Comparative Study of Plywood Boards Produced with Castor Oil-Based Polyurethane and Phenol-Formaldehyde Using Pinus taeda L. Veneers Treated with Chromated Copper Arsenate

Abstract

1. Introduction

- Loblolly pine (Pinus taeda Linnaeus) wood was considered due to its wide availability and utilization in Brazil, as cited by De Araujo et al. [5], for the timber industry and construction applications.

- Both adhesives were considered due to their easy commercial availability worldwide.

- CCA preservative was considered due to the greater aggressiveness of this chemical compound in protecting against wood degradation. Despite some restrictions and prohibitions on the use of CCA in different countries of the Northern hemisphere, the warmer climate and the greater proliferation of wood-decaying insects in the Southern Hemisphere region represent complex obstacles that still justify the use of this more powerful preservative to preserve wood-based parts and panels.

2. Materials and Methods

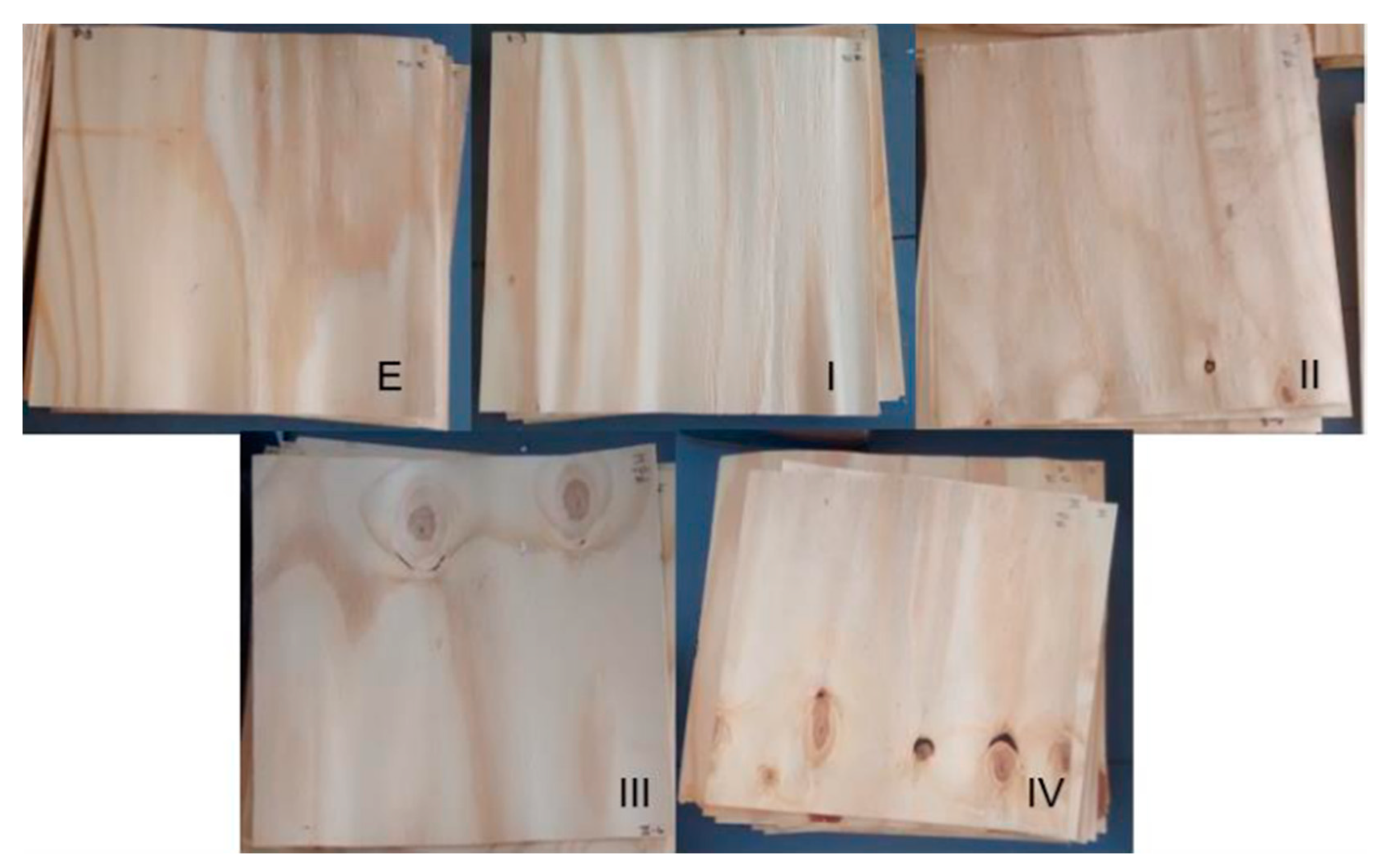

2.1. Materials

2.2. Methods

2.2.1. Preservative Treatment with CCA

2.2.2. Plywood Production

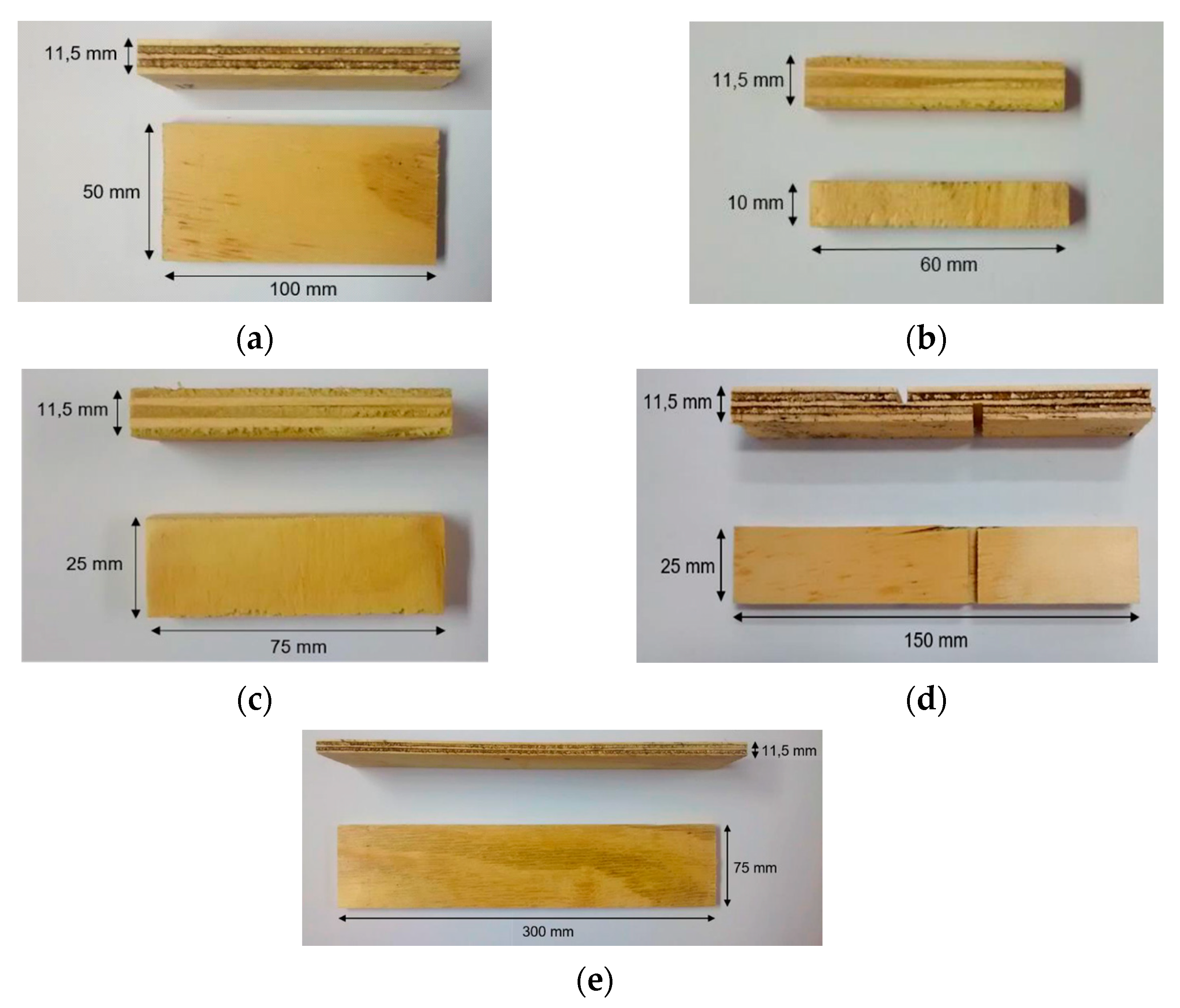

2.2.3. Physical and Mechanical Properties Evaluation

3. Results and Discussion

3.1. Physical Evaluations

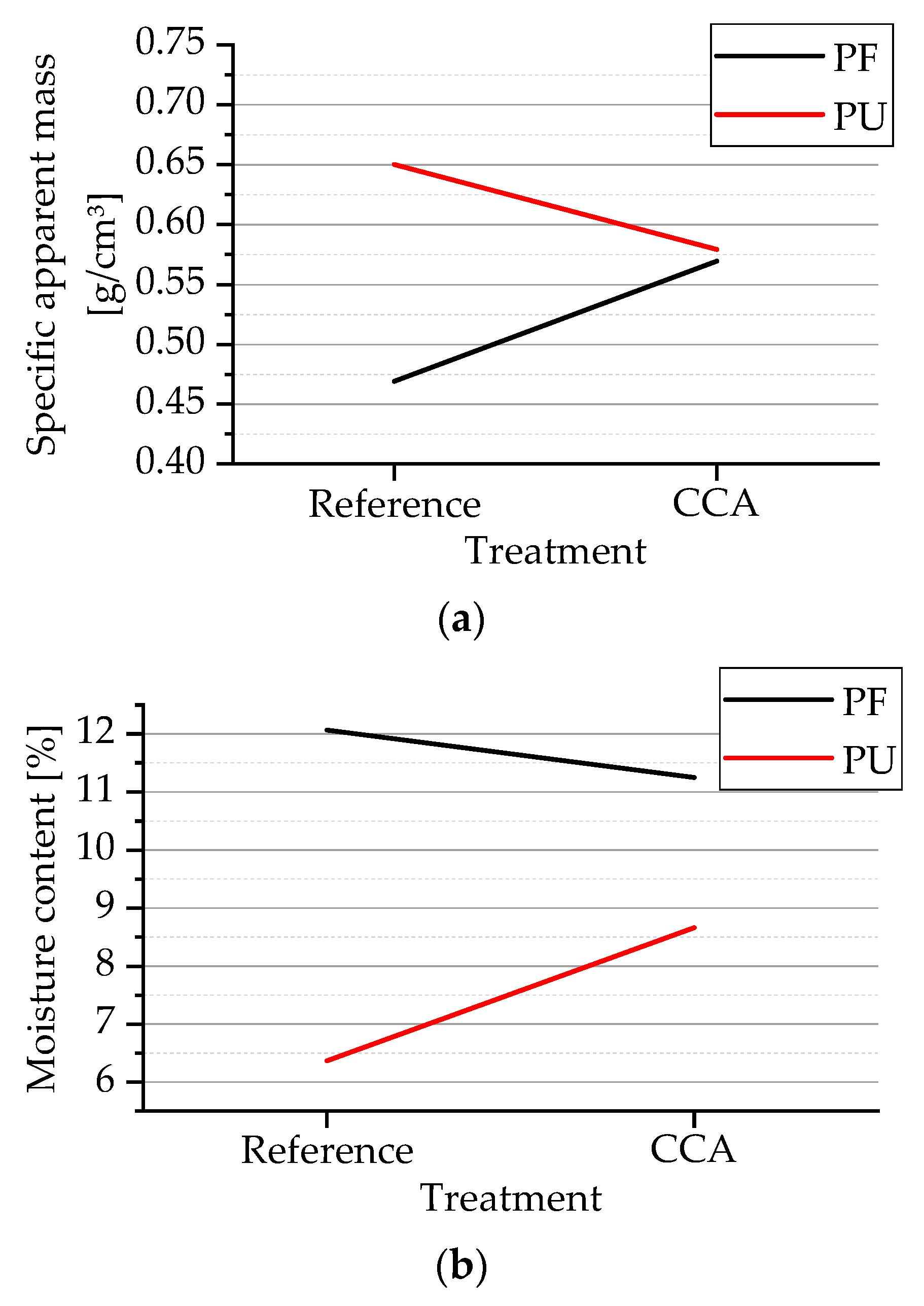

3.1.1. Specific Apparent Mass

3.1.2. Moisture Content

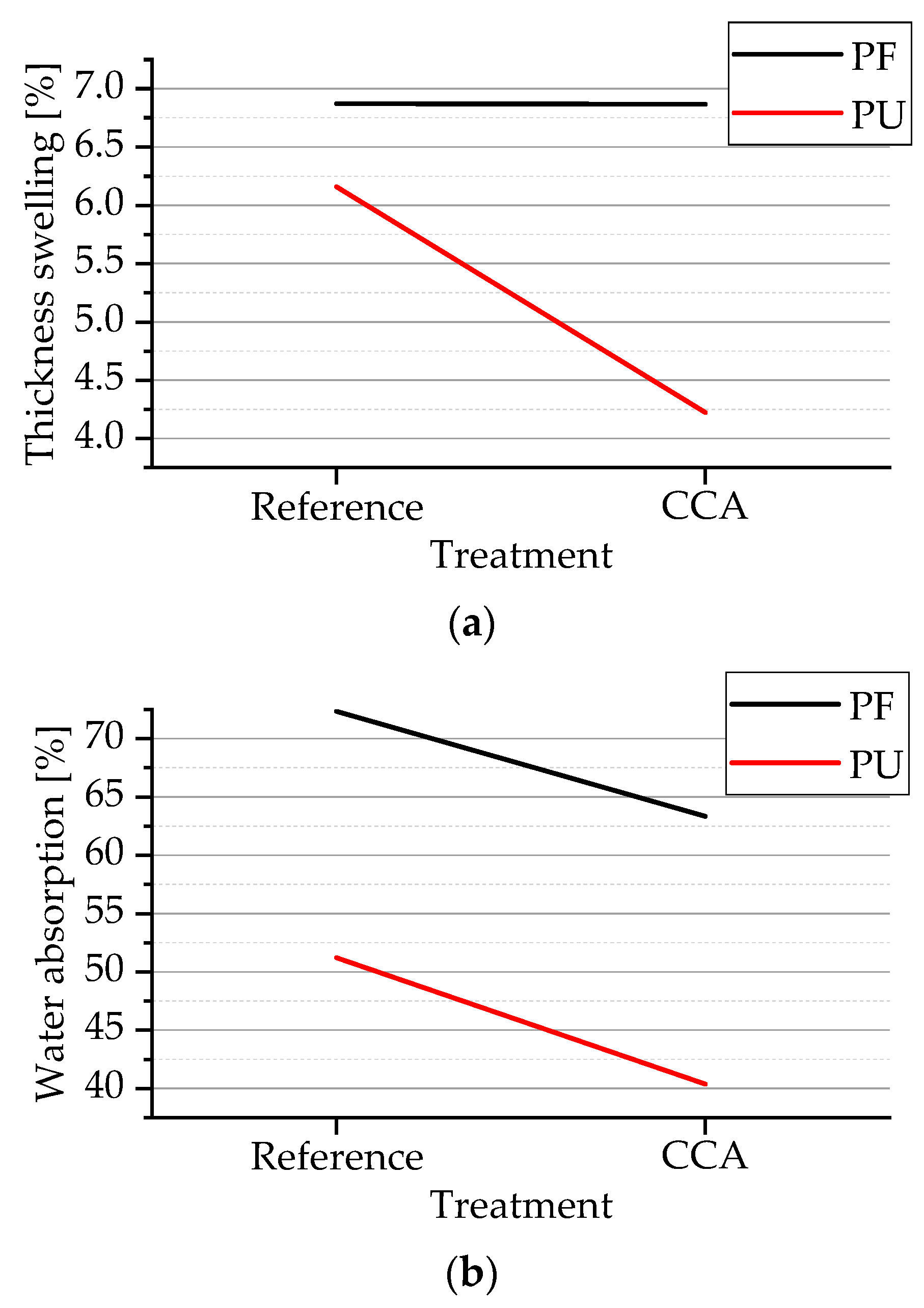

3.1.3. Thickness Swelling

3.1.4. Water Absorption

3.2. Mechanical Evaluations

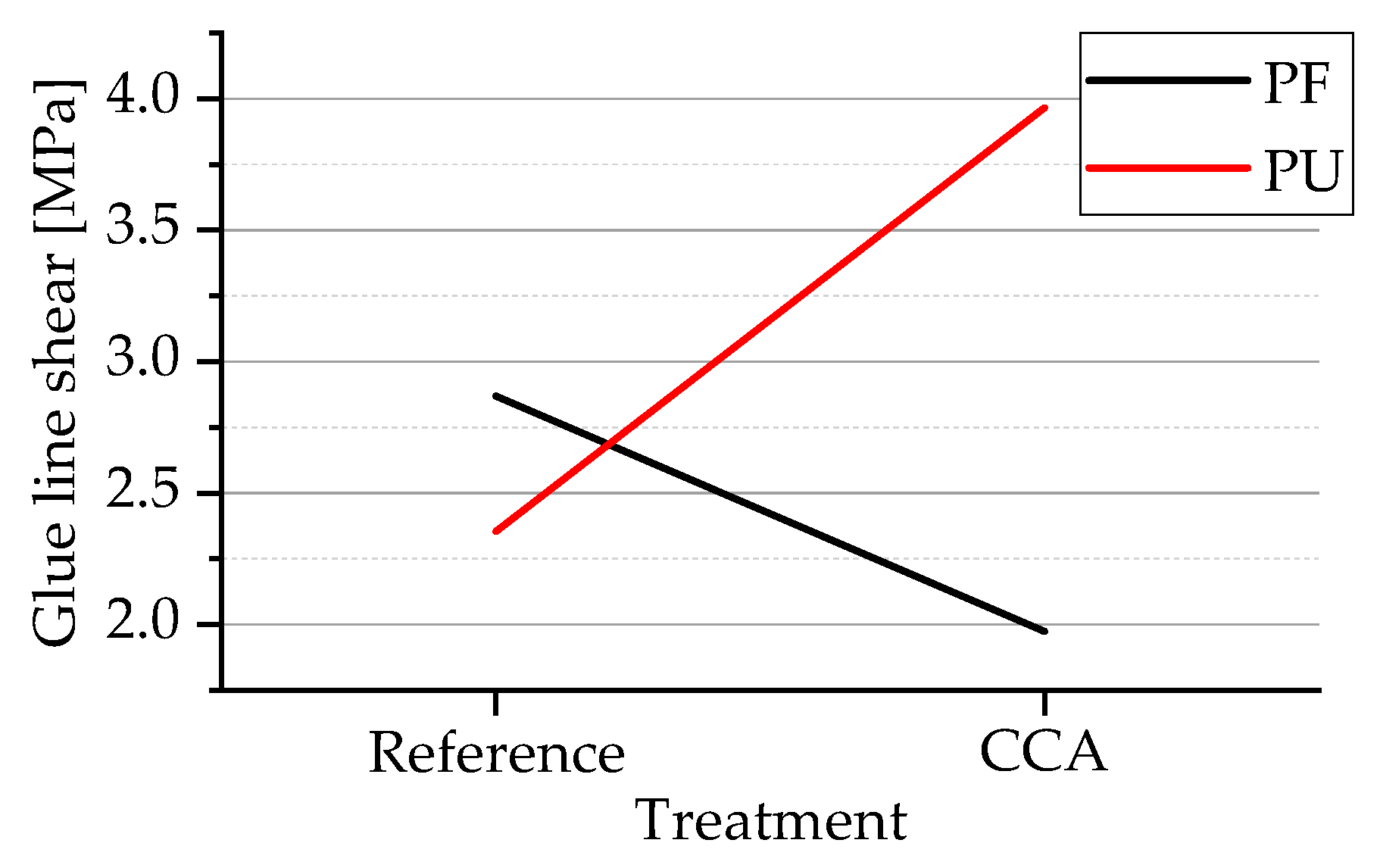

3.2.1. Glue Line Shear

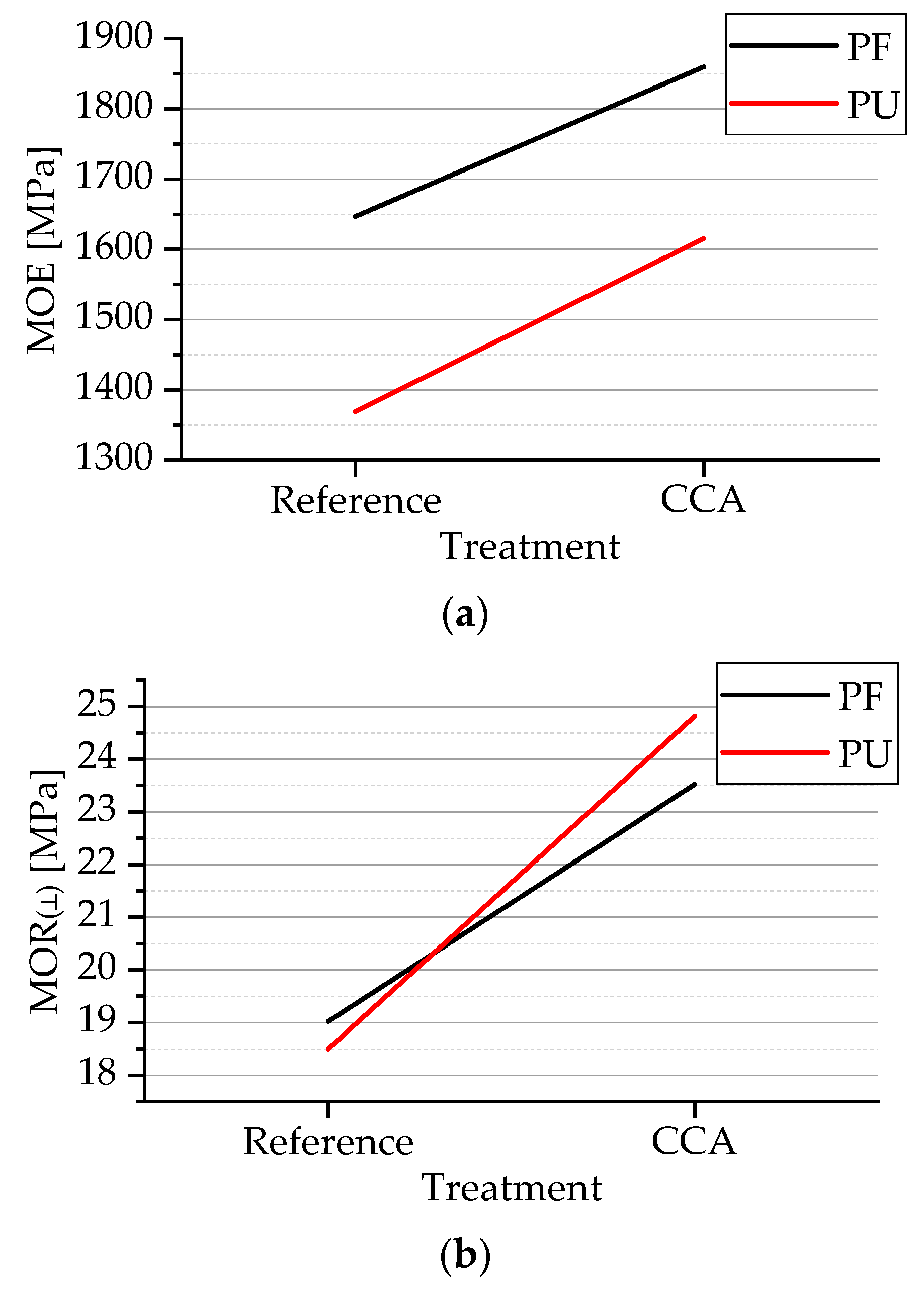

3.2.2. Parallel and Perpendicular Static Bending

