Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Veneer Acetylation

2.2. Hot-Bonding LVL

2.3. Compression Ratio

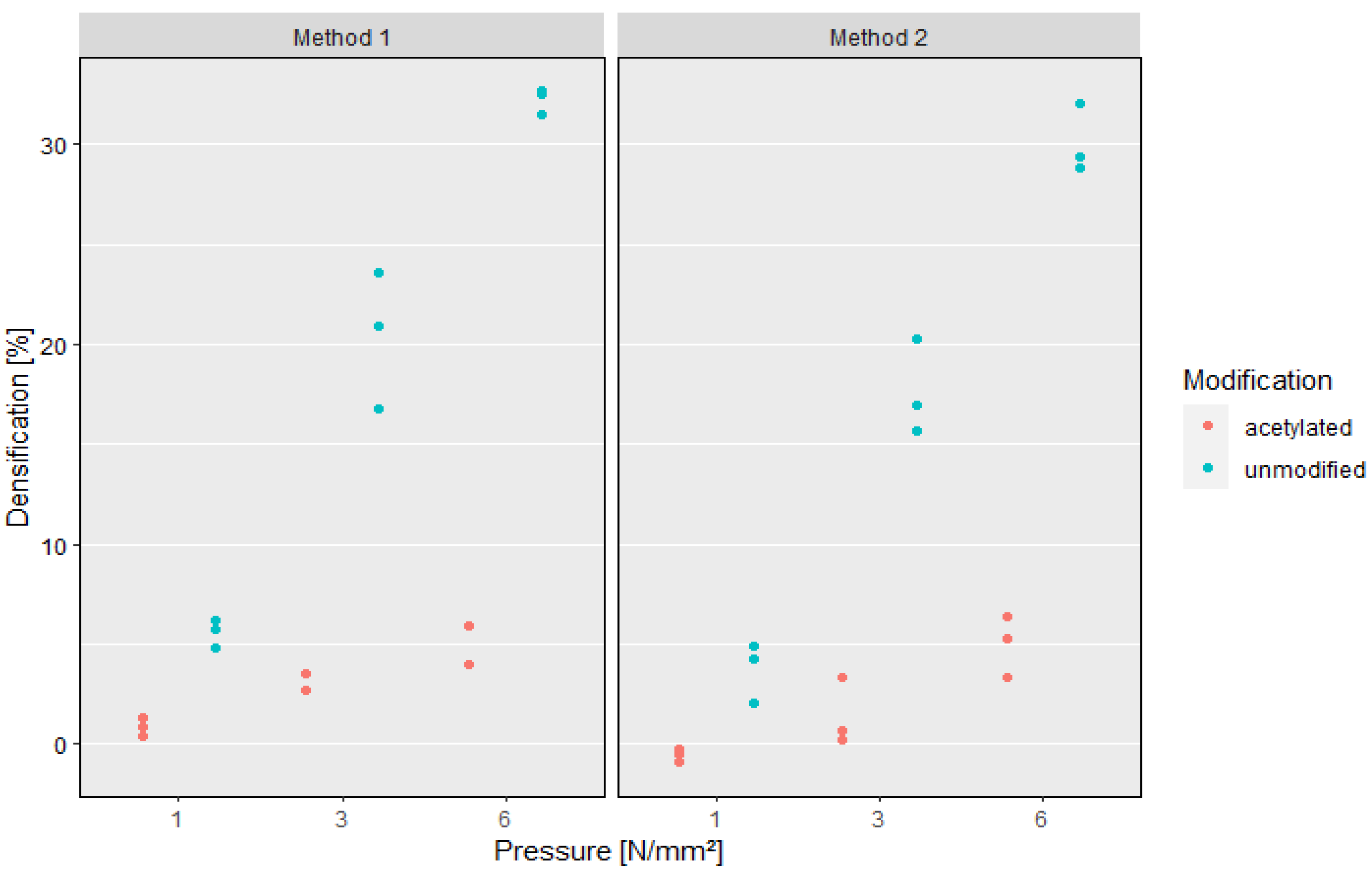

2.3.1. Method 1

2.3.2. Method 2

2.4. Density

2.4.1. Gravimetrical

2.4.2. X-ray Profile

3. Results and Discussion

4. Conclusions and Outlook

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Brunet, J.; Fritz, Ö.; Richnau, G. Biodiversity in European beech forests—A review with recommendations for sustainable forest management. Ecolog. Bull. 2010, 2010, 77–94. [Google Scholar]

- Bicke, S. Dimensionsstabile und Pilzresistente Furnierwerkstoffe durch Zellwandmodifizierung mit Niedermolekularem Phenol-Formaldehyd. Ph.D. Thesis, Georg-August-Universität Göttingen, Göttingen, Germany, 2019. Available online: https://ediss.uni-goettingen.de/handle/21.11130/00-1735-0000-0005-12BC-3 (accessed on 18 December 2021).

