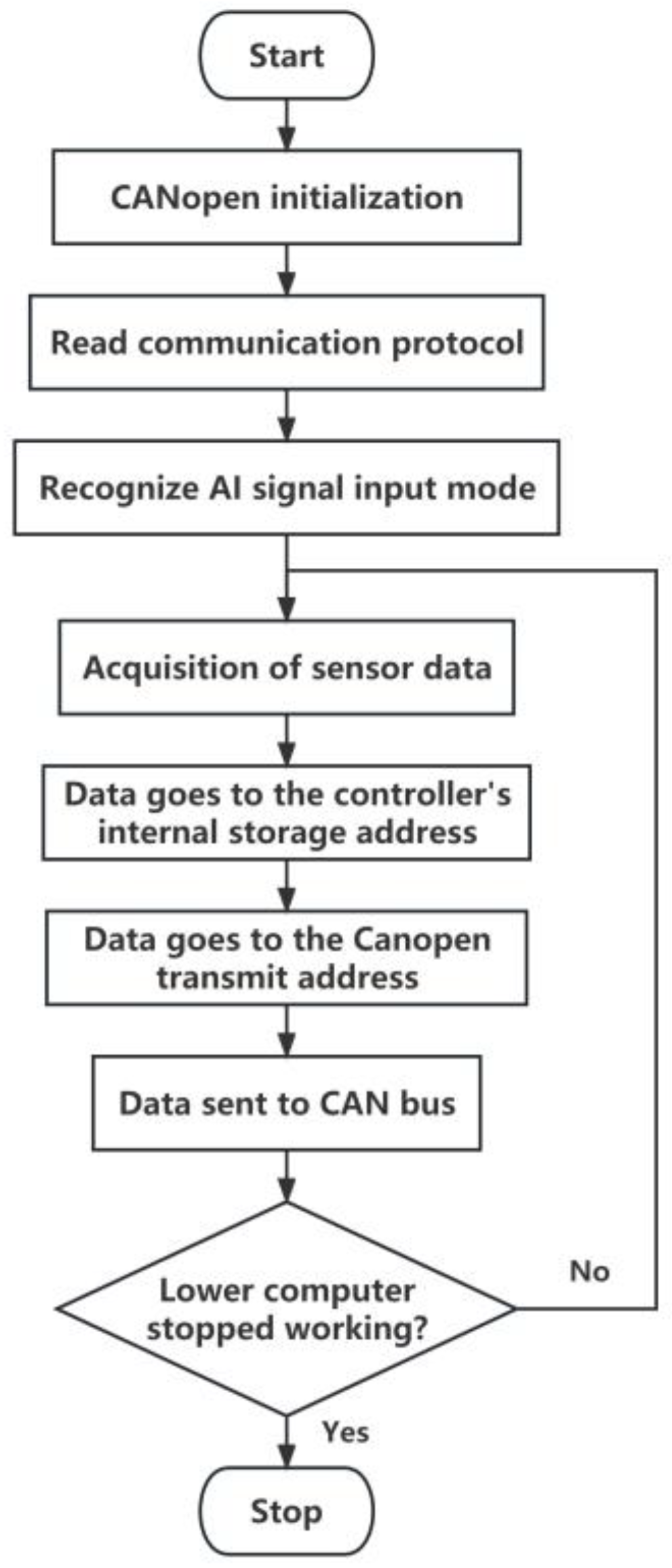

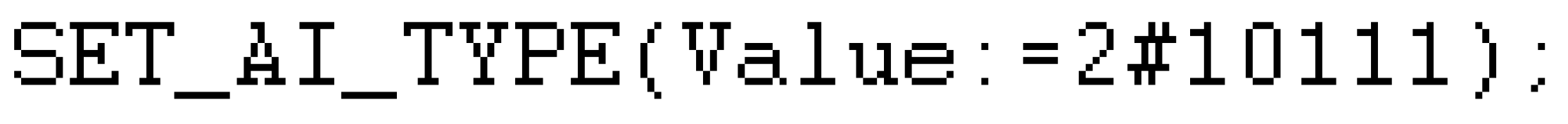

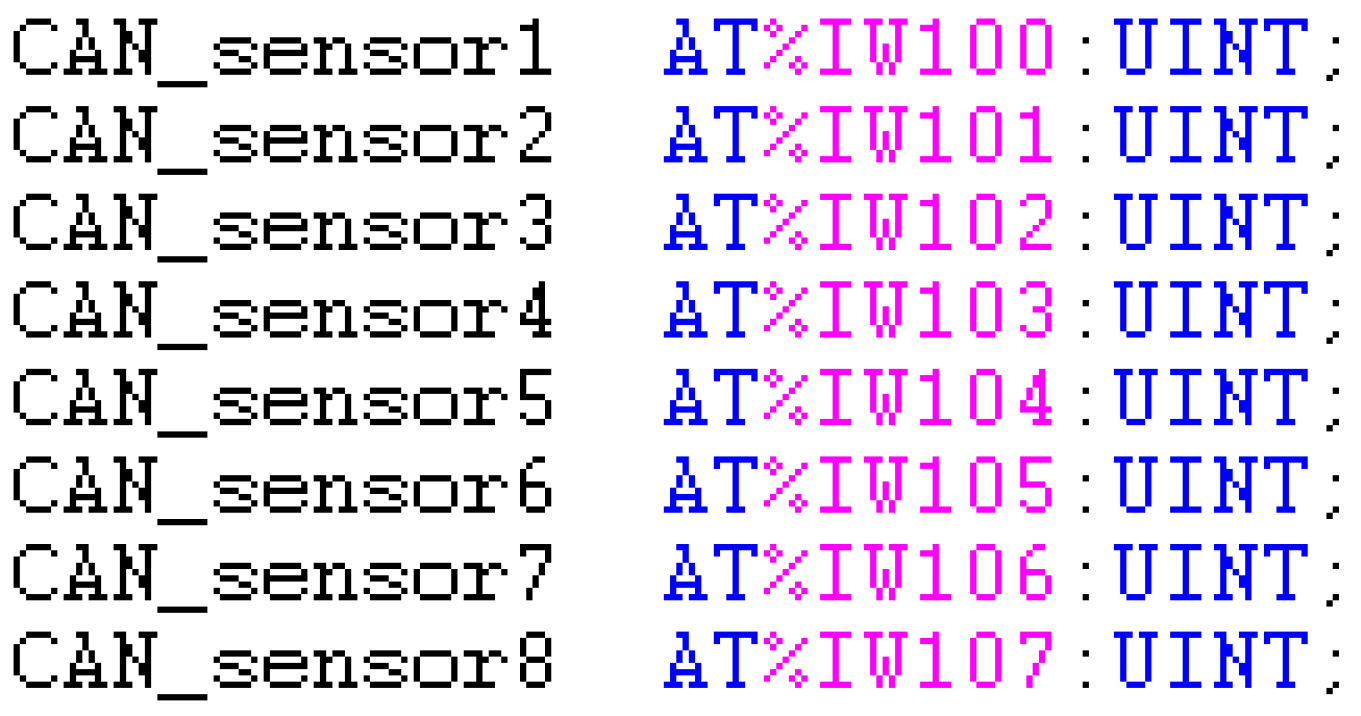