4. Conclusions

- The preservative treatment with CCA was usually efficient, as the same treatment improved the properties, above all, when compared to the reference panels.

- In the panels produced with PU, lower moisture content and better interactions with water (less swelling in thickness and water absorption) were observed.

- Most treatments had increases in the modulus of elasticity and modulus of rupture for both adhesives when the CCA treatment was applied to the wood veneers.

- Comparing both adhesives, PF presents the better values of modulus of elasticity.

- Glue line shear for all treatments met the requirements defined by the ABNT NBR ISO 12466-2: 2012.

- In the scientific scope, there were not significant limitations in the present research. Under commercial perspectives, the main limitation of this study may be related to the possible adaptation of the existing industrial plants oriented to the manufacture of PF-based plywoods with regard to the insertion of new processes driven by PU resin. However, this change will be in charge of the consideration of PU resin by the plywood industry, since it will imply adjustments in the manufacturing parameters, such as resin viscosity, mat pressing, pressing temperature, etc. Another limitation may be attributed to the utilization of the CCA wood preservative, which has been restricted and/or prohibited in some markets of North America and Europe.

- Despite the commercial uses of CCA-treated PF-based plywoods, the utilization of PU resin in plywood production represented a tangible novelty for the timber industry, above all, to satisfy severe conditions of wood uses in the Southern Hemisphere.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geldermann, J.; Kolbe, L.M.; Krause, A.; Mai, C.; Militz, H.; Osburg, V.S.; Schöbel, A.; Schumann, M.; Toporowski, W.; Westphal, S. Improved Resource Efficiency and Cascading Utilisation of Renewable Materials. J. Clean. Prod. 2016, 110, 1–8. [Google Scholar] [CrossRef]

- Frihart, C.R.; Brandon, R.; Ibach, R.E.; Hunt, C.G.; Gindl-altmutter, W. Comparative Adhesive Bonding of Wood Chemically Modified with Either Acetic Anhydride or Butylene Oxide. Forests 2021, 12, 546. [Google Scholar] [CrossRef]

- Ferro, F.S.; Silva, D.A.L.; Rocco Lahr, F.A.; Argenton, M.; González-García, S. Environmental Aspects of Oriented Strand Boards Production. A Brazilian Case Study. J. Clean. Prod. 2018, 183, 710–719. [Google Scholar] [CrossRef]