- DIN 68364:2003-05; Kennwerte von Holzarten–Rohdichte, Elastizitätsmodul und Festigkeiten. Beuth Verlag GmbH: Berlin, Germany, 2003. Available online: https://www.beuth.de/de/-/-/62090580 (accessed on 18 December 2021).

- DIN EN 350:2016-12; Dauerhaftigkeit von Holz und Holzprodukten–Prüfung und Klassifizierung der Dauerhaftigkeit von Holz und Holzprodukten Gegen Biologischen Angriff. Deutsche Fassung EN_350:2016; Beuth Verlag GmbH: Berlin, Germany, 2016. Available online: https://www.beuth.de/de/-/-/249162590 (accessed on 24 August 2021).

- Slabohm, M.; Militz, H. Improving durability and dimensional stability of beech (Fagus sylvatica L.) LVL by acetylation with acetic anhydride. In Proceedings of the European Conference on Wood Modification, Nancy, France, 25–26 April 2022. [Google Scholar]

- Beckers, E.; Bongers, F. Mechanical properties of acetylated solid wood treated on pilot plant scale. In Proceedings of the First European Conference on Wood Modification, Ghent, Belgium, 3–4 April 2003. [Google Scholar]

- Beckers, E.P.J.; Militz, H. Acetylation of Solid Wood. Initial Trials on Lab and Semi Industrial Scale; Second Pacific Rim Bio-Based Composites Symposium: Vancouver, BC, Canada, 1994; pp. 125–135. [Google Scholar]

- Hill, C.A.S. Wood Modification: An Update. BioResources 2011, 6, 918–919. Available online: https://ojs.cnr.ncsu.edu/index.php/BioRes/article/view/BioRes_06_2_0918_Hill_Wood_Modification_An_Update (accessed on 11 February 2011).

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; 293 S Wiley Series in Renewable Resources; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2006. [Google Scholar]

- Militz, H. Die Verbesserung des Schwind- und Quellverhaltens und der Dauerhaftigkeit von Holz mittels Behandlung mit unkatalysiertem Essigsäureanhydrid. Holz als Roh-und Werkstoff 1991, 49, 147–152. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2021. [Google Scholar]

- Emmerich, L.; Bollmus, S.; Militz, H. Wood modification with DMDHEU (1.3-dimethylol-4.5-dihydroxyethyleneurea)–State of the art, recent research activities and future perspectives. Wood Mater. Sci. Eng. 2019, 14, 3–18. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—a review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Jones, D.; Sandberg, D. A Review of Wood Modification Globally–Updated Findings from COST FP1407. IPBE. Available online: https://ipbe.innorenew.eu/ipbe/article/view/8 (accessed on 30 December 2020).

- Rowell, R. Acetylation of wood—A Review. Int. J. Lignocell. Prod. 2014, 1, 1–27. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef] [Green Version]

- Slabohm, M.; Mai, C.; Militz, H. Bonding Acetylated Veneer for Engineered Wood Products—A Review. Materials 2022, 15, 3665. [Google Scholar] [CrossRef]

- Zhang, H.J.; Chui, Y.H.; Schneider, M.H. Compression control and its significance in the manufacture and effects on properties of poplar LVL. Wood Sci. Technol. 1994, 28, 285–290. Available online: http://link.springer.com/10.1007/BF00204214 (accessed on 30 December 2020). [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M.; Lankveld, C. Surface densification of acetylated wood. Eur. J. Wood Prod. 2016, 74, 829–835. [Google Scholar] [CrossRef]

- Tarkow, H.; Seborg, R.M. Surface densification of wood. Forest Prod. J. 1968, 18, 104–107. [Google Scholar]

- Back, E.; Salmén, L. Glass Transit of wood compons hold Implic for Molding and Pulping Processes. Tappi J. 1982, 65, 107–110. [Google Scholar]

- Kelley, S.S.; Rials, T.G.; Glasser, W.G. Relaxation behaviour of the amorphous components of wood. J. Mater. Sci. 1987, 22, 617–624. [Google Scholar] [CrossRef]

- Cousins, W.J. Young’s modulus of hemicellulose as related to moisture content. Wood Sci. Technol. 1978, 12, 161–167. [Google Scholar] [CrossRef]

- Lenth, C.A.; Kamke, F. Moisture dependent softening behavior of wood. Wood Fiber Sci. 2001, 33, 492–507. [Google Scholar]