2.3.1. Lower Computer Programming

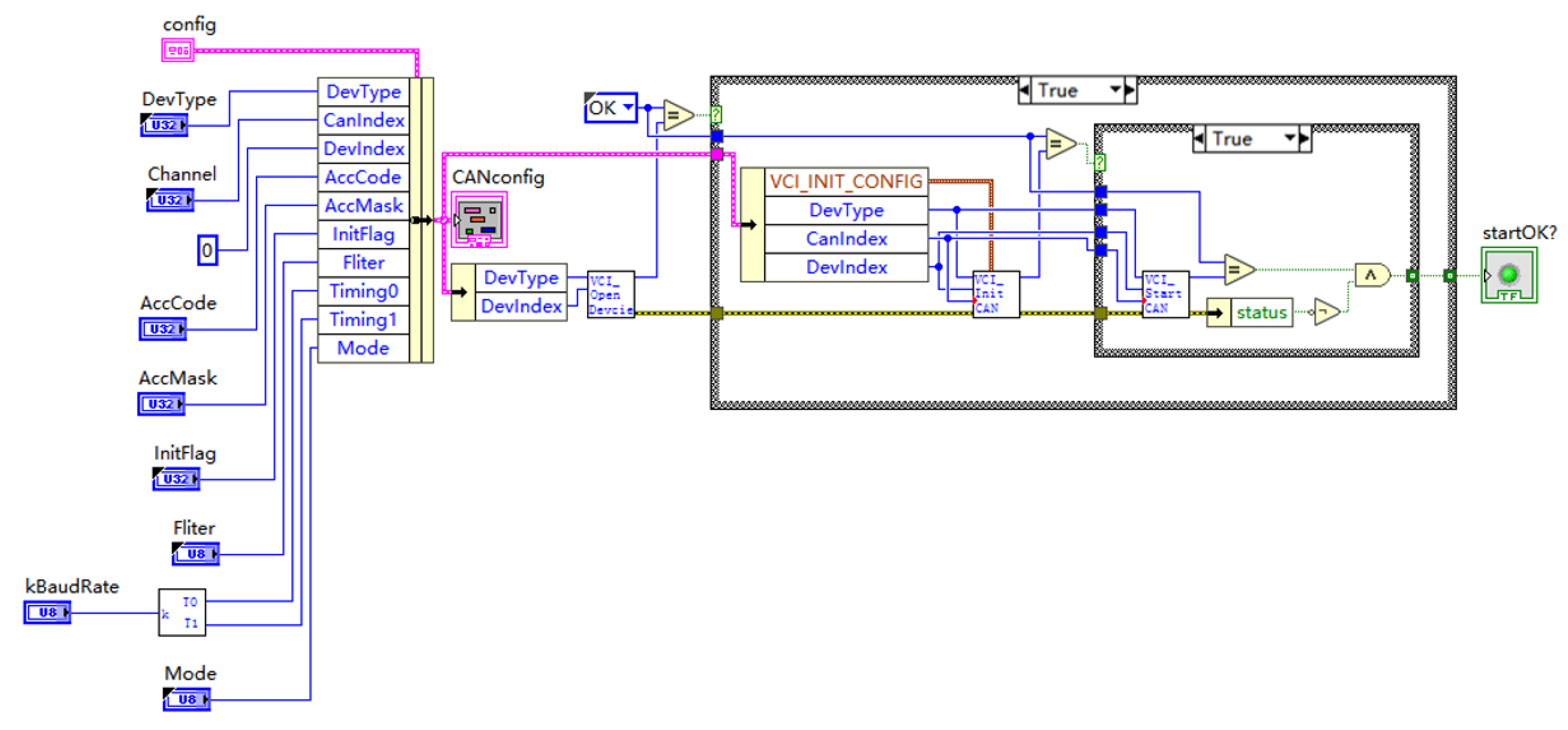

2.3.2. Upper Computer Programming