- De Araujo, V.A.; Garcia, J.N.; Cortez-Barbosa, J.; Gava, M.; Savi, A.F.; Morales, E.A.M.; Lahr, F.A.R.; Vasconcelos, J.S.; Christoforo, A.L. Importance of Wood from Planted Forests for Manufacturing Industry. Pesq. Flor. Bras. 2017, 37, 189–200. (In Portuguese) [Google Scholar] [CrossRef]

- De Araujo, V.; Vasconcelos, J.; Gava, M.; Christoforo, A.; Lahr, F.; Garcia, J. What Does Brazil Know About the Origin and Uses of Tree Species Employed in the Housing Sector? Perspectives on Available Species, Origin and Current Challenges. Int. For. Rev. 2021, 23, 392–404. [Google Scholar] [CrossRef]

- Barbirato, G.; Fiorelli, J.; Mejiaa, J.; Sarasini, F.; Tirillò, J.; Ferrante, L. Quasi-Static and Dynamic Response of Oriented Strand Boards Based on Balsa Wood Waste. Compos. Struct. 2019, 219, 83–89. [Google Scholar] [CrossRef]

- FAO. FAO Yearbook of Forest Products 2019; FAO: Rome, Italy, 2021. [Google Scholar]

- Cabral, M.R.; Fiorelli, J.; Savastano Junior, H.; Lagacé, R.; Godbout, S.; Palacios, J.H. Study of the Potential Use of the Sugarcane Bagasse in Cement-Panels. In Proceedings of the 10th International Conference on Composite Science and Technology ICCST/10, Lisboa, Portugal, 2 September 2015. [Google Scholar]

- Ferreira, B.S.; Silva, J.V.F.; Campos, C.I. Static Bending Strength of Heat-Treated and Chromated Copper Arsenate-Treated Plywood. BioResources 2017, 12, 6276–6282. [Google Scholar] [CrossRef]

- De Araujo, V.A.; Biazzon, J.C.; Morales, E.A.M.; Cortez-Barbosa, J.; Gava, M.; Garcia, J.N. Lignocellulosic Materials in Use by the Production Sector of Timber Houses in Brazil. Rev. Inst. Flor. 2020, 32, 129–141. (In Portuguese) [Google Scholar] [CrossRef]

- Beer, P.; Pacek, P.; Burawska-kupniewska, I. Influence of the Thickness of Scots Pine (Pinus Sylvestris L.) Veneers on Selected Properties of Flooring Materials. Forests 2022, 13, 175. [Google Scholar] [CrossRef]

- Huzyan, H.I.; Aziz, A.A.; Hussin, M.H. Ecofriendly Wood Adhesives from Date Palm Fronds Lignin for Plywood. BioResources 2021, 16, 20. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Chen, M.; Luo, J.; Shi, S.Q.; Gao, Q.; Li, J. A Tough, Water-Resistant, High Bond Strength Adhesive Derived from Soybean Meal and Flexible Hyper-Branched Aminated Starch. Polymers 2019, 11, 1352. [Google Scholar] [CrossRef] [PubMed]

- Román, J.K.; Wilker, J.J. Cooking Chemistry Transforms Proteins into High-Strength Adhesives. J. Am. Chem. Soc. 2019, 141, 1359–1365. [Google Scholar] [CrossRef] [PubMed]

- Kristak, L.; Antov, P.; Bekhta, P.; Lubis, M.A.R.; Iswanto, A.H.; Reh, R.; Sedliacik, J.; Savov, V.; Taghiyari, H.R.; Papadopoulos, A.N.; et al. Recent Progress in Ultra-Low Formaldehyde Emitting Adhesive Systems and Formaldehyde Scavengers in Wood-Based Panels: A review. Wood Mater. Sci. Eng. 2022, 1–20. [Google Scholar] [CrossRef]

- Li, C.; Tang, Y.; Wang, Y.; Yuan, X.; Zhang, B.; Wu, Z. A Novel Environment-Friendly Adhesive Based on Recycling of Broussonetia Papyrifera Leaf Forestry Waste Protein. Forests 2022, 13, 291. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Wu, Z.; Xi, X.; Du, G.; Pizzi, A. Fully Biobased Adhesive from Glucose and Citric Acid for Plywood with High Performance. ACS Appl. Mater. Interfaces 2022, 14, 23859–23867. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Labib, A.; Sudarmanto; Akbar, F.; Nuryawan, A.; Antov, P.; Kristak, L.; Papadopoulos, A.N.; Pizzi, A. Influence of Lignin Content and Pressing Time on Plywood Properties Bonded with Cold-Setting Adhesive Based on Poly (Vinyl Alcohol), Lignin, and Hexamine. Polymers 2022, 14, 2111. [Google Scholar] [CrossRef]

- Yue, H.; Xu, C.; Yao, J.; He, M.; Yin, G.; Cui, Y.; Yang, C.; Guo, J. Characterization and Properties of Plywood Bioadhesive Derived from Cottonseed Protein and Sawdust Cellulose. Cellulose 2022, 29, 5869–5881. [Google Scholar] [CrossRef]

- Aristri, M.A.; Adly, M.; Lubis, R.; Iswanto, A.H.; Fatriasari, W.; Sari, R.K.; Antov, P.; Gajtanska, M.; Papadopoulos, A.N.; Pizzi, A. Bio-Based Polyurethane Resins Derived from Tannin: Source, Synthesis, Characterisation, and Application. Forests 2021, 12, 1516. [Google Scholar] [CrossRef]