- Jakes, J.; Plaza, N.; Stone, D.; Hunt, C.; Glass, S.; Zelinka, S. Mechanism of Transport Through Wood Cell Wall Polymers. J. Forest Prod. Ind. 2013, 2, 10–13. [Google Scholar]

- Blechschmidt, J.; Engert, P.; Stephan, M. The glass transition of wood from the viewpoint of mechanical pulping. Wood Sci. Technol. 1986, 20, 263–272. [Google Scholar] [CrossRef]

- Dömény, J.; Čermák, P.; Pařil, P.; Pozsgayné, F.F.; Dejmal, A.; Rademacher, P. Application of Microwave Heating for Acetylation of Beech (Fagus sylvatica L.) and Poplar (Populus hybrids). Wood Biol. Resour. 2015, 10, 8181–8193. [Google Scholar] [CrossRef]

- Digaitis, R.; Thybring, E.E.; Thygesen, L.G.; Fredriksson, M. Targeted acetylation of wood: A tool for tuning wood-water interactions. Cellulose 2021, 28, 8009–8025. [Google Scholar] [CrossRef]

- Čermák, P.; Baar, J.; Dömény, J.; Výbohová, E.; Rousek, R.; Pařil, P.; Oberle, A.; Čabalová, I.; Hess, D.; Vodák, M.; et al. Wood-water interactions of thermally modified, acetylated and melamine formaldehyde resin impregnated beech wood. Holzforschung 2022, 76, 437–450. Available online: https://www.degruyter.com/document/doi/10.1515/hf-2021-0164/html (accessed on 30 December 2020). [CrossRef]

- Gröndahl, M.; Teleman, A.; Gatenholm, P. Effect of acetylation on the material properties of glucuronoxylan from aspen wood. Carbohydrate Polym. 2003, 52, 359–366. [Google Scholar] [CrossRef]

- Niemz, P.; Sonderegger, W.U. Holzphysik: Physik des Holzes und der Holzwerkstoffe: Mit zahlreichen Bildern und Tabellen; Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2017. [Google Scholar]

- Bavaneghi, F.; Ghorbani, M. Mechanical behavior and springback of acetylated particleboard made in different press times. Wood Mater. Sci. Eng. 2016, 11, 57–61. [Google Scholar] [CrossRef]

- Bongers, F.; Alexander, J.; Marcroft, J.; Crawford, D.; Hairstans, R. Structural design with Accoya Wood. Int. Wood Prod. J. 2013, 4, 172–176. [Google Scholar] [CrossRef]

- Forsman, K.; Fredriksson, M.; Serrano, E.; Danielsson, H. Moisture-dependency of the fracture energy of wood: A comparison of unmodified and acetylated Scots pine and birch. Holzforschung 2021, 75, 731–741. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Zhan, T.; Zhang, Y.; Lv, C.; He, Q.; Fang, L.; Lu, X. Preparation of hydro-thermal surface-densified plywood inspired by the stiffness difference in “sandwich structure” of wood. Construct. Build. Mater. 2018, 177, 83–90. [Google Scholar] [CrossRef]

- Engehausen, N.; Benthien, J.T.; Nopens, M.; Ressel, J.B. Density Profile Analysis of Laminated Beech Veneer Lumber (BauBuche). Fibers 2021, 9, 31. [Google Scholar] [CrossRef]

| Material | Pressure (N/mm2) | Oven-Dry Density (kg/m3) | Rounded Density Difference between Acetylated Samples and References Based on Mean (%) | |

|---|---|---|---|---|

| Mean | Standard Deviation | |||

| Reference | 1 | 715.6 | 22.1 | −4 |

| Acetylated | 1 | 740.7 | 16.9 | |

| Reference | 3 | 841.0 | 27.1 | 10 |

| Acetylated | 3 | 756.5 | 18.9 | |

| Reference | 6 | 947.8 | 34.8 | 20 |

| Acetylated | 6 | 792.4 | 21.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Slabohm, M.; Mayer, A.K.; Militz, H. Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL). Forests 2022, 13, 1122. https://doi.org/10.3390/f13071122

Slabohm M, Mayer AK, Militz H. Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL). Forests. 2022; 13(7):1122. https://doi.org/10.3390/f13071122

Chicago/Turabian StyleSlabohm, Maik, Aaron Kilian Mayer, and Holger Militz. 2022. "Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL)" Forests 13, no. 7: 1122. https://doi.org/10.3390/f13071122

APA StyleSlabohm, M., Mayer, A. K., & Militz, H. (2022). Compression of Acetylated Beech (Fagus sylvatica L.) Laminated Veneer Lumber (LVL). Forests, 13(7), 1122. https://doi.org/10.3390/f13071122