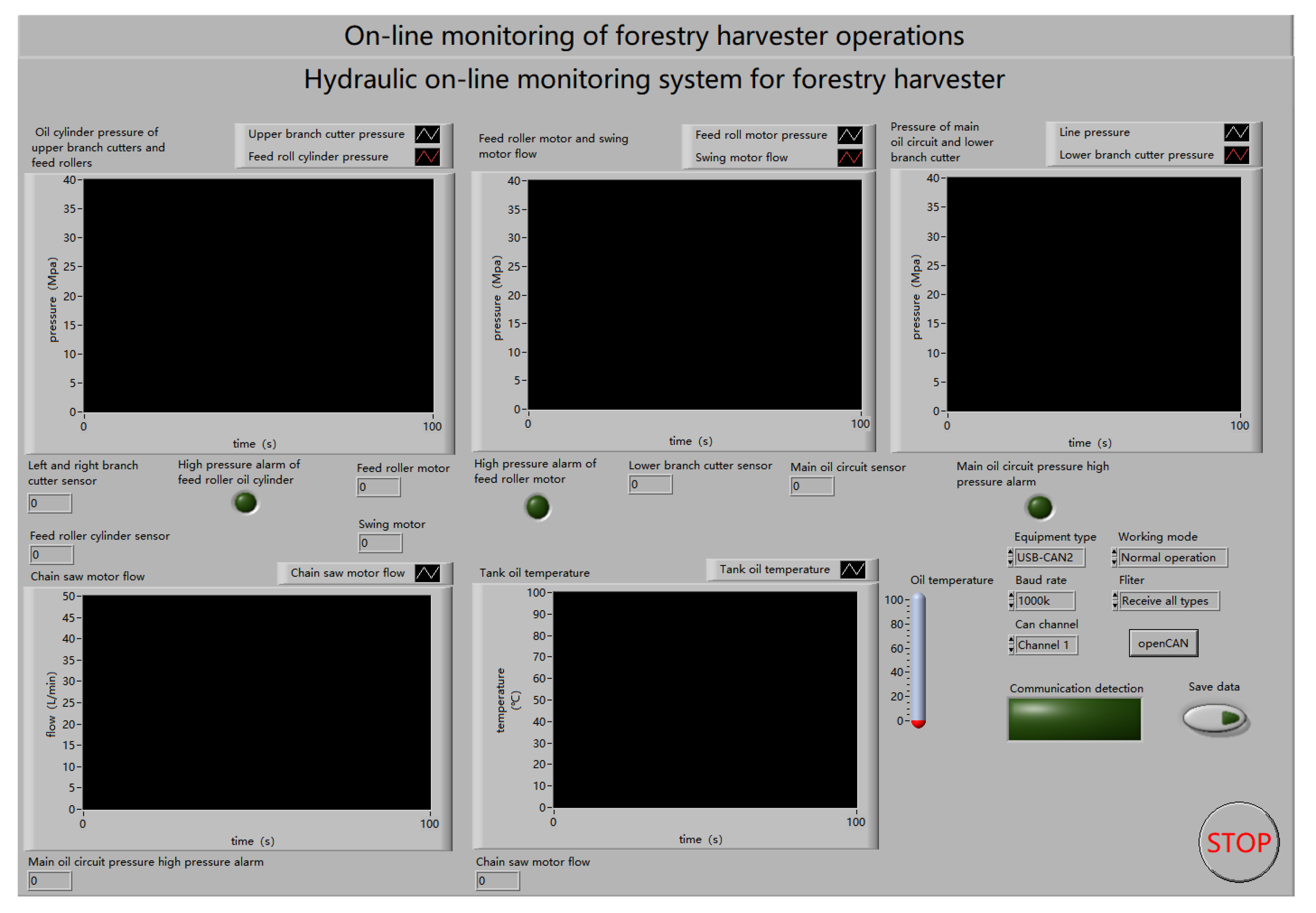

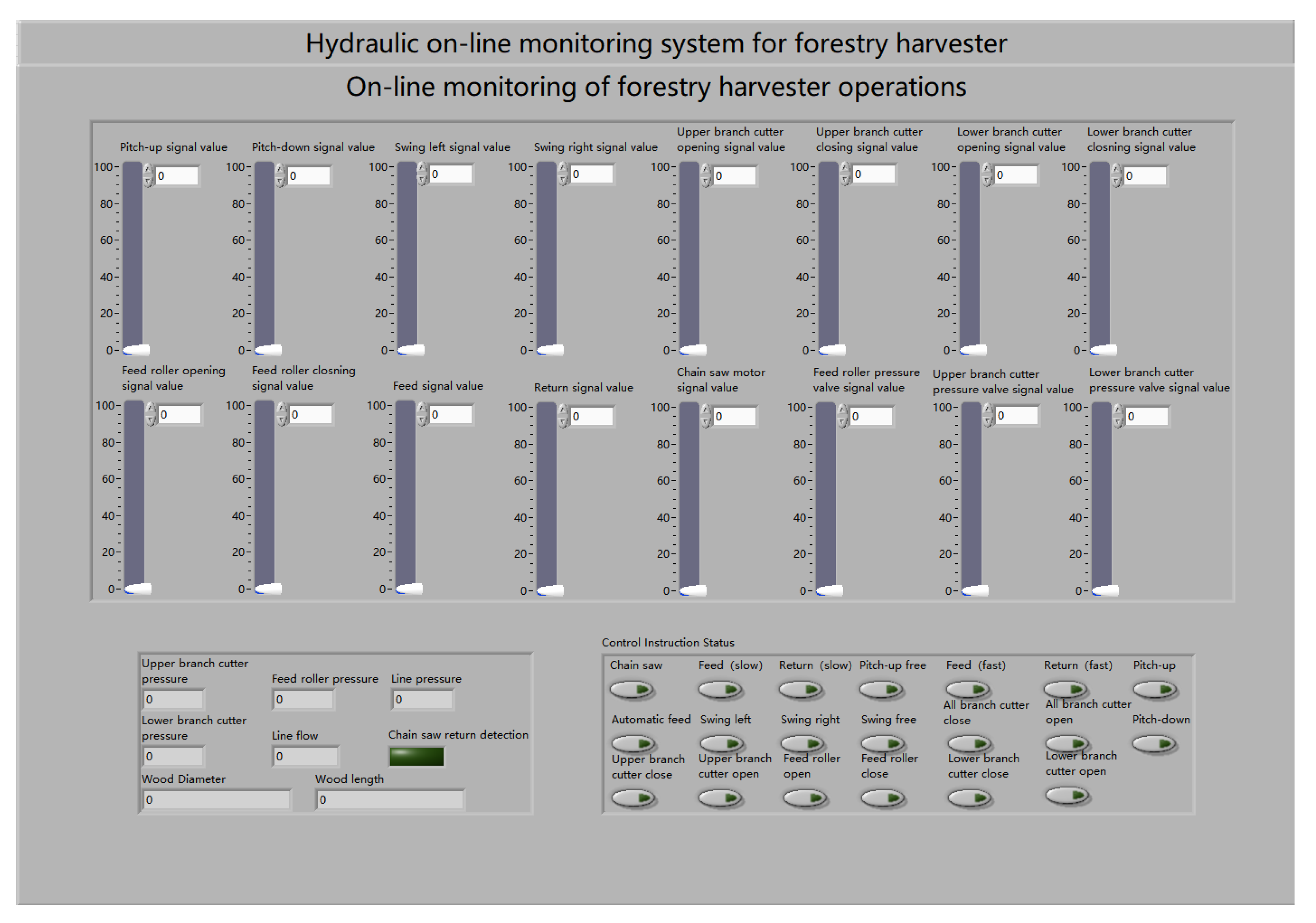

- Human–computer interface.