- Cai, L.; Li, Y.; Lin, X.; Chen, H.; Gao, Q.; Li, J. High-Performance Adhesives Formulated from Soy Protein Isolate and Bio-Based Material Hybrid for Plywood Production. J. Clean. Prod. 2022, 353, 131587. [Google Scholar] [CrossRef]

- Peng, J.; Chen, X.; Zhang, J.; Essawy, H.; Du, G.; Zhou, X. Characterization on the Copolymerization Resin between Bayberry (Myrica Rubra) Tannin and Pre-Polymers of Conventional Urea-Formaldehyde Resin. Forests 2022, 13, 624. [Google Scholar] [CrossRef]

- Bekhta, P. Effect of Heat Treatment on Some Physical and Mechanical Properties of Birch Plywood. Eur. J. Wood Wood Prod. 2020, 78, 683–691. [Google Scholar] [CrossRef]

- Hsu, F.Y.; Hung, K.C.; Xu, J.W.; Wu, T.L.; Wu, J.H. Physicomechanical Properties and Creep Behavior of Plywood Composed of Fully and Partially Heat-Treated Veneers. Wood Sci. Technol. 2021, 55, 445–460. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. ABNT NBR ISO 2426-3 PLYWOOD-Classification by Surface Appearance-Part 3: Softwood; ABNT: Rio de Janeiro, Brazil, 2006; p. 8. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR 9485 PLYWOOD-Determination of the Specific Apparent Mass; ABNT: Rio de Janeiro, Brazil, 2022; p. 3. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR 9484 PLYWOOD-Determination of Moisture Content; ABNT: Rio de Janeiro, Brazil, 2011; p. 2. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR 9535 PLYWOOD-Determination of Swelling-Test Method; ABNT: Rio de Janeiro, Brazil, 2011; p. 7. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR 9486 PLYWOOD-Determination of Water Absorption; ABNT: Rio de Janeiro, Brazil, 2011; p. 2. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR ISO 12466:1 PLYWOOD-Bonding Quality-Part 1: Test Methods; ABNT: Rio de Janeiro, Brazil, 2012; p. 16. (In Portuguese) [Google Scholar]

- Associação Brasileira de Normas Técnicas. ABNT NBR 9533 PLYWOOD-Determination of Bending Resistance; ABNT: Rio de Janeiro, Brazil, 2013; p. 5. (In Portuguese) [Google Scholar]

- ABIMCI. Pinus Plywood; ABIMCI: Curitiba, Brazil, 2002. (In Portuguese) [Google Scholar]

- Mendes, R.F.; Bortoletto, G.; Marcelo Vidal, J.; De Almeida, N.F.; Jankowsky, I.P. Effect of Preservative Treatment of Plywood Panels on their Physico-Mechanical Properties. Sci. For. Sci. 2013, 41, 507–513. (In Portuguese) [Google Scholar]

- Wilczak, L.; Trianoski, R.; Neto, S.C.; Pereira de Paula, C.R.; Villanova, R.L.; Azevedo, E. Efficiency of Castor Oil-Based Polyurethane in the Production of Plywood Panels. Sci. For. Sci. 2019, 47, 463–471. [Google Scholar] [CrossRef]

- Setter, C.; Zidanes, U.L.; de Novais Miranda, E.H.; Brito, F.M.S.; Mendes, L.M.; Junior, J.B.G. Influence of Wood Species and Adhesive Type on the Performance of Multilaminated Plywood. Environ. Sci. Pollut. Res. 2021, 28, 50835–50846. [Google Scholar] [CrossRef]

- De Windt, I.; Li, W.; Van den Bulcke, J.; Van Acker, J. Classification of Uncoated Plywood Based on Moisture Dynamics. Constr. Build. Mater. 2018, 158, 814–822. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. ABNT NBR 17002 Plywood-Requirements and Test Methods; ABNT: Rio de Janeiro, Brazil, 2021; p. 20. (In Portuguese) [Google Scholar]

- Amorim, F.V. Polyurethane Biocomposits Based on Mamona Oil (Ricinus Communis) Containing Agroindustry Waste for Organic Composite Adsorption. Ph.D. Thesis, Federal University of Pernambuco, Recife, Brazil, 2019. (In Portuguese). [Google Scholar]

- Buzo, A.L.S.C.; Sugahara, E.S.; Silva, S.A.M.; Morales, E.A.M.; Azambuja, M.A. Pinus and sugarcane bagasse panels using two adhesives for use in civil construction. Ambient. Construído 2019, 19, 183–193. [Google Scholar] [CrossRef]

- Sugahara, E.S.; Silva, S.A.M.; Buzo, A.L.S.C.; Campos, C.I.; Morales, E.A.M.; Ferreira, B.S.; Christoforo, A.L. High-Density Particleboard Made from Agro-Industrial Waste and Different Adhesives. BioResources 2019, 14, 5162–5170. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas. ABNT NBR ISO 12466:2 PLYWOOD-Bonding Quality-Part 2: Requirements; ABNT: Rio de Janeiro, Brazil, 2012; p. 5. (In Portuguese) [Google Scholar]