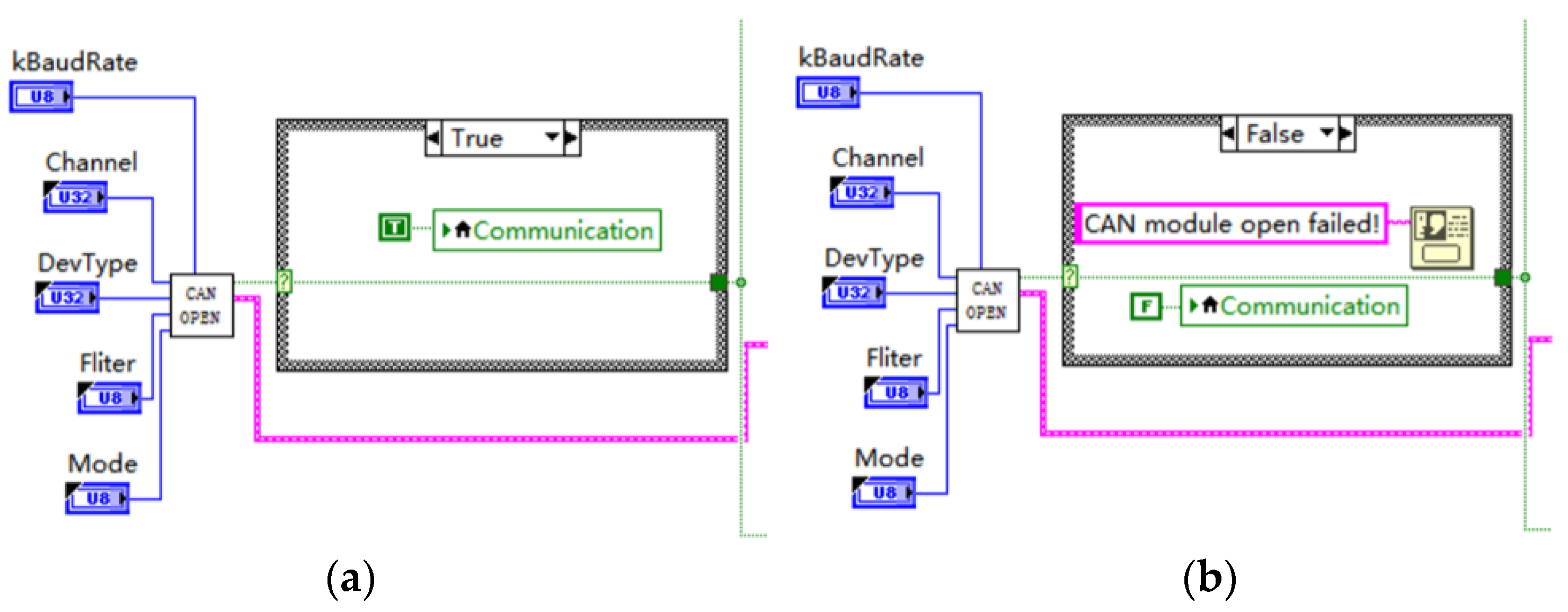

- Initialization of CAN analyzer.

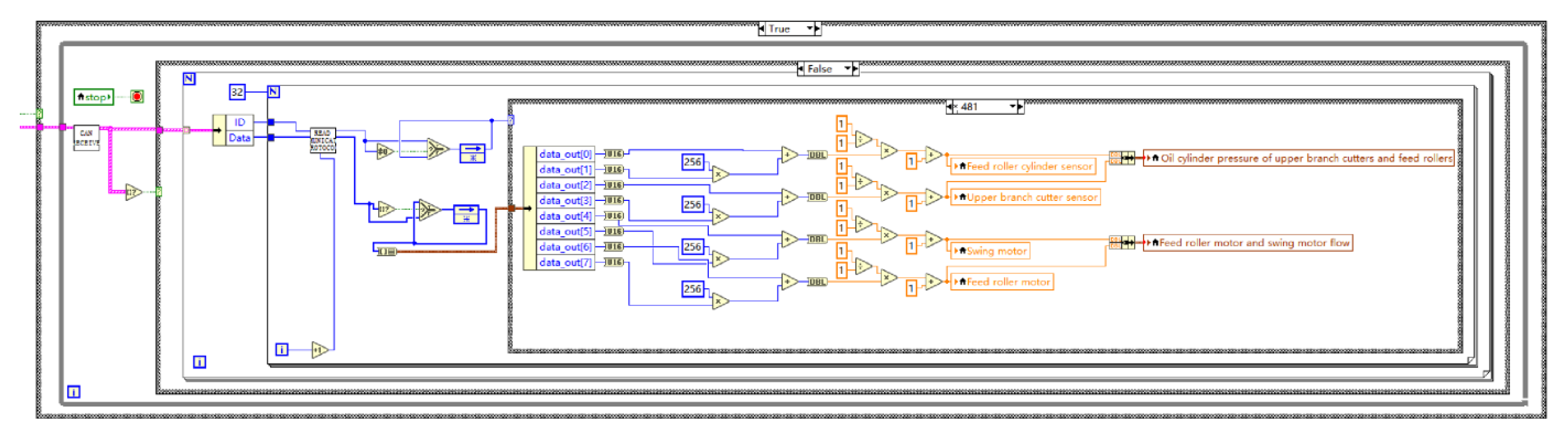

- Receiving and processing data.

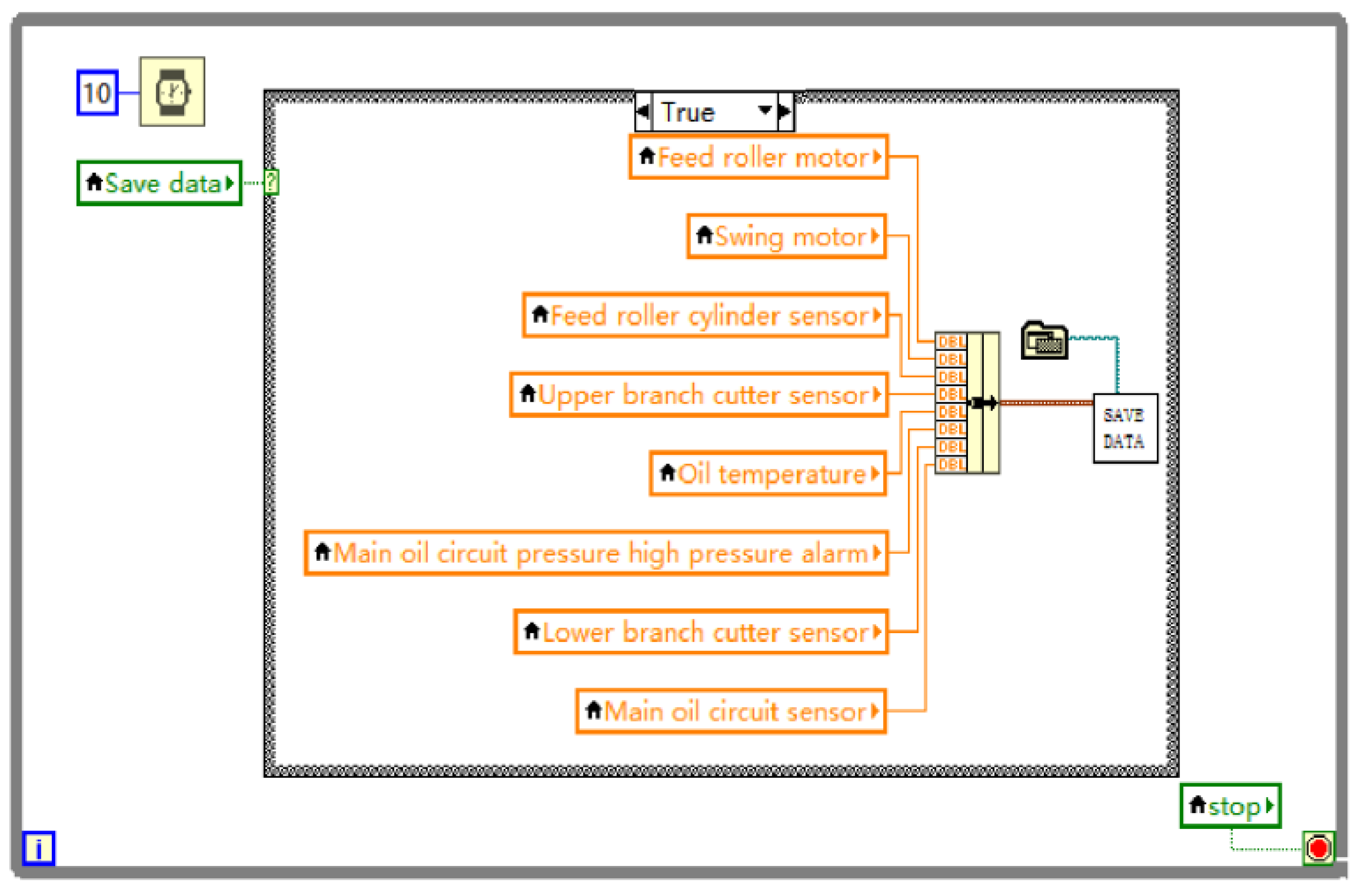

- Data storage.