- Kazmierczak, S.; Hillig, E.; Iwakiri, S. Plywood Panels Made with Veneers of Three Eucalyptus Species. Floresta E Ambient. 2017, 24, 1–9. (In Portuguese) [Google Scholar] [CrossRef]

| Treatment | Preservative | Adhesive |

|---|---|---|

| T1 | No treated (Reference) | PF 2 |

| T2 | No treated (Reference) | PU 3 |

| T3 | CCA 1 | PF |

| T4 | CCA | PU |

| Property | Standard |

|---|---|

| Specific apparent mass | ABNT NBR 9485:2011 [26] |

| Moisture content | ABNT NBR 9484:2011 [27] |

| Thickness swelling | ABNT NBR 9535:2011 [28] |

| Water absorption | ABNT NBR 9486:2011 [29] |

| Glue line shear | ABNT NBR ISO 12466-1:2012 [30] |

| Parallel and perpendicular static bending | ABNT NBR 9533:2013 [31] |

| Specific Apparent Mass (g/cm3) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| Phenol-formaldehyde (PF) | 0.47 (0.03) 1 | 0.57 (0.04) | 0.53 a 2 |

| Castor oil polyurethane (PU) | 0.65 (0.05) | 0.58 (0.03) | 0.62 b |

| Mean Values | 0.57 a | 0.58 a | - |

| Moisture Content (%) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| Phenol-formaldehyde (PF) | 12.1 (0.0027) 1 | 11.3 (0.0015) | 11.7 a 2 |

| Castor oil polyurethane (PU) | 6.4 (0.0044) | 8.7 (0.0008) | 7.5 b |

| Mean Values | 9.2 a | 10.0 b | - |

| Thickness Swelling (%) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| Phenol-formaldehyde (PF) | 6.85 (0.55) 1 | 6.83 (0.27) | 6.84 a 2 |

| Castor oil polyurethane (PU) | 6.13 (0.86) | 4.22 (0.59) | 5.17 b |

| Mean Values | 6.49 a | 5.52 b | - |

| Water Absorption (%) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| Phenol-formaldehyde (PF) | 72.8 (0.06) 1 | 63.4 (0.07) | 68.1 a 2 |

| Castor oil polyurethane (PU) | 51.2 (0.06) | 40.3 (0.02) | 45.8 b |

| Mean Values | 62.0 a | 51.9 a | - |

| Glue Line Shear (MPa) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| Phenol-formaldehyde (PF) | 2.87 (1.96) 1 | 1.95 (0.54) | 2.41 a 2 |

| Castor oil polyurethane (PU) | 2.35 (0.96) | 3.95 (0.98) | 3.15 a |

| Mean Values | 2.61 a | 2.95 a | - |

| MOE‖ 3 (MPa) | |||

|---|---|---|---|

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| PF | 4758.58 (417.17) 1 | 6711.09 (325.42) | 5734.83 a 2 |

| PU | 3969.92 (767.00) | 5206.10 (68.10) | 4588.01 b |

| Mean Values | 4364.25 a | 5958.59 b | - |

| MOR‖ (MPa) | |||

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| PF | 46.92 (8.92) 1 | 40.32 (2.47) | 43.62 a 2 |

| PU | 30.67 (3.16) | 43.40 (4.88) | 37.03 a |

| Mean Values | 38.79 a | 41.86 a | - |

| Adhesive | Preservative Treatment | Mean Values | |

|---|---|---|---|

| Reference | CCA | ||

| PF | 1648.34 (395.51) 1 | 1858.20 (579.84) | 1753.27 a 2 |

| PU | 1372.75 (347.64) | 1615.17 (253.98) | 1493.96 a |

| Mean Values | 1510.54 a | 1736.68 a | - |

| Adhesive | Preservative Treatment | Mean Values | |

| Reference | CCA | ||

| PF | 18.95 (0.97) 1 | 23.49 (5.89) | 21.22 a 2 |

| PU | 18.52 (3.00) | 24.73 (3.21) | 21.62 a |

| Mean Values | 18.73 a | 24.11 b | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sugahara, E.; Casagrande, B.; Arroyo, F.; De Araujo, V.; Santos, H.; Faustino, E.; Christoforo, A.; Campos, C. Comparative Study of Plywood Boards Produced with Castor Oil-Based Polyurethane and Phenol-Formaldehyde Using Pinus taeda L. Veneers Treated with Chromated Copper Arsenate. Forests 2022, 13, 1144. https://doi.org/10.3390/f13071144

Sugahara E, Casagrande B, Arroyo F, De Araujo V, Santos H, Faustino E, Christoforo A, Campos C. Comparative Study of Plywood Boards Produced with Castor Oil-Based Polyurethane and Phenol-Formaldehyde Using Pinus taeda L. Veneers Treated with Chromated Copper Arsenate. Forests. 2022; 13(7):1144. https://doi.org/10.3390/f13071144

Chicago/Turabian StyleSugahara, Estefani, Bruno Casagrande, Felipe Arroyo, Victor De Araujo, Herisson Santos, Emerson Faustino, Andre Christoforo, and Cristiane Campos. 2022. "Comparative Study of Plywood Boards Produced with Castor Oil-Based Polyurethane and Phenol-Formaldehyde Using Pinus taeda L. Veneers Treated with Chromated Copper Arsenate" Forests 13, no. 7: 1144. https://doi.org/10.3390/f13071144

APA StyleSugahara, E., Casagrande, B., Arroyo, F., De Araujo, V., Santos, H., Faustino, E., Christoforo, A., & Campos, C. (2022). Comparative Study of Plywood Boards Produced with Castor Oil-Based Polyurethane and Phenol-Formaldehyde Using Pinus taeda L. Veneers Treated with Chromated Copper Arsenate. Forests, 13(7), 1144. https://doi.org/10.3390/f13071144