3. Tests and Analyses

3.1. System Reliability Test

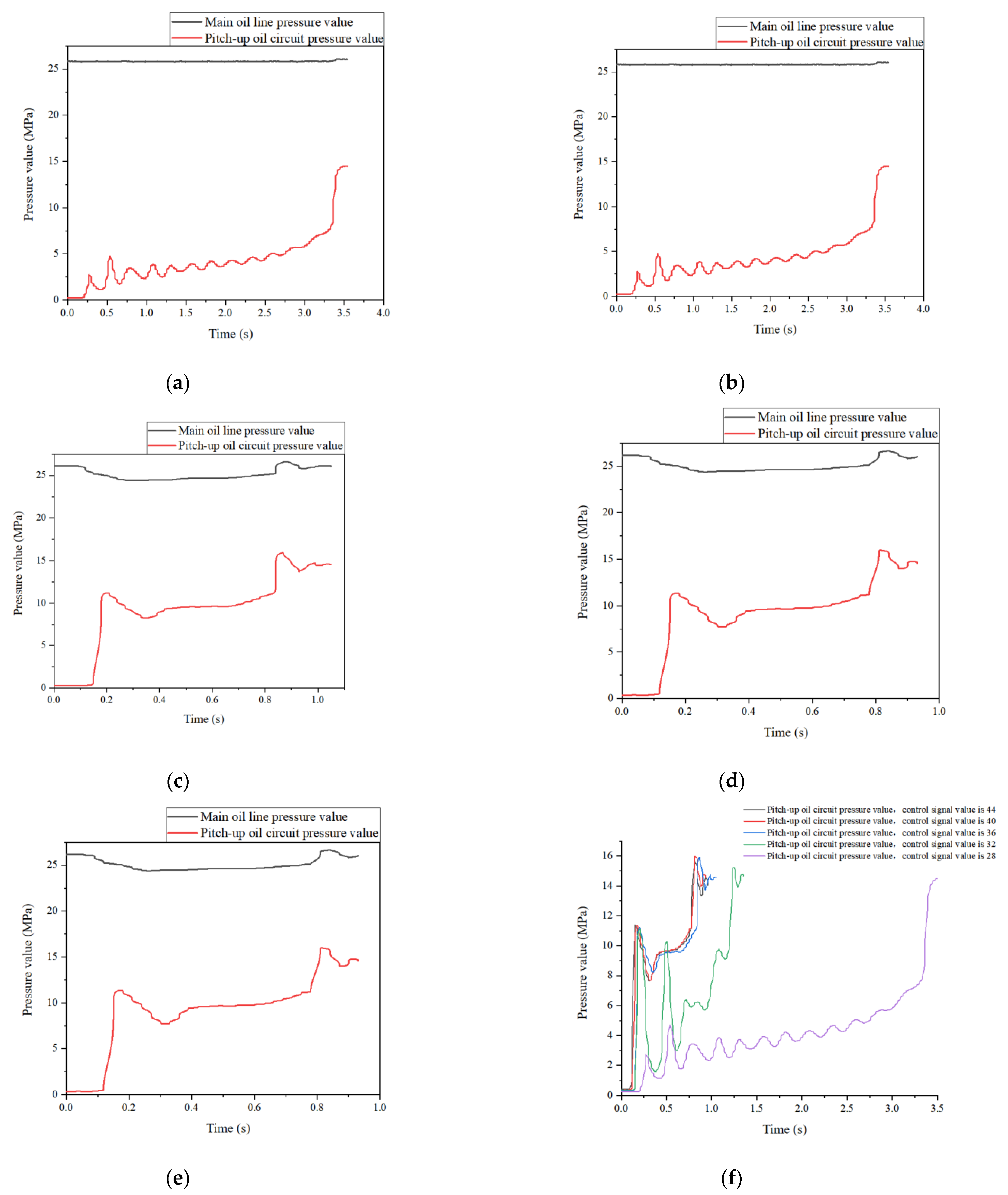

3.2. Real Machine Tests

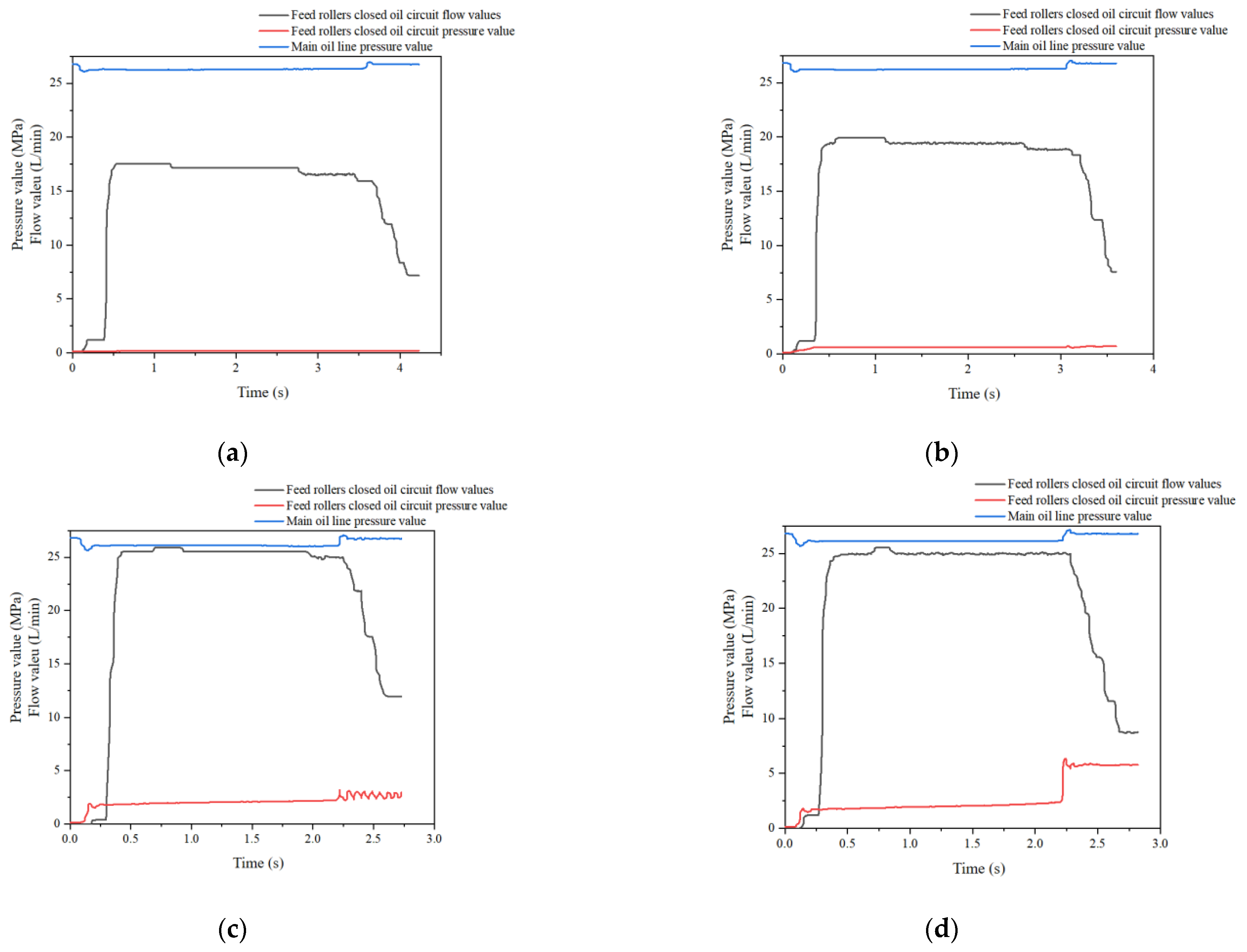

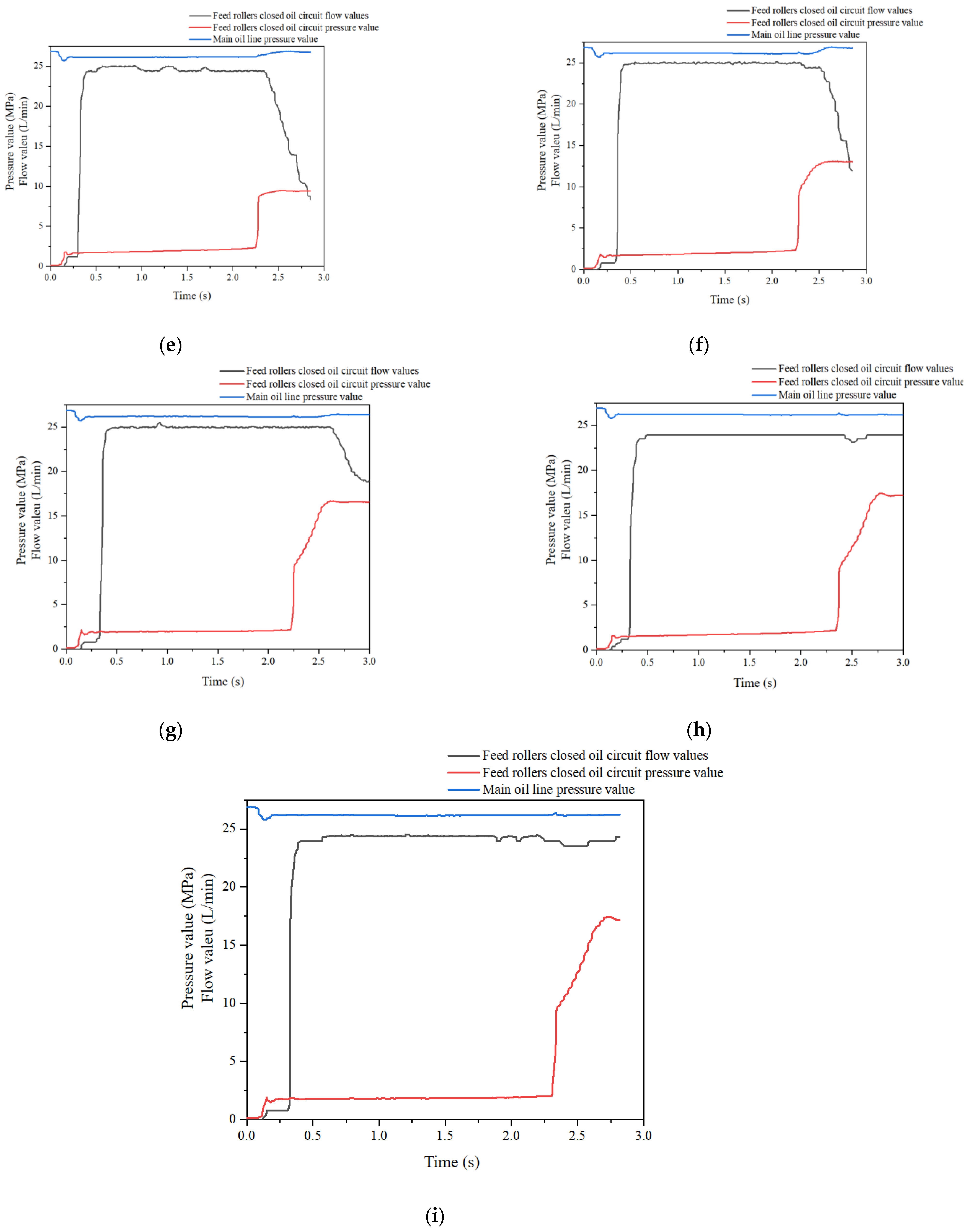

3.3. Data Acquisition Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Corona, P.; Chianucci, F.; Quatrini, V.; Civitarese, V.; Clementel, F.; Costa, C.; Floris, A.; Menesatti, P.; Puletti, N.; Sperandio, G.; et al. Precision forestry: Riferimenti concettuali, strumenti e prospettive di diffusione in Italia. Forest 2017, 14, 1–21. [Google Scholar] [CrossRef]

- Venanzi, R.; Latterini, F.; Civitarese, V.; Picchio, R. Recent Applications of Smart Technologies for Monitoring the Sustainability of Forest Operations. Forests 2023, 14, 1503. [Google Scholar] [CrossRef]

- Picchio, R.; Proto, A.R.; Civitarese, V.; Di Marzio, N.; Latterini, F. Recent Contributions of Some Fields of the Electronics in Development of Forest Operations Technologies. Electronics 2019, 8, 1465. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, Y.; Lyu, L. Research on braking performance test bench for forestry vehicle based on LabVIEW. J. For. Eng. 2016, 1, 103–108. [Google Scholar]

- Bacescu, N.M.; Cadei, A.; Moskalik, T.; Wiśniewski, M.; Talbot, B.; Grigolato, S. Efficiency Assessment of Fully Mechanized Harvesting System through the Use of Fleet Management System. Sustainability 2022, 14, 16751. [Google Scholar] [CrossRef]

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Ala-Ilomäki, J.; Salmivaara, A.; Launiainen, S.; Lindeman, H.; Kulju, S.; Finér, L.; Heikkonen, J.; Uusitalo, J. Assessing extraction trail trafficability using harvester CAN-bus data. Int. J. For. Eng. 2020, 31, 138–145. [Google Scholar] [CrossRef]

- Spencer, G.; Mateus, F.; Torres, P.; Dionísio, R.; Martins, R. Design of CAN Bus Communication Interfaces for Forestry Machines. Computers 2021, 10, 144. [Google Scholar] [CrossRef]

- Wempe, A.M.; Keefe, R.F.; Newman, S.M.; Paveglio, T.B. Intent to Adopt Location Sharing for Logging Safety Applications. Safety 2019, 5, 7. [Google Scholar] [CrossRef]

- Kaartinen, H.; Hyyppä, J.; Vastaranta, M.; Kukko, A.; Jaakkola, A.; Yu, X.; Pyörälä, J.; Liang, X.; Liu, J.; Wang, Y.; et al. Accuracy of Kinematic Positioning Using Global Satellite Navigation Systems under Forest Canopies. Forests 2015, 6, 3218–3236. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Labelle, E.R. The Effect of New Silvicultural Trends on Mental Workload of Harvester Operators. Croat. J. For. Eng. 2021, 41, 177–190. [Google Scholar] [CrossRef]

- Visser, R.; Obi, O.F. Automation and Robotics in Forest Harvesting Operations. Croat. J. For. Eng. 2021, 42, 13–24. [Google Scholar] [CrossRef]

- Lindroos, O.; La Hera, P.; Häggström, G. Drivers of advances in mechanized timber harvesting—A selective review of technological innovation. Croat. J. For. Eng. 2017, 38, 243–258. [Google Scholar]

- Amer, M.A.; Rajan, P.; Mehanny, S.; Artyszak, A.; Ahmed, M.A.A. Innovative Design of an Experimental Jasmine Flower Automated Picker System Using Vertical Gripper and YOLOv5. Agriculture 2023, 13, 1595. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Y.; Liu, L.; Zhang, B.; Shi, Z.; Guo, Y. Machine tool spindle vibration monitoring system based on Bluetooth wireless network and LabVIEW. Ferroelectrics 2023, 609, 137–147. [Google Scholar] [CrossRef]

- Deere, J. Smooth Boom Control/Intelligent Boom Control. Available online: https://www.deere.com/en/technology-products/forestry-and-logging-technology/operator-assistance-technology/index (accessed on 9 October 2023).

- Yuewei, M.; Jinhao, L. Forest harvester operation information collection system based on cloud platform. J. For. Eng. 2023, 8, 151–158. [Google Scholar]

| Data Name/Data Group | Group I | Group II | Group III | Group IV | Group V | Group VI |

|---|---|---|---|---|---|---|

| Output value of hydraulic station (MPa) | 5 | 8 | 10 | 12 | 15 | 20 |

| System measured values (MPa) | 4.9 | 8.2 | 10.1 | 12.1 | 14.8 | 20.2 |

| 5.1 | 8 | 9.9 | 11.9 | 14.9 | 20.3 | |

| 5.0 | 8.1 | 9.8 | 11.8 | 15.1 | 19.8 | |

| 5.1 | 7.9 | 10.1 | 12.1 | 14.7 | 20.1 | |

| 5.0 | 8 | 10.2 | 12.0 | 15.0 | 19.9 | |

| 4.8 | 7.9 | 9.9 | 12.3 | 15.1 | 20.1 | |

| 4.9 | 8.1 | 10.1 | 11.9 | 14.9 | 19.8 | |

| 5.0 | 8 | 9.9 | 12.1 | 15.2 | 20.3 | |

| 4.9 | 8.2 | 10.0 | 11.8 | 14.9 | 19.9 | |

| 5.1 | 8.1 | 9.7 | 12.2 | 15.1 | 20.2 | |

| Average value (MPa) | 4.98 | 8.05 | 9.97 | 12.02 | 14.97 | 20.06 |

| Standard deviation (MPa) | 0.1033 | 0.1080 | 0.1567 | 0.1687 | 0.1567 | 0.1955 |

| Relative standard deviation (%) | 2.07 | 1.34 | 1.57 | 1.40 | 1.05 | 0.97 |

| Data Name/Data Group | Group I | Group II | Group III | Group IV | Group V | Group VI |

|---|---|---|---|---|---|---|

| Output value of hydraulic station (L/min) | 80 | 100 | 120 | 150 | 180 | 200 |

| System measured values (L/min) | 80.2 | 101.2 | 119.7 | 148.7 | 181.4 | 201.2 |

| 80.5 | 100.8 | 120.6 | 149.5 | 180.7 | 200.5 | |

| 80.1 | 101.1 | 120.3 | 149.4 | 181.1 | 201.7 | |

| 80.3 | 99.8 | 121.2 | 150.2 | 181.9 | 200.3 | |

| 79.9 | 100.4 | 120.9 | 150.6 | 180.3 | 199.7 | |

| 79.7 | 100.1 | 120.1 | 150.1 | 179.6 | 198.9 | |

| 80.1 | 99.6 | 120.5 | 149.9 | 179.8 | 200.6 | |

| 79.8 | 100.9 | 119.8 | 150.8 | 180.6 | 200.9 | |

| 80.3 | 100.6 | 119.8 | 151.2 | 180.2 | 199.6 | |

| 79.6 | 100.3 | 121.1 | 151.5 | 179.8 | 201.2 | |

| Average value (L/min) | 80.05 | 100.48 | 120.4 | 150.19 | 180.54 | 200.46 |

| Standard deviation (L/min) | 0.2915 | 0.5391 | 0.5517 | 0.8621 | 0.7516 | 0.8579 |

| Relative standard deviation (%) | 0.36% | 0.54% | 0.46% | 0.57% | 0.42% | 0.43% |

| Data Name/Harvesting Operation | Harvester Pitch Up | Open Up the Loppers | Feed Roller Opening |

|---|---|---|---|

| Control signal value * (%) | 28 | 32 | 32 |

| 32 | 35 | 35 | |

| 36 | 38 | 38 | |

| 40 | 40 | 40 | |

| 44 | 45 | 45 |

| Data Name/Data Group | Group I | Group II | Group III | Group IV | Group V |

|---|---|---|---|---|---|

| Control signal value (%) | 32 | 35 | 38 | 40 | 45 |

| Pressure control valve signal value (%) | 0 | 0 | 0 | 0 | 0 |

| 10 | 10 | 10 | 10 | 10 | |

| 20 | 20 | 20 | 20 | 20 | |

| 30 | 30 | 30 | 30 | 30 | |

| 40 | 40 | 40 | 40 | 40 | |

| 50 | 50 | 50 | 50 | 50 | |

| 60 | 60 | 60 | 60 | 60 | |

| 70 | 70 | 70 | 70 | 70 | |

| 80 | 80 | 80 | 80 | 80 |

| Manually Measured Pressure Value (MPa) | System Acquisition Pressure Value (MPa) | Theoretical Value of Main Oil Circuit Pressure (MPa) | Relative Error between Manually Measured Value and Theoretical Value | Relative Error between System Acquisition Value and Theoretical Value |

|---|---|---|---|---|

| 27.4 | 26.2 | 25.5 | 7.45% | 2.75% |

| 29.1 | 25.8 | 14.12% | 1.18% | |

| 27.1 | 26.1 | 6.27% | 2.35% | |

| 28.5 | 25.8 | 11.76% | 1.18% | |

| 26.8 | 25.6 | 5.10% | 0.39% | |

| 27.1 | 25.9 | 6.27% | 1.57% | |

| 29.4 | 26.0 | 15.29% | 1.96% | |

| 26.7 | 25.7 | 4.71% | 0.78% | |

| 28.1 | 26.2 | 10.20% | 2.75% | |

| 26.8 | 25.9 | 5.10% | 1.57% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, H.; Xu, J.; Wang, J.; Huang, Q.; Ma, Y.; Liu, J. A Hydraulic Online Monitoring System for Forestry Harvesters Based on LabVIEW. Forests 2023, 14, 2100. https://doi.org/10.3390/f14102100

Qin H, Xu J, Wang J, Huang Q, Ma Y, Liu J. A Hydraulic Online Monitoring System for Forestry Harvesters Based on LabVIEW. Forests. 2023; 14(10):2100. https://doi.org/10.3390/f14102100

Chicago/Turabian StyleQin, Haoxian, Jingwei Xu, Jianli Wang, Qingqing Huang, Yuewei Ma, and Jinhao Liu. 2023. "A Hydraulic Online Monitoring System for Forestry Harvesters Based on LabVIEW" Forests 14, no. 10: 2100. https://doi.org/10.3390/f14102100

APA StyleQin, H., Xu, J., Wang, J., Huang, Q., Ma, Y., & Liu, J. (2023). A Hydraulic Online Monitoring System for Forestry Harvesters Based on LabVIEW. Forests, 14(10), 2100. https://doi.org/10.3390/f14102100